Page 1

Original operating instructions

Fail-safe inductive sensor

GM701S

UK

80236831 / 00 09 / 2016

Page 2

Contents

1 Preliminary note ��������������������������������������������������������������������������������������������������� 3

1�1 Symbols used ������������������������������������������������������������������������������������������������3

1�2 Warning signs used ���������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������4

2�1 Safety-related requirements regarding the application ���������������������������������� 4

3 Items supplied������������������������������������������������������������������������������������������������������5

4 Functions and features ����������������������������������������������������������������������������������������5

5 Function ��������������������������������������������������������������������������������������������������������������� 6

5�1 Enable zone ���������������������������������������������������������������������������������������������������6

5�2 Protection against simple defeating ���������������������������������������������������������������7

6 Installation������������������������������������������������������������������������������������������������������������8

6�1 Alignment of the sensing face ������������������������������������������������������������������������8

6�2 Installation conditions ������������������������������������������������������������������������������������8

7 Electrical connection ������������������������������������������������������������������������������������������ 10

8 Set-up ����������������������������������������������������������������������������������������������������������������10

8�1 Setting aid ���������������������������������������������������������������������������������������������������� 10

8�2 Determine the enable zone �������������������������������������������������������������������������10

8�3 Deactivate setting aid ���������������������������������������������������������������������������������� 11

9 Operation ����������������������������������������������������������������������������������������������������������� 12

9�1 Switching state of the outputs ����������������������������������������������������������������������12

9�1�1 The safe state ������������������������������������������������������������������������������������� 12

9�1�2 The switched state ������������������������������������������������������������������������������12

9�1�3 Output characteristics ������������������������������������������������������������������������� 12

9�1�4 Cross faults �����������������������������������������������������������������������������������������12

9�2 Operating mode ������������������������������������������������������������������������������������������� 13

9�2�1 Delayed switching of the LED �������������������������������������������������������������13

9�2�2 Switching of the LED without delay ����������������������������������������������������14

9�3 Response times ������������������������������������������������������������������������������������������� 14

9�4 LED display �������������������������������������������������������������������������������������������������16

10 Technical data �������������������������������������������������������������������������������������������������� 17

11 Troubleshooting �����������������������������������������������������������������������������������������������19

2

Page 3

12 Maintenance, repair and disposal �������������������������������������������������������������������� 19

13 Terms and abbreviations ���������������������������������������������������������������������������������� 20

1 Preliminary note

The instructions are part of the unit� They are intended for authorised persons

according to the EMC, Low Voltage and Machinery Directives and safety

regulations�

The instructions contain information about the correct handling of the product�

Read the instructions before use to familiarise yourself with operating conditions,

installation and operation�

Follow the safety instructions�

1.1 Symbols used

► Instructions

→ Cross-reference

Important note

Non-compliance can result in malfunction or interference�

Information

Supplementary note�

LED on

UK

LED off

LED flashes (2 Hz)

LED flashes quickly (5 Hz)

1.2 Warning signs used

WARNING

Warning of serious personal injury�

Death or serious irreversible injuries may result�

3

Page 4

2 Safety instructions

• Follow the operating instructions�

• Improper use may result in malfunctions of the unit� This can lead to personal

injury and/or damage to property during operation of the machine� For this

reason note all remarks on installation and handling given in this document�

Also adhere to the safety instructions for the operation of the whole installation�

• In case of non-observance of notes or standards, especially when tampering

with and/or modifying the unit, any liability and warranty is excluded�

• If the sensor is damaged, the safety function cannot be guaranteed�

• Errors caused by damage cannot be detected by the sensor�

• The unit must be installed, connected and put into operation by a qualified

electrician trained in safety technology�

• The applicable technical standards for the corresponding application must be

complied with�

• For installation the requirements according to EN 60204 must be observed�

• In case of malfunction of the unit please contact the manufacturer� Tampering

with the unit is not allowed�

• Disconnect the unit externally before handling it� Also disconnect any

independently supplied relay load circuits�

• After installation, maintenance or repair of the system perform a complete

function check�

• Use the unit only in specified environmental conditions (→ 10 Technical data)�

In case of special operating conditions please contact the manufacturer�

• Use only as described below (→ 4)�

2.1 Safety-related requirements regarding the application

It must be ensured that the safety requirements of the respective application

correspond to the requirements stated in these instructions�

4

Page 5

WARNING

Failure of the safety function

When used outside of the defined environmental conditions, the safety-related

function of the sensor cannot be guaranteed�

► Use only in accordance with the defined environmental conditions (→ 10

Technical data)�

Use of the sensor in the vicinity of chemical and biological media (solid, liquid,

gaseous) as well as ionising radiation is not permitted�

UK

Observe the following requirements:

► Take measures to avoid metallic objects being placed on the sensing face

unintentionally�

► Adhere to EN 14119 for interlocking devices associated with guards�

► Adhere to the principle of normally closed operation for all external safety

circuits connected to the system�

► In case of faults within the fail-safe sensor which result in the defined safe

state: take measures to maintain the safe state when the complete control

system continues to be operated�

► Replace damaged units�

3 Items supplied

1 fail-safe sensor GM701S with premounted angle bracket,

Allen key for fixing the fail-safe sensor onto the angle bracket

1

1 original operating instructions GM701S, ident no� 80236831�

If one of the above-mentioned components is missing or damaged, please contact

one of the ifm branch offices�

4 Functions and features

The fail-safe inductive sensor GM701S detects metal without contact�

Safety function SF: the safe state (output stage switched off; logic "0") is achieved

when undamping greater than or equal to the safe switch-off distance s

Technical data)

�

Also observe the notes on installation of the sensor (→ 6 Installation)

ar

�

(→ 10

5

Page 6

The fail-safe inductive sensor is a proximity device with defined behaviour under

fault conditions (PDDB) to IEC 60947-5-3�

The fail-safe sensor conforms to Performance Level e according to

EN ISO 13849-1 as well as to the requirements SIL 3 to IEC 61508 and meets

SILcl 3 to IEC 62061�

Depending on the type of installation the unit corresponds to the classification

I1C40SP2 to IEC 60947-5-2 for flush installation as well as I2C40SP2 to

IEC 60947-5-2 for non-flush installation (→ 6 Installation)�

The fail-safe inductive sensor has been certified by TÜVNord�

The unit is suited for applications up to 5 Hz�

5 Function

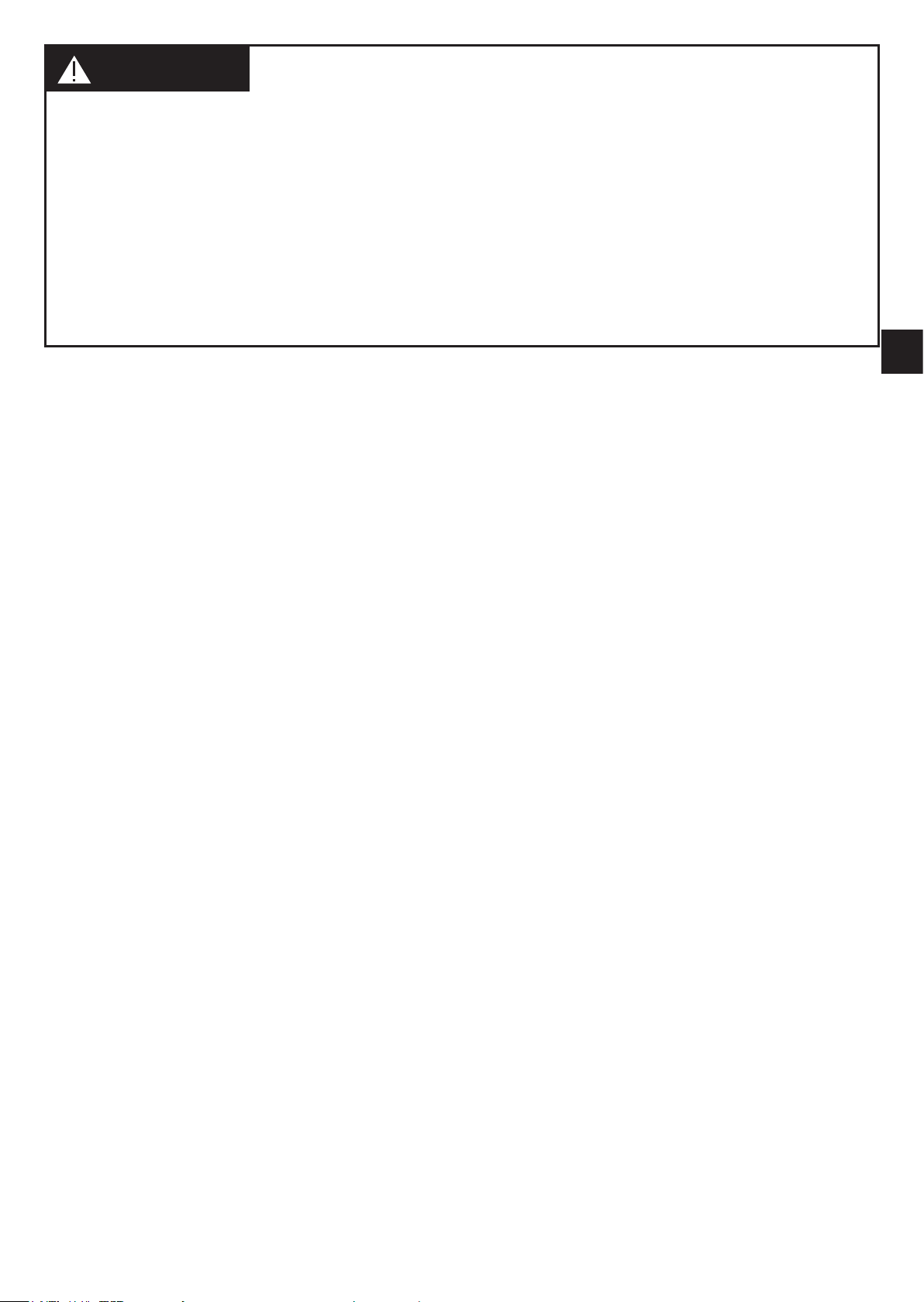

"1"

1: dual LED: signal (yellow); power (green)

2: close zone

3: enable zone

4: safe switch-off distance s

5: target

ar

"0"

5.1 Enable zone

The outputs (OSSD) are only enabled when a damping target is present in the enable zone� Outside this enable zone the outputs remain switched off�

The safe switch-off distance sar is > 30 mm�

The enable zone is different if damping elements which deviate from the

standard target plate in terms of material, form and size are used�

Enable zone for selected materials*:

6

Page 7

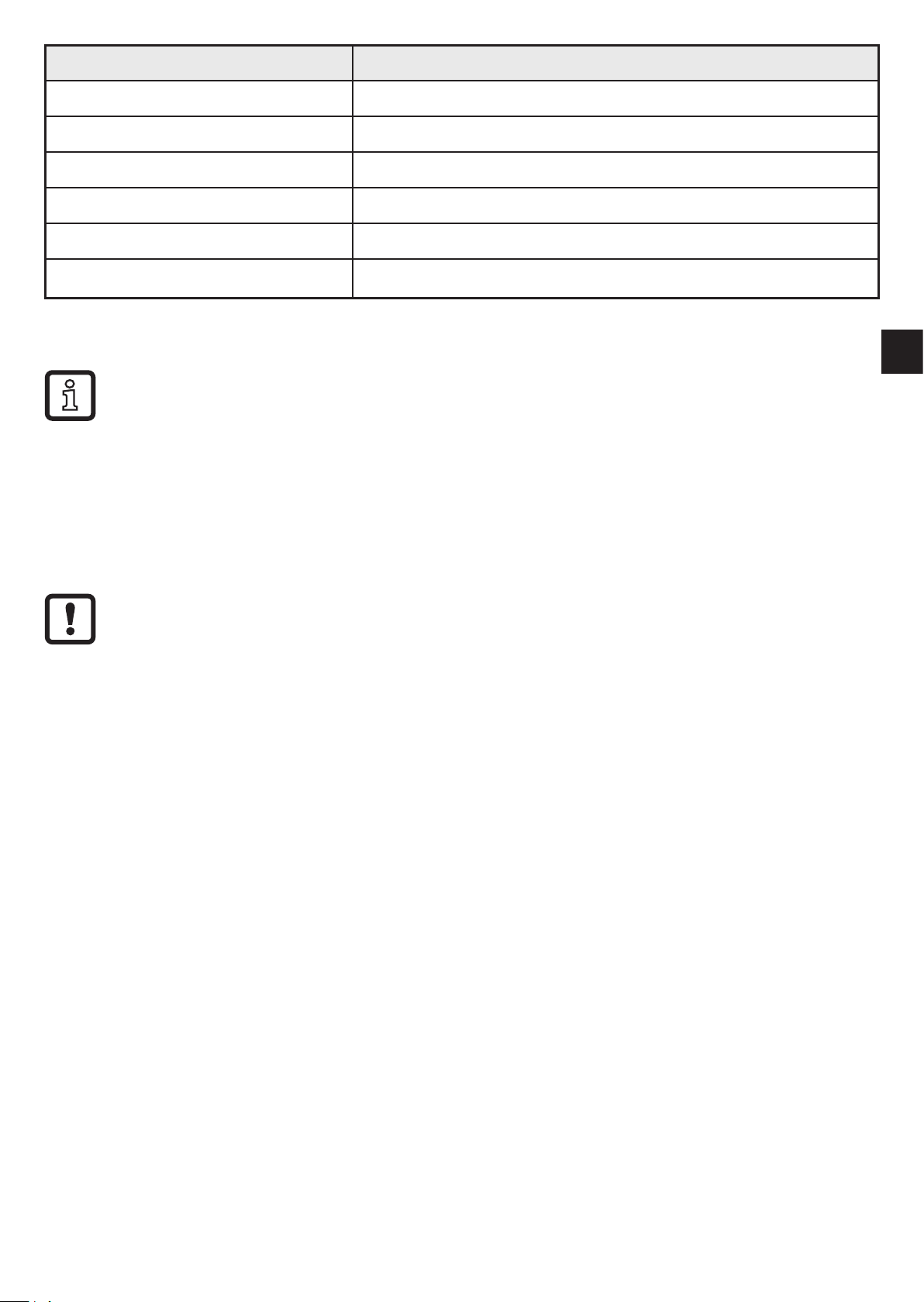

Material Enable zone

FE360 (= mild steel) 10���15 mm

Stainless steel 7�5���13�2 mm

AIMg3G22 2�0���5�8 mm

AI 99 % 1�4���5�0 mm

CuZn37 2�3���6�2 mm

Copper 0�8���4�3 mm

* Typical values for damping with a reference target of 45 x 45 x 1 mm and non-flush installation to IEC 60947-5-2 at an ambient temperature of 20 °C�

UK

Depending on the characteristics of the damping element there may be no

close zone�

5.2 Protection against simple defeating

The fail-safe sensor reacts to metal objects, e�g� the frame of a safety door� Other

metal objects that are not intended to enable the sensor must not be allowed to

enable the fail-safe sensor unintentionally�

► Take measures to prevent metal objects, except the designated target,

from being placed on the sensing face or in the enable zone unintentionally�

In addition, the sensor has the following switching characteristics to make simple

defeating of its safety function more difficult:

1� By slowly introducing a metallic object into the enable zone, the outputs are

immediately switched, but displayed by the LED with a delay of approx� 3 s (→

9�2�1 Delayed switching of the LED)� By doing so, the object is generally in the

close range before the LED indication is lit� The technical instructions concerning the restart of the installation must be observed�

2� If the object remains in the close zone for over approx� 2 s, the outputs are

completely disabled and no longer enabled in case of damping in the enable

zone� If the object stays in the close range for longer than approx� 5 s, the setting aid is activated (→ 8.1)�

Release of the enable zone can be carried out

• either by undamping (> 30 mm) for a time of more than 2 s

• or by a voltage interruption

(→ 8.3 Deactivate setting aid)�

7

Page 8

6 Installation

6.1 Alignment of the sensing face

21

3

The socket is rotatable:

4

6 75

► Tighten the socket according to the manufacturer's indications� Observe the

tightening torque for the ifm socket (e�g� EVxxxx: 0�6���1�5 Nm)�

6.2 Installation conditions

• The unit is non flush mountable in steel in accordance with IEC 60947-5-2,

type I2C40SP2� In addition one side of the unit can be mounted flush with

steel�

8

Page 9

• The unit can be mounted flush with copper, aluminium and brass according to

IEC 60947-5-2, type I1C40SP2�

► Ensure the unit cannot work loose�

► Tighten captive screws with 1 Nm�

► Limit the use of oblong holes to the initial setting�

► Adhere to the installation conditions in accordance with the figures 1 to 5:

1

3

2

Angle mounting Channel mounting

UK

80

105

80

4

80

80

5

80

80

80

9

Page 10

7 Electrical connection

mm

Power

Wiring diagram → 10 Technical data

► Disconnect power� Also disconnect any independently supplied relay load

circuits�

► Supply voltage: connect L+ to pin 1 and L- to pin 3 of the connector�

The nominal voltage is 24 V DC� This voltage may vary between 19�2 V and

30 V incl� 5 % residual ripple to EN 61131-2�

In case of one fault the supply voltage must not exceed 60 V DC for more

than 0�2 s up to a max� value of 120 V DC� (This requires the safe separation between power supply and transformer�)

8 Set-up

8.1 Setting aid

For easy and reliable installation the sensor features an optical setting aid to

visualise the enable zone�

The setting aid is activated by

placing a metal object in front of the

fail-safe sensor (close range)�

After approx� 5 s the yellow LED

starts to flash: the setting aid is

300

> 5 s

active�

While this mode is active, the output

Signal

1: close zone

remains in the safe state ("0")�

2: enable zone

8.2 Determine the enable zone

When the setting aid is active, the enable zone can be determined by moving the

target (or the sensor if the target is fixed)�

10

Page 11

mm

Power

Power

Power

As soon as the target enters the en-

r

Powe

r

able zone, the yellow LED goes out�

If the target is just outside the enable

zone in either direction the LED

starts to flash again�

300

Signal

Signal

Signal

1: close zone

2: enable zone

8.3 Deactivate setting aid

300

mm

< 2 s

UK

If the sensor is undamped for more

than 2 s (> 30 mm), the setting aid

is switched off and the yellow LED

goes out�

This can also be achieved by power

off�

1: close zone

2: enable zone

Signal

Powe

> 2 s

Signal

11

Page 12

9 Operation

9.1 Switching state of the outputs

9.1.1 The safe state

The safe state is when at least one of the outputs A1 or A2 (OSSDs) is switched

off (zero-current state: logic "0")�

If one of the outputs A1 or A2 is switched off, the subsequent safety-related logic

unit must bring the complete system into the state defined as safe�

9.1.2 The switched state

If the damping element is in the enable zone and if there is no sensor error, both

outputs A1 and A2 (OSSDs) are enabled (logic "1")�

9.1.3 Output characteristics

The output characteristics are compatible with the input characteristics to

EN 61131-2 type 1 or 2:

Logic "1" ≥ 15 V 2���15 mA

≥ 11 V 15���30 mA

Logic "0" ≤ 5 V leakage current 0�2 mA *)

*) pull-down current typ� 30 mA

The interface corresponds to interface type C class 0 according to the ZVEI

position paper "Klassifizierung binärer 24-V-Schnittstellen mit Testung im Bereich

der Funktionalen Sicherheit" (Classification of binary 24V interfaces tested with

regard to functional safety)�

9.1.4 Cross faults

• A cross fault between both outputs (A1 and A2) is detected by the fail-safe

sensor and results in the outputs (OSSD) being switched off at the next safety

request� The outputs A1 and A2 remain switched off until the error has been

removed�

• A cross fault between one of the two outputs (A1 or A2) and the supply voltage

leads to switching off the other output (A2 or A1) in case of a safety request�

12

Page 13

9.2 Operating mode

mm

Power

The length of the preceding undamping determines whether the yellow LED

comes on with a delay (→ 9.2.1) or without delay (→ 9.2.2) when a target moves

into the enable zone� In any case, the outputs switch on without delay�

In case of undamping the outputs switch off and the yellow LED goes out without

delay�

In case of damping in the close range the outputs switch off immediately whereas

the yellow LED goes out with a delay of approx� 2 s� When the LED goes out the

outputs are maintained in the safe state ("0")� Thus, switching on again in the en-

UK

able zone is not possible� Enabling is done by undamping (> 30 mm) of more than

2 s or by interrupting the voltage (→ 5.2 Protection against simple defeating)�

9.2.1 Delayed switching of the LED

Undamping > 2 s:

If the target was away from the

sensor for more than approx� 2 s

(> 30 mm), the yellow LED goes on

with a delay of approx� 3 s in case of

damping in the enable zone�

This is also the case if the target is in

300

> 3 s

the enable zone when the voltage is

switched on�

1: close zone

2: enable zone

Signal

13

Page 14

9.2.2 Switching of the LED without delay

mm

Power

Undamping < 2 s:

*)

≈ 0 s

Signal

1: close zone

2: enable zone

9.3 Response times

If the target was away from the sensor for less than 2 s (> 30 mm), the

yellow LED comes on without delay

in case of damping in the enable

zone�

300

*) except for the first start-up

Response time on safety request (removal from the enable zone) ≤ 50 ms

Response time when approaching the close range (non safety-

≤ 100 ms

related zone)

Response time when approaching the enable zone (enable time) typ�≤100 ms

200 ms

Risk time / response time for safety-related faults ≤ 100 ms

Permissible dwell time in the close range approx� 2 s

Delay time to activate the setting aid (→ 8.1) approx� 5 s

Dwell time in the undamped condition (≥ 30 mm) to return into the

approx� 2 s

operating mode (→ 8.3 Deactivate setting aid)

Simultaneity of switching on and off of the outputs in case of a safety

≤ 50 ms

request

Test pulse duration t

on A1/A2(1) max� 1 ms

i_max

Test pulse interval Tp (2) [pulse package] min� 2 ms

14

max� 5 ms

Page 15

1

0

1

0

t

t

1: Test pulse duration

2: Test pulse interval Tp (pulse package)

3: Test pulse interval T

Test pulse interval T (repetition pulse package) min� 30 ms

max� 50 ms

UK

15

Page 16

9.4 LED display

LED Operating status Outputs A1

(OSSD)

Signal

Power

Signal

Power

Signal

Power

Signal

Power

Signal

Power

No voltage supply Both outputs

switched off

Undervoltage 0 0

Overvoltage Both outputs

switched off

Taget outside the enable zone

(operating mode) or in the enable

zone (setting aid)

Target in the enable zone

(operating mode)

Both outputs

switched off

Both outputs

enabled

0 0

0 0

0 0

1 1

A2

(OSSD)

Signal

Power

Signal

Power

Target outside the enable zone

(setting aid)

Internal or external fault

(→ 11 Troubleshooting)

Both outputs

switched off

0 0

0

0

1

0

1

0

16

Page 17

10 Technical data

GM701

S

GIMC-4030-US/2OSSD

Inductive sensors

UK

Product characteristics

Fail-safe inductive sensor

Rectangular, plastics

M12 connector

Enable zone 10...15 mm; [nf] non-flush mountable

Complies with the requirements:

EN ISO 13849-1: 2015 category 4 PL e

IEC 61508: SIL 3

IEC 62061: SILcl 3

Application

Type of operation continuous operation (maintenance-free)

Electrical data

Electrical design DC PNP

Operating voltage 24 DC (19.2...30 DC)

Rated insulation voltage 30

Current consumption < 15

Protection class III

Reverse polarity protection yes

Outputs

Output function 2 x OSSD (A1 and A2)

Output data Interface type C class 0

Output voltage at 24 V compatible with EN 61131-2 inputs type 1, 2, 3

Voltage drop < 2.5; (100 mA)

Short-circuit protection yes

Max. capacitive load CL_max 20

[V]

[V]

[mA]

[V]

[nF]

17

Page 18

Range

Enable zone 10...15

Safe switching off distance s(ar) 30

Reaction times

Power-on delay time 5

Response time to safety request ≤ 50

Response time when approaching

the enable zone (enable time) ≤ 200

Risk time (response time for safety

-related faults) ≤ 100

Environment

Applications Class C to EN 60654-1 weatherproof application

Ambient temperature -25...70, for service life ≤ 87600 h

Rate of temperature change 0.5

Max. relative air humidity 5...95, briefly

Air pressure 80...106

Height above sea level ≤ 2000

Ionising radiation not permissible

Salt spray no

Protection IP 65 / IP 67

Tests / approvals

EMC

[mm]

[mm]

[s]

[ms]

[ms]

[ms]

[°C]

10...40, for service life ≤ 175200 h

[K/min]

[%]

5...70, permanently

[kPa]

[m]

IEC 60947-5-2

IEC 60947-5-3

EN 60947-5-2

EN 61000-4-2 ESD: 6 kV CD / 8 kV AD

EN 61000-4-3 HF radiated: 20 V/m

EN 61000-4-4 Burst: 2 kV

EN 61000-4-6 HF conducted: 10 V

EN 61000-4-8: 30 A/m

EN 55011: class B

Shock resistance IEC 60947-5-2

Vibration resistance IEC 60947-5-2

Safety classification

Mission time TM ≤ 175200, (20 years)

Safety-related reliability PFHd 2.5E-09

Mechanical data

Mounting non-flush mountable

Housing materials PPE; diecast zinc

Weight 0.346

Displays / operating elements

Display

Electrical connection

Connection M12 connector; Gold-plated contacts

[h]

[1/h]

[kg]

LED yellow (signal), LED green (power)

18

Page 19

GM701S

GIMC-4030-US/2OSSD

Inductive sensors

Wiring

Remarks

Remarks

1: Safety-related logic unit

Unless stated otherwise, all data refer to the 45x45x1 mm reference target plate to IEC

60947-5-2 (FE360 = mild steel) over the whole temperature range.

Pack quantity 1

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen — We reserve the right to make technical alterations without prior notice. — GB — GM701S-03 — 02.05.2016

[piece]

11 Troubleshooting

LED display → 9.4

Problem Possible cause Troubleshooting

No LED display No voltage supply Apply voltage

Power LED flashes and

sensor does not switch

Sensor does not switch,

not even after undamping

and redamping

• Undervoltage

• Overvoltage

Sensor was brought into the

safe state (logic "0")� Cause:

• cross fault between both

outputs A1 and A2

Correct the voltage

(→ 10 Technical data)

• Switch the operating voltage off and on again

• Check wiring and connections

UK

• cross fault between one

output (A1 or A2) and the

supply voltage

• error in the sensor detected

• Check external electronics

(e�g� PLC)

• Remove the cross fault

• Replace the unit

12 Maintenance, repair and disposal

If used correctly, no maintenance and repair measures are necessary�

Only the manufacturer is allowed to repair the unit�

After use dispose of the unit in an environmentally friendly way in accordance with

the applicable national regulations�

19

Page 20

13 Terms and abbreviations

OSSD Output Signal Switch Device

PDDB Proximity devices with defined

behaviour under fault conditions

PFH

(PFHD)

Probability of (dangerous)

Failure per Hour

PL Performance Level PL to EN ISO 13849-1

SIL Safety Integrity Level SIL 1-4 to IEC 61508� The higher the

SIL, the lower the probability that a safety

function will fail�

SIL

T

M

cl

Safety Integrity Level

claim limit

According to IEC 62061

Mission time Lifetime to EN 60947-5-3

(= max� service life)

20

Page 21

UK

21

Loading...

Loading...