Page 1

Installation instructions

Process and dialogue module

PDM360 NG

CR1083

UK

7390910 / 00 12 / 2011

Page 2

PDM360 NG process and dialogue module (CR1083)

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�1 Symbols used� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�2 Warning signs used � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�1 General� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�2 Target group � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�3 Electrical connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�4 Tampering with the device � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�5 Electromagnetic compatibility� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3 Functions and features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Application example � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�2 Overview of the characteristics � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4 Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�1 Mounting accessory � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�2 General installation instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�2�1 Locator for mounting accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�2�2 Orientation of the device with panel and surface mounting � � � � � � � 9

4�2�3 Light sensor � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

4�3 Panel mounting using the mounting frame� � � � � � � � � � � � � � � � � � � � � � � � 10

4�3�1 Mounting steps� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

4�4 Surface mounting with RAM

4�4�1 Mounting steps� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

®

mount system � � � � � � � � � � � � � � � � � � � � � � 13

5 Electrical connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

5�1 Connection accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

5�2 General electrical connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

5�2�1 Cover all unused connectors � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

5�3 Operating voltage � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

5�4 Ground connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

5�5 Ethernet interface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

5�5�1 Ethernet cameras� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

5�6 USB interfaces � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

5�6�1 USB connection via M12 connector� � � � � � � � � � � � � � � � � � � � � � � � � 16

5�6�2 Short-circuit protection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

5�6�3 USB connection behind the service cover � � � � � � � � � � � � � � � � � � � � 17

6 Set-up � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

6�1 General� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

6�2 First steps� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

6�3 Set-up� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

6�4 Required documentation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

7 Technical data� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

2

Page 3

PDM360 NG process and dialogue module (CR1083)

8 Maintenance, repair and disposal� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

8�1 Battery change � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

8�2 Cleaning the display surface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

8�3 Cleaning the housing surface� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

8�4 Repair� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

8�5 Disposal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

9 Approvals / standards � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

UK

This document is the original instructions�

Licences and trademarks

Microsoft

All trademarks and company names are subject to the copyright of the respective companies�

®

, Windows®, Windows XP® and Windows Vista® are registered trademarks of Microsoft Corporation�

3

Page 4

PDM360 NG process and dialogue module (CR1083)

1 Preliminary note

This document applies to devices of the type "PDM360 NG"� These instructions

are part of the device�

This document is intended for specialists� These specialists are people who are

qualified by their appropriate training and their experience to see risks and to

avoid possible hazards that may be caused during operation or maintenance of

the device� The document contains information about the correct handling of the

device�

Read this document before use to familiarise yourself with operating conditions,

installation and operation� Keep this document during the entire duration of use of

the device�

Adhere to the safety instructions�

1.1 Symbols used

► Instructions

> Reaction, result

[…] Designation of pushbuttons, buttons or indications

→ Cross-reference

Important note

Non-compliance can result in malfunction or interference�

Information

Supplementary note

1.2 Warning signs used

WARNING

Warning of serious personal injury�

Death or serious irreversible injuries may result�

CAUTION

Warning of personal injury�

Slight reversible injuries may result�

NOTE

Warning of damage to property�

4

Page 5

PDM360 NG process and dialogue module (CR1083)

2 Safety instructions

2.1 General

These instructions contain texts and figures concerning the correct handling of the

device and must be read before installation or use�

Observe the operating instructions� Non-observance of the instructions, operation

which is not in accordance with use as prescribed below, wrong installation or

incorrect handling can seriously affect the safety of operators and machinery�

2.2 Target group

These instructions are intended for authorised persons according to the EMC and

low-voltage directives� The device must only be installed, connected and put into

operation by a qualified electrician�

2.3 Electrical connection

Disconnect the unit externally before handling it� If necessary, also disconnect any

independently supplied output load circuits�

If the device is not supplied by the mobile on-board system (12/24 V battery

operation), it must be ensured that the external voltage is generated and supplied

according to the criteria for safety extra-low voltage (SELV) as this voltage is

supplied without further measures to the connected controller, the sensors and the

actuators�

The wiring of all signals in connection with the SELV circuit of the device must also

comply with the SELV criteria (safety extra-low voltage, safe electrical isolation

from other electric circuits)�

If the supplied SELV voltage is externally grounded (SELV becomes PELV), the

responsibility lies with the user and the respective national installation regulations

must be complied with� All statements in this document refer to the device the

SELV voltage of which is not grounded�

UK

The connections may only be supplied with the signals indicated in the technical

data and/or on the device label and only the approved accessories of ifm

electronic gmbh may be connected�

2.4 Tampering with the device

In case of malfunctions or uncertainties please contact the manufacturer�

Tampering with the device can seriously affect the safety of operators and

machinery� It is not permitted and leads to the exclusion of any liability and

warranty claims�

2.5 Electromagnetic compatibility

This is a class A product� It can cause radio interference in domestic areas� In this

case the operator may be requested to take appropriate measures�

5

Page 6

PDM360 NG process and dialogue module (CR1083)

3 Functions and features

The PDM360 NG process and dialogue module is a programmable graphic display

for controlling, parameter-setting and operation of mobile machines and plants�

Communication with other system components, e�g� decentralised I/O modules, is

handled via a CAN interface using the CANopen protocol�

For service purposes, additional interfaces such as Ethernet and USB are

available� Together with the Linux operating system they form a universal platform

for networking and communication with other CAN devices, networks or PCs�

WARNING

The PDM360 NG process and dialogue module is not approved for safetyrelated tasks in the sense of the safety of persons�

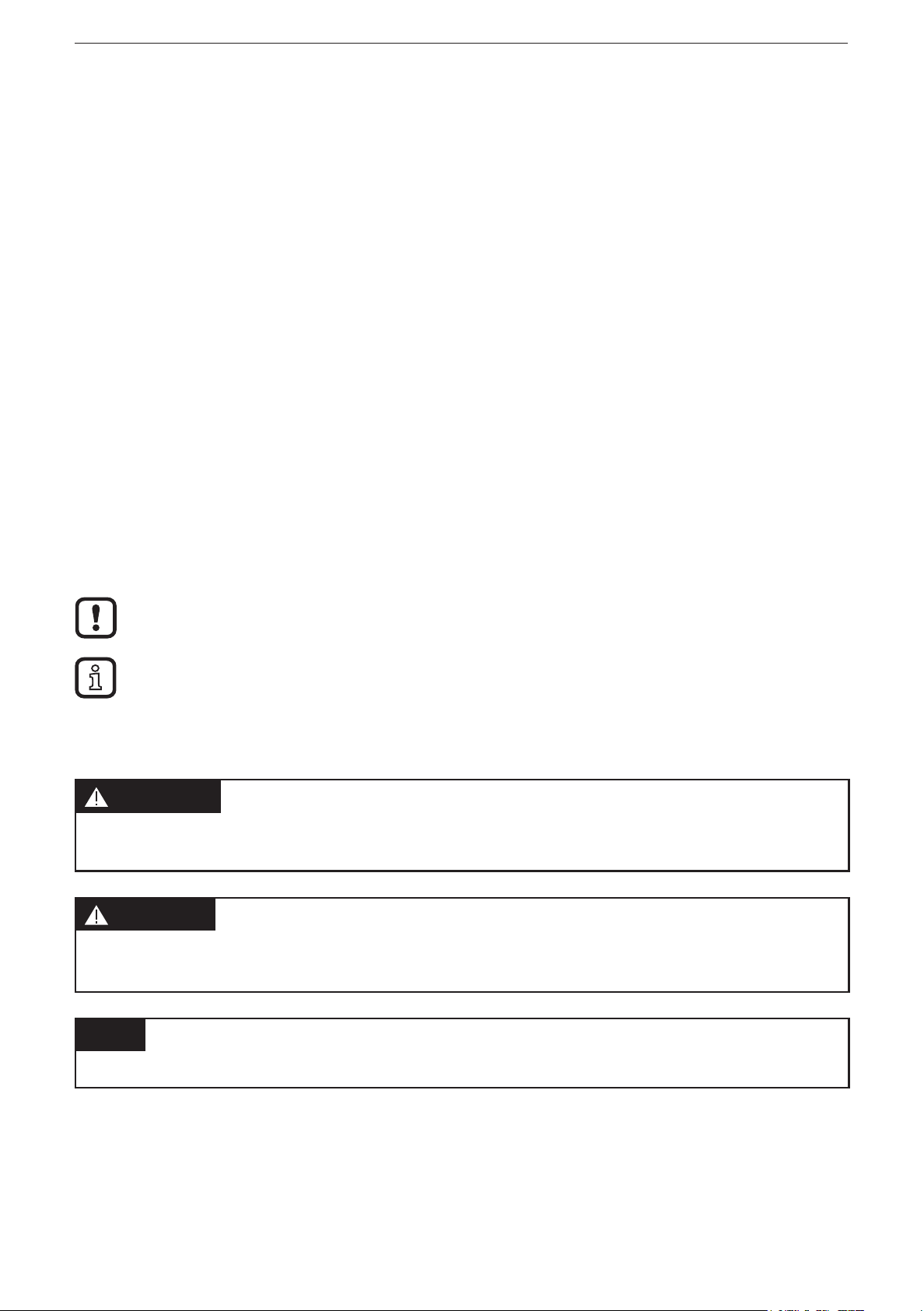

3.1 Application example

Networking of 4 Ethernet cameras with a PDM360 NG

1� PDM360 NG (CR1083)

2� Ethernet switch (e�g� EC2095)

3� Ethernet cameras (e�g� 4 x O2M11x)

6

Page 7

PDM360 NG process and dialogue module (CR1083)

3.2 Overview of the characteristics

● 7" Colour display

● Programmable backlit function keys

● Closed metal housing suitable for panel mounting and surface mounting

outside or in the cabin

● Freely programmable to IEC 61131-3 with target visualisation

● 32-bit controller and Embedded Linux operating system

● CAN interface with CANopen and SAE J 1939 protocol�

● Ethernet and USB interfaces

● Multi-function input (digital/analogue)

● Switching output (digital)

● Analogue video input

UK

7

Page 8

PDM360 NG process and dialogue module (CR1083)

4 Installation

4.1 Mounting accessory

The unit is supplied without mounting accessories�

Depending on the intended location and type of mounting the following mounting

accessories are available:

● EC2110, mounting frame for panel mounting incl� mounting material and seal

● EC1410��EC1414, RAM

You can find more information about the available accessories at:

www.ifm.com → data sheet search → CR1083 → Accessories

4.2 General installation instructions

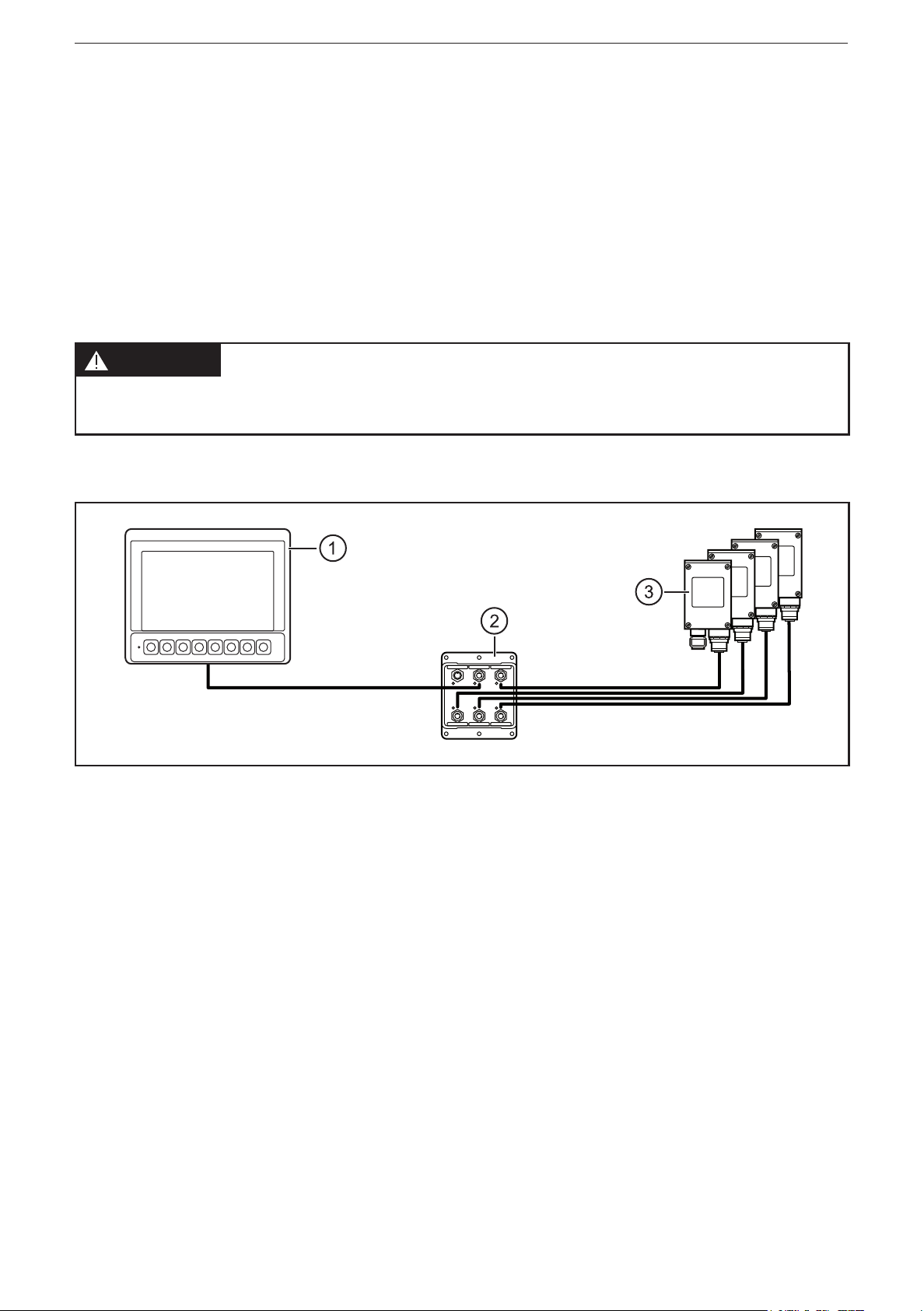

4.2.1 Locator for mounting accessories

The back of the unit has been prepared for fixing the mounting accessories�

®

mount system for surface mounting

38,1

30

M5

Locator for mounting accessories

(back of the unit)

1: type label

2: pressure compensation element

3: ventilation duct

Usable M5 thread depth: ≤ 8 mm

The hole dimensions correspond to the RAM® mount mounting plate (→ 4.4).

ACHTUNG

A pressure compensation element is located under the type label� Use of elastic

materials to seal or close the associated ventilation duct may cause damage to

the device�

► Do not use sealing materials in the ventilation duct area�

8

Page 9

PDM360 NG process and dialogue module (CR1083)

4.2.2 Orientation of the device with panel and surface mounting

Horizontal orientation for panel and surface

mounting

UK

4.2.3 Light sensor

The device is equipped with a light sensor� It is used for automatic brightness

adaptation of the display and the operating elements to the ambient brightness�

1: Light sensor

► Do not cover up the light sensor by construction measures�

9

Page 10

PDM360 NG process and dialogue module (CR1083)

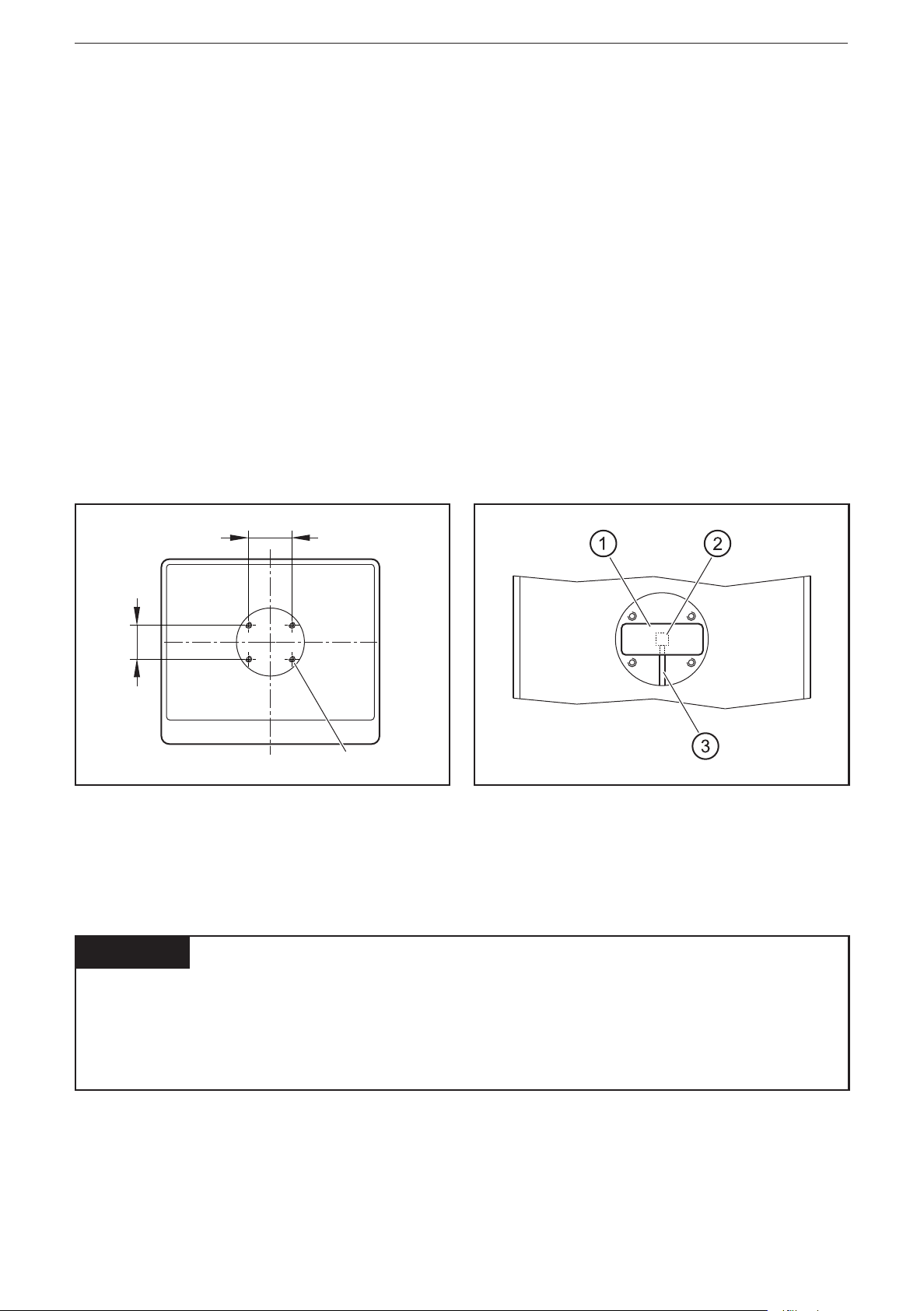

4.3 Panel mounting using the mounting frame

The mounting frame ensures horizontal, vertical or up-side down mounting of the

device in a panel cutout�

This type of mounting is suited for materials with a thickness from 1 to 10 mm�

The M5 hexagon nuts, washers, M5 set screws and a seal are supplied with the

device�

Mounting frame Dialogue module with mounted mounting frame

Only insert the mounting frame together with the seal�

10

Page 11

4.3.1 Mounting steps

PDM360 NG process and dialogue module (CR1083)

UK

A

Mounting principle

1: mounting frame with M5 hexagon nuts (self-

locking) and washers

2: panel cutout

3: dialogue module with attached seal and screwed

set screws

Installation depth A: approx� 60���65 mm

(depending on the panel thickness and the length of

the set screws, without connector)

► Make a cut-out�

Cutout for panel mounting (→ 7 Technical data)

► Attaching the seal to the unit�

Procedure:

– Remove 2 protective films from the seal (1 continuous, narrow strip and the

lower, long side)�

The protective films of the two short sides and the protective film of the

upper, long side remain on the seal�

– Place the seal onto the device from the back and attach it�

– Remove protruding sides of the seal�

1� adhesive area

2� protective films remaining on the seal

Place the seal onto the device

11

Page 12

PDM360 NG process and dialogue module (CR1083)

Attached seal Removed sides

► Screw the set screws into the M5 thread on the back of the device�

(→ 4.2.1 Locator for mounting accessories)

Select the set screws in accordance with the panel thickness�

Panel thickness Set screws

1��� 5 mm M5 x 25

> 5���10 mm M5 x 30

► Insert the device into the cutout�

► Screw the mounting frame to the back of the device�

Tightening torque of the M5 hexagon nuts: 5

±0�5

Nm

12

Page 13

PDM360 NG process and dialogue module (CR1083)

4.4 Surface mounting with RAM® mount system

Using the RAM® mount components, available as accessories, the dialogue

unit can be used as a firmly mounted desktop unit� Two balls allow a variable

orientation of the unit�

UK

RAM® mount components

1: mounting arm with fastening screw

2: mounting plate with ball

Dialogue module with mounted RAM® mount

system

4.4.1 Mounting steps

► Screw the mounting plate onto an even surface�

38 (1,5")

56

6

62

38,1

30

5,3

Mounting plate with ball Hole dimensions

Tightening torque: 5

±0�5

(Nm

► Screw the second mounting plate to the back of the device�

► Slightly loosen the fastening screw of the mounting arm�

► Place the mounting arm onto the balls and tighten the fastening screw�

You can find more information about the available RAM

®

mount components at:

www.ifm.com → data sheet search → CR1083 → Accessories

13

Page 14

PDM360 NG process and dialogue module (CR1083)

5 Electrical connection

5.1 Connection accessories

You can find more information about the available accessories at:

www.ifm.com → data sheet search → CR1083 → Accessories

or

www.ifm.com → Products → Accessories → Connection technology

5.2 General electrical connection

Wiring of the M12 connectors (→ 7 Technical data)

1: Supply, input/output

2: CAN1

3: USB

4: Ethernet

5: N/A

6: N/A

7: Analogue video input

8: N/A

M12 connector (back of the unit)

NOTE

Wrong connection may cause damage to the device�

► Observe the safety instructions�

► Basically all supply and signal cables must be laid separately�

► Lay supply and signal cables away from the device using the shortest possible

route�

► All connected cables must be provided with a strain relief�

5.2.1 Cover all unused connectors

NOTE

Moisture penetrating through unused or unprotected connectors may destroy the

device�

► Cover unused connectors with protective caps�

14

Page 15

PDM360 NG process and dialogue module (CR1083)

5.3 Operating voltage

► To protect the device use fuses for the operating voltages�

Description Potential Connector 1 Fuse

Operating voltage

clamp 30

Operating voltage

clamp5

10…30 V DC

positive directly from the battery

10…30 V DC

connected positive from the ignition-starter

switch

pin 1 max� 5 A

pin 5 max� 5 A

5.4 Ground connection

► To ensure the protection of the device against electrical interference, the

housing must be connected to GND (e�g� to the ground of the vehicle)�

► Ensure a well-conductive connection�

5.5 Ethernet interface

► Use a shielded CAT5 cable�

STP, Shielded Twisted Pair, according to EIA/TIA-568�

Max� length 25 m

The max� cable length depends for example on the bus topology, the

selected operating mode (10/100 Mbits/s) or the quality of the connectors�

UK

► Use screened connector housings and connect the screen of the Ethernet

cable to the connector housing�

► Do not lay the Ethernet cable in parallel to live cables�

Interference due to external influences

Faulty or insufficient radio interference suppressors in other electrical

equipment, such as inverters or generators, as well as voltage fluctuations

when switching on/off electric loads may lead to problems with the data

transmission�

5.5.1 Ethernet cameras

The device supports ifm Ethernet cameras (e�g� O2M110) firmware 5�1001 or

higher�

Networking example (→ 3.1 Application example)

15

Page 16

PDM360 NG process and dialogue module (CR1083)

5.6 USB interfaces

The USB interfaces are used for the temporary connection of an external

keyboard, a mouse or a USB memory stick�

They are not intended for actual operation�

► Remove the USB devices after their use�

5.6.1 USB connection via M12 connector

Wiring (→ 7 Technical data)

This USB interface is connected to a USB connector in the control panel or in the

dashboard�

It is used for the temporary connection of operating devices (USB mouse /

keyboard) and storage media (e�g� USB memory stick)�

≤ 3 m

USB connection via M12 connector

1: Dialogue module

2: USB connector, for example in the control panel or in the dashboard

3: USB keyboard, mouse or memory stick

Permanent connection: Dialogue module – USB connector

► Use prewired cable�

(e�g� art� no� EC2099, M12 connector, B-coded on USB socket, type A,

watertight, cable length 1�5 m, wires twisted and screened)

► Use only cables with twisted and screened wires for individual wiring�

Keep length "A" as short as possible and position the USB connector in

immediate vicinity to the dialogue module� The length "A" considerably

influences the quality of the USB data transmission�

Temporary connection: USB connector – USB device

► Use a connection cable with the designation "Full Speed/High Speed"

(= USB connection cable with twisted and screened cores)�

► Do not make a connection using several USB connection cables�

► Remove connection cable after the programming or service works�

16

Page 17

PDM360 NG process and dialogue module (CR1083)

5.6.2 Short-circuit protection

NOTE

The USB interface (M12 connector) is not protected against short circuits with a

live wire outside the following voltage ranges:

–data 0�3���3�6 V DC (3: pin 2)

+data 0�3���3�6 V DC (3: pin 3)

ID 0�3���3�6 V DC (3: pin 4)

A short circuit will destruct the USB interface�

5.6.3 USB connection behind the service cover

► Remove the service cover on the back of the unit�

(2 M3 socket head screws)

► Connect the USB keyboard, mouse or memory stick with the USB interface�

► Remove the USB devices after their use and close the service cover again�

UK

1: service cover

2: USB socket, type A

17

Page 18

PDM360 NG process and dialogue module (CR1083)

6 Set-up

6.1 General

As delivered the device is prepared for programming with CoDeSys version 2�3 or

higher�

Factory setting:

IP address: 192�168�82�247

Subnet mask: 255�255�255�0

The user is responsible for the safe function of the application programs

which he created himself� If necessary, he must additionally have an

approval test carry out by corresponding supervisory and test organisations

according to the national regulations�

6.2 First steps

► Connect the device to the notebook/PC via the Ethernet interface�

► Switch on the notebook/PC; check the IP settings of the notebook/PC and

change them if necessary�

Internet protocol: TCP/IP:

IP address: 192�168�82�xxx (except for �247, s�a�)

Subnet mask: 255�255�255�0

Gateway IP address: 192�168�100�1

► Switch on the operating voltage of the dialogue module�

> Shortly after switch-on of the unit the start image is shown for approx� 10 to 15

seconds�

During this time booting is running in the background�

After booting the set-up program opens automatically�

6.3 Set-up

The set-up allows the setting of the device parameters�

The menu items are selected using the function keys or via a connected USB

keyboard�

Function keys USB keyboard Description

SELECT TAB select menu item

SAVE F3 save entries

UP arrow up increase value or variable

DOWN arrow down decrease value or variable

ENTER ENTER open selected menu item

EXIT ESC leave set-up

leave menu item

entries will not be saved

18

Page 19

PDM360 NG process and dialogue module (CR1083)

After leaving the set-up a project can be loaded�

Libraries (�lib) are available for the use of the operating elements, interfaces

and other internal functions of the device� They have to be integrated into the

application program�

6.4 Required documentation

In addition to the CoDeSys programming system, the following documents are

required for programming and set-up of the device:

● Programming manual CoDeSys V2�3

(alternatively as online help)

● PDM360 NG system manual

(alternatively as online help)

The manuals can be downloaded from the internet:

www.ifm.com → data sheet search → CR1083 → Additional data

CoDeSys and PDM360 NG online help:

www.ifm.com → Service → Download → Control systems*

*) Download area with registration

UK

19

Page 20

PDM360 NG process and dialogue module (CR1083)

Control systems

7 Technical data

CR1083

192

153,4

746,6

Process and dialogue module

PDM360 NG

7" colour display

8 freely programmable

backlit

function keys

92,5

157

analogue video input

1 input / 1 output

10...32 V DC

LED

Technical data Programmable graphic display for controlling, parameter-setting and

operation of mobile machines and plants

Display

Display TFT LCD colour display, trans ective

Format 15:9 (wide VGA), 153.4 x 92.4 mm, 7" diagonal

Resolution 800 x 480 pixels

Alignment horizontal

Surface glass, anti-re ective (coating) based on the principle of optical interference

Colours 262.144 (18 bits)

Background illumination LED (lifetime ≥ 20,000 h, typically 30,000 h)

Brightness ≥ 350 cd/m², typically 400 cd/m²

(adjustable 0...100%, increments 1%)

Contrast ratio ≥ 250:1, typically 400:1

Character sets can be uploaded individually and is freely scalable

preinstalled: ifm ISO fonts with vehicle-speci c symbols, Arial, Courier, Arphic Ukai

(Arphic Ukai has to be again installed manually if the device is reset to the factory

setting)

55

Mechanical data

Mounting variants panel mounting with mounting frame

Dimensions (W x H x D) 192 x 157 x 64,5 mm

Cutout for panel mounting (W x H) 183 ± 0.5 x 136 ± 0.5 mm

Housing material die-cast aluminium housing, powder coating (RAL 9005)

Pushbuttons 8 function keys (silicone keyboard) with tactile feedback

Encoder / Rocker switch – / –

Background illumination operating

elements

Protection rating IP 67 (with mounted connectors and/or protective caps)

Operating temperature -30...65° C

Storage temperature -30...80° C

Weight approx. 1.5 kg

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 07.12.2011CR1083 / page 1

surface mounting with RAM

(mounting accessories not included)

freely programmable (softkey function)

lifetime ≥ 1,000,000 activations

LED (brightness adjustable 0...100%, individual control)

®

mount system

20

Page 21

PDM360 NG process and dialogue module (CR1083)

Control systems

CR1083 Technical data

Electrical data

Operating voltage 10...32 V DC

Overvoltage detection

at U

Overvoltage shutdown

> 34 V (hysteresis 1 V, i.e. switching on again at UB < 33 V)

B

Undervoltage detection

Undervoltage shutdown

at U

< 8 V (hysteresis 1 V, i.e. switching on again at UB > 9 V)

B

Current consumption 300 mA (without external load at 24 V DC)

Short-circuit / reverse polarity protection electronic

Processor MPC5121, 32 bits, 400 MHz

Total memory 128-Mbyte RAM / 128-Mbyte ash

Memory allocation see system manual PDM360 NG

Interfaces

CAN 1 CAN interface 2.0 A/B, ISO 11898

50 Kbits/s...1 Mbit/s (default 125 Kbits/s)

CANopen, CiA DS 301 version 4, CiA DS 401 version 1.4

or SAE J 1939 or free protocol (Raw CAN)

Ethernet transmission rate 10/100 Mbits/s

USB 2 x USB 2.0 full speed, transmission rate up to 12 Mbit/s

USB master operation (service and maintenance connection for keyboard, mouse etc.)

Analogue video input 2 FBAS inputs, 1 Vss, 75 ohms (inputs selectable)

supported video standards: PAL and NTSC

cable length: ≤ 30 m

Input con gurable

digital for positive / negative sensor signals

analogue 0...10, 0...32 V, 0...20 mA, ratiometric

Output digital, positive switching (high side)

at U

at U

> 32 V

B

< 10 V

B

UK

Characteristics of the input Resolution 8 bits

Accuracy ± 3 % FS

Current input 0...20 mA Input resistance 390 Ω

Input frequency 10 Hz

Voltage input 0...10 V Input resistance 65.6 kΩ

Input frequency 10 Hz

Voltage input 0...32 V Input resistance 50.7 kΩ

Input frequency 10 Hz

Voltage input ratiometric Input resistance 50.7 kΩ

Input frequency 10 Hz

Digital input Input resistance 3.2 kΩ

Input frequency 10 Hz

Switch-on level > 0.7 U

Switch-off level < 0.3 U

B

B

Characteristics of the output Switching voltage 10...32 V DC

Switching current ≤ 1 A

Free-wheeling diodes integrated

Software/programming

Operating system Embedded Linux 2.6

Programming system CoDeSys version 2.3 (IEC 61131-3)

Graphic functions via integrated target visualisation

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 07.12.2011CR1083 / page 2

21

Page 22

PDM360 NG process and dialogue module (CR1083)

Control systems

CR1083 Technical data

Other features

Acoustic signal output –

Temperature monitoring 2 integrated sensors for measuring the temperature inside the housing

Brightness adaptation light sensor in the front of the device to adapt the brightness of the display and the

Clock real-time clock (RTC), battery buffered

Battery CR2032 (3 V, 230 mAh)

Status LED RGB LED (colours and states programmable by means of the application software)

Operating states (preset)

Colour Status Description

– permanently off no operating voltage

green 5 Hz boot process application

2 Hz application running (RUN) or set-up running

permanently on application has stopped (STOP) or no project

red 2 Hz application is running with an error (RUN with

permanently on system error (fatal error), device is in reset

red/orange 2 Hz colour

change

orange 5 Hz boot process system recovery/update

2 Hz system recovery/update running

brie y on System reset

operating elements

available

error)

(e.g. internal voltage error)

overtemperature/undertemperature, device is

in reset until temperature in normal range

Test standards and regulations

CE marking EN 61000-6-2: 2005 Electromagnetic compatibility (EMC)

EN 61000-6-4: 2007 Electromagnetic compatibility (EMC)

EN 61010-1: 2001 Safety requirements for electrical equipment for

Electrical tests ISO 7637-2: 2004 Pulse 1, severity level: IV; function state C

Climatic tests EN 60068-2-30: 2006 Damp heat, cyclic

EN 60068-2-78: 2002 Damp heat, constant

EN 60068-2-52: 1996 Salt spray test

Mechanical tests ISO 16750-3: 2007 Test VII; Vibration, random

EN 60068-2-6: 2008 Vibration, sinusoidal

ISO 16750-3: 2007 Bumps

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 07.12.2011CR1083 / page 3

Noise immunity

Emission standard

measurement, control and laboratory use

Pulse 2a, severity level: IV; function state A

Pulse 2b, severity level: IV; function state C

Pulse 3a, severity level: IV; function state A

Pulse 3b, severity level: IV; function state A

Pulse 4, severity level: IV; function state A

Pulse 5, severity level: III; function state C

data valid for the 24 V system

upper temperature 55°C, number of cycles: 6

test temperature 40°C / 93% RH,

test duration: 21 days

severity level 3 (motor vehicle)

mounting location: vehicle body

10...500 Hz; 0.72 mm/10 g; 10 cycles/axis

30 r/6 ms; 24,000 shocks

22

Page 23

PDM360 NG process and dialogue module (CR1083)

Control systems

CR1083 Technical data

Back of the unit

M12 connector

Wiring

13

24

1: Service cover for USB connection, battery and watchdog reset

2: Locator for RAM

3: M12 connector (fig. shows max. number of connectors)

®

mount system and mounting frame

68

57

1 2, 5, 6, 7, 8 3 4

Connector

A-coded, 5 poles

Socket

A-coded, 5 poles

12

5

3

4

Socket

B-coded, 5 poles

12

3

4

(1) Supply, input/output (2) CAN1

1

2

3

4

5

10...32 V DC (clamp 30)

IN

GND (clamp 31)

OUT

10...32 V DC (clamp 15)

1

2

3

4

5

Shield

VBB

CAN1_GND

CAN1_H

CAN1_L

UK

Socket

D-coded, 4 poles

C

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

(3) USB (4) Ethernet

1

2

3

4

5

+5 V DC

-Data

+Data

ID

GND

1

2

3

4

TxD+

RxD+

TxDRxDHousing = screen

(5) N/A (6) N/A

1

2

3

4

5

1

2

3

4

5

(7) Analogue video input (8) N/A

1

2

3

4

5

We reserve the right to make technical alterations without prior notice! 07.12.2011CR1083 / page 4

Shield

GND

GND

FBAS1 (video1)

FBAS2 (video2)

1

2

3

4

5

23

Page 24

PDM360 NG process and dialogue module (CR1083)

8 Maintenance, repair and disposal

8.1 Battery change

1: service cover

2: socket head screws

1: battery cover

2: indentation for opening

3: battery case

► Remove the service cover on the back of the unit�

(2 M3 socket head screws)

► Open the battery compartment using a pointed object (e�g� a screwdriver)�

► Remove the battery and replace it with a new one�

Observe the polarity: Positive side up (see also marking on the cover)

Battery type (→ 7 Technical data)

Disposal of used batteries (→ 8.5 Disposal)

8.2 Cleaning the display surface

Unsuitable cleaning agents and chemicals can damage the display surface�

The following agents are not suited for cleaning the display:

● chemicals dissolving plastics such as methylated spirit, benzine, thinner,

alcohol, acetone or ammonia�

● paper towels, crepe paper etc�

● abrasive cleaners

● polish or wax

► Clean the device from dirt using a soft, chemically untreated and dry cloth�

► In case of heavy dirt, use a damp cloth�

Micro-fibre cloths without chemical additives are recommended�

24

Page 25

PDM360 NG process and dialogue module (CR1083)

8.3 Cleaning the housing surface

► Disconnect the device�

► Clean the device from dirt using a soft, chemically untreated and dry cloth�

► In case of heavy dirt, use a damp cloth�

8.4 Repair

► The device must only be repaired by the manufacturer�

Observe the safety instructions (→ 2.4 Tampering with the device)

8.5 Disposal

► Do not dispose of used batteries with household waste�

Dispose of used batteries in accordance with the national environmental

regulations�

► Dispose of the device in accordance with the national environmental

regulations�

9 Approvals / standards

Test standards and regulations (→ 7 Technical data)

The EC declaration of conformity and approvals can be found at:

www.ifm.com → data sheet search → CR1083 → Approvals

UK

25

Loading...

Loading...