IFM Electronic OY951S, OY952S, OY953S Original Operating Instructions

Original operating instructions

Photoelectric safety sensors

(safety light grid)

Protected area width (range) 8...60 m

OY95xS

UK

704857 / 02 12 / 2018

Contents

1 Preliminary note ................................................................................................... 4

1.1 Symbols used ................................................................................................4

1.2 Warning signs used .......................................................................................4

2 Safety instructions ...............................................................................................5

2.1 Safety-related requirements regarding the application .................................. 6

3 Items supplied......................................................................................................7

4 Functions and features ........................................................................................7

5 Function ............................................................................................................... 8

6 Installation............................................................................................................9

6.1 Installation instructions ..................................................................................9

6.2 Calculation of the minimum safety distance ................................................10

6.3 Installation of the safety light grids .............................................................. 11

6.4 Minimum distance between transmitter and receiver .................................. 11

6.5 Fixing and optical alignment ........................................................................12

6.5.1 Optical alignment ................................................................................ 12

6.6 Distance of reflective surfaces .....................................................................13

6.7 Multiple systems ..........................................................................................14

6.8 Use of corner mirrors ................................................................................... 15

7 Electrical connection .......................................................................................... 16

7.1 Wiring diagram transmitter...........................................................................16

7.2 Wiring diagram receiver ...............................................................................17

8 Operating modes ...............................................................................................18

8.1 Automatic operation ..................................................................................... 19

8.2 Manual operation ......................................................................................... 19

8.3 Connection of external feedback contacts ..................................................20

8.4 Internal test function ....................................................................................20

9 Operating and display elements ........................................................................20

9.1 LED indicators for optical alignment ............................................................20

9.1.1 Alignment in the automatic mode .......................................................21

9.1.2 Alignment in the manual mode ...........................................................21

9.2 LED states ...................................................................................................22

9.2.1 Transmitter ..........................................................................................22

2

9.2.2 Receiver .............................................................................................23

10 Operation ......................................................................................................... 24

10.1 Switching state of the outputs ....................................................................24

10.1.1 The safe state ................................................................................... 24

10.1.2 The switched state ............................................................................ 24

10.1.3 Interface classification ......................................................................24

10.2 Functional test of the safety light grids ......................................................25

11 Scale drawing ..................................................................................................26

11.1 Position of the light beams .........................................................................27

12 Technical data .................................................................................................. 28

12.1.1 Safety light grids 2, 3 and 4 beams ..................................................29

13 Troubleshooting ...............................................................................................29

13.1 Configuration error .....................................................................................29

13.2 System error ..............................................................................................30

13.3 System failure ............................................................................................ 30

14 Maintenance, repair and disposal .................................................................... 31

15 Terms and abbreviations ..................................................................................32

16 Annex ............................................................................................................... 33

16.1 Check list ...................................................................................................33

UK

3

1 Preliminary note

The instructions are part of the unit. They are intended for authorised persons

according to the EMC and Low Voltage Directive and safety regulations.

The instructions contain information about the correct handling of the product.

Read the instructions before use to familiarise yourself with operating conditions,

installation and operation. Adhere to the safety instructions.

1.1 Symbols used

► Instructions

> Reaction, result

→ Cross-reference

LED off

LED on

LED flashes

Important note

Non-compliance can result in malfunction or interference.

Information

Supplementary note.

Access prevention body protection

1.2 Warning signs used

WARNING

Warning of serious personal injury.

Death or serious irreversible injuries may result.

4

2 Safety instructions

• Follow the operating instructions.

• In case of non-observance of notes or standards, specially when tampering

with and / or modifying the unit, any liability and warranty is excluded.

• The unit must be installed, connected and put into operation by a qualified

electrician trained in safety technology.

• The applicable technical standards for the corresponding application must be

complied with.

• For the installation the standards EN 60204, EN 999 and ISO 13855 have to be

observed.

• In case of malfunction of the unit please contact the manufacturer. Tampering

with the unit is not allowed.

• Disconnect the unit externally before handling it. Disconnect all relay load

circuits that are supplied independently.

• After setup the system has to be subjected to a complete function check.

• Only use the unit under the specified operating conditions (→ 12 Technical

data). In case of special operating conditions please contact the manufacturer.

• In case of any questions concerning safety - if required - contact the safety

expert in charge of your country.

WARNING

UK

In case of improper handling of the product, the safety and physical

integrity of operators and machinery cannot be guaranteed.

Death or serious irreversible injuries may result.

► Observe all notes on installation and handling in these instructions.

► The photoelectric safety sensors must only be used under the specified

operating conditions and in accordance with use as prescribed below.

5

2.1 Safety-related requirements regarding the application

It must be ensured that the safety requirements of the respective application

correspond to the requirements stated in these instructions.

Observe the following requirements:

► Adhere to the specified operating conditions (→ 12 Technical data). Use of the

photoelectric safety sensors in the vicinity of chemically and biologically active

media as well as ionising radiation is not permitted.

► For applications in the food industry contact your ifm branch office to check

the compatibility of the materials of the photoelectric safety sensors with the

chemicals used.

► Adhere to the principle of normally closed operation for all external safety

circuits connected to the system.

► If the photoelectric safety sensors go into the state defined as safe due to an

internal fault, measures have to be taken to maintain the safe state when the

installation resumes operation.

► Replace damaged units.

The protective function of the photoelectric safety sensors is only ensured with the

following conditions:

• The machine control can be electrically controlled and the hazardous machine

motion can be stopped immediately at any time of the operation cycle.

• There is no danger for machine operators due to ejection of materials or

machine parts.

• The hazardous area is only accessible via the protected area.

6

3 Items supplied

• 2 photoelectric safety sensors (1 transmitter and 1 receiver)

• OY951S: 4 angle brackets, 4 slot nuts with M6 thread and suitable

screws

• OY952S, OY953S: 6 angle brackets, 6 slot nuts with M6 thread and suitable

screws

• 1 copy operating instructions photoelectric safety sensors, reference no.

704857.

If one of the above-mentioned components is missing or damaged, please contact

one of the ifm branch offices.

UK

4 Functions and features

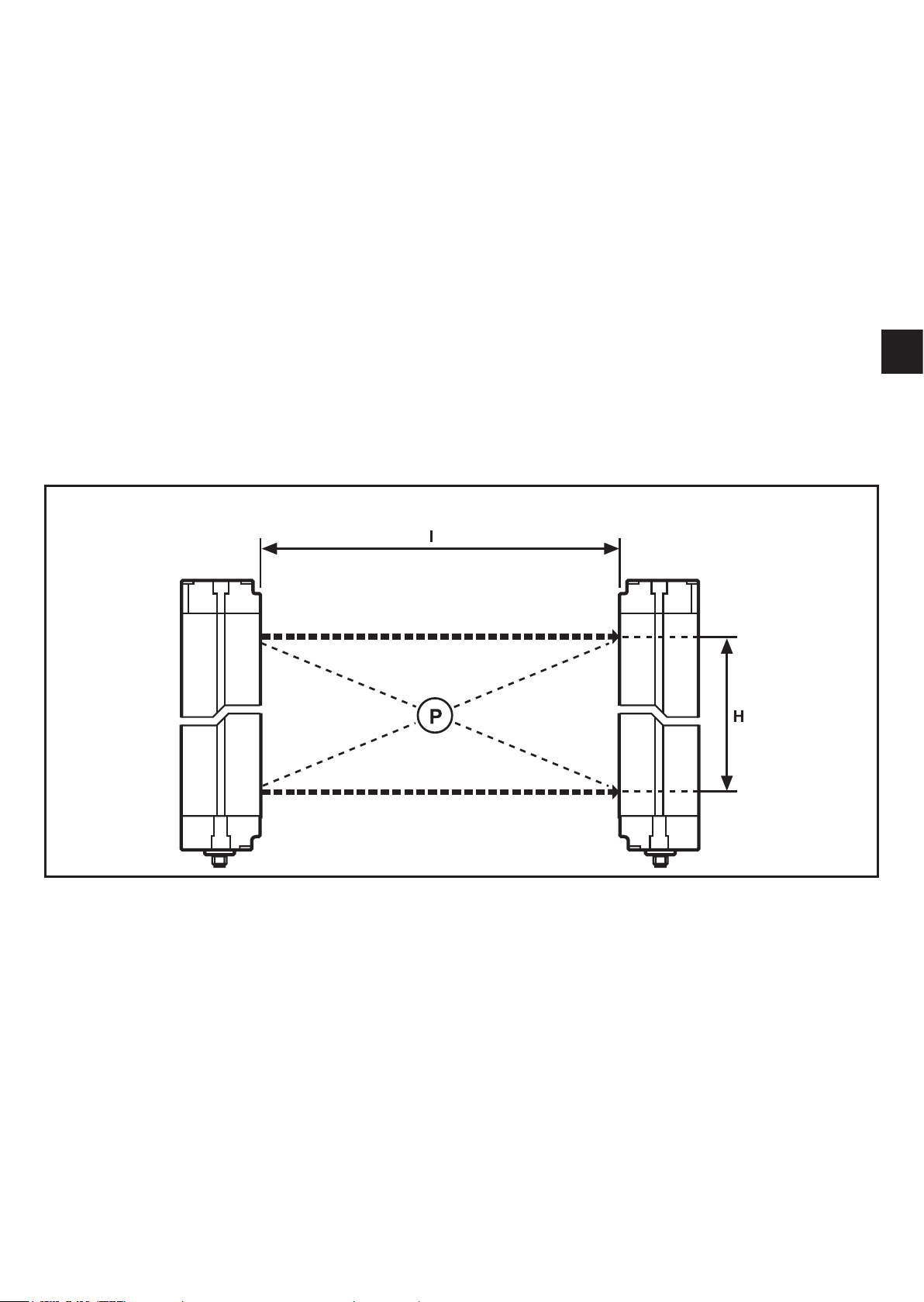

transmitter (T) receiver (R)

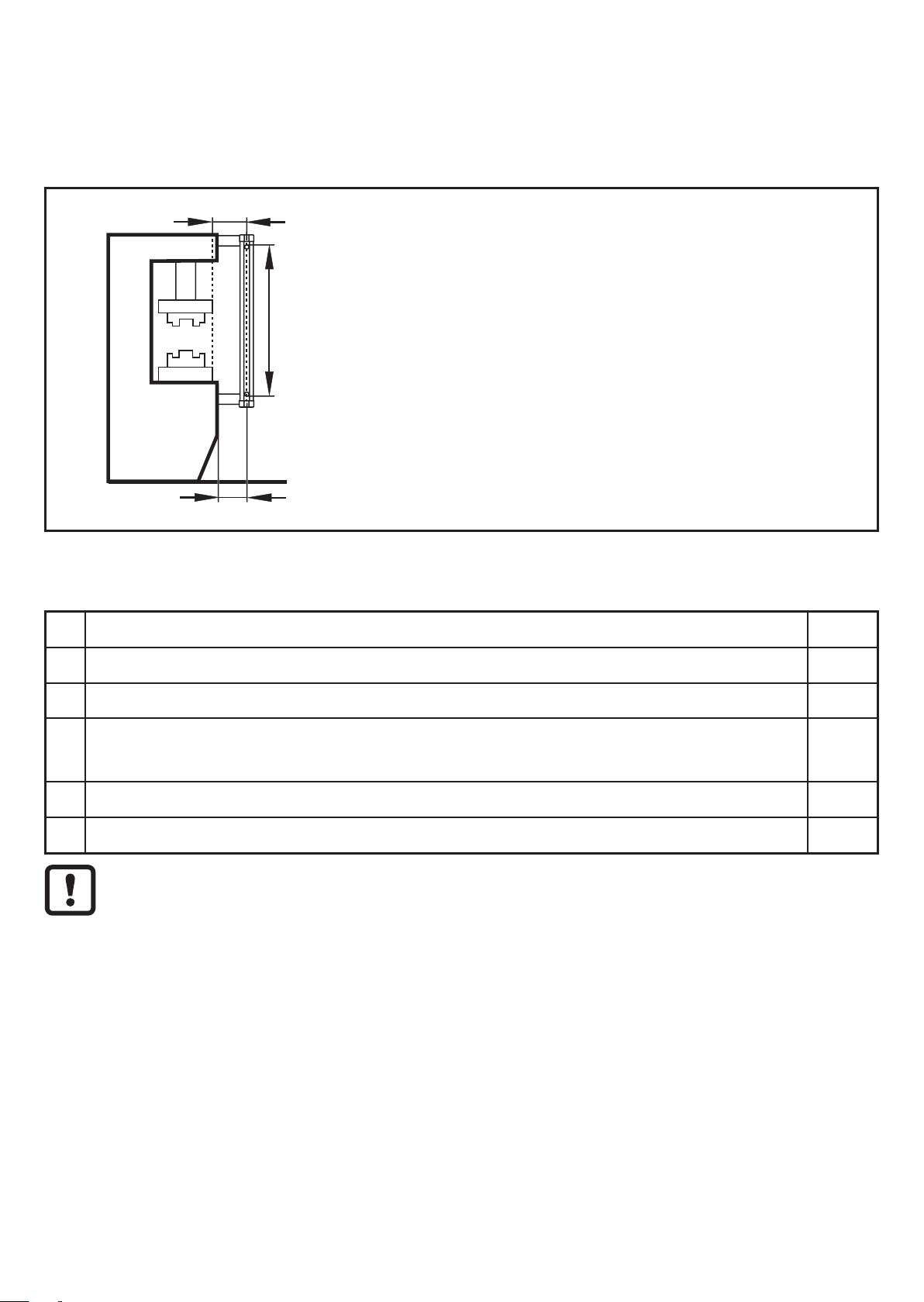

P = protected area; I = protected area width (range) H = protected area height

The OY95xS safety light grids are multi-beam optoelectronic protective devices to

IEC 61496 and consist of one transmitter and one receiver.

7

5 Function

The protected area (P) is generated between the transmitter and the receiver and

is defined by the protected area height (H) and the protected area width (range)

(I).

The protected area height is the height protected by the safety light grid. It

depends on the design (→ 12 Technical data).

The protected area width (range) is the maximum distance between transmitter

and receiver (→ 12 Technical data).

If the protected area is clear, the two outputs (OSSDs) of the receiver are active.

When one of the light beams is interrupted, the light grid switches off the outputs.

8

6 Installation

6.1 Installation instructions

The following conditions are to be ensured before installation of the photoelectric

safety sensors:

• The degree of protection of the electro-sensitive equipment (ESPE) has to

correspond with the risk assessment of the machine to be monitored.

• The safety system ensures a safety function and is not required for the

operation of a machine.

• It must be possible to stop any hazardous motion of the machine immediately.

In this respect the shutdown delay of the machine has to be determined.

Install the photoelectric safety sensors so that the hazardous area can only

be accessed via the protected area. Depending on the application other

mechanical protective equipment may be necessary.

UK

The operating conditions at the mounting location must not affect the functioning

of the photoelectric safety sensors. Please note especially:

• The transmitter and the receiver must not be affected by intensive light sources

(emitters, sunlight etc.).

• The ambient temperature must be within the range indicated (→ 12 Technical

data).

• Fogging of the lenses due to considerable temperature fluctuations can affect

the functioning of the photoelectric safety sensors. Take appropriate measures

to prevent this.

• Certain operating conditions can affect the functioning of the photoelectric

safety sensors. For mounting locations where fog, rain, smoke or dust may

occur, it is recommended to take appropriate measures.

• The standards EN 999 and ISO 13855 must be adhered to.

9

6.2 Calculation of the minimum safety distance

There must be a minimum safe distance between the photoelectric safety sensor

and the point of danger. This distance must be ensured so that the point of danger

cannot be accessed before the hazardous state of the machine has been stopped.

► Install the photoelectric safety sensor at a distance

that is greater than or equal to the minimum safety

distance (S) so that the hazardous area (A) can

A = hazardous area

H = protected area height

S

K

t

t

Total response time of the protective equipment, from release to switching off s

1

Total response time of the machine, from the stop signal to switching off or to

2

Speed of approach of the object towards the hazardous area mm/s

passing into the state defined as safe

only be accessed after complete standstill of the

hazardous machine motion.

According to the European Standard EN 999:2008 the

following formula is to be used to calculate the minimum

safety distance (S):

S = K (t1 + t2) + C

C = 8 (d - 14)

S = minimum safety distance

C = additional distance

Minimum safety distance mm

s

C

d

Additional distance mm

Resolution (detection capacity) mm

Non-compliance with the minimum safety distance may lead to restrictions

to or loss of the safety function.

10

Loading...

Loading...