Page 1

Mounting and installation

instructions

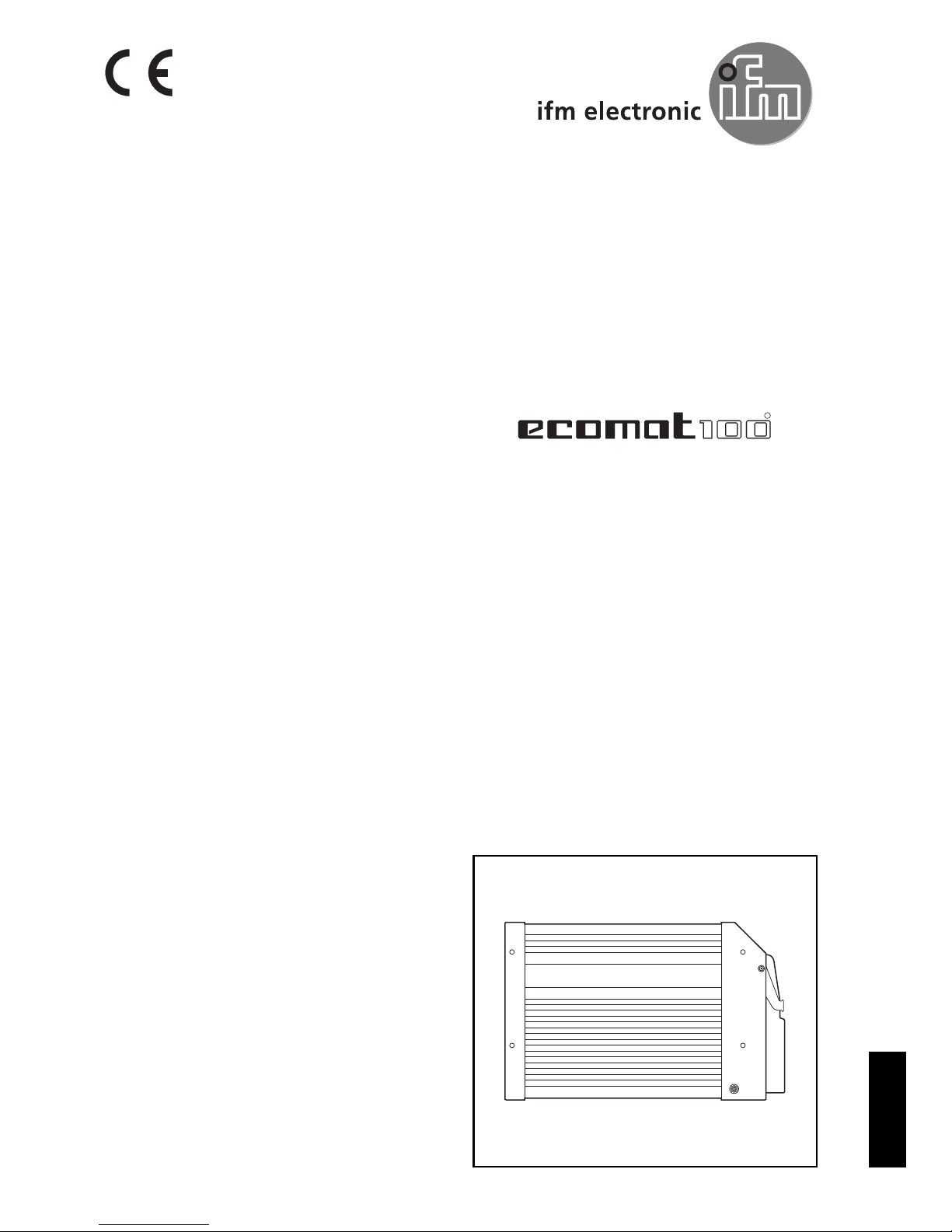

ClassicController R 360

CR0505

ENGLISH

R

7390428 / 02 09 / 2015

Page 2

CLASSICCONTROLLER CR0505

PAGE 2

Safety instructions

This description is part of the unit. It contains texts and drawings

concerning the correct handling of the controller and must be

read before installation or use.

Observe the information of the description. Non-observance of the notes,

operation which is not in accordance with use as prescribed below, wrong

installation or handling can result in serious harm concerning the safety of

persons and plant.

The instructions are for authorised persons according to the EMC and low

voltage guidelines. The controllers must be installed and commissioned by a

skilled electrician (programmer or service technician).

If the unit is not supplied by the mobile on-board system (12/24 V battery

operation) it must be ensured that the external voltage is generated and

supplied according to the criteria for safety extra-low voltage (SELV) as this is

supplied without further measures to the connected controller, the sensors,

and the actuators.

The wiring of all signals in connection with the SELV circuit of the unit must

also comply with the SELV criteria (safe extra-low voltage, safe electrical

separation from other electric circuits).

If the supplied SELV voltage has an external connection to ground (SELV

becomes PELV) the responsibility lies with the user and the respective national

regulations for installation must be complied with. All statements in these

operating instructions refer to the unit the SELV voltage of which is not

grounded.

The terminals may only be supplied with the signals indicated in the technical

data or on the unit label and only the approved accessories of ifm electronic

gmbh may be connected.

The unit can be operated within a wide temperature range according to the

technical specification indicated below. Due to the additional self-heating the

housing walls can have high perceptible temperatures when touched in hot

environments.

In case of malfunctions or uncertainties please contact the manufacturer.

Tampering with the unit can lead to considerable risks for the safety of

persons and plant. It is not permitted and leads to the exclusion of any

liability and warranty claims.

Page 3

Contents

1. Function and features page 3

2. Programming page 3

3. Mounting page 4

4. Electrical connection page 4

5. Maintenance, repair and disposal page 7

6. Approvals/standards page 7

Technical data (data sheets 1...5)

Dimensions, mechanics, electronics page 8

Operating status (status LED) page 9

Test standards and regulations page 9

Characteristics of the inputs/outputs page 10

Wiring page 12

1. Function and features12

The freely programmable controllers of the "ClassicController R 360" series are

rated for use under difficult conditions (e.g. extended temperature range, strong

vibration, intensive EMC interference).

They are thus suited for direct mounting into machines in mobile and rugged

applications. Due to their specification the inputs and outputs are especially rated

for this use. Integrated hardware and software functions (operating system) offer

high protection of the machine.

The controllers can be used as CANopen master.

The controllers "ClassicController R 360" are not approved for safetyrelevant tasks in the field of safety of persons.

2. Programming

The application software can be easily created by the user with the ifm

programming system CODESYS according to IEC 61131-3.

In addition to the programming system the complete system manual is required

to program the controller.

If this manual is not available, please contact one of the ifm branch offices

overleaf for your free copy. The system manual (pdf format) can also be

downloaded from the web (www.ifm.com).

➔ System manual R 360; English (order no. EC2041)

➔ Data sheet direct ➔ CR0505 ➔ Additional data

The user is responsible for the safe functioning of the application programs

which he creates himself. If necessary, he must additionally obtain an

approval according to the corresponding national regulations by the

corresponding testing and supervisory organisations.

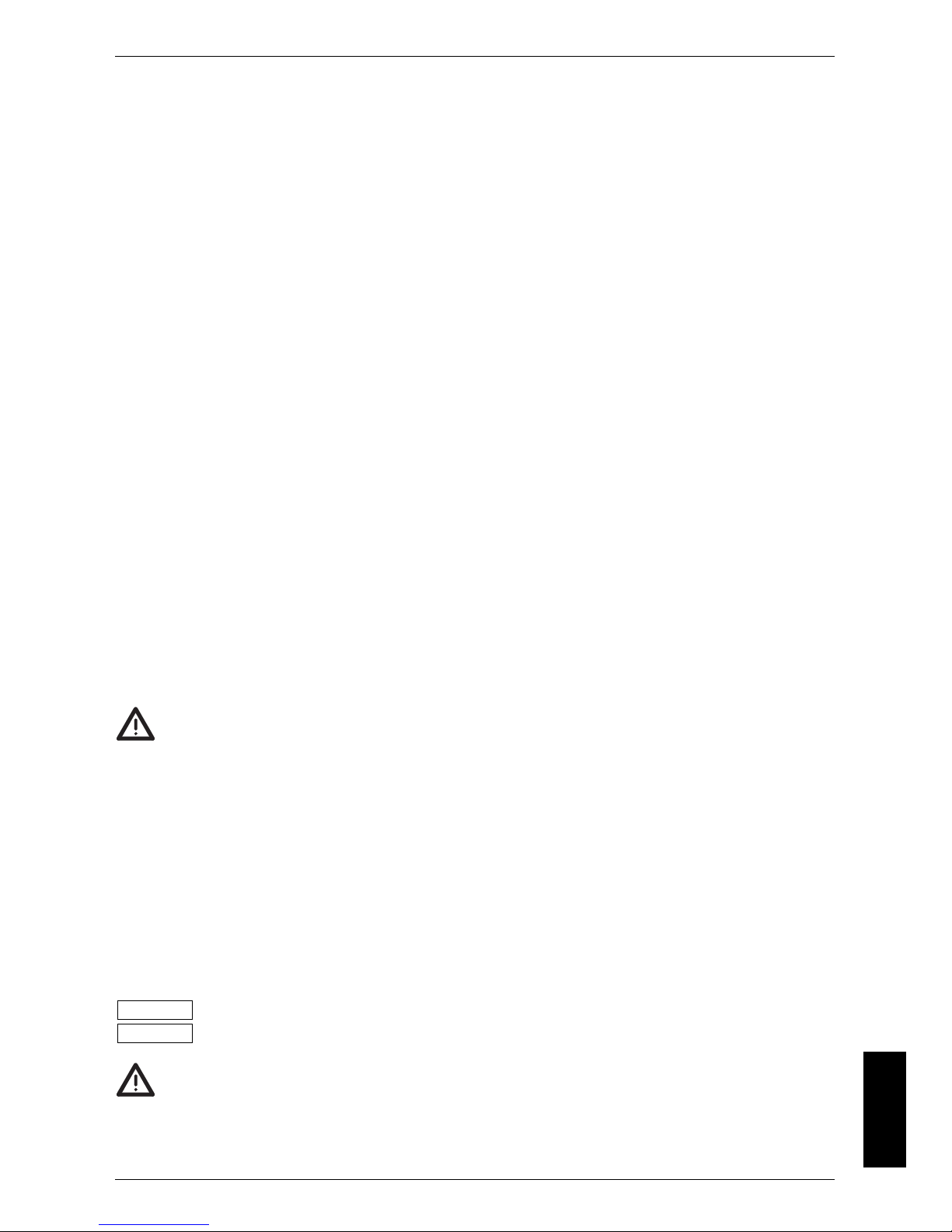

Internet

Request

ENGLISH

CLASSICCONTROLLER CR0505

PAGE 3

Page 4

3. Installation

3.1 Fastening

Fix the controller to a flat surface using 4 M5 screws.

Tightening torque: 8±2Nm

Use screws with a low head to avoid that the connector is damaged when placed

and locked..

3.2 Installation position

Align the controller in such a way that the cable entry of the connector faces

downwards.

CLASSICCONTROLLER CR0505

PAGE 4

Screws to be used (examples) Standard

Button head hexagon socket screws (M5 x L) ISO 7380

Cylinder screws with hexagon socket and low head (M5 x L) DIN 7984

Cutting screws for metric ISO thread with low head DIN 7500

Screw material: steel or stainless steel

Example button head

hexagon socket screw

Page 5

3.3 Mounting surface

The housing must not be exposed to any torsional forces or mechanical

stress.

Use compensating elements if there is no flat mounting surface available.

3.4 Heat dissipation

Ensure sufficient heat dissipation as the internal heating of the electronics is

conducted away via the housing..

In case of sandwich mounting of controllers use spacers.

ENGLISH

CLASSICCONTROLLER CR0505

PAGE 5

Page 6

CLASSICCONTROLLER CR0505

PAGE 6

4. Electrical connection

4.1 Wiring

Wiring see technical data.

Only connect the connector pins as shown in the pin layout.

Unspecified connector pins remain unconnected..

Connect all supply cables and GND terminals.

4.2 Ground connection

To ensure the protection of the device against electrical interference and the safe function of the device, the housing must be connected to the ground of the vehicle.

1: Drill hole for ground connection

Establish a connection between the device and the ground of the vehicle using

M5 screws. Screws to be used ( ¨ 4.1 Fastening)

4.3 Fuses

The individual electric circuits must be protected in order to protect the whole

system.

4.4 Interaction between the inputs and outputs within one group of

connections

In the applications the following must be observed as regards the use of the terminals as input and

output:

Within one output group inputs and outputs should not be mixed. One output

group is marked by a common VBBXpotential.

The background is a possible internal cross-connection of the outputs from the

externally supplied inputs. This may occur unexpectedly if the supply to the outputs is switched off externally. Should a mixture still be carried out for reasons of

optimising the terminals, please inform yourself in detail about the situations

described in the system manual and the restrictions resulting from this. Follow

these instructions for your application and keep records of this.

Designation Potential Pin no. Fuse

supply voltage sensors/module VBB

S

23 max. 2 A T

supply voltage outputs VBB

O

05 max. 15 A

supply voltage via relais VBB

R

34 max. 15 A

Page 7

4.5 Laying the supply and signal leads

As a basic principle all supply and signal leads to be laid separately.

Supply and ground leads to the controller and to the sensors / actuators to

be connected via a common neutral point.

Linking connections in the connector is not permitted and can lead to an

incapacitation of men and machines.

5. Maintenance, repair and disposal

As the Controller does not contain any components which must be maintained

by the user, the housing must not be opened. The repair of the controller may

only be carried out by the manufacturer. The disposal must be carried out according to the corresponding national environmental regulations.

6. Approvals/standards

The EC declaration of conformity and approvals can be found at:

www.ifm.com ➔ Data sheet search ➔ CR0505 ➔ More information

ENGLISH

CLASSICCONTROLLER CR0505

PAGE 7

supply

output

nn

output

nn

output

nn

controller

VBB

O

05

VBB

S

23

VBB

R

34

GND

S

01

GND

A

12

GND

O

15

input

nn

input

nn

input

nn

sensor

sensor

sensor

load

load

load

GND

S

01

GND

A

12

GND

O

15

= not permissible

Page 8

CLASSICCONTROLLER CR0505

PAGE 8

*) only positive sensor signals

with diagnostic capability

226

5,5

26

80

15

45°

153

LED

43

200,5

±1

±0,5

±1

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

18.09.2015

CR0505

Mobile controller

ClassicController

2nd CAN interface

for gateway function

according to SAE J 1939

Programming

according to IEC 61131-3

Operating voltage

10...32 V DC

We reserve the right to make technical alterations without prior notice. CR0505 / page 1

Technical data Controller as black box system

for the implementation of a central or decentralised system design

Housing closed, screened metal housing with flange fastening

Dimensions (H x W x D) 153 x 226 x 43 mm

Mounting screw connection by means of 4 M5xL screws according to DIN 7500 or DIN 7984

mounting position horizontal or vertical to the mounting wall

Connection 55-pin connector, latched, protected against reverse polarity, type AMP or Framatome

AMP junior timer contacts, crimp connection 0.5/2.5 mm²

Weight 1.2 kg

Housing / storage temperature – 40...85 °C (depending on the load) / – 40...85 °C

Protection IP 67 (for inserted plug with individually sealed cores e.g. EC2084)

Input/output channels max. 24 (the total number which is available depends

total on the wiring and configuration of the controller)

Inputs max. 24 (corr. to 0 outputs)

possible configurations

Outputs max. 8 (corr. to 16 inputs)

possible configurations

Number Signal Version

8 digital for positive sensor signals, with diagnostic capability B

L

or

analogue 0...10/32 V DC, 0/4...20 mA or ratiometric A

8 digital for positive sensor signals B

L

4 digital for positive sensor signals, with diagnostic capability B

L

or

frequency max. 50 kHz I

L

4 digital for positive/negative sensor signals, with diagnostic capability

*

B

L/H

or

frequency max. 1 kHz I

L

Number Signal Version

8 digital positive switching (High Side), with diagnostic capability B

H

or

PWM PWM frequency 20...250 Hz PWM

or

current-controlled 0,1...4 A PWM

I

Abbreviations

A = analogue

B

H

= binary High Side

B

L

= binary Low Side

FRQ/CYL = frequency inputs

I

H

= pulse High Side

I

L

= pulse Low Side

PWM = pulse width modulation

PWM

I

= current-controlled output

%IWx = IEC address for analogue input

%IX0.xx = IEC address for binary input

%QX0.xx = IEC address for binary output

Page 9

ENGLISH

CLASSICCONTROLLER CR0505

PAGE 9

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

18.09.2015We reserve the right to make technical alterations without prior notice. CR0505 / page 2

CR0505 Technical data

Operating voltage U

B

10...32 V DC

overvoltage 36 V for t ≤ 10 s

undervoltage detection for U

B

≤ 10 V

switching-off in case of undervoltage for UB≤ 8 V

Current consumption ≤ 160 mA (without external load at 24 V DC)

CAN interface 1 CAN interface 2.0 B, ISO 11898

Baud rate 50 kbits/s...1 Mbits/s (default setting 125 kbits/s)

Communication profile CANopen, CiA DS 301 version 4, CiA DS 401 version 1.4

Node-ID (CANopen) hex 7F (= dec. 127)

CAN interface 2 CAN interface 2.0 A/B, ISO 11898

Baud rate 50 kbits/s...1 Mbit/s (default setting 125 kbits/s)

Communication profile SAE J 1939 or free protocol

Serial interface RS-232 C

Baud rate 9.6 / 19.2 / 28.8 / 38.4 / 57.6 kBit/s (default setting 57.6 kbits/s)

Topology point-to-point (max. 2 participants); master-slave connection

Protocol predefined ifm protocol (INTELHEX)

Processor CMOS microcontroller 16 bits C167CS

cycle frequency 20/40 MHz

Device monitoring undervoltage monitoring

watchdog function

check sum test for program and system

excess temperature monitoring

Process monitoring concept Two relays according to EN 954

monitor two groups of 4 outputs each

Physical memory Flash: 2 MByte

RAM: 256 kByte

Remanent memory: 32 kByte

Memory allocation See system manual

www.ifm.com → Data sheet search → CR0505 → More information

Status indication three-colour LED (R/G/B)

Operating states (Status-LED)

Test standards and regulations

Climatic test Damp heat to EN 60068-2-30, test Db

(≤ 95% rel. humidity, non-condensing)

Salt mist test to EN 60068-2-52, test Kb, severity level 3

Degree of protection to EN 60529

Mechanical resistance Vibration to EN 60068-2-6, test Fc

Shock to EN 60068-2-27, test Ea

Immunity to conducted interference to ISO 7637-2, pulses 2, 3a, 3b, severity level 4, function state A

to ISO 7637-2, pulse 5, severity level 1, function state A

to ISO 7637-2, pulse 1, severity level 4, function state C

Immunity to interfering fields according to UN/ECE-R10 at 100 V/m (E1 type approval)

and EN 61000-6-2 (CE)

Interference emission according to UN/ECE-R10 (E1 type approval)

and EN 61000-6-3 (CE)

Tests for the approval to BN 411 002 (DIN EN 50155 clause 10.2)

for railway applications

LED colour Status Description

– off no operating voltage

yellow 1 x on initialisation or reset checks

green 5 Hz no operating system loaded

green 2.0 Hz Run

on Stop

red 2.0 Hz Run with error

on fatal error or stop with error

Page 10

CLASSICCONTROLLER CR0505

PAGE 10

CR0505 Characteristics of the inputs

Digital/analogue inputs (B

L

, A) ■ Voltage inputs

%IW03...10 input voltage 0...10/32 V

%IX0.00...07 resolution 12 bits

can be configured as ... precision ± 1.0% FS

input resistance 50/30 kΩ

input frequency 50 Hz

■ Current inputs

input current 0/4...20 mA

resolution 12 bits

precision ± 1.0% FS

input resistance 400 Ω

input frequency 50 Hz

■ Digital inputs for positive sensor signals, with diagnostic capability *)

switch-on level 0.7 U

B

switch-off level 0.4 U

B

input resistance 30 kΩ

input frequency 50 Hz

Digital inputs (B

L

) ■ Digital inputs for positive sensor signals

%IX0.08...11 switch-on level 0.43...0.73 U

B

%IX1.00...03 switch-off level 0.29 U

B

can be configured as ... input resistance 3.21 kΩ

input frequency 50 Hz

Digital inputs (B

L

, IL) ■ Digital inputs for positive sensor signals, with diagnostic capability *)

%IX0.12...15 switch-on level 0.7 U

B

can be configured as ... switch-off level 0.4 U

B

input resistance 2.86 kΩ

input frequency 50 Hz

■ Frequency inputs for positive sensor signals

with diagnostic capability, evaluation with integrated comparator

switch-on level 0.43...0.73 U

B

switch-off level 0.29 U

B

input resistance 2.86 kΩ

input frequency max. 50 kHz

Digital inputs (B

L/H

, IL) ■ Digital inputs for positive/negative sensor signals, positive with diagnostic capability

*

%IX1.04...07 switch-on level 0.7 U

B

can be configured as ... switch-off level 0.4 U

B

input resistance 3.21 kΩ

input frequency 50 Hz

■ Frequency inputs for positive sensor signals

with diagnostic capability, evaluation with integrated comparator

switch-on level 0.43...0.73 U

B

switch-off level 0.29 U

B

input resistance 3.21 kΩ

input frequency max. 1 kHz

Test input During the test mode (e.g. programming) the "TEST" connection must be connected

to VBB

S

(10...32 V DC).

For the "RUN" mode the test input must not be connected.

input resistance 3.21 kΩ

*)NAMUR inputs ■ Digital inputs with diagnostic capability can be used as NAMUR inputs when used

with an external resistor connection.

supply voltage 5...25 V; e.g. ifm NAMUR sensors NT5001...NN5002

wiring see page 5

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

18.09.2015We reserve the right to make technical alterations without prior notice. CR0505 / page 3

Page 11

ENGLISH

CLASSICCONTROLLER CR0505

PAGE 11

CR0505 Characteristics of the outputs

Outputs (B

H

, PWM, PWMI) ■ Semiconductor outputs, with diagnostic capability

%QX0.00...07 positive switching (high side), short-circuit and overload protected

can be configured as ... switching voltage 10...32 V DC

switching current max. 4 A

output frequency max. 100 Hz (depending on the load)

■ PWM outputs, diagnosis via current feedback

PWM frequency max. 250 Hz

mark-to-space ratio 1...99 %

resolution depends on the PWM frequency

load current max. 4 A

integrated pull-down resistor (4.7 kΩ) to trigger valves (Danfoss type PVH)

■ Current-controlled outputs, diagnosis via current feedback

load current 0,1...4 A

load resistance min. 3 Ω (at U

B

= 12 V DC)

min. 6 Ω (at U

B

= 24 V DC)

setting resolution 1 mA

control resolution 5 mA

accuracy ± 2% FS

Overload protection max. 5 minutes (at 100%)

(valid for all outputs)

Internal relay outputs Normally open contacts in series to 2 groups of 4 semiconductor outputs.

for electrically isolated Sustained forcing by means of hardware and additional controlling

deactivation of the outputs by means of user program.

The relays must always be switched without load!

total current max. 12 A per group

switching current 0.1...15 A

overload current 20 A

number of operating cycles

≥ 106(without load)

switching-time constant

≤ 3 ms

Output Error ■ Semiconductor output, positive switching (high side)

switching voltage 10...32 V DC

switching current max. 100 mA

overload current 0.5 A

switching function OFF (0 V) in case of an error

wiring see page 5

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

18.09.2015We reserve the right to make technical alterations without prior notice. CR0505 / page 4

Abbreviations

A = analogue

B

H

= binary High Side

B

L

= binary Low Side

FRQ/CYL = frequency inputs

I

H

= pulse High Side

I

L

= pulse Low Side

PWM = pulse width modulation

PWM

I

= current-controlled output

%IWx = IEC address for analogue input

%IX0.xx = IEC address for binary input

%QX0.xx = IEC address for binary output

Page 12

CLASSICCONTROLLER CR0505

PAGE 12

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

18.09.2015We reserve the right to make technical alterations without prior notice. CR0505 / page 5

ANSCHLUSSBELEGUNG / wiring / branchement

Pin Potential Bezeichnung / description Bemerkung / note

23 VBBS(10...32 V DC) Versorgung Sensoren und Modul / supply sensors and module

05 VBBO(10...32 V DC) Versorgung Ausgänge / supply outputs relaisgeschaltet / relay switched (1)

34 VBBR(10...32 V DC) Versorgung über Relais / supply via relay relaisgeschaltet / relay switched (2)

01 GND

S

Masse Sensoren und Modul / ground sensors and module

15 GND

O

Masse Ausgänge / ground outputs

12 GND

A

Masse Analogeingänge / ground analogue outputs

CAN, RS-232, ERROR, TEST

Pin Potential Bezeichnung / description Bemerkung / note

14 CAN 1

H

CAN-Interface 1 (High)

32 CAN 1

L

CAN-Interface 1 (Low)

26 CAN 2

H

CAN-Interface 2 (High) SAE J 1939

25 CAN 2

L

CAN-Interface 2 (Low) SAE J 1939

33 GND Masse / ground (RS-232/CAN)

06 RxD RS-232 Interface (Programmierung / programming) Pin 03, PC D-Sub (9 pin)

07 TxD RS-232 Interface (Programmierung / programming) Pin 02, PC D-Sub (9 pin)

13 ERROR Fehlerausgang BH / error output B

H

24 TEST TEST-Eingang / test input

EIN-/AUSGÄNGE / inputs/outputs / entrées/sorties

Pin EINGÄNGE Konfiguration AUSGÄNGE Konfiguration diagnosefähig

*

relaisgeschaltet

pin INPUTS configuration OUTPUTS configuration diagnostic capability*relay switched

INPUT / OUTPUT

08 %IX0.00 / %IW03 BLA–– • / –

27 %IX0.01 / %IW04 BLA–– • / –

09 %IX0.02 / %IW05 BLA–– • / –

28 %IX0.03 / %IW06 BLA–– • / –

10 %IX0.04 / %IW07 BLA–– • / –

29 %IX0.05 / %IW08 BLA–– • / –

11 %IX0.06 / %IW09 BLA–– • / –

30 %IX0.07 / %IW10 BLA–– • / –

44 %IX0.08 B

L

%QX0.00 BHPWM PWM

I

– / • VBBO(1)

45 %IX0.09 B

L

%QX0.01 BHPWM PWM

I

– / • VBBO(1)

46 %IX0.10 B

L

%QX0.02 BHPWM PWM

I

– / • VBBO(1)

47 %IX0.11 B

L

%QX0.03 BHPWM PWM

I

– / • VBBO(1)

20 %IX0.12 BLIL(FRQ 0) – – • / –

02 %IX0.13 BLIL(FRQ 1) – – • / –

21 %IX0.14 BLIL(FRQ 2) – – • / –

38 %IX0.15 BLIL(FRQ 3) – – • / –

36 %IX1.00 B

L

%QX0.04 BHPWM PWM

I

– / • VBBR(2)

54 %IX1.01 B

L

%QX0.05 BHPWM PWM

I

– / • VBBR(2)

17 %IX1.02 B

L

%QX0.06 BHPWM PWM

I

– / • VBBR(2)

53 %IX1.03 B

L

%QX0.07 BHPWM PWM

I

– / • VBBR(2)

19 %IX1.04 B

L/HIL

(CYL 0) – – • / –

55 %IX1.05 B

L/HIL

(CYL 1) – – • / –

18 %IX1.06 B

L/HIL

(CYL 2) – – • / –

37 %IX1.07 B

L/HIL

(CYL 3) – – • / –

Note the double pin connection of inputs/outputs. *) only positive sensor signals with diagnostic capability

Loading...

Loading...