Page 1

Operating instructions

Electronic level sensor

LK10xx

LK70xx

UK

80264293 / 00

06 / 2017

Page 2

2

Contents

1 Preliminary note ................................................................................................... 4

1.1 Symbols used ................................................................................................4

2 Safety instructions ...............................................................................................4

3 Functions and features ........................................................................................5

3.1 Applications ..................................................................................................5

3.2 Restriction of the application area ................................................................5

4 Getting started .....................................................................................................6

4.1 Example configuration 1 ................................................................................6

4.2 Example configuration 2 ................................................................................7

5 Function ............................................................................................................... 8

5.1 Measuring principle ......................................................................................8

5.2 Operating principle / features of the unit ........................................................8

5.2.1 Operating modes ..................................................................................9

5.2.2 Notes on the integrated overflow protection ......................................... 9

5.2.3 Display and switching functions ..........................................................10

5.2.4 Offset to indicate the real level in the tank .......................................... 11

5.2.5 Defined state in case of a fault ........................................................... 11

5.2.6 IO-Link function .................................................................................. 11

6 Installation..........................................................................................................12

6.1 Installation instructions for operation with overflow protection ...................13

6.2 Installation instructions for operation without overflow protection ..............14

6.2.1 Installation in the inactive zone ...........................................................14

6.2.2 Installation in the active zone A of the probe ......................................15

6.3 Further notes on installation ........................................................................16

6.3.1 Marking the installation height ...........................................................16

6.3.2 Mounting accessories: ........................................................................ 16

7 Electrical connection .......................................................................................... 17

8 Operating and display elements ........................................................................18

9 Menu .................................................................................................................. 19

9.1 Menu structure ............................................................................................. 19

10 Parameter setting ............................................................................................20

10.1 Parameter setting in general .....................................................................20

Page 3

3

UK

10.2 Basic settings ...........................................................................................21

10.2.1 Setting the unit of measurement [uni] ............................................... 21

10.2.2 Setting the offset [OFS] ....................................................................21

10.2.3 Setting the medium [MEdI] ...............................................................21

10.2.4 Setting the overflow protection [OP] ...............................................22

10.2.5 Adjusting the overflow protection [cOP] ............................................22

10.3 Setting of output signals ............................................................................24

10.3.1 Setting the output function [oux] for OUTx .......................................24

10.3.2 Set the switching limits [SPx] /[rPx] (hysteresis function) ................. 24

10.3.3 Set the switching limits [FHx] / [FLx] (window function) ....................24

10.3.4 Set the switching delays [dSx] for switching outputs ........................ 24

10.3.5 Set the switch-off delay [drx] ...........................................................25

10.3.6 Set output logic [P-n] .......................................................................25

10.3.7 Response of the outputs in case of a fault [FOUx] ........................... 25

10.3.8 Configuration of the display [diS] ...................................................... 25

10.3.9 Reset all parameters to factory settings [rES] ..................................25

11 Operation .........................................................................................................26

11.1 Operating indicators ................................................................................... 26

11.2 Read the set parameters ...........................................................................26

11.3 Error indications .........................................................................................27

11.4 Output response in different operating states ............................................27

12 Technical data ..................................................................................................28

12.1 Setting values [OFS] .................................................................................. 28

12.2 Setting values [OP] .................................................................................... 28

12.3 Calculation aids [OP] .................................................................................29

12.3.1 Definition “from the cover“ ................................................................29

12.3.2 Definition “from the bottom“ ..............................................................29

12.4 Setting ranges [SPx] / [FHx] and [rPx] / [FLx] ........................................... 30

13 Maintenance / cleaning / change of medium ..................................................30

13.1 Maintenance information for operation without overflow protection ..........30

14 Factory setting .................................................................................................31

15 Applications......................................................................................................32

15.1 Hydraulic tank ............................................................................................ 32

15.2 Pumping station ......................................................................................... 33

15.3 Storage tank ..............................................................................................34

Page 4

4

1 Preliminary note

1.1 Symbols used

► Instructions

> Reaction, result

[…] Designation of keys, buttons or indications

→ Cross-reference

Important note

Non-compliance may result in malfunction or interference.

Information

Supplementary note.

2 Safety instructions

• Please read this document prior to set-up of the unit. Ensure that the product is

suitable for your application without any restrictions.

• If the operating instructions or the technical data are not adhered to, personal

injury and/or damage to property can occur. Installation, electrical connection,

set-up, operation and maintenance of the unit must be carried out by qualified

personnel authorised by the machine operator.

• In order to guarantee the correct operation of the unit, it is necessary to use the

unit in media for which it is sufficiently resistant (→ Technical data).

• The responsibility as to the suitability of the unit for the application lies with the

operator The manufacturer assumes no liability for consequences of misuse by

the operator.

• Improper installation and use of the units result in a loss of the warranty claims.

• The unit complies with the standard EN 61000-6-4. The unit may cause radio

interference in domestic areas. If interference occurs, the user must take

appropriate remedial actions.

Page 5

5

UK

3 Functions and features

3.1 Applications

The unit was specially designed to meet the requirements of machine tool

building. It is specially suitable for monitoring coolant emulsions (also dirty) as well

as cutting and hydraulic oils.

3.2 Restriction of the application area

• The unit is not suitable for:

- acids and alkalis

- hygienic and electroplating applications

- highly conductive and adhesive media (e.g. glue, shampoo)

- granulates, bulk material

- use in grinders (increased risk of formation of deposits).

• It is possible that foam of good conductivity is detected as level:

► Test proper functioning in an application test.

• For water and hydrous media with temperatures > 35 °C, install the unit in a

climatic tube (→ accessories).

• For automatic medium detection:

For media which are very inhomogeneous, separate from each other and thus

forming separation layers (e.g. oil layer on water), the following applies:

► Test proper functioning in an application test.

Page 6

6

4 Getting started

For fast set-up, the example configurations described in the following can be used

for most applications. The indicated minimum distances apply exclusively for each

separately described case.

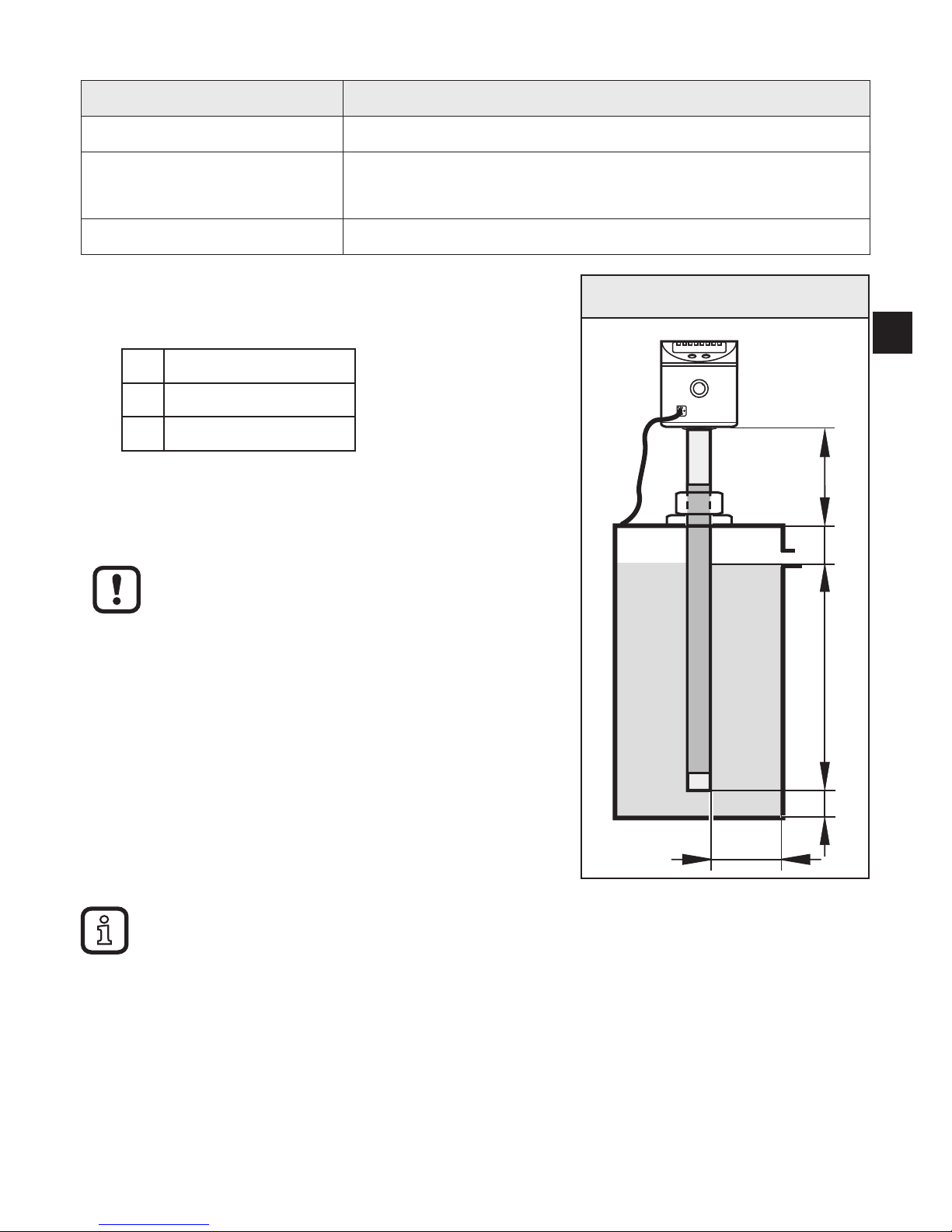

4.1 Example configuration 1

Applied sensor: LK1022 (probe length L = 264 mm)

Medium to be detected: Mineral oil

Operating mode: Manual media selection with overflow protection

(factory setting LK10xx) → 5.2.1

Type of installation: Metal tank, installation to Fig.4-1

► Install sensor.

► Observe the distances (x), (u) and (c):

x: min. 4.0 cm

u: min. 1.0 cm

c: max. 14.0 cm

► Ground sensor and tank via an electrical

connection (→ 7).

► Observe the parameter setting sequence:

- [MEdI] = [OIL.2] (→ 10.2.3)

- [OFS] = (u); e.g. (u) = 2.0 cm (→ 5.2.4)

- [OP]: Set the overflow protection OP at a

distance (y) greater than 4.5 cm below the

mounting element.

For distances (y) smaller than 4.5 cm there

may be malfunctioning and error messages

during the adjustment process [cOP]

Fig. 4-1

OP

c

Step increment and setting range: → 12.2

Calculation aids for [OP]: → 12.3

► Adjustment of the overflow protection OP to [cOP] (→ 10.2.5)

> The unit is ready for operation.

► Make further settings if necessary.

► Check whether the unit operates correctly.

Page 7

7

UK

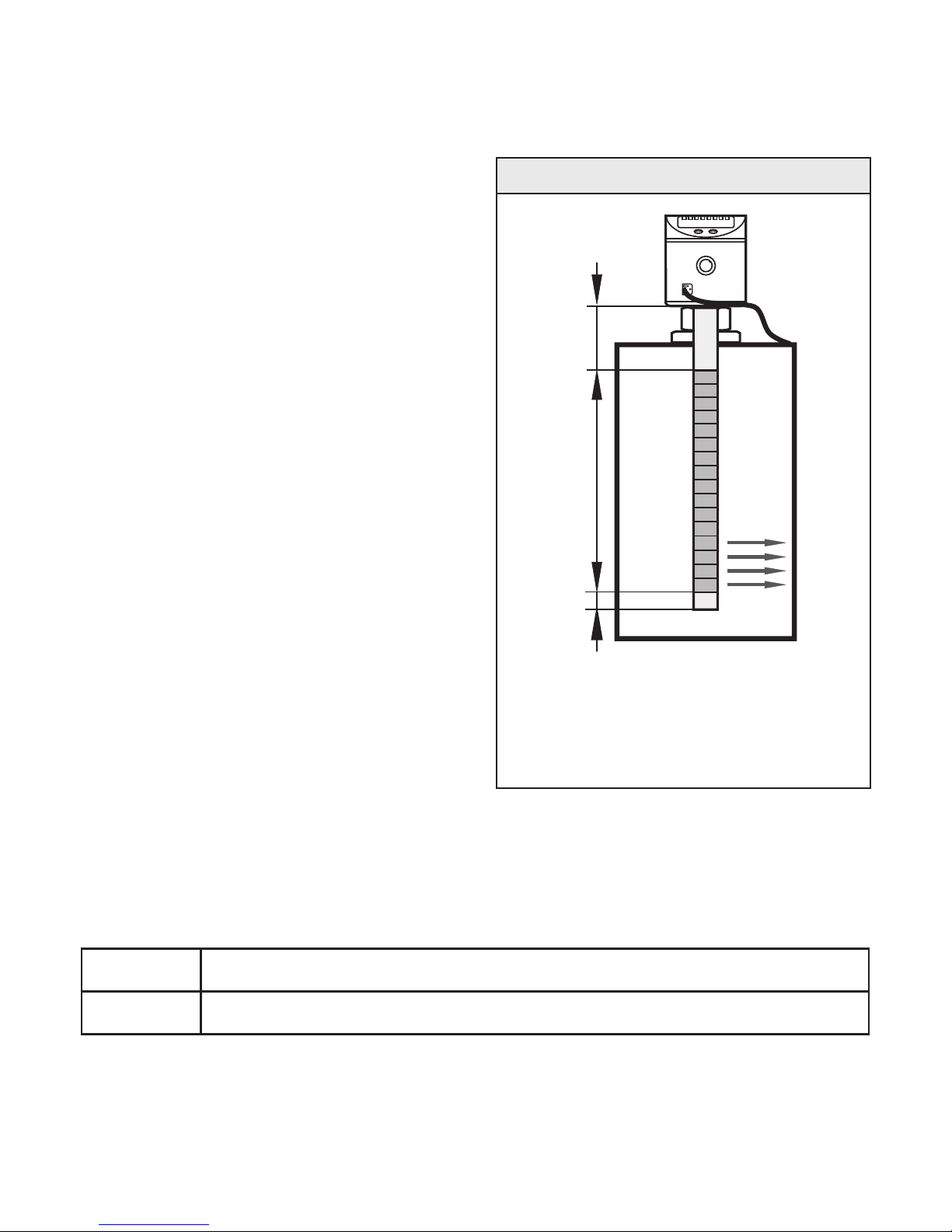

4.2 Example configuration 2

Applied sensor: LK7023 (probe length L = 472 mm)

Medium to be detected: Coolant emulsion

Operating mode: Automatic medium detection

(factory setting LK70xx) → 5.2.1.

Type of installation: Metal tank, installation to Fig.4-2

► Install sensor.

► Observe the distances (x), (u) and (c):

x: min. 4.0 cm

u: min. 1.0 cm

c: max. 23.0 m

► Ground sensor and tank via an electrical

connection (→ 7).

► Observe the maximum permissible level (b).

A distance (a2) greater than 5.0 cm must

be observed between maximum level (b)

and mounting element.

► Observe the parameter setting sequence:

- [MEdI] = [Auto] (→ 10.2.3)

- [OFS] = (u), e.g. (u) = 1.0 m (→ 5.2.4)

- [SP1] = Set the switch point at a distance

(a2) greater than 5.0 cm below the

mounting element.

Fig. 4-2

c

bu a2

x

Adjustable in step increments of 0.5 cm.

Switch point [SP1] is used as overflow protection (pump off, close inlet, ...)

► Unit must be reinitialised:

► Switch the operating voltage off and on again.

> The unit is ready for operation.

► Make further settings if necessary.

► Check whether the unit operates correctly.

Page 8

8

5 Function

5.1 Measuring principle

The sensor determines the level according to the capacitive measuring principle:

• An electrical field (E) is generated

and influenced by the medium to be

detected. This change to the field

causes a measurement signal that

is electronically evaluated.

• The dielectric constant of a medium

is important for its detection. Media

with a high dielectric constant

(e.g. water) generate a strong

measurement signal, media with a

low dielectric constant (e.g. oils) a

correspondingly lower signal.

• The active measurement zone of

the sensor probe is composed of

16 capacitive measuring segments.

They generate measurement

signals depending on the degree of

coverage.

Fig. 5-1

A II

E

I: Inactive zone

A: Active zone (16 active segments)

E: Electrical field

Dimensions → Technical data sheet

5.2 Operating principle / features of the unit

The unit can be installed in tanks of different sizes.

2 outputs are available. They can be set separately.

OUT1 Switching signal for level limit value / IO-Link

OUT2 Switching signal for level limit value

To adjust the unit to the application, choose the required operating modes.

Page 9

9

UK

5.2.1 Operating modes

1. Manual media selection with overflow protection (factory setting LK10xx)

Recommended! Highest operational reliability!

The medium to be detected is set manually [MEdI]. In addition, an integrated,

independently functioning overflow protection is available.

2. Manual media selection without overflow protection

Medium operational reliability!

The medium to be detected is set manually as described under 1. However

,

the overflow protection is deactivated. For this reason, no adjustment is

possible.

3. Automatic media detection (factory setting LK70xx)

Lowest operational reliability!

Each time the operating voltage is switched on, the unit adjusts itself to the

medium and the installation environment.

For automatic media detection, no overflow protection is available!

Automatic media detection can only function properly under certain

conditions (e.g. compliance with special mounting specifications,

restrictions for operation and maintenance).

5.2.2 Notes on the integrated overflow protection

With the parameter [OP] (OP = overfill protection), one of the upper measuring

segments is defined as integrated overflow protection.

• If the overflow protection OP is activated, an adjustment to the installation

situation has to be made [cOP].

• The overflow protection OP can be deactivated ([OP] = [OFF]).

Deactivating the overflow protection can impair the operational reliability.

For optimum operation and maximum operational reliability, we therefore

recommend to not deactivate the overflow protection!

• The overflow protection is the maximum limit of the measuring range. The

switch points [SPx] / [FHx] are always below [OP]!

• The overflow protection is not assigned to a separate output! It offers additional

protection and only leads to switching if one of the outputs has not commuted

Page 10

10

even though the corresponding switch point has been exceeded (e.g. due to

application-related malfunctions).

• Typically the overflow protection OP reacts when the selected measuring

segment has been reached (a few mm before the set OP value).

• The overflow protection OP replies immediately and without delay. The set

delay times (e.g. of a switch point directly below) have no effect on the overflow

protection OP.

• The response of the overflow protection is indicated on the display ("Full" and

indication of the current level change every second).

5.2.3 Display and switching functions

The unit displays the current level, selectable in cm or inch. The display unit is

defined by parameter setting. The set unit of measurement and the switching

status of the outputs are indicated by LEDs. The unit signals via two switching

outputs (OUT1, OUT2) that a set limit has been exceeded or that the level is

below the limit. The parameters of the switching outputs can be set.

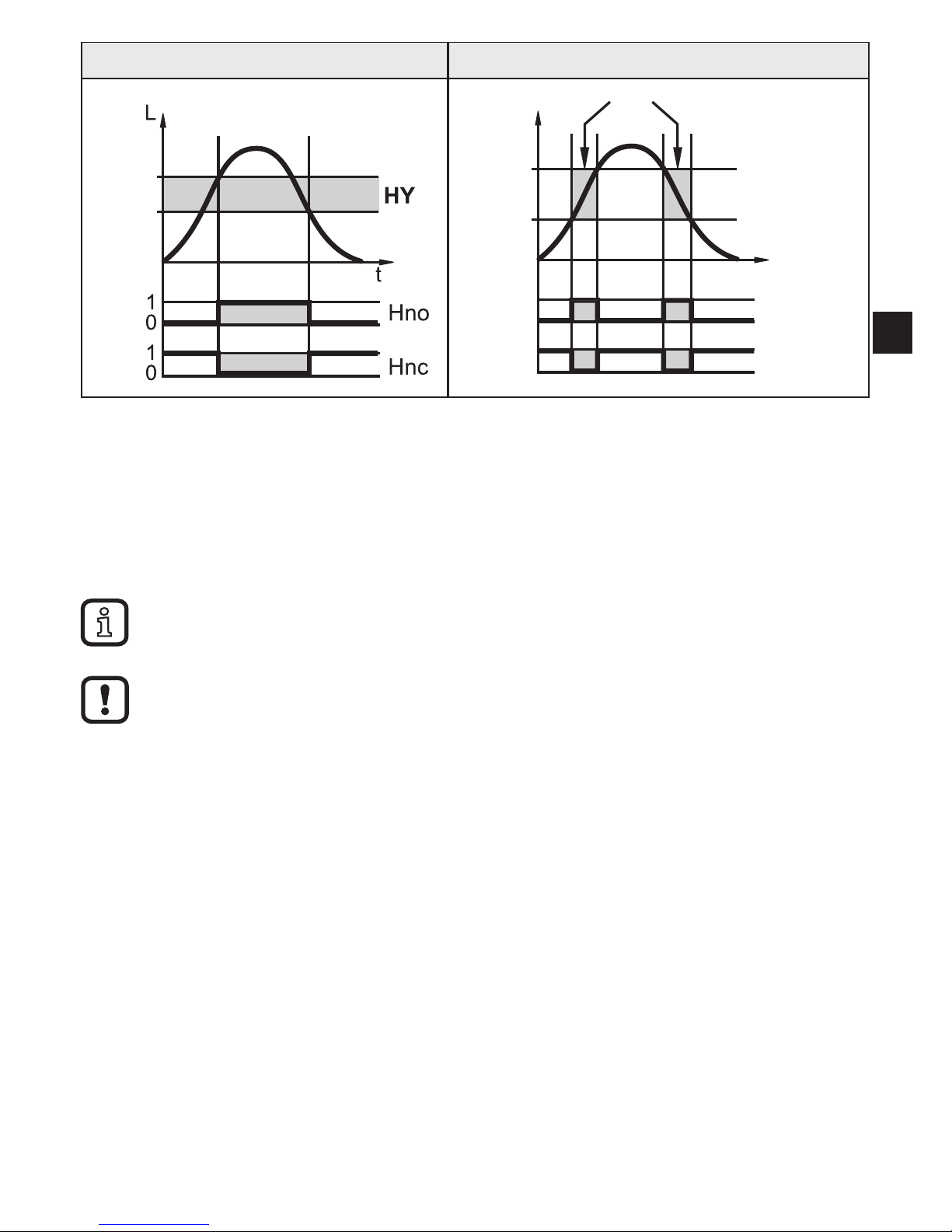

• Hysteresis function / normally open (Fig. 5-2): [oux] = [Hno].

• Hysteresis function / normally closed (Fig. 5-2): [oux] = [Hnc].

First the set point [SPx] is set, then the reset point [rPx] with the requested

difference.

The hysteresis for the overfill protection OP is fixed.

• Window function / normally open (Fig. 5-3): [oux] = [Fno].

• Window function / normally closed (Fig. 5-3): [oux] = [Fnc].

The width of the window can be set by means of the difference between

[FHx] and [FLx]. [FHx] = upper value, [FLx] = lower value.

Page 11

11

UK

Fig. 5-2 Fig. 5-3

SP

rP

t

L

FH

FL

1

0

1

0

FE

Fno

Fnc

L : level HY: hysteresis FE:window

5.2.4 Offset to indicate the real level in the tank

The distance between tank bottom and lower edge of the probe can be entered as

offset value [OFS]. So display and switch points refer to the actual level (reference

point = bottom of the tank).

For [OFS] = [0]: the reference point is the lower edge of the probe.

The set offset only refers to the display on the unit. It has no effect on

the process value transmitted via IO-Link. The OFS parameter, however,

is correctly transmitted via IO-Link and can therefore be taken into

consideration. More information → 5.2.6 .

5.2.5 Defined state in case of a fault

In case of a fault, a safe state can be defined for each output. If a fault is detected

or if the signal quality is below a minimum value, the outputs pass into a defined

state. For this case the response of the outputs can be set via the parameters

[FOU1], [FOU2] (→ 10.3.7).

5.2.6 IO-Link function

This unit has an IO-Link communication interface which enables direct access to

process and diagnostic data.

In addition it is possible to set the parameters of the unit during operation.

Operation of the unit via IO-Link interface requires an IO-Link capable module

(IO-Link master).

Page 12

12

With a PC, suitable IO-Link software and an IO-Link adapter cable communication

is possible when the system is not in operation.

For the IODDs necessary for the configuration of the unit, detailed information

about process data structure, diagnostic information, parameter addresses and

the necessary information about the required IO-Link hardware and software visit

www.ifm.com.

6 Installation

Fig. 6-1

OP

c

L:

M:

c:

Probe length

Zone for mounting elements

Maximum extension length

u ... y:

OP:

B:

Minimum distances

Overflow protection

Metal object inside the tank

Table 6-1

LKx022 LKx023 LKx024

[cm] [inch] [cm] [inch] [cm] [inch]

L (rod length) 26.4 10.4 47.2 18.6 72.8 28.7

M (mounting zone)

14.0 5.5 23.0 9.1 36.0 14.2

c (max. extension length)*

* Applies to installation as shown (wall thickness of the tank lid not taken into account;

mounting element does not protrude into the tank).

Otherwise note mounting zone M.

Page 13

13

UK

6.1 Installation instructions for operation with overflow

protection

[MEdI] = [CLW..] or [OIL..]

[OP] = [value ...] (Overflow protection OP activated)

It is permitted to fix the mounting elements within the mounting zone (M)

(Fig. 6-1).

► Observe the maximum permitted extension length (c) according to Table 6-1.

► Observe the minimum distances according to Fig. 6-1 and Table 6-2.

► Observe the notes on the integrated overflow protection!

The overflow protection (OP) must:

1. be below the mounting element

2. be adjusted at a minimum distance (y) to it, measured between the

lower edge of the mounting element and the OP value

.

Table 6-2

MEdI = CLW.1 MEdI = CLW.2, OIL.1 MEdI = OIL.2

[cm] [inch] [cm] [inch] [cm] [inch]

x 2.0 0.8 3.0 1.2 4.0 1.6

u 1.0 0.4 1.0 0.4 1.0 0.4

y (LKx022) 2.5 1.0 3.5 1.4 4.5 1.8

y (LKx023) 4.5 1.8 5.5 2.2 6.5 2.6

y (LKx024) 6.0 2.4 7.0 2.8 8.0 3.2

v 4.5 1.8 4.5 1.8 4.5 1.8

w 4.0 1.6 5.0 2.0 6.0 2.4

Calculation aids for [OP]: (→ 12.3).

Page 14

14

6.2 Installation instructions for operation without overflow

protection

[MEdI] = [Auto] or [OP] = [OFF] (Overflow protection OP deactivated!)

6.2.1 Installation in the inactive zone

Between the maximum level (b1) and the inactive zone (I1), minimum

distance (a1) must be adhered to (see Fig. 6-2 and Table 6-3)!

► Fix the unit using mounting elements

in the inactive zone (I1). The extension

length (c) may not exceed (I1) (see

Table 6-3).

► Make sure that the maximum level (b1)

is not exceeded after installation (see

Table 6-3).

► Observe further minimum distances

according to Table 6-4.

Fig. 6-2

A I1

c

I2

b1 a1

x

u

I1 / I2: Inactive zones

A: Active zone

a1: Minimum distance between the

inactive zone (I1) and the maximum

level (b)

b1: Max. level from the lower edge of the

sensor (without offset)

c: Max. permitted extension length

(Observe footnote Table 6-1)

Table 6-3

LKx022 LKx023 LKx024

[cm] [inch] [cm] [inch] [cm] [inch]

I1 5.3 2.1 6.0 2.4 10.4 4.1

A 19.5 7.7 39.0 15.4 58.5 23.0

a1 1.0 0.4 1.5 0.6 2.5 1

b1 20.0 7.9 39.5 15.6 59.5 23.4

Page 15

15

UK

6.2.2 Installation in the active zone A of the probe

A minimum distance (a2) between maximum level (b2) and mounting

element has to be observed (see Fig. 6-3 and Table 6-4).

► Fix mounting elements in the mounting

zone (M). Adhere to maximum

permitted extension length (c) (see

Table 6-1 ).

► Ensure that the maximum level (b2)

is not exceeded after completed

installation:

► (b) = (L) - (c) - (a2) (without offset)

► Observe further minimum distances

according to Table 6-4.

Fig. 6-3

cb2

L

u a2

x

c: Max. permitted extension length

a2: Minimum distance between the

mounting element and the maximum

level (b).

b2: Max. level from the lower edge of

the sensor

Table 6-4

MEdI = CLW.1 MEdI = CLW.2, OIL.1 MEdI = OIL.2 / Auto

[cm] [inch] [cm] [inch] [cm] [inch]

x 2.0 0.8 3.0 1.2 4.0 1.6

u 1.0 0.4 1.0 0.4 1.0 0.4

a2 (LKx022) 2.0 0.8 2.5 1.0 3.0 1.2

a2 (LKx023) 4.0 1.6 4.5 1.8 5.0 2.0

a2 (LKx024) 6.0 2.4 7.0 2.8 8.0 3.2

v *

)

4.5 1.8 4.5 1.8 4.5 1.8

w *

)

4.0 1.6 5.0 2.0 6.0 2.4

*) → Fig. 6-1.

Page 16

16

In case of automatic medium detection [MEdl] = [Auto] or deactivated

overflow protection [OP] = [OFF], the sensor reinitialises itself each time it

is switched on and makes adjustments to the medium and the installation

environment. The active zone / measuring range may not be completely

covered by the medium! The indicated minimum distances ensure this.

Too short distances may lead to maladjustments and malfunctions!

6.3 Further notes on installation

• For mounting in plastic pipes/plastic tanks, the inside (pipe) diameter must at

least be 12.0 cm (4.8 inch). Install sensor in the centre.

• For mounting in metal pipes, the inside pipe diameter (d) must be at least:

Table 6-5

MEdI = CLW.1 MEdI = CLW.2, OIL.1 MEdI = OIL.2 / Auto

[cm] [inch] [cm] [inch] [cm] [inch]

d 4.0 1.6 6.0 2.4 10.0 4.0

Marking the installation height

► Fix the set installation height with the supplied

stainless steel tube clip.

If the sensor is removed from the fixture for

maintenance reasons, the clip serves as a

limit stop when remounting the sensor. Thus

an inadvertent maladjustment of the sensor is

excluded. This is in particular necessary to ensure

correct functioning of the overflow protection.

► Fit the stainless steel tube clip using pliers.

► Ensure a safe fit.

► To remove the clip it has to be destroyed.

6.3.1 Mounting accessories:

Available accessories: www.ifm.com

Page 17

17

UK

7 Electrical connection

The unit must be connected by a qualified electrician.

The national and international regulations for the installation of electrical

equipment must be adhered to.

Voltage supply according to EN 50178, SELV, PELV.

► Disconnect power.

► Connect the unit as follows:

Core colours

43

2 1

BN

WH

BK

BU

4

1

3

2

OUT2

L

+

L

OUT1

BK black

BN brown

BU blue

WH white

OUT1: Switching output / IO-Link

OUT2: Switching output

Colours to DIN EN 60947-5-2

Example circuits

2 x positive switching 2 x negative switching

L

L

+

3

4

2

1

BU

BK

WH

BN

2: OUT2

4: OUT1

L

L

+

3

4

2

1

BU

BK

WH

BN

2: OUT2

4: OUT1

For safe function, the sensor housing must be

electrically connected to the counter-electrode

(grounding).

► For this, use the housing connection (see

drawing) and a short piece of cable with a core

cross-section of at least 1.5 mm2.

When using metal tanks, the tank wall serves as

the machine earth.

For plastic tanks, a counter-electrode must be

provided, e.g. a metal plate inside the tank in

parallel with the probe. Adhere to minimum

distances to the probe.

Page 18

18

8 Operating and display elements

10

Mode/Enter Set

1 2 7

8

3 4 5 6

11

9

1 to 8: Indicator LEDs

LED 1 Indication in cm.

LED 2 Indication in inch.

LED 3 - 6 Not used.

LED 7 Switching status OUT2 (lights when output 2 is switched).

LED 8 Switching status OUT1 (lights when output 1 is switched).

9: [Mode / Enter] button

- Selection of the parameters and acknowledgement of the parameter values

10: [Set] button

- Setting of the parameter values (scrolling by holding pressed; incremental by pressing

briefly).

12: Alphanumeric display, 4 digits

- Display of the current level.

- Indication of the parameters and parameter values.

- Operating and fault indication.

Page 19

19

UK

9 Menu

9.1 Menu structure

M

M

SP1 FH1

S

M

M

M

M

M

M

M

M

M

M

M

M

M

S

10.0 10.0

8.0

rP1 FL1

19.5

SP2

rP2

MEdl CLW.1

OP

20.0

20.4

cOP

EF

donE

S

S

S

S

S

S

M

M

rES

S

M

M

M

M

M

M

M

M

S

- - - -

ou1

Hno

0.0

ou2

dS1

dr1 0.0

S

S

S

M

Hnc

M

M

dS2

0.0

S

M

M

M

M

M

uni

P-n

M

M

dr2

0.0

S

S

S

S

M

M

M

OFS

S

M

M

M

S

0

FOU1

OFF

M

S

FOU2

OFF

diS

On

cm

PnP

M

S

M

S

M

9.5 9.5

FH2 20.0

FL2

S

M

S

M

19.5

cOP

Menu items highlighted in grey,

e.g. [

cOP

], are only active when assigned parameters have been selected .

Page 20

20

10 Parameter setting

10.1 Parameter setting in general

1

Mode/Enter Set

► Press [Mode/Enter] several times

until the required parameter is

displayed.

To select parameters in the extended

menu (menu level 2):

► Select [EF] and briefly press [Set].

2

Mode/Enter Set

► Press and hold [Set].

> The current parameter value flashes

for 5 s.

> Value is increased* (step by step

by pressing the button once or

continuously by keeping the button

pressed).

3

Mode/Enter Set

► Briefly press [Mode/Enter]

(= confirmation).

> The parameter is displayed again; the

new parameter value is effective.

4

Change more parameters:

► Start again with step 1.

Finishing the parameter setting:

► Wait for 30 s or press and hold

[Mode/Enter].

> The current measured value is

displayed.

► Release [Mode/Enter],

> the parameter setting is completed.

*) Decrease the value: let the display move to the maximum setting value.

Then the cycle starts again at the minimum setting value.

Timeout: If no button is pressed for 30 s during programming, the unit returns to the

operating mode with unchanged values (exception: cOP).

Locking / unlocking: The unit can be locked electronically to prevent unauthorised setting

(factory setting: not locked).

► Make sure that the unit is in the normal operating mode.

To lock the unit:

► press both buttons simultaneously for 10 s.

> [Loc] is displayed.

To unlock the unit:

► press both buttons simultaneously for 10 s.

> [uLoc] is displayed.

Page 21

21

UK

The unit can be programmed before or after installation. Exception: to

adjust the overflow protection [cOP], the unit must be installed in the tank.

10.2 Basic settings

Setting ranges of all parameters: → 12

Factory settings of all parameters: → 14

10.2.1 Setting the unit of measurement [uni]

► Enter [uni] before entering the values for SPx, rPx, OP or OFS.

This avoids unintentional maladjustments.

► Select [uni]

► Set the unit of measurement: [cm], [inch]

uni

10.2.2 Setting the offset [OFS]

The distance between tank bottom and lower edge of the measuring probe can be

entered as offset value (→ 5.2.4).

► Set [OFS] before entering the values for SPx, rPx or OP.

This avoids unintentional maladjustments.

► Select [OFS].

► Set the value for the offset. Note the set unit of measurement [uni].

OFS

10.2.3 Setting the medium [MEdI]

► Select [MEdI] and set the corresponding sensitivity:

MEdI

[CLW.1] = water, hydrous media, coolant emulsions.

[CLW.2] = water-based media for temperatures > 35 °C (installation in

climatic tube).

[OIL.1] = oils with an increased DC value (e.g. some synthetic oils).

[OIL.2] = oils with a low DC value (e.g. mineral oils).

[Auto] = automatic medium detection.

► In case of doubt, select [OIL.2] for oils.

► Proper functioning is to be ensured by carrying out an application test!

Page 22

22

The settings [CLW.1] and [CLW.2] suppress deposits (e.g. metal swarf).

The settings [OIL.1] and [OIL.2] suppress a bottom layer of higher dielectric

water or swarf which is a few cm high. If no oil layer is present (or if it is

very thin), the bottom layer is detected.

With the setting [MEdI] = [Auto], no overflow protection is available. In that case,

the menu points [OP] and [cOP] are not available.

10.2.4 Setting the overflow protection [OP]

► Comply with minimum distances and installation instructions.

► Select [OP].

► Define the position of the overflow protection.

The option [OP] = [OFF] deactivates the overflow protection.

OP

► Set [OP] before [SPx] or [FHx].

> [SPx] / [FHx] decreases if [OP] is reduced to a value ≤ [SPx] / [FHx] after

setting [SPx] / [FHx].

> If [OP] is increased, [SPx] / [FHx] also increases if [OP] and [SPx] /

[FHx] are close together (1 x step increment).

When the overflow protection is deactivated [OP] = [OFF] or

[MEdl] = [Auto], the safe function of the sensor must be verified with

particular care. For this, switch-on and switch-off processes and special

operating states such as very full tanks, possible maintenance and cleaning

operations are to be considered in the verification.

For setting [OP] = [OFF] the menu item [cOP] is not available.

10.2.5 Adjusting the overflow protection [cOP]

Only adjust the overflow protection OP when the unit is installed.

If possible, carry out the adjustment when the tank is empty!

However, the tank may be partly filled.

► Make sure that the overflow protection OP is not covered by the

medium! Observe the minimum distance between the overflow

protection OP and the level (→ Table 10-1).

Page 23

23

UK

► Select [cOP]

► Press [SET] and keep it pressed.

> [cOP] flashes for some seconds; then the continuous display indicates

that the adjustment is being made.

> If the adjustment is successful, [donE] is displayed.

► Confirm with [Mode/Enter].

> If the adjustment is not successful, [FAIL] is displayed.

► Lower the level if necessary or correct the position of the overflow

protection [OP] and repeat the adjustment operation.

cOP

Minimum distance between the overflow protection OP and the level during

adjustment:

Table 10-1

[cm] [inch]

LKx022 2.0 0.8

LKx023 3.5 1.4

LKx024 5.0 2.0

The position of the overflow protection OP can be determined by calling up

the parameter [OP]. Note the offset if necessary.

The current level is to be determined manually since the unit is not yet

ready for operation before the adjustment.

With the setting [MEdI] = [Auto] or [OP] = [OFF], the parameter [cOP] is not

available.

When the overflow protection is activated ([OP] = [value...]), an adjustment

[cOP] must be carried out each time:

• [MEdI] or [OP] has been changed. In this case appears in the

display.

• the installation position (height, orientation) has been changed.

• the connection between the sensor and the tank ground (e.g. length of

the jumper cable) has been changed.

With deactivated overflow protection [OP] = [OFF] or [MEdI] = [Auto]:

To assign the basic settings and to adapt to the medium and installation

environment the unit has to be reinitialised when installed.

► Switch the operating voltage off and on again.

Page 24

24

10.3 Setting of output signals

10.3.1 Setting the output function [oux] for OUTx

► Select [oux] and adjust the switching function:

ou1

ou2

[Hno] = hysteresis function / normally open

[Hnc] = hysteresis function / normally closed

[Fno] = window function / normally open

[Fnc] = window function / normally closed

If the switching output is used as an overflow protection, the setting

[oux] = [Hnc] (NC function) is recommended. The principle of normally

closed operation ensures that wire break or cable break is also detected.

10.3.2 Set the switching limits [SPx] /[rPx] (hysteresis function)

► Make sure that the function [Hno] or [Hnc] is set for [oux].

► Set [SPx] first, then [rPx].

► Select [SPx] and set the value at which the output is set.

SP1

SP2

► Select [rPx] and set the value at which the output resets.

rP1

rP2

[rPx] is always smaller than [SPx]. The unit only accepts values which are lower than the

value for [SPx]. If [SPx] is shifted, [rPx] also shifts provided that the lower end of the setting

range is not reached.

10.3.3 Set the switching limits [FHx] / [FLx] (window function)

► Make sure that for [oux] the function [Fno] or [Fnc] is set.

► Set [FHx] first, then [FLx].

► Select [FHx] and set the upper limit of the acceptable range.

FH1

FH2

► Select [FLx] and set the lower limit of the acceptable range.

FL1

FL2

[FLx] is always lower than [FHx]. The unit only accepts values which are lower than the

value for [FHx]. If [FHx] is shifted, [FLx] also shifts provided that the lower end of the setting

range is not reached.

10.3.4 Set the switching delays [dSx] for switching outputs

► Select [dSx] and set the value between 0.0 and 60 s.

The switching delay takes place according to VDMA.

dS1

dS2

Page 25

25

UK

10.3.5 Set the switch-off delay [drx]

► Select [drx] and set the value between 0.0 and 60 s.

The switching delay takes place according to VDMA.

dr1

dr2

10.3.6 Set output logic [P-n]

► Select [P-n] and set [PnP] or [nPn].

P-n

10.3.7 Response of the outputs in case of a fault [FOUx]

► Select [FOUx] and set the value:

FOU1

FOU2

[On] = the output switches ON in case of a fault

[OFF] = the output switches OFF in case of a fault.

A hardware fault or too low a signal quality is considered to be a fault.

Overflow is not considered to be a fault.

10.3.8 Configuration of the display [diS]

► Select [diS] and set the value:

diS

[On] = The display is switched on in the operating mode.

Update of the measured values every 500 ms

[OFF] = The display is switched off in the operating mode. When one of

the buttons is pressed, the current measured value is displayed

for 30 s. The indicator LEDs remain active even if the display is

deactivated.

10.3.9 Reset all parameters to factory settings [rES]

► Select [rES]

► Press and hold [Set] until [----] is displayed.

► Briefly press [Mode/Enter].

> The unit reboots and the factory settings are restored.

rES

Page 26

26

11 Operation

After switch-on of the operating voltage, the unit is in the operating mode

(= normal operating mode). It carries out its measurement and evaluation

functions and generates output signals according to the set parameters.

► Check whether the unit operates correctly.

11.1 Operating indicators

[----] (continuous) Initialisation phase after power on.

[Numerical value] + LED 1 Current level in cm.

[Numerical value] + LED 2 Current level in inch.

LED 7 / LED 8 Switching status OUT2 / OUT1 (LED x is lit if output x is

switched).

[----] Level below the active zone.

[FULL] + [numerical value]

alternately

The overflow protection OP is reached (overflow warning) or

the level is above the active zone.

It is necessary to adjust [cOP] of the overflow protection OP.

[Loc] Unit locked via operating keys; parameter setting impossible.

For unlocking press the two setting buttons for 10 s.

[uLoc] Unit is unlocked / parameter setting is possible again.

[C.Loc] The unit is temporarily locked. Parameter setting via IO-Link is

active (temporary locking).

[S.Loc] Unit is permanently locked via software. This locking can only

be removed with a parameter setting software.

11.2 Read the set parameters

► Briefly press [Mode/Enter] (if required, repeat several times).

> Menu items are passed through until the requested parameter has been

reached.

► Briefly press [Set].

> Respective parameter value is displayed for 30 s.

Page 27

27

UK

11.3 Error indications

Possible cause Recommended measures

[Err] Fault in the electronics. ► Replace the unit.

[SEnS]

• Interfering sources

• Faulty wiring

• Problems with the supply

voltage

► Check electrical connection.

► Check the connection between the

sensor and the tank ground.

[FAIL]

Error during adjustment of the

overflow protection OP:

• Overflow protection covered by

the medium during adjustment.

• Overflow protection soiled.

• Minimum distances too short.

• Mounting element detected

below the overflow protection.

• Measured value not constant.

► Lower the level, if necessary.

► Clean the probe.

► Observe the notes on installation.

► Correct the position of the overflow

protection.

► Repeat the adjustment.

► Deactivate OP (→ 5.2.2).

[SC1] + LED 8

[SC2] + LED 7

Flashing:

Short circuit in switching output

OUT1 or OUT2.

► Remove the short circuit.

[SC] + LED 7

+ LED 8

Flashing:

Short circuit in both switching

outputs.

► Remove the short circuit.

[PArA] Faulty data set. ► Reset to factory settings [rES].

11.4 Output response in different operating states

Table 11-1

OUT1 OUT2

Initialisation phase OFF OFF

Overflow protection OP not

adjusted

OFF OFF

Overflow protection OP not

adjusted or deactivated,

normal operation

According to the level and

[ou1] setting

According to the level and

[ou2] setting

Fault

OFF for [FOU1] = [OFF]

ON for [FOU1] = [On]

OFF for [FOU2] = [OFF]

ON for [FOU2] = [On]

Page 28

28

12 Technical data

Technical data and scale drawing at www.ifm.com.

12.1 Setting values [OFS]

Table 12-1

[cm] [inch]

Setting range 0...200.0 0...78.8

LKx022

LKx023

LKx024

LKx022

LKx023

LKx024

Step increment 0.5 1 0.2 0.5

Setting values [OP]

Tab. 12-2

OPx

LKx022 LKx023 LKx024

[cm] [inch] [cm] [inch] [cm] [inch]

20,4 8,0 40,7 16,0 61 23,9

19,1 7,5 38,3 15,1 57 22,4

17,9 7,1 35,8 14,1 53 21,0

16,7 6,6 33,4 13,1 50 19,5

15,5 6,1 31,0 12,2 46 18,1

14,3 5,6 28,5 11,2 42 16,7

13,0 5,1 26,1 10,3 39 15,2

11,8 4,7 23,6 9,3 35 13,8

10,6 4,2 21,2 8,3 31 12,3

9,4 3,7 18,8 7,4 28 10,9

8,2 3,2 16,3 6,4 24 9,5

6,9 2,7 13,9 5,5 20 8,0

OPx: Setting Range [OP]

Page 29

29

UK

The indicated values for [OP] refer to the distance between OP and the

lower edge of the probe. The values apply if [OFS] = [0].

If [OFS] > [0], they increase by the set offset value.

Example LK1022: According to Table 12-2 OP has to be set to segment

20.4 cm.

[OFS] = 7.0 cm

[OP] is to be set to 20.4 cm + 7.0 cm = 27.4 cm.

Page 30

30

12.2 Calculation aids [OP]

For proper functioning of the overflow protection OP a minimum distance

(y) (Fig. 12-1) must be observed (→ 6.1).

The following applies (Fig. 12-1):

B + c = L + u

and

B = z + y

B: tank height

c: outside length (maximal → 6)

y: required response level OP

from the cover (minimum →

6.1, maximum → 12.2)

L: probe length

u: distance between probe and tank

bottom

z: required response level OP from

the bottom (maximum: z < L - c - y

or z < B - y)

12.2.1 Definition “from the cover“

Requested distance (y) of the overflow protection OP

“from the cover“ is defined.

• Without offset ([OFS] = [0]): [OP] = L - c - y

• With offset ([OFS] = u): [OP] = L - c - y + u

or

[OP] = B – y

Example:

c = 3.0 cm, y = 5.0 cm, u = 1.0 cm

Without offset: [OP] = 26.4 cm - 3.0 cm - 5.0 cm

= 18.4 cm

With offset: [OP] = 26.4 cm - 3.0 cm - 5.0 cm - 1.0 cm

= 19.4 cm

Fig. 12-1

OP

c

z

B

L

12.2.2 Definition “from the bottom“

Response level (z) of the overflow protection OP from the tank bottom is defined.

• Without offset ([OFS] = [0]): [OP] = z - u

• With offset ([OFS] = u): [OP] = z

Example:

z = 18.0 cm (from the tank bottom), u = 1.0 cm

Without offset: [OP] = 18.0 cm - 1.0 cm = 17.0 cm

With offset: [OP] = 18.0 cm

Round the calculated value to the next lower adjustable value → 11.2.

Page 31

31

UK

12.3 Setting ranges [SPx] / [FHx] and [rPx] / [FLx]

Table 12-3

LKx022 LKx023 LKx024

[cm] [inch] [cm] [inch] [cm] [inch]

[SPx] / [FHx] 2.5...20.0 1.0...8.0 3.5...39.0 1.4...15.4 6.0...59.0 2.5...23.5

[rPx] / [FLx] 2.0...19.5 0.8...7.8 3.0...38.5 1.2...15.2 5.0...58.0 2.0...23.0

Step

increment

0.5 0.2 0.5 0.2 1.0 0.5

The values apply if [OFS] = [0].

If [OFS] > [0], they increase by the set offset value.

13 Maintenance / cleaning / change of medium

When removing or installing the unit for maintenance and cleaning work:

► Make sure that the stainless steel tube clip is fixed to the sensor.

> It must be possible to exactly reproduce the installation height and position!

► Remove the sensor and clean it / carry out maintenance.

► Install sensor exactly in the same position as before.

► Otherwise check the parameter [OP] and carry out [cOP] once again.

13.1 Maintenance information for operation without overflow

protection

[MEdI] = [Auto] or [OP] = [OFF] (the overflow protection is deactivated).

The unit must be reinitialised in the following cases (switch the operating voltage

briefly off and on again):

• After all maintenance operations.

• After cleaning operations (e.g. water jet cleaning of the sensor probe)

• If the sensor has been removed from the tank and inserted again during

operation.

• If the active zone of the sensor has been touched with the hand or grounded

objects (e.g. a screwdriver, a cleaning lance).

• If the connection between the sensor and the tank wall/counter-electrode has

been changed.

Page 32

32

• After a change of media with dielectric constants that differ significantly. For

manual selection of media, first the [MEdI] setting needs to be adjusted.

14 Factory setting

Factory setting User setting

LKx022 LKx023 LKx024

SP1 10.0 19.5 29.0

rP1 9.5 19.0 28.0

SP2 20.0 39.0 59.0

rP2 19.5 38.5 58.0

OP*

20.4 40.7

60.6

MEdI LK10xx: CLW.1

LK70xx: Auto

cOP ---rES ---ou1 Hno

ou2 Hnc

dS1 0.0

dr1 0.0

dS2 0.0

dr2 0.0

uni cm

P-n PnP

OFS 0

FOU1 OFF

FOU2 OFF

diS On

* Not available / inactive for LK70xx

Page 33

33

UK

15 Applications

15.1 Hydraulic tank

Minimum level monitoring with early warning and alarm

Switching output 1: early warning

SP1 slightly above rP1 (to suppress wave movements)

rP1 below preset level → early warning, start refilling

ou1 hysteresis function, normally closed (Hnc)

Switching output 2: alarm

SP2 min. value reached again → alarm reset

rP2 below min. value → alarm

ou2 hysteresis function, normally open (Hno)

XX.X = display value,

A = early warning, B = alarm

• If the level is below rP1, output 1 switches until liquid is refilled. If SP1 is

reached again, output 1 switches off.

• If the level is above SP2, output 2 switches. If the level falls below rPs or if

there is a wire break, output 2 switches off.

• By setting SP1 the maximum level can be controlled / monitored: the value of

SP1 determines up to which level (max) is to be refilled. When the maximum

level is reached, this is signalled by the LED OUT1 going out and output 1

switching off.

Page 34

34

15.2 Pumping station

Empty the tank with overflow protection

Switching output 1: control to empty tank

SP1 upper value exceeded → submersible pump ON

rP1 lower value reached → submersible pump OFF

ou1 hysteresis function, normally open (Hno)

Switching output 2: overfill protection (for the LK10xx, it is recommended to use the

integrated overflow protection (parameter [OP])

SP2 maximum value exceeded → alarm

rP2 slightly below SP2 (to suppress wave movements)

ou2 hysteresis function, normally closed (Hnc)

OP overflow protection *)

XX.X = display value,

A = empty, B = overflow protection

• If SP1 is exceeded, output 1 switches (submersible pump ON). If the level is

below rP1 again, output 1 switches off (submersible pump OFF).

• If SP2 is exceeded or if there is a wire break, output 2 switches off.

*) It is recommended to use the integrated overflow protection (parameter [OP]). If SP2 is set

to a maximum value, the response of the overflow protection (OP) immediately leads to a

switching operation. In that case, SP2 functions as a directly acting overflow switch point.

Page 35

35

UK

15.3 Storage tank

Monitoring of the acceptable range (alarm) and level control

Switching output 1: refilling

SP1 upper preset value reached → finish refilling

rP1 below lower preset value → start refilling

ou1 hysteresis function, normally closed (Hnc)

Switching output 2: safety function min - max

SP2 max. value exceeded → alarm

rP2 below min. value → alarm

ou2 window function, normally open (Fno)

FH2

SP1

rP1

FL2

XX.X = display value,

A = refill; B = min. monitoring; C = max. monitoring

• If the level is below rP1, output 1 switches until liquid is refilled. If SP1 is

reached again, output 1 switches off.

• If the level is below FL2 or above FH2 or if there is a wire break, output 2

switches OFF (→ alarm).

• The logical operation between the outputs 1 and 2 indicates whether there is

overflow or the actual level is below the minimum level.

- Overflow: output 1 and output 2 switched off.

- Below min. value: output 1 switched on and output 2 switched off.

More information at www.ifm.com

Loading...

Loading...