Page 1

Operating instructions

Optical distance sensor

O1D102

80262529 / 00 03 / 2017

UK

Page 2

2

Content

1 Preliminary note ��������������������������������������������������������������������������������������������������� 4

1�1 Symbols used ������������������������������������������������������������������������������������������������4

1�2 Warning signs used ���������������������������������������������������������������������������������������4

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Functions and features ����������������������������������������������������������������������������������������6

3�1 Applications ���������������������������������������������������������������������������������������������������6

4 Functions �������������������������������������������������������������������������������������������������������������6

4�1 Output function hysteresis �����������������������������������������������������������������������������6

4�2 Output function window ���������������������������������������������������������������������������������6

4�3 Analogue output function �������������������������������������������������������������������������������6

4�4 Switch off the laser ���������������������������������������������������������������������������������������6

5 Installation������������������������������������������������������������������������������������������������������������7

5�1 Installation conditions ������������������������������������������������������������������������������������7

5�2 Mounting accessories ������������������������������������������������������������������������������������ 7

6 Electrical connection �������������������������������������������������������������������������������������������� 8

6�1 Operation with IO-Link master ����������������������������������������������������������������������� 8

7 Operating and display elements ��������������������������������������������������������������������������9

8 Menu ������������������������������������������������������������������������������������������������������������������ 10

8�1 Menu structure ��������������������������������������������������������������������������������������������� 10

8�2 Explanation of the menu ������������������������������������������������������������������������������ 11

9 Operating modes �����������������������������������������������������������������������������������������������13

9�1 Run mode ����������������������������������������������������������������������������������������������������13

9�2 Display mode ����������������������������������������������������������������������������������������������� 13

9�3 Object reflectivity �����������������������������������������������������������������������������������������13

9�4 Programming mode �������������������������������������������������������������������������������������13

10 Parameter setting ��������������������������������������������������������������������������������������������14

10�1 Parameter setting in general ���������������������������������������������������������������������14

10�1�1 Setting of the parameter value ���������������������������������������������������������14

10�1�2 Change from menu level 1 to menu level 2 �������������������������������������� 15

10�1�3 Electronic lock ����������������������������������������������������������������������������������15

10�2 Configuration of the basic settings ������������������������������������������������������������16

10�2�1 Selection of the display unit �������������������������������������������������������������� 16

Page 3

3

UK

10�2�2 Setting of the display ������������������������������������������������������������������������16

10�2�3 Configuration of OUT1 ����������������������������������������������������������������������16

10�2�4 Hysteresis function ���������������������������������������������������������������������������17

10�2�5 Setting of the switch point for hysteresis function OUT1 ������������������ 18

10�2�6 Window function �������������������������������������������������������������������������������18

10�2�7 Setting of the switch points for window function OUT1 ��������������������19

10�2�8 Configuration of OUT1 ����������������������������������������������������������������������20

10�2�9 Setting of the switch point for hysteresis function OUT2 ������������������ 20

10�2�10 Setting of the switch points for window function OUT2 ������������������20

10�2�11 Scaling of the measuring range (analogue output) ������������������������� 20

10�3 Teach mode �����������������������������������������������������������������������������������������������22

10�3�1 Setting of the sampling rate �������������������������������������������������������������� 22

10�3�2 Setting of the repeatability ����������������������������������������������������������������22

10�3�3 Table repeatability and accuracy ������������������������������������������������������22

10�4 Extended functions ������������������������������������������������������������������������������������23

10�4�1 Setting of the time delay for switching outputs ���������������������������������23

10�4�2 Setting of the damping of the measured signal ��������������������������������23

10�4�3 Reset of all parameters to factory setting �����������������������������������������23

10�4�4 Display of the software version number �������������������������������������������23

11 IO-Link �������������������������������������������������������������������������������������������������������������24

11�1 General information �����������������������������������������������������������������������������������24

11�2 Device-specific information ������������������������������������������������������������������������ 24

11�3 Parameter setting tools ������������������������������������������������������������������������������ 24

11�4 Extended functions ������������������������������������������������������������������������������������24

11�5 Teach function �������������������������������������������������������������������������������������������� 24

11�5�1 Object reflectivity ������������������������������������������������������������������������������24

12 Set-up / operation ��������������������������������������������������������������������������������������������24

12�1 Fault indication ������������������������������������������������������������������������������������������25

13 Maintenance, repair and disposal �������������������������������������������������������������������� 26

14 Scale drawing ��������������������������������������������������������������������������������������������������26

15 Factory setting �������������������������������������������������������������������������������������������������27

Page 4

4

1 Preliminary note

1.1 Symbols used

► Instruction

> Reaction, result

[…] Designation of pushbuttons, buttons or indications

→ Cross-reference

Important note

Non-compliance can result in malfunctions or interference�

Information

Supplementary note�

1.2 Warning signs used

WARNING

Warning of serious personal injury�

Death or serious irreversible injuries may result�

2 Safety instructions

• Please read this document prior to set-up of the unit� Ensure that the product is

suitable for your application without any restrictions�

• Improper or non-intended use may lead to malfunctions of the unit or to

unwanted effects in your application� That is why installation, electrical

connection, set-up, operation and maintenance of the unit must only be carried

out by qualified personnel authorised by the machine operator�

• In case of malfunction of the unit please contact the manufacturer� If the unit is

tampered with and/or modified, any liability and warranty is excluded�

Page 5

5

UK

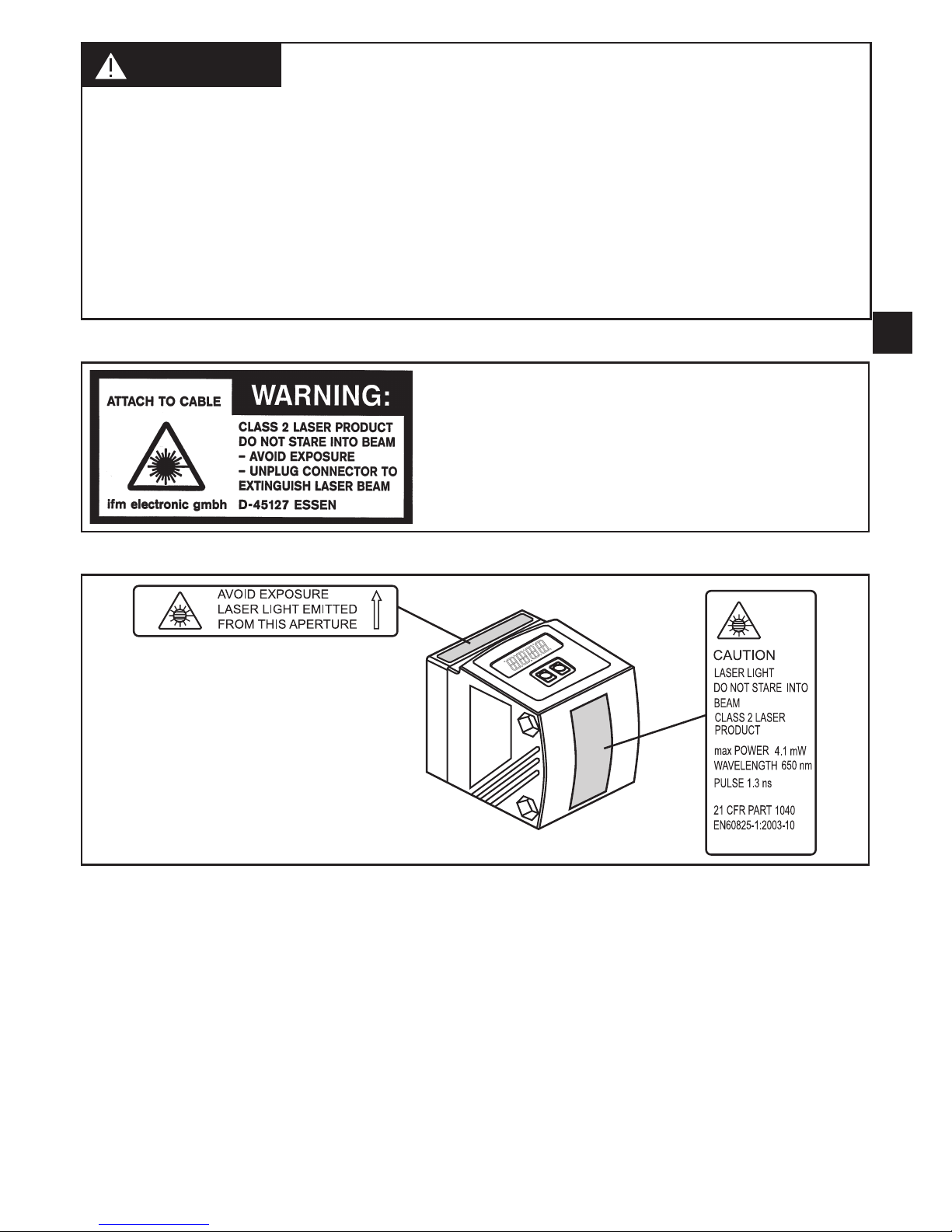

WARNING

Visible laser light; laser protection class 2�

Use of controls or adjustments other than those specified herein may result in hazardous

radiation exposure� Damage to the retina is possible�

► Do not stare into the laser beam!

► Apply the enclosed labels (laser warning) in the immediate vicinity of the unit�

► Adhere to the caution and warning notes on the product label�

► Use the enclosed label for the power supply cable�

Label for supply cable

Product label

Page 6

6

3 Functions and features

The unit is used as an optical distance sensor�

3.1 Applications

• The optical distance sensor measures distances between 0�2 and 3�5 m�

• It has a background suppression at > 3�5���4 m�

• The measured value is shown in a 10-segment display�

• According to the set output functions 2 output signals can be generated�

• O1D102: Certification 21 CFR PART 1040

The distance between the sensor and the background must be limited

to max� 4 m by the customer� Otherwise the measured value may be

ambiguous. → 5.1 Installation conditions

4 Functions

4.1 Output function hysteresis

The hysteresis keeps the switching state of the output stable if the measured

value varies about the sensing range� Both outputs (OUT1 and OUT2) can be set

as hysteresis function. → 10.2.4 Hysteresis function

4.2 Output function window

The window function enables the monitoring of a defined acceptable range� Both

outputs (OUT1 and OUT2) can be set as window function. → 10.2.6 Window function

4.3 Analogue output function

The sensor can also output an analogue signal on output 2 (OUT2) which is proportional

to the distance. → 10.2.11 Scaling of the measuring range (analogue output).

4.4 Switch off the laser

For safety and maintenance purposes the laser of the unit can be temporarily

switched off via the input on pin 5�

Input signal at pin 5 Laser

Low / not connected On

High Off

Page 7

7

UK

5 Installation

5.1 Installation conditions

► Install the unit so that the object to be detected is within a measuring range of

0�2���3�5 m�

The unambiguity range of the sensor is fixed to 4 m� Objects within a range

> 3�5…4 m are suppressed�

Reflecting objects in the direct beam path of the sensor - also in the range

> 4 m – are to be avoided by the customer� Otherwise the measured

values may be ambiguous�

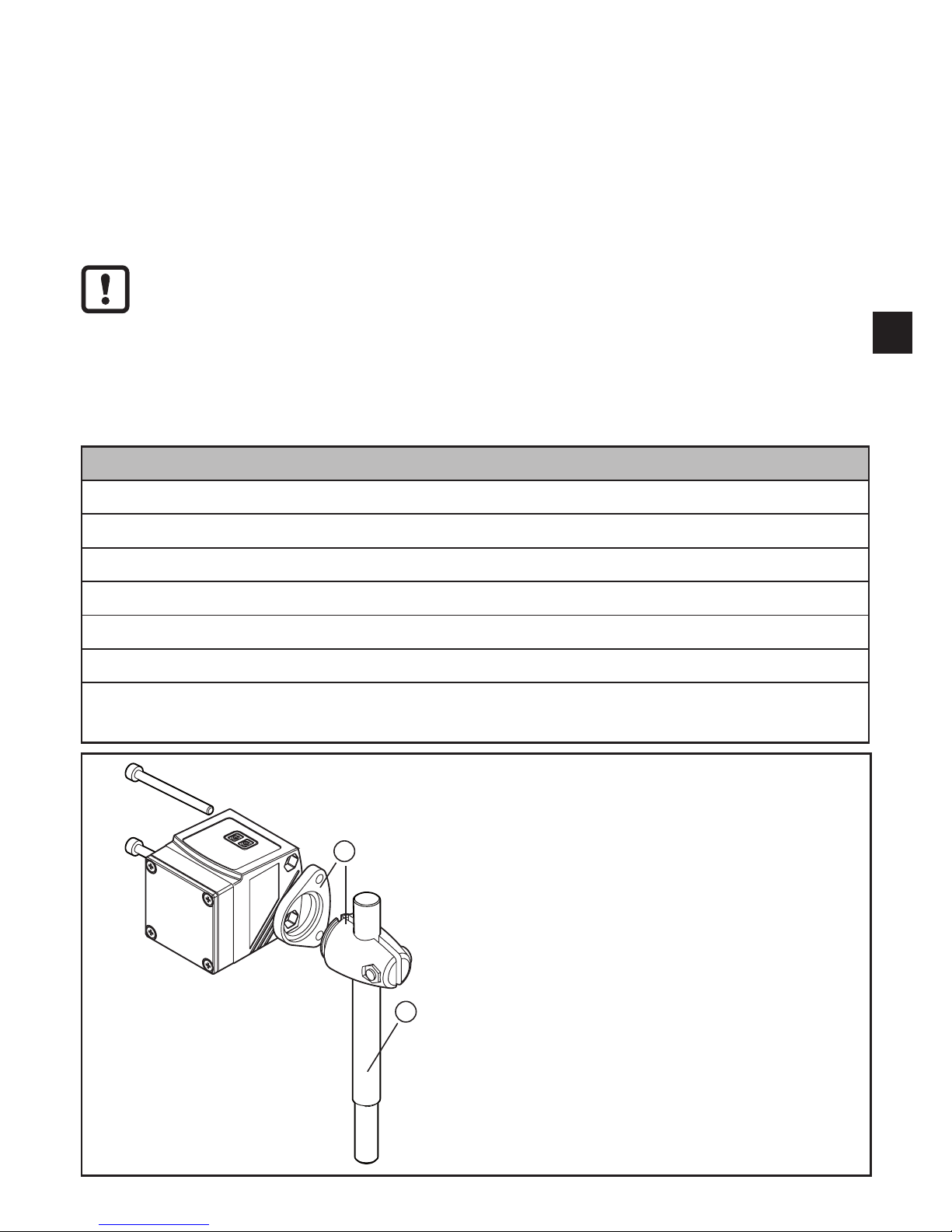

5.2 Mounting accessories

The unit is supplied without mounting accessories�

Examples of mounting accessories Art. no.

Protective cover O1D E21133

Mounting set E2D101 + E20938 + E20951 E21079

Mounting set O1D (for rod mounting Ø 12 mm) E2D101

Mounting rod straight Ø 12 mm / M10 E20938

Mounting set O1D (for rod mounting Ø 14 mm) E2D111

Mounting rod straight Ø 14 mm / M12 E20939

Fixture for mounting and fine adjustment of O1D laser units

(rod or free-standing; depending on the clamp)

E1D100

1

2

Example mounting:

1: Mounting set for Ø 12 mm rod

art� no� E2D101

2: Mounting rod straight Ø 12 mm / M10

art� no� E20938

Page 8

8

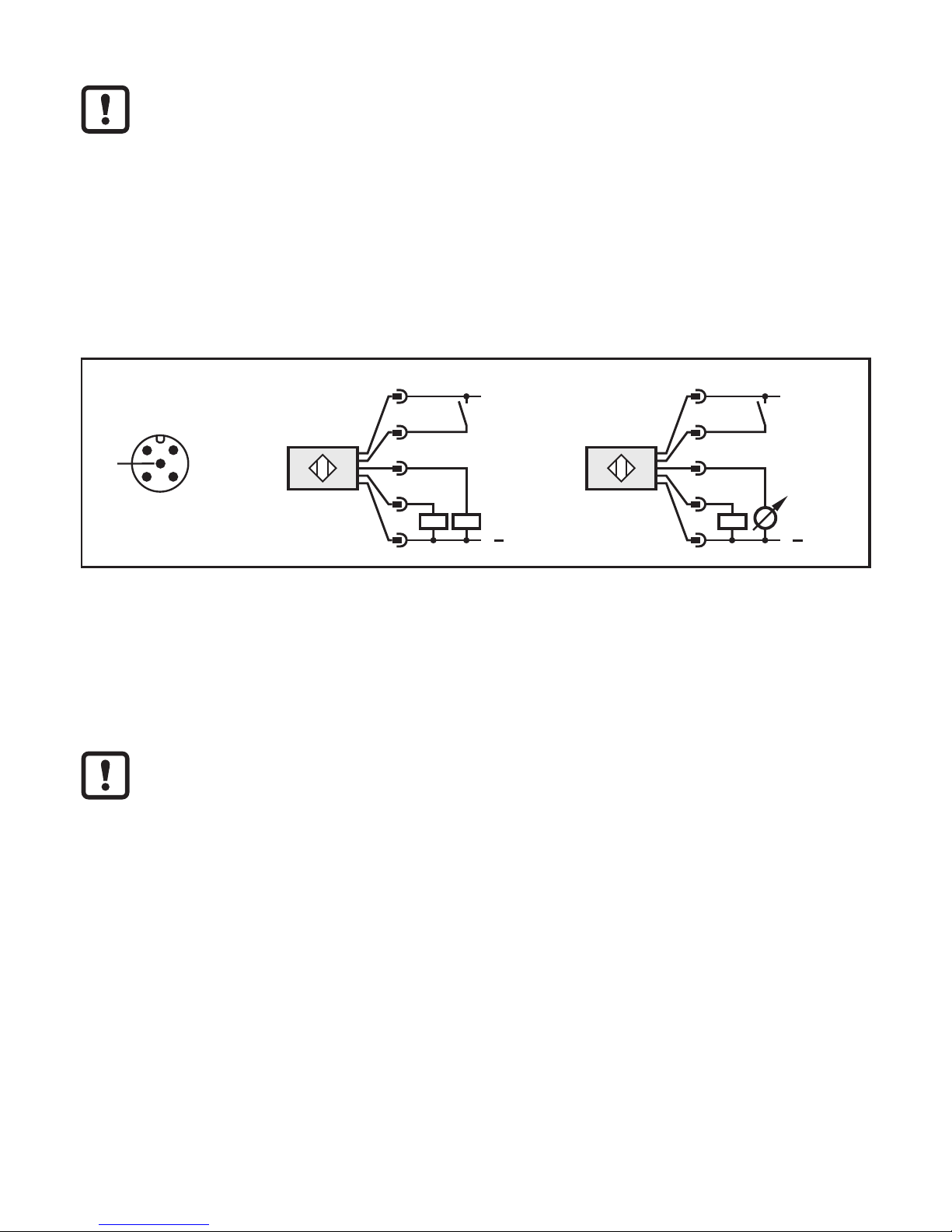

6 Electrical connection

The unit must be connected by a qualified electrician�

► The national and international regulations for the installation of electrical

equipment must be adhered to�

► Ensure voltage supply according to EN 50178, SELV, PELV�

O1D102: cULus, Supply Class 2

► Disconnect power�

► Connect the unit as follows:

O1D102 PNP

4

21

3

5

L

+

L

5

1

4

3

2

IN

L

+

L

5

1

4

3

2

IN

2: Out 2

4: Out 1

2: Out 2

4: Out 1

Core colours of ifm sockets:

1 = BN (brown), 2 = WH (white), 3 = BU (blue), 4 = BK (black), 5 = GR (grey)�

6.1 Operation with IO-Link master

The unit is compatible with IO-Link master port class A (type A)�

For operation with IO-Link master port class B (type B) observe the following:

As a standard, the unit is not compatible with master port class B (type B)�

Pin 2 (OU2) and pin 5 (IN1) are used for manufacturer-specific functions�

That means that the main supply voltage of the unit and the additional

voltage supply (master port class B on pins 2/5) are not electrically isolated�

With the following configurations the unit can be used with master port class B:

• Connect unit and IO-Link master via 3 wires: Connect pins 1, 3 and 4 of the

unit with the IO-Link master (do not connect pins 2 and 5)�

• Connect unit and IO-Link master via 4 wires: Deactivate pin 2 (OU2) via IOLink (setting OU2 = "off") and connect pins 1, 2, 3 and 4 of the unit with the

IO-Link master (do not connect pin 5)�

Page 9

9

UK

7 Operating and display elements

1: 4 x LED green Lighting LED = power and set display unit (mm, m, inch)

2: 4 x LED yellow

(two not

connected)

Indication of the switching status; lights, if the corresponding

output is switched�

3: 4-digit

alphanumeric

display

Indication of the measured distance, the parameters and

parameter values�

4: Programming

button

[SET]

Setting of the parameter values (scrolling by holding pressed;

incrementally by pressing once)�

5: Programming

button

[MODE/ENTER]

Selection of the parameters and acknowledgement of the

parameter values�

Page 10

10

8 Menu

8.1 Menu structure

= [MODE / ENTER] = [SET]

Page 11

11

UK

8.2 Explanation of the menu

For the factory settings please refer to the end of these instructions

(→ 14 Factory setting).

Configuration for output 1

4 switching functions can be selected:

[Hno], [Hnc], [Fno], [Fnc] → 10.2.3 Configuration of OUT1

Switch point for hysteresis function OUT1

Limit value at which the output with selected hysteresis function changes

its switching state (object nearer/farther than distance set)�

[SP1] is only active if [OU1] = [Hno] or [Hnc]�

→ 10.2.5 Setting of the switch point for hysteresis function OUT1

Switch points for window function OUT1

Limit values at which the output with selected window function changes its

switching state (object present / not present between the distance "near"

and the distance "far")�

[nSP1] = switch point “near” / [FSP1] = switch point “far”�

[nSP1] / [FSP1] are only active if [OU1] = [Fno] or [Fnc]�

→ 10.2.7 Setting of the switch points for window function OUT1

Configuration for output 2

4 switching functions and 2 analogue signals can be selected:

[Hno], [Hnc], [Fno], [Fnc], [I], [U] → 10.2.8 Configuration of OUT2

Switch point for hysteresis function OUT2

Limit value at which the output with selected hysteresis function changes

its switching state (object nearer/farther than distance set)�

[SP2] is only active if [OU2] = [Hno] or [Hnc]�

→ 10.2.9 Setting of the switch point for hysteresis function OUT2

Switch points for window function OUT2

Limit values at which the output with selected window function changes its

switching state (object present / not present between the distance "near"

and the distance "far")�

[nSP2] = switch point “near” / [FSP2] = switch point “far”�

[nSP2] / [FSP2] are only active if [OU2] = [Fno] or [Fnc]�

→ 10.2.10 Setting of the switch points for window function OUT2

Analogue start point

Measured value at which 4 mA / 0 V are provided�

[ASP] is only active if [OU2] = [I] or [U]�

→ 10.2.11 Scaling of the measuring range (analogue output)

Page 12

12

Analogue end point

Measured value at which 20 mA / 10 V are provided�

[AEP] is only active if [OU2] = [I] or [U]�

→ 10.2.11 Scaling of the measuring range (analogue output)

Teach mode

Selection "sampling rate" or "repeatability"

→ 10.3 Teach mode

Extended functions

Press [SET] to open the submenu "Extended functions"

→ 10.4 Extended functions

Delay for the switching outputs

[dSx] = switch-on delay; [drx] = switch-off delay�

The output does not immediately change its switching status when the

switching condition is met but only after the delay has elapsed� If the

switching condition is no longer met after the delay has elapsed, the

switching status of the output does not change�

[dS2] and [dr2] are not effective if [OU2] = [I] or [U]�

→ 10.4.1 Setting of the time delay for switching outputs

Damping of the measured signal

This function allows to suppress short-time saturation of the measuring

element (such saturation can result from direct reflection or strong

fluctuations in brightness)�

During the delay set, the latest valid value measured is displayed, the

output signals remain unchanged�

→ 10.4.2 Setting of the damping of the measured value

Display setting

7 settings can be selected:

[d1], [d2], [d3], [rd1], [rd2], [rd3], [OFF]

→ 10.2.2 Setting of the display

Setting of the display unit

Selection of the unit of measurement for [SP1], [SP2], [ASP], [AEP]

Selection options: [mm] [m] [inch]

→ 10.2.1 Selection of the display unit

Restore factory setting

→ 10.4.3 Reset of all parameters to factory setting

Display of the software version number

→ 10.4.4 Display of the software version number

Page 13

13

UK

9 Operating modes

9.1 Run mode

The run mode is the normal operating mode�

After power on the unit is in the Run mode� It carries out its monitoring function

and generates output signals according to the set parameters�

The display indicates the current distance, the yellow LEDs signal the switching

status of the outputs�

9.2 Display mode

Indication of the parameters and the set parameter values�

► Press [MODE/ENTER] briefly�

> Unit goes to the Display mode� Internally it remains in the operating mode�

The set parameter values can be read�

► To scroll through the parameters, press [MODE/ENTER] briefly�

► To display the respective parameter value, press [SET] briefly�

> After 15 s the unit returns to the Run mode�

9.3 Object reflectivity

Display of the object reflectivity (formerly: align mode)�

► Press [SET] in the Run mode�

> The unit displays an orientation value for the object reflectivity

(e�g� +100 corresponds to a white object, +020 corresponds to a grey object)�

9.4 Programming mode

Setting the parameter values → 10.1 Parameter setting in general

Page 14

14

10 Parameter setting

During parameter setting the unit remains internally in the operating mode� It

continues its monitoring function with the existing parameters until the change has

been finished�

10.1 Parameter setting in general

10.1.1 Setting of the parameter value

Select the display unit [Uni] before you define the values for the

parameters� In case of subsequent changes of the display unit rounding

errors during internal conversion to other units may falsify the set values�

→ 10.2.1 Selection of the display unit

1

Selection of the parameter

► Press [MODE/ENTER] until the

requested parameter is displayed�

2

Setting of the parameter value

► Press [SET] and keep it pressed�

> The current parameter value flashes

for 5 s�

► Increase the setting value

incrementally by pressing the button

once or

continuously

by pressing it

permanently�

Decrease the value: let the display move to the maximum setting value� Then the

cycle starts again at the minimum setting value�

3

Confirmation of the parameter

value

► Press [MODE/ENTER] briefly�

> The parameter is displayed again; the

new parameter value is effective�

4

Setting of other parameters

► Start again with step 1�

5

Finishing the parameter setting

► Wait for 15 s or press [MODE/ENTER]�

> The current measured value is displayed�

Page 15

15

UK

10.1.2 Change from menu level 1 to menu level 2

► Press [MODE/ENTER] several times until

[EF] is displayed.

► Press [SET] briefly�

> The first parameter of the sub-menu is

displayed (here: [dr1])�

10.1.3 Electronic lock

The unit can be locked electronically to prevent unintentional settings� On delivery

the unit is not locked�

Locking

► Make sure that the unit is in the normal

operating mode�

► Keep [MODE/ENTER] + [SET] pressed

until [Loc] is displayed�

> The unit is locked�

[Loc] is displayed briefly if you try to change parameter values on the locked unit during

operation�

Unlocking

► Keep [MODE/ENTER] + [SET] pressed

until [uLoc] is displayed�

> The unit is unlocked�

Timeout

If no button is pressed for 15 s during the setting procedure, the unit returns to the

Run mode with unchanged values�

Page 16

16

10.2 Configuration of the basic settings

10.2.1 Selection of the display unit

Set [Uni] before the values for the parameters [SPx], [nSPx], [FSPx],

[ASP], [AEP] are defined�

In case of subsequent changes of the display unit rounding errors during

internal conversion to other units may falsify the set values�

► Change to [EF]�

► Select [Uni] and set the unit of measurement�

Selection of the unit of measurement: [mm], [m], [inch]

► Confirm with [MODE/ENTER]�

> The selected unit is indicated by a green LED on the display�

10.2.2 Setting of the display

► Change to [EF]�

► Select [diS] and make the settings�

7 settings can be selected:

• [d1] = update of the measured value every 50 ms�

• [d2] = update of the measured value every 200 ms�

• [d3] = update of the measured value every 600 ms�

• [rd1], [rd2], [rd3] = display like [d1], [d2], [d3] rotated by 180°�

The update of the measured value only refers to the display� It has no

effect on the outputs�

• [OFF] = The measured value display is deactivated in the Run mode�

Press one button to indicate the current measured value for 15 s�

► Confirm with [MODE/ENTER]�

The LEDs remain active even if the display is deactivated�

10.2.3 Configuration of OUT1

► Select [OU1] and set the switching functions�

Switching functions:

• [Hno] = hysteresis function / normally open

• [Hnc] = hysteresis function / normally closed

• [Fno] = window function / normally open

• [Fnc] = window function / normally closed

► Confirm with [MODE/ENTER]�

Page 17

17

UK

10.2.4 Hysteresis function

The hysteresis keeps the switching state of the output stable if the measured

value varies about the sensing range� In either case set and reset points are

symmetrically arranged around the selected switch point [SPx]� The hysteresis

is the distance between set and reset points; it is calculated on the basis of the

repeatability with a safety factor of 1.5. → 10.3.3 Table repeatability and accuracy

Example Hno

1� For the output function [Hno] the output switches when the object approaches

and when the switch point (A) is reached�

2� When the object is removed again, the output does not switch back before the

reset point (B) is exceeded�

The reset point (B) is greater than the set point (A)�

1

2

[SPx] =

switch point;

A = set point; B = reset point

When the output function [Hnc] was selected, set and reset point are reversed�

The output is switched off when the object approaches� When the object is removed, the output switches on�

Page 18

18

Switching status of the outputs

Output function Object distance (D) Output status

[Hno] D < [SPx] Closed

D > [SPx] Open

[Hnc] D < [SPx] Open

D > [SPx] Closed

Example of output function [Hno]

Sampling rate 5 Hz, distance to the object 1200 mm, grey value (18 % remission):

Hysteresis = ± 9,5 mm (repeatability → 10.3.3 table) x factor 1.5 = 14 mm

- Reset point 1200 mm + (14 mm) = 1214 mm

- Set point 1200 mm - (14 mm) = 1186 mm

10.2.5 Setting of the switch point for hysteresis function OUT1

► Select the output function [Hno] or [Hnc] at [OU1]�

► Confirm with [MODE/ENTER]�

► Select [SP1] and set the switch point�

► Confirm with [MODE/ENTER]�

10.2.6 Window function

It is possible to define a window for the object recognition for each of the two

outputs (OUT1 / OUT2)�

Switches off when the object is detected

[nSPx] =

switch point "near

"; [FSPx] =

switch point "far

"; FE = window

If the measured value is between the switch point "near" [nSPx] and the switch

point "far" [FSPx], the output is open (when [OUx] = [Fnc])�

Page 19

19

UK

Switches when the object is detected

[nSPx] =

switch point "near

"; [FSPx] =

switch point "far

"; FE = window

If the measured value is between the switch point "near" [nSPx] and the switch

point "far" [FSPx], the output is closed (when [OUx] = [Fno])�

Switching status of the outputs

Output function Object distance (D) Output status

[Fno]

D < [nSPx]

Open

D > [FSPx]

[nSPx] < D < [FSPx] Closed

[Fnc]

D < [nSPx]

Closed

D > [FSPx]

[nSPx] < D < [FSPx] Open

Both window limit values ([nSPx] and [FSPx]) work with a switching hysteresis

→ 10.2.4 Hysteresis function / example of the output function [Hno].

10.2.7 Setting of the switch points for window function OUT1

► Select the output function [Fno] or [Fnc] at [OU1]�

► Confirm with [MODE/ENTER]�

► Select [nSP1] and set the switch point "near"�

► Confirm with [MODE/ENTER]�

► Select [FSP1] and set the switch point "far"�

► Confirm with [MODE/ENTER]�

Page 20

20

10.2.8 Configuration of OUT1

► Select [OU2]�

► Set the switching functions or analogue signals:

• [Hno] = hysteresis function / normally open

• [Hnc] = hysteresis function / normally closed

• [Fno] = window function / normally open

• [Fnc] = window function / normally closed

• [I] = current output analogue 4���20 mA

• [U] = voltage output analogue 0���10 V

► Confirm with [MODE/ENTER]�

10.2.9 Setting of the switch point for hysteresis function OUT2

► Select [Hno] or [Hnc] at [OU2]�

► Confirm with [MODE/ENTER]�

► Select [SP2] and set the switch point�

► Confirm with [MODE/ENTER]�

→ 10.2.4 Hysteresis function

10.2.10 Setting of the switch points for window function OUT2

► Select [Fno] or [Fnc] at [OU2]�

► Confirm with [MODE/ENTER]�

► Select [nSP2] and set the switch point "near"�

► Confirm with [MODE/ENTER]�

► Select [FSP2] and set the switch point "far"�

► Confirm with [MODE/ENTER]�

→ 10.2.6 Window function

10.2.11 Scaling of the measuring range (analogue output)

► Select [I] or [U] at [OU2]�

► Confirm with [MODE/ENTER]�

► Select [ASP] and set "Analogue start point"�

With [ASP] you define at which measured value the output signal is

4 mA / 0 V�

► Confirm with [MODE/ENTER]�

► Select [AEP] and set the "Analogue end point"�

With [AEP] you define at which measured value the output signal is

20 mA / 10 V� It can also be selected so that it is before [ASP]� This

implements a falling edge�

► Confirm with [MODE/ENTER]�

Minimum distance between [ASP] and [AEP]:100 mm

When the minimum distance is not reached, the error message "SIZE" is

displayed�

Page 21

21

UK

Current output 4 ... 20 mA

Factory setting Measuring range scaled

MEW = final value of the measuring range

In the set measuring range the output signal is between 4 and 20 mA�

Faults are also displayed:

Too much light or object too near: 3�5 mA for a rising edge ([ASP] < [AEP]), 20�5 mA for a

falling edge ([ASP] > [AEP])�

Object too far or no object present:

20�5 mA for a rising edge; 3�5 mA for a falling edge�

Voltage output 0 ... 10 V

Factory setting Measuring range scaled

MEW = final value of the measuring range

In the set measuring range the output signal is between 0 and 10V�

Page 22

22

10.3 Teach mode

10.3.1 Setting of the sampling rate

The sampling rate indicates the time after which a new result of

measurement is provided and the outputs are updated�

The switching frequency is typ� approx� 1/3 of the sampling rate�

► Select [TEAC], then press [SET] and keep pressed until [WAIT] is

displayed�

> [rATE] and [rEPr] are displayed alternately�

► When [rATE] is displayed: Press [SET] until the preset measured

sampling rate value flashes�

► Enter a value incrementally by pressing [SET] once�

► Confirm with [MODE/ENTER]�

> [WAIT] is displayed while the repeatability [rEPr] is calculated�

> The sampling rate [rATE] and the repeatability [rEPr] are displayed

alternately�

10.3.2 Setting of the repeatability

► Select [TEAC], then press [SET] and keep pressed until [WAIT] is

displayed�

> [rATE] and [rEPr] are displayed alternately�

► When [rEPr] is displayed: Press [SET] until the preset repeatability

value flashes�

► Enter value incrementally by pressing [SET] once�

► Confirm with [MODE/ENTER]�

> [WAIT] is displayed while the sampling rate [rATE] is calculated�

> The sampling rate [rATE] and the repeatability [rEPr] are displayed

alternately�

10.3.3 Table repeatability and accuracy

Values for sampling rate 5 Hz

Distance

in [mm]

Repeatability Accuracy

white

90 % remission

grey

18 % remission

white

90 % remission

grey

18 % remission

200���1000 ± 6,5 mm ± 7,5 mm ± 32 mm ± 40 mm

1000���2000 ± 8 mm ± 9,5 mm ± 33 mm ± 40 mm

2000���3000 ± 17 mm ± 19 mm ± 42 mm ± 50 mm

3000���3500 ± 23 mm ± 25 mm ± 50 mm ± 55 mm

Page 23

23

UK

The values apply at:

• constant ambient conditions (23°C / 960 hPa)

• extraneous light of max�: 100 klx

• only after unit powered up for 10 minutes

10.4 Extended functions

10.4.1 Setting of the time delay for switching outputs

► Select [EF]�

► Press [SET] to change to the menu [EF]�

► Select parameters with [MODE/ENTER]:

[dSx] = switch-on delay; [drx] = switch-off delay

► Set the parameter value with [SET]:

Setting range [s]: 0 / 0�1 ��� 5 s in steps of 0�1s

(0 = delay time is not active)

► Confirm with [MODE/ENTER]�

10.4.2 Setting of the damping of the measured signal

► Select [EF]�

► Press [SET] to change to the menu [EF]�

► Select [dFo] (formely: [dAP])�

► Set the parameter value with [SET]:

Setting range [s]: 0���0�1���0�2���0�5���1���2���5�

► Confirm with [MODE/ENTER]�

10.4.3 Reset of all parameters to factory setting

► Select [EF]�

► Press [SET] to change to the menu [EF]�

► Select [rES], then press [SET] and keep it pressed until [----] is

displayed�

► Confirm with [MODE/ENTER]�

> The unit changes to the Run mode�

10.4.4 Display of the software version number

► Select [EF]�

► Press [SET] to change to the menu [EF]�

► Select [SW], then press [SET]�

> The software version number is displayed�

► Press [MODE/ENTER] to return to the menu [EF]�

Page 24

24

11 IO-Link

11.1 General information

This unit has an IO-Link communication interface which requires an IO-Linkcapable module (IO-Link master) for operation�

The IO-Link interface enables direct access to the sensor values and parameters

and provides the possibility to set the parameters of the unit during operation�

In addition communication is possible via a point-to-point connection with a USB

adapter cable�

You will find more detailed information about IO-Link at www�ifm�com/uk/io-link�

11.2 Device-specific information

You will find the IODDs necessary for the configuration of the IO-Link device and

detailed information about sensor values, diagnostic information and parameters

in the overview table at www�ifm�com/uk/io-link�

11.3 Parameter setting tools

You will find all necessary information about the required IO-Link hardware and

software (e�g� ifm LINERECORDER SENSOR ZGS210) at www�ifm�com/uk/io-link�

11.4 Extended functions

With IO-Link extended functions and measured data are available�

11.5 Teach function

The following teach functions are available:

• Teach on background

• Two-point teaching

The teach functions are described in detail in the IODD�

11.5.1 Object reflectivity

The object reflectivity is provided via the display and as process data value (PDV)�

The object reflectivity can, for example, be used to detect sensor soiling�

12 Set-up / operation

► After mounting, wiring and programming check whether the unit operates correctly�

> If the unit has been correctly set up, the distance to the object is indicated�

Page 25

25

UK

Lifetime of a laser diode: 50000 hours

12.1 Fault indication

Display

Possible

cause

Switching output

Current output /

voltage output

IO-Link process

value distance

3)

IO-Link process

value object

reflectivity

3)

[Hno] [Hnc] [Fno] [Fnc]

[ASP] <

[AEP]

[ASP] >

[AEP]

[++]

too much

light,

e�g� reflective

surface

ON OFF OFF ON

3,5 mA /

0 V

20,5 mA /

10 V

NoData OL

[- -]

too little light,

no object

OFF ON OFF ON

20,5 mA /

10 V

3,5 mA /

0 V

NoData

UL

[nEAr]

object to be

measured

outside the

measuring

range < 0�2 m

ON OFF OFF ON

3,5 mA /

0 V

20,5 mA /

10 V

UL NoData

[FAr]

object to be

measured

outside the

measuring

range > 3�5 m

OFF ON OFF ON

20,5 mA /

10 V

3,5 mA /

0 V

OL

NoData

[Errp]

plausibility

(e�g� object

too fast)

X

1)

X

1)

X

1)

X

1)

X

1)

X

1)

X

1)

X

1)

[LoFF]

laser switched

off

OFF ON OFF ON

20,5 mA /

10 V

3,5 mA /

0 V

NoData NoData

[SC1]

short circuit in switching output 1

2) 2)

n�a� n�a�

[SC2]

short circuit in switching output 2

2) 2)

X

1)

X

1)

[SC] short circuit in all switching outputs

n�a� n�a�

1)

unchanged

2)

[SC1] or [SC] only active, if output 2 is configured as switching output�

3)

See IODD of the device

Page 26

26

13 Maintenance, repair and disposal

Faulty sensors must only be repaired by the manufacturer�

► Keep the front lens of the sensor free from soiling�

► After use dispose of the unit in an environmentally friendly way in accordance

with the applicable national regulations�

14 Scale drawing

Dimensions in mm

1: 4-digit alphanumeric display / LED function display

2: programming buttons

Page 27

27

UK

15 Factory setting

Parameter Setting range Factory setting

Own setting

Uni

mm, m, inch mm

OU1

Hno, Hnc, Fno, Fnc Hno

SP1

200���3500 1000

nSP1

200���3500 800

FSP1

200���3500 1200

OU2

Hno, Hnc, Fno, Fnc, I, U

I

SP2

200���3500 2000

nSP2

200���3500 1800

FSP2

200���3500 2200

ASP

0���3500 0

AEP

0���3500 3500

rATE

1���50 5 Hz

dS1

0���0�1���5 0 s

dr1

0���0�1���5 0 s

dS2

0���0�1���5 0 s

dr2

0���0�1���5 0 s

dFo

0���0�1���0�2���0�5���1���2���5 0 s

diS

d1���3; rd1���3; OFF d3

Technical data and further information at www�ifm�com

Loading...

Loading...