Page 1

Device manual

Ethernet camera

for mobile applications

O2M110

UK

7390715 / 00 03 / 2012

Page 2

Contents

1 Safety instructions page 4

2 Functions and features page 5

2.1 Features at a glance page 5

3 Mounting

3.1 Mounting accessories page 6

3.2 Mounting dimensions page 6

3.3 Mounting location page 7

4 Electrical connection

4.1 Ethernet camera page 8

4.1.1 Ethernet connection page 8

4.1.2 Interference due to external influences

4.2 PDM360 page 9

4.3 PC/notebook page 10

4.4 Connection principle without hub/switch

- One camera at one PDM360 page 11

- One camera at one PC/notebook (service mode) page 11

4.5 Connection principle with hub/switch

- Several cameras at one PDM360 page 12

5 Operating and display elements page 13

6 Set-up

6.1 IP addresses page 14

6.1.1 IP address allocation PDM360 page 14

6.1.2 IP address allocation cameras page 15

6.2 Parameter setting PDM360 page 19

6.2.1 Library ifm_Camera_O2M_Vxxxxxx page 19

6.2.2 Function block CAM_O2M page 19

6.2.3 Parameter overview page 20

6.2.4 MODE combinations (1...4 cameras) page 22

7 Technical data

7.1 O2M110/111 page 24

8 Maintenance, repair and disposal page 25

9 Approvals/standards page 25

ETHERNET CAMERA O2M110

2

Page 3

Licences and trademarks

Microsoft

®

, Windows®, Windows XP®and Windows Vista®are registered trademarks of Microsoft

Corporation. All trademarks and company names are subject to the copyright of the respective

companies.

Open source software

This unit contains (maybe modified) Open Source software, which is subject to special licensing terms.

For copyright information and licensing terms please refer to: www.ifm.com/int/GNU

For software subject to the GNU General Public License or the GNU Lesser General Public License the

source code can be requested against payment of the copying and shipping costs.

ETHERNET CAMERA O2M110

3

UK

Page 4

1 Safety instructions

These instructions are part of the device. They contain information

and illustrations about the correct handling of the device and must

be read before installation or use.

Adhere to the instructions. Non-observance of the instructions, operation which

is not in accordance with use as prescribed below, wrong installation or handling

can result in serious harm concerning the safety of persons and plant.

These instructions are intended for “authorised” persons according to the EMC

and low-voltage directives. The device must only be installed, connected and put

into operation by a qualified electrician.

Disconnect the device externally before handling it. If necessary, also disconnect

any independently supplied output load circuits.

If the device is not supplied by the mobile on-board system (12/24 V battery

operation), it must be ensured that the external voltage is generated and

supplied according to the criteria for safety extra-low voltage (SELV) as this

voltage is supplied without further measures to the connected controller, the

sensors and the actuators.

The wiring of all signals in connection with the SELV circuit of the device must

also comply with the SELV criteria (safety extra-low voltage, safe electrical

separation from other electric circuits).

If the supplied SELV voltage has an external connection to ground (SELV becomes

PELV), the responsibility lies with the user and the respective national regulations

for installation must be complied with. All statements in this manual refer to the

device the SELV voltage of which is not grounded.

The connection terminals may only be supplied with the signals indicated in the

technical data and/or on the device label and only the approved accessories of

ifm electronic gmbh may be connected.

In case of malfunctions or uncertainties please contact the manufacturer.

Tampering with the device can lead to serious risks for the safety of persons and

plant. It is not permitted and leads to the exclusion of any liability and warranty

claims.

ETHERNET CAMERA O2M110

4

Page 5

2 Functions and features

The Ethernet camera serves for monitoring of areas outside of the field of view in

mobile vehicles and utility vehicles. Connection, control and visualisation of the

images is carried out via the process and dialogue module PDM360 with colour

display.

The camera operates as a server and permanently transmits images to the

connected dialogue module.

Applications are for example:

• Rear area or blind spot monitoring for municipal vehicles

• Machine monitoring in construction machinery

• Rear view camera on vehicles

2.1 Features at a glance

• Use and operation with process and dialogue module PDM360

(version with colour display, art. no. CR1051 from software version V4.3.2)

• Display of up to 4 camera images per PDM360

• 10 Mbits/s Ethernet interface

(10Base-T/100Base-TX according to IEEE 802.3/802.3u)

• Sealed diecast zinc housing

• Protection rating IP 69 K

• Regulated lens heating (can be deactivated)

• CMOS image sensor, resolution ¼ VGA, 320 x 240 pixels

• Angle of aperture 75°

• Parameter setting and control functions via the CoDeSys application program,

e.g.:

- image mirror function (rear view mode)

- rotating

- parallel display of several camera images (split screen)

- positioning of the images

- activation/deactivation

- debug mode (adjustable use of the band width of the network)

• Operation display via integrated LED

• Mixed display of camera image and PDM360 visualisation elements (text

and/or graphics)

ETHERNET CAMERA O2M110

5

UK

Page 6

3 Mounting

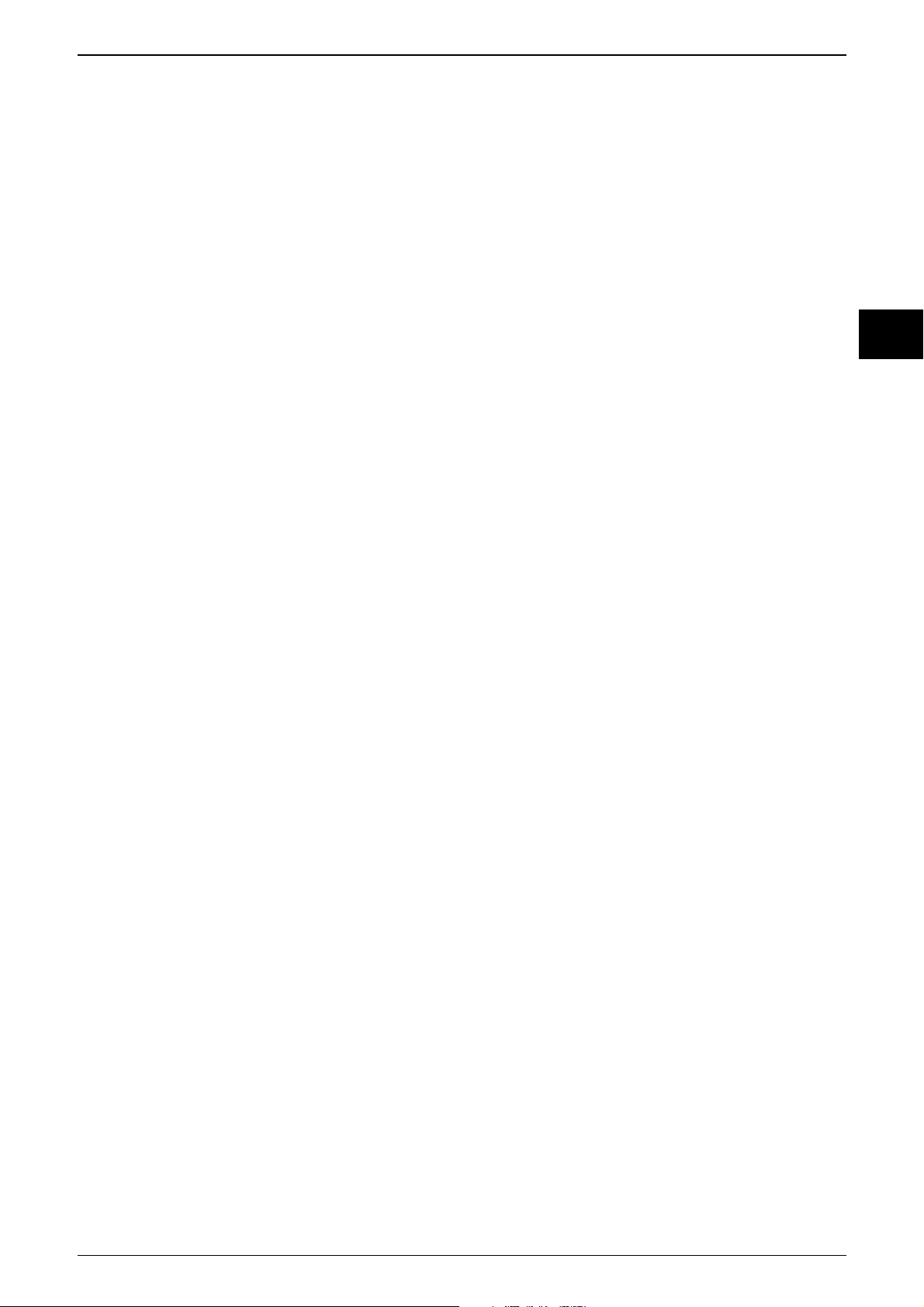

3.1 Mounting accessories

The device is supplied without mounting accessories.

Depending on the intended location and type of mounting the following

mounting accessories are available, for example:

You can find more information about the available accessories at:

➔ Data sheet direct ➔ e.g. O2M110 ➔ Accessories

or directly

➔ Data sheet direct ➔ e.g. E2D110

3.2 Mounting dimensions

Mounting is done using two M 4 x L screws.

Mounting dimensions of the camera → 7 Technical data (data sheets).

www.ifm-electronic.com

www.ifm-electronic.com

ETHERNET CAMERA O2M110

6

Mounting accessories (examples): Art. no.

Mounting set for shaft Ø 12 mm E2D110

(clamp cylinder and fixing element for the types O2D, O2M)

Shaft, straight Ø 12 mm, length 130 mm, M10 E20938

Shaft, angled Ø 12 mm, length 200 mm, M10 E20940

Mounting set for shaft Ø 14 mm E2D112

(clamp cylinder and fixing element for the types O2D, O2M)

Shaft, straight Ø 14 mm, length 130 mm, M12 E20939

Shaft, angled Ø 14 mm, length 200 mm, M12 E20941

Mounting accessories (example)

Mounting set for shaft Ø 12 mm

art. no. E2D110

Shaft, straight Ø 12 mm

E20938

Mounting example

Page 7

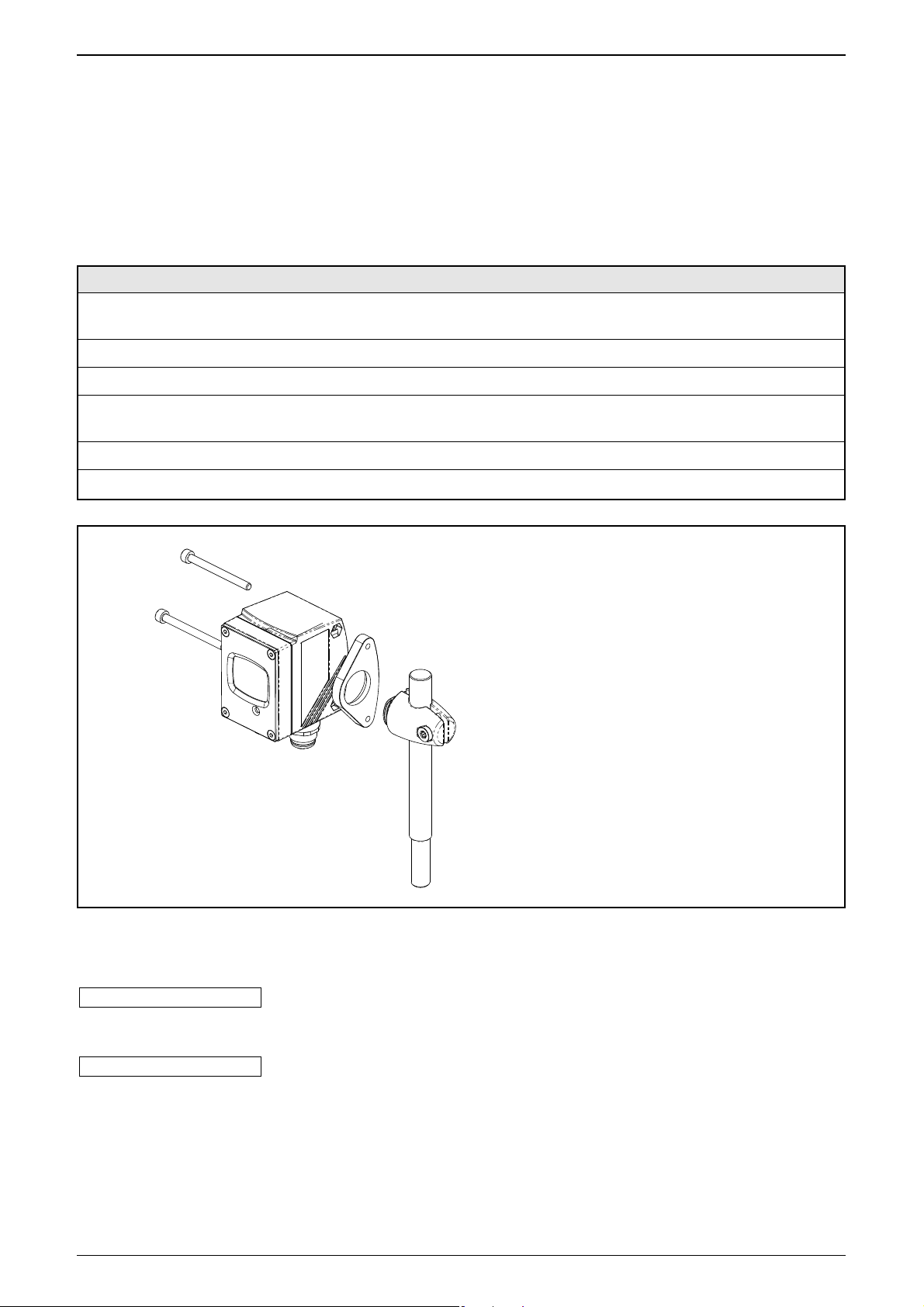

3.3 Mounting location

Mount the camera in front of or above the area to be monitored.

The size of the area to be monitored depends on the operating distance:

Device-specific data → 7 Technical data (data sheets).

Note in general

To avoid adverse effects on the image detection, avoid installation in heavily

polluting areas of the machine (e.g. splashing water, tyre abrasion, etc.).

Avoid back light.

Do not position lighting elements directly facing the camera lens.

Mount the device in such a way that the cables/connectors are connected from

below.

The connected cables must be provided with a strain relief.

ETHERNET CAMERA O2M110

7

UK

Arbeitsabstand [m]

Bildfeldbreite [m]

1

2

3

4

5

0

1,5

3,0

7,5

4,5

6,0

Ethernet Kamera

x 1,1

x 2,2

x 5,5

x 3,3

x 4,4

Bildfeldhöhe [m]

width of field of view [m] height of field of view [m]

Operating distance and field of view size (example O2M110)

operating distance [m]

Ethernet camera

i

x 1.3

x 2.6

x 3.9

x 5.2

x 6.6

Page 8

4 Electrical connection

4.1 Ethernet camera

For information about available connectors please go to:

➔ Data sheet direct➔ e.g. O2M110 ➔ Accessories

The supply voltage is electrically separated from the housing.

4.1.1 Ethernet connection

Use a shielded CAT5 cable.

(STP, Shielded Twisted Pair, according to EIA/TIA-568). Max. length 100 m

Use screened connector housings.

Connect the screen of the Ethernet cable to the connector housing.

Avoid transmission problems caused by induction.

Do not lay the Ethernet connection cable in parallel to current-carrying cables.

Lay supply and signal cables away from the camera using the shortest possible

route.

4.1.2 Interference due to external influences

Faulty or insufficient radio interference suppressors in electrical equipment, such

as inverters or generators, as well as voltage fluctuations when switching on/off

electric loads may lead to problems with the image transmission.

www.ifm-electronic.com

ETHERNET CAMERA O2M110

8

4

21

3

12

34

Supply voltage

Pin Potential

1 8...32 V DC

2 n.c.

30 V

4 n.c.

Ethernet

Pin Potential

1 TxD +

2 RxD +

3 TxD –

4 RxD –

M12 supply connection

(4-pole, A-coded)

M12 Ethernet

(4-pole, D-coded)

Wiring

Page 9

4.2 PDM360

The Ethernet service interface behind the side cover is not intended for

actual operation.

ETHERNET CAMERA O2M110

9

UK

RJ45

Pin Potential

1 TxD + pair 1

2 TxD – ”

3 RxD + pair 2

6 RxD – ”

18

12

11

10

9

8

7

6

5

4

3

2

1

18

19

15

17

13

16

14

M23 round connector

Pin Potential

1 GND (Power)

2 GND (Power)

3 VBB + (Supply)

4 CAN 1 Low

5 CAN 1 High

6 n.c.

7 2nd RS 232, RxD

8 2nd RS 232, TxD

9 VBB + (supply switched)

10 GND (Power)

11 GND (Power)

12 n.c.

13 CAN 2 Low

14 CAN 2 High

15 Ethernet RxD –

16 Ethernet RxD +

17 Ethernet TxD –

18 Ethernet TxD +

19 Shield

Operating connection

M23 round connector

(19-pole central plug)

Ethernet service interface

(8-pole RJ45 plug)

A

B

A B

PDM360 rear view and side view

PDM360 operating connection

PDM360 service connection

Page 10

4.3 PC/notebook

Connection to a PC or to a notebook may be necessary for service purposes (e.g.

setting of the IP address).

The configuration of the PC Ethernet interface corresponds to that of the service

interface (B) of the PDM360.

Note:

The IP address range (Net ID) of the PC must correspond to the IP address range

of the camera. For the PC/notebook setting is carried out in the Control Panel →

Network Connections → Properties

(also see → 6.1.2 IP address allocation Ethernet cameras).

ETHERNET CAMERA O2M110

10

RJ45

Pin Potential

1 TxD + pair 1

2 TxD – “

3 RxD + pair 2

6 RxD – “

18

Ethernet interface

(8-pole RJ45 plug)

PC/notebook

Page 11

4.4 Connection principle without hub/switch

■ One camera at one PDM360

■ One camera at one PC/notebook (e.g. service mode)

For further information about the connector go to:

➔ Data sheet direct ➔ E11898

www.ifm-electronic.com

ETHERNET CAMERA O2M110

11

UK

crosslink cable

Display Ethernet Camera

crosslink cable

Ethernet Camera

PC / Notebook

Crosslink cable (example): art. no.

Ethernet connection cable, 2m

M12 connector (4-pole, D-coded) – RJ45 (8-pole) E11898

Operating connection:

M23 round connector (19-pole)

Service connection:

RJ45 plug (8-pole)

Connection:

RJ45 plug (8-pole)

Ethernet interface

Definition crosslink:

crosslink cable = crossover cable = for the direct connection

of network participants

Connection principle without hub/switch

TxD +

TxD

RxD +

RxD

TxD +

TxD

RxD +

RxD

crosslink cable

Crosslink cable principle

Page 12

4.5 Connection principle with hub/switch

■ Several cameras at one PDM360

Adhere to the documentation of the switch manufacturer.

Some switches have an “autocrossing” function. The transmit and receive

wires are automatically recognised by these devices.

In this case, 1:1 patch cables are not compulsory.

ETHERNET CAMERA O2M110

12

patch cable (1:1)

Display

Ethernet Cameras

patch cables (1:1)

Hub / Switch

Definition patch cable:

patch cable = uncrossed cable = 1:1 wiring = straightthrough cable = point-to-point

i

Connection principle with hub/switch

TxD +

TxD

RxD +

RxD

TxD +

TxD

RxD +

RxD

patch cable (1:1)

Patch cable principle (1:1)

Page 13

5 Operation display

ETHERNET CAMERA O2M110

13

UK

LED

green

LED Description

ON supply voltage ok

camera ready for operation

OFF no supply voltage

power supply interrupted

Operating indication O2M110/111

Page 14

6 Set-up

6.1 IP addresses

The address ranges of all network participants must be identical. This range of

the IP address is also called Net ID.

Factory preset (subnet mask 255.255.255.0, class C):

Ethernet camera: 192. 168. 82. 15

general ... ↓ = ↓ = ↓ = ↓ ≠

PDM360: 192. 168. 82. 247

\..... Net ID ...../ Host ID

6.1.1 IP address allocation PDM360

For PDM360, the IP address is set via the PDM setup.

Open the PDM setup start menu:

Press F1 and F5 simultaneously and switch on the voltage supply.

Select “IP address” by turning and then pressing the rotary switch. Set the IP

address range in the menu “Setup Server IP”.

ETHERNET CAMERA O2M110

14

Ethernet CameraDisplay

Hub / Switch

PC / Notebook

Example 1: IP address allocation

192.168.82.247

192.168.82.248

PC/notebook

only for parameter setting

factory setting

192.168.82.15

Page 15

PDM360 online help:

The online description of the functions, operation and device-specific libraries of

the PDM360 family is part of the CoDeSys online help.

It is also available for download on the internet.

➔ Data sheet direct ➔ e.g. O2M110 ➔ Download/Software

6.1.2 IP address allocation cameras

When using several cameras, set the IP addresses of the cameras via the

“Hypertext Transfer Protocol” (HTTP). To do so, use standard programs such as

Microsoft Internet Explorer, Mozilla Firefox or Opera.

Procedure:

1. Check the IP settings of the PC/notebook and change them if necessary.

(Start → Control Panel → Network Connections → Local Area Connection)

Internet protocol: TCP/IP

IP address: 192.168.82.xx (except 15)

Subnet mask: 255.255.255.0

Connection: 10 MBits, half-duplex

Gateway IP address: 192.168.82.15

2. Establish an Ethernet connection between the camera and the PC/notebook.

3. Connect the camera to supply voltage.

Do not interrupt the supply voltage during IP address allocation!

Avoid voltage fluctuations during IP address allocation!

4. Open the internet browser.

5. Enter the preset IP address of the camera in the address line of the browser

and confirm with “Enter” (http://192.168.82.15/).

The start window “O2M1xxx WebConfig” appears in the browser.

www.ifm-electronic.com

ETHERNET CAMERA O2M110

15

UK

patch cable (1:1)

Display

Ethernet Cameras

patch cables (1:1)

Hub / Switch

Example 2: IP address allocation when using 4 cameras

192.168.82.247

factory setting

192.168.82.15

192.168.82.16

192.168.82.17

192.168.82.18

Page 16

6. Click on “Change IP address”.

7. Enter the new address in the field “IP address” and click on “Submit” to send

it to the camera.

ETHERNET CAMERA O2M110

16

Start window “O2M1xx WebConfig”

O2M1xx IP configuration

Page 17

A confirmation appears if the address was successfully written to the flash

memory of the camera.

ETHERNET CAMERA O2M110

17

UK

Confirmation of the address change

Error message in case of invalid IP address (e.g. wrong address range)

Page 18

An inadvertent, wrong address allocation makes subsequent

communication with the camera impossible. For this reason, the following

final test must be carried out.

8. Click on “Reboot”.

9. Enter the new IP address of the camera in the address line of the browser and

confirm with “Enter” (here e.g.: http://192.168.82.17/).

If the address corresponds to the previously allocated address, the start

window “O2M1xxx WebConfig” appears again.

10. Repeat the steps 2 to 9 with further cameras.

The new camera IP address will become effective on reboot.

(camera supply voltage off/on).

ETHERNET CAMERA O2M110

18

O2M1xx IP configuration, reboot request to check the allocated IP address

i

Page 19

6.2 Parameter setting PDM360

6.2.1 Library ifm_Camera_O2M_Vxxxxxx

The CoDeSys library “ifm_Camera_O2M_Vxxxxxx” is part of the CD-ROM

“ecolog Software & Tools”. It contains all parameters and functions for the

control of the dialogue module PDM360 (art. no. CR1051) and the camera.

After installation of the CD, the library will be stored in the directory:

...\ ifm electronic \ CoDeSys V2.3 \ Targets \ ifm \ Library \ ifm_CR1051

The library uses functions of the library “ifm_Camera_Vxxxxxx”. It is loaded

automatically.”ifm_Camera_Vxxxxxx” must not be inserted.

2 demo programs in the directory “...\ Projects \ DEMO_PDM” serve for

introduction (CR1051Demo_O2M_1CAM.pro und

CR1051Demo_O2M_2CAM.pro).

6.2.2 Function CAM_O2M

The function is part of the above-mentioned library. It serves for parameter

setting / control of one camera and its image data.

One function block is required per camera.

ETHERNET CAMERA O2M110

19

UK

Function block CAM_O2M (extract CoDeSys programming surface)

Page 20

6.2.3 Parameter overview

ETHERNET CAMERA O2M110

20

Name Data type Description

Inputs

C_ENABLE BOOL camera ON/OFF

TRUE: initialisation of the function, transmission of image data

Note:

If TRUE, the PDM360 visualisation is not refreshed

C_ADDR STRING (15) IP address camera, factory setting: 192.168.82.15

C_ROTATION WORD rotate image clockwise (values: 90/180/270)

C_MIRROR BOOL image mirrored along the vertical axis

TRUE: mirroring ON (rear view mode)

C_MODE BYTE image position on PDM360 display

1: full screen (320 x 240 px)

2: part screen (320 x “H” px)

Define “H” with C_WINDOWS_HEIGHT

30: ¼ screen, at the top left

no PDM360 visualisation

31: ¼ screen, at the top left

PDM360 visualisation at the bottom (height 120 px)

40: ¼ screen, at the top right

no PDM360 visualisation

41: ¼ screen, at the top right

PDM360 visualisation at the bottom (height 120 px)

50: ¼ screen, at the bottom left

no PDM360 visualisation

51: ¼ screen, at the bottom left

PDM360 visualisation at the top (height 120 px)

60: ¼ screen, at the bottom right

no PDM360 visualisation

61: ¼ screen, at the bottom right

PDM360 visualisation at the top (height 120 px)

(¼ screen scales the image to 160 x 120 px)

C_WINDOWS_HEIGHT

BYTE visible height of the image data on the PDM360 display

valid range: 120...240 px

C_DEBUG BOOL TRUE: greater bandwidth for CoDeSys programming

or debugging

(= lower transmission rate for image data)

Factory setting: FALSE

Page 21

ETHERNET CAMERA O2M110

21

UK

Name Data type Description

Outputs

C_RESULT BYTE 0: function not initialised or not active

1: function successfully initialised

parameters successfully written

2: function being processed

3: error; connection disturbed or interrupted

parameter not written

reinitialise function

97: check last byte of IP dress

last byte of the IP adress between camera

and PDM has to be different

98: PDM IP adress and camera IP adress

are not in the same group

99: wrong IP adress

check format of the input string

PDM_IP STRING (15) IP address of the connected PDM360

Page 22

6.2.4 MODE combinations (1...4 cameras)

Full screen

1 camera active, no visualisation

C_MODE = 1

C_WINDOW_HEIGHT = not defined

Part screen

1 camera active, visualisation up to 120 px at the bottom

C_MODE = 2

C_WINDOW_HEIGHT = 120...240 px (height camera image)

¼ screen at the top left

1 camera active, visualisation 120 px at the bottom

C_MODE = 31

C_WINDOW_HEIGHT = not defined

¼ screen at the top right

1 camera active, visualisation 120 px at the bottom

C_MODE = 41

C_WINDOW_HEIGHT = not defined

¼ screen at the bottom left

1 camera active, visualisation 120 px at the top

C_MODE = 51

C_WINDOW_HEIGHT = not defined

¼ screen at the bottom right

1 camera active, visualisation 120 px at the top

C_MODE = 61

C_WINDOW_HEIGHT = not defined

¼ screen at the top left / top right

2 cameras active,

visualisation 120 px at the bottom, controlled by camera 1

Camera 1: C_MODE = 31

Camera 2: C_MODE = 40

C_WINDOW_HEIGHT = not defined (both cameras)

¼ screen at the bottom left / bottom right

2 cameras active,

visualisation 120 px at the top, controlled by camera 1

Camera 1: C_MODE = 51, at the bottom left

Camera 2: C_MODE = 60, at the bottom right

C_WINDOW_HEIGHT = not defined (both cameras)

ETHERNET CAMERA O2M110

22

Page 23

¼ screen at the top left / bottom left / bottom right

3 cameras active, no visualisation

Camera 1: C_MODE = 30, at the top left

Camera 2: C_MODE = 50, at the bottom left

Camera 3: C_MODE = 60, at the bottom right

C_WINDOW_HEIGHT = not defined (all cameras)

¼ screen at the top right / bottom left / bottom right

3 cameras active, no visualisation

Camera 1: C_MODE = 40, at the top right

Camera 2: C_MODE = 50, at the bottom left

Camera 3: C_MODE = 60, at the bottom right

C_WINDOW_HEIGHT = not defined (all cameras)

¼ screen at the top left / top right / bottom left / bottom right

4 cameras active, no visualisation

Camera 1: C_MODE = 30, at the top left

Camera 2: C_MODE = 40, at the top right

Camera 3: C_MODE = 50, at the bottom left

Camera 4: C_MODE = 60, at the bottom right

C_WINDOW_HEIGHT = not defined (all cameras)

Legend:

Camera image

Active PDM360 visualisation area (text and/or graphics)

Note: activate visualisation only for one camera!

Static background image

(visualisation before activating one or several cameras)

ETHERNET CAMERA O2M110

23

UK

Page 24

7 Technical data

7.1 O2M110/111

ETHERNET CAMERA O2M110

24

DC

-125--

- 1.5 x 1.1 3 x 2.2 7.5 x 5.5 - -

8...32 DC

typ. 4 (excl. lens heating)

typ. 6

CMOS image sensor colour, QVGA resolution 320 x 240

min. 15

image transmission via UDP/IP

8-bit Windows® bitmap format / image format QVGA

green

-30...75

-40...85

IP 69K, III

DIN EN 61326 / IEC 60255-5 / DIN EN 61373 cat. 1B / Automotive Directive 05/49/EC (e1)

housing: diecast zinc / coating: cathodic dip painting (KTL)

front lens: glass

Ethernet 10Base-T / 100Base-TX

10 Mbits/s (fixed)

192.168.82.15

Electrical design

Operating distance [m]

Field of view size [m]

Operating voltage [V]

Power consumption [W]

Lens heating [W]

Type of sensor

Image repetition rate [Hz]

Protocol

Data format

Readiness for operation [LED]

Operating temperature [°C]

Storage temperature [°C]

Protection

Standards, tests

Materials

Interface

Transmission rate

IP address (default)

Wiring

55

45

45,6

21,1

34,1

4,3

42

57

80

M12 x1

M12x1

60

20,524,5

30,5

1

O2M110

Ethernet camera

Angle of aperture 75°

Lens heating

1: TD+

2: RD+

3: TD4: RD-

Power supply connection:

M12, 4-pole

Parameter setting connection:

M12, 4-pole, D-coded

1: U+

2: not connected

3: 0 V

4: not connected

4

21

3

12

34

e1

1) Centre of the lens axes

ifm electronic gmbh • Teichstraße 4 • 45127 Essen We reserve the right to make technical alterations without prior notice. 29.11.2007O2M110 / page 1

O2M110/111

Page 25

8 Maintenance, repair, disposal

Keep the lens window of the camera free from soiling.

Soiling may considerably affect the image quality!

To clean the lens window, do not use any detergents or solvents which might

damage the front glass.

Do not open the housing, as the device does not contain any components which

must be maintained by the user. The unit may only be repaired by the

manufacturer.

Dispose of the device in accordance with the national environmental regulations.

9 Approvals/standards

Test standards and provisions → 7 Technical data.

The CE Declaration of Conformity and the e1 approval are available at:

➔ Data sheet direct ➔ e.g. O2M110 ➔ Approvals

www.ifm-electronic.com

ETHERNET CAMERA O2M110

25

UK

i

Loading...

Loading...