Page 1

Original Programming Manual

BasicController

CR0403

Runtime system v03.02

CODESYS® v2.3

English

7391000_04_UK 2015-04-01

1

Page 2

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Contents

Contents

1 About this manual 4

1.1 Copyright .............................................................................................................................. 4

1.2 Overview: documentation modules for ecomatmobile devices ............................................ 5

1.3 CODESYS programming manual ........................................................................................ 5

1.4 What do the symbols and formats mean? ........................................................................... 6

1.5 How is this documentation structured? ................................................................................ 7

1.6 History of the instructions (CR040n) .................................................................................. 8

2 Safety instructions 9

2.1 Please note! ......................................................................................................................... 9

2.2 What previous knowledge is required? ..............................................................................10

2.3 Start-up behaviour of the controller....................................................................................10

3 System description 11

3.1 Information about the device ..............................................................................................11

3.2 Hardware description .........................................................................................................11

3.2.1 Hardware setup .......................................................................................................................... 12

3.2.2 Inputs (technology) ..................................................................................................................... 13

3.2.3 Outputs (technology) .................................................................................................................. 18

3.2.4 Note on wiring ............................................................................................................................ 25

3.2.5 Safety instructions about Reed relays ........................................................................................ 25

3.2.6 Status LED ................................................................................................................................. 26

3.3 Interface description ...........................................................................................................27

3.3.1 CAN interfaces ........................................................................................................................... 27

3.4 Software description ..........................................................................................................28

3.4.1 Software modules for the device ................................................................................................ 28

3.4.2 Programming notes for CODESYS projects ............................................................................... 31

3.4.3 Operating states ......................................................................................................................... 35

3.4.4 Performance limits of the device ................................................................................................ 37

4 Configurations 39

4.1 Set up the runtime system .................................................................................................39

4.1.1 Reinstall the runtime system ...................................................................................................... 40

4.1.2 Update the runtime system ......................................................................................................... 41

4.1.3 Verify the installation .................................................................................................................. 41

4.2 Set up the programming system ........................................................................................42

4.2.1 Set up the programming system manually ................................................................................. 42

4.2.2 Set up the programming system via templates ........................................................................... 46

4.3 Function configuration in general .......................................................................................46

4.3.1 System variables ........................................................................................................................ 46

4.4 Function configuration of the inputs and outputs ...............................................................47

4.4.1 Configure inputs ......................................................................................................................... 48

4.4.2 Configure outputs ....................................................................................................................... 53

4.5 Variables ............................................................................................................................56

4.5.1 Retain variables .......................................................................................................................... 56

4.5.2 Network variables ....................................................................................................................... 57

5 ifm function elements 58

5.1 ifm libraries for the device CR0403 ....................................................................................58

5.1.1 Library ifm_CR0403_V03yyzz.LIB .............................................................................................. 59

5.1.2 Library ifm_RAWCan_NT_Vxxyyzz.LIB...................................................................................... 60

5.1.3 Library ifm_CANopen_NT_Vxxyyzz.LIB ..................................................................................... 61

5.1.4 Library ifm_J1939_NT_Vxxyyzz.LIB ........................................................................................... 63

2

Page 3

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Contents

5.2 ifm function elements for the device CR0403 ....................................................................64

5.2.1 Function element outputs ........................................................................................................... 65

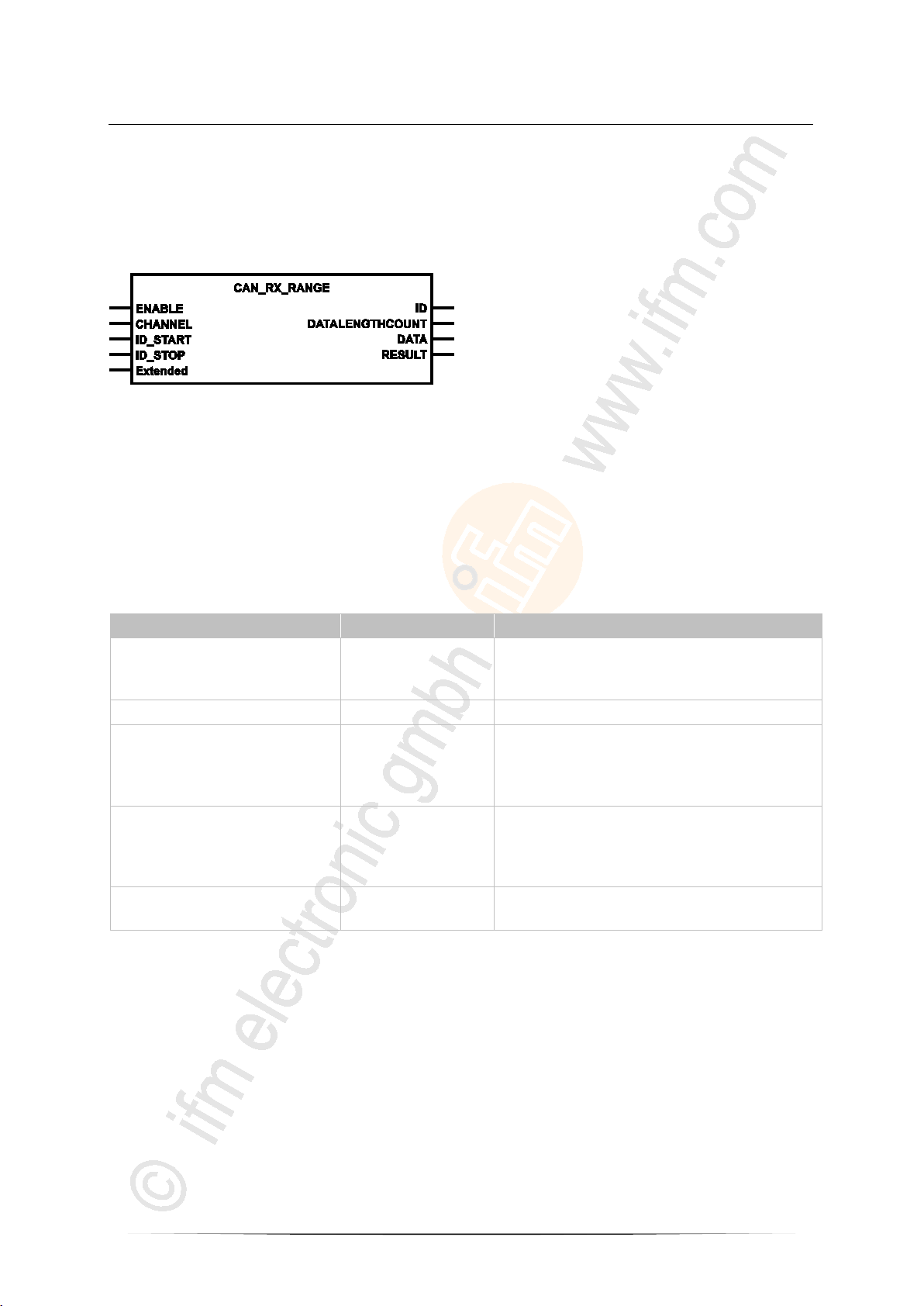

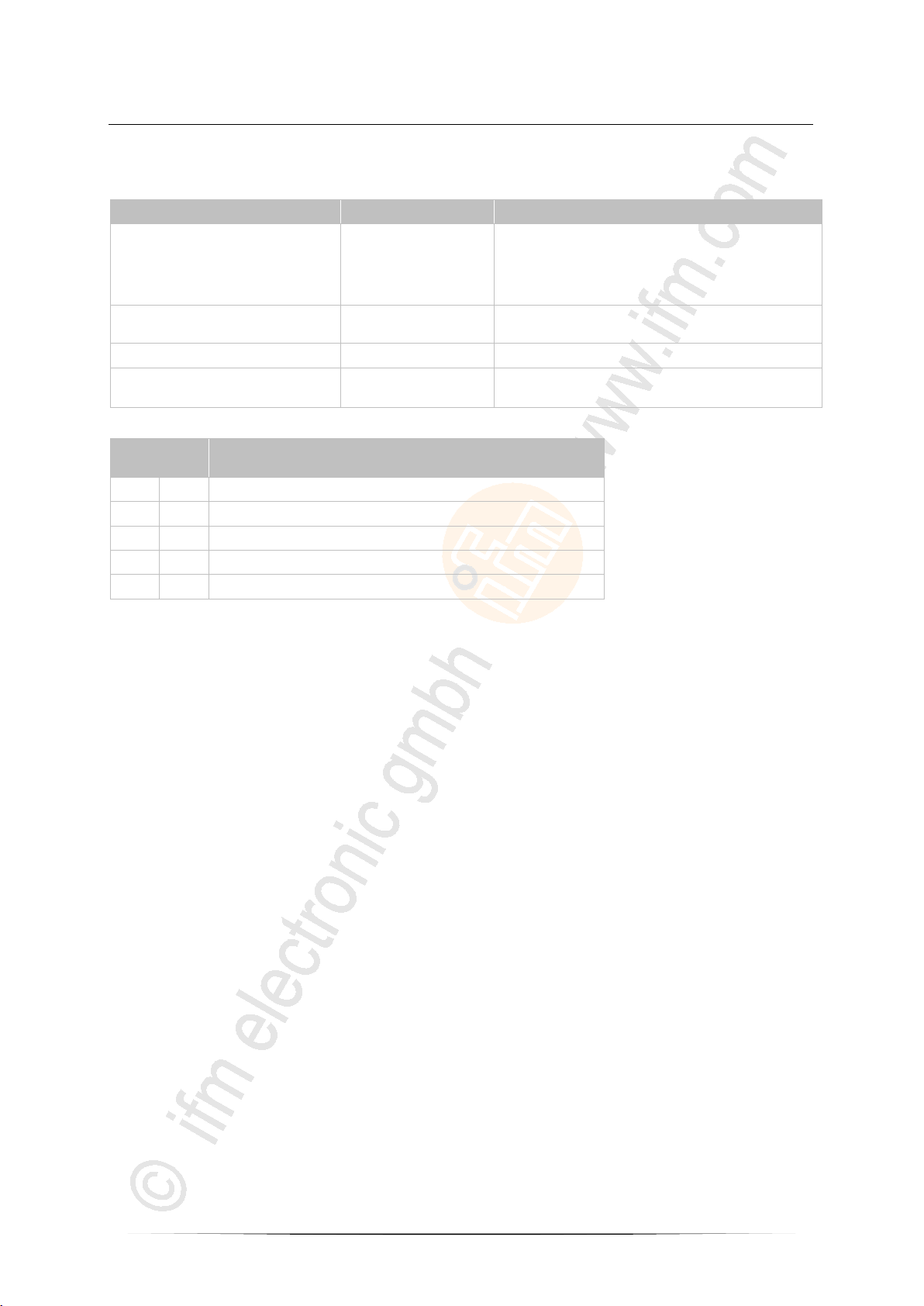

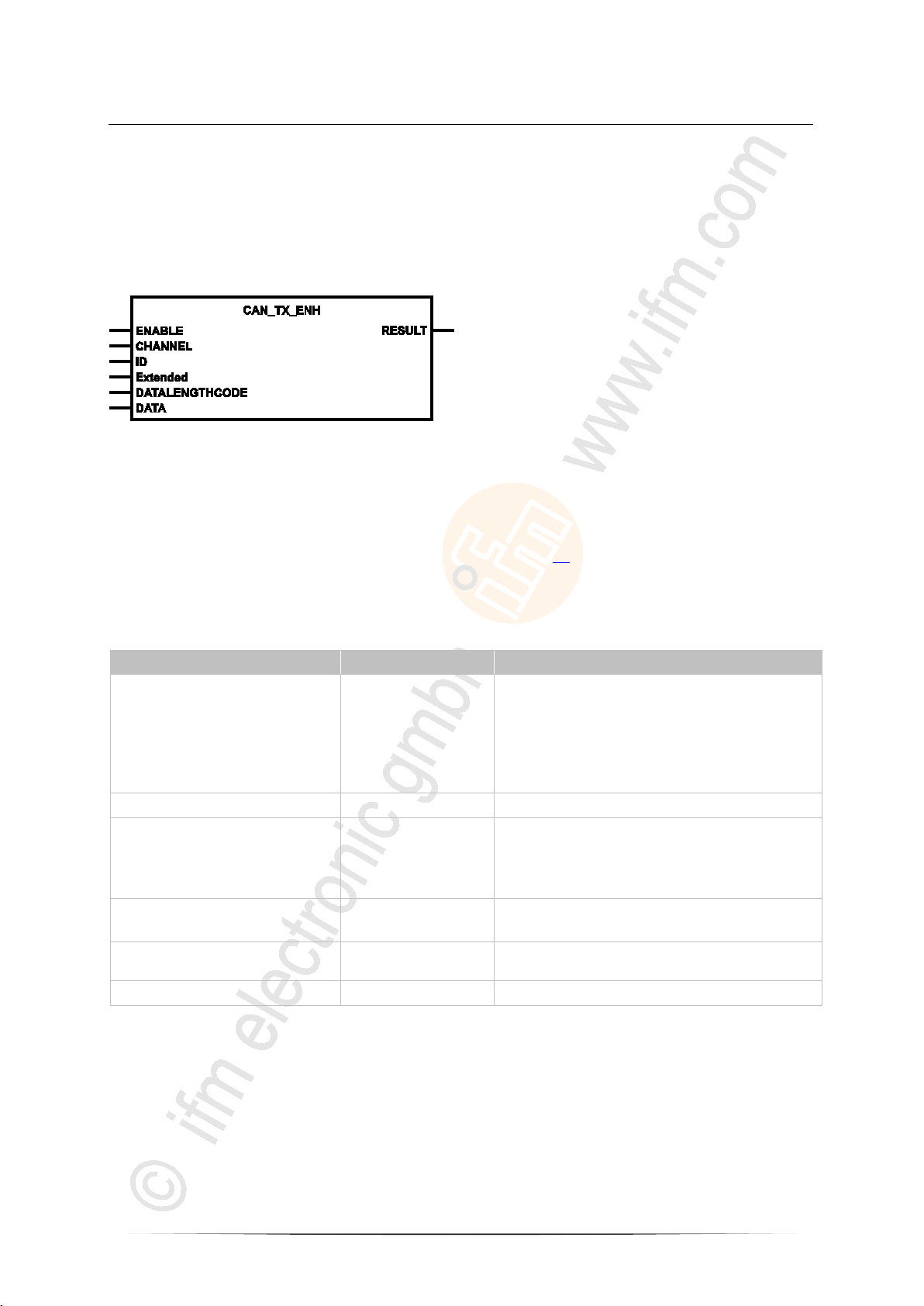

5.2.2 Function elements: RAW-CAN (Layer 2) .................................................................................... 66

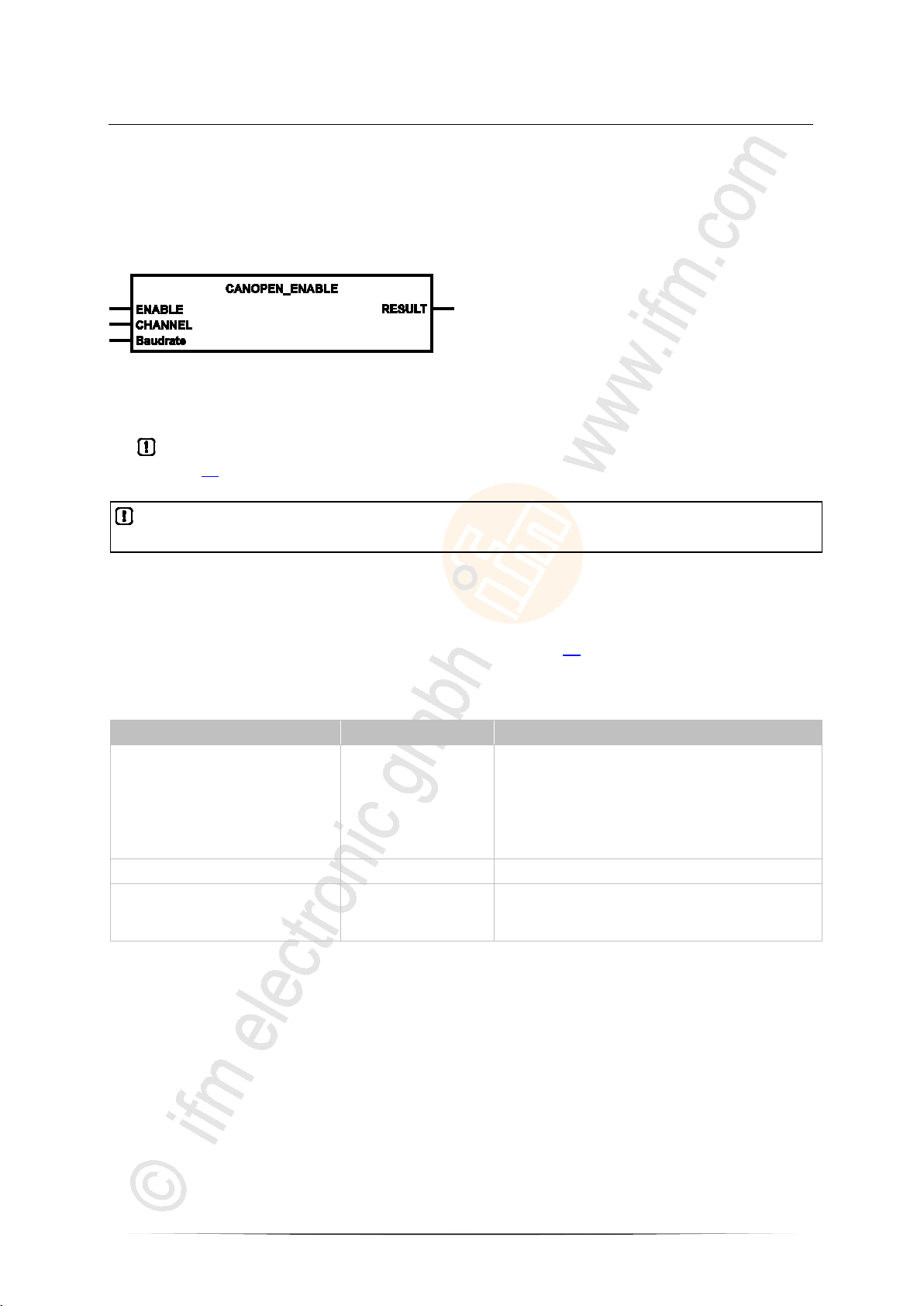

5.2.3 Function elements: CANopen ..................................................................................................... 92

5.2.4 Function elements: SAE J1939 ................................................................................................ 137

5.2.5 Function elements: processing input values ............................................................................. 168

5.2.6 Function elements: output functions ......................................................................................... 177

5.2.7 Function elements: system ....................................................................................................... 184

6 Diagnosis and error handling 202

6.1 Diagnosis .........................................................................................................................202

6.2 Fault .................................................................................................................................202

6.3 Response to system errors ..............................................................................................203

6.3.1 Example process for response to an error message ................................................................ 203

6.4 CAN / CANopen: errors and error handling .....................................................................203

7 Annex 204

7.1 System flags .....................................................................................................................204

7.2 Address assignment and I/O operating modes ................................................................205

7.2.1 Address assignment inputs / outputs ........................................................................................ 205

7.2.2 Possible operating modes inputs/outputs ................................................................................. 207

7.3 Error tables .......................................................................................................................210

7.3.1 Error flags ................................................................................................................................. 210

7.3.2 Errors: CAN / CANopen............................................................................................................ 210

8 Glossary of Terms 212

9 Index 225

10 Notizen • Notes • Notes 229

11 ifm weltweit • ifm worldwide • ifm à l’échelle internationale 233

3

Page 4

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

History of the instructions (CR040n) ................................................................................................... 8

About this manual Copyright

1 About this manual

Copyright ............................................................................................................................................... 4

Overview: documentation modules for ecomatmobile devices ............................................................. 5

CODESYS programming manual .......................................................................................................... 5

What do the symbols and formats mean? ............................................................................................. 6

How is this documentation structured? ................................................................................................. 7

>

1.1 Copyright

6088

© All rights reserved by ifm electronic gmbh. No part of this manual may be reproduced and used

without the consent of ifm electronic gmbh.

All product names, pictures, companies or other brands used on our pages are the property of the respective rights owners:

• AS-i is the property of the AS-International Association, (→ www.as-interface.net)

• CAN is the property of the CiA (CAN in Automation e.V.), Germany (→ www.can-cia.org)

• CODESYS™ is the property of the 3S – Smart Software Solutions GmbH, Germany (→ www.codesys.com)

• DeviceNet™ is the property of the ODVA™ (Open DeviceNet Vendor Association), USA (→ www.odva.org)

• EtherNet/IP® is the property of the →ODVA™

• IO-Link

• Microsoft® is the property of the Microsoft Corporation, USA (→ www.microsoft.com)

• PROFIBUS® is the property of the PROFIBUS Nutzerorganisation e.V., Germany (→ www.profibus.com)

• PROFINET® is the property of the →PROFIBUS Nutzerorganisation e.V., Germany

• Windows

®

(→ www.io-link.com) is the property of the →PROFIBUS Nutzerorganisation e.V., Germany

®

is the property of the →Microsoft Corporation, USA

202

4

Page 5

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

About this manual Overview: documentation modules for ecomatmobile devices

>

1.2 Overview: documentation modules for ecomatmobile devices

The documentation for ecomatmobile devices consists of the following modules:

1. Data sheet

Contents Technical data in a table

Source → www.ifm.com > select your country > [Data sheet search] > CR0403 > [Technical data in PDF format]

2. Installation instructions / operating instructions

Contents Instructions for installation, electrical installation, (commissioning*), technical data

Source The instructions are supplied with the device

They are also found on ifm's homepage:

3. Programming manual + online help

Contents Description of the configuration and the functions of the device software

Source → www.ifm.com > select your country > [Data sheet search] > CR0403 > [Operating instructions]

4. System manual "Know-how ecomatmobile"

→ www.ifm.com > select your country > [Data sheet search] > CR0403 > [Operating instructions]

17405

Contents Know-how about the following topics:

• Overview Templates and demo programs

• CAN, CANopen

• Control outputs

• User flash memory

• Visualisations

• Overview of the files and libraries used

Source → www.ifm.com > select your country > [Data sheet search] > CR0403 > [Operating instructions]

*) The descriptions in brackets are only included in the instructions of certain devices.

>

1.3 CODESYS programming manual

17542

In the additional "Programming Manual for CODESYS V2.3" you obtain more details about the use of

the programming system.

This manual can be downloaded free of charge from ifm's website:

→ www.ifm.com > Select your country > [Service] > [Download] > [Systems for mobile machines]

You also find manuals and online help for ecomatmobile at:

→ ecomatmobile DVD "Software, tools and documentation"

5

Page 6

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

NOTICE

About this manual What do the symbols and formats mean?

>

1.4 What do the symbols and formats mean?

The following symbols or pictograms illustrate the notes in our instructions:

WARNING

Death or serious irreversible injuries may result.

CAUTION

Slight reversible injuries may result.

Property damage is to be expected or may result.

Important notes concerning malfunctions or disturbances

Other remarks

► ... Request for action

203

> ... Reaction, result

→ ... "see"

abc Cross-reference

123

0x123

0b010

[...] Designation of pushbuttons, buttons or indications

Decimal number

Hexadecimal number

Binary number

6

Page 7

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

About this manual How is this documentation structured?

>

1.5 How is this documentation structured?

This documentation is a combination of different types of manuals. It is for beginners and also a

reference for advanced users. This document is addressed to the programmers of the applications.

How to use this manual:

• Refer to the table of contents to select a specific subject.

• Using the index you can also quickly find a term you are looking for.

• At the beginning of a chapter we will give you a brief overview of its contents.

• Abbreviations and technical terms → Annex.

In case of malfunctions or uncertainties please contact the manufacturer at:

→ www.ifm.com > Select your country > [Contact].

We want to become even better! Each separate section has an identification number in the top right

corner. If you want to inform us about any inconsistencies, indicate this number with the title and the

language of this documentation. Thank you very much for your support!

We reserve the right to make alterations which can result in a change of contents of the

documentation. You can find the current version on ifm's website at:

→ www.ifm.com > Select country > [Data sheet search] > (Article no.) > [Operating instructions]

204

1508

7

Page 8

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

About this manual History of the instructions (CR040n)

>

1.6 History of the instructions (CR040n)

12110

What has been changed in this manual? An overview:

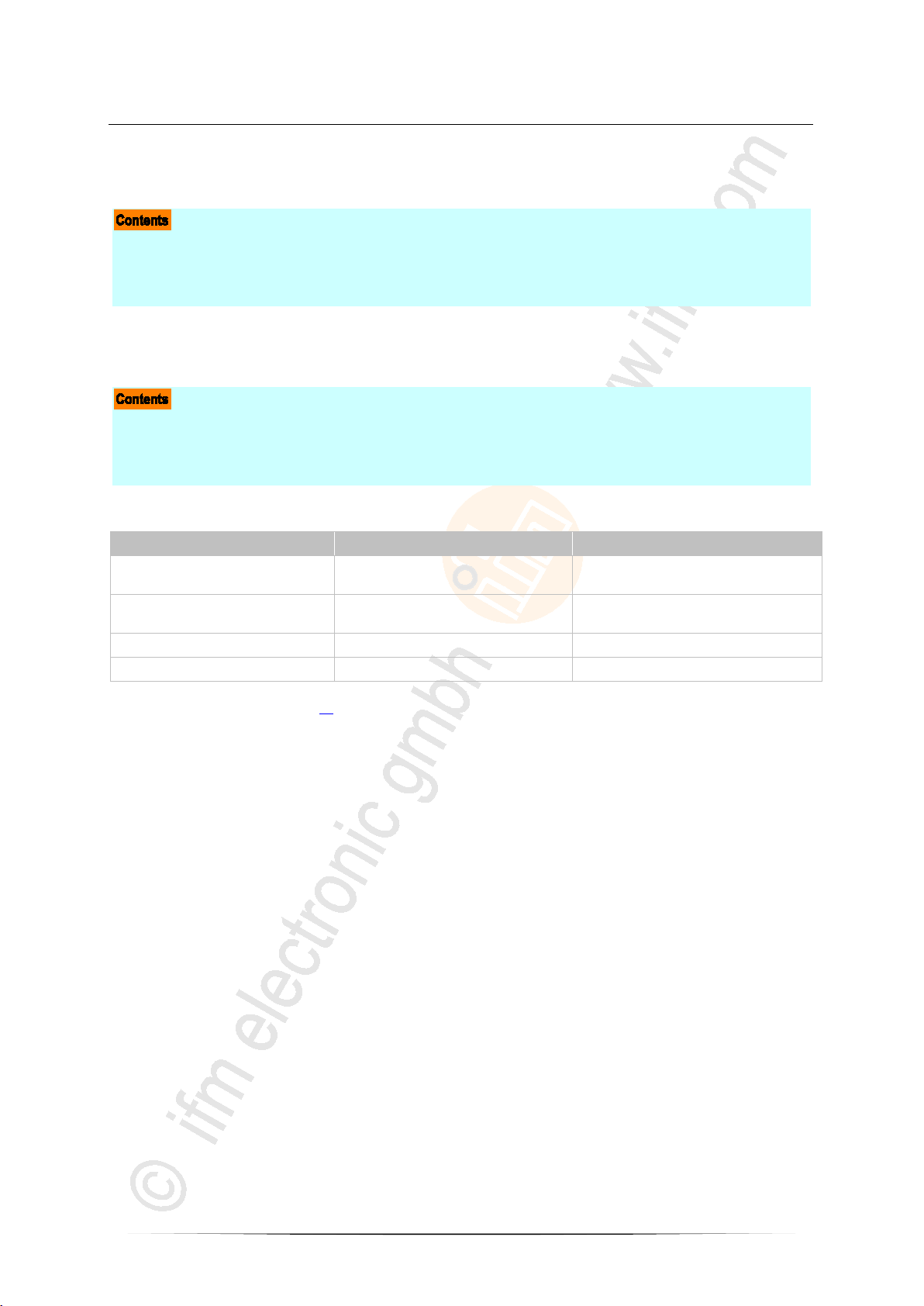

Date Theme Change

2012-07-24 Target upgrade to v02

2012-10-04 FB PWM1000 RESULT corrected

2013-06-24 various new document structure

2013-09-05 Target Upgrade to V03

2014-01-13 FBs FASTCOUNT, INC_ENCODER, PERIOD • permissible frequency areas corrected

2014-04-28 Various function blocks More precise description of the function block input

2014-04-29 FB CAN_REMOTE_RESPONSE More precise description of the function block ENABLE

2014-05-12 Limitations CAN Limitations added for CAN, CANopen and CAN J1939

2014-06-30 Name of the documentation "System manual" renamed as "Programming manual"

2014-08-08 FB PERIOD completed by operating mode "phase measurement"

2014-08-26 Description of inputs, outputs highside / lowside replaced by positive / negative

2014-11-12 Chapter "Outputs (technology)" Section "Diagnostics of the binary outputs"

2015-01-13 Structure of documentation for error codes, system

flags

2015-03-10 Available memory Description improved

>

• new RESULT for FB PERIOD

CHANNEL

(LZS V03.02.zz or higher)

switching

supplemented or corrected

• error flags:

now only in the annex, chapter System flags

• CAN / CANopen errors and error handling:

now only in the system manual "Know-How"

• error codes, EMCY codes:

now in the annex, chapter Error tables

8

Page 9

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Start-up behaviour of the controller ..................................................................................................... 10

Safety instructions Please note!

2 Safety instructions

Please note! ........................................................................................................................................... 9

What previous knowledge is required? ............................................................................................... 10

>

213

2.1 Please note!

6091

11212

No characteristics are warranted with the information, notes and examples provided in this manual.

With the drawings, representations and examples given no responsibility for the system is assumed

and no application-specific particularities are taken into account.

► The manufacturer of the machine/equipment is responsible for ensuring the safety of the

machine/equipment.

► Follow the national and international regulations of the country in which the machine/installation is

to be placed on the market!

WARNING

Non-observance of these instructions can lead to property damage or bodily injury!

ifm electronic gmbh does not assume any liability in this regard.

► The acting person must have read and understood the safety instructions and the corresponding

chapters in this manual before working on and with this device.

► The acting person must be authorised to work on the machine/equipment.

► The acting person must have the qualifications and training required to perform this work.

► Adhere to the technical data of the devices!

You can find the current data sheet on ifm's homepage at:

→ www.ifm.com > Select your country > [Data sheet search] > (article number.) > [Technical data

in PDF format]

► Note the installation and wiring information as well as the functions and features of the devices!

→ supplied installation instructions or on ifm's homepage:

→ www.ifm.com > Select your country > [Data sheet search] > (article number.) > [Operating

instructions]

► Please note the corrections and notes in the release notes for the existing documentation,

available on the ifm website:

→ www.ifm.com > Select your country > [Data sheet search] > (article number.) > [Operating

instructions]

9

Page 10

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Safety instructions What previous knowledge is required?

>

2.2 What previous knowledge is required?

215

This document is intended for people with knowledge of control technology and PLC programming

with IEC 61131-3.

To program the PLC, the people should also be familiar with the CODESYS software.

The document is intended for specialists. These specialists are people who are qualified by their

training and their experience to see risks and to avoid possible hazards that may be caused during

operation or maintenance of a product. The document contains information about the correct handling

of the product.

Read this document before use to familiarise yourself with operating conditions, installation and

operation. Keep the document during the entire duration of use of the device.

Adhere to the safety instructions.

>

2.3 Start-up behaviour of the controller

6827

15233

WARNING

Danger due to unintentional and dangerous start of machine or plant sections!

► When creating the program, the programmer must ensure that no unintentional and dangerous

start of machines or plant sections after a fault (e.g. e-stop) and the following fault elimination can

occur!

Realise restart inhibit!

► In case of an error, set the outputs concerned to FALSE in the program!

A restart can, for example, be caused by:

• voltage restoration after power failure

• reset after watchdog response because of too long a cycle time

• error elimination after an E-stop

To ensure a safe behaviour of the controller:

► monitor the voltage supply in the application program.

► In case of an error switch off all relevant outputs in the application program.

► Additionally monitor relay contacts which can cause hazardous movements in the application

program (feedback).

► If necessary, ensure that welded relay contacts in the application project cannot trigger or continue

hazardous movements.

► Additionally monitor relay contacts which can cause hazardous movements in the application

program (feedback).

► If necessary, ensure that welded relay contacts in the application project cannot trigger or continue

hazardous movements.

>

10

Page 11

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Software description ............................................................................................................................ 28

Status LED .......................................................................................................................................... 26

System description Information about the device

3 System description

Information about the device ............................................................................................................... 11

Hardware description........................................................................................................................... 11

Interface description ............................................................................................................................ 27

>

3.1 Information about the device

This manual describes of the ecomatmobile family for mobile machines of ifm electronic gmbh:

• BasicController: CR0403

>

3.2 Hardware description

Hardware setup ................................................................................................................................... 12

Inputs (technology) .............................................................................................................................. 13

Outputs (technology) ........................................................................................................................... 18

Note on wiring ...................................................................................................................................... 25

Safety instructions about Reed relays ................................................................................................. 25

975

14551

14081

11

Page 12

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

3.2.1 Hardware setup

Basic device without cover

Protection IP 20

>

Available memory

>

FLASH-Speicher

14561

13736

13053

FLASH memory (non-volatile, slow memory)

1 536 kByte

overall existing in the device

Thereof the following memory areas are reserved for ...

maximum size of the application program 512 kByte

data other than the application program

64 kByte

read data with FB FLASH_READ (→ page 186)

(files: 128 bytes less for header)

The remaining rest of the memory is reserved for system internal purposes.

>

SRAM

SRAM (volatile, fast memory)

overall existing in the device

SRAM indicates here all kinds of volatile and fast memories.

Thereof the following memory areas are reserved for ...

data reserved by the application program 128 kByte

The remaining rest of the memory is reserved for system internal purposes.

>

592 kByte

FRAM

14027

2262

FRAM (non-volatile, fast memory)

2 kByte

overall existing in the device

FRAM indicates here all kinds of non-volatile and fast memories.

Thereof the following memory areas are reserved for ...

variables in the application program, declared as VAR_RETAIN 128 Byte

fixed as remanent defined flags (%MB0...127) 128 Byte

The remaining rest of the memory is reserved for system internal purposes.

12

Page 13

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Input group I2 (IN8...IN11) ................................................................................................................... 17

System description Hardware description

>

3.2.2 Inputs (technology)

Analogue inputs ................................................................................................................................... 13

Digital inputs ........................................................................................................................................ 14

Input group I0 (IN0...IN3) ..................................................................................................................... 15

Input group I1 (IN4...IN7) ..................................................................................................................... 15

>

14090

Analogue inputs

15444

The analogue inputs can be configured via the application program. The measuring range can be set

as follows:

• current input 0...20 mA

• voltage input 0...10 V

• voltage input 0...32 V

• resistance measurement 16...30 000 Ω (measurement to GND)

The voltage measurement can also be carried out ratiometrically (0...1000 ‰, adjustable via function

blocks). This means potentiometers or joysticks can be evaluated without additional reference voltage.

A fluctuation of the supply voltage has no influence on this measured value.

As an alternative, an analogue channel can also be evaluated binarily.

In case of ratiometric measurement the connected sensors should be supplied with VBBS of the

device. So, faulty measurements caused by offset voltage are avoided.

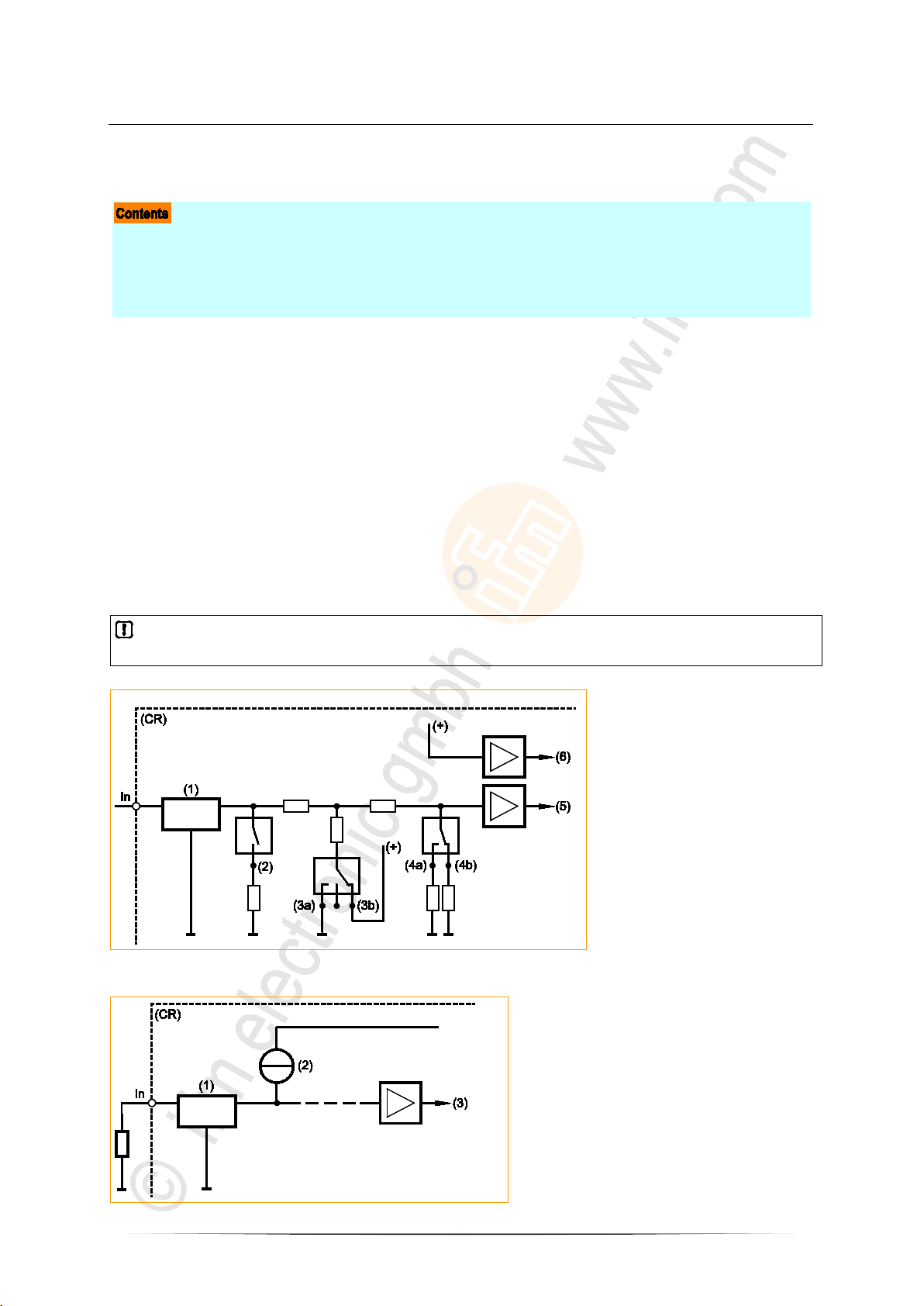

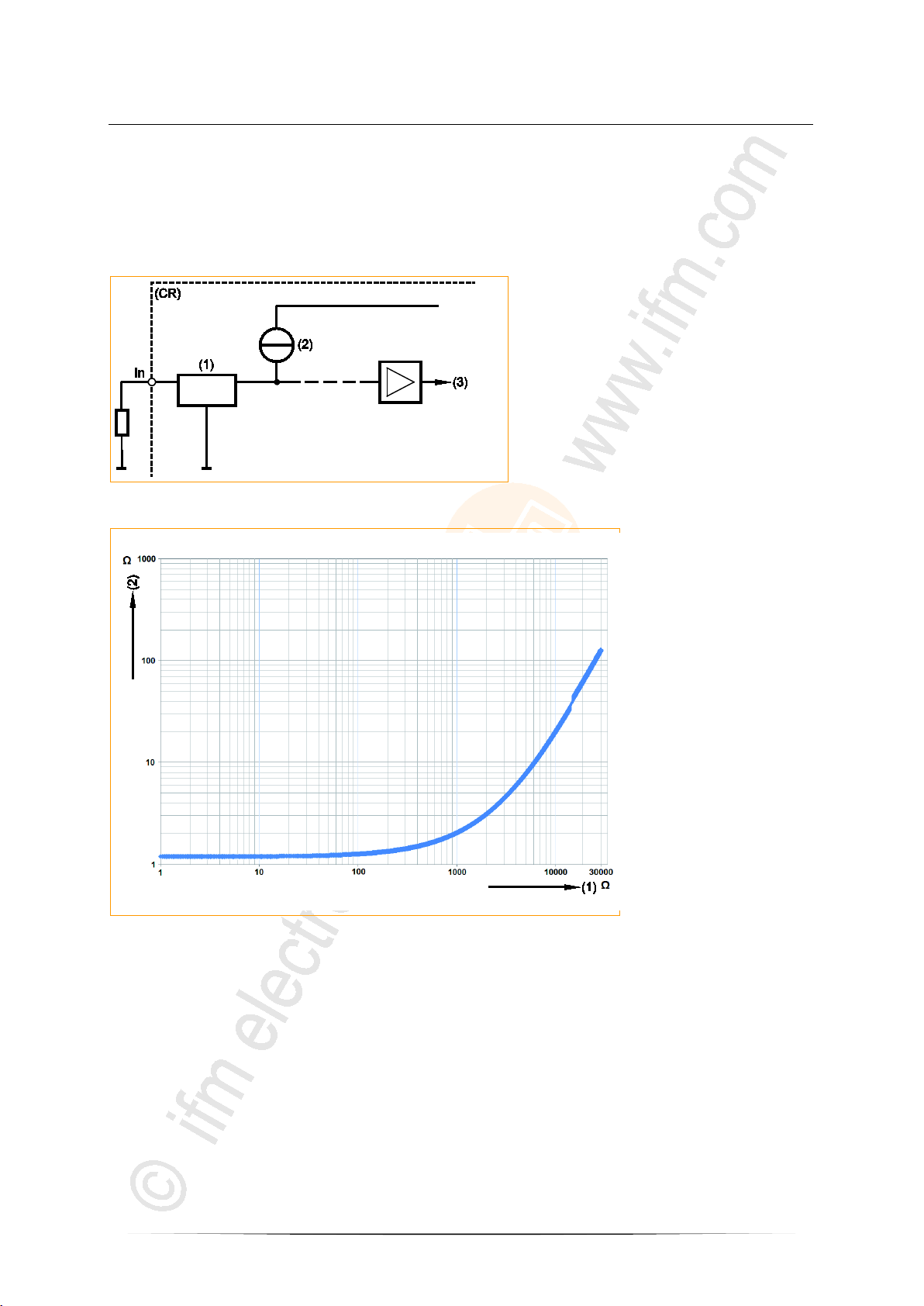

In = pin multifunction input n

(CR) = device

(1) = input filter

(2) = analogue current measuring

(3a) = binary-input plus switching

(3b) = binary-input minus switching

(4a) = analogue voltage measuring 0...10 V

(4b) = analogue voltage measuring 0...32 V

(5) = voltage

(6) = reference voltage

8971

Figure: principle block diagram multifunction input

Figure: block diagram of the resistor survey input

In = pin resistor survey input n

(CR) = device

(1) = input filter

(2) = constant-current source

(3) = voltage

13

8972

Page 14

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

Digital inputs

The binary input can be operated in following modes:

• binary input plus switching (BL) for positive sensor signal

• binary input minus switching (BH) for negative sensor signal

Depending on the device the binary inputs can configured differently. In addition to the protective

mechanisms against interference, the binary inputs are internally evaluated via an analogue stage.

This enables diagnosis of the input signals. But in the application software the switching signal is

directly available as bit information

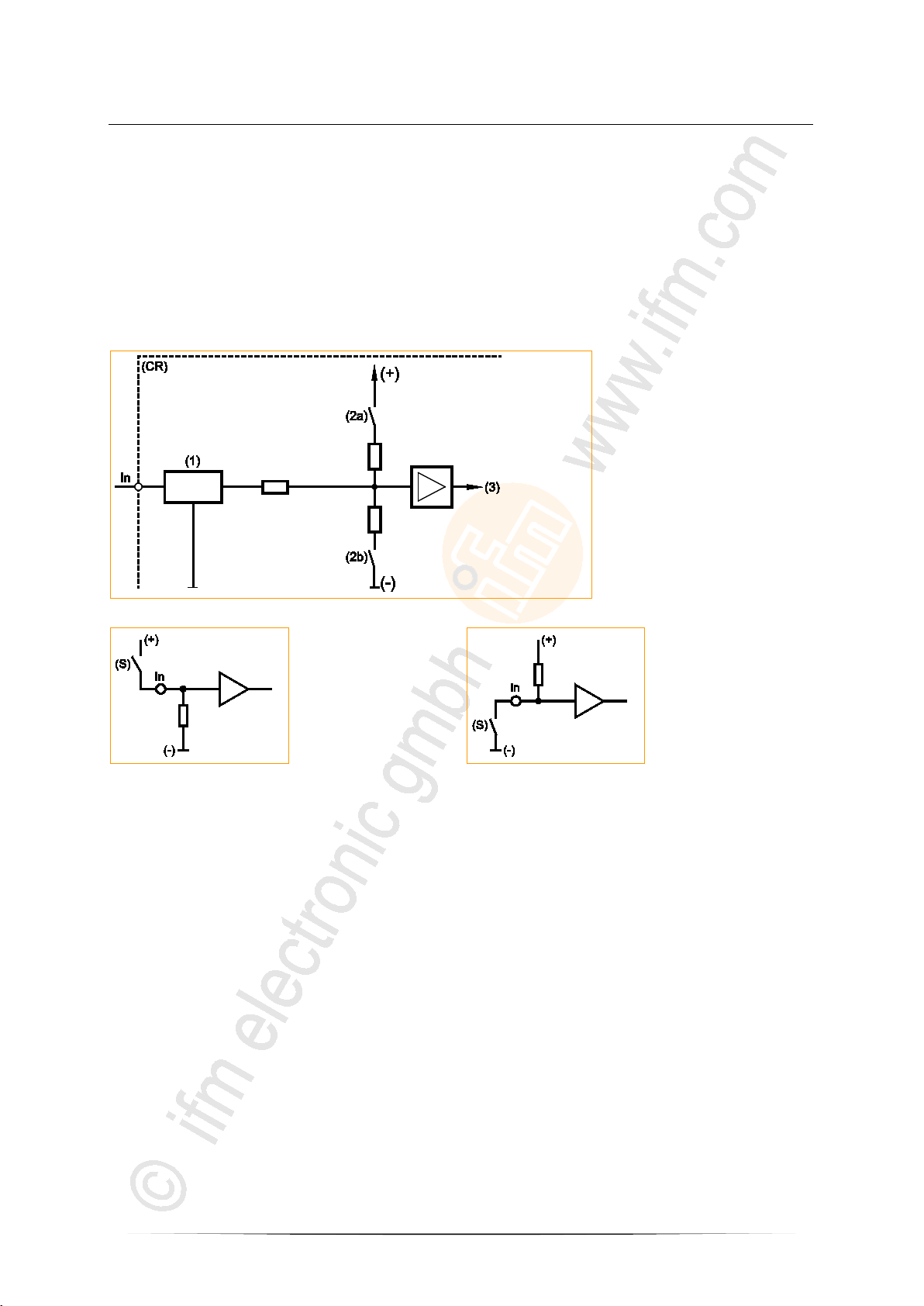

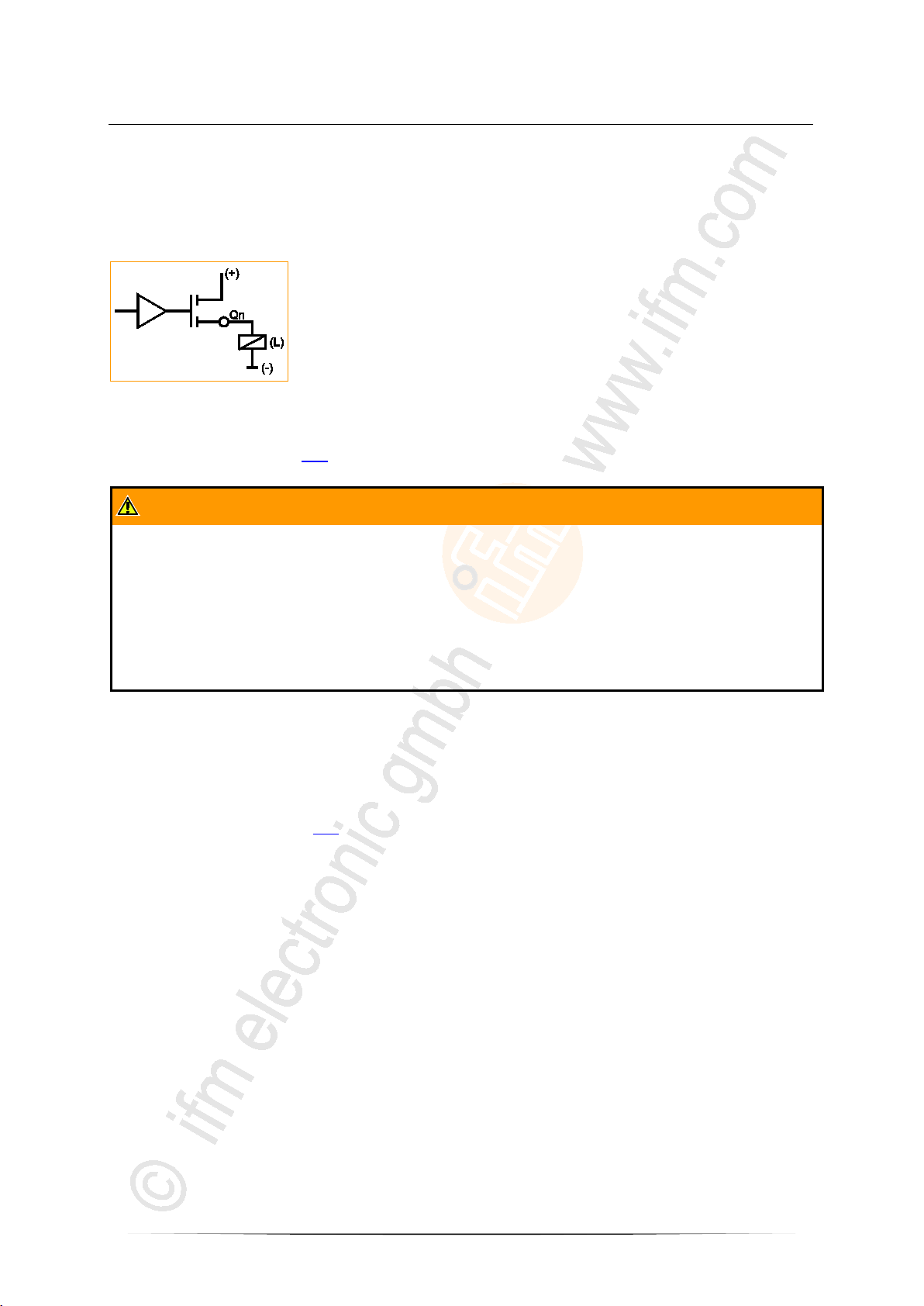

In = pin binary-input n

(CR) = device

(1) = input filter

(2a) = input minus switching

(2b) = input plus switching

(3) = voltage

1015

7345

Figure: basic circuit of binary input minus switching / plus switching for negative and positive sensor signals

In = pin binary-input n

(S) = sensor

Basic circuit of binary input plus switching (BL)

for positive sensor signal:

Input = open signal = low (GND)

For some of these inputs (→ data sheet) the potential can be selected to which it will be switched.

Basic circuit of binary input minus switching (BH)

for negative sensor signal:

Input = open signal = high (supply)

In = pin binary-input n

(S) = sensor

14

Page 15

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

Input group I0 (IN0...IN3)

These inputs are a group of multifunction channels.

These inputs can be used as follows (each input separately configurable):

• analogue input 0...20 mA

• analogue input 0...10 V

• analogue input 0...32 V

• voltage measurement ratiometric 0...1000 ‰

• binary input plus switching (BL) for positive sensor signal (with/without diagnosis)

• binary input minus switching (BH) for negative sensor signal

• fast input for e.g. incremental encoders and frequency or interval measurement

→ chapter Possible operating modes inputs/outputs (→ page 207)

Sensors with diagnostic capabilities to NAMUR can be evaluated.

All inputs show the same behaviour concerning function and diagnosis.

Detailed description → chapter Address assignment inputs / outputs (→ page 205)

Configuration of each input is made via the application program:

• FB INPUT (→ page 173) > input MODE

• FBs FASTCOUNT (→ page 169), INC_ENCODER (→ page 171) or PERIOD (→ page 175)

> If the analogue inputs are configured for current measurement, the device switches to the safe

voltage measurement range (0...32 V DC) and the output RESULT is set accordingly in the

function block INPUT when the final value (23 mA for > 40 ms) is exceeded. After about one

second the input automatically switches back to the current measuring range.

>

14568

Input group I1 (IN4...IN7)

These inputs are a group of multifunction channels.

These inputs can be used as follows (each input separately configurable):

• binary input plus switching (BL) for positive sensor signal

• input for resistance measurement (e.g. temperature sensors or fuel sensors)

→ chapter Possible operating modes inputs/outputs (→ page 207)

Sensors with diagnostic capabilities to NAMUR can be evaluated.

► Configuration of each input is made via the application program:

• FB INPUT (→ page 173) > input MODE

14569

15

Page 16

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

Resistance measurement

Typical sensors on these inputs:

• tank level

• temperature (PT1000, NTC)

Figure: block diagram of the resistor survey input

In = pin resistor survey input n

(CR) = device

(1) = input filter

(2) = constant-current source

(3) = voltage

9773

8972

The resistance for this device is not linearly dependent on the resistance value, → figure:

Figure: resolution dependent on the

resistance value

(1) = resistance value at the input

(2) = resolution

By how many ohms does the measured value change when the signal of the A/D converter on the input changes by 1?

Examples:

• In the range of 1...100 Ω the resolution is 1.2 Ω.

• In the range of 1 kΩ the resolution is approx. 2 Ω.

• In the range of 2 kΩ the resolution is approx. 3 Ω.

• In the range of 3 kΩ the resolution is approx. 6 Ω.

• In the range of 6 kΩ the resolution is approx. 10 Ω.

• In the range of 10 kΩ the resolution is approx. 11 Ω

• In the range of 20 kΩ the resolution is approx. 60 Ω.

8970

16

Page 17

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

Input group I2 (IN8...IN11)

These inputs are a group of multifunction channels.

These inputs can be used as follows (each input separately configurable):

• binary input plus switching (BL) for positive sensor signal (with/without diagnosis)

→ chapter Possible operating modes inputs/outputs (→ page 207)

Sensors with diagnostic capabilities to NAMUR can be evaluated.

► Configuration of each input is made via the application program:

• FB INPUT (→ page 173) > input MODE

14570

17

Page 18

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Output group Q3 (OUT10, OUT11) ..................................................................................................... 24

System description Hardware description

>

3.2.3 Outputs (technology)

Protective functions of the outputs ...................................................................................................... 18

Output group Q0 (OUT0, OUT1) ......................................................................................................... 20

Output group Q1 (OUT2, OUT3, OUT8, OUT9) .................................................................................. 22

Output group Q2 (OUT4...OUT7) ........................................................................................................ 23

>

Protective functions of the outputs

The outputs of this device are protected against overload and short circuit within specific ranges.

→ data sheet

>

Definition: overload

Overload can only be detected on an output with current measurement.

Overload is defined as ...

"a nominal maximum current of 12.5 %" according to the data sheet.

>

Definition: short circuit

A short circuit can be detected on all outputs with diagnostic capabilities and is defined as follows:

A short circuit is defined as ...

"a drop of the output voltage below 93.5% (± 2.0%) of the corresponding supply voltage."

> A ground fault can only be detected in case of output = TRUE.

14093

15248

15249

15644

18

Page 19

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

Reaction of the outputs to overload or short circuit

>

Self-protection of the output

The hardware protects itself, irrespective of the operating mode of the output and of the fault

detection. In case of a too high thermal load (caused by short circuit or overload), the output driver

begins to clock.

The driver may be damaged in case of too long clocking of the output (several hours).

We therefore recommend:

that you operate device outputs with diagnostic capabilities in the following mode, since, in this case,

the software protects the drivers additionally by switching off:

• FB OUTPUT (→ page 180) > input MODE = 16

This is also the default setting if only the flags in the control configuration are used.

>

Reaction according to the operating mode of the output

In case of an overload or a short circuit, the behaviour of the output depends on its operating mode

(→ FB OUTPUT (→ page 180) > input MODE):

• MODE=2: binary output plus switched: no diagnosis and no protection

> the output continues to be operated.

• MODE=15: binary output plus switched with diagnosis

> error is detected and signalled on the output RESULT by the FB OUTPUT:

e.g.: RESULT = 128, 141, 142 or 145.

This depends on the type of output and the current or voltage at the output.

The programmer can react to the error in the program.

• MODE=16: binary output plus switched with diagnosis and protection

> error is detected and signalled on the output RESULT by the FB OUTPUT.

> The respective output is switched off.

> The logic state of the output remains unaffected by this!

>

15251

15253

15252

Reaction when using PWM or CURRENT_CONTROL

The situation is different when the FBs PWM or CURRENT_CONTROL are used:

There is no diagnosis. The →self-protection of the output becomes active.

► For outputs with current feedback:

Query the typical current for the output in the application program!

It is the responsibility of the programmer to react to the event.

15254

19

Page 20

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

Output group Q0 (OUT0, OUT1)

14583

These outputs are a group of multifunction channels.

These outputs provide several function options (each output separately configurable):

• binary output, plus switching (BH) with diagnostic function and protection

• analogue current-controlled output (PWMi)

• analogue output with Pulse Width Modulation (PWM)

→ chapter Possible operating modes inputs/outputs (→ page 207)

► Configuration of each output is made via the application program:

→ FB OUTPUT (→ page 180)> input MODE

PWM output: → FB PWM1000 (→ page 182)

Current control and load current indication → FB CURRENT_CONTROL (→ page 178)

► For the limit values please make sure to adhere to the data sheet!

>

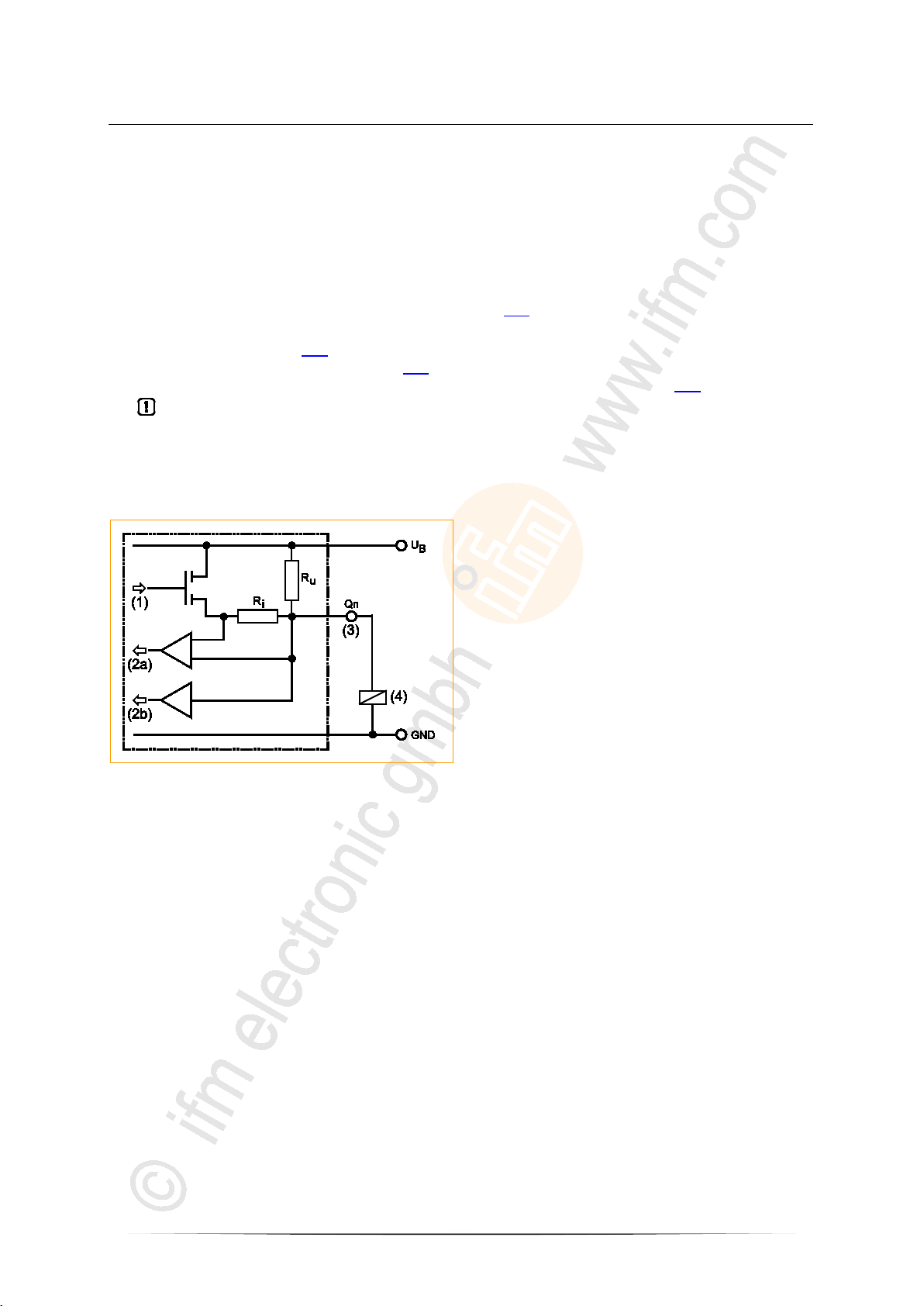

Diagnosis: binary outputs (via current and voltage measuring)

19433

19434

The diagnostics of these outputs is made via internal current and voltage measurement in the output:

Figure: principle block diagram

(1) Output channel

(2a) Read back channel for diagnosis via current measuring

(2b) Read back channel for diagnosis via voltage measuring

(3) Pin output n

(4) Load

>

Diagnosis: overload

19437

15249

Overload can only be detected on an output with current measurement.

Overload is defined as ...

"a nominal maximum current of 12.5 %" according to the data sheet.

>

Diagnosis: wire break (via current measurement)

19435

19400

Wire-break detection is done via the read back channel. When the output is switched (Qn=TRUE) wire

break is detected when no current flows on the resistor Ri (no voltage drops). Without wire break the

load current flows through the series resistor Ri generating a voltage drop which is evaluated via the

read back channel.

>

Diagnosis: wire break (via voltage measurement)

19436

19404

Wire-break detection is done via the read back channel. When the output is blocked (Qn=FALSE) wire

break is detected when the resistor Ru pulls the read back channel to HIGH potential (VBB). Without

the wire break the low-resistance load (RL < 10 kΩ) would force a LOW (logical 0).

20

Page 21

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

Diagnosis: short circuit

Short-circuit detection is done via the read back channel. When the output is switched (Qn=TRUE)

short circuit against GND is detected when the read back channel is pulled to LOW potential (GND).

19405

21

Page 22

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

Output group Q1 (OUT2, OUT3, OUT8, OUT9)

These outputs are a group of multifunction channels.

These outputs provide several function options (each output separately configurable):

• binary output, plus switching (BH) with/without diagnostic function

• analogue output with Pulse Width Modulation (PWM)

→ chapter Possible operating modes inputs/outputs (→ page 207)

► Configuration of each output is made via the application program:

→ FB OUTPUT (→ page 180)> input MODE

PWM output: → FB PWM1000 (→ page 182)

► For the limit values please make sure to adhere to the data sheet!

>

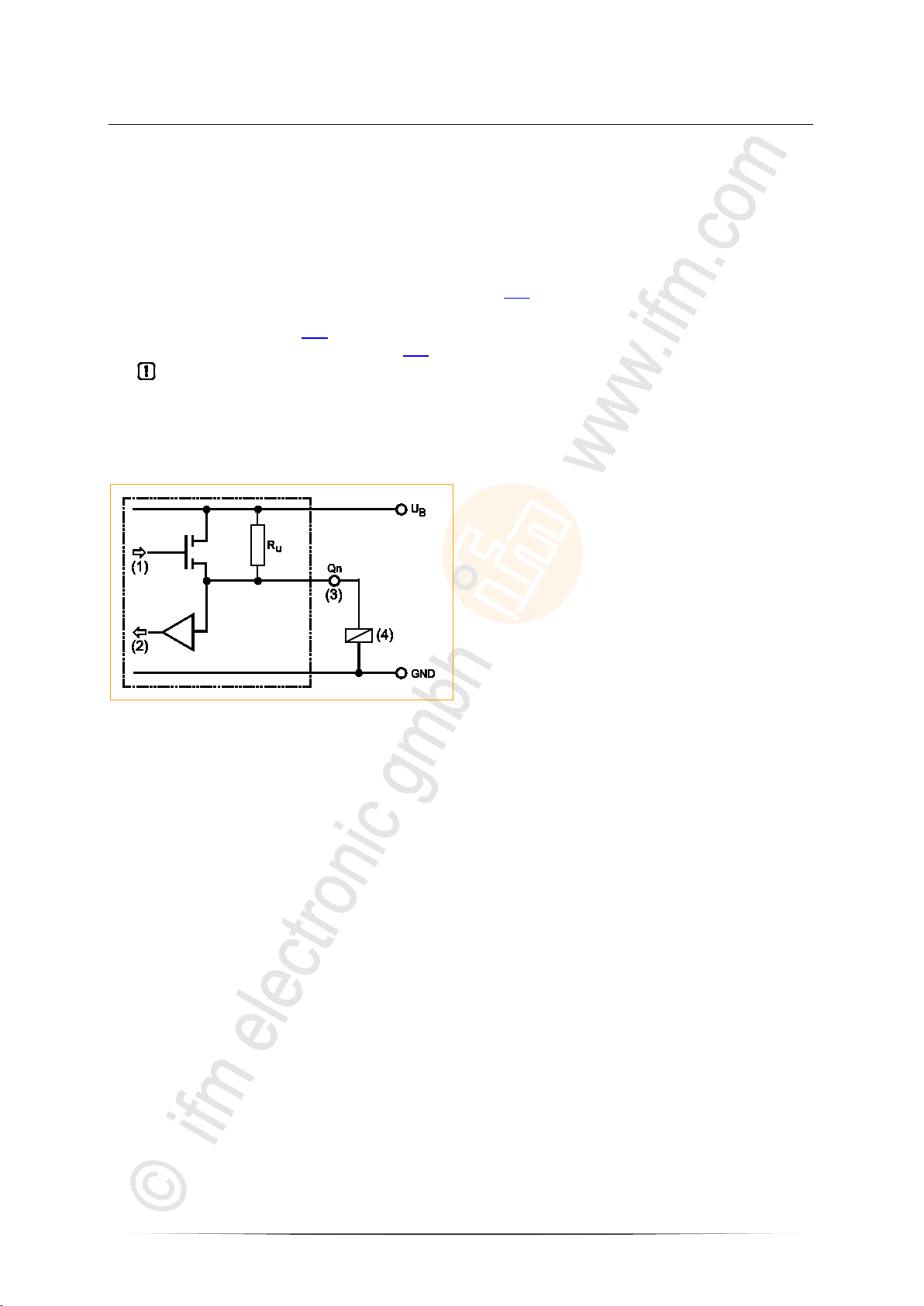

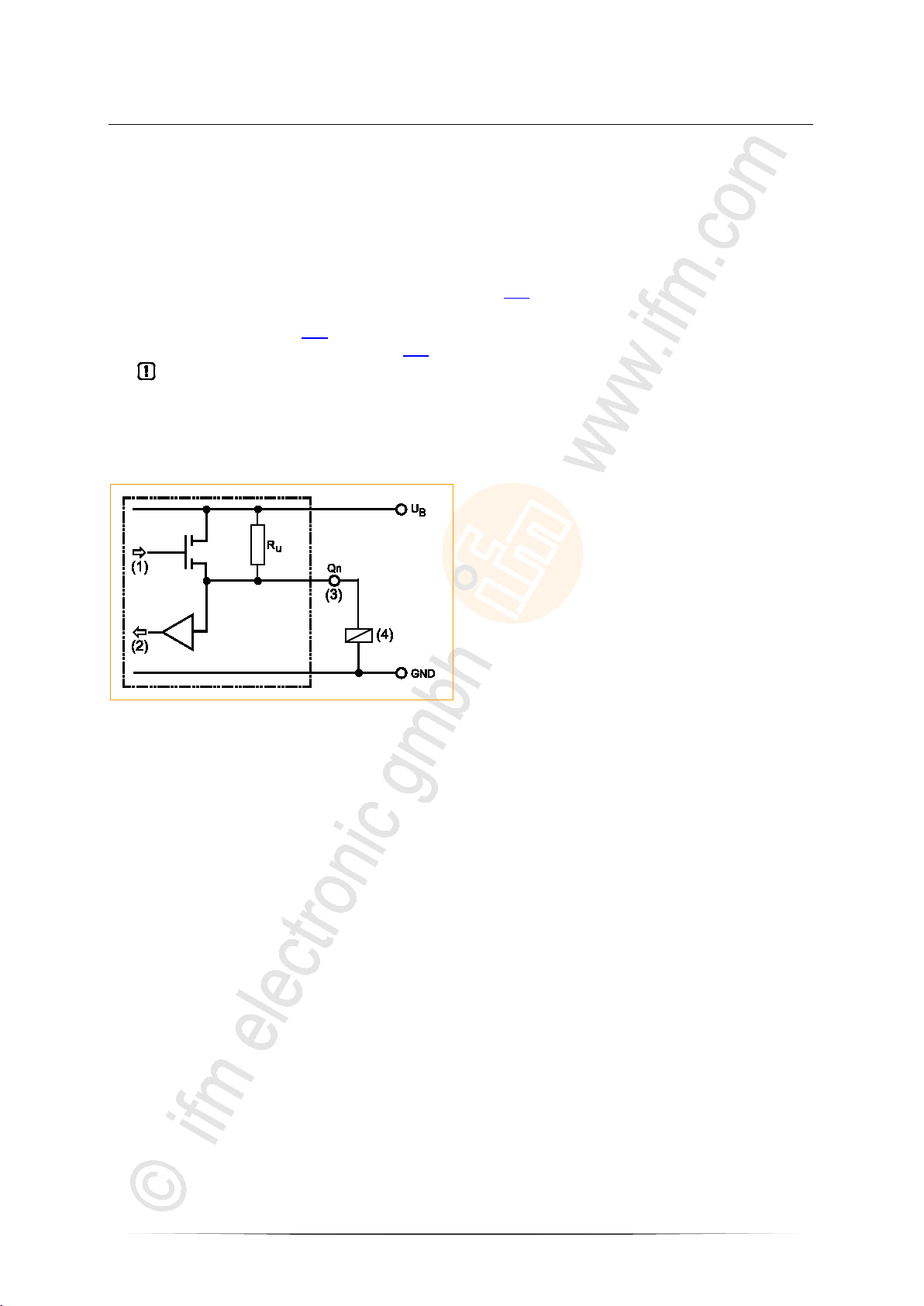

Diagnosis: binary outputs (via voltage measuring)

The diagnostics of these outputs is made via internal voltage measurement in the output:

14577

19403

19397

Figure: principle block diagram

(1) Output channel

(2) Read back channel for diagnosis

(3) Pin output n

(4) Load

>

Diagnosis: overload

19448

The outputs have no current measuring, no overload detection.

>

Diagnosis: wire break

19404

Wire-break detection is done via the read back channel. When the output is blocked (Qn=FALSE) wire

break is detected when the resistor Ru pulls the read back channel to HIGH potential (VBB). Without

the wire break the low-resistance load (RL < 10 kΩ) would force a LOW (logical 0).

>

Diagnosis: short circuit

19405

Short-circuit detection is done via the read back channel. When the output is switched (Qn=TRUE)

short circuit against GND is detected when the read back channel is pulled to LOW potential (GND).

22

Page 23

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

Output group Q2 (OUT4...OUT7)

These outputs are a group of multifunction channels.

These outputs provide several function options (each output separately configurable):

• binary output, plus switching (BH)

• analogue output with Pulse Width Modulation (PWM)

• These outputs are not able for diagnosis.

→ chapter Possible operating modes inputs/outputs (→ page 207)

► Configuration of each output is made via the application program:

→ FB OUTPUT (→ page 180)> input MODE

PWM output: → FB PWM1000 (→ page 182)

► For the limit values please make sure to adhere to the data sheet!

15235

23

Page 24

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

Output group Q3 (OUT10, OUT11)

These outputs are a group of multifunction channels.

These outputs provide several function options (each output separately configurable):

• binary output, plus switching (BH) with/without diagnostic function

• analogue output with Pulse Width Modulation (PWM)

→ chapter Possible operating modes inputs/outputs (→ page 207)

► Configuration of each output is made via the application program:

→ FB OUTPUT (→ page 180)> input MODE

PWM output: → FB PWM1000 (→ page 182)

► For the limit values please make sure to adhere to the data sheet!

>

Diagnosis: binary outputs (via voltage measuring)

The diagnostics of these outputs is made via internal voltage measurement in the output:

15237

19403

19397

Figure: principle block diagram

(1) Output channel

(2) Read back channel for diagnosis

(3) Pin output n

(4) Load

>

Diagnosis: overload

19448

The outputs have no current measuring, no overload detection.

>

Diagnosis: wire break

19404

Wire-break detection is done via the read back channel. When the output is blocked (Qn=FALSE) wire

break is detected when the resistor Ru pulls the read back channel to HIGH potential (VBB). Without

the wire break the low-resistance load (RL < 10 kΩ) would force a LOW (logical 0).

>

Diagnosis: short circuit

19405

Short-circuit detection is done via the read back channel. When the output is switched (Qn=TRUE)

short circuit against GND is detected when the read back channel is pulled to LOW potential (GND).

24

Page 25

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

3.2.4 Note on wiring

1426

The wiring diagrams (→ installation instructions of the devices, chapter "Wiring") describe the standard

device configurations. The wiring diagram helps allocate the input and output channels to the IEC

addresses and the device terminals.

The individual abbreviations have the following meaning:

A Analogue input

BH Binary high side input: minus switching for negative sensor signal

BL Binary low side input: plus switching for positive sensor signal

CYL Input period measurement

ENC Input encoder signals

FRQ Frequency input

H bridge Output with H-bridge function

PWM

PWMi PWM output with current measurement

IH Pulse/counter input, high side: minus switching for negative sensor signal

IL Pulse/counter input, low side: plus switching for positive sensor signal

R Read back channel for one output

Binary high side output: plus switching for positive output signal

Binary low side output: minus switching for negative output signal

Pulse-width modulated signal

Allocation of the input/output channels: → Catalogue, mounting instructions or data sheet

>

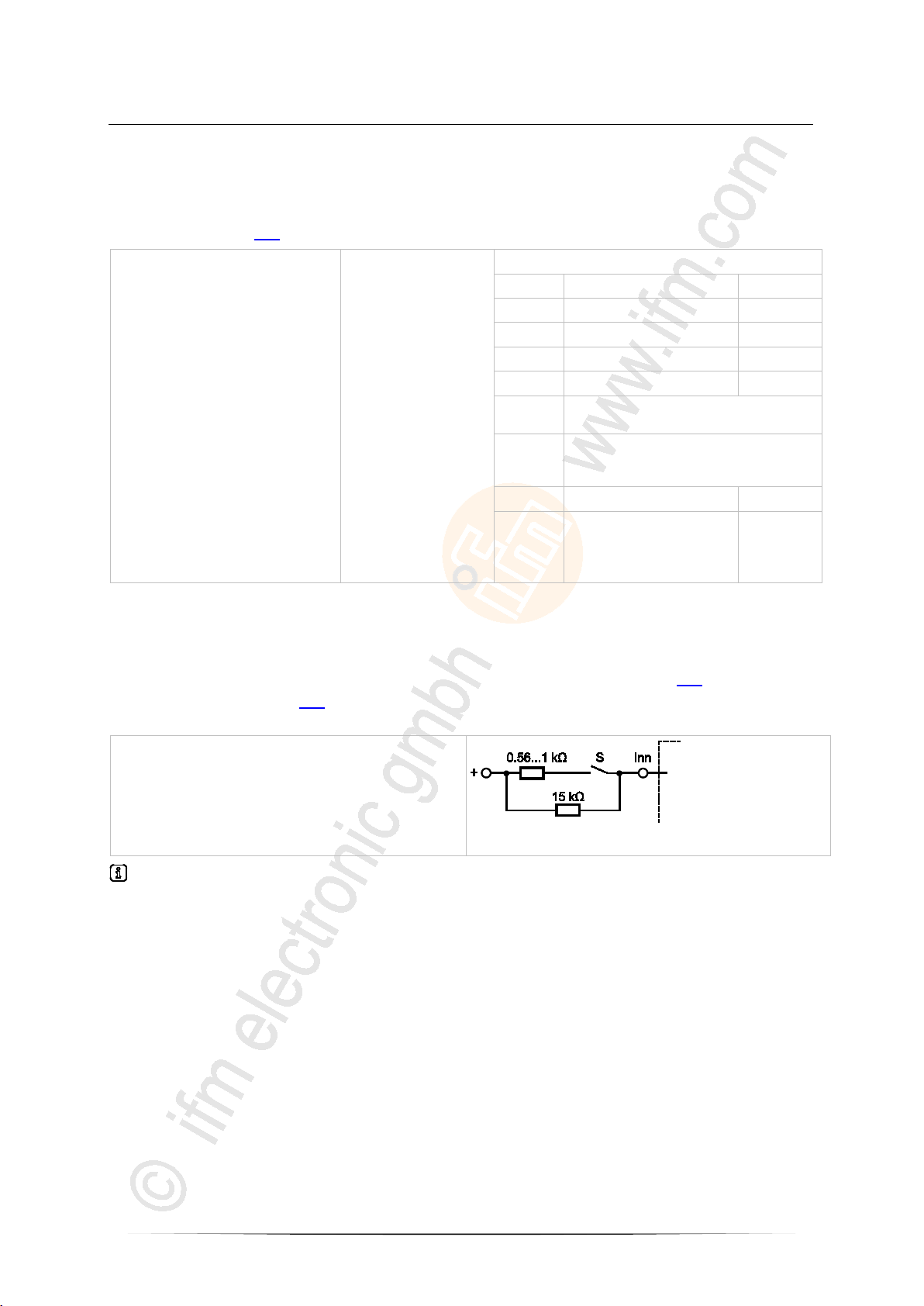

3.2.5 Safety instructions about Reed relays

For use of non-electronic switches please note the following:

Contacts of Reed relays may be clogged (reversibly) if connected to the device inputs without

series resistor.

► Remedy: Install a series resistor for the Reed relay:

Series resistor = max. input voltage / permissible current in the Reed relay

Example: 32 V / 500 mA = 64 Ohm

► The series resistor must not exceed 5 % of the input resistance RE of the device input (→ data

sheet). Otherwise, the signal will not be detected as TRUE.

Example:

RE = 3 000 Ohm

⇒ max. series resistor = 150 Ohm

7348

25

Page 26

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Hardware description

>

3.2.6 Status LED

The operating states are indicated by the integrated status LED (default setting).

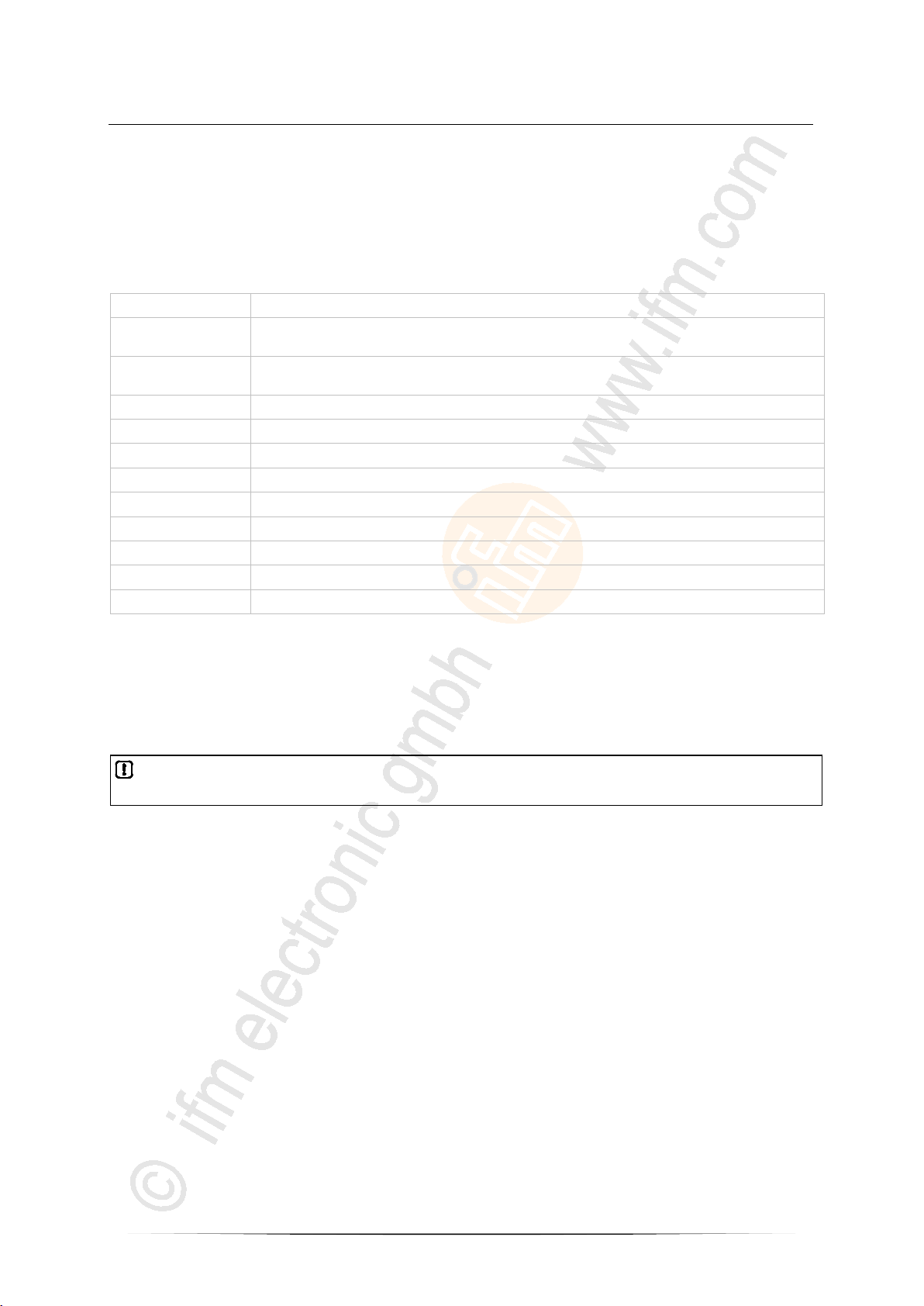

LED colour Flashing frequency Description

Off permanently off no operating voltage

Red / green briefly on INIT state, reset checks

Green 5 Hz no runtime system loaded

Green 2 Hz RUN state: application is running

Green permanently on STOP state: application is stopped

Red 5 Hz

Red 10 Hz

Red permanently on

.

The operating states STOP and RUN can be changed by the programming system.

>

STOP state with error: application is stopped

reason: undervoltage

STOP state with error: application is stopped

Cause: exceeded timeout of the application or visualisation:

Delete the application!

PowerOn reset

Reload the application into the device

FATAL ERROR: application is stopped

Cause: software watchdog has failed

PowerOn reset

If without success:

Goto Bootloader

PowerOn reset

Reload the BasicSystem into the device

Reload the application into the device

If without success:

Hardware error: send device to ifm!

7998

Control the LED in the application program

Via SET_LED frequency and color of the status LED can be changed in the application program.

The use of the LED function block in the application program replaces the system setting of the

status LED in the RUN state.

15481

26

Page 27

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

CAN interfaces .................................................................................................................................... 27

CAN: interfaces and protocols ............................................................................................................. 27

System description Interface description

>

3.3 Interface description

>

14098

3.3.1 CAN interfaces

14101

Connections and data → data sheet

>

CAN: interfaces and protocols

14589

15238

The devices are equipped with several CAN interfaces depending on the hardware design. Basically,

all interfaces can be used with the following functions independently of each other:

• RAW-CAN (Layer 2): CAN on level 2 (→ chapter Function elements: RAW-CAN (Layer 2) (→ page 66))

• CANopen master / CANopen slave (→ chapter Function elements: CANopen (→ page 92))

• CANopen network variables (via CODESYS) (→ chapter Network variables (→ page 57))

• SAE J1939 (for drive management, → chapter Function elements: SAE J1939 (→ page 137))

• Bus load detection

• Error frame counter

• Download interface

• 100 % bus load without package loss

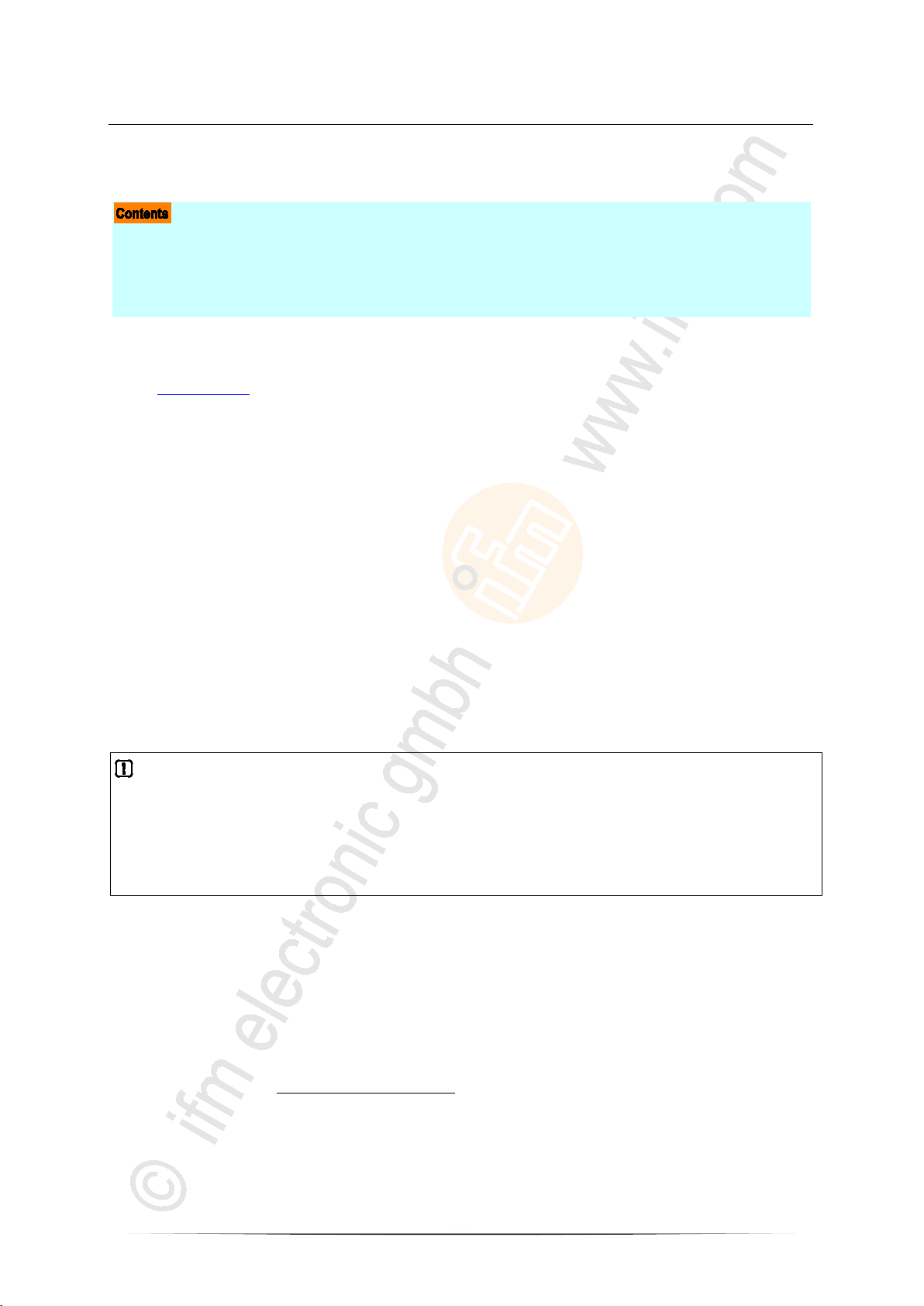

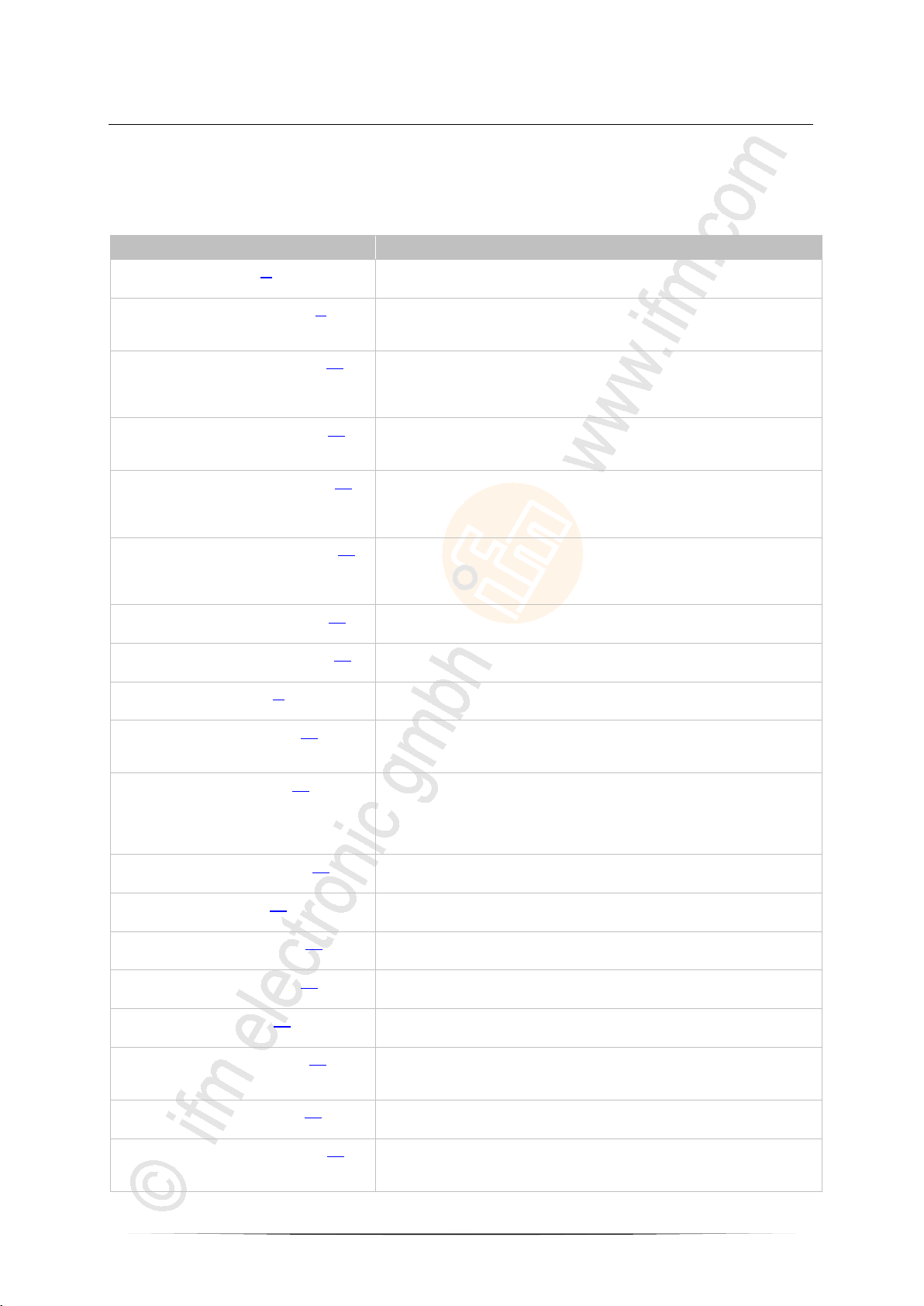

The following CAN interfaces and CAN protocols are available in this ecomatmobile device:

14591

CAN interface

Default download ID

CAN 1 CAN 2 CAN 3 CAN 4

ID 127 ID 126 ID 125 ID 124

CAN Layer 2 CAN Layer 2

CAN protocols

CANopen CANopen

Interface do not

exist

Interface do not

SAE J1939 SAE J1939

Standard baud rate = 250 Kbits/s

All CAN interfaces can operate with all CAN protocols at the same time. The IDs used must not

impair each other!

exist

27

Page 28

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Performance limits of the device ......................................................................................................... 37

Libraries ............................................................................................................................................... 30

System description Software description

>

3.4 Software description

Software modules for the device ......................................................................................................... 28

Programming notes for CODESYS projects ....................................................................................... 31

Operating states .................................................................................................................................. 35

>

3.4.1 Software modules for the device

Bootloader ........................................................................................................................................... 29

Runtime system ................................................................................................................................... 29

Application program............................................................................................................................. 29

The software in this device communicates with the hardware as below:

software module Can user change the module? By means of what tool?

Application program

with libraries

Runtime system *)

Yes

Upgrade yes

Downgrade no

Bootloader No ---

(Hardware) No ---

*) The runtime system version number must correspond to the target version number in the CODESYS target system setting.

→ chapter Set up the target (→ page 43)

Below we describe this software module:

CODESYS,

MaintenanceTool

MaintenanceTool

14107

14110

28

Page 29

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Software description

>

Bootloader

14111

On delivery ecomatmobile controllers only contain the boot loader.

The boot loader is a start program that allows to reload the runtime system and the application

program on the device.

The boot loader contains basic routines...

• for communication between hardware modules,

• for reloading the operating system.

The boot loader is the first software module to be saved on the device.

>

Runtime system

14112

Basic program in the device, establishes the connection between the hardware of the device and the

application program.

On delivery, there is normally no runtime system loaded in the controller (LED flashes green at 5 Hz).

Only the bootloader is active in this operating mode. It provides the minimum functions for loading the

runtime system, among others support of the interfaces (e.g. CAN).

Normally it is necessary to download the runtime system only once. Then, the application program can

be loaded into the controller (also repeatedly) without affecting the runtime system.

The runtime system is provided with this documentation on a separate data carrier. In addition, the

current version can be downloaded from the website of ifm electronic gmbh:

→ www.ifm.com > Select your country > [Service] > [Download]

>

Application program

14118

Software specific to the application, implemented by the machine manufacturer, generally containing

logic sequences, limits and expressions that control the appropriate inputs, outputs, calculations and

decisions.

8340

WARNING

The user is responsible for the reliable function of the application programs he designed. If necessary,

he must additionally carry out an approval test by corresponding supervisory and test organisations

according to the national regulations.

29

Page 30

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Software description

>

Libraries

ifm electronic offers a series of libraries (*.LIB) suitable for each device, containing the program

modules for the application program. Examples:

Library Use

ifm_CR0403_Vxxyyzz.LIB Device-specific library

ifm_RawCAN_NT_Vxxyyzz.LIB (optional)

ifm_CANopen_NT_Vxxyyzz.LIB (optional)

ifm_J1939_NT_Vxxyyzz.LIB (optional)

Detail information → ifm libraries for the device CR0403 (→ page 58)

Must always be contained in the application program!

when a CAN interface of the device is to be operated with CAN

Layer 2

when a CAN interface of the device is to be operated as

CANopen master or CANopen slave

when a CAN interface of the device is to communicate with a

motor control

15409

30

Page 31

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Distribution of the application program ................................................................................................ 34

System description Software description

>

3.4.2 Programming notes for CODESYS projects

FB, FUN, PRG in CODESYS .............................................................................................................. 31

Note the cycle time! ............................................................................................................................. 32

Creating application program .............................................................................................................. 33

Using ifm maintenance tool ................................................................................................................. 34

Here you receive tips how to program the device.

► See the notes in the CODESYS programming manual

→ www.ifm.com > select your country > [Data sheet search] > CR0403 > [Operating instructions]

→ ecomatmobile DVD "Software, tools and documentation".

>

FB, FUN, PRG in CODESYS

In CODESYS we differentiate between the following types of function elements:

FB = function block

• An FB can have several inputs and several outputs.

• An FB may be called several times in a project.

• An instance must be declared for each call.

• Permitted: Call FB and FUN in FB.

FUN = function

• A function can have several inputs but only one output.

• The output is of the same data type as the function itself.

PRG = program

• A PRG can have several inputs and several outputs.

• A PRG may only be called once in a project.

• Permitted: Call PRG, FB and FUN in PRG.

7426

15410

NOTE

Function blocks must NOT be called in functions!

Otherwise: During execution the application program will crash.

All function elements must NOT be called recursively, nor indirectly!

An IEC application may contain maximum 8000 function elements; in this device maximum 512

function elements!

Background:

All variables of functions...

• are initialised when called and

• become invalid after return to the caller.

Function blocks have 2 calls:

• an initialisation call and

• the actual call to do something.

Consequently that means for the function block call in a function:

• every time there is an additional initialisation call and

• the data of the last call gets lost.

31

Page 32

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Software description

>

Note the cycle time!

For the programmable devices from the controller family ecomatmobile numerous functions are

available which enable use of the devices in a wide range of applications.

As these units use more or fewer system resources depending on their complexity it is not always

possible to use all units at the same time and several times.

NOTICE

Risk that the device acts too slowly!

Cycle time must not become too long!

► When designing the application program the above-mentioned recommendations must be

complied with and tested.

► If necessary, the cycle time must be optimised by restructuring the software and the system set-

up.

8006

32

Page 33

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Software description

>

Creating application program

The application program is generated by the CODESYS programming system and loaded in the

controller several times during the program development for testing:

In CODESYS: [Online] > [Login] > load the new program.

For each such download via CODESYS the source code is translated again. The result is that each

time a new checksum is formed in the controller memory. This process is also permissible for safety

controllers until the release of the software.

8007

Graphics: Creation and distribution of the software

33

Page 34

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Software description

>

Using ifm maintenance tool

8492

The ifm Maintenance Tool serves for easy transfer of the program code from the programming station

to the controller. As a matter of principle each application software can be copied to the controllers

using the ifm Maintenance Tool. Advantage: A programming system with CODESYS licence is not

required.

Here you will find the current ifm Maintenance Tool:

→ www.ifm.com > Select your country > [Service] > [Download] > [Systems for mobile machines]

→ ecomatmobile DVD "Software, tools and documentation" under the tab 'R360 tools [D/E]'

>

Distribution of the application program

8493

We recommend the following sequence, if the application software is to be copied to the series

machine and used:

• Saving the software

After completion of program development the latest version of the application program loaded in

the controller using the ifm Maintenance Tool has to be read from the controller and saved on a

data carrier using the name project_file.RESX. Only this process ensures that the application

software and its checksums are stored.

• Download of the software.

To equip all machines of a series production with an identical software only this file may be loaded

in the controllers using the ifm Maintenance Tool.

• An error in the data of this file is automatically recognised by the integrated checksum when

loaded again using the ifm Maintenance Tool.

34

Page 35

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Software description

>

3.4.3 Operating states

After power on the ecomatmobile device can be in one of five possible operating states:

• BOOTLOADER

• INIT

• STOP

• RUN

• SYSTEM STOP

>

INIT state (Reset)

Premise: a valid runtime system is installed.

This state is passed through after every power on reset:

> The runtime system is initialised.

> Various checks are carried out, e.g. waiting for correctly power supply voltage.

> This temporary state is replaced by the RUN or STOP state.

> The LED lights orange.

Change out of this state possible into one of the following states:

• RUN

• STOP

>

1075

1076

STOP state

A transition into this state is possible in the following cases:

• from the INIT state if no application program is loaded.

• From the RUN state if the following condition is met:

• The STOP command is sent via the CODESYS interface.

In the STOP state:

> The outputs of the device are switched off.

> Processing of the application program is stopped.

> The LED lights green.

A transition from this state into one of the following states is possible:

• RUN

• ERROR

• FATAL ERROR

• INIT (after power-on-reset)

8288

35

Page 36

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Software description

>

RUN state

A transition into this state is possible in the following cases:

• from the INIT state (autostart) if the following conditions are met:

• The operating voltage has reached a minimum value. AND:

• The application program exists.

• From the STOP state:

• via the CODESYS command RUN.

• The operating voltage has reached or exceeded a minimum value.

In the RUN state:

> The runtime system is running.

> The application program is running.

> The LED flashes green with 2 Hz.

The LED can be controlled differently by the application program → FB SET_LED (→ page 198).

A transition from this state into one of the following states is possible:

• INIT (after power-on-reset)

• STOP

• ERROR

• FATAL ERROR

>

8287

ERROR state

A transition into this state is possible in the following cases:

• if the supply voltage is too low.

In the ERROR state:

> The outputs of the device are switched off.

> Processing of the application program is stopped.

> System parameters are saved.

> The LED flashed red with 5 Hz.

A transition from this state into one of the following states is possible:

• INIT (after power-on-reset)

• RUN

• STOP

• FATAL ERROR

>

FATAL ERROR state

A transition into this state is possible in the following cases:

• memory error (RAM / Flash)

• exception error

• runtime system error

In the FATAL ERROR state:

> The outputs of the device are switched off.

> The application program is terminated.

> The runtime system is terminated.

> The LED lights red.

A transition from this state into one of the following states is possible:

• INIT (after power-on-reset)

8290

8289

36

Page 37

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Software description

>

3.4.4 Performance limits of the device

Note the limits of the device! → Data sheet

>

Watchdog behaviour

In this device, a watchdog monitors the program runtime of the CODESYS application.

If the maximum watchdog time (100 ms) is exceeded:

> the device changes to the "Timeout Error" state

> all processes are stopped (reset)

> all outputs are switched off

> the status LED flashes red at 10 Hz

Eliminate the fault:

Delete application program!

PowerOn reset

Reload the application program into the device

If the watchdog in question fails:

> a second watchdog leads the device to the state "Fatal Error"

> the status LED lights red

Eliminate the fault:

PowerOn reset

If without success:

Goto Bootloader

PowerOn reset

Reload the runtime system into the device

Reload the application program into the device

If without success:

Hardware error: send device to ifm!

7358

15365

37

Page 38

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

System description Software description

>

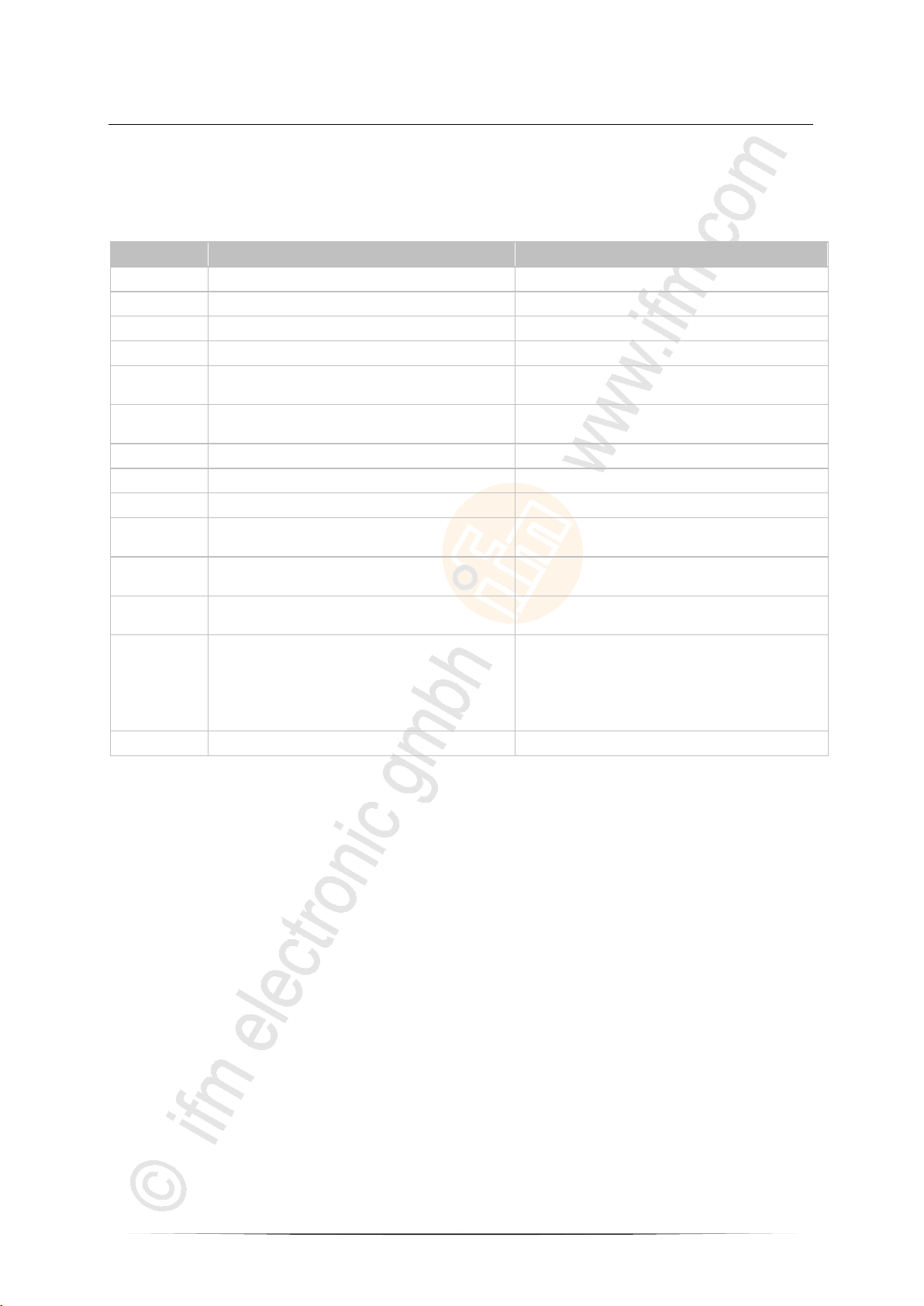

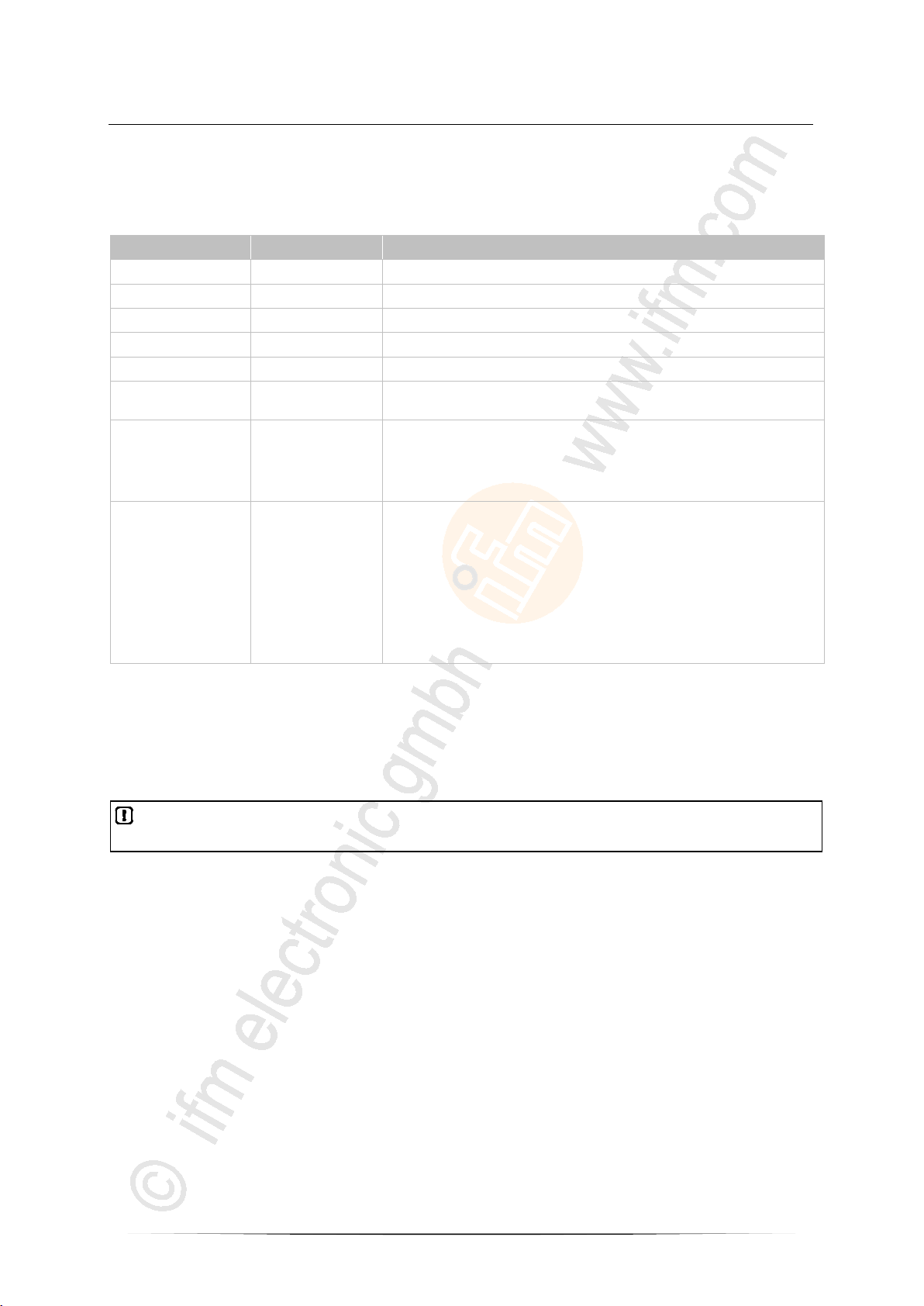

Limitations for CAN in this device

17975

FIFO (First In, First Out) = Operating principle of the stack memory: The data packet that was

written into the stack memory first, will also be read first. Each identifier has such a buffer (queue).

Some Raw-CAN function elements enable transmitting and receiving of several messages in one PLC

cycle as the messages are temporarily stored in a FiFo:

- CAN_TX..., → Function elements: transmit RAW-CAN data

- CAN_RX_ENH_FIFO (→ page 76)

- CAN_RX_RANGE_FIFO (→ page 80)

The number of FIFo messages is limited. The following limitations of the devices are valid:

Device

Criterion

max. FiFo transmit

- with FB CAN_TX...

- with FB CAN_TX_ENH...

max. FiFo receive

- with FB CAN_RX_..._FIFO

>

BasicController: CR040n,

CR041n, CR043n

BasicDisplay: CR045n

SmartController: CR253n

4 messages

16 messages

32 messages

PDM360 NG: CR108n

4 messages

16 messages

32 messages

Limitations for CANopen in this device

The following limitations of the devices are valid:

Device

Criterion

max. guarding error 32 messages 128 messages

max. SDO data 2 048 bytes 2 048 bytes

>

BasicController: CR040n,

CR041n, CR043n

BasicDisplay: CR045n

SmartController: CR253n

PDM360 NG: CR108n

Limitations for CAN J1939 in this device

The following limitations of the devices are valid:

Device

Criterion

max. FiFo transmit

- with FB J1939_TX

- with FB J1939_TX_ENH

max. FiFo receive

- with FB J1939_RX_FIFO

max. DTCs 64 messages 64 messages

max. data J1939 1 785 bytes 1 785 bytes

>

BasicController: CR040n,

CR041n, CR043n

BasicDisplay: CR045n

SmartController: CR253n

4 messages

16 messages

32 messages

PDM360 NG: CR108n

4 messages

16 messages

32 messages

17976

17977

38

Page 39

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Variables .............................................................................................................................................. 56

Verify the installation ........................................................................................................................... 41

Configurations Set up the runtime system

4 Configurations

Set up the runtime system ................................................................................................................... 39

Set up the programming system ......................................................................................................... 42

Function configuration in general ........................................................................................................ 46

Function configuration of the inputs and outputs ................................................................................ 47

The device configurations described in the corresponding installation instructions or in the Annex

(→ page 204) to this documentation are used for standard devices (stock items). They fulfil the

requested specifications of most applications.

Depending on the customer requirements for series use it is, however, also possible to use other

device configurations, e.g. with respect to the inputs/outputs and analogue channels.

>

4.1 Set up the runtime system

Reinstall the runtime system ............................................................................................................... 40

Update the runtime system ................................................................................................................. 41

1016

14091

39

Page 40

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

NOTICE

Configurations Set up the runtime system

>

4.1.1 Reinstall the runtime system

14635

8486

On delivery of the ecomatmobile controller no runtime system is normally loaded (LED flashes green

at 5 Hz). Only the boot loader is active in this operating mode. It provides the minimum functions for

loading the operating system (e.g. RS232, CAN).

Normally it is necessary to download the runtime system only once. The application program can then

be loaded to the device (also several times) without influencing the runtime system.

The runtime system is provided with this documentation on a separate data carrier. In addition, the

current version can be downloaded from the website of ifm electronic gmbh at:

→ www.ifm.com > Select your country > [Service] > [Download] > [Systems for mobile machines]

Risk of data loss!

In case of power failure during the data transmission data can be lost so that the device is no longer

functionable. Repair is only possible by ifm electronic.

► Ensure an uninterrupted power supply during the data transmission!

NOTE

The software versions suitable for the selected target must always be used:

• runtime system (ifm_CR0403_Vxxyyzz.RESX),

• PLC configuration (ifm_CR0403_Vxx.CFG),

• device library (ifm_CR0403_Vxxyyzz.LIB ) and

• the further files.

V

xx: 00...99

yy: 00...99

zz: 00...99

The basic file name (e.g. "CR0403") and the software version number "xx" (e.g. "01") must always

have the same value! Otherwise the device goes to the STOP mode.

The values for "yy" (release number) and "zz" (patch number) do not have to match.

The following files must also be loaded:

• the internal libraries (created in IEC 1131) required for the project,

• the configuration files (*.CFG) and

• the target files (*.TRG).

It may happen that the target system cannot or only partly be programmed with your currently

installed version of CODESYS. In such a case, please contact the technical support department of ifm

electronic gmbh.

The runtime system is transferred to the device using the separate program "Maintenance Tool". (The

downloader is on the ecomatmobile DVD "Software, tools and documentation" or can be downloaded

from ifm's website, if necessary):

→ www.ifm.com > Select your country > [Service] > [Download] > [Systems for mobile machines].

Normally the application program is loaded to the device via the programming system. But it can also

be loaded using the "Maintenance Tool" if it was first read from the device.

version

target version number

release number

patch number

4368

40

Page 41

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Configurations Set up the runtime system

>

4.1.2 Update the runtime system

13269

An older runtime system is already installed on the device. Now, you would like to update the runtime

system on the device?

14158

NOTICE

Risk of data loss!

When deleting or updating the runtime system all data and programs on the device are deleted.

► Save all required data and programs before deleting or updating the runtime system!

3084

When the operating system software or the CODESYS runtime system is considerably improved, ifm

releases a new version. The versions are numbered consecutively (V01, V02, V03, ...).

Please see the respective documentation for the new functions of the new software version. Note

whether special requirements for the hardware version are specified in the documentation.

If you have a device with an older version and if the conditions for the hardware and your project are

OK, you can update your device to the new software version.

For this operation, the same instructions apply as in the previous chapter 'Reinstall the runtime

system'.

>

4.1.3 Verify the installation

► After loading of the runtime system into the controller:

• Check whether the runtime system was transmitted correctly!

• Check whether the correct runtime system is loaded in the controller!

► 1st test:

Test with the ifm maintenance tool if the correct runtime system version was loaded:

• Read name and version of the runtime system in the device!

• Manually compare this information with the target data!

► 2nd test (optional):

Check in the application program if the correct runtime system version was loaded:

• read name and version of the runtime system in the device!

• Compare this data with the specified values!

The following FB serves for reading the data:

GET_SW_INFO (→ page 190) Delivers information about the system software of the device:

>

• software name,

• software version,

• build number,

• build date

14637

41

Page 42

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Set up the programming system via templates ................................................................................... 46

CAN declaration (e.g. CR1080) ........................................................................................................... 45

Configurations Set up the programming system

>

4.2 Set up the programming system

Set up the programming system manually .......................................................................................... 42

>

4.2.1 Set up the programming system manually

Set up the target .................................................................................................................................. 43

Activate the PLC configuration ............................................................................................................ 44

14461

3963

42

Page 43

ifm Programming Manual ecomatmobile BasicController (CR0403) Runtime System V03.02 2015-04-01

Configurations Set up the programming system

>

Set up the target

13136

11379

When creating a new project in CODESYS the target file corresponding to the device must be loaded.

► Select the requested target file in the dialogue window [Target Settings] in the menu

[Configuration].

> The target file constitutes the interface to the hardware for the programming system.