Page 1

80001217/00 06/2013

Original Installation Instructions

Safety Standstill Monitor

DA102S

UK

For hardware version 1.0

Page 2

2

Contents

1 Preliminary note ................................................................................................... 4

1.1 Symbols used ................................................................................................4

2 Safety instructions ...............................................................................................5

3 Items supplied......................................................................................................6

4 Functions and features ........................................................................................6

4.1 Requirements for the hardware configuration ...............................................7

4.1.1 Product-independent requirements ......................................................7

4.1.2 Product-dependent requirements .........................................................7

5 Function ............................................................................................................... 8

5.1 Block diagram ................................................................................................ 8

5.2 Operating principle ........................................................................................8

5.3 Switching function .......................................................................................... 9

5.4 Switch point setting ........................................................................................ 9

5.5 Switching outputs 14-23 and 24-24 ...............................................................9

5.6 Y7 transistor output ......................................................................................10

5.7 Pulse pick-ups (sensors) .............................................................................10

5.8 Sensor monitoring .......................................................................................10

5.8.1 Pulse comparison input 1 and 2 .........................................................10

5.8.2 Mechanical requirements on damping cams and gaps ......................10

5.9 Error message ............................................................................................. 11

5.10 Feedback contact ...................................................................................... 11

6 Installation..........................................................................................................12

6.1 Installation of the device ..............................................................................12

6.2 Installation of the pulse pick-ups (sensors) .................................................12

6.3 Arrangement of the damping cams ..............................................................12

6.3.1 Example rack ...................................................................................... 12

6.3.2 Example cam disc ..............................................................................13

7 Electrical connection .......................................................................................... 14

7.1 Connections (overview) ...............................................................................14

7.2 Supply voltage .............................................................................................15

7.3 Switch point setting ...................................................................................... 15

7.4 Pulse pick-ups (sensors) .............................................................................16

7.5 Feedback contact ........................................................................................16

Page 3

3

UK

7.6 Switching outputs 14-23 and 24-24 .............................................................17

7.7 Y7 transistor output ......................................................................................17

8 Set-up ................................................................................................................18

9 Display elements ...............................................................................................18

9.1 LED indications and switching characteristics ............................................. 19

9.1.1 General ............................................................................................... 19

9.1.2 External errors ....................................................................................19

9.1.3 Internal faults ......................................................................................20

10 Maintenance, repair and disposal .................................................................... 20

11 Technical data ..................................................................................................21

12 Tests / approvals .............................................................................................. 23

13 Terms and abbreviations ..................................................................................24

14 EC Declaration of Conformity ..........................................................................25

This document is the original instructions.

Page 4

4

1 Preliminary note

The instructions are part of the unit. They are intended for authorised persons

according to the EMC and Low Voltage Directives and safety regulations.

The instructions contain information about the correct handling of the product.

Read the instructions before use to familiarise yourself with operating conditions,

installation and operation.

Follow the safety instructions.

1.1 Symbols used

► Instructions

> Reaction, result

→ Cross-reference

Important note

Non-compliance can result in malfunction or interference.

Information

Supplementary note.

LED off

LED on

LED flashes

LED flashes quickly

2 LEDs flash alternately

Page 5

5

UK

2 Safety instructions

• Follow the operating instructions.

• Improper use may result in malfunctions of the unit. This can lead to personal

injury and/or damage to property during operation of the machine. For this

reason note all remarks on installation and handling given in this document.

Also adhere to the safety instructions for the operation of the whole installation.

• In case of non-observance of notes or standards, especially when tampering

with and/or modifying the unit, any liability and warranty is excluded.

• The unit must be installed, connected and put into operation by a qualified

electrician trained in safety technology.

• The applicable technical standards for the corresponding application must be

complied with.

• For installation the requirements according to EN 60204 must be observed.

• Connect and lay all cables according to EN ISO 13849-2 D.5.2 (Safety of

machinery - Safety-related parts of control systems).

• In case of malfunction of the unit please contact the manufacturer. Tampering

with the unit is not allowed.

• Disconnect the unit externally before handling it. Also disconnect any

independently supplied relay load circuits.

• After installation of the system perform a complete function check.

• Usetheunitonlyinspecifiedenvironmentalconditions(→11Technicaldata).

In case of special operating conditions please contact the manufacturer.

• Useonlyasdescribedbelow(→4Functionsandfeatures).

Page 6

6

3 Items supplied

• 1 safe standstill monitor DA102S including 5 Combicon connectors with screw

terminals

• 1 original operating instructions "Safe standstill monitor" reference no.

80001217.

If one of the above-mentioned components is missing or damaged, please contact

one of the ifm branch offices.

4 Functions and features

The device is a 2-channel pulse evaluation system for the safe detection of

underspeed or standstill of an object.

For evaluation, the device requires 2 pulse pick-ups (pnp-switching sensors

with "normally open" function).

The safe state is when the output contacts (13-14 and 23-24) of the device

are open.

ifm electronic gmbh does not assume any liability for the function and the

interaction of the device with devices from other manufacturers.

Suitability of the device for a certain application cannot be assured and

must be ensured by the user.

The device can be used in applications up to

• PL e according to ISO 13849-1

• SIL 3 according to IEC 61508

• SIL

CL

3 according to EN 62061

Page 7

7

UK

4.1 Requirements for the hardware configuration

The following requirements must be met when using the device:

4.1.1 Product-independent requirements

It must be ensured that the safety requirements of the respective application

correspond to the requirements stated in these instructions.

The specified technical data indicated in these instructions must be complied with.

The principle of normally closed operation must be applied to all external safety

circuits connected to the system.

The following points have to be ensured in the application by taking administrative

measures:

• The devices of type "safe standstill monitor", DA102S, in operation must be

subjected to a self-test (switching on) within a period of maximum 6 months

(intermittent operation).

The self-test starts when the supply voltage is applied.

(→7.2Supplyvoltage)

• The safety-relevant relay contacts have to be protected by respective fuses of

3.6 A as short-circuit/overload protection.

(→7.6Switchingoutputs14-23and24-24)

4.1.2 Product-dependent requirements

In case of faults within the device which result in the defined safe state, the device

must be replaced.

Any faulty unit should be returned to the manufacturer.

Page 8

8

5 Function

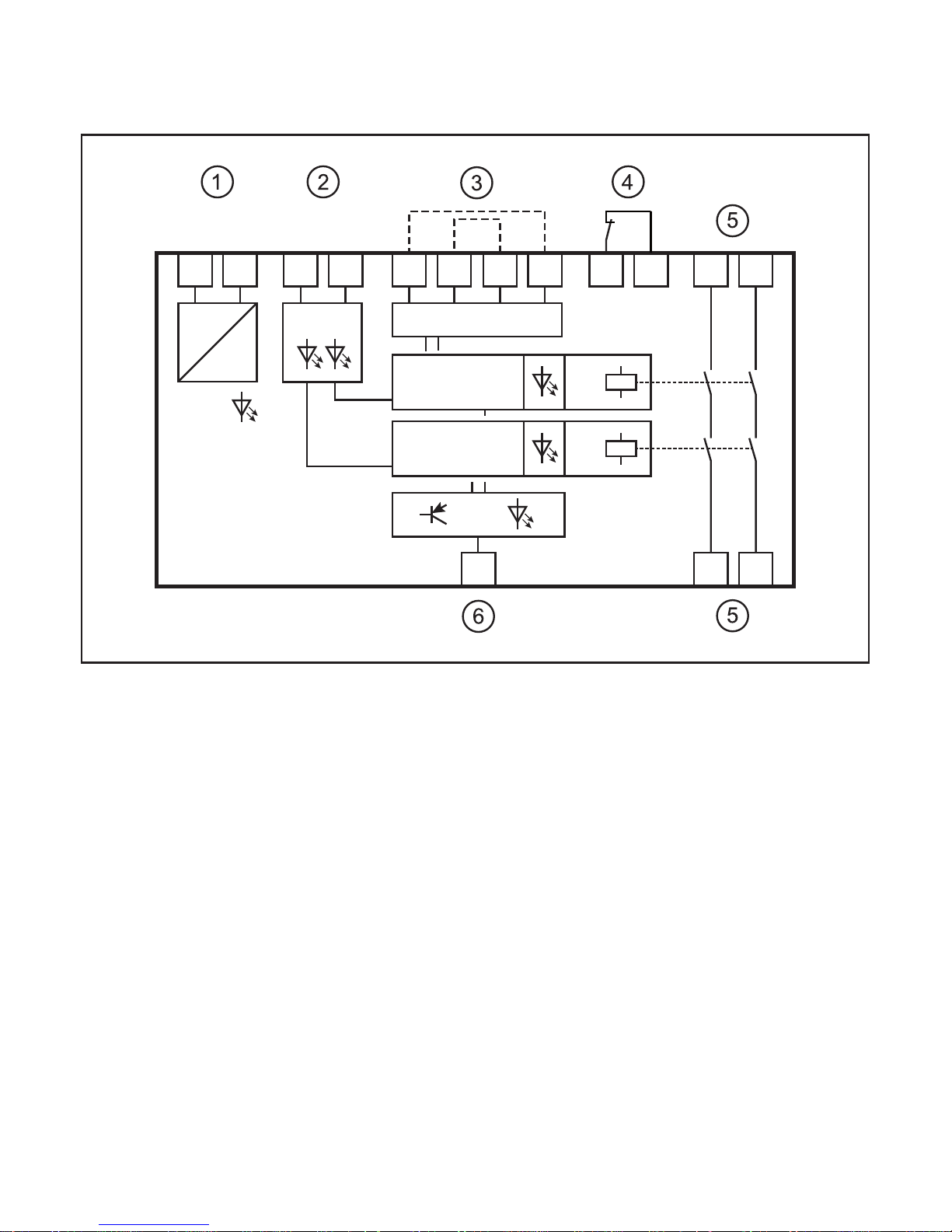

5.1 Block diagram

Y7 14 24

L+ L-

S34 S43

E124 V DC E2

S33

inputs switchpoint

DC

DC

power

controller 1

fault

S44

Y4 Y5 13 23Y4 Y5Y2 Y6

K1

controller 2

K2

1: Supply voltage

2: Inputs

3: Switch point setting (bridging)

4: Feedback contact

5: "Standstill" switching outputs

6: "Fault" transistor output

5.2 Operating principle

The device is a 2-channel pulse evaluation system for the safe detection of

underspeed or standstill. In this respect the device picks up the pulse sequences

of 2 connected pulse pick-ups.

The microprocessors calculate the resulting frequency. The device detects

underspeed as compared to the set switch point by constantly comparing the

frequency of the actual and the preset values.

Page 9

9

UK

5.3 Switching function

In accordance with a "safe standstill message", the output relays are energised

when the switch point is not reached or with standstill.

The output relays K1/K2 switch (are energised) when the set switch point is 5%

below the set level. They switch back (are de-energised) when the set switch point

is exceeded by 5%.

[Hz]

1,00

1,05

0,95

f

− 5 %

+ 5 %

t

Switching function

e.g. switch point setting 1 Hz

1: Switching outputs close

"Standstill" message

2: Switching outputs open

"No standstill" message

5.4 Switch point setting

Via an external circuit the switch point can be selected from 4 preset values (0.2 /

0.5 / 1 / 2 Hz).

(→7.3Switchpointsetting)

5.5 Switching outputs 14-23 and 24-24

Each input channel has an effect on the output relay.

The NO contacts of the output relays K1/K2 are connected in series. The

switching outputs are closed when both output relays have switched.

By means of the switching outputs a door guard locking system can, for example,

be controlled.

Page 10

10

5.6 Y7 transistor output

The Y7 transistor output provides a non-safety related signal for communication to

a PLC.

Status Y7 transistor output

Normal operation (no error) HIGH (ON)

Error LOW (OFF)

The output data is compatible with the input data of the current-sinking inputs of

type 1, 2, 3 to EN 61131-2.

5.7 Pulse pick-ups (sensors)

2 pnp-switching sensors with the "normally open" output function are connected to

the device as pulse pick-ups.

The position of the sensors and the mechanical design of the cams are not

arbitrary since one sensor must always be damped.

(→6.3Arrangementofthedampingcams)

5.8 Sensor monitoring

In order to prevent faulty standstill signalling, the sensors are permanently

monitored during operation of the installation.

5.8.1 Pulse comparison input 1 and 2

By permanently comparing the pulses it is evaluated whether the pulse sequences

of both sensors differ from each other.

If during operation a mechanical or electrical error causes one sensor to fail, there

willbeaninterruptionoftheotherwiseidenticalpulsesequence(f1≠f2).

In accordance with "safe" standstill monitoring this is not considered as

underspeed.

The output relays K1/K2 do not switch, there is an error message.

5.8.2 Mechanical requirements on damping cams and gaps

The arrangement of the mark-to-space ratio of the damping cams and gaps

ensure that at least one sensor is damped all the time.

Therefore the gap between the damping cams must not be of a size that both

sensors face a gap at the same time and are not damped.

Page 11

11

UK

The device monitors continuously if this condition is met.

If this regulation is violated, there is an error and the device goes into the safe

state.

(→6.3Arrangementofthedampingcams)

5.9 Error message

If the device detects an error, the switching outputs are kept in the safe state.

The "Fault" LED is lit and the transistor output Y7 opens ("LOW" status).

Definition "safe state":

• Output relays K1/K2 are de-energised

• Switching outputs 13-14 and 23-24 open

• No standstill message

The error message is reset by interrupting the voltage supply.

5.10 Feedback contact

The device monitors the position of the guard locking by means of a feedback

contact.

• When a movement starts, the output relays K1/K2 are de-energised.

The switching outputs open.

The output LEDs K1/K2 flash when the feedback contact is open.

• If the input frequency is greater than the switch point and the feedback contact

is open, the output LEDs K1/K2 flash.

With resulting standstill and continually open feedback circuit the output relays

K1/K2 are not energised.

The switching outputs remain open.

There is no error message.

Transistor output Y7 remains closed ("HIGH" state).

(→7.5Feedbackcontact)

Page 12

12

6 Installation

6.1 Installation of the device

► Mount the device on a DIN rail in a housing protected against dust and

humidity (min. IP54 - degree of soiling 2).

6.2 Installation of the pulse pick-ups (sensors)

► Mount the pulse pick-ups mechanically separated from each other.

(Not together on a mounting bracket.)

► Lay the cables to the pulse pick-ups separately and protect them against

damage.

6.3 Arrangement of the damping cams

The arrangement of the damping cams and the gaps must ensure that at

leastonesensorisalwaysdamped(→5.8Sensormonitoring).

6.3.1 Example rack

3 x D ≥ 5 x D

3 x D

D

D

Mechanical requirements

Page 13

13

UK

6.3.2 Example cam disc

≥ 5 x D

D

D

3 x D

Mechanical requirements

Page 14

14

7 Electrical connection

► Use 60/75°C copper conductors only.

Do not use unconnected terminals as support point terminal.

7.1 Connections (overview)

A3

A2

A1

C1

C2

S34 S43S33

A3

S44

Y5 Y6Y4A2 Y7

Y2L-A1 L+

13C1 14

23C2 24

Combicon connector

Connector Terminal Connection

A1 L-, L+ Supply voltage (→7.2)

Y2 Switch point setting (bridging) (→7.3)

A2 Y4, Y5 Feedback contact (→7.5)

Y6 Switch point setting (bridging) (→7.3)

Y7 Transistor output (→7.7)

A3 S34, S43 Pulse inputs (→7.4)

S33, S44 Switch point setting (bridging)

Supply voltage sensors

(→7.3)

(→7.4)

C1 13, 14 Switching output 1

(→7.6)

C2 23, 24 Switching output 2

Page 15

15

UK

7.2 Supply voltage

► Connect the supply voltage of the device to terminals L+ and L-.

For safety reasons the unit can only be restarted by separation from the voltage

supply in case of a fault.

It is thus recommended to install a RESET button in series with the L+ circuit.

Y2L-A1 L+

24 V DC

Y2L-A1 L+

24 V DC

RESET

Supply voltage RESET button

The external supply unit must have a safe separation. In case of a fault the

supply voltage can exceed the value of 60 V DC for a maximum of 200 ms,

but must not exceed the value of 120 V DC.

After power on or a RESET the device carries out self diagnostic functions.

This self diagnosis lasts approx. 6 seconds. The unit is then ready for

operation.

7.3 Switch point setting

► Set the requested switch point via a hard-wired bridge on the terminals S33,

S44, Y2 or Y6.

Only change the switch point when disconnected from power.

When switched on, a change of the circuitry will produce an error message

of the device.

Wiring Wiring

0.2 Hz

S33 S44

Y2 Y6

1.0 Hz

S33 S44

Y2 Y6

0.5 Hz

S33 S44

Y2 Y6

2.0 Hz

S33 S44

Y2 Y6

Page 16

16

7.4 Pulse pick-ups (sensors)

► Use pnp-switching sensors with the "normally open” function.

► Connect the supply voltage of the sensors to the terminals S33 and S44.

► Connect the mass of the sensors to the terminals L- and Y4.

E1 E2

Y5 Y6Y4A2 Y7

S34 S43S33

A3 S44

Y2L-A1 L+

24 V DC

24 V DC

L-

L+

L-

L+

1 2

Pulse pick-ups (sensors)

Observe the current consumption of the sensors.

Supply the sensors externally if the current consumption exceeds the

currentratingoftheterminalsS33andS44(→11Technicaldata).

7.5 Feedback contact

► Connect the feedback contact to input A2 (Y4-Y5).

► Observethecharacteristicdataoftheinput(→11Technicaldata).

If the monitoring function is not required, the terminals Y4-Y5 can be

permanently bridged.

Y5 Y6Y4A2 Y7 Y5 Y6Y4A2 Y7

Without monitoring with bridge 1: Feedback contact (normally closed )

Page 17

17

UK

7.6 Switching outputs 14-23 and 24-24

► Connect to load to be controlled to the outputs C1 (13-14) and/or C2 (23-24).

► Observethemaximumandminimumloadconditions(→11Technicaldata).

13C1 14

K13,6 A

L1

L+

N

GND

23C2 24

K23,6 A

L1

L+

N

GND

Switching outputs

7.7 Y7 transistor output

► Connect transistor output Y7 to the signal input of the PLC.

► Observethecharacteristicdataoftheoutput(→11Technicaldata).

Y5 Y6Y4A2 Y7

SPS

Fault

Transistor output

Page 18

18

8 Set-up

The device is ready for operation after application of the supply voltage and the

self-diagnosis.

► After installation and electrical connection, check whether the device operates

safely.

9 Display elements

E1

K1

K2

E2

Power

Fault

Display elements

LED Colour Meaning (normal operation)

E

1 Yellow Input signal channel 1

K

1 Output relay channel 1

E

2 Yellow Input signal channel 2

K

2 Output relay channel 2

Power Green Supply voltage

Fault Red Error

Detailedstatusdescriptionanderrordescription(→9.1LEDindicationsand

switching characteristics)

Page 19

19

UK

9.1 LED indications and switching characteristics

9.1.1 General

Status Power Fault K1, K2 E1, E2 Outputs

13-14, 23-24

Transistor

Y7

Standstill

*) ON HIGH

No standstill

*) OFF HIGH

Feedback contact

open

*) OFF HIGH

Overvoltage/

undervoltage

*) *) *) HIGH

Symbolsused(→1.1)

*) current status

9.1.2 External errors

Status Power Fault K1, K2 E1, E2 Outputs

13-14, 23-24

Transistor

Y7

S33 and S44

Short-circuit against

mass or U

B

OFF LOW

Inputs 1 and 2

simultaneously "0"

OFF LOW

Relay fault, e.g.

contacts welded

because of overload

or life expectancy

reached

OFF LOW

Impermissible pulse

difference between the

inputs(f1≠f2)

OFF LOW

Impermissible switchpoint change during

operation

OFF LOW

Symbolsused(→1.1)

Page 20

20

9.1.3 Internal faults

Status Power Fault K1, K2 E1, E2 Outputs

13-14, 23-24

Transistor

Y7

Device-internal error

OFF LOW

A flash code is output via the "Power" LED.

This flash code enables the manufacturer to analyse the device-internal error.

► If the error message is not reset in spite of the interruption of the supply

voltage,exchangethedevice(→4.1.2Product-dependentrequirements).

10 Maintenance, repair and disposal

If used correctly, no maintenance and repair measures are necessary.

► Observetheproduct-dependentrequirements(→4.1.1).

► Check the safe functioning of the unit after a fault.

Only the manufacturer is allowed to repair the unit.

After use dispose of the unit in an environmentally friendly way in accordance with

the applicable national regulations.

Page 21

21

UK

11 Technical data

Page 22

22

Page 23

23

UK

12 Tests / approvals

The device was tested and certified by TÜV-Nord.

The device was developed and tested in accordance with the following directives

and standards:

• 2006/42/EC Machinery Directive

• 2004/108/EC EMC Directive

• 73/23/EEC or 93/68 Low voltage directive

• ISO 13849-1: 2008 Safety of machines - safety-related parts of control systems

• IEC 61508: 2011 Functional safety of electrical/electronic/programmable

electronic safety-related systems

• EN 60204-1: (1997) (where applicable) Electrical equipment of machines

• UL 508

Page 24

24

13 Terms and abbreviations

Cat. Classification of the safety-related parts of a controller

as regards their resistance to failures.

CCF Common Cause Failure

DC Diagnostic Coverage

MTTF Mean Time to Failure

MTTF

D

Mean Time To Dangerous Failure

PFH

(PFH

D

)

Probability of (dangerous) Failure per Hour

PL Performance Level PL to ISO 13849-1

SIL Safety Integrity Level SIL 1-4 to IEC 61508

PLC Programmable Logic Controller

Loading...

Loading...