Page 1

Operating instructions

Electronic rising stem valve sensor

IX5030

UK

704770 / 00 04 / 2010

Page 2

Contents

1 Preliminary note ���������������������������������������������������������������������������������������������������3

1�1 Symbols used ������������������������������������������������������������������������������������������������3

2 Functions and features ����������������������������������������������������������������������������������������4

2�1 Permissible shapes and dimensions of the target �����������������������������������������5

2�2 Non-permissible shapes and dimensions of the target ����������������������������������5

3 Function description���������������������������������������������������������������������������������������������6

3�1 Application example ���������������������������������������������������������������������������������������6

4 Installation������������������������������������������������������������������������������������������������������������7

5 Electrical connection ��������������������������������������������������������������������������������������������8

5�1 Assignment of the data bits ���������������������������������������������������������������������������8

6 Operation �������������������������������������������������������������������������������������������������������������9

7 Programming �������������������������������������������������������������������������������������������������������9

7�1 Programming overview ����������������������������������������������������������������������������������9

7�2 Adjustment of the valve positions of valves with 2 operating positions ������� 11

7�3 Adjustment of the valve positions of valves with 3 operating positions �������12

7�4 Locking / unlocking ���������������������������������������������������������������������������������������13

8 Set-up / operation �����������������������������������������������������������������������������������������������13

8�1 Indication by LED for the different operating modes������������������������������������13

9 Error messages �������������������������������������������������������������������������������������������������15

10 Scale drawing ��������������������������������������������������������������������������������������������������16

2

Page 3

1 Preliminary note

1.1 Symbols used

► Instruction

> Reaction, result

→ Cross-reference

Important note

Non-compliance can result in malfunction or interference�

Information

Supplementary note�

UK

3

Page 4

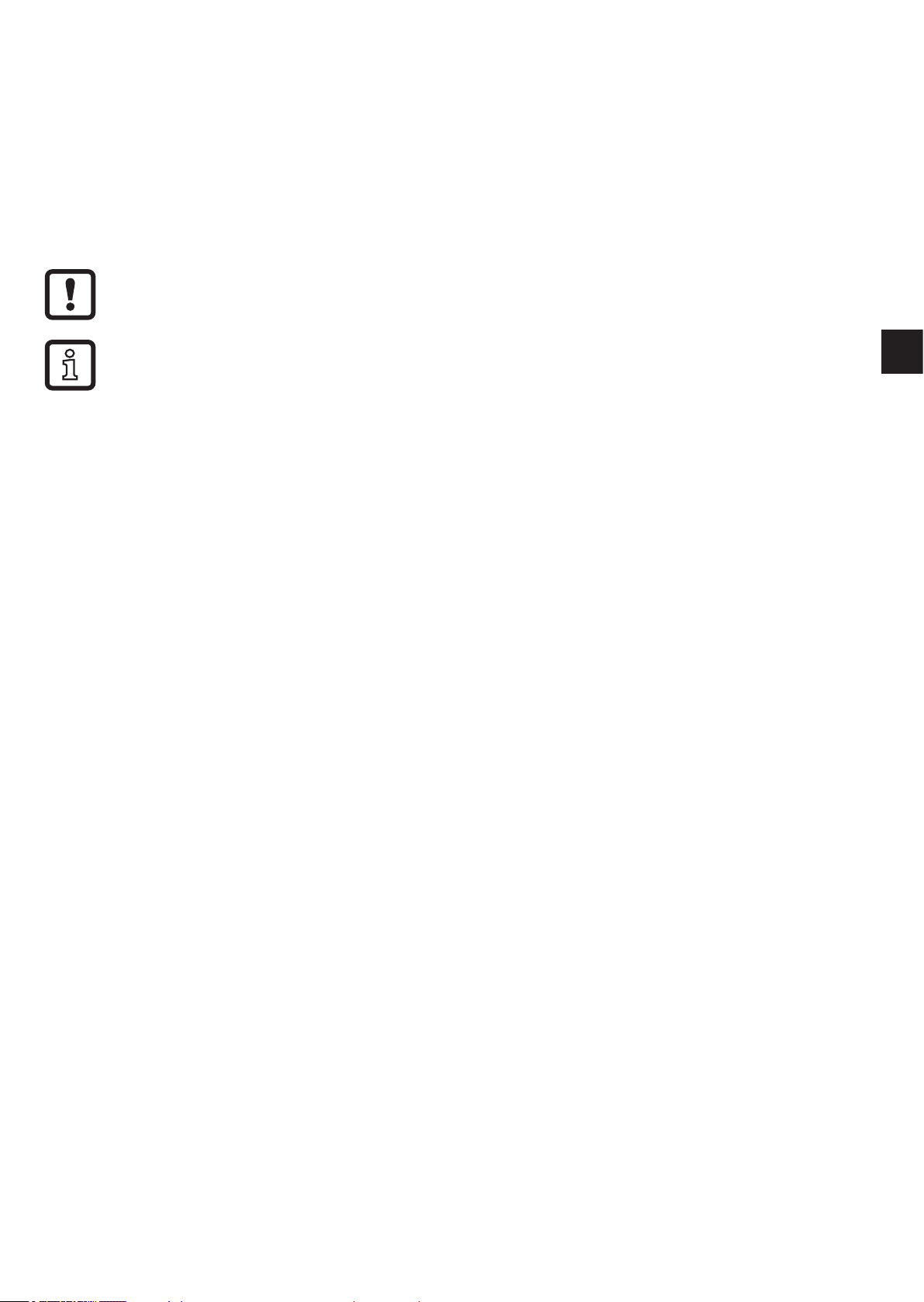

2 Functions and features

The rising stem valve sensor IX5030 is a continuous absolute linear measurement

system with a measuring stroke of 80 mm� The sensor is used for position

feedback for rising stem valves� For position detection three programmable switch

points can be freely selected in the measuring range� The position is signalled

visually by 3 LEDs�

sensor

valve spindle with target

adapter / fixture

actuator of the valve

position button

Teach button

5 LEDs (open, close, seat, AS-i voltage, error)

The rising stem valve sensor IX5030 can be adapted to different valve

types� The instructions in the chapter Installation are to be observed when

designing the adapters and the fixtures�

4

Page 5

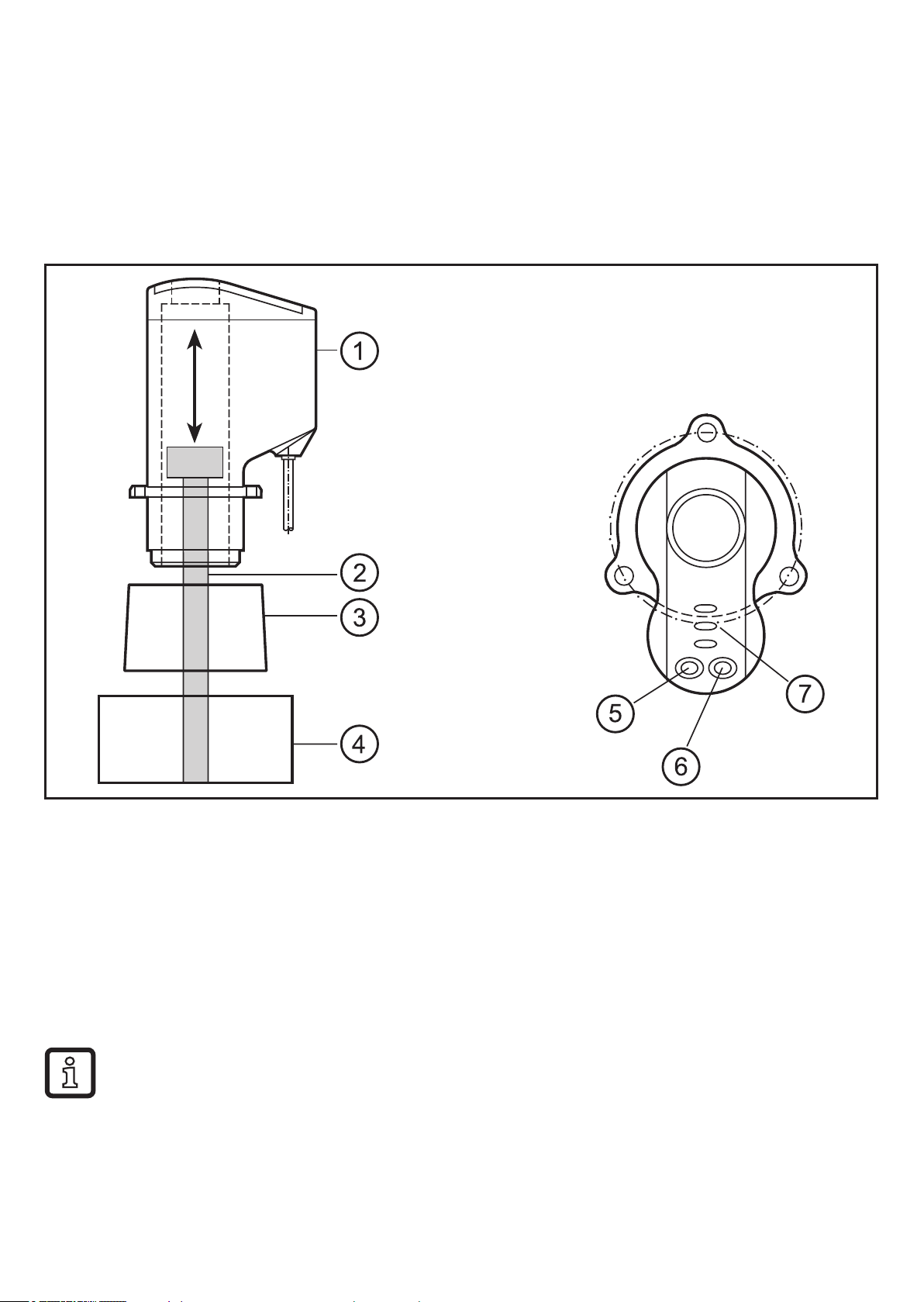

The valve spindle to be measured must have the following characteristics:

• Diameter 24 mm (tolerance: ± 0�05 mm), height at least 10 mm

• The end surface must be flat

• Material: stainless steel to DIN 17440, material number 316L / 1�4404

2.1 Permissible shapes and dimensions of the target

Ø24mm

10mm

Ø24mm Ø24mm

10mm

Ø24mm

10mm

15mm

UK

2.2 Non-permissible shapes and dimensions of the target

Ø24mm

5mm

Ø24mm

10mm

Ø24mm

10mm

Ø18mm

10mm

5

Page 6

3 Function description

• The sensor measures the upper edge of the valve spindle

• Non-contact and wear-free detection of the valve positions: closed (close),

open (open) and the position for seat lift (seat) during the cleaning process�

• It is also possible to monitor the state of the valve seals instead of the seat lift�

Due to the high resolution of 0�2 mm even slight changes can be detected�

• Easy and time-saving adjustment by "teaching" (reading) the valve positions�

The taught valve positions are automatically assigned certain switching

characteristics of the three outputs, several operating modes are available (see

chapters Programming and Set-up)�

• Monitored stroke (detection zone) 80 mm� The condition "valve spindle outside

detection zone" is indicated�

• After adjustment the unit can be electronically locked to prevent unauthorised

manipulation�

3.1 Application example

closed* seat lift open*

Active detection range of

the sensor

Closed position is taught

Position seat lift is taughtOpen position is taught

* The valve positions closed and open may also be reversed�

6

Page 7

4 Installation

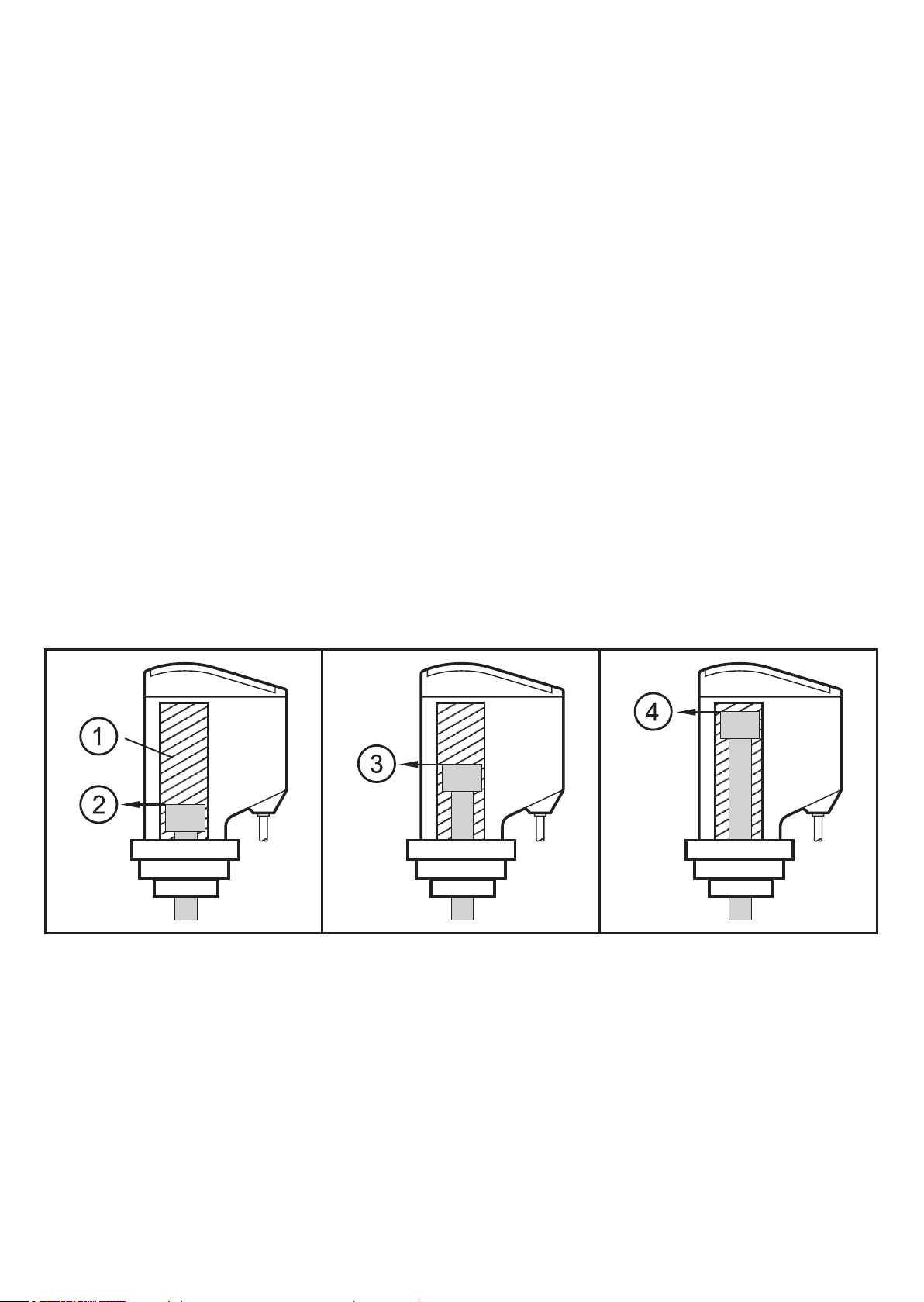

Place the sensor (1) on the valve spindle

(2) until the limit stop in a suitable fixture /

adapter (3)�

Fix the sensor to the 3-hole flange (3) by

means of the included fixing screws (6)�

The sensor (1) must either be integrated into

a valve top or correctly fitted to the actuator

(4) by means of a suitable adapter (3)�

If necessary adapt the length of the valve

spindle to the measuring range�

UK

7

Page 8

Ensure a tight and secure fit�

1

Make sure that no metallic components

are in the immediate vicinity of the

sensor or approach the sensor during

operation (especially no metal rings which

enclose the sensor)! This might affect the

functioning of the sensor�

Fixing elements such as screws, clamps

and similar small metal parts (< 20 x 20 x

30 mm) have no impact on the sensor� For

safe functioning the adapter (3) must be

made of plastic�

A = metallic objects

x = min� 10 mm

y = min� 46�5 mm

5 Electrical connection

The unit must be connected by a qualified electrician� The national and

international regulations for the installation of electrical equipment must be

adhered to�

Disconnect power before connecting

the unit as follows:

3

5.1 Assignment of the data bits

AS-i+

AS-i

Data bit D0 D1 D2 D3

Description close seat open not used

state = 0 plunger outside

the 'close' zone

state = 1 plunger inside

the 'close' zone

plunger outside

the 'seat' zone

plunger inside the

'seat' zone

plunger outside

the 'open' zone

the 'open' zone

plunger inside

default value

-

8

Page 9

6 Operation

The sensor is operated via the pushbuttons

Pos� and Teach� To do so, press the buttons

with a blunt object�

Sharp edges may damage the

buttons!

openclose

seat

Powerfault

UK

7 Programming

7.1 Programming overview

Teach mode

P

yes

no

Run mode

P

>2s

adjust close

yes

position?

no

P

Check

P

>5s

TT

adjust seat

adjust open

position?

position?

no

P

P: actuate Pos� button T: actuate Teach button

T

yes

9

Page 10

After installation you have to adjust the unit to the valve positions to be detected�

You can carry out the adjustment process in a variable and time-saving way� First

clarify which type of valve you have� The sensor differentiates between two types:

1� Valves with 2 operating positions (closed and open)

2� Valves with 3 operating positions (closed, open and a position inbetween for

the seat lift)

For valves with 2 operating positions the wear of the valve seals is monitored

automatically� This function is not possible for the detection of three operating

positions�

The programming options are shown in the programming overview ( → 7�1) After

entering into the programming mode (Teach mode) the unit first expects the

adjustment of the closed position (close)�

However, you can also start with any other position�

If e�g� the valve is already in the open position (open), just start adjusting this

position� To do so, press the Pos� button 2 x, thus skipping the adjustment of the

closed and the seat position� You can carry out the skipped adjustment steps

afterwards�

Skipping a current programming step is also required for example if you use

valves with only 2 operating positions for which the position of the seat lift is not

available� If the position seat lift is not adjusted ("taught") the unit automatically

passes into an operating mode which monitors the wear of the valve seals (see

also chapter Set-up / operation)�

The unit cannot be taught via the AS-i bus�

10

Page 11

7.2 Adjustment of the valve positions of valves with 2

operating positions

Press the Pos� button for at

1

least 2 s�

Put the valve into the

2

closed position and press the

Teach button�

Press the Pos� button once,

3

thus skipping the current

programming step� This is

necessary because your

valve does not have the

position seat lift�

All LEDs flash 2 x simultaneously� The unit is

in the programming mode� Then only the LED

"close" is lit�

The unit is now ready for the adjustment of the

closed position (close)�

The LED "close" goes out and the LED "seat"

lights� The unit has stored the closed position

and is now ready for the adjustment of the

position seat lift (seat)�

The LED "open" lights� The unit is now ready

for the adjustment of the open position�

UK

Put the valve into the open

4

position and press the Teach

button�

Press the Pos� button for at

5

least 5 s� After 5 s the LED

"open" flashes at about 2 Hz�

The LED "open" goes out and the LED "close"

lights again� The unit has now stored all

positions�

After releasing all stored measured values

are checked� If no errors are detected all

LEDs simultaneously flash 2 x� The unit

automatically quits the programming mode

and immediately passes into the operating

mode�

If, however, an error is found during the

check the LED "close" flashes at about 8 Hz�

Acknowledge the error message by pressing

the Pos� button and repeat the adjustment�

11

Page 12

7.3 Adjustment of the valve positions of valves with 3

operating positions

Press the Pos� button for at

1

least 2 s�

Put the valve into the

2

closed position and press

the Teach button�

Put the valve into the position

3

seat lift and press the Teach

button�

Put the valve into the open

4

position and press the Teach

All LEDs flash 2 x simultaneously� The unit is

in the programming mode� Then only the LED

"close" is lit�

The unit is now ready for the adjustment of the

closed position (close)�

The LED "close" goes out and the LED "seat"

lights� The unit has stored the closed position

and is now ready for the adjustment of the

position seat lift (seat)�

The LED "seat" goes out and the LED "open"

lights� The unit has stored the position seat

lift and is now ready for the adjustment of the

open position (open)�

The LED "open" goes out and the LED "close"

lights again� The unit has now stored all

button�

Press the Pos� button for at

5

least 5 s� After 5 s the LED

"open" flashes at about 2 Hz�

positions�

After releasing all stored measured values

are checked� If no errors are detected all

LEDs simultaneously flash 2 x� The unit

automatically quits the programming mode

and immediately passes into the operating

mode�

If, however, an error is found during the

check the LED "close" flashes at about 8 Hz�

Acknowledge the error message by pressing

the Pos� button and repeat the adjustment�

12

Page 13

7.4 Locking / unlocking

The unit can be locked electronically to prevent unintentional operations�

Press both setting pushbuttons simultaneously for at least 10 s in the operating

mode� After 10 s each LED lights briefly one after the other� Then the unit is locked

or unlocked�

In the locked state operations are ignored�

On delivery: unlocked�

8 Set-up / operation

After installation, wiring and adjustment check whether the unit operates correctly�

If possible, put the valve into all available positions and check whether the unit

switches correctly and whether the operations are correctly indicated by the LEDs�

8.1 Indication by LED for the different operating modes

The sensor has 3 operating modes which the sensor automatically generates

depending on the programming�

• Mode A:

For valves with 2 operating positions� The wear of the valve seals is monitored�

• Mode B:

For valves with 3 operating positions� The position seat lift (seat) is between

the positions closed and open�

• Mode C:

UK

For valves with 3 operating positions� The position seat lift (seat) is outside the

positions closed and open�

13

Page 14

80

Pos [mm]

70

60

50

40

30

Teach

Mode A Mode B Mode C

open + seat

open

Teach Teach

open

seat

open

close

20

10

0

LED "close" flashes at 8 Hz�

= valve spindle at the limit or outside the detection range

close

close + seat

close

seat

• The respective LED at the zones marked in grey lights, at the same time the

output corresponding to this state is closed (switched)� At the zones marked in

white and outside the detection area (zones hatched diagonally) all outputs are

open (not switched)�

• All modes are also possible in inverted form, i�e� the open and closed positions

can be inverted� The sensor detects this automatically, the assignment of the

switching characteristics is carried out automatically�

• The open and closed zones are placed nearly at the limits, i�e� the Teach

positions are at the limit of the zones� The seat zones are placed in the middle,

i�e� symmetrically around the Teach position�

• To monitor the seal the open and closed zones in the mode A are only 1�5

mm� The zones open+seat and close+seat are adjacent� In these zones the

14

Page 15

outputs "open" and "seat" and the outputs "close" and "seat" are switched

simultaneously� This signals wear of the valve seal!!

• In the mode A only 2 valve positions are to be adjusted, the positions closed

and open� The adjustment of the seat lift must not be carried out, please skip

this program step by pressing the Pos� button� The sensor then automatically

generates the mode A�

9 Error messages

LED Fault description Measure

close Flashes at 8 Hz directly after

leaving the programming mode =

adjustment error!

Taught position values are not within

the detection range or positions are not

during adjustment

close Flashes at 8 Hz = target is at the limit or

close Flashes at 8 Hz = fault in the electronics�

during operation

allowed or plausible�

outside the detection range or the target

is in non defined zones (white zones, see

above diagram) for longer than 20 s�

Contrary to the other error messages this

error message cannot be acknowledged

or terminated�

UK

► Acknowledge the error

message by pressing the

Pos� button and repeat the

adjustment�

► Check the position of the

valve�

► Replace the sensor�

15

Page 16

10 Scale drawing

65

110

99,6

26,5

88,6

80

4,5

15,5

26

6,2

52

34,8

38

3

4

Max� spindle stroke

Measuring distance

Initial value of the measuring range (zero point)

Programming buttons (Pos� / Teach)

LED green = open / LED red = close

LED green = AS-i voltage / LED red = error

LED yellow = seat

16

4,3

Page 17

UK

17

Loading...

Loading...