Page 1

Device manual

Valve sensor

MVQ101

UK

80270936/00 04/2018

Page 2

1 Preliminary note

Technical data, approvals, accessories and further information at

www.ifm.com.

2 Safety instructions

• Read this document before setting up the product and keep it during the entire

service life.

• The product must be suitable for the corresponding applications and

environmental conditions without any restrictions.

• Only use the product for its intended purpose (→ Functions and features).

• If the operating instructions or the technical data are not adhered to, personal

injury and/or damage to property may occur.

• The manufacturer assumes no liability or warranty for any consequences

caused by tampering with the product or incorrect use by the operator.

• Installation, electrical connection, set-up, operation and maintenance of the

product must be carried out by qualified personnel authorised by the machine

operator.

• The plant operator is responsible for the safety of the plant in which the device

is installed.

• If the device is not used as intended by the manufacturer, the protection

supported by the device may be impaired.

• Protect units and cables against damage.

2.1 Symbols used

► Instruction

→ Cross-reference

Important note

2

Non-compliance may result in malfunction or interference.

Information

Supplementary note.

Page 3

3 Functions and features

With this unit angular movements and positions of the valve between 0°...179.9°

and -180°...0° can be determined. The unit generates output signals according to

the operating mode and the parameter setting.

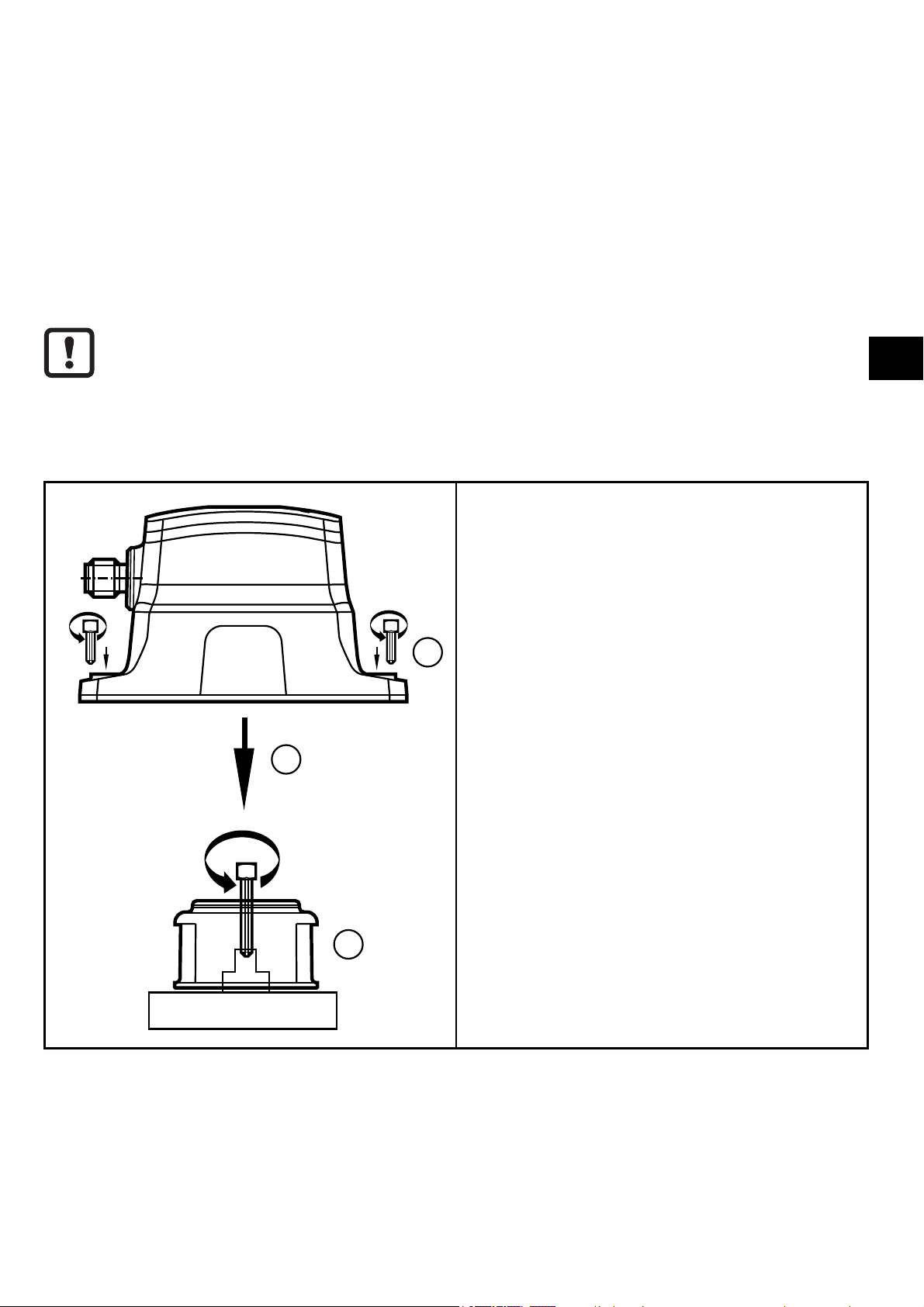

4 Installation

► Disconnect power before installation.

► Ensure that the machine stands still.

► Do not start the drive during installation.

► Keep potential interfering sources (magnets, heat sources) at a distance.

This product complies with the standard EN 61000-6-4. The unit may cause radio

interference in domestic areas. The user must take appropriate measures to avoid

this interference, if necessary.

1: Use the two notches at the bottom of

the target puck as a mounting aid for a

precise positioning on the shaft. Align

target puck. The yellow indicator can

be rotated to show the desired open

3

2

position.

Fix the target puck to the valve head

using the supplied screw, tightening

torque 1.2 Nm.

2: Put the unit over the target puck.

3: Fix the unit to the actuator housing

UK

using the supplied screws, tightening

torque 1.5 Nm. Use an optional

mounting plate, depending on the

mechanical interface.

1

3

Page 4

5 Electrical connection

► Disconnect the installation from power and connect the unit.

3

1

5

4

2

+

L

2: OUT 2

4: OUT 1 / IO-Link

5: OUT 3

5

2

1

5.1 Switching functions

OUT1 (pin 4) Communication IO-Link

Switching output valve position open in SIO mode

OUT 2 (pin 2) Switching output valve position closed

OUT 3 (pin 5) Programmable:

- Switching output valve position open

- Switching output valve position closed

- Fault output

4

3

L

6 Function diagram

HYS HYS

OFF

1: Tolerance range

2: Leak warning range

3: Angle of the valve

SP = set point

HYS = hysteresis

SP

OFFON

4

Page 5

7 Operating and display elements

2

LED 5

1

LED 5

LED 1

LED PWR

LED 3

LED 4

1: Window for optical position indication (OPEN)

2: Inductive teach button

LED 1 yellow on switching status OUT1 – valve position open

LED 2 PWR green on voltage applied to the unit

LED 3 not used

LED 4 white on switching status OUT2 - valve position closed

LED 5 (ring) yellow on - switching status OUT1

blue on - switching status OUT2

UK

(colours programmable, yellow and blue preset at the

factory)

red flashing - fault in the unit

• no pulse pick-up available

• teach error - switch points SSC1 and SSC2 overlap

• end position not reached after set time has elapsed

• unit faulty

The LED colours in the table are the default colours and can be customised.

8 IO-Link

This unit has an IO-Link communication interface which enables direct access to

process and diagnostic data. In addition it is possible to set the parameters of the

unit while it is in operation. Operation of the unit via an IO-Link interface requires

an IO-Link master.

With a PC, suitable IO-Link software and an IO-Link adapter cable communication

is possible when the system is not in operation.

5

Page 6

The IODDs necessary for the unit's configuration, detailed information about

process data structure, diagnostic information, parameter addresses and the

necessary information about required IO-Link hardware and software can be

found at www.ifm.com.

9 Parameter setting

The parameters of the unit can be set both via the inductive teach button and via

IO-Link. To be able to use all the functions of the unit, an IO-Link communication

is required.

9.1 Parameter setting with IO-Link

Using an IO-Link capable parameter setting tool, the following options are

available:

- Reading current process values.

- Reading, changing and saving current parameter settings and transmitting

them to other units of the same type.

► Connect the unit via the IO-Link interface to a PC or PLC with suitable

parameter setting software.

ifm offers an IO-Link interface for the connection of the sensor via USB

port.

9.2 Setting parameters via IO-Link

Parameters Description Setting range

TI Select Teach selection SSC1 / SSC2 / SSC3

default = SSC1

SSC Param SP1 Switch point 1 -180.0°...179.9°

Steps 0.1°

SSC Config Logic Switch point logic 0 High active (NO)

1 Low active (NC)

SSC Config Hyst Switch point hysteresis 0.1°...5°

SSC Tol Tolerance of the switching

channel 1

Pin 5 /gr assignment Functional assignment for pin

5 / grey

0.1°...15.0°

0 = open / 1 = close /

2 = seat / -32768 error

6

Page 7

Power cycles Number of switching opera-

tions since delivery

0...2147483647

Operating hours Operating hours counter since

delivery

Valve offset Installation offset of the valve -180.0°...179.9°

SSC1 and SSC2

Swap switch points

Leak warning range Setting of the leak warning

Swap switch point

range

0...2147483647

Steps 0.1°

0.0...15°

UK

9.3 Manual parameter setting

9.3.1 Switch points

The unit has three switch points (SSCs). Two of them can be set via the inductive

teach button, the third switch point can be configured via IO-Link. Tolerance and

hysteresis can be set separately for each switch point, with an additional seal

monitoring for SSC2.

9.3.2 Parameter setting via inductive teach button

The sensor is adjusted using a metal object, e.g. a screwdriver.

Teach switch point 1 (SSC1) - valve open

► Activate teach button until the LED ring flashes yellow. Remove metal tool.

> LED ring yellow on, switch point is set.

Teach switch point 2 (SSC2) - valve closed

► Change valve position manually.

► Activate teach button until the LED ring flashes blue. Remove metal tool.

> LED ring blue on, switch point is set.

Swap switch points SSC1 and SSC2

► Activate teach button until the LED ring flashes yellow / blue. Remove metal

tool.

> LED ring yellow or blue on, switch point has been swapped.

7

Page 8

Lock unit

► Activate teach button (approx. 20 s) until the LED ring briefly flashes once.

> Unit is locked, no parameter setting possible.

Unlock unit

► Activate teach button (approx. 20 s) until the LED ring briefly flashes once.

10 Settings

1

2

2

Settings tolerance

Set a tolerance range between 0.1° and 15°

around the taught/set switch point.

1: Teach point

2: Tolerance width

Setting hysteresis

1

2

3

2

The hysteresis is around the tolerance range,

3

can be set between 0.1° and 5°.

1: Teach point

2: Tolerance width

3: Hysteresis

8

Page 9

Setting leak warning range

1

2

3

2

3

In the closed position SSC2, the unit features

leak monitoring in the range from 0.0° to 15°.

Deposits or wear can be detected. This leak

warning range lies within the tolerance range

and is activated and defined by selecting a

value (>0) which is deduced from the tolerance

range limits.

1: Teach point

2: Leak warning range

3: Tolerance width

UK

10.1 Timeout

Timeout indicates the maximum duration for closing or opening before the sensor

signals a blockage.

Adjustable time: between 0.1...30 s (factory setting 30 s).

In parallel, the parameters for the maximum closing and opening duration must be

adjusted manually (timeout ≥ maximum closing / opening duration).

10.2 Colours

For each switching output (SSC) different display colours of the LED ring can be

set individually.

You can choose among the following colours:

blue, green, cyan, red, magenta, yellow and white.

The colour feedback can be deactivated.

9

Page 10

10.3 Parameter setting pin 5

Pin 5 of the sensor can have different functions:

1. Switching output valve position open

2. Switching output valve position closed

3. Switching output seat position

4. Fault output

- Defect of the unit

- Puck not used

- Limit value for the timeout exceeded

10.4 Opening / closing duration

The minimum/maximum closing/opening duration of the drive can be freely set

and monitored. The sensor provides a warning via IO-Link if the actual value is

above or below the limit value.

Adjustable time: between 0.1...30 s

(factory setting: minimum opening/closing duration: 0 s; maximum opening/closing

duration: 30 s).

10

Loading...

Loading...