Page 1

Operating instructions

3D camera

O3D301

O3D303

O3D311

O3D313

706397 / 03 10/2015

UK

Page 2

3D camera

2

Inhalt

1. Preliminary note...................................................................4

1.1 Symbols used .................................................................4

1.2 Warnings used ................................................................4

2. Safety instructions .................................................................4

2.1 General ......................................................................4

2.2 Target group ..................................................................4

2.3 Electrical connection............................................................4

2.4 Tampering with the device .......................................................4

3. Functions and features .............................................................5

4. Items supplied ....................................................................5

5. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6. Installation ......................................................................6

6.1 Select installation location .......................................................6

6.2 Additional camera installation guidance .............................................7

6.2.1 Typical warning limits for O3D301 / O3D303 .....................................7

6.2.2 Typical warning limits for O3D311 / O3D313 .....................................8

6.2.3 Reduce surface temperature .................................................8

6.3 Install camera .................................................................9

6.4 Mounting accessories ...........................................................9

7. Electrical connection ..............................................................10

7.1 Wiring .....................................................................10

7.1.1 Pin 1 / 3 (24 V / GND)......................................................11

7.1.2 Pin 2 (trigger input) ........................................................11

7.1.3 Pin 4 / 5 (ready / cascading).................................................11

7.2 Wiring examples ..............................................................12

7.2.1 Trigger image capture with proximity sensor ....................................12

7.2.2 Install several cameras next to each other .....................................13

8. Indicators .....................................................................14

9. Set-up .....................................................................15

9.1 Set parameters of the camera ...................................................15

9.2 Detect object.................................................................15

10. Maintenance, repair and disposal ...................................................16

10.1 Clean .....................................................................16

10.2 Update firmware .............................................................16

10.3 Replace camera .............................................................16

11. Approvals/standards .............................................................16

12. Scale drawings..................................................................17

12.1 O3D303 / O3D313 ...........................................................17

12.2 O3D301 / O3D311 ...........................................................17

13. Appendix .....................................................................18

13.1 Required Ports ..............................................................18

13.2 XML-RPC Interface...........................................................18

13.2.1 Sample XML-RPC command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

13.2.2 XML-RPC Objects .......................................................19

13.3 Process Interface ............................................................22

13.3.1 Sending Commands ......................................................22

13.3.2 Receiving Images ........................................................22

13.3.3 Image data .............................................................23

13.3.4 Additional Information for CONFIDENCE_IMAGE ...............................26

13.3.5 Configuration of PCIC Output...............................................27

13.4 Process Interface Command Reference...........................................31

13.4.1 t Command (Asynchronous Trigger)..........................................31

13.4.2 T? Command (Synchronous Trigger) .........................................31

13.4.3 I? Command ............................................................31

Page 3

3

3D camera

UK

13.4.4 p Command ............................................................32

13.4.5 a Command ............................................................33

13.4.6 A? Command ...........................................................33

13.4.7 v Command ............................................................34

13.4.8 V? Command ...........................................................34

13.4.9 c Command ............................................................34

13.4.10 C? Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

13.4.11 S? Command ..........................................................35

13.4.12 G? Command ..........................................................36

13.4.13 H? Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

13.5 XML-RPC Command Reference ................................................38

13.5.1 Parameter API ..........................................................38

13.5.2 Main Object.............................................................39

13.5.3 Session Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

13.5.4 Edit Mode Object ........................................................44

13.5.5 Device Config Object .....................................................45

13.5.6 Device/Network Config Object ..............................................49

13.5.7 Application Config Object ..................................................49

13.5.8 Application/Imager Config Object ............................................51

13.5.9 Image Settings and Filter Parameters ........................................56

Licences and trademarks

Microsoft®, Windows®, Windows XP®, Windows Vista®, Windows 7®, Windows 8® and Windows 8.1®

are registered trademarks of Microsoft Corporation.

Adobe® and Acrobat® are registered trademarks of Adobe Systems Inc.

All trademarks and company names are subject to the copyright of the respective companies.

This device contains (maybe modified) open source software which is subject to special licensing terms.

For copyright information and licensing terms please refer to:

www.ifm.com/int/GNU

For software subject to the GNU General Public License or the GNU Lesser General Public License the

source code can be requested against payment of the copying and shipping costs.

Page 4

3D camera

4

1. Preliminary note

This document is intended for specialists. These specialists are people who are qualified by their

appropriate training and their experience to see risks and to avoid possible hazards that may be caused

during operation or maintenance of the device. The document contains information about the correct

handling of the device.

Read this document before use to familiarise yourself with operating conditions, installation and operation.

Keep this document during the entire duration of use of the device.

1.1 Symbols used

► Instructions

> Reaction, result

[…] Designation of keys, buttons or indications

→ Cross-reference

Important note

Non-compliance may result in malfunction or interference.

Information

Supplementary note

1.2 Warnings used

NOTICE

Warning of damage to property.

2. Safety instructions

2.1 General

These instructions are an integral part of the device. They contain texts and figures concerning the correct

handling of the device and must be read before installation or use.

Observe the operating instructions. Non-observance of the instructions, operation which is not in

accordance with use as prescribed below, wrong installation or incorrect handling can seriously affect the

safety of operators and machinery.

2.2 Target group

These instructions are intended for authorised persons according to the EMC and low-voltage directives.

The device must be installed, connected and put into operation by a qualified electrician.

2.3 Electrical connection

Disconnect the device externally before handling it.

The connection pins may only be supplied with the signals indicated in the technical data and on the

device label and only the approved accessories of ifm may be connected.

2.4 Tampering with the device

In case of malfunctions or uncertainties please contact the manufacturer. Any tampering with the

device can seriously affect the safety of operators and machinery. This is not permitted and leads to the

exclusion of any liability and warranty claims.

Page 5

5

3D camera

UK

3. Functions and features

The O3D3xx 3D camera is an optical camera which measures the distance between the camera and the

nearest surface point by point using the time-of-flight principle. The camera illuminates the scene with an

infrared light source and calculates the distance by means of the light reflected from the surface.

The camera supplies data which describes the captured scene three-dimensionally. This distance data

can be output via Ethernet and evaluated by the user. Parameter setting of the camera is also done via

Ethernet.

The camera may only be used under the operating conditions specified in the data sheet.

The camera safety is rated for use under the following operating conditions:

• Indoor use

• Altitudes up to 2000 m

• Relative air humidity up to max. 90 %, non condensing

• Degree of soiling 3

4. Items supplied

The following items are supplied:

● O3D3xx 3D camera

● USB memory stick with software and documentation

● Brief instructions, ident no. 80227244

The data sheet and other documentation (software manual, etc.) are available on our website:

www.ifm.com

→ Data sheet search → e.g. O3D303 → Operating instructions

5. Accessories

The following accessories are needed for the operation of the camera:

Article number Description

E11950 Power supply cable for camera

E11898 M12 industrial Ethernet connection cable

The ifm Vision Assistant software is available free of charge on our website:

www.ifm.com

→ Service → Download → Industrial imaging

Page 6

3D camera

6

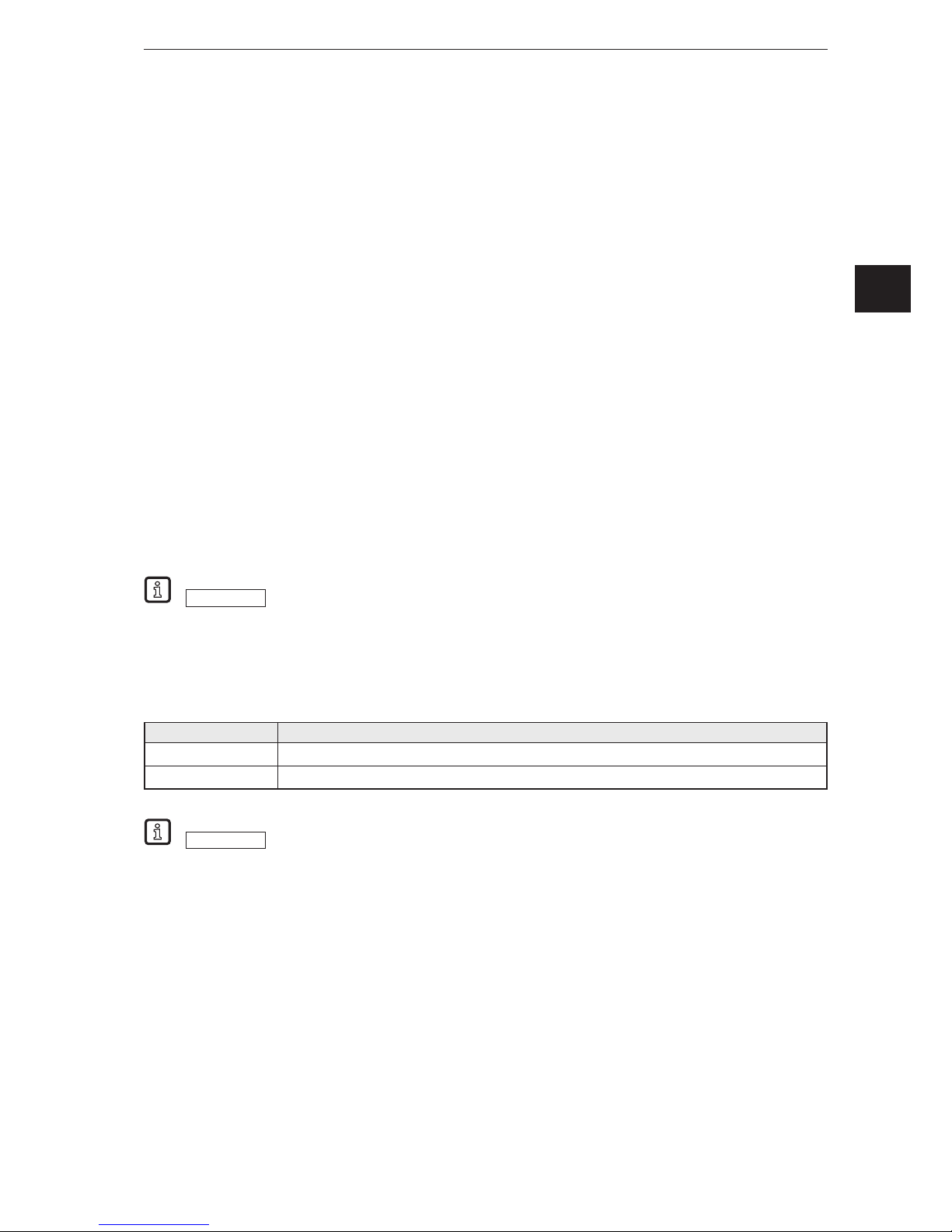

6. Installation

The chapter describes what has to be observed before installation and how to install the camera.

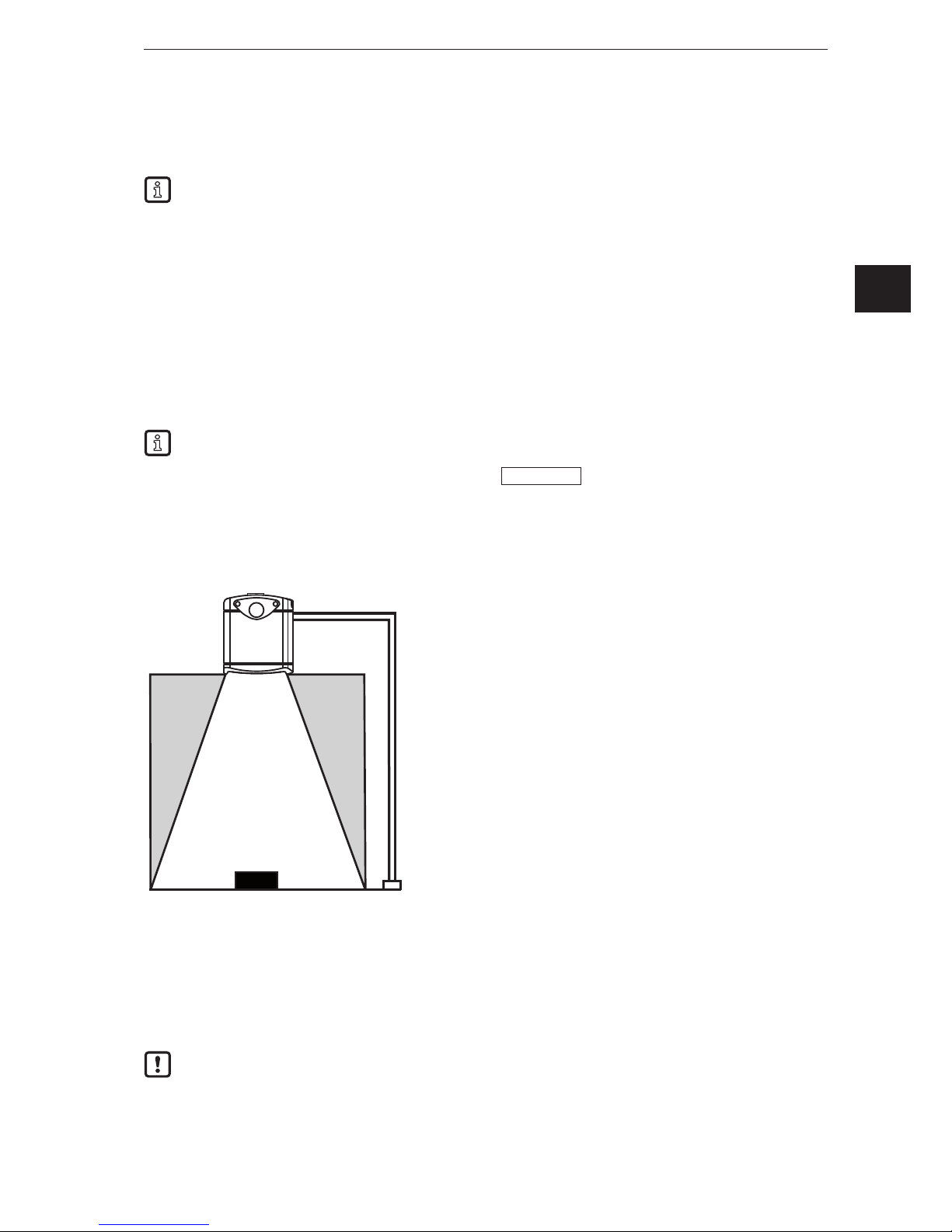

②

①

③

④

⑤

①: Camera

②: Angle of aperture

③: Object

④: Field of view

⑤: Distance between camera and object

6.1 Select installation location

Observe the following instructions for the selection of the installation location:

► The object ③ must be completely in the field of view ④.

> The size of the field of view depends on the camera type and is indicated in the data sheet. The size

of the field of view also depends on the distance of the camera to the object ⑤: With increasing

distance the field of view becomes larger.

► Take tolerances into account when positioning the object.

► When determining the distance between camera and object ⑤ take the measuring range of the camera

into account.

> The measuring range is indicated in the data sheet of the camera.

► Select a distance as small as possible between camera and object ⑤.

> If the distance is as small as possible, the object is detected with the maximum resolution.

► Avoid any strong ambient light and sunlight at the installation location.

> An extraneous light level of over 8 klx (with solar spectrum) causes measurement errors. In fact, only

the infrared component between 800 and 900 nm is of concern.

► Avoid installation in heavily polluted environments.

> In heavily polluted environments the camera lense will get dirty despite downwards orientation ①.

► Avoid transparent panes between the camera ① and the object ③.

> Transparent panes reflect part of the light even if a very clean glass pane is used.

If the instructions are not observed, measurement errors may occur.

Page 7

7

3D camera

UK

6.2 Additional camera installation guidance

The surface temperature of the camera depends on the operating mode, the parameter selection and the

thermal exposure of the camera to the environment.

Make sure that the camera complies with the following requirement:

The surface temperature for easily accessible surfaces may be max. 25 °C higher than the ambient

temperature (to IEC 61010-2-201).

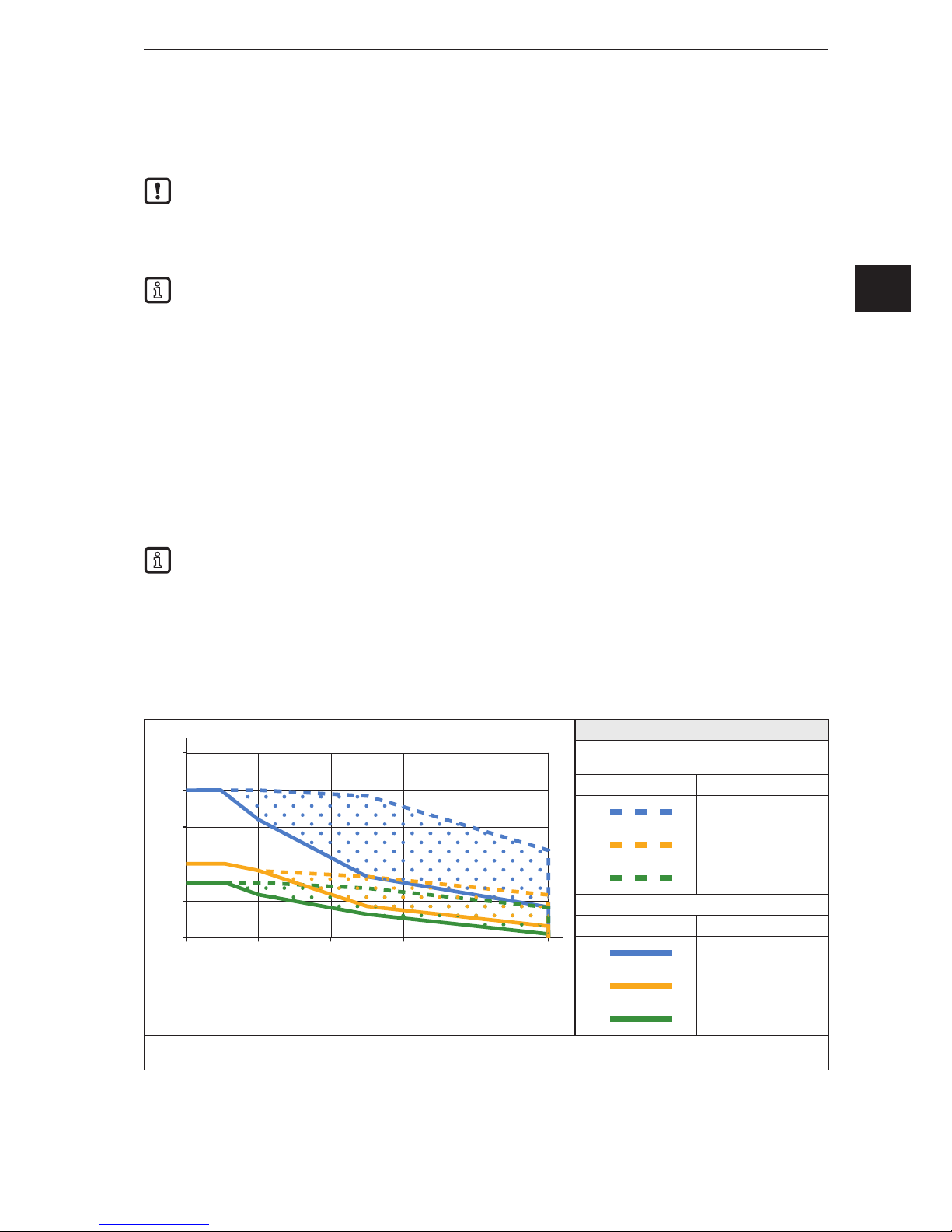

The following diagrams contain typical warning limits as a reference for the installer.

The diagrams are valid for the following operating modes:

● Low [1 exposure]

● Moderate [2 exposures]

● High [3 exposures]

In the event of moderate and high exposures the typical warning limits must be determined via the

sum of the exposure times. The exposure times are indicated in the software ifm Vision Assistant.

Follow one of the instructions if the warning limits are exceeded:

► Reduce the surface temperature (→ 6.2.3).

► Mount the camera in a location or housing that provides protection from the heat source but maintains

air circulation around the camera.

> An increase in the surface temperature of the camera should be prevented.

The parameter "Max. background distance" is set in the ifm Vision Assistant. In the diagrams the

warning limits of the parameter are shown with dashed and continuous lines.

If the camera is in one of the dotted areas, the surface temperature must be reduced, (→ 6.2.3).

If the warning limit is exceeded despite a heat-dissipating installation, it is possible to additionally

mount the contact protection.

If you stay below the typical warning limits in case of normal installation, no measures need to be taken.

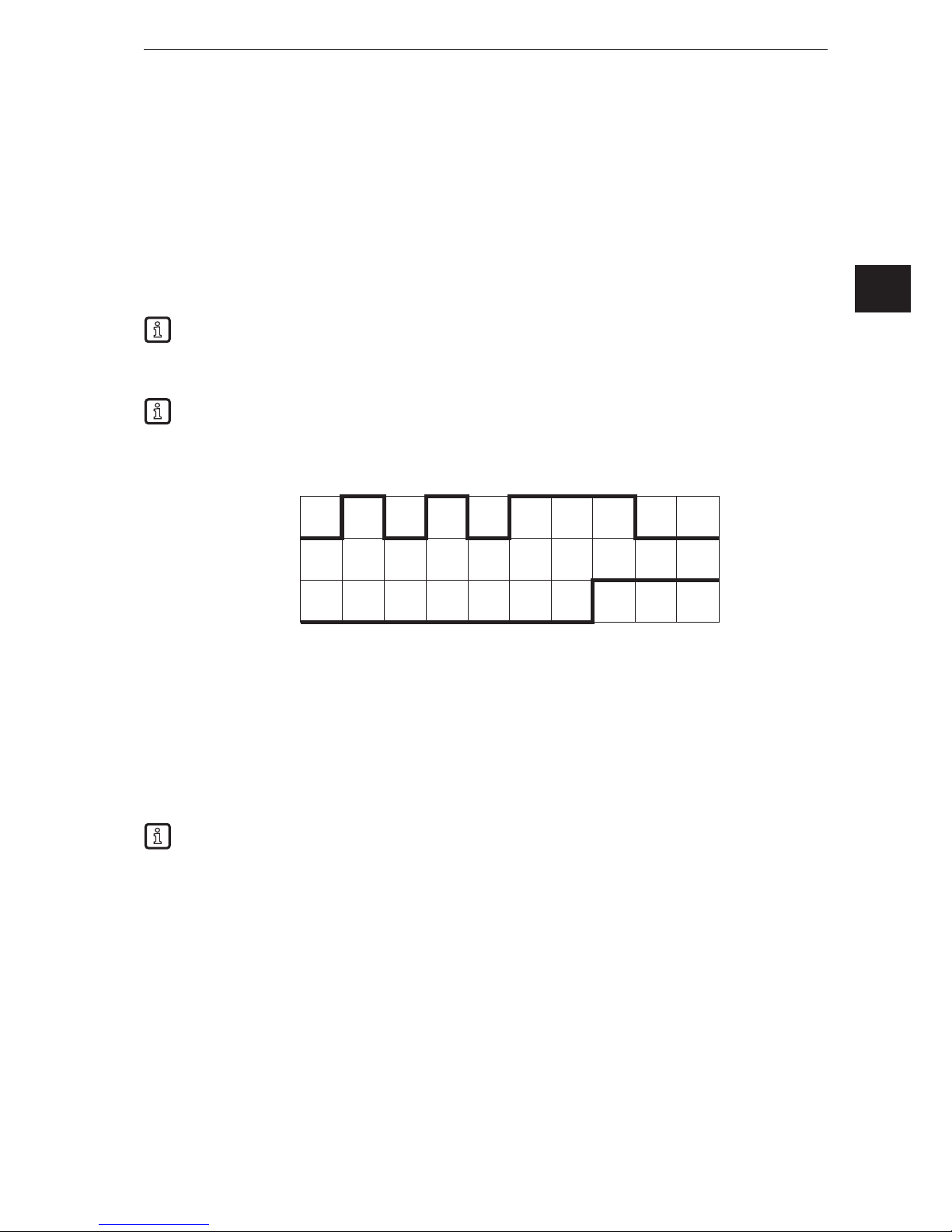

6.2.1 Typical warning limits for O3D301 / O3D303

0

5

10

15

0 2 4 6 8 10

x

y

20

25

Parameter "Max. background distance"

Installation on heat-conductive metal parts

with heat conductor (→ 6.2.3)

Warning limit Parameter

< 5 m

< 30 m

> 30 m

Normal installation

Warning limit Parameter

< 5 m

< 30 m

> 30 m

x = exposure time [ms]

y = frame rate [fps]

Page 8

3D camera

8

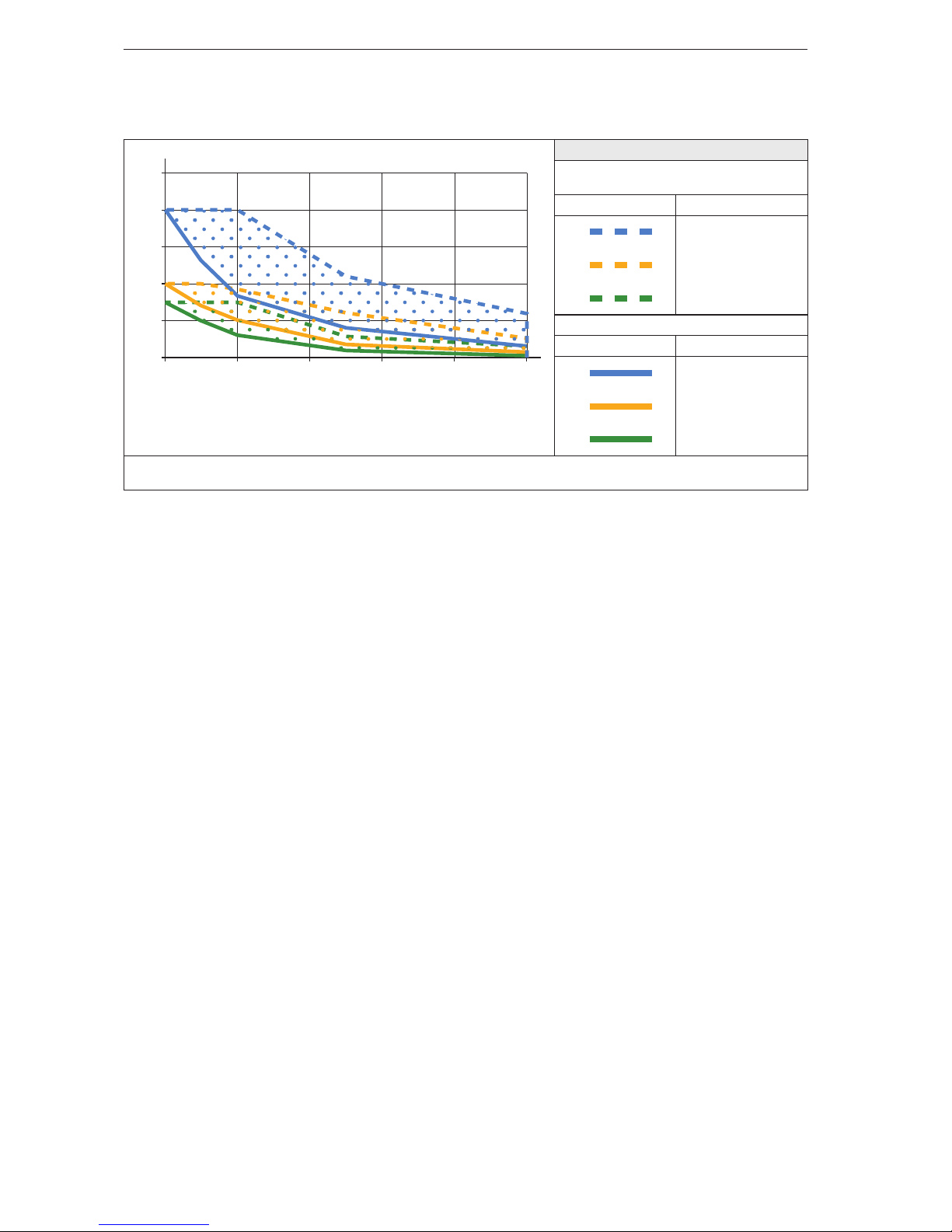

6.2.2 Typical warning limits for O3D311 / O3D313

0

5

10

15

0 2 4 6 8 10

x

y

20

25

Parameter "Max. background distance"

Installation on heat-conductive metal parts

with heat conductor (→ 6.2.3)

Warning limit Parameter

< 5 m

< 30 m

> 30 m

Normal installation

Warning limit Parameter

< 5 m

< 30 m

> 30 m

x = exposure time [ms]

y = frame rate [fps]

6.2.3 Reduce surface temperature

With the following measures the surface temperature can be reduced:

► Mount the camera on heat-conductive metal parts.

> A large-surface contact of the camera with metal parts increases heat dissipation (e.g. aluminium).

► Use a heat conductor when mounting the camera on metal parts.

> The heat-conductive effect is increased by means of the heat conductor. The heat conductor is

available as accessories (→ 6.4).

► Reduce obstructions around the camera. Reduce the density of objects mounted near to the camera.

> Obstructions around the camera and a high installation density may have a negative impact on

convection (air movement).

► Mount one or two heat sinks on the camera.

> The heat sinks increase the surface of the camera, reducing the surface temperature. The heat sinks

are available as accessories (→ 6.4).

► Reduce exposure time, frame rate or max. background distance.

> The operating mode used and the parameters can increase the surface temperature.

Page 9

9

3D camera

UK

6.3 Install camera

Observe the following instructions when installing the camera:

► Mount the camera using 2x M5 screws or mounting set.

> The bore dimensions for the M5 screws are indicated in the data sheet.

> The mounting set is available as accessories (→ 6.4).

► Use strain reliefs for all cables connected to the camera.

Observe the following instructions when installing an O3D301 and O3D311:

► Mount the camera so that the focus adjustment screw can be accessed with a screw driver.

> The position of the focus adjustment screw is indicated in the scale drawing (→ 12).

If the device is permanently used in wet areas, the nut of the M12 Industrial Ethernet cable

(e.g. E11898) may corrode. Use a cable with a high-grade stainless steel nut for permanent use in

wet areas.

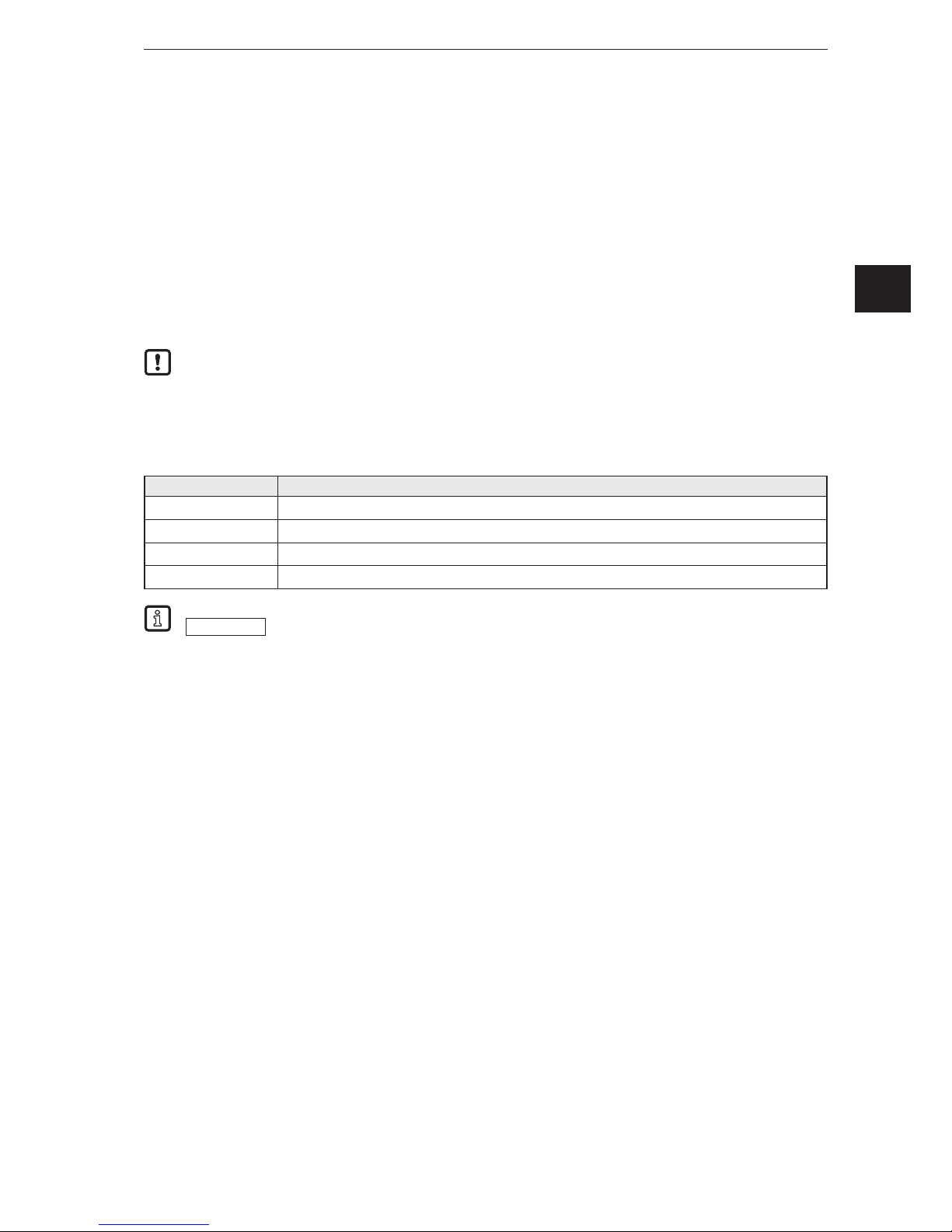

6.4 Mounting accessories

Depending on the location and type of installation, you can use the following mounting accessories:

Article number Description

E3D301 Mounting set Smart Camera

E3D302 Cooling Element Smart Camera

E3D303 Heat conductor Smart Camera

E3D304 2x Cooling Element Smart Camera

You can find more information about the accessories at:

www.ifm.com

→ Data sheet search → e.g. O3D303 → Accessories

Page 10

3D camera

10

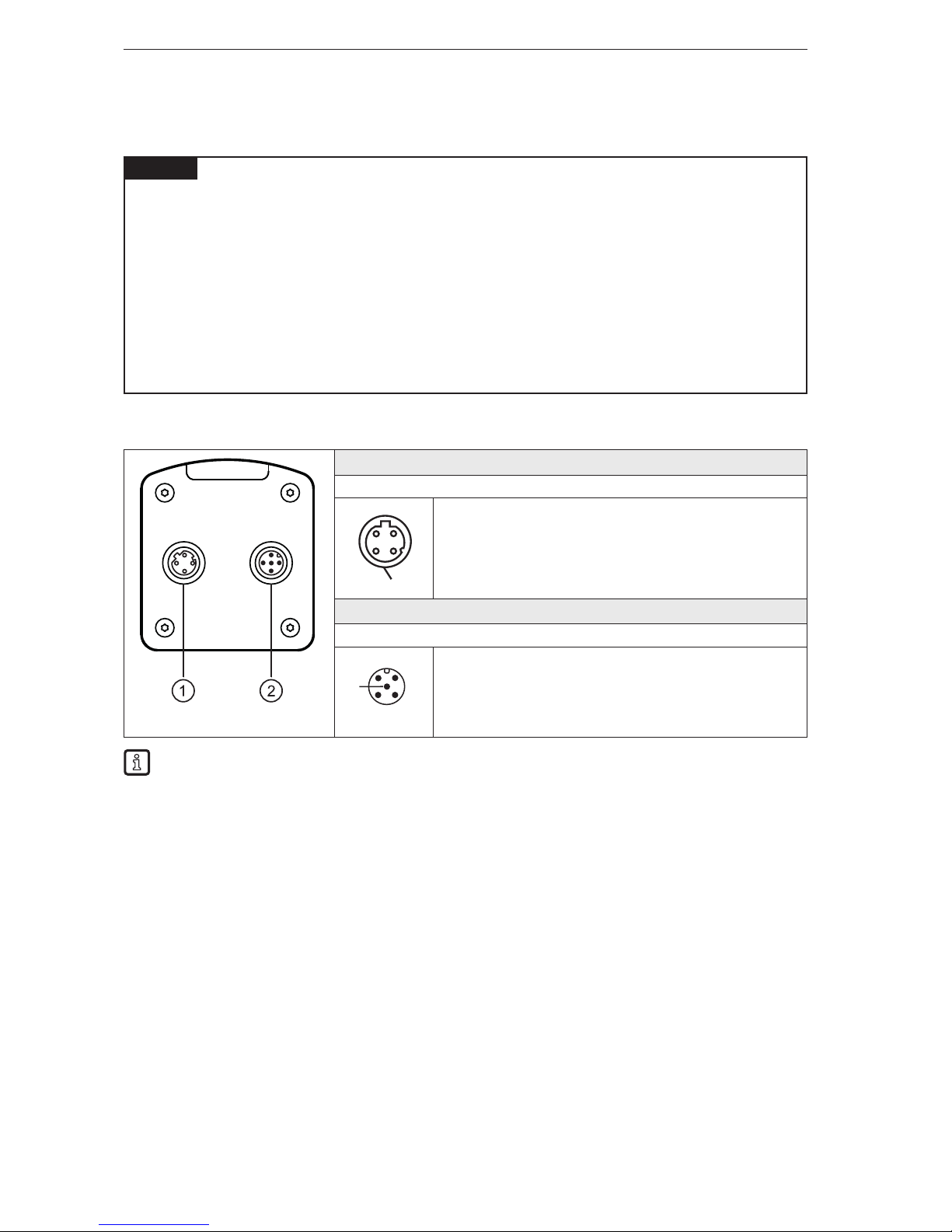

7. Electrical connection

Observe the following instructions before electrical installation.

NOTICE

The camera must be connected by a qualified electrician. Observe the electrical data in the data sheet.

Camera of protection class III (PC III)

The electric supply must only be made via PELV circuits.

Electric supply must correspond to UL61010-1, chapter 9.4 - Limited Energy:

The overcurrent protection device must switch off a current of 6.6 A in 120 s. For the correct rating of the

overcurrent protection device take the technical data of the camera and wiring into account.

The separation of external circuits must comply with UL61010-2-201, fig. 102.

For cable lengths > 30 m use an additional protection against surge voltages to IEC 6100-4-5.

Disconnect power before connecting the camera.

7.1 Wiring

① Ethernet

M12 socket, D-coded, 4 poles

1 TD +

2 RD +

3 TD 4 RD S Shield

② Power supply

M12 connector, A-coded, 5 poles

4

2 1

3

5

1 U+

2 trigger input

3 GND

4 switching output 1 - ready

5 switching output 2 - cascading

The behaviour of the switching inputs and outputs can be set with the software ifm Vision Assistant.

The setting PNP or NPN always applies to all switching inputs and outputs.

When installing actuators and sensors make sure that the setting is correct (e.g. photoelectric

sensors for triggering).

The switching outputs can also be operated as pulse outputs which reset their switching signal

after an adjustable time.

Page 11

11

3D camera

UK

7.1.1 Pin 1 / 3 (24 V / GND)

The permissible voltage range is indicated in the data sheet of the camera.

7.1.2 Pin 2 (trigger input)

The image capture of the camera can be triggered with a switching signal via the trigger input.

The following trigger edges can be used:

● Falling edge triggers image capture

● Rising edge triggers image capture

● Falling and rising edges trigger image capture

Further possibilities to trigger the camera:

● Process interface commands (→ 13.3)

● Continuous image capture with fixed frame rate

The trigger input is internally debounced. Depending on the electrical installation debouncing of the

trigger wire is not necessary.

Internal debouncing prevents several short pulses from triggering. The pulse must be at least 2 ms

long to be recognised as a trigger.

7.1.3 Pin 4 / 5 (ready / cascading)

The electrical data of the switching outputs 1 and 2 (ready / cascading) is indicated in the data sheet.

The switching outputs provide the following camera status set as default:

● Switching output 1: "Ready for trigger"

● Switching output 2: "Image capture finished"

"Switching output switched" means that the respective camera status has occurred.

Depending on the setting the camera status can have one of the following values:

● "Ready for trigger"

The camera signals that a new image can be captured. Only with this camera status trigger operations

are processed. For the continuous image capture the camera status "Ready for trigger" is not output.

● "Image capture finished"

The camera signals that the image capture is finished. The camera status can be used for cascading

cameras.

● "Evaluation finished"

The camera signals that image processing is finished. At that moment the switching outputs are

already updated. The image data is transmitted via Ethernet.

● "Error"

The camera signals an internal error. Detailed information about errors can be requested via Ethernet.

image capture

Trigger input

Time [ms]

1 2 3 4 5 6 7 8 9 10 11

Page 12

3D camera

12

7.2 Wiring examples

Wiring examples of the camera are given below.

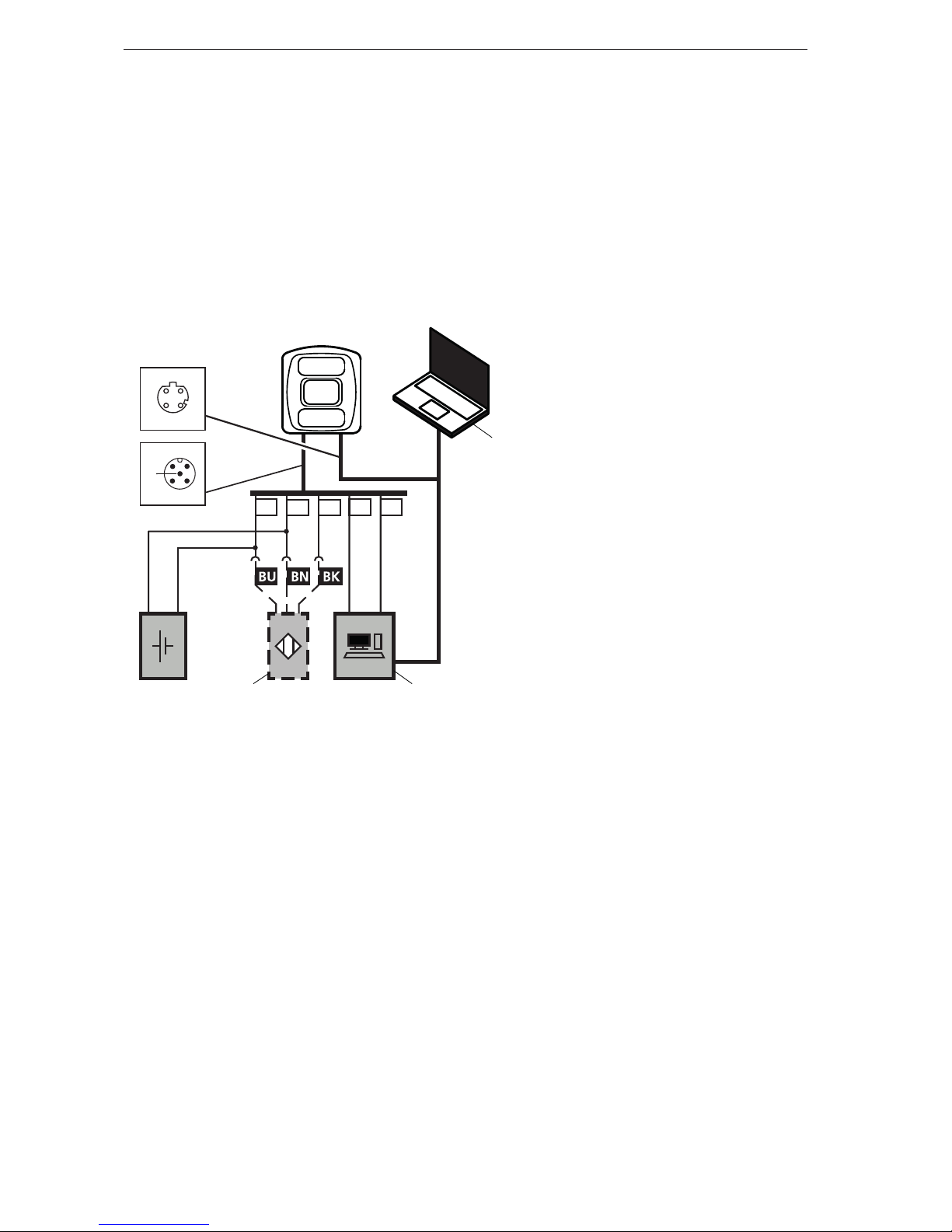

7.2.1 Trigger image capture with proximity sensor

The camera can be triggered externally:

● via Ethernet

● via a proximity sensor connected to the trigger input

The following illustration shows the wiring of the camera with a proximity sensor.

3 1 2 4 5

1 2

34

4

2 1

3

5

DC 24 V

+

-

IN IN

①

② ③

①: Notebook (parameter setting)

②: Proximity sensor

③: Industrial PC (evaluate / trigger)

Page 13

13

3D camera

UK

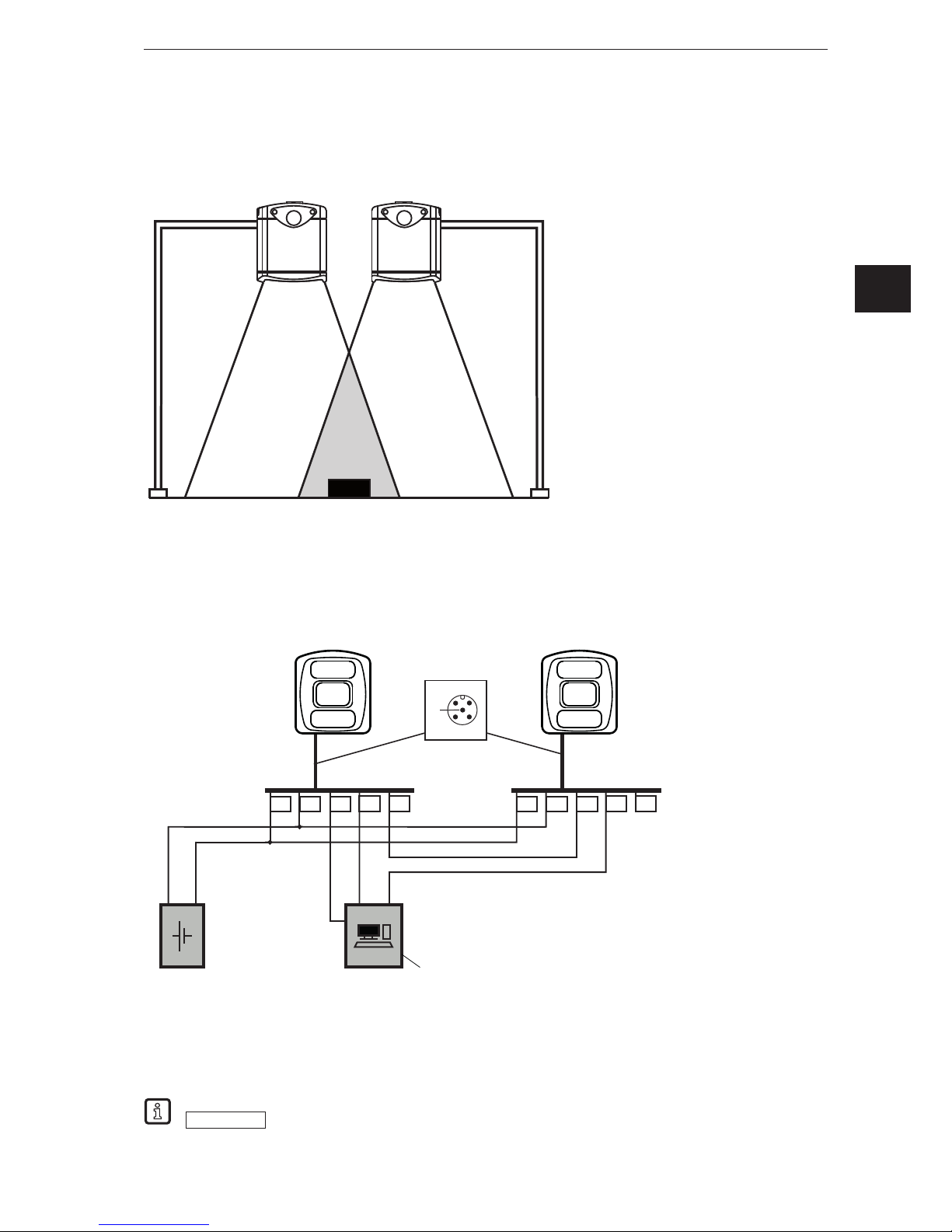

7.2.2 Install several cameras next to each other

Cameras installed next to each other can cause measurement errors due to simultaneous exposure.

①: 1st camera

②: 2nd camera

③: Object

The measurement errors can be avoided in two ways:

● Cascade cameras via HW trigger

During cascading a controller triggers the image capture of the 1st camera. After completion of the

image capture the 1st camera automatically triggers the 2nd camera. The 2nd camera signals the end

of the sequence to the controller.

3 1 2 4 5

4

2 1

3

5

DC 24 V

+

-

IN IN

3 1 2 4 5

①

①: Industrial PC

(evaluate /

trigger)

● Use different frequency channels

With the software ifm Vision Assistant each camera can be assigned its own frequency channel. The

different frequency channels reduce the occurrence of measurement errors.

The ifm Vision Assistant software is available free of charge on our website:

www.ifm.com

→ Service → Download → Industrial imaging

①

②

③

Page 14

3D camera

14

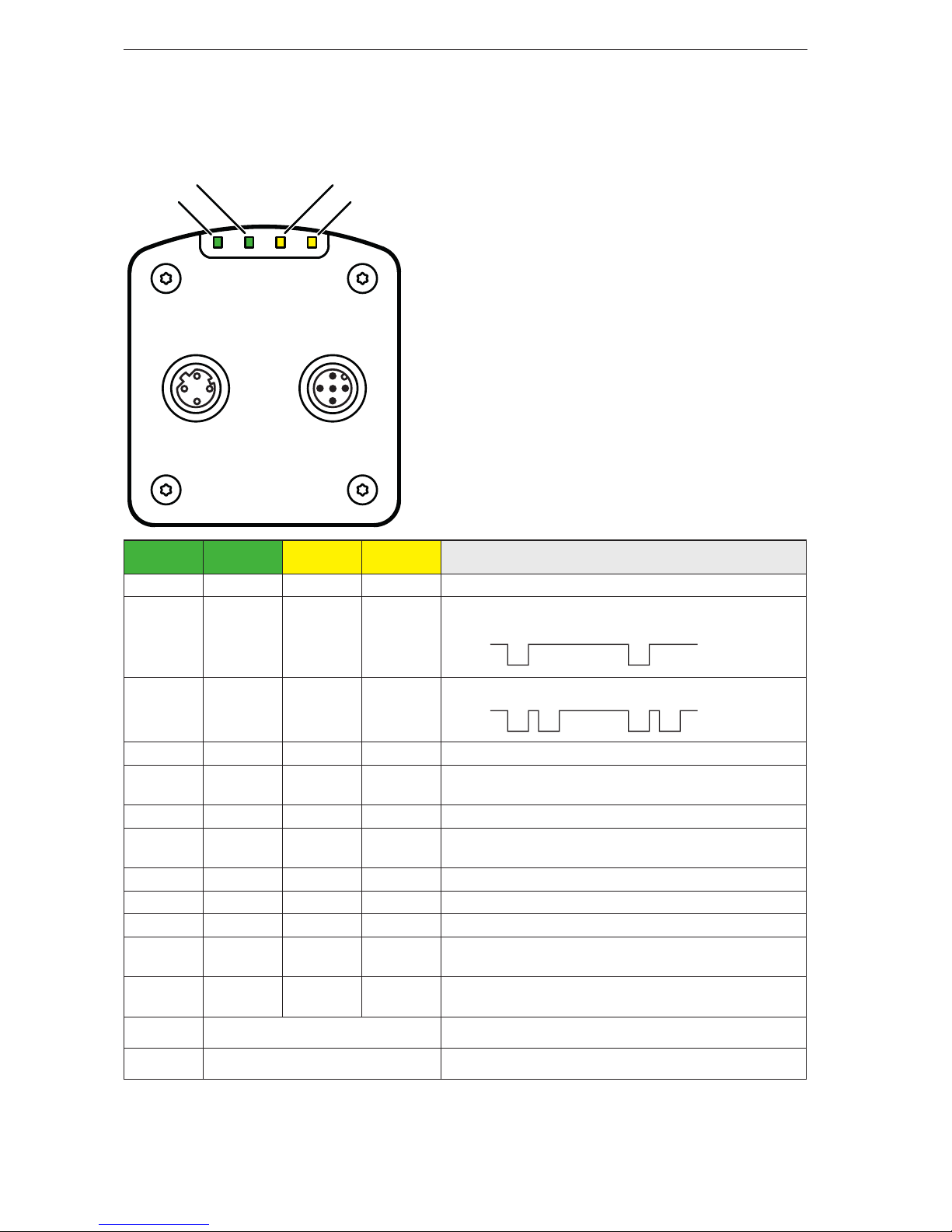

8. Indicators

Via the LED indicators 1 - 4 the camera signals the current operating state.

LED 4

(Ethernet)

LED 1

(Power)

LED 2

(Out 1)

LED 3

(Out 2)

Description

Lights Camera is ready for operation, supply voltage applied

Flashes

at 0.5 Hz

No parameters set or parameter setting was not

loaded into the camera

On

Off

Flashes

2x at 0.5

Hz

Camera is in the parameter setting mode

On

On

Off

Off

Lights Switching output 1 switched

Flashes

at 8 Hz

Switching output 1 shorted

Lights Switching output 2 switched

Flashes

at 8 Hz

Switching output 2 shorted

Lights Ethernet connected

Flashes Ethernet transmitting data

Off Ethernet not connected

Flashes

at 8 Hz

Flashes

at 8 Hz

Camera signals internal error

Flashes

at 2 Hz

Flashes

at 2 Hz

Camera signals correctable error. The error information

can be read via Ethernet

Running light ⇒

Camera booting

Running light ⇐

Camera carrying out firmware update

LED 4 LED 3

LED 1 LED 2

Page 15

15

3D camera

UK

9. Set-up

After power on the camera is put into operation. After 15 seconds the camera is in the evaluation mode

where saved applications are executed. The indicators signal the current operating state (→ 8).

Up to 32 applications can be saved on the camera. Typically, an application contains the following

parameters:

● Image capture: e.g. triggering of the image capture, exposure time, image processing filter

● Interface: Ethernet, switching outputs

The respective application can be activated with the software ifm Vision Assistant or via process

interface commands.

9.1 Set parameters of the camera

The camera parameters can be set in two ways:

● Software ifm Vision Assistant (→ see software manual)

● XML-RPC command (→ 13.5)

The software ifm Vision Assistant and detailed information about the measuring principle of the

camera are described in the software manual.

The software manual is available on our website:

www.ifm.com

→ Data sheet search → e.g.

O3D303 → Operating instructions

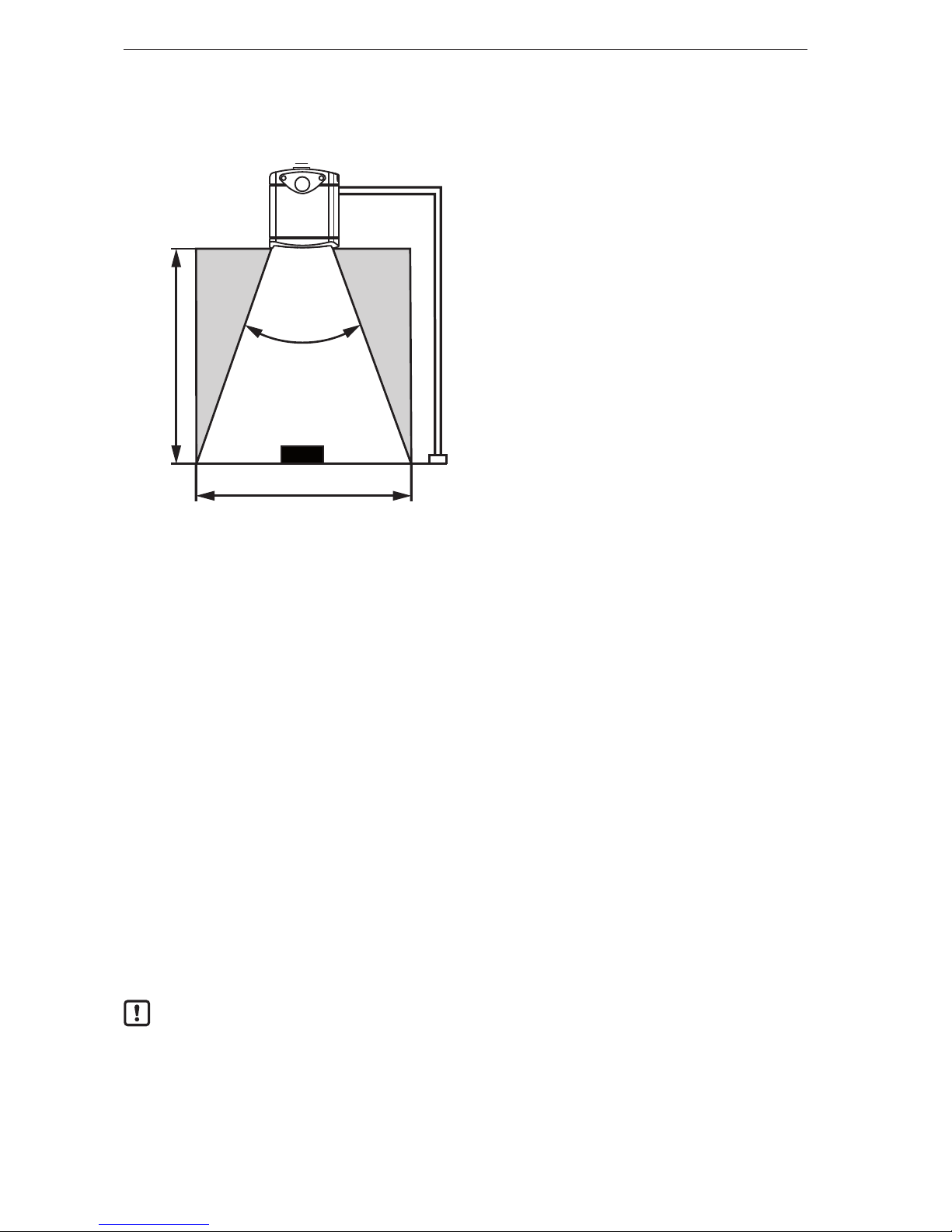

9.2 Detect object

The conditions which lead to a high detection rate of objects are described below.

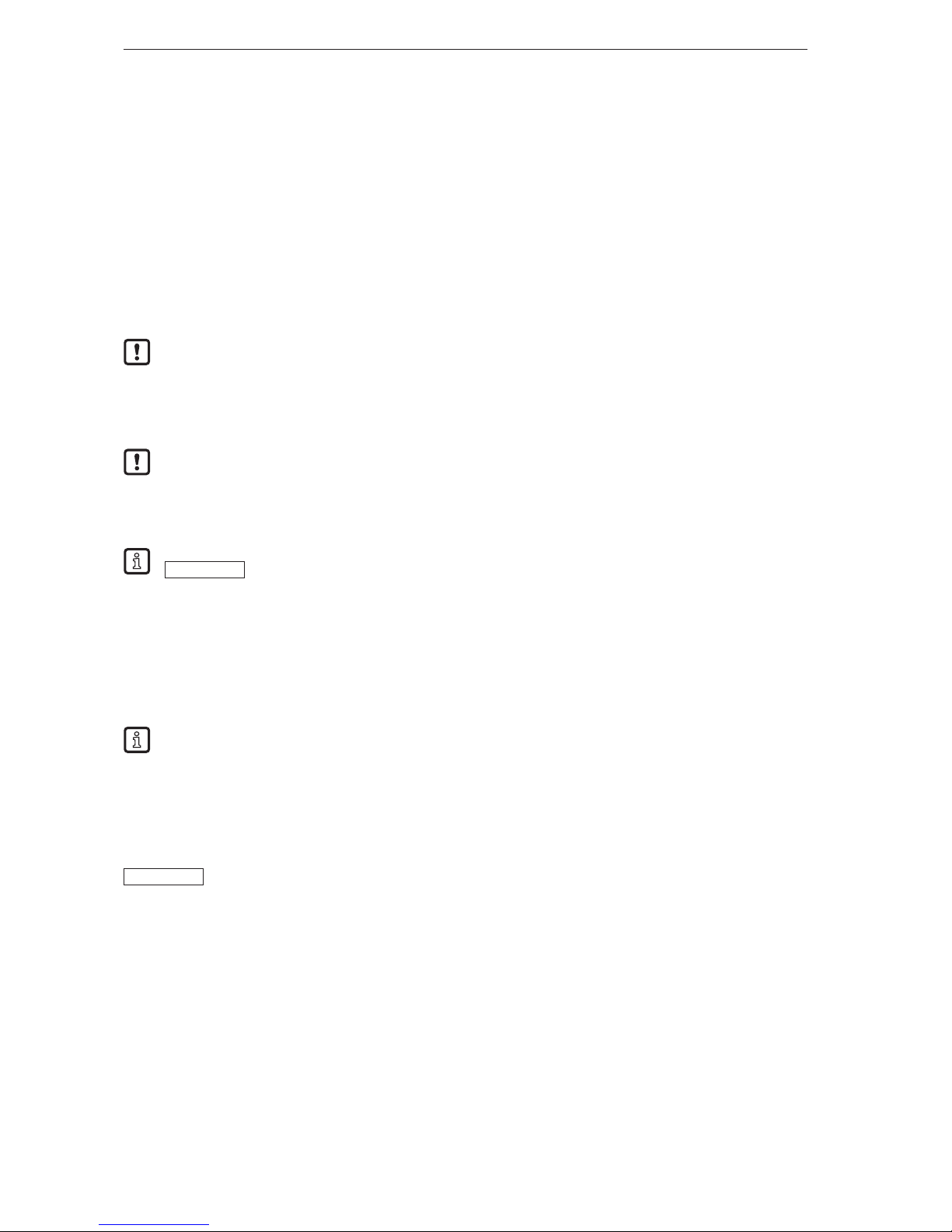

①: Camera

②: Zone of influence

③: Field of view

④: Object

Optimum detection of an object ④ is given if the following conditions are met:

● Object is positioned in the field of view ③

● Object is the nearest visible object to the camera ①

● Zone of influence ② is clear from objects (obstructions etc.)

● Lens window of the camera is free from soiling.

If the conditions are not met, measurement errors may occur.

③

②

④

②

①

Page 16

3D camera

16

10. Maintenance, repair and disposal

Observe the following instructions:

► Do not open the housing as the camera does not contain any components which can be maintained by

the user. The camera must only be repaired by the manufacturer.

► Dispose of the camera in accordance with the national environmental regulations.

10.1 Clean

Observe the following instructions before cleaning the camera:

► Use clean and lint-free cloth.

► Use glass cleaner as cleaning agent.

If the instructions are not observed, scratches on the lens window may cause measurement errors.

10.2 Update firmware

With the software ifm Vision Assistant the firmware of the camera can be updated.

Parameters saved in the camera get lost by the firmware update. Create a backup copy of the

parameters before updating the firmware:

► Before updating the firmware export parameters.

► After updating the firmware import parameters.

Firmware updates are available on our website:

www.ifm.com

→ Service → Download → Industrial imaging

10.3 Replace camera

When a camera is replaced the parameters get lost. Before replacing the camera create a backup copy of

the parameters:

► Before replacement export the parameters of the old camera.

► After replacement import the parameters into the new camera.

With the export and import of parameters several cameras can be quickly provided with the same

parameters.

11. Approvals/standards

The CE declaration of conformity is available at:

www.ifm.com

→ Data sheet search → e.g. O3D303 → Approvals

Page 17

17

3D camera

UK

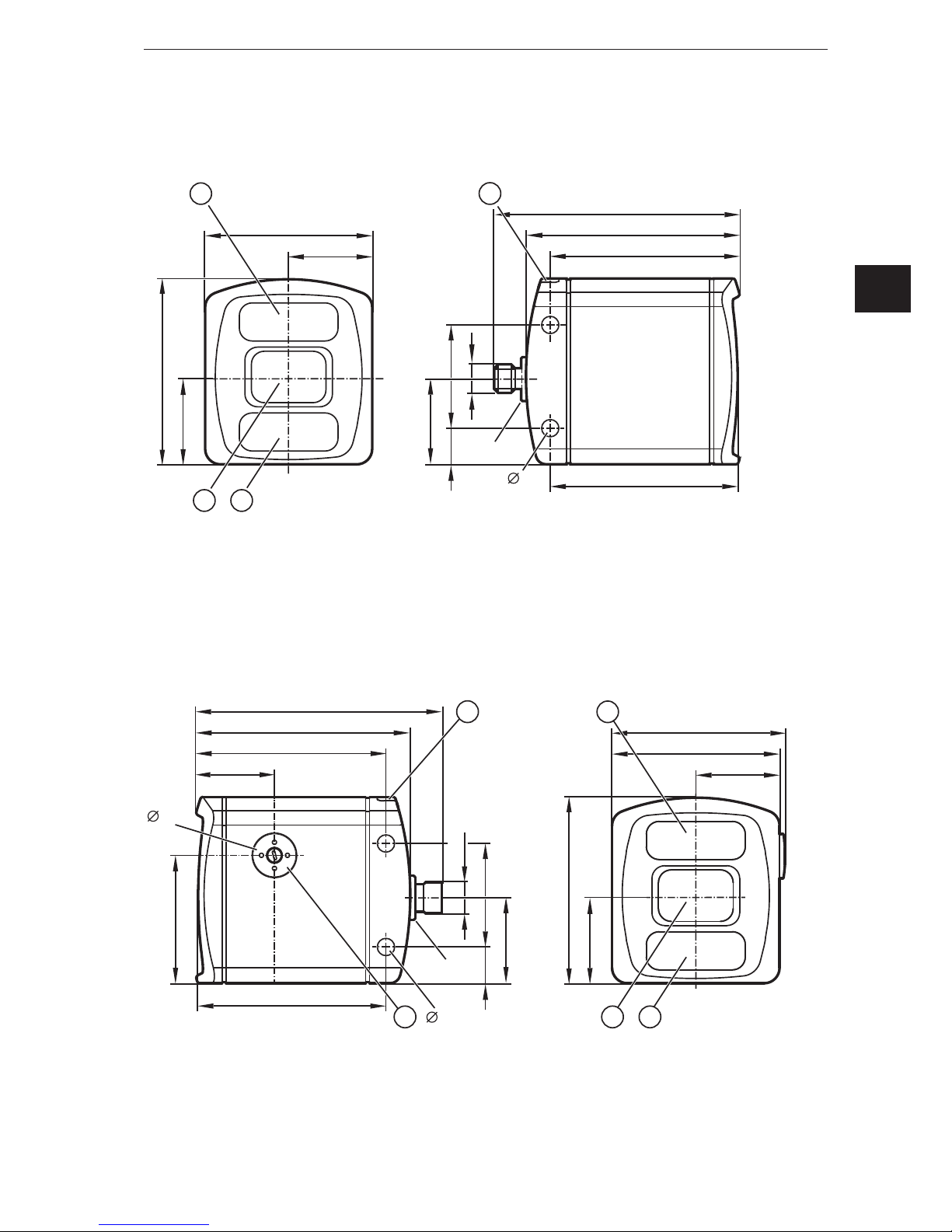

12. Scale drawings

12.1 O3D303 / O3D313

①: Lens

②: Illumination unit

③: LED 2 colours (yellow/green)

12.2 O3D301 / O3D311

①: Lens

②: Illumination unit

③: LED 2 colours (yellow/green)

④: Focal setter

Original Scale Drawing (MTD)

33

3

5,7

M12x1

4014

95

82,6

73,3

71,6

72

65

32,5

21

33

2

M12x1

Original Scale Drawing (MTD)

33

3

5,7

M12x1

4014

95

82,6

73,3

71,6

49

17,1

28,7

4

M12x1

72

65

32,5

2

21

33

67,1

Page 18

3D camera

18

13. Appendix

13.1 Required Ports

The following ports are required for the camera configuration using XML-RPC and for receiving data on

the process interface. They must not be blocked by a firewall or router.

● TCP/HTTP: 80

● TCP: 50010

If the ifm Vision Assistant is used, the following additional ports must also be available:

● UDP: 3321

● TCP/HTTP: 8080

It is possible to configure another port than 50010 for the process interface. If a different port is used, it

must not be blocked either.

13.2 XML-RPC Interface

In case the O3D3xx camera should not be configured by the “ifmVisionAssistant”, the XML-RPC interface

can be used instead.

General information about XML-RPC is found on the website http://xmlrpc.scripting.com/spec

To send a command via the XML-RPC interface the command has to be in a special layout. In this

command, linefeeds and carriage returns are essential.

Every command which has to be sent via the XML-RPC interface must end with

carriage return <CR> and linefeed <LF>.

Several commands will use different URLs in the XML-RPC header.

13.2.1 Sample XML-RPC command

All following XML-RPC commands will have this type of layout:

POST /RPC3 HTTP/1.0<CR><LF>

User-Agent: Frontier/5.1.2 (WinNT)<CR><LF>

Host: betty.userland.com<CR><LF>

Content-Type: text/xml<CR><LF>

Content-length: 181<CR><LF>

<CR><LF>

<?xml version="1.0"?><CR><LF>

<methodCall><CR><LF>

<methodName>examples.getStateName</methodName><CR><LF>

<params><CR><LF>

<param><CR><LF>

<value><i4>41</i4></value><CR><LF>

</param><CR><LF>

</params><CR><LF>

</methodCall><CR><LF>

Page 19

19

3D camera

UK

The following example contains one O3D3xx command:

POST /api/rpc/v1/com.ifm.efector/ HTTP/1.1 <CR><LF>

User-Agent: Frontier/5.1.2 (WinNT)<CR><LF>

Host: 192.168.0.69<CR><LF>

Content-Type: text/xml<CR><LF>

Content-length: 94<CR><LF>

<CR><LF>

<?xml version="1.0"?><CR><LF>

<methodCall><CR><LF>

<methodName>getParameter</methodName><CR><LF>

</methodCall><CR><LF>

13.2.2 XML-RPC Objects

To communicate and to configure the device via XML-RPC the XML-RPC commands have to use

different XML-RPC objects. Different commands need different XML-RPC objects (see XML-RPC

command references).

The interface of O3D3xx is structured in an object-oriented way. Some of the objects are available all

the time, others are only available after bringing the device into a special mode by calling a method

on an already available object. This mechanism is used to create system requirements (e.g. password

protection).

It could be necessary to send heartbeats so that there will be no session timeout.

The following diagram should give an overview how objects are related to each other and which methods

must be called to make others available:

Main API

Session

EditMode

ApplicationConfig

requestSession(...)

setOperatingMode(1)

editApplication(1)

DeviceConfig

NetworkConfig

ImagerConfig

Page 20

3D camera

20

Main Object

Object-URI: /api/rpc/v1/com.ifm.efector/

This is the main object of RPC. It contains methods to open a session. The session contains methods for

activating the edit mode. Most of its methods are only getters, because it should be possible to protect

editing with a password.

Session Object

Object URI e.g.: /api/rpc/v1/com.ifm.efector/session_d21c80db5bc1069932fbb9a3bd841d0b/

The URL part “d21c80db5bc1069932fbb9a3bd841d0b” is the session ID. It is returned by the command

"requestSession" of the main object. If the command "requestSession" is called without a user-defined

session ID, which can be passed as a parameter, a random session ID is generated automatically.

EditMode Object

Object URI e.g.: /api/rpc/v1/com.ifm.efector/session_d21c80db5bc1069932fbb9a3bd841d0b/edit/

This object is only available if the device is in the edit operating mode. The index of applications must be

between 1 and 32. The device must only support 32 applications and the indexes must start at 1.

DeviceCong Object

Object-URI e.g.: /api/rpc/v1/com.ifm.efector/session_d21c80db5bc1069932fbb9a3bd841d0b/edit/device/

Device/NetworkCong Object

Object URI e.g.:

/api/rpc/v1/com.ifm.efector/session_d21c80db5bc1069932fbb9a3bd841d0b/edit/device/network/

Application Cong Object (editable application)

Object URI e.g.:

/api/rpc/v1/com.ifm.efector/session_d21c80db5bc1069932fbb9a3bd841d0b/edit/application/

Main API

Session

EditMode

ApplicationConfig

cancelSession(...) removes itself from RPC. Session will also

be removed, if heartbeat(...) is not called at the right time

setOperatingMode(0) will remove EditMode from RPC

stopEditApplication() will remove ApplicationConfig from RPC

Page 21

21

3D camera

UK

Application/Imager Cong Object (O3D3xx)

Object URI e.g.:

/api/rpc/v1/com.ifm.efector/session_d21c80db5bc1069932fbb9a3bd841d0b/edit/application/imager_001/

As there is only one imager config on O3D3xx, the ID must be fixed to "001". Data of this object is

persistently saved when calling "save" on the application config object. The imager config RPC object

has multiple sub-types. Only parameters relevant for a specific type are available while it is active. They

are based on frequency (extending the distance) and integration intervals (extending the measurement

details).

Type names, based on GUI draft (under 5 metres -> single frequency, up to 30 metres -> double

frequency, more than 30 metres -> triple frequency.):

under5m_low

under5m_moderate

under5m_high

upto30m_low

upto30m_moderate

upto30m_high

morethan30m_low

morethan30m_moderate

Image Settings and Filter Parameters

There is an RPC object for spatial filter parameters in each imager configuration.

Object URI e.g.: /api/rpc/v1/com.ifm.efector/session_d21c80db5bc1069932fbb9a3bd841d0b/edit/

application/imager_001/spatialfilter

There is an RPC object for temporal filter parameters in each imager configuration.

Object URI e.g.: /api/rpc/v1/com.ifm.efector/session_d21c80db5bc1069932fbb9a3bd841d0b/edit/

application/imager_001/temporalfilter

Data of these objects is persistently saved when calling "save" on application config object.

Page 22

3D camera

22

13.3 Process Interface

The process interface is used during the normal operation mode to get operational data (e.g. 3D images,

process values) from the O3D3xx.

13.3.1 Sending Commands

For sending commands via the process interface the commands have to be sent with a special protocol

and as ASCII character strings. This protocol conforms to the version 3 of the O2V/O2D products.

Structure of the protocol:

<Ticket><length>CR LF <Ticket><content>CR LF

Abbreviation Description ASCII code (dec) ASCII code (hex)

CR Carriage Return 13 D

LF Linefeed 10 A

< > Marking of a placeholder

(e.g. <code> is a placeholder for code)

[ ] Optional argument

(possible but not required)

Command Description

<content> It is the command to the device (e.g. trigger the unit).

<ticket> It is a character string of 4 digits between 0-9. If a message with a specific ticket is sent

to the device, it will response with the same ticket.

<length> It is a character string beginning with the letter 'L' followed by 9 digits. It indicates the

length of the following data (<ticket><content>CR LF) in bytes.

They are different protocol versions available:

Version Input format Output format

V1 <Content>CR LF as input

V2 <Ticket><Content>CR LF as input

V3 <Ticket><Length>CR+LF<Ticket><Content>CR LF as input

V4 <Content>CR LF <length>CR LF<Content>CR LF

The default protocol version is "V3". It is recommended to use protocol version 3 for machine

to machine communication. This is due to the fact that only version 3 supports asynchronous

messages and provides length information.

13.3.2 Receiving Images

For receiving the image data a TCP/IP socket communication has to be established. The default port

number is 50010. The port number may differ based on the configuration. After opening the socket

communication, the O3D3XX device will automatically (if the device is in free run mode) send the data

through this socket to the TCP/IP client (PC).

PCIC output per frame. The following data shall be submitted in this sequence:

Component Content

Ticket and length information (→ 13.4.2)

Ticket „0000“

Start sequence String "star" (4 bytes)

Normalised amplitude image

Output format: 16-bit unsigned integer

1 image

Page 23

23

3D camera

UK

Component Content

Distance image

Output format: 16-bit integer. Unit: mm.

1 image

X image

Output format: 16-bit signed integer. Unit:

mm.

1 image

Y image

Output format: 16-bit signed integer. Unit:

mm.

1 image

Z image

Output format: 16-bit signed integer. Unit:

mm.

1 image

Confidence image

Output format: 8-bit unsigned integer

1 image

Diagnostic data

Stop sequence String "stop" (4 bytes)

Ticket signature <CR><LF>

13.3.3 Image data

For every image there will be a separate chunk. The chunk is part of the response frame data of the

process interface.

The header of each chunk contains different kinds of information. This information is separated into bytes.

The information contains e.g. the kind of image which will be in the “PIXEL_DATA” and the size of the

chunk.

Chunk type:

Offset Name Description Size [byte]

0x0000 CHUNK_TYPE Defines the type of the chunk. For each distinct chunk

an own type is defined.

4

0x0004 CHUNK_SIZE Size of the whole image chunk in bytes. After this count

of bytes the next chunk starts.

4

0x0008 HEADER_SIZE Number of bytes starting from 0x0000 until PIXEL_

DATA.

4

0x000C HEADER_VERSION Version number of the header 4

0x0010 IMAGE_WIDTH Image width in pixel 4

0x0014 IMAGE_HEIGTH Image height in pixel 4

0x0018 PIXEL_FORMAT Pixel format 4

0x001C TIME_STAMP Time stamp in microseconds 4

0x0020 FRAME_COUNT Frame counter 4

0x0024 PIXEL_DATA The pixel data in the given type and dimension of the

image. Padded to 4-byte boundary.

4

Page 24

3D camera

24

Available chunk types:

Constant Value Description

USERDATA 0 Undefined user data with arbitrary content

RADIAL_DISTANCE_

IMAGE

100 Each pixel of the distance matrix denotes the ToF distance

measured by the corresponding pixel or group of pixels of

the imager. The distance value is corrected by the camera's

calibration, excluding effects caused by multipath and multiple

objects contributions (e.g. "flying pixels"). Reference point is the

optical centre of the camera inside the camera housing.

Invalid PMD pixels (e.g. due to saturation) have a value of zero.

Data type: 16-bit unsigned integer (little endian)

Unit: millimetres

NORM_AMPLITUDE_

IMAGE

101 Each pixel of the normalized amplitude image denotes the raw

amplitude (see amplitude image below for further explanation),

normalized to exposure time. Furthermore, vignetting effects

are compensated, ie the darkening of pixels at the image border

is corrected. The visual impression of this grayscale image is

comparable to that of a common 2D camera.

Invalid PMD pixels (e.g. due to saturation) have an amplitude value

of 0.

Data type: 16-bit unsigned integer

AMPLITUDE_IMAGE 103 Each pixel of the amplitude matrix denotes the amount of

modulated light (i.e. the light from the camera's active illumination)

which is reflected by the appropriate object. Higher values indicate

higher PMD signal strengths and thus a lower amount of noise on

the corresponding distance measurements. The amplitude value

is directly derived from the PMD phase measurements without

normalisation to exposure time. In multiple exposure mode,

the lack of normalisation may lead (depending on the chosen

exposure times) to inhomogeneous amplitude image impression, if

a certain pixel is taken from the short exposure time and some of

its neighbours are not.

Invalid PMD pixels (e.g. due to saturation) have an amplitude value

of 0.

Data type: 16-bit unsigned integer

CARTESIAN_X_

COMPONENT

200 The X matrix denotes the X component of the Cartesian coordinate

of a PMD 3D measurement. The origin of the camera's coordinate

system is in the middle of the lens' front glass, if the extrinsic

parameters are all set to 0.

Data type: 16-bit signed integer

Unit: millimetres

CARTESIAN_Y_

COMPONENT

201 The Y matrix denotes the Y component of the Cartesian coordinate

of a PMD 3D measurement. The origin of the camera's coordinate

system is in the middle of the lens' front glass, if the extrinsic

parameters are all set to 0.

Data type: 16-bit signed integer

Unit: millimetres

Page 25

25

3D camera

UK

Constant Value Description

CARTESIAN_Z_

COMPONENT

202 The Z matrix denotes the Z component of the Cartesian coordinate

of a PMD 3D measurement. The origin of the camera's coordinate

system is in the middle of the lens' front glass, if the extrinsic

parameters are all set to 0.

Data type: 16-bit signed integer

Unit: millimetres

CARTESIAN_ALL 203 CARTESIAN_X_COMPONENT,

CARTESIAN_Y_COMPONENT,

CARTESIAN_Z_COMPONENT

UNIT_VECTOR_ALL 223 The unit vector matrix contains 3 values [ex, ey, ez] for each PMD

pixel, i.e. the data layout is [ex_1,ey_1,ez_1, ... ex_N, ey_N,

ez_N], where N is the number of PMD pixels.

Data type: 32-bit floating point number (3x per pixel)

CONFIDENCE_IMAGE 300 See Additional Information for Image Data (→ 13.3.4)

DIAGNOSTIC 302 See Receiving Images (→ 13.3.2)

Pixel format:

Constant Value Description

FORMAT_8U 0 8-bit unsigned integer

FORMAT_8S 1 8-bit signed integer

FORMAT_16U 2 16-bit unsigned integer

FORMAT_16S 3 16-bit signed integer

FORMAT_32U 4 32-bit unsigned integer

FORMAT_32S 5 32-bit signed integer

FORMAT_32F 6 32-bit floating point number

FORMAT_64U 7 64-bit unsigned integer

FORMAT_64F 8 64-bit floating point number

Reserved 9 N/A

FORMAT_32F_3 10 Vector with 3x32-bit floating point number

Page 26

3D camera

26

13.3.4 Additional Information for CONFIDENCE_IMAGE

Further information for the confidence image:

Bit Value Description

0 1 = pixel invalid Pixel invalid

The pixel is invalid. To determine whether a pixel is valid or not

only this bit needs to be checked. The reason why the bit is

invalid is recorded in the other confidence bits.

1 1 = pixel saturated Pixel is saturated

Contributes to pixel validity: yes

2 1 = bad A-B symmetry A-B pixel symmetry

The A-B symmetry value of the four phase measurements is

above threshold.

Remark: This symmetry value is used to detect motion

artefacts. Noise (e.g. due to strong ambient light or very short

integration times) or PMD interference may also contribute.

Contributes to pixel validity: yes

3 1 = amplitude below

minimum amplitude

threshold

Amplitude limits

The amplitude value is below minimum amplitude threshold.

Contributes to pixel validity: yes

4+5 Bit 5, bit 4

0 0 = unused

0 1 = shortest exposure

time (only used in 3

exposure mode)

1 0 = middle exposure

time in 3 exposure mode,

short exposure in double

exposure mode

1 1 = longest exposure

time (always 1 in single

exposure mode)

Exposure time indicator

The two bits indicate which exposure time was used in a

multiple exposure measurement.

Contributes to pixel validity: no

6 N/A Currently not used

7 1 = suspect/defective pixel Suspect pixel

This pixel has been marked as "suspect" or "defective" and

values have been replaced by interpolated values from the

surroundings.

Contributes to pixel validity: no

Page 27

27

3D camera

UK

13.3.5 Conguration of PCIC Output

The user has the possibility to define his own PCIC output. This configuration is only valid for the current

PCIC connection. It does not affect any other connection and will get lost after disconnecting.

For configuring the PCIC output a “flexible” layouter concept is used, represented by a JSON string. The

format of the default configuration is as follows:

{

"layouter": "flexible",

"format": { "dataencoding": "ascii" },

"elements": [

{ "type": "string", "value": "star", "id": "start_string" },

{ "type": "blob", "id": "normalized_amplitude_image" },

{ "type": "blob", "id": "X_image" },

{ "type": "blob", "id": "Y_image" },

{ "type": "blob", "id": "Z_image" },

{ "type": "blob", "id": "confidence_image" },

{ "type": "blob", "id": "diagnostic_data" },

{ "type": "string", "value": "stop", "id": "end_string" }

]

}

This string can be retrieved by the C? command, altered and sent back using the c command.

The layout software has the following main object properties:

Name Description Details

layouter Defines the basic data output format.

So far only “flexible” is supported

Type: string

format Defines format details, the definitions in the main object are

the defaults for any of the following data elements (e.g. if it

says dataencoding=binary, all data elements should be binary

encoded instead of ASCII).

Type: object

elements List of data elements which must be written. Type: array of objects

The actual data is defined within the “elements” properties and may consist of these settings:

Name Description Details

type Defines the type of data which must be written.

The data might be stored in a different type (e.g. stored as integer but

should be output as Float32)

The type "records" will need some special handling.

Type: string

id Defines an identifier for this data element.

If there is no fixed value (property "value"), the data should be

retrieved via id.

Type: string

value Optional property for defining a fixed output value. Type: any JSON value

format Type-depending option for fine-tuning the output format.

E.g. cut an integer to less than 4 bytes.

Type: object

Page 28

3D camera

28

Available values for the type property:

Type Description

records Defines that this element represents a list of records.

If type is set to "records", there must be an "elements" property.

The "elements" property defines which data should be written per record.

string Data is written as string.

Most of the time this will be used with "value" property to write fixed start, end or delimiter

text.

Text encoding should be UTF8 if there is nothing else specified in format properties.

float32 Data is written as floating point number.

This has a lot of formatting options (at least with "flexible" layout software)

See following section about format properties.

uint32 Data is written as integer.

This has a lot of formatting options (at least with "flexible" layout software)

See following section about format properties.

int32 Data is written as integer.

This has a lot of formatting options (at least with "flexible" layout software)

See following section about format properties.

uint16 Limits the output to two bytes in binary encoding, besides the binary limitation it acts like

uint32.

int16 Limits the output to two bytes in binary encoding, besides the binary limitation it acts like

int32.

uint8 Limits the output to one byte in binary encoding, besides the binary limitation it acts like

uint32.

int8 Limits the output to one byte in binary encoding, besides the binary limitation it acts like

int32.

blob Data is written as a BLOB (byte by byte as if it came from the data provider).

(Binary Large Object)

Depending on the desired data format the user may tune his output data with further “format” properties.

Common format properties:

Format

properties

Allowed values Default

dataencoding "ascii" or "binary" can be defined in top-level-object and

overwritten by element objects.

"ascii"

scale "float value with decimal separator" to scale the results for

output byte width

1.0

offset "float value with decimal separator" 0.0

Binary format properties:

Format properties Allowed values Default

order Little, big and network Little

Page 29

29

3D camera

UK

ASCII format properties:

Format properties Allowed values Default

width Output width. If the resulting value exceeds the width field the

result will not be truncated.

0

fill Fill character " "

precision Precision is the number of digits behind the decimalseparator. 6

displayformat Fixed, scientific Fixed

alignment Left, right Right

decimalseparator 7-bit characters for e.g. "." "."

base Defines if the output should be:

● binary (2)

● octal (8)

● decimal (10)

● hexadecimal (16)

10

Example of a format configuration of the temperature (id: temp_illu) element.

1. Illumination temperature like this "33,5___":

c000000226{ "layouter": "flexible", "format": { "dataencoding": "ascii" },

"elements": [ { "type": "float32", "id": "temp_illu", "format": { "width": 7,

"precision": 1, "fill": "_", "alignment": "left", "decimalseparator": "," }

} ] }

2. Illumination temperature as binary (16-bit integer, 1/10 °C):

c000000194{ "layouter": "flexible", "format": { "dataencoding": "ascii"

}, "elements": [ { "type": "int16", "id": "temp_illu", "format": {

"dataencoding": "binary", "order": "network", "scale": 10 } } ] }

3. Illumination temperature in °F (e.g. "92.3 Fahrenheit" ):

c000000227{ "layouter": "flexible", "format": { "dataencoding": "ascii" },

"elements": [ { "type": "float32", "id": "temp_illu", "format": { "precision":

1, "scale": 1.8, "offset": 32 } }, { "type": "string", "value": " Fahrenheit"

} ] }

Page 30

3D camera

30

The following element IDs are available:

ID Description Native datatype

evaltime Evaluation time for current frame in milliseconds 32-bit unsigned

integer

framerate Current frame rate in Hz Float32

temp_front1 Temperature measured in the device while capturing this

result.

Measured by first sensor on imager board.

Float32, unit: °C"

temp_illu Temperature measured in the device while capturing this

result.

Measured on the illumination board.

Float32, unit: °C

extrinsic_calibration Extrinsic calibration, constisting of 3 translation

parameters (unit: millimeters) and 3 angles

(unit: degree): [t_x, t_y, t_z, alpha_x, alpha_y, alpha_z]

Float32

amplitude_image PMD raw amplitude image 16-bit unsigned

integer

normalized_amplitude_

image

Normalized amplitude image 16-bit unsigned

integer

distance_image Radial distance image. 16-bit unsigned

integer

unit: millimetres

x_image

y_image

z_image

Cartesian coordinates for each pixel.

Each dimension is a separate image.

16-bit signed

integer

all_cartesian_vector_

matrices

All Cartesian images (X+Y+Z) concatenated to one

package

16-bit signed

integer

confidence_image Confidence image 8-bit unsigned

integer

all_unit_vector_matrices Matrix of unit vectors. Each element consists of a

3 component vector [e_x, e_y, e_z]

Float32

Page 31

31

3D camera

UK

13.4 Process Interface Command Reference

All received messages which are sent because of the following commands will be sent without

“start”/”stop” at the beginning or ending of the string.

13.4.1 t Command (Asynchronous Trigger)

Command

t

Description Executes trigger. The result data

is send asynchronously

Type Action

Reply * Trigger was executed, the device

captures an image and evaluates

the result.

! ● Device is busy with an

evaluation

● Device is in an invalid state

for this command, e.g.

configuration mode

● Device is set to a different

trigger source

● No active application

13.4.2 T? Command (Synchronous Trigger)

Command

T?

Description Executes trigger. The result data

is send synchronously

Type Request

Reply Process data within the

configured layout

Trigger was executed, the device

captures an image, evaluates

the result and sends the process

data.

! ● Device is busy with an

evaluation

● Device is in an invalid state

for this command, e.g.

configuration mode

● Device is set to a different

trigger source

● No active application

13.4.3 I? Command

Command

I<image-ID>?

Description Request last image taken

Type Request

Reply <length><image data>

! ● No image available

● Wrong ID

? ● Invalid command length

Page 32

3D camera

32

Note <image-ID>

2 digits for the image type

<length>

char string with exactly 9 digits

as decimal number for the image

data size in bytes

<image data>

image data

Valid image ID:

01- amplitude image

02 - normalised amplitude image

03 - distance image

04 – X image (distance

information)

05 – Y image (distance

information)

06 – Z image (distance

information)

07 - confidence image (status

information)

08 - extrinsic calibration

09 - unit_vector_matrix_ex, ey,ez

10 - last result output as

formatted for this connection

11 - all distance images: X, Y,

and Z

13.4.4 p Command

Command

p<state>

Description Turns the PCIC output on or off

Type Action

Reply *

! <state> contains wrong value

? Invalid command length

Note <state> 1 digit

0: deactivates all asynchronous

output

1: activates asynchronous result

output

2: activates asynchronous error

output

3: activates asynchronous error

and data output

On device restart the value

configured within the application

is essential for the output of data.

This command can be executed

in any device state.

Page 33

33

3D camera

UK

13.4.5 a Command

Command

a<application number>

Description Activates the selected

application

Type Action

Reply *

! ● Application not available

● <application number>

contains wrong value

● External application switching

activated

● Device is in an invalid state

for this command, e.g.

configuration mode

? Invalid command length

Note <application number>

2 digits for the application

number as decimal value

13.4.6 A? Command

Command

A?

Description Requests the occupancy of the

application list

Type Request

Reply <amount><t><number active

application><t>

...

<number><t><number>

? Invalid command length

! Invalid state (e.g. no application

active)

Note <amount>

char string with 3 digits for the

amount of applications saved on

the device as decimal number

<t>

tabulator (0x09)

<number active application>

2 digits for the active application

<number>

2 digits for the application

number

The active application is

repeated within the application

list.

Page 34

3D camera

34

13.4.7 v Command

Command

v<version>

Description Sets the current protocol version.

The device configuration is not

affected

Type Action

Reply *

! Invalid version

? Invalid command length

Note <version>

2 digits for the protocol version

(→ 13.3.1)

The default protocol version is „V3“.

13.4.8 V? Command

Command

V?

Description Requests current protocol

version

Type Request

Reply <current version><empty><min

version><empty><max version>

Note <current version>

2 digits for the currently set

version

<empty>

space sign: 0x20

<min/max version>

2 digits for the available min and

max version that can be set

13.4.9 c Command

Command

c<length><configuration>

Description Uploads a PCIC output

configuration lasting this session

Type Action

Reply *

! ● Error in configuration

● Wrong data length

? Invalid command length

Note <length>

9 digits as decimal value for the

data length

<configuration>

configuration data

Page 35

35

3D camera

UK

13.4.10 C? Command

Command

C?

Description Retrieves the current PCIC

configuration

Type Request

Reply <length><configuration>

? Invalid command length

Note <length>

9 digits as decimal value for the

data length

<configuration>

configuration data

13.4.11 S? Command

Command

S?

Description Requests current decoding

statistics

Type Request

Reply <number of

results><t><number of positive

decodings><t><number of false

decodings>

! No application active

Note <t>

tabulator (0x09)

<number of results>

Images taken since application

start. 10 digits decimal value with

leading 0s

<number of positive decodings>

Number of decodings leading

to a positive result. 10 digits

decimal value with leading 0s

<number of false decodings>

Number of decodings leading

to a negative result. 10 digits

decimal value with leading 0s

Page 36

3D camera

36

13.4.12 G? Command

Command

G?

Description Requests device information

Type Request

Reply <vendor><t><article number><t>

<name><t><location><t><descri

ption><t><ip>

<subnet mask><t><gateway><

t><MAC><t><DHCP><t><port

number>

Note ● <vendor>

IFM ELECTRONIC

● <t>

Tabulator (0x09)

● <article number>

e.g. O3D300

● <name>

UTF8 Unicode string

● <location>

UTF8 Unicode string

● <description>

UTF8 Unicode string

● <ip>

IP address of the device as

ASCII character sting

e.g. 192.168.0.96

● <port number>

port number of the XML-RPC

● <subnet mask>

subnet mask of the device as

ASCII

e.g. 192.168.0.96

● <gateway>

gateway of the device as

ASCII

e.g 192.168.0.96

● <MAC>

MAC adress of the device as

ASCII

e.g. AA:AA:AA:AA:AA:AA

● <DHCP>

ASCII string "0" for off and

"1" for on

Page 37

37

3D camera

UK

13.4.13 H? Command

Command

H?

Description Returns a list with available

commands

Type Request

Reply H? - show this list

t - execute Trigger

T? - execute Trigger and wait for

data

o<io-id><io-state> - sets IO state

O<io-id>? - get IO state

I<image-id>? - get last image of

defined type

A? - get application list

p<state> - activate / deactivate

data output

a<application number> - set

active application

V? - get current protocol version

v<version> - sets protocol

version

c<length of configuration

file><configuration file> configures process date

formatting

C? - show current configuration

G? - show device information

S? - show statistics

L? - retrieves the connection ID

Page 38

3D camera

38

13.5 XML-RPC Command Reference

13.5.1 Parameter API

The parameters setParameter, getParameter, getAllParameters and getAllParameterLimits are

implemented in the following RPC objects:

● Device

● Network

● Application

● ImagerConfig

● Filter

● Model

setParameter

Method name

setParameter

Description Sets a parameter to a specific value

Input parameters 1. Name of parameter:string

2. New value: string

Output parameters Empty string (compatibility with classic XmlRPC client)

getParameter

Method name

getParameter

Description Returns the current value of the parameter

Input parameters Name of parameter: string

Output parameters Value of parameter: string

getAllParameters

Method name

getAllParameters

Description Returns all parameters of the object in one data structure

Input parameters None

Output parameters 1. Struct (name contains the parameter name, value contains the

stringified parameter value)

getAllParameterLimits

Method name

getAllParameterLimits

Description Returns limits of all numeric parameters, that have limits defined on

the device

Input parameters None

Output parameters 1. Struct of Structs (name in first struct is the parameter name,

substructs contains: min :string, max :string)

E.g.

{"ExposureTime1": { "min": "123", "max": "432" },

"ExposureTime2": { "min": "123", "max": "432" }}

Page 39

39

3D camera

UK

Parameter string encoding

Non-string parameters must be encoded in the following format.

Type Stringified

bool "true" / "false"

setParameter method also accepts "1"/"0", getter methods must always return

"true"/"false"

int decimal ( e.g "-1234" / "1234" )

Values should be in the range of int32 (-2^31 .. 2^31)

double English floating point notation (optional with exponent)

E.g. "1.2", ".3", "4.5e6", "-7E-8", "-inf", "nan"

Structured types (array or structs) can't be put into parameter storage in an general way. Encoding

of arrays must specified on specific parameters.

13.5.2 Main Object

getParameter

Method name

getParameter

Description Getter for the device-global parameters

Input parameters Name of a device parameter: string

Output parameters Value of the requested parameter: string

getAllParameters

Method name

getAllParameters

Description Getter for the parameters described here.

This is an additional getter outside of edit sessions, so it is possible

to read device information without login.

Input parameters none

Output parameters Struct (name contains the parameter name, value contains the

stringified parameter value)

Page 40

3D camera

40

getSWVersion

Method name

getSWVersion

Description Returns version information of all software components

Input parameters none

Output parameters Struct of strings (e.g. { "IFM_Software": "0.01.07", "Frontend":

"01.05.02", ... } )

*mandatory keys:

"IFM_Software"

"Linux"

"Main_Application"

"Diagnostic_Controller"

"Algorithm_Version"

"Calibration_Version"

"Calibration_Device"

getHWInfo

Method name

getHWInfo

Description Returns hardware information of all components

Input parameters none

Output parameters Struct of strings ( e.g. { "MACAddress": "00:02:01:40:06:C9",

"Frontend": "#!01_F340_001_...", ... } )

*mandatory keys:

"MACAddress"

"Connector"

"Diagnose"

"Frontend"

"Illumination"

"Mainboard"

getApplicationList

Method name

getApplicationList

Description Delivers basic information of all applications stored on the device.

Input parameters none

Output parameters Array of structs (Index: int, Id: int, Name: string, Description: string)

Page 41

41

3D camera

UK

requestSession

Method name

requestSession

Description Requests a session object for access to the configuration and for

changing the device operating mode.

This blocks parallel editing and allows protection of editing with a

password.

The ID could optionally be defined by the external system but it must

be the defined format (32char "hex").

If it is called with only one parameter, the device will generate a

session ID.

The session will start with a default timeout ("SessionTimeout"

device parameter), the timeout can be extended by calling

"heartbeat".

The device will stay in RUN mode.

If password is disabled on the device, the value given as password

parameter is ignored.

Input parameters 1. Password: string

2. Session ID: string (optional)

Output parameters Session ID: string

reboot

Method name

reboot

Description Reboot system, parameter defines which mode/system will be

booted

Input parameters Type of system that should be booted after shutdown: int

0: Productive mode

1: Recovery mode

Output parameters Output: string

systemCommand

Method name

systemCommand

Description Performs a generic command on the device.

Input parameters 1. Command: string

2. Parameter: string

Output parameters Output: string

Page 42

3D camera

42

13.5.3 Session Object

heartbeat

Method name

heartbeat

Description Extends the life time of the edit session.

If the given value is outside the range of "SessionTimeout", the

saved default timeout will be used.

Input parameters Requested timeout interval till next heartbeat, in seconds: int

Output parameters The used timeout interval, in seconds: int

cancelSession

Method name

cancelSession

Description Explicit stop of this session

If an application is still in edit mode, it will implicitly do the same as

"stopEditingApplication".

Input parameters none

Output parameters Empty string (compatibility with classic XmlRPC-client)

exportCong

Method name

exportConfig

Description Exports the whole configuration of the sensor device

Input parameters none

Output parameters Configuration as a data BLOB: binary/base64

importCong

Method name

importConfig

Description Imports whole configuration with the option to skip specific parts

Input parameters 1. Configuration as a data BLOB: binary/base64

2. Flags describing which parts should be loaded:

0x0001: Includes configuration (Name, Description, Location, ...)

0x0002: Includes network configuration (IP, DHCP, ...)

0x0010: Includes all application configurations

Output parameters Empty string (compatibility with classic XmlRPC-client)

exportApplication

Method name

exportApplication

Description Exports one application config

Input parameters Application index

Output parameters Application config as a data BLOB: binary/base64

Page 43

43

3D camera

UK

importApplication

Method name

importApplication

Description Imports an application config and creates a new application with it.

The device will put the new application on the first free index.

Input parameters Application config as one data BLOB: binary/base64

Output parameters Index of new application

setOperatingMode

Method name

setOperatingMode

Description Changes the operating mode of the device.

Setting this to "edit" will enable the "edit mode object” on RPC.

Input parameters Mode: integer

0: Run mode

1: Edit mode

Output parameters Empty string (compatibility with classic XmlRPC-client)

Page 44

3D camera

44

13.5.4 Edit Mode Object

factoryReset

Method name

factoryReset

Description Resets all configurations to factory settings

Input parameters none

Output parameters Empty string (compatibility with classic XmlRPC-client)

A factory reset will delete all applications which are saved on the camera.

editApplication

Method name

editApplication

Description Puts a specified application into the edit status.

This will attach an application object to the RPC interface.

The name of the object will be application independent.

This does not change the "ActiveApplication" parameter.

Input parameters Application index: int

Output parameters Empty string (compatibility with classic XmlRPC-client)

stopEditingApplication

Method name

stopEditingApplication

Description Tells the device that editing this application was finished.

Unsaved changes are discarded.

Input parameters none

Output parameters Empty string (compatibility with classic XmlRPC-client)

createApplication

Method name

createApplication

Description Creates an "empty" application. The embedded side should initialise

all needed parameters and structures.

Input parameters none

Output parameters Index of new application: int

Page 45

45

3D camera

UK

copyApplication

Method name

copyApplication

Description Creates a new application by copying the configuration of another

application.

The device will generate an ID for the new application and put it on

a free index.

Input parameters Index of the application which should be copied: int

Output parameters Index of new application: int

deleteApplication

Method name

deleteApplication

Description Deletes the application from sensor

If the deleted application was the active one, the sensor will have no

active application anymore until the user picks one.

Input parameters Index of application: int

Output parameters Empty string (compatibility with classic XmlRPC-client)

moveApplications

Method name

moveApplications

Description Moves applications to other index.

There must be all applications in the new list, none of them

duplicated and no index used twice.

The ID is a fixed value that stays the same as long as the

application stays on the sensor.

The index could be changed and is used to address the application

via PCIC, XML-RPC and digital IO.

Input parameters Array of structs (Id: int, Index: int)

Output parameters Empty string (compatibility with classic XmlRPC-client)

13.5.5 Device Cong Object

activatePassword

Method name

activatePassword

Description Sets a password and activates it for the next edit session.

Making this change persistently requires to call "save" on device

config.

Input parameters Password: string

Output parameters Empty string (compatibility with classic XmlRPC-client)

Page 46

3D camera

46

disablePassword

Method name

disablePassword

Description Disables the password protection.

Making this change persistently requires to call "save" on device

config.

Input parameters none

Output parameters Empty string (compatibility with classic XmlRPC-client)

save

Method name

save

Description Stores current configuration in persistent memory.

If this is not called after changing device parameters (via

setParameter), changes will get lost on reboot.

Input parameters none

Output parameters Empty string (compatibility with classic XmlRPC-client)

Parameters of device cong

Methods for parameter access are defined here:

Parameter name Data type Description

Name String (utf8) User-defined name of the device (max. 64 characters).

Description String (utf8) User-defined description of the device

(max. 500 characters).

ActiveApplication Int

*has limits

Index of active application

This applies only to RUN mode:

* defines the application active on startup (if staticapplication switching is disabled)

* contains the current active application (could also be

changed via PCIC command)

* 0 means no application is active

PcicTcpPort Int TCP/IP port for PCIC connections.

PcicProtocolVersion Int

*has limits

Sub-protocol of PCIC, see specification of PCIC.

IOLogicType Int

*has limits

Defines logic type of all digital pins.

Allowed values:

0: NPN

1: PNP

IODebouncing Bool Applies to all inputs

IOExternApplicationSwitch Int

*has limits

Allowed values:

0: off

1: static via I/O

2: pulse driven via I/O

3: pulse driven via trigger

Page 47

47

3D camera

UK

Parameter name Data type Description

SessionTimeout Int

*has limits

Number of seconds which a session stays before a call

to "heartbeat" method is needed

ServiceReportFailedBuffer Int

*has limits

Number of buffers reserved for failed results

ServiceReportPassedBuffer Int

*has limits

Number of buffers reserved for passed results

ExtrinsicCalibTransX Double

Unit: millimetres

Extrinsic calibration, transition in X direction

ExtrinsicCalibTransY Double

Unit: millimetres

Extrinsic calibration, transition in Y direction

ExtrinsicCalibTransZ Double

Unit: millimetres

Extrinsic calibration, transition in Z direction

ExtrinsicCalibRotX Double

Unit: degrees

Extrinsic calibration, rotation around X axis

ExtrinsicCalibRotY Double

Unit: degrees

Extrinsic calibration, rotation around Y axis

ExtrinsicCalibRotZ Double

Unit: degrees

Extrinsic calibration, rotation around Z axis

IPAddressConfig Int readonly: The GUI requires to know if the device is on

a discovery IP address for multiple-use cases. This

information was extended to reflect all kinds of IPaddress situations.

Allowed values:

0: Static (IP address explicitly defined inside the

device)

1: DHCP (using a DHCP server in the network)

2: LinkLocal (configured to DHCP, but no server which

provided an address)

3: Discovery (changed by IP4Discovery mechanism)

PasswordActivated Bool readonly: Is true if the password protection is enabled

OperatingMode Int readonly: Mode of device (RUN, EDIT)