Page 1

Operating instructions

Electronic pressure sensor

PF2058

UK

704590 / 00 03 / 2009

Page 2

Contents

Menu structure.........................................................................................................3

Safety instructions ...................................................................................................4

Controls and indicating elements ............................................................................4

Function and features ..............................................................................................5

Operating modes .....................................................................................................6

Installation ...............................................................................................................7

Electrical connection................................................................................................9

Programming .........................................................................................................10

Installation and set-up / operation ......................................................................... 11

Technical information / Functioning / Parameters..................................................12

Adjustable parameters .......................................................................................12

Technical data ....................................................................................................17

Scale drawing .....................................................................................................18

Setting ranges ....................................................................................................19

2

Page 3

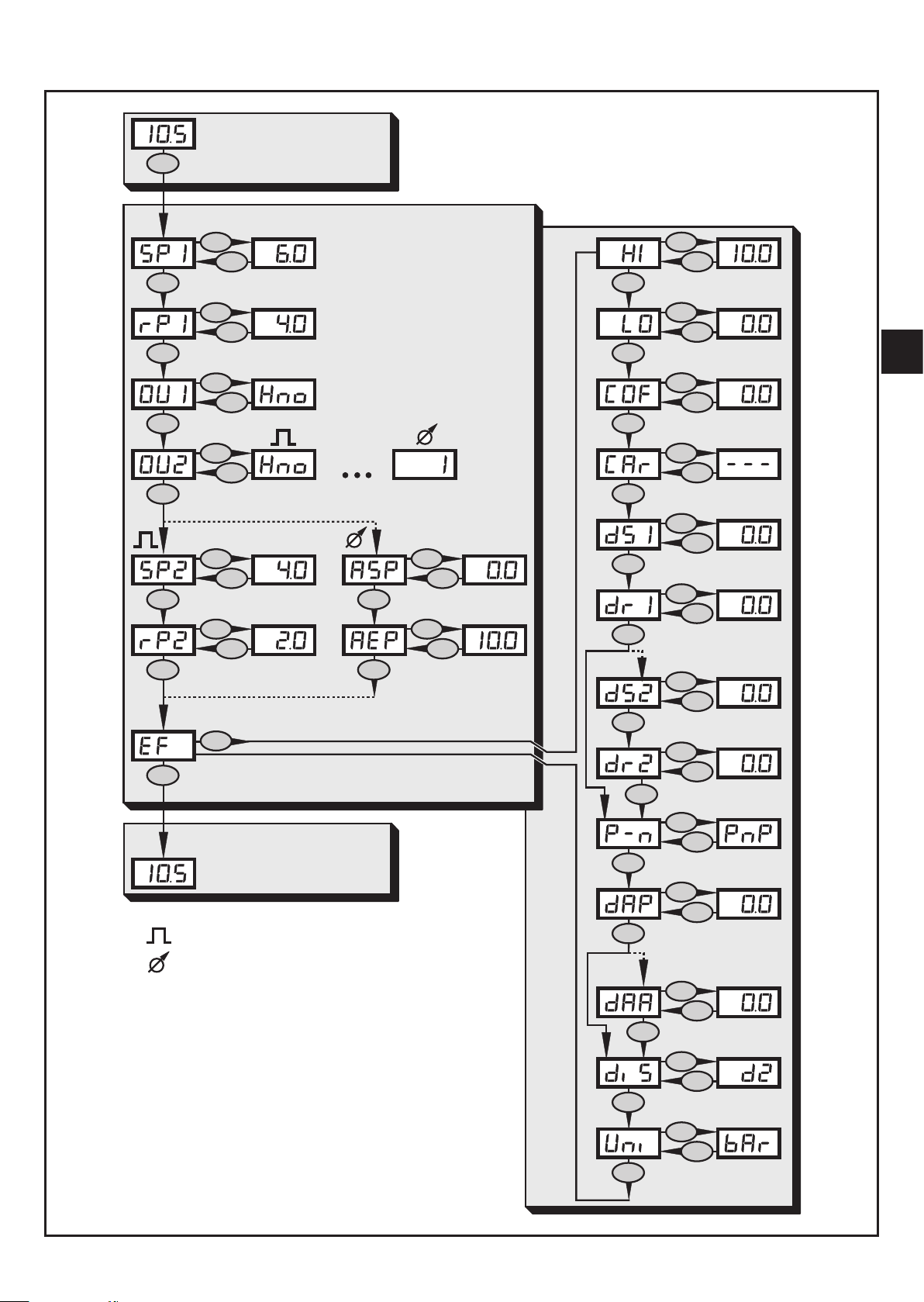

Menu structure

RUN

M

S

M

M

M

S

M

M

S

M

S

M

M

S

M

M

S

M

S

M

M

S

M

S

M

S

M

M

S

M

M

S

M

M

S

M

M

S

M

M

S

M

M

S

M

RUN

M

M

M

M

M

M

M

S

M

M

S

M

M

S

M

M

S

M

S

S

M

UK

OU2 = Hno, Hnc, Fno, Fnc

OU2 = I, U

3

Page 4

Safety instructions

Read the product description before installing the unit. Ensure that the product is

suitable for your application without any restrictions.

Non-adherence to the operating instructions or technical data can lead to personal

injury and/or damage to property.

In all applications check compliance of the product materials (see Technical data)

with the media to be measured.

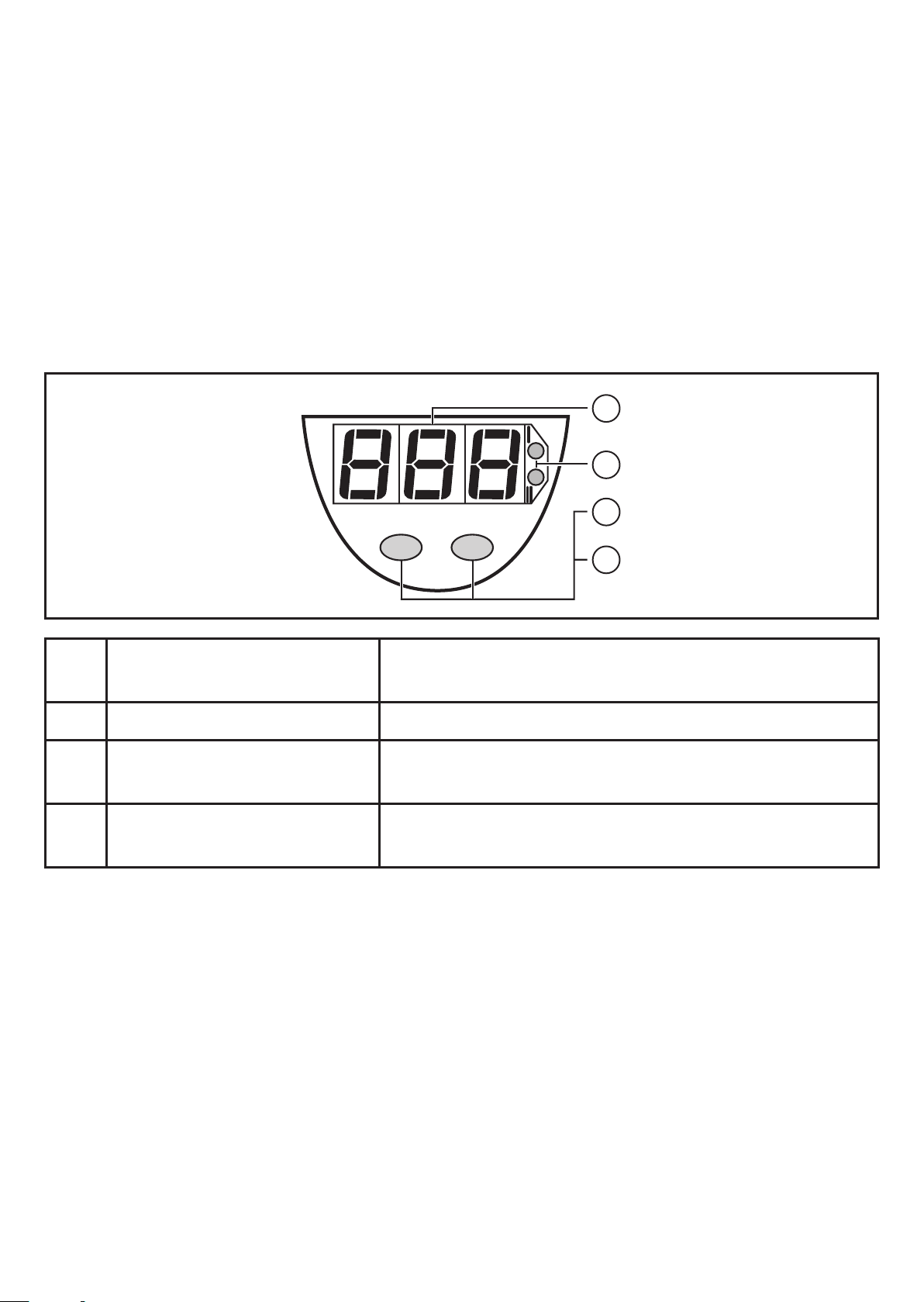

Controls and indicating elements

1

2

3

4

7-segment display

2 x LED red

Mode / Enter button

Set button

Display of the system pressure,

display of parameters and parameter values.

Switching status; lights if output I / II has switched.

Selection of the parameters and acknowledgement of

the parameter values.

Setting of the parameter values (scrolling by holding

pressed; incremental by pressing briefly).

4

Page 5

Function and features

The pressure sensor detects the system pressure.•

It unit shows the current system pressure on its display,•

It generates 2 output signals according to the set output configuration.•

Output 1 Output 2

Analogue output

(only output 2)

hysteresis function / N.O (Hno)

Switching function

(output 1 and output 2; function can be

selected for each output separately)

Output polarity

(applies to both switching outputs)

hysteresis function / N.C (Hnc)

window function / N.O. (Fno)

window function / N.C. (Fnc)

p-switching (PnP)

n-switching (nPn)

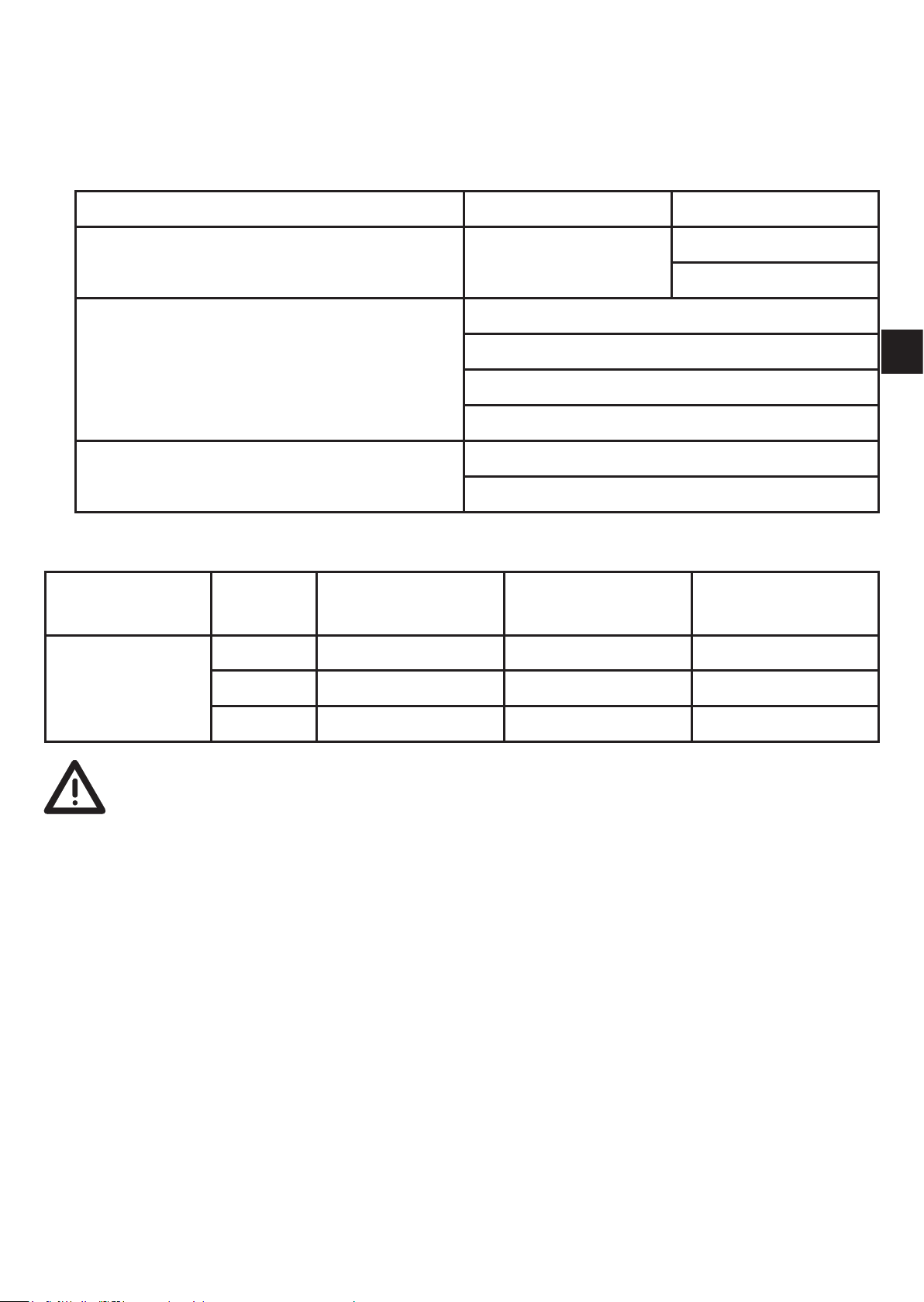

Applications (Type of pressure: relative pressure)

Order no. Measuring range

mbar -13 ... 250 10 000 (10 bar) 30 000 (30 bar)

PF2058

inH2O -5.0 ... 100 4 000 12 000

Permissible

overl. pressure

I: 4 ... 20 mA

U: 0 ... 10 V

UK

Bursting

pressure

kPa -1.3 ... 25.0 1 000 (1 MPa) 3 000 (3MPa)

Avoid static and dynamic overpressure exceeding the given overload

pressure.

Even if the bursting pressure is exceeded only for a short time the unit can

be destroyed (danger of injuries)!

5

Page 6

Operating modes

Run mode

Normal operating mode

At power on the unit is in the Run mode. It carries out its measurement and

evaluation functions and provides output signals according to the set parameters.

The display shows the current system pressure (can be deactivated). The red

LEDs indicate the switching state of the outputs.

Display mode

Indication of parameters and the set parameter values

When the “Mode/Enter” button is pressed briefly, the unit passes to the Display

mode which allows parameter values to be read. The internal sensing, processing

and output functions of the unit continue as if in Run mode.

The parameter names are scrolled with each pressing of the “Mode/Enter” •

button.

When the “Set” button is pressed briefly, the corresponding parameter value is •

displayed for 15 s. After another 15 s the unit returns to the Run mode.

Programming mode

Setting of the parameter values

While viewing a parameter value pressing the “Set” button for more than 5 s

causes the unit to enter the programming mode. You can alter the parameter

value by pressing the “Set” button and confirm the new value by pressing the

“Mode/Enter” button. The internal sensing, processing and output functions of the

unit continue as if in Run mode with the original parameter values unless a new

value is confirmed. The unit returns to the Run mode when no button has been

pressed for 15 s.

6

Page 7

Installation

C

A

B

Before mounting and removing the sensor, make sure that no pressure is

applied to the system.

The unit is adaptable for various

process fittings by Aseptoflex

adapters (to be ordered separately as

accessories).

Mount adapter (C) to the sensor first,

then sensor + adapter to the process

connection by means of a nut, a

clamping flange or similar (B).

A = freely rotatable housing

If it is not possible to slide the fixing element (B) down over the top of the sensor:

slide it up over the bottom of the sensor before the adapter is mounted.

UK

NOTE: A guarantee for a long-term stable and maintenance-free fitting, with no

bug traps in the hygienic sealing of the metal seal (Aseptoflex connection) is only

valid for once-only mounting.

Welding adapter

Weld the adapter first. Then mount the sensor.

7

Page 8

Mounting of the Aseptoflex adapter

D

�

E

F

36

Step 1

Grease thread and sealing chamfer of

the sensor and of the adapter with the

greasing paste supplied.

The greasing paste is food-grade

(USDA-H1 84-201).

Make sure that the O-ring (D) is

correctly positioned.

1

1 = Grease

Step 2

Screw the sensor into the adapter.

Avoid mechanical influence on the

sealing chamfers.

Step 3

Clamp sensor and adapter into a

clamping device (E). The sealing

chamfers (F) must not be damaged.

Tighten the sensor with a spanner until

you can feel the end stop.

If you continue to turn, this can have adverse effect on the sealing.

8

Page 9

Electrical connection

L

L

+

3

4

2

1

BU

BK

WH

BN

2: OUT2

4: OUT1

L

L

+

3

4

2

1

BU

BK

WH

BN

2: OUT2

4: OUT1

L

L

+

3

4

2

1

BU

BK

WH

BN

2: OUT2

4: OUT1

L

L

+

3

4

2

1

BU

BK

WH

BN

2: OUT2

4: OUT1

3

1

4

2

The unit must be connected by a suitably qualified electrician.

The national and international regulations for the installation of electrical

equipment must be observed.

Voltage supply to EN50178, SELV, PELV.

Disconnect power before connecting the unit as follows:

2 x p-switching 2 x n-switching

UK

1 x p-switching / 1 x analogue 1 x n-switching / 1 x analogue

Connector view (sensor)

Core colours of ifm sockets:

1 = BN (brown),

2 = WH (white),

3 = BU (blue),

4 = BK (black)

9

Page 10

Programming

Mode/Enter Set

Mode/Enter Set

Mode/Enter Set

Press the Mode/Enter button several

1

2

3

4

Change more parameters:

Start again with step 1.

times until the respective parameter is

displayed.

Press the Set button and keep it

pressed. The current parameter value

flashes for 5 s, then the value is

increased* (incremental by pressing

briefly or scrolling by holding pressed).

Press the Mode/Enter button briefly

(= acknowledgement).

The parameter is displayed again, the

set parameter value becomes effective.

Finish programming:

Wait for 15 s or press the Mode/Enter

button until the current measured value

is indicated again.

*Decrease the value: Let the display of the parameter value move to the maximum setting

value. Then the cycle starts again at the minimum setting value.

Select the display unit (Uni) before setting the switch points (SPx, rPx) or the limits for the

analogue output signal (ASP, AEP). This avoids rounding errors generated internally during

the conversion of the units and enables exact setting of the values.

If no button is pressed for 15 s during the setting procedure, the unit returns to the Run

mode with unchanged values.

The unit can be electronically locked to prevent unwanted adjustment of the set

parameters: Press both pushbuttons for 10 s (the unit must be in Run mode).

Indication goes out briefly (acknowledgement of locking / unlocking).

Units are delivered from the factory in the unlocked state.

With the unit in the locked state

is indicated briefly when you try to change

parameter values.

10

Page 11

Installation and set-up / operation

AB

After mounting, wiring and setting check whether the unit operates correctly.

Faults displayed during operation

Overload (above measuring range of the sensor).

Underload (below measuring range of the sensor).

Flashing: short circuit in the switching output 1*.

Flashing: short circuit in the switching output 2*.

Flashing: short circuit in both switching outputs*.

*The output concerned is switched off as long as the short circuit exists.

Cleaning of the filter cover

If viscous and residues producing

media clog the filter cover of

the sensor (and thus reduce the

measuring accuracy slightly), you

can clean it.

Unscrew the filter cover (B) (use •

a pair of pliers with plasticcovered jaws for this). Clean the

cover thoroughly.

The vent (A) should only be •

UK

cleaned by skilled personnel and

with utmost care.

Possible medium residues must not be compressed and pressed into the

vent. This could clog the filter system and reduce the measuring accuracy

of the sensor.

Screw the filter cover again tightly.•

The sensor is sufficiently protected against harsh ambient conditions (protection

IP 67). The protection rating can be increased by a special accessory (order no.

E30043).

11

Page 12

Technical information / Functioning / Parameters

Adjustable parameters

Switch-on point 1 / 2

Upper limit value at which the output changes its switching status.

SP2 is active only if OU2 = Hno, Hnc, Fno or Fnc.

Switch-off point 1 / 2

Lower limit value at which the output changes its switching status.

rPx is always lower than SPx. The unit only accepts values which are lower

than SPx.

Changing the switch-on point also changes the switch-off point (the distance

between SPx and rPx remains constant).

If the distance is higher than the new switch point, it is automatically

reduced (rPx is set to the minimum setting value).

rP2 is active only if OU2 = Hno, Hnc, Fno or Fnc.

SettingrangeforSPx/rPx:→page19.

Configuration of output 1

4 switching functions can be set:

Hno = hysteresis / normally open Hnc = hysteresis / normally closed Fno = window function / normally open Fnc = window function / normally closed -

Configuration of output 2

4 switching functions and 2 analogue signals can be set:

Hno = hysteresis / normally open Hnc = hysteresis / normally closed Fno = window function / normally open Fnc = window function / normally closed I = analogue output 4 ... 20mA U = analogue output 0 ... 10V -

Analogue start point

Measured value at which 4 mA / 0 V is provided.

12

ASP is active only if OU2 = I or U.

Analogue end point

Measured value at which 20 mA / 10 V is provided.

Minimum distance between ASP and AEP = 25% of the final value of the

measuring range (scaling factor 4).

AEP is active only if OU2 = I or U.

SettingrangeforASP/AEP:→page19.

Page 13

Enhanced functions

This menu item contains a submenu with additional parameters.

You can access these parameters by pressing the SET button briefly.

Min-Max memory for system pressure

HI: displays the highest measured pressure•

LO: displays the lowest measured pressure•

Erase the memory:

Press the “Mode/Enter” button until HI or LO is displayed. Press the “Set” button and keep it pressed until “- - -” is displayed. Then press the “Mode/Enter” button briefly. -

Calibration offset

The internal measured value (operating value of the sensor) is offset

against the real measured value.

Setting range: -5 ... +5% of the value of the measuring range (with scaling •

as factory setting (ASP = 0% and AEP = 100%),

in steps of 0.1% of the value of the measuring range.•

Calibration reset

Resets the calibration set by COF to the value set at the factory.

Press the “Mode/Enter” button until CAr is displayed. Press the “Set” button and keep it pressed until “- - -” is displayed. Then press the “Mode/Enter” button briefly. -

Delay time for the switching outputs

dSx = switch-on delay; drx = switch-off delay

The output does not immediately change its switching status when the

switching condition is met but when the delay time has elapsed. If the

switching condition is no longer met when the delay time has elapsed, the

UK

switching state of the output does not change.

Setting range: 0 / 0.1 ... 50 s adjustable in steps 01 s •

(0 = delay time not active),

indicated in seconds.•

dS2 and dr2 are not active, if OU2 = I or U.

Output polarity

2 options can be selected:

PnP = positive switching nPn = negative switching -

This setting applies to both switching outputs.

13

Page 14

Damping for the switching outputs

Pressure peaks of short duration or high frequency can be filtered out.

dAP-value = response time between pressure change and change of the

switching status in seconds (s).

Setting range: 0 ... 4 s (0 = dAP is not active),•

in steps of 0.01 s.•

Correlation between switching frequency and dAP: f

max

=

1

2 × dAP

Damping for the analogue signal

Pressure peaks of short duration or high frequency can be filtered out.

dAA-value = response time between pressure change and change of the

switching status in seconds (s).

Setting range: 0 (= dAA is not active) / 0.1 s / 0.5 s / 2 s.•

dAA is active only if OU2 = I or U.

Setting of the display

9 options can be selected:

d1 = update of the measured value every 50 ms•

d2 = update of the measured value every 200 ms•

d3 = update of the measured value every 600 ms•

The update interval only refers to the display. It has no effect on the outputs.

ph = display of the measured peak value remains for a short time (peak •

hold).

rd1, rd2, rd3, rph = display as d1, d2, d3, Ph; but rotated 180°.•

OFF = In the Run mode the display of the measured value is deactivated.•

If one of the buttons is pressed, the current measured value is displayed for

15 s. Another press of the Mode/Enter button opens the Display mode. The

LEDs remain active even if the display is deactivated.

Display unit

The measured value and the values for SPx / rPx can be displayed in the

following units:

bAr (= mbar), H2O (inH2O), PA (= kPa).

Select the display unit before setting the switch points (SPx, rPx) and the

limits for the analogue output signal (ASP, AEP). This avoids rounding

14

errors generated internally during the conversion of the units and enables

exact setting of the values.

Setting at the factory: Uni = bAr.

Page 15

Hysteresis function:

t

P

SP

rP

1

0

1

0

The hysteresis keeps the switching state

of the output stable if the system pressure

varies about the preset value. With the

system pressure rising, the output switches

when the switch-on point has been reached

(SPx). With the system pressure falling

1

the output does not switch back until the

switch-off point (rPx) has been reached.

The hysteresis can be adjusted: First the

switch-on point is set, then the switch-off

Hysteresis1:

point with the requested distance.

Window function:

The window function enables the

monitoring of a defined acceptable range.

When the system pressure varies between

the switch-on point (SPx) and the switch-off

point (rPx), the output is switched (window

function / NO) or not switched (window

function / NC).

The width of the window can be set by

means of the difference between SPx and

Hno

Hnc

UK

1

Fno

Fnc

rPx. SPx = upper value, rPx = lower value.

Acceptable range1:

Scaling the measuring range (analogue output)

With the parameter “Analogue start point” (ASP) the measured value at which •

the output signal is 4 mA or 0 V is defined.

With the parameter “Analogue end point” (AEP) the measured value at which •

the output signal is 20 mA or 10 V is defined.

Minimum distance between ASP and AEP = 25 % of the final value of the

measuring range (scaling factor 4).

15

Page 16

Voltage output 0 ... 10 V

U [V]

P

10

MEW

0-1

U [V]

P

10

AEP

ASP-1 0

MEW

U [V]

P

10

AEP

ASP-1 0

MEW

I [mA]

P

4

20

MEW (AEP)

0 (ASP)-1

I [mA]

P

4

20

AEP

ASP-1

0

MEW

I [mA]

P

4

20

AEP

ASP-1 0

MEW

Factory preset Measuring range scaled

MEW = final value of the measuring range

The output signal is between 0 and 10 V in the set measuring range.

It is also indicated:

System pressure above the measuring range: output signal > 10 V.

Current output 4 ... 20 mA

Factory preset Measuring range scaled

MEW = final value of the measuring range

The output signal is between 4 and 20 mA in the set measuring range.

It is also indicated:

System pressure above the measuring range: output signal > 20 mA.•

System pressure below the measuring range: output signal drops to max. 3.2 mA •

(depending on the scaling).

16

Page 17

Technical data

Operating voltage [V] ......................................................................................... 20 ... 30 DC

Current consumption [mA] ..............................................................................................< 60

Current rating [mA] ....................................................................................................2 x 250

Short-circuit protection, reverse polarity protection / overload protection,

Integrated Watchdog

Voltage drop [V] ................................................................................................................< 2

Power-on delay time [s] ................................................................................................... 0.2

Min. response time switching outputs [s] .............................................................................3

Switching frequency [Hz] .....................................................................................170...0.125

Analogue output (measuring range scaleable) ................................... 4 ... 20 mA / 0 ... 10 V

Max. load current output [Ω] ..............................................(UB - 10) x 50; 700 bei U

Min. load with voltage output [

Ω

] ...................................................................................2000

= 24V

B

UK

Min. response time analogue output [ms]............................................................................3

Accuracy / deviations (in % of the span)

Characteristics deviation (linearity, incl. hysteresis and repeatability) -

1)

2)

................< ± 0.6

Linearity - .................................................................................................................< ± 0.5

Hysteresis - ..............................................................................................................< ± 0.1

Repeatability (with temperature fluctuations < 10K) - ..............................................< ± 0.1

Long-time stability (in % of the span per year) - ......................................................< ± 0.1

Temperature coefficients (TEMPCO) in the compensated temperature range 0 ... +80°C (in % of the span per 10 K)

Greatest TEMPCO of the zero point / of the span - .................................. < ± 0.1 / < ± 0.4

Materials (wetted parts) ....................................................ceramics (99.9 % Al2 O3); PTFE;

stainless steel 316L / 1.4435; surface characteristics: Ra < 0.4 / Rz 4

Housing material..............stainless steel 316L / 1.4404; PBT (Pocan); PC (Macrolon); PEI;

EPDM/X (Santoprene); FPM (Viton)

Protection ............................................................................................................... IP 67 / III

Ω

Insulation resistance [M

] ........................................................................> 100 (500 V DC)

Shock resistance [g] ............................................................... 50 (DIN / IEC 68-2-27, 11ms)

Vibration resistance [g] ................................................. 20 (DIN / IEC 68-2-6, 10 - 2000 Hz)

Switching cycles min. .......................................................................................... 100 million

Operating temperature [°C] .................................................................................. -25 ... +80

Medium temperature [°C] ..................................................................................... -25 ... +80

Storage temperature [°C]...................................................................................... -40...+100

EMC IEC 1000-4-2 ESD: ................................................................................ 4 / 8 KV

IEC 1000-4-3 HF radiated: ......................................................................... 10 V/m

IEC 1000-4-4 Burst: .......................................................................................2 KV

IEC 61000-4-6 HF conducted: ....................................................................... 10 V

1)

all indications are referred to a turn down of 1:1

2)

limit value setting to DIN 16086

17

Page 18

Scale drawing

1: 7-segment display

2: programming button

3: Aseptoflex sealing edge

4: Aseptoflex thread

18

Page 19

Setting ranges

SP1 / SP2 rP1 / rP2 ASP AEP

Uni = bAr

min max min max min max min max

PF2058 mbar -11 250 -12 249 -13 188 50 250 1

SP1 / SP2 rP1 / rP2 ASP AEP

Uni = H2O

min max min max min max min max

∆P

∆P

PF2058

Uni = PA

PF2058 kPa -1.1 25.0 -1.2 24.9 -1.3 18.8 5.0 25.0 0.1

∆P=increments

inH2O

-4.4 100 -4.8 99.6 -5.0 74.9 20.1 100 0.1

SP1 / SP2 rP1 / rP2 ASP AEP

min max min max min max min max

UK

∆P

19

Page 20

Set parameter values

20

Loading...

Loading...