Page 1

Operating instructions

Optical level sensor

O1D300

UK

80269857 / 00 09 / 2017

Page 2

Contents

1 Preliminary note ��������������������������������������������������������������������������������������������������� 4

1�1 Symbols used ������������������������������������������������������������������������������������������������4

1�2 Warning signs used ���������������������������������������������������������������������������������������4

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Functions and features ����������������������������������������������������������������������������������������6

3�1 Application areas �������������������������������������������������������������������������������������������6

3�2 Restriction of the application area �����������������������������������������������������������������6

4 Function ��������������������������������������������������������������������������������������������������������������� 6

4�1 Switching function ������������������������������������������������������������������������������������������6

4�1�1 Hysteresis function �������������������������������������������������������������������������������6

4�1�2 Window function �����������������������������������������������������������������������������������8

4�2 Analogue function ������������������������������������������������������������������������������������������9

4�2�1 Current output ���������������������������������������������������������������������������������������9

4�2�2 Voltage output �������������������������������������������������������������������������������������10

4�3 Switch off the laser �������������������������������������������������������������������������������������10

4�4 IO-Link ���������������������������������������������������������������������������������������������������������10

4�4�1 Operation with IO-Link master ������������������������������������������������������������ 11

4�4�2 Extended functions ����������������������������������������������������������������������������� 11

5 Installation����������������������������������������������������������������������������������������������������������12

5�1 Installation conditions ����������������������������������������������������������������������������������12

5�2 Location �������������������������������������������������������������������������������������������������������12

5�3 Mounting accessories ���������������������������������������������������������������������������������� 13

6 Electrical connection ������������������������������������������������������������������������������������������ 14

7 Operating and display elements ������������������������������������������������������������������������15

8 Menu ������������������������������������������������������������������������������������������������������������������ 16

8�1 Menu structure ��������������������������������������������������������������������������������������������� 16

8�2 Explanation of the menu ������������������������������������������������������������������������������ 17

8�2�1 Factory setting ������������������������������������������������������������������������������������17

8�2�2 Main menu ������������������������������������������������������������������������������������������ 17

8�2�3 Extended functions �����������������������������������������������������������������������������19

9 Set-up ����������������������������������������������������������������������������������������������������������������20

10 Parameter setting ��������������������������������������������������������������������������������������������20

2

Page 3

10�1 General parameter setting ������������������������������������������������������������������������� 20

10�1�1 Setting of the parameter value ���������������������������������������������������������20

10�1�2 Change from menu level 1 to menu level 2 �������������������������������������� 21

10�1�3 Electronic lock ����������������������������������������������������������������������������������22

10�2 Entering the reference level (unit on delivery) �������������������������������������������22

10�2�1 Free choice of the tank height ����������������������������������������������������������22

10�2�2 Carry out the basic teach empty state ����������������������������������������������23

10�2�3 Carry out the adjustment to the reference level ��������������������������������24

10�2�4 Unsuccessful adjustment ������������������������������������������������������������������25

10�2�5 Successful setting of the reference level ������������������������������������������ 25

10�3 Configuration of the basic settings ������������������������������������������������������������25

10�3�1 Selection of the display unit �������������������������������������������������������������� 25

10�3�2 Setting the display ����������������������������������������������������������������������������26

10�3�3 Configure OUT1 �������������������������������������������������������������������������������26

10�3�4 Setting of the switch points for hysteresis function OUT1 ����������������26

10�3�5 Setting of the switch points for window function OUT1 ��������������������26

10�3�6 Configure OUT2 �������������������������������������������������������������������������������27

10�3�7 Setting of the switch points for hysteresis function OUT2 ����������������27

10�3�8 Setting of the switch points for window function OUT2 ��������������������27

10�3�9 Scaling of the measuring range (analogue output) ���������������������������27

10�4 Extended functions ������������������������������������������������������������������������������������28

10�4�1 Setting of the delay time for switching outputs ���������������������������������28

10�4�2 Response of the outputs in case of a fault ���������������������������������������28

UK

10�4�3 Setting of the delay time after signal loss ����������������������������������������� 28

10�4�4 Setting of the sampling rate �������������������������������������������������������������� 28

10�4�5 Table repeatability and accuracy ������������������������������������������������������29

10�4�6 Setting of the mean filter �������������������������������������������������������������������30

10�4�7 Reset of all parameters to factory setting �����������������������������������������30

11 Operation ���������������������������������������������������������������������������������������������������������31

11�1 Operating modes ���������������������������������������������������������������������������������������31

11�1�1 Run mode �����������������������������������������������������������������������������������������31

11�1�2 Display mode ������������������������������������������������������������������������������������31

11�1�3 Object reflectivity ������������������������������������������������������������������������������31

11�1�4 Programming mode ��������������������������������������������������������������������������31

12 Troubleshooting �����������������������������������������������������������������������������������������������32

13 Maintenance, repair, disposal ��������������������������������������������������������������������������34

3

Page 4

14 Factory setting �������������������������������������������������������������������������������������������������35

1 Preliminary note

Technical data, approvals, accessories and further information at www�ifm�com�

1.1 Symbols used

► Instruction

> Reaction, result

[…] Designation of pushbuttons, buttons or indications

→ Cross-reference

Important note:

Non-compliance can result in malfunctions or interference�

Information

Supplementary note�

1.2 Warning signs used

WARNING

Warning of serious personal injury�

Death or serious irreversible injuries may result�

2 Safety instructions

• Read this document before setting up the product and keep it during the entire

service life�

• The product must be suitable for the corresponding applications and environmental conditions without any restrictions�

• Only use the product for its intended purpose (→ 3 Functions and features)�

• Only use the product for permissible media (→ Technical data).

• If the operating instructions or the technical data are not adhered to, personal

injury and/or damage to property may occur�

• The manufacturer assumes no liability or warranty for any consequences

caused by tampering with the product or incorrect use by the operator�

4

Page 5

• Installation, electrical connection, set-up, operation and maintenance of the unit

must be carried out by qualified personnel authorised by the machine operator�

• Protect units and cables against damage�

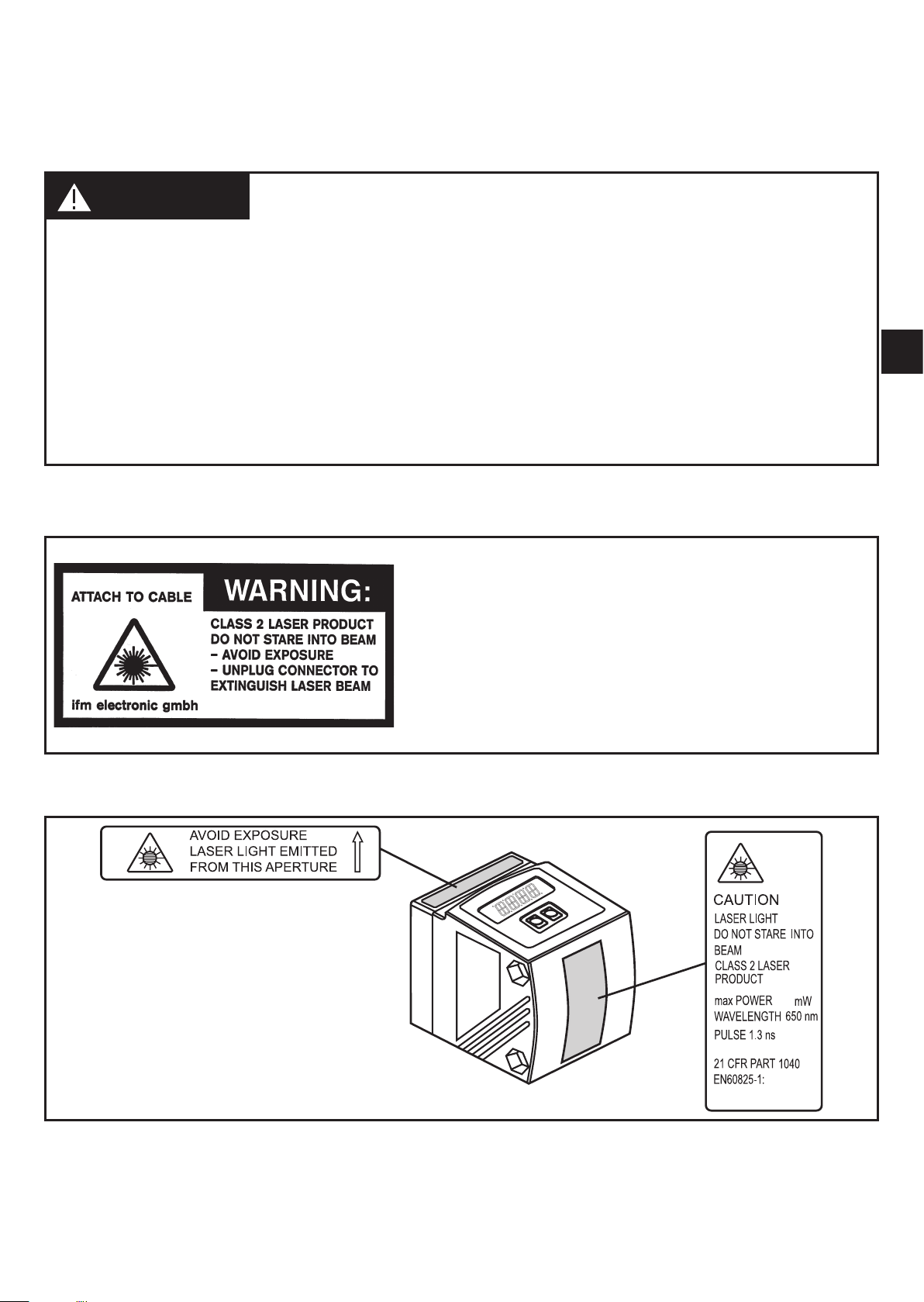

WARNING

Visible laser light; laser protection class 2�

Use of controls or adjustments other than those specified herein may result in hazardous

radiation exposure� Damage to the retina is possible�

► Do not stare into the laser beam!

► Apply the enclosed labels (laser warning) in the immediate vicinity of the unit�

► Adhere to the caution and warning notes on the product label�

► Use the enclosed label for the power supply cable�

Label for supply cable

D-45128 Essen

UK

Product label

4.0

2007

5

Page 6

3 Functions and features

The unit continuously detects the level optically and generates output signals

according to the parameter settings�

3.1 Application areas

• The optical level sensor detects media in the measuring range of

20�0���1000�0 cm� They are displayed in relation to a previously defined reference level�

• It has a background suppression at > 10���100 m�

• Two output signals can be generated, depending on the function mode�

The distance between the sensor and the background must be limited

to max� 100 m by the customer� Otherwise the measured value may be

ambiguous. → 5.1 Installation conditions

3.2 Restriction of the application area

• The unit is suited for granulates, bulk material and cloudy liquids�

• Dust and vapour can impact the quality of the measurements�

• The unit is not suited for oils and clear liquids�

4 Function

4.1 Switching function

4.1.1 Hysteresis function

The outputs change their switching status when the value is above or below the

set switching limits� The hysteresis is the distance between the set and reset

points� The hysteresis keeps the switching status of the output stable if the measured value varies about the sensing range�

Both outputs (OUT1 and OUT2) can be set as hysteresis function (→ 10.3.3 and

→ 10.3.6)�

6

Page 7

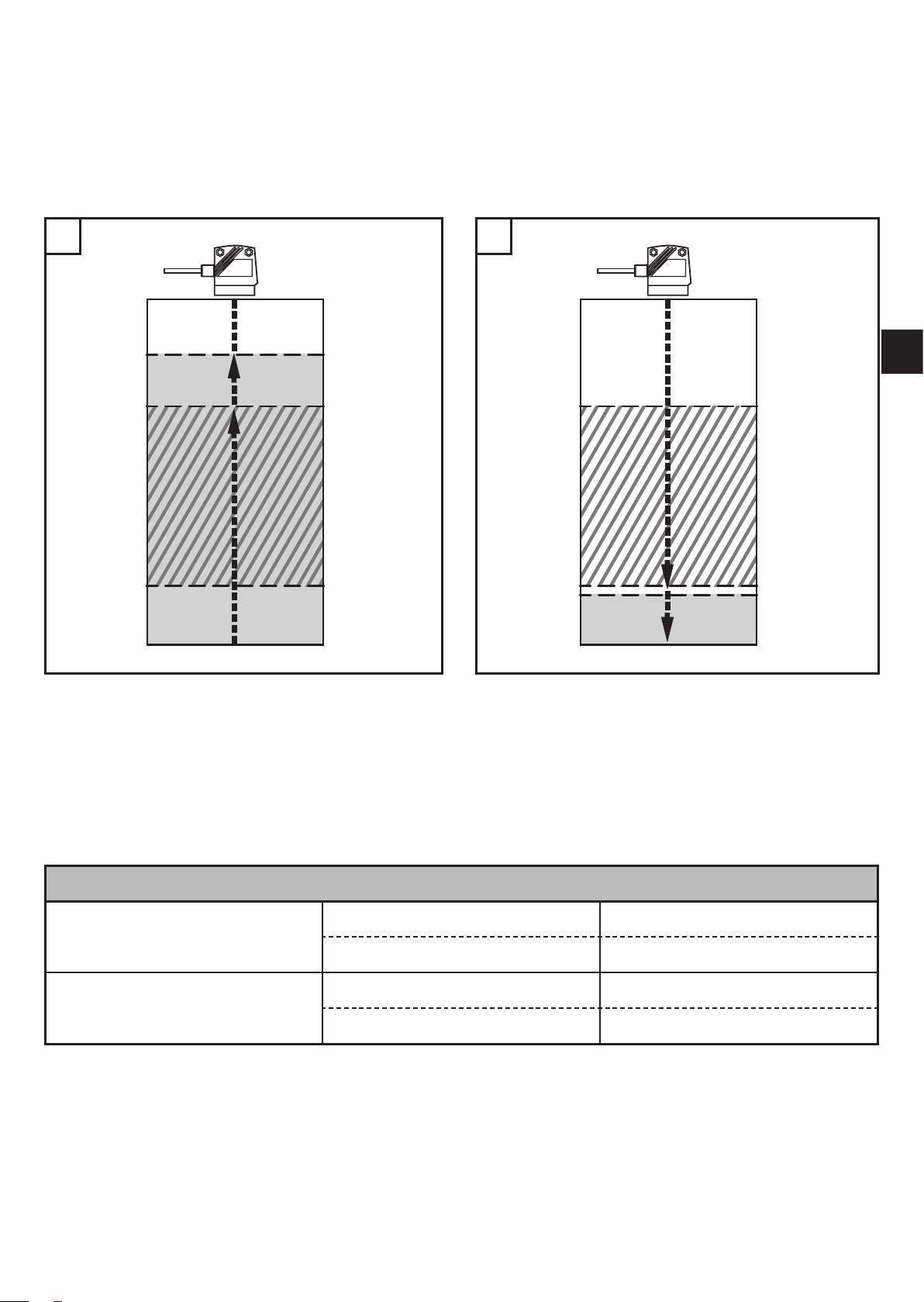

Example Hno

1� For the output function [Hno] the output switches on when the set point [SPx]

is exceeded in case of a rising level�

2� If the level falls again, the output switches off as soon as the level is below the

reset point [rPx]� The reset point [rPx] is below the set point [SPx]�

1

2

UK

[SPx] =

set point;

[rSPx] = reset point; HY = hysteresis

If the output function [Hnc] has been selected, set and reset point are exchanged�

The output switches off for rising level� If the level falls below [rPx] again, the

output switches on�

Switching status of the outputs

Output function Level (L) Output status

[Hno] L > [SPx] Closed

L < [rPx] Open

[Hnc] L > [SPx] Open

L < [rPx] Closed

7

Page 8

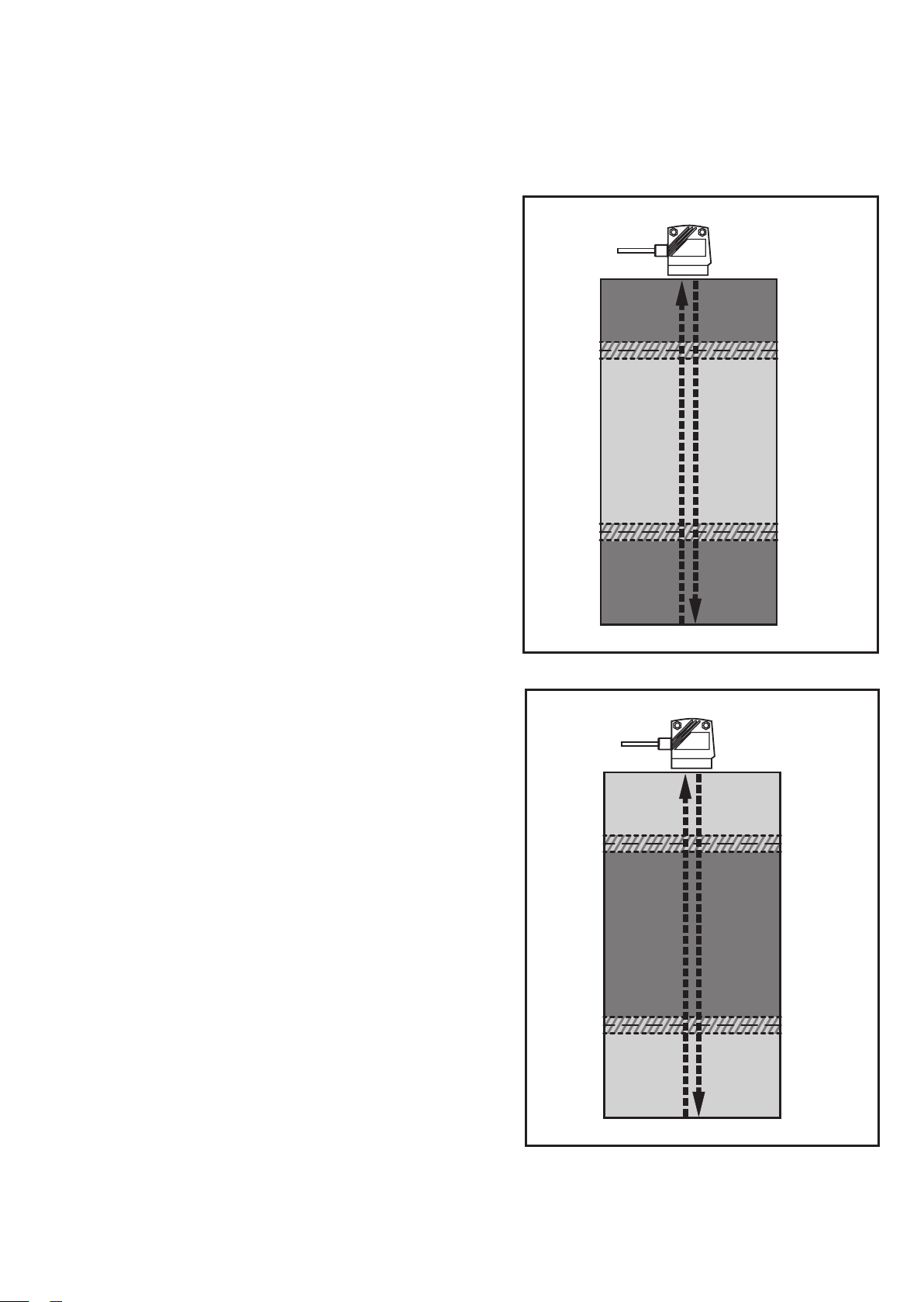

4.1.2 Window function

The window function enables the monitoring of a defined acceptable range� Both

outputs (OUT1 and OUT2) can be set as window function (→ 10.3.3 and →

10�3�6)�

Switches when the medium is detected

If the measured value is between the lower

limit value [rPx] and the upper limit value

[SPx], the output is closed (if [OUx] = [Fno])�

FE = window; HY = hysteresis*;

[SPx] =

[rPx] =

upper limit value

;

lower limit value

Switches off when the medium is

detected

If the measured value is between the lower

limit value [rPx] and the upper limit value

[SPx], the output is open (if [OUx] = [Fnc])�

FE = window; HY = hysteresis*;

[SPx] = upper limit value;

[rPx] = lower limit value

* A switching hysteresis is set for each window limit value� It cannot be configured but

depends on distance and sampling rate�

8

Page 9

Switching status of the outputs

Output function Level (L) Output status

L < [SPx]

Closed

[Fno]

[Fnc]

L > [rPx]

[SPx] < L < [rPx] Open

L < [SPx]

Open

L > [rPx]

[SPx] < L < [rPx] Closed

Both window limit values ([SPx] and [rPx]) work with a switching hysteresis�

→ 4.1.1 Hysteresis function / example for output function [Hno]

4.2 Analogue function

An analogue signal, which is proportional to the distance, can be provided at output 2 (OUT2) → 10.3.9 Scaling of the measuring range (analogue output)�

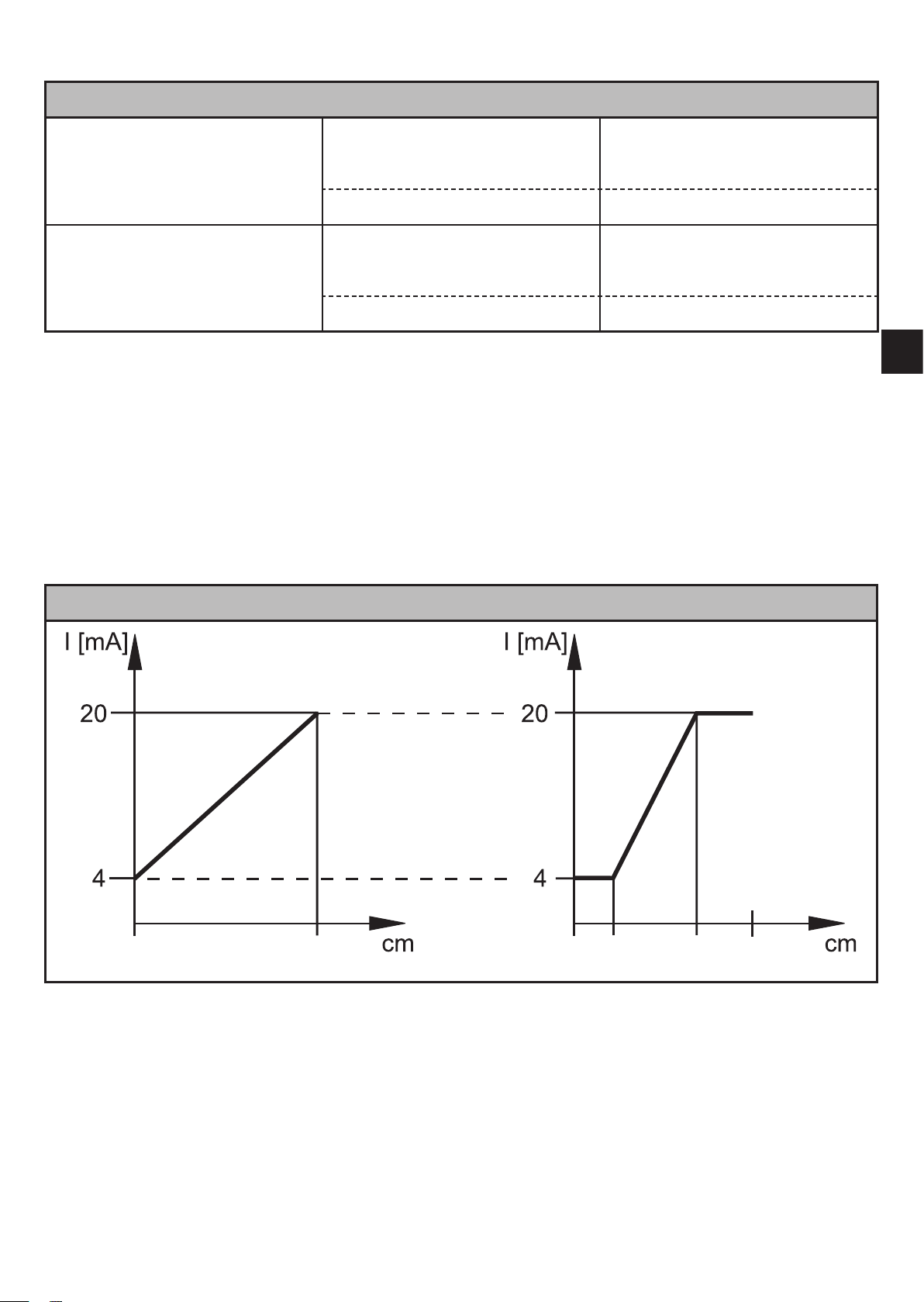

4.2.1 Current output

Factory setting Measuring range scaled

UK

9795,5 (AEP) 0 MEWASP AEP0 (ASP)

MEW= final value of the measuring range

In the set measuring range the output signal is between 4 and 20 mA�

Faults are also displayed → 12 Troubleshooting�

9

Page 10

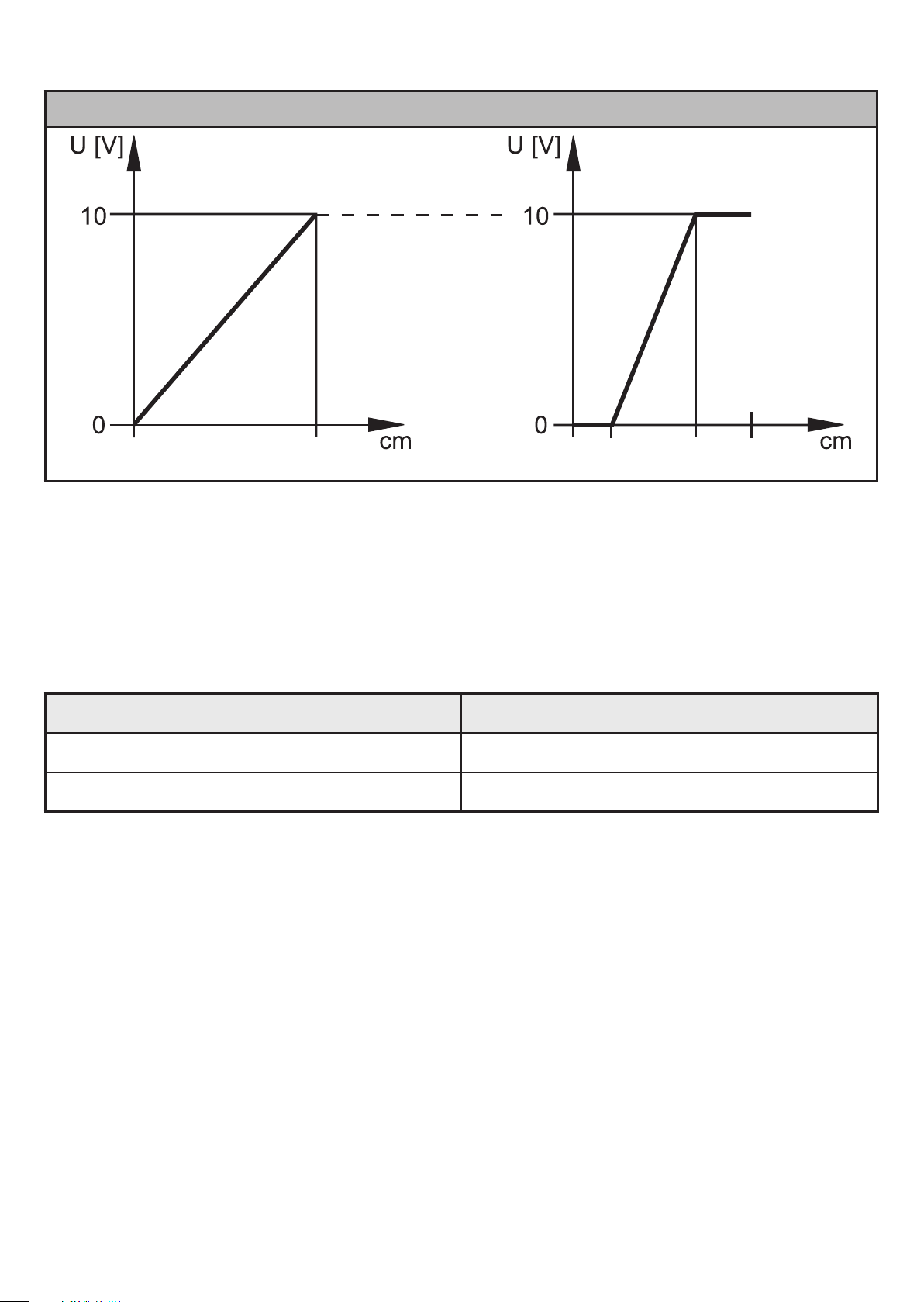

4.2.2 Voltage output

9795,5 (AEP) 0 MEWASP AEP0 (ASP)

Factory setting Measuring range scaled

MEW= final value of the measuring range

In the set measuring range the output signal is between 0 and 10 V�

4.3 Switch off the laser

For safety and maintenance purposes the laser of the unit can be temporarily

switched off via the input on pin 5�

Input signal at pin 5 Laser

Low / not connected On

High Off

4.4 IO-Link

This unit has an IO-Link communication interface which enables direct access

to process and diagnostic data� In addition it is possible to set the parameters of

the unit during operation� Operation of the unit via IO-Link interface requires an

IO-Link master�

With a PC, suitable IO-Link software and an IO-Link adapter cable communication

is possible when the system is not in operation�

The IODDs necessary for the configuration of the unit, detailed information about

process data structure, diagnostic information, parameter addresses and the

necessary information about the required IO-Link hardware and software can be

found at www�ifm�com�

10

Page 11

4.4.1 Operation with IO-Link master

The unit is compatible with IO-Link master port class A (type A)�

For operation with IO-Link master port class B (type B) observe the following:

As a standard, the unit is not compatible with master port class B (type B)�

Pin 2 (OU2) and pin 5 (IN1) are used for manufacturer-specific functions�

That means that the main supply voltage of the unit and the additional voltage supply (master port class B on pins 2/5) are not electrically isolated�

With the following configurations the unit can be used with master port class B:

UK

• Connect unit and IO-Link master via 3 wires: Connect pins 1, 3 and 4 of the

unit with the IO-Link master (do not connect pins 2 and 5)�

• Connect unit and IO-Link master via 4 wires: Deactivate pin 2 (OU2) via IOLink (setting OU2 = "off") and connect pins 1, 2, 3 and 4 of the unit with the

IO-Link master (do not connect pin 5)�

4.4.2 Extended functions

By means of IO-Link extended measured data are available�

The object reflectivity is provided via the display and as process data value (PDV)

via IO-Link�

The object reflectivity can, for example, be used to detect sensor soiling�

11

Page 12

5 Installation

5.1 Installation conditions

► Install the unit so that the medium to be detected is within a measuring range of

20�0���1000�0 cm�

The unambiguity range of the sensor is fixed to 100 m� Levels within a range

> 10…100 m are suppressed�

Reflecting surfaces in the direct beam path of the sensor – also in the

range > 100 m – are to be avoided by the customer� Otherwise the measured value may be ambiguous�

5.2 Location

► Mount the sensor in a way that a distance (D) of min� 20�0 cm remains between

the highest possible level and the front lens of the sensor�

► The maximum measuring distance (H) between the front lens of the sensor and

the tank bottom or the programmed level is 10 m� A reference height at a longer

distance cannot be set�

12

D = min� measuring distance / dead zone

H = max� measuring distance

Page 13

5.3 Mounting accessories

The unit is supplied without mounting accessories�

Examples of mounting accessories Art. no.

Protective cover O1D E21133

Mounting set E2D101 + E20938 + E20951 E21079

Mounting set O1D, O2D (for rod mounting Ø 12 mm) E2D101

Mounting rod straight Ø 12 mm / M10 E20938

Mounting set O1D, O2D (for rod mounting Ø 14 mm) E2D111

Mounting rod straight Ø 14 mm / M12 E20939

Fixture for mounting and fine adjustment of O1D laser units

E1D100

(rod or free-standing; depending on the clamp)

1

UK

2

Example mounting:

1: Mounting set for Ø 12 mm rod

Art� no� E2D101

2: Mounting rod straight Ø 12 mm / M10

Art� no� E20938

13

Page 14

6 Electrical connection

4

21

3

1

+

1

The unit must be connected by a qualified electrician�

► The national and international regulations for the installation of electrical

equipment must be adhered to�

► Voltage supply according to EN 50178, SELV, PELV�

► Disconnect power�

► Connect the unit as follows:

5

2

5

4

2: Out 2

4: Out 1

3

L

IN

L

+

5

2

4

2: Out 2

4: Out 1

3

L

IN

L

Core colours of ifm sockets:

1 = BN (brown), 2 = WH (white), 3 = BU (blue), 4 = BK (black), 5 = GR (grey)�

14

Page 15

7 Operating and display elements

UK

1: 4 x LED yellow

(two not connected)

2: 4 x LED green Lighting LED = power and set display unit (cm, m, inch)�

3: 4-digit alphanumeric

display

4: Programming button

[MODE/ENTER]

5: Programming button

[SET]

Indication of the switching status; lit, if the corresponding

output is switched�

Indication of the measured distance, the parameters and

parameter values�

Selection of the parameters and acknowledgement of the

parameter values

Setting of the parameter values (hold down to scroll; press

briefly to increment)�

15

Page 16

8 Menu

8.1 Menu structure

1: On delivery

2: RUN mode

3: Main menu

4: Extended functions

= [MODE / ENTER] = [SET]

16

Page 17

8.2 Explanation of the menu

For the factory settings please refer to the end of these instructions (→ 14 Factory

setting)�

8.2.1 Factory setting

Setting of the display unit

Selection of the unit of measurement for [SP1], [SP2], [ASP], [AEP]

Options: [cm] [m] [inch]

→ 10.3.1 Selection of the display unit

Free choice of the tank height

If the height of the tank is known, it can be entered without the unit being

mounted� The entered distance is used as reference level�

Distances between 20�0���999�5 cm can be selected�

→ 10.2.1 Free choice of the tank height

Carry out the basic teach empty state

UK

The bottom of an empty tank can be set as reference level�

→ 10.2.2 Carry out the basic teach empty state

Adjustment to the reference level

The current level of a partly filled tank can be entered as numerical value�

Based on this data the future reference level is calculated�

→ 10.2.3 Carry out the adjustment to the reference level

8.2.2 Main menu

Configuration for output 1

4 switching functions can be selected:

[Hno], [Hnc], [Fno], [Fnc] → 10.3.3 Configure OUT1

Switch point for window and hysteresis function OUT1

Hysteresis function

Upper limit value at which the output with selected hysteresis function

changes its switching status (medium nearer / farther than distance set)�

• [SP1] is the set point if [OU1] = [Hno]

• [SP1] is the reset point if [OU1] = [Hnc]�

→ 10.3.4 Setting of the switch points for hysteresis function OUT1

Window function

[SP1] is the upper limit value at which the output with selected window

function changes its switching status if [OU1] = [Fno] or [Fnc]�

→ 10.3.5 Setting of the switch points for window function OUT1

17

Page 18

The reset point for window and hysteresis function OUT1

[rP1] must be set separately from [SP1]� [rP1] < [SP1]

Hysteresis function

Lower limit value at which the output with selected hysteresis function

changes its switching status (medium nearer / farther than distance set)�

• [rP1] is the reset point if [OU1] = [Hno]�

• [rP1] is the set point if [OU1] = [Hnc]�

→ 10.3.4 Setting of the switch points for hysteresis function OUT1

Window function

[rP1] is the lower limit value at which the output with selected window

function changes its switching status if [OU1] = [Fno] or [Fnc]�

→ 10.3.5 Setting of the switch points for window function OUT1

Configuration for output 2

4 switching functions and 2 analogue signals can be selected:

[Hno], [Hnc], [Fno], [Fnc], [I], [U] → 10.3.6 Configure OUT2

Switch point for window and hysteresis function OUT2

Hysteresis function

Upper limit value at which the output with selected hysteresis function

changes its switching status (medium nearer / farther than distance set)�

• [SP2] is the set point if [OU2] = [Hno]�

• [SP2] is the reset point if [OU2] = [Hnc]�

→ 10.3.7 Setting of the switch points for hysteresis function OUT2

Window function

[SP2] is the upper limit value at which the output with selected window

function changes its switching status if [OU2] = [Fno] or [Fnc]�

→ 10.3.8 Setting of the switch points for window function OUT2

The reset point for window and hysteresis function OUT2

[rP2] must be set separately from [SP1]� [rP2] < [SP1]

Hysteresis function

Lower limit value at which the output with selected hysteresis function

changes its switching status (medium nearer / farther than distance set)�

• [rP2] is the reset point if [OU2] = [Hno]�

18

• [rP2] is the set point if [OU2] = [Hnc]�

→ 10.3.7 Setting of the switch points for hysteresis function OUT2

Window function

[rP2] is the lower limit value at which the output with selected window

function changes its switching status if [OU2] = [Fno] or [Fnc]�

→ 10.3.8 Setting of the switch points for window function OUT2

Analogue start point

Measured value at which 4 mA / 0 V are provided�

[ASP] is only active if [OU2] = [I] or [U]�

→ 10.3.9 Scaling of the measuring range (analogue output)

Page 19

Analogue end point

Measured value at which 20 mA / 10 V are provided�

[AEP] is only active if [OU2] = [I] or [U]�

→ 9.3.11 Scaling of the measuring range (analogue output)

8.2.3 Extended functions

Extended functions

Press [SET] to open the submenu "Extended functions"

→ 10.4 Extended functions

Delay for the switching outputs

[drx] = switch-off delay�

The output changes its switching status only after the delay has elapsed�

If the switching condition is no longer met after the delay has elapsed, the

switching status of the output does not change�

→ 10.4.1 Setting of the delay time for switching outputs

Error reply for the switching outputs

UK

With [FOUx] the behaviour of [OUx] can be defined in case of an internal

error�

[FOUx] = [ON] The switching output is switched or the analogue value

20 mA / 10 V is provided�

[FOUx] = [OFF] The switching output is not switched or the analogue

value 4 mA / 0 V is provided�

→ 10.4.2 Response of the outputs in case of a fault

Time delay after signal loss

A time delay of 0���5 s can be set for the switching behaviour of OUT1 and

OUT2� Error situations can be suppressed for a short period�

At [0] the delay time is not active�

→ 10.4.3 Setting of the delay time after signal loss

Display setting

2 settings can be selected: [ON], [OFF]� → 10.3.2 Setting the display

Setting of the sampling rate

The sampling rate indicates the maximum time after which a new result of

measurement is provided and the outputs are updated�

→ 10.4.4 Setting of the sampling rate

Setting of the mean filter

The mean filter suppresses level fluctuations during the set period� The

measurement results during this period are averaged and influence the

switching status accordingly� Then a new averaging starts� Setting range

is [OFF] or 1���60 s�

→ 10.4.6 Setting of the mean filter

19

Page 20

Restore the factory setting

→ 10.4.7 Reset of all parameters to factory setting

9 Set-up

► After installation, electrical connection and parameter setting, check whether

the unit operates correctly�

> If the unit has been correctly set up, the distance to the level is indicated�

→ 10.2 Entering the reference level (unit on delivery)�

Lifetime of a laser diode: 50 000 hours�

10 Parameter setting

During parameter setting the unit remains in the operating mode internally� It

continues its monitoring function with the existing parameters until the change has

been completed�

On delivery the reference level has to be set first, otherwise the unit is not

operational� → 10.2 Entering the reference level (unit on delivery)

The parameters can also be set via the IO-Link interface → 4.4 IO-Link�

10.1 General parameter setting

10.1.1 Setting of the parameter value

Set the display unit [Uni] before the values for the parameters are defined�

In case of subsequent changes of the display unit rounding errors during

internal conversion to other units may falsify the set values → 10.3.1

Selection of the display unit�

20

Page 21

Selection of the parameter

1

2

3

► Press [MODE/ENTER] so often until

the requested parameter is displayed�

Setting of the parameter value

► Press [Set] and keep it pressed�

> The current parameter value flashes

for 5 s�

► Increase the setting value step by step

by pressing the button once or continuously by holding it down�

Decrease the value: let the display move to the maximum setting value� Then the

cycle starts again at the minimum setting value�

Confirmation of the parameter

value

► Press [MODE/ENTER] briefly�

UK

> The parameter is displayed again; the

new parameter value is effective�

Setting of other parameters

4

5

► Start again with step 1�

Finishing the parameter setting

► Wait for 15 s or press [MODE/ENTER]�

> The current measured value is displayed�

10.1.2 Change from menu level 1 to menu level 2

► Press [MODE/ENTER) until [EF] is

displayed�

► Press [SET] briefly�

> The first parameter of the sub-menu is

displayed (here: [dr1])�

21

Page 22

10.1.3 Electronic lock

The unit can be locked electronically to prevent unauthorised setting� On delivery

the unit is not locked�

Locking

► Make sure that the unit is in the normal

operating mode�

► Keep [MODE/ENTER] + [SET] pressed

until [Loc] is displayed�

> The unit is locked�

[Loc] is displayed briefly if you try to change parameter values on the locked unit during

operation�

Unlocking

► Keep [MODE/ENTER] + [SET] ] pressed

until [uLoc] is displayed�

> The unit is unlocked�

Timeout

If no button is pressed for 15 s during the setting procedure, the unit changes to the

Run mode with unchanged values�

10.2 Entering the reference level (unit on delivery)

On delivery the unit is not operational� The reference level has to be set first� The

complete parameter setting menu cannot be accessed before this has been done�

There are three different ways to define the reference level�

10.2.1 Free choice of the tank height

If the height of the tank (distance between the front lens of the O1D to the tank

bottom) is known, it can be entered without the unit being mounted� The distance

entered is used as reference level�

1

► Apply operating voltage�

> Initial display is shown�

22

Page 23

2

► Press [MODE/ENTER] until [EMP] is

displayed�

3

4

► Press [SET] and keep it pressed until

the preset value is flashing�

► After 5 s the setting value can be set

incrementally be pressing the button

once or continuously by keeping the

button pressed�

The value is incremented continuously� For reducing the value: let the display move to

the maximum setting value� Then the cycle starts again at the minimum setting value�

► Confirm with [MODE/ENTER]�

10.2.2 Carry out the basic teach empty state

UK

The bottom of an empty tank can be set as reference level�

1

2

3

► Apply operating voltage�

> Initial display is shown�

► Press [MODE/ENTER] until [cEMP]

is displayed�

► Press [SET] and keep it pressed until

[cEMP] is flashing�

23

Page 24

4

> After 5 s [WAIT] is displayed while

the measurement is being made�

> [donE] shows that the new setting

value has been stored�

If the setting was unsuccessful the

cause is displayed briefly and then

[FAIL] is displayed� The new reference

point is rejected�

10.2.3 Carry out the adjustment to the reference level

The current level of a partly filled tank can be entered as numerical value� On this

basis the reference level is calculated�

1

2

3

► Apply operating voltage�

> Initial display is shown�

► Press [MODE/ENTER] until [cMEd]

is displayed�

► Press [SET] and keep it pressed until

the display flashes�

► After 5 s the setting value can be set

incrementally be pressing the button

once or continuously be keeping the

button pressed�

The value is incremented continuously� For reducing the value: let the display move to

4

24

the maximum setting value� Then the cycle starts again at the minimum setting value�

► Confirm with [MODE/ENTER]�

> [WAIT] is displayed while the meas-

urement is being made�

> [donE] shows that the new setting

value has been stored�

If the setting was unsuccessful the

cause is displayed briefly and then

[FAIL] is displayed� The new reference

point is rejected�

Page 25

10.2.4 Unsuccessful adjustment

In case of unsuccessful adjustment, the cause is displayed briefly([++], [- -],

[nEAr], [Far], [bAd], [dEEP]), then [FAIL]� The new reference point is rejected�

Display Possible cause

[++] too much light, e�g reflective surface

[- -] not enough light, no medium

[nEAr] The level is below the min� measuring distance < 20�0 cm

[Far] The level exceeds the max� measuring distance > 1000�0 cm

UK

[bAd] The measurement is too noisy

[dEEP] Reference level > 1000�0 cm

10.2.5 Successful setting of the reference level

Parameter values ([SPx], [rPx], [ASP], [AEP]) which are not possible with the

newly set reference level are recalculated on the basis of the new measuring

range available�

10.3 Configuration of the basic settings

10.3.1 Selection of the display unit

Set [Uni] before the values for the parameters [SPx], [ASP], [AEP] are

defined�

In case of subsequent changes of the display unit rounding errors during

internal conversion to other units may falsify the set values�

► Change to [EF]�

► Select [Uni] and set the unit of measurement�

Selection of the unit of measurement: [cm], [m], [inch]

► Confirm with [MODE/ENTER]�

> The selected unit is indicated by a green LED on the display�

25

Page 26

10.3.2 Setting the display

► Change to [EF]�

► Select [diS] and make settings�

2 settings can be selected:

• [ON] = the measured value display is activated in the Run mode�

Update of the measured values every 600 ms�

• [OFF] = The measured value display is deactivated in the Run mode�

Press one button to indicate the current measured value for 15 s�

The update of the measured value only refers to the display� It has no

effect on the outputs�

► Confirm with [MODE/ENTER]�

The LEDs remain active even if the display is deactivated�

10.3.3 Configure OUT1

► Select [OU1] and set the switching functions�

Switching functions:

• [Hno] = hysteresis function / normally open

• [Hnc] = hysteresis function / normally closed

• [Fno] = window function / normally open

• [Fnc] = window function / normally closed

► Confirm with [MODE/ENTER]�

10.3.4 Setting of the switch points for hysteresis function OUT1

► In [OU1] select the output function [Hno] or [Hnc]�

► Confirm with [MODE/ENTER]�

► Select [SP1] and set the set point�

► Confirm with [MODE/ENTER]�

► Select [rP1] and set the reset point�

► Confirm with [MODE/ENTER]�

10.3.5 Setting of the switch points for window function OUT1

► In [OU1] select the output function [Fno] or [Fnc]�

► Confirm with [MODE/ENTER]�

► Select [SP1] and set the upper limit value�

► Confirm with [MODE/ENTER]�

► Select [rP1] and set the lower limit value�

► Confirm with [MODE/ENTER]�

26

Page 27

10.3.6 Configure OUT2

► Select [OU2]�

► Set switching functions or analogue signals:

• [Hno] = hysteresis function / normally open

• [Hnc] = hysteresis function / normally closed

• [Fno] = window function / normally open

• [Fnc] = window function / normally closed

• [I] = current output analogue 4���20 mA

• [U] = voltage output analogue 0���10 V

► Confirm with [MODE/ENTER]�

10.3.7 Setting of the switch points for hysteresis function OUT2

► In [OU2] select the output function [Hno] or [Hnc]�

► Confirm with [MODE/ENTER]�

► Select [SP2] and set the set point�

► Confirm with [MODE/ENTER]�

► Select [rP2] and set the reset point�

► Confirm with [MODE/ENTER]�

10.3.8 Setting of the switch points for window function OUT2

UK

► In [OU2] select the output function [Fno] or [Fnc]�

► Confirm with [MODE/ENTER]�

► [Select SP2] and set the upper limit value�

► Confirm with [MODE/ENTER]�

► Select [rP2] and set the lower limit value�

► Confirm with [MODE/ENTER]�

10.3.9 Scaling of the measuring range (analogue output)

► In [OU2] select [I] or [U]�

► Confirm with [MODE/ENTER]�

► Select [ASP] and set the "Analogue start point"� With [ASP] you define

at which measured value the output signal is 4 mA / 0 V�

► Confirm with [MODE/ENTER]�

► Select [AEP] and set the "Analogue end point"�

With [AEP] you define at which measured value the output signal is 20

mA / 10 V� [AEP] can also be selected so that it is below [ASP]� This

implements a falling edge�

► Confirm with [MODE/ENTER]�

Minimum distance between [ASP] and [AEP]: 10.0 cm.

When the minimum distance is not reached, the error message "SIZE" is

displayed�

27

Page 28

10.4 Extended functions

10.4.1 Setting of the delay time for switching outputs

► Select [EF]�

► Press [SET] to change to the menu [EF]�

► Select parameters with [MODE/ENTER]:

[drx] = switch-off delay�

► Set the parameter value with [SET]:

Setting range [s]: 0 / 0�1���5 s in steps of 0�1 s

(0 = delay time is not active)

► Confirm with [MODE/ENTER]�

10.4.2 Response of the outputs in case of a fault

► Select [EF]�

► Press [SET] to change to the menu [EF]�

► Select [FOUx]�

► Set the parameter value with [SET]:

• [ON] = The output switches in case of a fault or analogue value

20 mA / 10 V is provided�

• [OFF] = The output switches back in case of a fault or analogue value

4 mA / 0 V is provided�

► Confirm with [MODE/ENTER]�

10.4.3 Setting of the delay time after signal loss

► Select [EF]�

► Press [SET] to change to the menu [EF]�

► Select [dFo]�

► Set the parameter value with [SET]:

Setting range [s]: 0�0���1�0���5�0�

► Confirm with [MODE/ENTER]�

10.4.4 Setting of the sampling rate

► Select [EF]�

► Press [SET] to change to the menu [EF]�

► Select [rATE]�

► Press [SET] until the preset measured sampling rate value flashes�

► Enter a value incrementally by pressing [SET] once�

► Confirm with [MODE/ENTER]�

> [rATE] is displayed again�

28

Page 29

10.4.5 Table repeatability and accuracy

Values for sampling rate 15 Hz, extraneous light of max. 40 klx*

Repeatability Accuracy

Distance

in [cm]

20�0���100�0 ± 0�45 cm ± 0�6 cm ± 1�5 cm ± 1�6 cm

100�0���200�0 ± 0�5 cm ± 0�8 cm ± 1�5 cm ± 1�8 cm

200�0���400�0 ± 1�6 cm ± 1�9 cm ± 2�5 cm ± 3�0 cm

400�0���600�0 ± 2�4 cm ± 3�3 cm ± 3�5 cm ± 4�5 cm

600�0���1000�0 ± 5�0 cm — ± 6�5 cm —

Values for sampling rate 15 Hz, extraneous light of 40...100 klx*

Distance

in [cm]

20�0���200�0 ± 1�4 cm ± 1�4 cm ± 2�4 cm ± 2�4 cm

200�0���400�0 ± 2�5 cm ± 3�0 cm ± 3�5 cm ± 4�0 cm

white

90 % remission

Repeatability Accuracy

white

90 % remission

grey

18 % remission

grey

18 % remission

white

90 % remission

white

90 % remission

grey

18 % remission

grey

18 % remission

UK

400�0���600�0 ± 3�1 cm ± 4�5 cm ± 4�1 cm ± 5�5 cm

600�0���1000�0 ± 6�0 cm — ± 7�0 cm —

Values for sampling rate 1 Hz, extraneous light of max. 40 klx*

Repeatability Accuracy

Distance

in [cm]

20�0���100�0 ± 0�40 cm ± 0�45 cm ± 1�4 cm ± 1�5 cm

100�0���200�0 ± 0�45 cm ± 0�6 cm ± 1�5 cm ± 1�6 cm

200�0���400�0 ± 1�35 cm ± 1�4 cm ± 2�3 cm ± 2�4 cm

400�0���600�0 ± 1�9 cm ± 2�1 cm ± 2�9 cm ± 3�1 cm

600�0���1000�0 ± 3�7 cm — ± 4�7 cm —

white

90 % remission

grey

18 % remission

white

90 % remission

grey

18 % remission

29

Page 30

Values for sampling rate 1 Hz, extraneous light of 40...100 klx*

Repeatability Accuracy

Distance

in [cm]

20�0���200�0 ± 1�0 cm ± 1�0 cm ± 2�0 cm ± 2�0 cm

200�0���400�0 ± 1�8 cm ± 1�9 cm ± 2�8 cm ± 2�9 cm

400�0���600�0 ± 2�3 cm ± 2�7 cm ± 3�3 cm ± 3�7 cm

600�0���1000�0 ± 3�8 cm — ± 4�8 cm —

* Range referred to black (6 % remission) ≤ 400.0 cm.

The values apply at:

- constant ambient conditions (23°C /960 hPa)

- only after unit powered up for 10 minutes�

white

90 % remission

grey

18 % remission

white

90 % remission

grey

18 % remission

10.4.6 Setting of the mean filter

► Select [EF]�

► Press [SET] to change to the menu [EF]�

► Select [mEAn]�

► Set the parameter value with [SET]:

► Setting range [s]: 1���60

► [OFF] = mean filter not active

► Confirm with [MODE/ENTER]�

10.4.7 Reset of all parameters to factory setting

► Select [EF]�

► Press [SET] to change to the menu [EF]�

► Select [rES]�

► Press [SET] and keep it pressed until [- - - -] is displayed�

► Confirm with [MODE/ENTER]�

> The unit returns to the factory setting�

> Initial display is shown�

30

Page 31

11 Operation

11.1 Operating modes

11.1.1 Run mode

The run mode is the normal operating mode�

After power on the unit is in the Run mode� It carries out its monitoring function

and generates output signals according to the set parameters�

The display indicates the current level (relative to the reference level), the yellow

LEDs signal the switching status of the outputs�

UK

11.1.2 Display mode

Indication of the parameters and the set parameter values

► Press [MODE/ENTER] briefly�

> Unit goes to the Display mode� Internally it remains in the operating mode�

The set parameter values can be read:

► To scroll through the parameters, press [MODE/ENTER] briefly�

► To display the respective parameter value, press [SET] briefly�

> After another 15 s the unit returns to the Run mode�

11.1.3 Object reflectivity

Indication of object reflectivity:

► Press [SET] in the Run mode�

> The unit displays an orientation value for the object reflectivity (for instance

+100 corresponds to a white object, +020 corresponds to a grey object)�

11.1.4 Programming mode

Setting the parameter values → 10.1 General parameter setting�

31

Page 32

12 Troubleshooting

Display Possible causes Switching output Current output

Initial display

- - - -

- - - -

- - - -

++

Reference level not

taught

Too much light, e�g�

reflective surface

Not enough light, no

- -

medium

near Level < 20 cm

far Level > 999�5 cm

Hno Hnc Fno Fnc

AEP

< ASP

OFF Not active 3�5 mA

Depending on settings

FOU1 / FOU2

FOU = [ON]:

Switching output switched or

analogue value = 20�5 mA / 10 V

FOU = [OFF]:

ASP

< AEP

Switching output off or

Errp

LoFF Laser switched off

- - - -

SC1 Short circuit channel 1

SC2 Short circuit channel 2

SC Short circuit channel 1 & 2

Plausibility (e�g� medium

is too fast)

Underfill� Level is below

the taught reference

level�

OFF ON OFF ON

analogue value = 3�5 mA / 0 V

20�5 mA

10 V

[SC2] or [SC] only

active if OUT2 is

configured as

switching output�

3�5 mA

0 V

32

Page 33

Display IO-Link process value

Level *) Object reflectivity *)

IO-Link device

status *)

- - - -

- - - -

- - - -

NoData

++ OL

- -

near OL

far UL

Errp Last valid measured value

Normal operation Functional check

UL

NoData

UK

Out of specification

LoFF NoData

Device is operating

properly

- - - -

SC1 IO-Link disturbed

SC2 Normal operation Functional check

SC IO-Link disturbed

*) see device-related IODD

UL Normal operation

33

Page 34

13 Maintenance, repair, disposal

Faulty sensors must only be repaired by the manufacturer�

► Keep the front lens of the sensor clean�

► After use dispose of the unit in an environmentally friendly way in accordance

with the applicable national regulations�

34

Page 35

14 Factory setting

On delivery the parameter setting menu is not displayed completely� Only the parameter values [Uni], [EMP], [cEMP], [cMED] can be set� The complete parameter

setting menu is only accessible when the reference level has been set�

Parameter Setting range Factory setting

Uni

OU1

SP1 [cm]

rP1 [cm]

OU2

SP2 [cm]

rP2 [cm]

ASP [cm]

AEP [cm]

dr1 [s]

Hno, Hnc, Fno, Fnc, I, U

cm, m, inch Cm

Hno, Hnc, Fno, Fnc Hno

20�0���999�5 100

20�0���999�5 80

I

20���999�5 200

20���999�5 180

20���999�5 0

20���999�5 979�5

0���0�1���5 0

Own setting

UK

dr2 [s]

FOU1

FOU2

DFO [s]

EMP [cm]

CMEd [cm]

DiS

rATE [Hz]

mEAn [s]

0���0�1���5 0

ON ; OFF OFF

ON ; OFF OFF

0���0�1���5 0,2

20�0���999�5 20�0

20�0���999�5 —

ON ; OFF ON

1���33 15

OFF; 1���60 OFF

Technical data and further information at www�ifm�com

35

Loading...

Loading...