Page 1

Installation instructions

BasicController

and

BasicController

plus

CR0401

CR0403

CR0411

80010113 / 00 10 / 2014

UK

Page 2

BasicController / BasicController

plus

2

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�1 Symbols used� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�2 Warning signs used � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�1 General� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�2 Target group � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�3 Electrical connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

2�4 Tampering with the device � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3 Functions and features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Overview of the common characteristics � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�2 Application example � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�3 Devices of the Basic series (examples) � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4 Installation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�1 General installation instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�1�1 Protection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�1�2 Mounting surface � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�2 Fastening � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�3 Cover and cable seal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�3�1 Installation of the cable seal� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�3�2 Removal of the cable seal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�3�3 Installation of the cover � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

4�3�4 Removing the cover � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

5 Electrical connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

5�1 General electrical connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

5�2 Connection accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

5�2�1 Example accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

5�3 Frequency inputs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

5�4 Fuses � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

6 Indicators � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

7 Set-up � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

7�1 Programming � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

7�2 Required documentation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

7�3 Required hardware� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

8 Technical data� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

8�1 CR0401 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

8�2 CR0403 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

8�3 CR0411 � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

9 Maintenance, repair and disposal� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

9�1 Maintenance� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

9�2 Cleaning the housing surface� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

9�3 Repair� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

Page 3

UK

BasicController / BasicController

plus

3

This document is the original instructions�

Valid as from device status CR0401AC, CR0403AD und CR0411AA

All trademarks and company names are subject to the copyright of the respective companies�

9�4 Disposal � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

10 Approvals/standards � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

Page 4

BasicController / BasicController

plus

4

1 Preliminary note

This document applies to devices of the type "BasicController" (art� no�: CR0401,

CR0403) and "BasicController

plus

" (art� no�: CR0411)�

These instructions are an integral part of the device�

This document is intended for specialists� These specialists are people who are

qualified by their appropriate training and their experience to see risks and to

avoid possible hazards that may be caused during operation or maintenance of

the device� The document contains information about the correct handling of the

device�

Read this document before use to familiarise yourself with operating conditions,

installation and operation� Keep this document during the entire duration of use of

the device�

Adhere to the safety instructions�

1.1 Symbols used

► Instruction

> Reaction, result

[…] Designation of keys, buttons or indications

→ Cross-reference

Important note

Non-compliance can result in malfunction or interference�

Information

Supplementary note

1.2 Warning signs used

WARNING

Warning of serious personal injury�

Death or serious irreversible injuries may result�

CAUTION

Warning of personal injury�

Slight reversible injuries may result�

NOTE

Warning of damage to property�

Page 5

UK

BasicController / BasicController

plus

5

2 Safety instructions

2.1 General

These instructions contain texts and figures concerning the correct handling of the

device and must be read before installation or use�

Observe the operating instructions� Non-observance of the instructions, operation

which is not in accordance with use as prescribed below, wrong installation or

incorrect handling can seriously affect the safety of operators and machinery�

2.2 Target group

These instructions are intended for authorised persons according to the EMC and

low-voltage directives� The device must only be installed, connected and put into

operation by a qualified electrician�

2.3 Electrical connection

Disconnect the device externally before handling it� If necessary, also disconnect

any independently supplied output load circuits�

If the device is not supplied by the mobile on-board system (12/24 V battery

operation), it must be ensured that the external voltage is generated and supplied

according to the criteria for safety extra-low voltage (SELV) as this voltage is

supplied without further measures to the connected controller, the sensors and the

actuators�

The wiring of all signals in connection with the SELV circuit of the device must also

comply with the SELV criteria (safety extra-low voltage, safe electrical isolation

from other electric circuits)�

If the supplied SELV voltage is externally grounded (SELV becomes PELV), the

responsibility lies with the user and the respective national installation regulations

must be complied with� All statements in this document refer to the device the

SELV voltage of which is not grounded�

The connections may only be supplied with the signals indicated in the technical

data and/or on the device label and only the approved accessories of ifm

electronic gmbh may be connected�

2.4 Tampering with the device

In case of malfunctions or uncertainties please contact the manufacturer� Any

tampering with the device can seriously affect the safety of operators and

machinery� This is not permitted and leads to the exclusion of any liability and

warranty claims�

Page 6

BasicController / BasicController

plus

6

3 Functions and features

The freely programmable controllers of the "BasicController" and

"BasicController

plus

" series are rated for use under difficult conditions (e�g�

extended temperature range, strong vibration, intensive EMC interference)� They

are suitable for direct installation in mobile vehicles�

By means of the application software the user can configure the inputs and

outputs to adapt to the respective application� The controllers can be used as CAN

controller, CANopen master or intelligent I/O module. (→ 8 Technical data).

Application-specific extensions and adaptations are possible in conjunction with

additional products of the modular Basic series�

WARNING

The "BasicController" and "BasicController

plus

" series are not approved for safety

tasks in the field of safety of persons�

NOTE

"BasicController" and "BasicController

plus

" are intended for installation in vehicle

bodies, not in engines�

3.1 Overview of the common characteristics

● Freely programmable to IEC 61131-3

● 2 CAN interfaces (incl� interface for BasicDisplay CR0451 or CR0452)

● Configurable inputs/outputs

● Protection IP 20 (with cover and cable seal IP 54)

● Status LED

3.2 Application example

Use with cover and BasicDisplay

Page 7

UK

BasicController / BasicController

plus

7

3.3 Devices of the Basic series (examples)

● BasicDisplay (art� no�: CR0451)

programmable 2�8 inch colour display with graphic capabilities

5 freely programmable backlit function keys

1 rocker switch for cursor function

● BasicDisplay XL ( art� no�: CR0452)

programmable 4�3 inch colour display with graphic capabilities

6 freely programmable backlit function keys

1 rocker switch for cursor function

● BasicRelay (art� no�: CR0421)

freely wirable relay and fuse carrier for 6 automotive relays and 10 automotive

fuses

● Cover (art� no�: EC0401)

● Cover with built-in display recess (art� no�: EC0402)

incl� cable seal to obtain protection rating IP 54

For information about the available Basic products see:

www.ifm.com → Products → Control systems

or directly

www.ifm.com → Data sheet search → e.g. CR0451

Page 8

BasicController / BasicController

plus

8

4 Installation

4.1 General installation instructions

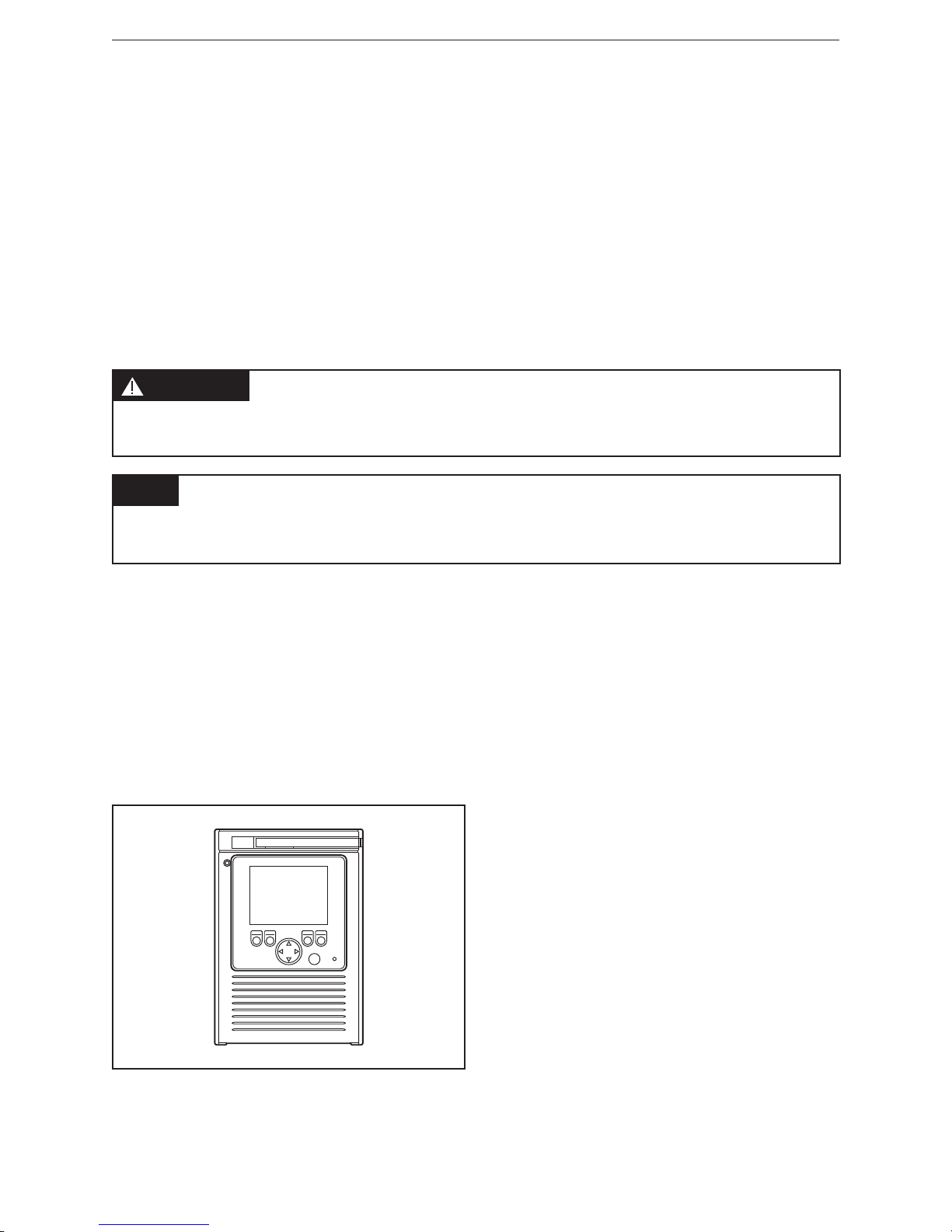

4.1.1 Protection

The achievable protection rating of the device depends on the accessories used

and the mounting position�

Protection Accessories Installation position Art. no.

IP 20 – freely selectable –

IP 54 cover with cable seal cable connection from the

bottom

e�g� EC0401

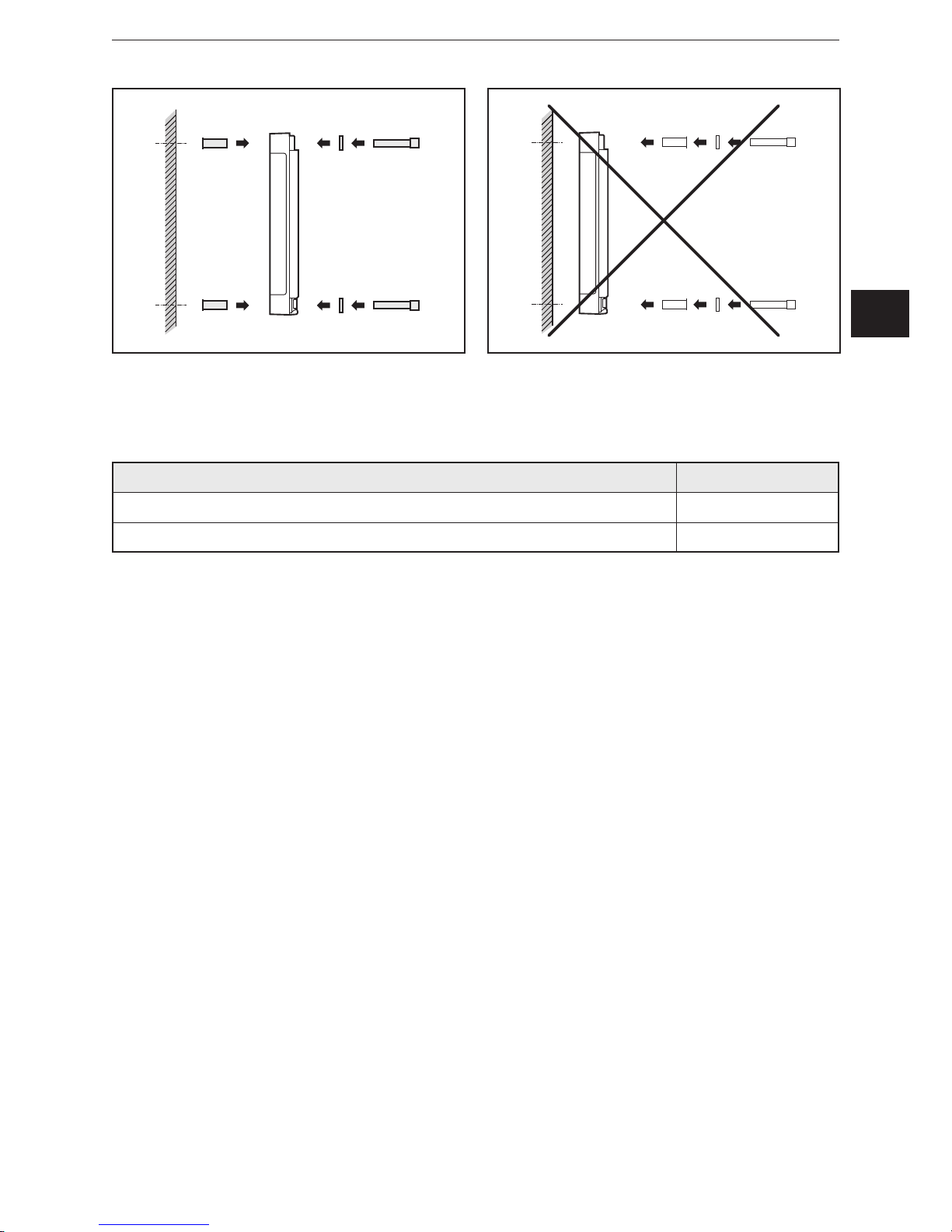

4.1.2 Mounting surface

NOTE

The housing must not be exposed to any torsional forces or mechanical stress�

► Mount the device on a flat surface�

► Use compensating elements if there is no flat mounting surface available�

Mounting surface

4.2 Fastening

► Insert the enclosed tubular rivets from the back of the module in the 4 fixing

holes�

► Fix the module using 4 washers and M4 screws�

Tighten the screws alternately crosswise�

Page 9

UK

BasicController / BasicController

plus

9

Use of the tubular rivets

Tightening torque: 1�5 Nm

Hole dimensions (→ 8 Technical data)

Screws to be used (examples): Standard

Cylinder screws with hexagon socket (M4 x L) DIN 912

Cylinder screws with hexagon socket and low head (M4 x L) DIN 7984

Page 10

BasicController / BasicController

plus

10

4.3 Cover and cable seal

NOTE

Protection IP 54 can only be guaranteed if the cover is used together with the

cable seal�

NOTE

When a cover is installed, the device temperature can increase�

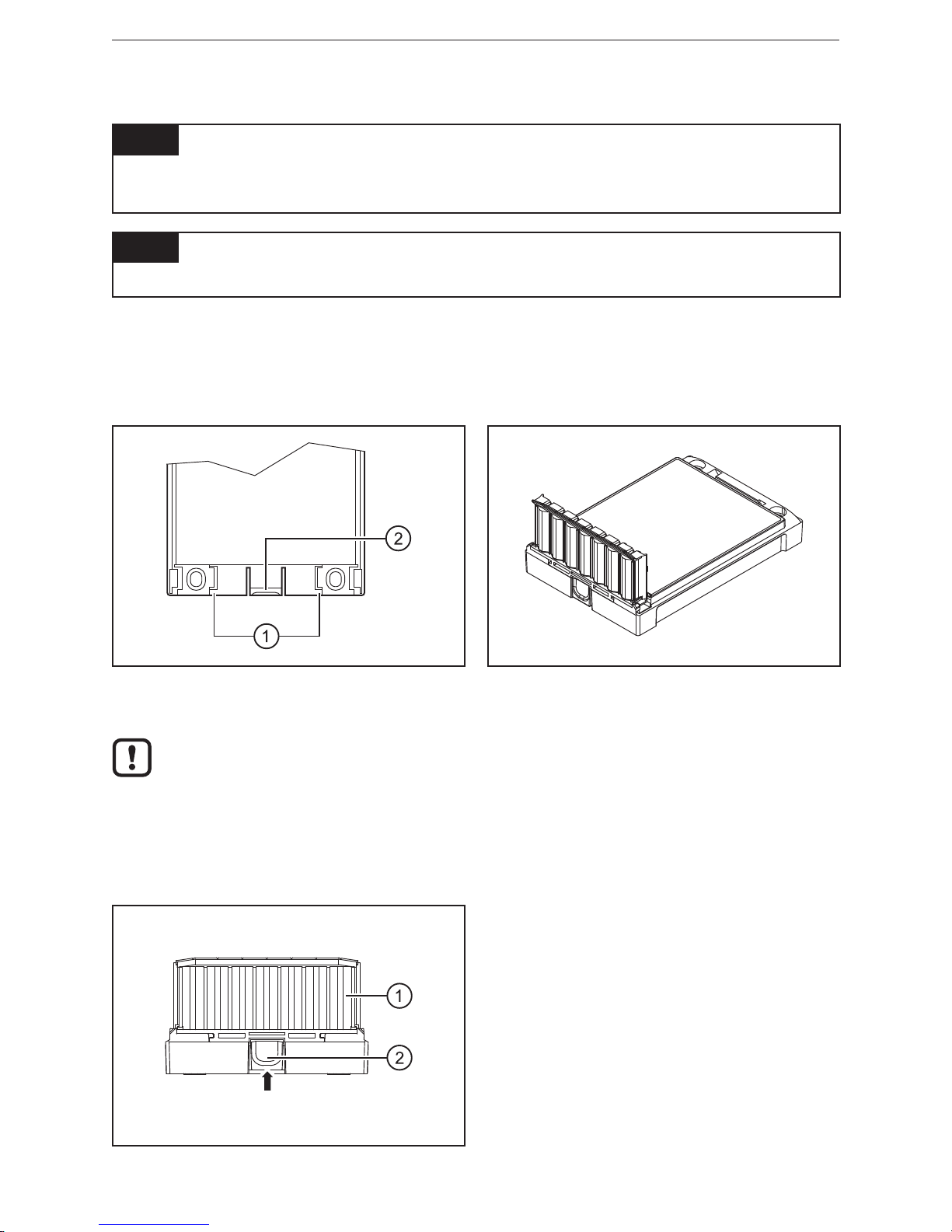

4.3.1 Installation of the cable seal

► Insert the cable seal into the locator from below�

> The locking of the cable seal audibly clips into place�

1� Locator for cable seal

2� Locking

Mounted cable seal

The cable seal cannot be used as strain relief of the cables�

(→ 5.1 General electrical connection)

4.3.2 Removal of the cable seal

► Press the locking at the bottom of the device and remove the cable seal from

the device by pulling downwards�

1� Cable seal

2� Locking

Bottom of the device

Page 11

UK

BasicController / BasicController

plus

11

4.3.3 Installation of the cover

The covers of the Basic series feature a single-lever locking� Installation is done

without tools�

1: locking lever

2: cover guides

3: insertion slots for cover guides

► Pull out the locking lever and rotate it towards you�

► Place the cover diagonally onto the device�

Insert the 2 cover guides, found at the bottom of the cover, into the slots�

► Close the cover onto the lower part�

The 2 guides and slots provide a pivot point�

► Move the locking lever back into its initial position�

> The cover is locked�

1: BasicController

2: cover

4.3.4 Removing the cover

► Pull out the locking lever and rotate it towards you�

> The cover is unlocked and can be removed�

Page 12

BasicController / BasicController

plus

12

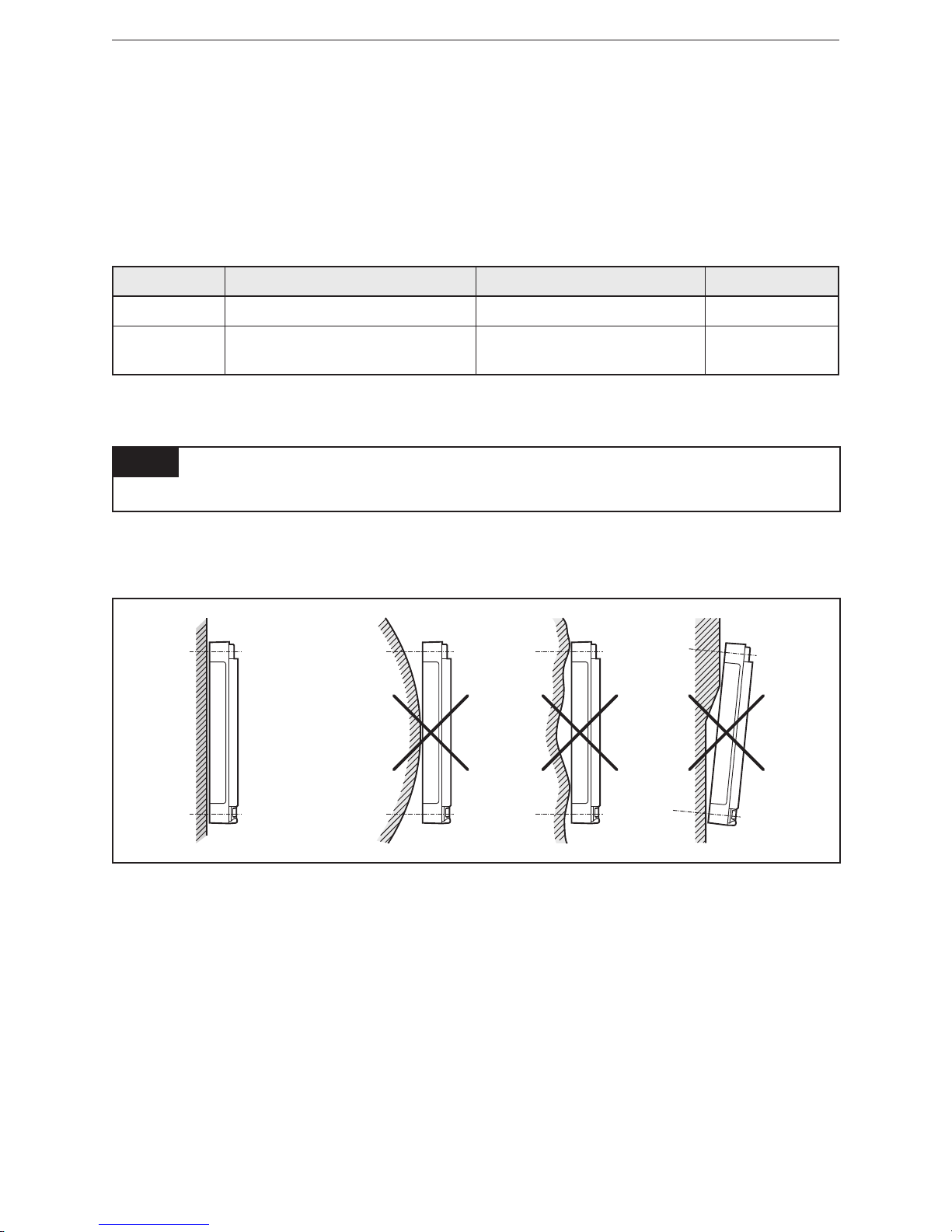

5 Electrical connection

5.1 General electrical connection

The supply cables, CAN interfaces and input/outputs are connected via 6�3 x 0�8

mm blade male terminals on the front of the device�

Wiring (→ 8 Technical data)

A B C D E F

N2

P/N1

1: Inputs

2: Outputs

3: Supply and CAN interfaces

Connector area (here e�g� CR0403)

Connector Connection CR0401 CR0403 CR0411 Number of

poles

A Inputs IN0���3 IN0���3 IN0���3 8

B IN4���7 IN4���7 IN4���7

C IN8���11 IN8���11 –

D Outputs – OUT0���3 OUT0���3

E OUT0���3 OUT4���7 OUT4���7

F OUT4���7 OUT8���11 –

P/N1 CAN interface 1 and supply 6

N2 CAN interface 2 (e�g� for BasicDisplay CR0451 or CR0452) 4

– = not connected

NOTE

Wrong connection may cause damage to the device�

► Observe the safety instructions (→ 2.3 Electrical connection).

► Basically all supply and signal cables must be laid separately�

► Lay supply and signal cables away from the device using the shortest possible

route�

► All connected cables must be provided with a strain relief at least 100 mm

behind the cable entry�

► Protect unused terminals with unpopulated sockets if no cover is used�

Page 13

UK

BasicController / BasicController

plus

13

5.2 Connection accessories

You can find more information about the available accessories at:

www.ifm.com → Data sheet search → e.g. CR0401 → Accessories

5.2.1 Example accessories

BasicDisplay CR0451

cover with EC0402 built-in display recess

EC0452 connection cable

Accessories and example connection

5.3 Frequency inputs

► Operate frequency inputs with screened cables, so that useful signals are not

affected by external interference�

5.4 Fuses

► The individual electric circuits must be protected in order to protect the whole

system�

Description Potential Connector: pin Fuse

VBB

S

Supply sensors/module 8…32 V DC P/N1: 1 ≤ 2 A T

VBB

1

Supply outputs

CR0401: OUT0���3

CR0403: OUT0���7

CR0411: OUT0���3

8…32 V DC P/N1: 2 15 A

VBB

2

Supply outputs

CR0401: OUT4���7

CR0403: OUT8���11

CR0411: OUT4���7

8…32 V DC P/N1: 3 15 A

Page 14

BasicController / BasicController

plus

14

6 Indicators

1: Status LED 2: LED lighting in the cover (e�g� EC0401)

Operating states (→ 8 Technical data)

Page 15

UK

BasicController / BasicController

plus

15

7 Set-up

7.1 Programming

The user can easily create the application software by means of the IEC 61131-3

compliant programming system CODESYS 2�3�

WARNING

The user is responsible for the safe function of the application programs which

he created himself� If necessary, he must additionally carry out an approval test

by corresponding supervisory and test organisations according to the national

regulations�

7.2 Required documentation

In addition to the CODESYS programming system, the following documents are

required for programming and set-up of the device:

● Programming manual CODESYS V2�3

(alternatively as online help)

● BasicController system manual

(alternatively as online help)

The manuals can be downloaded from the internet:

www.ifm.com → Data sheet search → e.g. CR0401 → Additional data

CODESYS and BasicController online help

www.ifm.com → Service → Download → Control systems*

*) Download area with registration

7.3 Required hardware

A CAN interface for the connection to a PC or a notebook is required to load the

application program to the device�

Example:

● CAN/RS232 USB interface CANfox (art� no�: EC2112)

● Adapter cable for CANfox (art� no�: EC2113)

You can find more information about the available accessories at:

www.ifm.com → Data sheet search → CR0451 → Accessories

or directly

www.ifm.com → Data sheet search → EC2112

Page 16

BasicController / BasicController

plus

16

8 Technical data

8.1 CR0401

Control systems

CR0401

18

ABCD E F

N2

P/N1

25,5

127

163

145

12,5

8,5

6,5

10,5

79,7

112

LED

8,5

Mobile controller

BasicController

12 inputs

8 outputs

2 CAN interfaces

Programming

to IEC 61131-3

8...32 V DC

Technical data Modular control system

Usable as CANopen controller or intelligent I/O module

Mechanical data

Housing plastic housing (black)

Dimensions (H x W x D)

without cover

with EC0401 cover

with EC0402 cover and BasicDisplay

CR0451

163 x 112 x 25.5 mm

163 x 112 x 68 mm

163 x 112 x 73.4 mm

Installation xing by means of 4 M4 screws to DIN 912 or DIN 7984 and 4 tubular rivets to

DIN 7340 (tubular rivets are supplied)

Connection AMP blade male terminals 6.3 mm, to be clipped into place and thus vibration-

resistant, protected against reverse polarity

contacts AMP timer, CuZn pre-tin-plated

core cross-section 0.5...2.5 mm²

Inputs

Outputs

Operating voltage , CAN bus

3 x 8-pole

2 x 8-pole

1 x 6-pole, 1 x 4-pole

Protection rating IP 20 (with cover and cable seal IP 54)

Operating/storage temperature -40...85° C / -40...85° C

Weight 0.30 kg

Electrical data

Operating voltage 8...32 V DC

Current consumption 45 mA (at 24 V DC)

Overvoltage

Undervoltage detection

Undervoltage shutdown

36 V for t ≤ 10 s

at U

B

≤ 7.8 V

at U

B

≤ 7.0 V

Processor Freescale PowerPC, 50 MHz

Memory (total) 208 Kbytes RAM / 1536 Kbytes Flash / 1 Kbyte FRAM

Memory allocation see BasicController system manual

www.ifm.com → data sheet search → e.g. CR0401 → Additional data

Device monitoring undervoltage monitoring

watchdog function

checksum test for program and system

excess temperature monitoring

Page 17

UK

BasicController / BasicController

plus

17

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0401 / page 2

CR0401 Technical data

Control systems

CAN interfaces 1/2

Baud rate

Communication pro le

CAN interface 2.0 A/B, ISO 11898

20 kBit/s...1 MBit/s (default CAN1: 250 kBit/s, CAN2: 250 kBit/s)

CANopen, CiA DS 301 version 4, CiA DS 401 version 1.4

or SAE J 1939 or free protocol

Software/programming

Programming system CODESYS version 2.3 (IEC 61131-3)

Inputs 12 (con gurable),

Con gurations

Number Version

4 digital for positive / negative sensor signals

analogue (0…10/32 V DC, 0..20 mA, ratiometric)

frequency (≤ 30 kHz)

B

L/BH

A

FRQ

4 digital for positive sensor signals

resistance measurement (0,016...3.6 kΩ)

B

L

4 digital for positive sensor signals B

L

positive sensor signals have diagnostic capabilities

Outputs 8 (con gurable),

Con gurations

Number Version

2 positive switching (high side)

PWM output (20…250 Hz), 2 A, diagnosis

B

H

PWM

4 positive switching (high side)

PWM output (20…250 Hz), 1 A

B

H

PWM

2 positive switching (high side)

PWM output (20…250 Hz), 4 A, diagnosis

B

H

PWM

Status LED two-colour LED (red/green)

Operating states (preset)

Colour Status Description

– permanently off no operating voltage

orange 1 x on initialisation or reset checks

green 5 Hz no operating system loaded

2 Hz application is running (RUN)

permanently on application stopped (STOP)

red 10 Hz application stopped (STOP with error)

5 Hz application stopped due to undervoltage

permanently on system fault (fatal error)

Page 18

BasicController / BasicController

plus

18

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0401 / page 3

CR0401 Technical data

Control systems

Characteristics of the inputs

Analogue inputs (A)

Connection A: 02, 03, 06, 07

IN0...IN3

can be con gured as:

● Voltage inputs

Input voltage 0...10 V or 0...32 V

Resolution 12 bits

Accuracy ± 1% FS

Input resistance 65.6 kΩ (0...10 V), 50.7 kΩ (0...32 V)

Input frequency ≤ 500 Hz

● Current inputs, with diagnostic capability

Input current 0...20 mA

Resolution 12 bits

Accuracy ± 1% FS

Input resistance 400 Ω

Input frequency ≤ 500 Hz

At a current of > 23 mA the input is switched to the voltage input!

● Voltage inputs, 0...32 V, ratiometric

Function (U

IN

÷ UB) x 1000 ‰

Value range 0...1000 ‰

Input resistance 50.7 kΩ

● Binary voltage inputs for positive sensor signals

Switch-on level > 0.7 U

B

Switch-off level < 0.3 U

B

Input resistance 3.2 kΩ

Input frequency 50 Hz

Diagnosis wire break > 0.95 U

B

Diagnosis short circuit < 1 V

● Binary voltage inputs for negative sensor signals

Switch-on level > 0.7 UB

Switch-off level < 0.3 UB

Input resistance 3.2 kΩ

Input frequency 50 Hz

● Frequency inputs

Input resistance 3.2 kΩ

Input frequency ≤ 30 kHz

Switch-on level > 0.35...0.48 U

B

Switch-off level < 0.29 U

B

Digital input (BL)

Connection B: 02, 03, 06, 07

IN4…IN7

can be con gured as...

● Binary voltage inputs for positive sensor signals

Switch-on level > 0.7 U

B

Switch-off level < 0.3 U

B

Input resistance 3.2 kΩ

Input frequency 50 Hz

Diagnosis wire break > 0.95 U

B

Diagnosis short circuit < 1 V

● Resistor input

Measuring range 16…3.6 kΩ

Accuracy ± 3 %

Page 19

UK

BasicController / BasicController

plus

19

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0401 / page 4

CR0401 Technical data

Control systems

Digital input (BL)

Connection C: 02, 03, 06, 07

IN8…IN11

can be con gured as...

● Binary voltage inputs for positive sensor signals

Switch-on level > 0.7 U

B

Switch-off level < 0.3 U

B

Input resistance 3.2 kΩ

Input frequency 50 Hz

Diagnosis wire break > 0.95 U

B

Diagnosis short circuit < 1 V

Characteristics of the outputs

Digital outputs (B

H

, PWM)

Connection F: 01, 03,

OUT4…OUT5

● Semiconductor outputs, positive switching (high side), short-circuit and

overload protected. Diagnosis via voltage feedback, pullup resistance can be

deactivated (wire break/ short circuit)

Switching voltage 8...32 V DC

Switching current ≤ 2A

● PWM outputs

Output frequency 20...250 Hz

Pulse/pause ratio 1…1000 ‰

Switching current ≤ 2A

If only one output of the output pair is active, the switching current is ≤ 2.5 A.

Max. switch-on current ≤ 11 A

Digital outputs (B

H

, PWM)

Connection E: 01, 03, 05, 07

OUT0…OUT3

● Semiconductor outputs, positive switching (high side), short-circuit and over-

load protected

Switching voltage 8...32 V DC

Switching current ≤ 1 A

● PWM outputs

Output frequency 20...250 Hz

Pulse/pause ratio 1…1000 ‰

Switching current ≤ 1 A

Max. switch-on current ≤ 11 A

Digital outputs (B

H

, PWM)

Connection F: 05, 07

OUT6…OUT7

● Semiconductor outputs, positive switching (high side), short-circuit and

overload protected. Diagnosis via voltage feedback, pullup resistance can be

deactivated (wire break/ short circuit)

Switching voltage 8...32 V DC

Switching current ≤ 4 A

● PWM outputs

Output frequency 20...250 Hz

Pulse/pause ratio 1…1000 ‰

Switching current ≤ 4 A

Max. switch-on current ≤ 30 A

Free wheel diodes free wheel diodes for the deactivation of inductive loads are integrated

Overload protection

(valid for all outputs)

≤ 5 minutes (at 100% overload)

Short-circuit strength

(valid for all inputs and outputs)

≤ 5 minutes (contact +VBB with GND)

Max. total current of the output supplies

VBB

1

/VBB2 (Continuous current load)

permanently ≤ 50 % of the nominal current

Page 20

BasicController / BasicController

plus

20

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0401 / page 5

CR0401 Technical data

Control systems

Test standards and regulations

CE marking EN 61000-6-2 Electromagnetic compatibility (EMC)

Noise immunity

EN 61000-6-4 Electromagnetic compatibility (EMC)

Emission standard

EN 61010-1 Safety requirements for electrical equipment for

measurement, control and laboratory use

E1 marking UN/ECE-R10 Emission standard

Immunity with 100 V/m

Electrical tests ISO 7637-2 Pulse 1, severity level: IV; function state C

Pulse 2a, severity level: IV; function state A

Pulse 2b, severity level: IV; function state C

Pulse 3a, severity level: IV; function state A

Pulse 3b, severity level: IV; function state A

Pulse 4, severity level: IV; function state A

Pulse 5, severity level: III; function state C

(data valid for the 24 V system)

Pulse 4, severity level: III; function state C

(data valid for the 12 V system)

Climatic tests EN 60068-2-30 Damp heat, cyclic

Upper temperature 55°C, number of cycles: 6

EN 60068-2-78 Damp heat, steady state

Test temperature 40°C / 93% RH,

Test duration: 21 days

EN 60068-2-52 Salt spray test

Severity level 3 (motor vehicle)

only with installed EC0401 or EC0402 cover

Mechanical tests ISO 16750-3 Test VII; Vibration, random

Mounting location: vehicle body

EN 60068-2-6 Vibration, sinusoidal

10...500 Hz; 0.72 mm/10 g; 10 cycles/axis

ISO 16750-3 Bumps

30 g/6 ms; 24,000 shocks

Note The EC declaration of conformity and approvals can be found at:

www.ifm.com → data sheet search → CR0401 → More information

Wiring

A B C D E F N2 P/N1

8 poles 4 poles 6 poles

VBB

S

IN0

IN1

GND

GND

IN2

IN3

VBB

S

VBB

S

IN4

IN5

GND

GND

IN6

IN7

VBB

S

VBB

S

IN8

IN9

GND

GND

IN10

IN11

VBB

S

OUT0

GND

OUT1

GND

OUT2

GND

OUT3

GND

OUT4

GND

OUT5

GND

OUT6

GND

OUT7

GND

VBB

S

GND

CAN2_H

CAN2_L

VBB

S

VBB

1

VBB

2

GND

CAN1_H

CAN1_L

D = not used

Abbreviations A = analogue

B

H

= binary high side

B

L

= binary low side

FRQ = frequency/pulse inputs

PWM = pulse width modulation

VBB

S

= supply sensors/module

VBB

1

= supply OUT 0...3

VBB

2

= supply OUT 4...7

Page 21

UK

BasicController / BasicController

plus

21

8.2 CR0403

Control systems

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0403 / page 1

CR0403

18

A B C D E F

N2

P/N1

25,5

127

163

145

12,5

8,5

6,5

10,5

79,7

112

LED

8,5

Mobile controller

BasicController

12 inputs

12 outputs

2 CAN interfaces

Programming

to IEC 61131-3

8...32 V DC

Technical data Modular control system

Usable as CANopen master or intelligent I/O module

Mechanical data

Housing plastic housing (black)

Dimensions (H x W x D)

without cover

with EC0401 cover

with EC0402 cover and BasicDisplay

CR0451

163 x 112 x 25.5 mm

163 x 112 x 68 mm

163 x 112 x 73.4 mm

Installation xing by means of 4 M4 screws to DIN 912 or DIN 7984 and 4 tubular rivets to

DIN 7340 (tubular rivets are supplied)

Connection AMP blade male terminals 6.3 mm, to be clipped into place and thus vibration-

resistant, protected against reverse polarity

contacts AMP timer, CuZn pre-tin-plated

core cross-section 0.5...2.5 mm²

Inputs

Outputs

Operating voltage, CAN bus

3 x 8-pole

3 x 8-pole

1 x 6-pole, 1 x 4-pole

Protection rating IP 20 (with cover and cable seal IP 54)

Operating/storage temperature -40...85° C / -40...85° C

Weight 0.30 kg

Electrical data

Operating voltage 8...32 V DC

Current consumption 45 mA (at 24 V DC)

Overvoltage

Undervoltage detection

Undervoltage shutdown

36 V for t ≤ 10 s

at U

B

≤ 7.8 V

at U

B

≤ 7.0 V

Processor Freescale PowerPC, 50 MHz

Memory (total) 592 Kbytes RAM / 1536 Kbytes Flash / 1 Kbyte FRAM

Memory allocation see BasicController system manual

www.ifm.com → data sheet search → e.g. CR0403 → Additional data

Device monitoring undervoltage monitoring

watchdog function

checksum test for program and system

excess temperature monitoring

Page 22

BasicController / BasicController

plus

22

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0403 / page 2

CR0403 Technical data

Control systems

CAN interfaces 1/2

Baud rate

Communication pro le

CAN interface 2.0 A/B, ISO 11898

20 kBit/s...1 MBit/s (Default CAN1: 250 kBit/s, CAN2: 250 kBit/s)

CANopen, CiA DS 301 version 4, CiA DS 401 version 1.4

or SAE J 1939 or free protocol

Software/programming

Programming system CODESYS version 2.3 (IEC 61131-3)

Inputs 12 (con gurable)

Con gurations

Number Version

4 digital for positive / negative sensor signals

analogue (0…10/32 V DC, 0..20 mA, ratiometric)

frequency (≤ 30 kHz)

B

L/BH

A

FRQ

4 digital for positive sensor signals

resistance measurement (0,016...3.6 kΩ)

B

L

4 digital for positive sensor signals B

L

positive sensor signals have diagnostic capabilities

Outputs 12 (con gurable)

Con gurations

Number Version

2 positive switching (high side)

PWM output (20…250 Hz), 2A,

current-controlled 0.02…2 A, diagnosis

B

H

PWM

PWM-I

4 positive switching (high side)

PWM output (20…250 Hz), 2 A, diagnosis

B

H

PWM

4 positive switching (high side)

PWM output (20…250 Hz), 1 A

B

H

PWM

2 positive switching (high side)

PWM output (20…250 Hz), 4 A, diagnosis

B

H

PWM

Status LED two-colour LED (red/green)

Operating states (preset)

Colour Status Description

– permanently off no operating voltage

orange 1 x on initialisation or reset checks

green 5 Hz no operating system loaded

2 Hz application is running (RUN)

permanently on application stopped (STOP)

red 10 Hz application stopped (STOP with error)

5 Hz application stopped due to undervoltage

permanently on system fault (fatal error)

Page 23

UK

BasicController / BasicController

plus

23

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0403 / page 3

CR0403 Technical data

Control systems

Characteristics of the inputs

Analogue inputs (A)

Connection A: 02, 03, 06, 07

IN0...IN3

can be con gured as:

● Voltage inputs

Input voltage 0...10 V or 0...32 V

Resolution 12 bits

Accuracy ± 1% FS

Input resistance 65.6 kΩ (0...10 V), 50.7 kΩ (0...32 V)

Input frequency ≤ 500 Hz

● Current inputs, with diagnostic capability

Input current 0...20 mA

Resolution 12 bits

Accuracy ± 1% FS

Input resistance 400 Ω

Input frequency ≤ 500 Hz

At a current of > 23 mA the input is switched to the voltage input!

● Voltage inputs, 0...32 V, ratiometric

Function (U

IN

÷ UB) x 1000 ‰

Value range 0...1000 ‰

Input resistance 50.7 kΩ

● Binary voltage inputs for positive sensor signals

Switch-on level > 0.7 U

B

Switch-off level < 0.3 U

B

Input resistance 3.2 kΩ

Input frequency 50 Hz

Diagnosis wire break > 0.95 U

B

Diagnosis short circuit < 1 V

● Binary voltage inputs for negative sensor signals

Switch-on level > 0.7 UB

Switch-off level < 0.3 UB

Input resistance 3.2 kΩ

Input frequency 50 Hz

● Frequency inputs

Input resistance 3.2 kΩ

Input frequency < 30 kHz

Switch-on level > 0.35...0.48 U

B

Switch-off level < 0.29 U

B

Digital input (BL)

Connection B: 02, 03, 06, 07

IN4…IN7

can be con gured as...

● Binary voltage inputs for positive sensor signals

Switch-on level > 0.7 U

B

Switch-off level < 0.3 U

B

Input resistance 3.2 kΩ

Input frequency 50 Hz

Diagnosis wire break > 0.95 U

B

Diagnosis short circuit < 1 V

● Resistor input

Measuring range 16…3.6 kΩ

Accuracy ± 3 %

Page 24

BasicController / BasicController

plus

24

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0403 / page 4

CR0403 Technical data

Control systems

Digital input (BL)

Connection C: 02, 03, 06, 07

IN8…IN11

can be con gured as...

● Binary voltage inputs for positive sensor signals

Switch-on level > 0.7 U

B

Switch-off level < 0.3 U

B

Input resistance 3.2 kΩ

Input frequency 50 Hz

Diagnosis wire break > 0.95 U

B

Diagnosis short circuit < 1 V

Characteristics of the outputs

Digital outputs (B

H

, PWM, PWM-I)

Connection D: 01, 03

OUT0…OUT1

● Semiconductor outputs, positive switching (high side), short-circuit and over-

load protected

Diagnosis via current feedback (wire break / overload)

Diagnosis via voltage feedback, pullup resistance can be deactivated (wire

break/ short circuit)

Switching voltage 8...32 V DC

Switching current ≤ 2A

Load resistance ≥ 6 Ω (at 12 V DC)

≥ 12 Ω (at 24 V DC)

● PWM outputs

Output frequency 20...250 Hz

Pulse/pause ratio 1…1000 ‰

Switching current ≤ 2A

● Current-controlled output

Output frequency 20...250 Hz

Control range 0.02…2 A

Setting resolution 1 mA

Control resolution 2 mA

If only one output is active, the switching current is ≤ 2.5 A.

Max. switch-on current ≤ 11 A

Digital outputs (B

H

, PWM)

Connection D: 05, 07

OUT2…OUT3

Connection F: 01, 03,

OUT8…OUT9

● Semiconductor outputs, positive switching (high side), short-circuit and over-

load protected

Diagnosis via voltage feedback, pullup resistance can be deactivated (wire

break/ short circuit)

Switching voltage 8...32 V DC

Switching current ≤ 2A

● PWM outputs

Output frequency 20...250 Hz

Pulse/pause ratio 1…1000 ‰

Switching current ≤ 2 A

If only one output of the output pair is active, the switching current is ≤ 2.5 A.

Max. switch-on current ≤ 11 A

Page 25

UK

BasicController / BasicController

plus

25

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0403 / page 5

CR0403 Technical data

Control systems

Digital outputs (BH)

Connection E: 01, 03, 05, 07

OUT4…OUT7

● Semiconductor outputs, positive switching (high side), short-circuit and over-

load protected

Switching voltage 8...32 V DC

Switching current ≤ 1 A

● PWM outputs

Output frequency 20...250 Hz

Pulse/pause ratio 1…1000 ‰

Switching current ≤ 1 A

Max. switch-on current ≤ 11 A

Digital outputs (B

H

, PWM)

Connection F: 05, 07

OUT10…OUT11

● Semiconductor outputs, positive switching (high side), short-circuit and over-

load protected

Diagnosis via voltage feedback, pullup resistance can be deactivated (wire

break/ short circuit)

Switching voltage 8...32 V DC

Switching current ≤ 4 A

● PWM outputs

Output frequency 20...250 Hz

Pulse/pause ratio 1…1000 ‰

Switching current ≤ 4 A

Max. switch-on current ≤ 30 A

Free wheel diodes free wheel diodes for the deactivation of inductive loads are integrated

Overload protection

(valid for all outputs)

≤ 5 minutes (at 100% overload)

Short-circuit strength

(valid for all inputs and outputs)

≤ 5 minutes (contact +VBB with GND)

Max. total current of the output supplies

VBB

1

/VBB

2

(continuous current load)

permanently ≤ 50 % of the nominal current

Page 26

BasicController / BasicController

plus

26

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0403 / page 6

CR0403 Technical data

Control systems

Test standards and regulations

CE marking EN 61000-6-2 Electromagnetic compatibility (EMC)

Noise immunity

EN 61000-6-4 Electromagnetic compatibility (EMC)

Emission standard

EN 61010-1 Safety requirements for electrical equipment for

measurement, control and laboratory use

E1 marking UN/ECE-R10 Emission standard

Immunity with 100 V/m

Electrical tests ISO 7637-2 Pulse 1, severity level: IV; function state C

Pulse 2a, severity level: IV; function state A

Pulse 2b, severity level: IV; function state C

Pulse 3a, severity level: IV; function state A

Pulse 3b, severity level: IV; function state A

Pulse 4, severity level: IV; function state A

Pulse 5, severity level: III; function state C

(data valid for the 24 V system)

Pulse 4, severity level: III; function state C

(data valid for the 12 V system)

Climatic tests EN 60068-2-30 Damp heat, cyclic

Upper temperature 55°C, number of cycles: 6

EN 60068-2-78 Damp heat, steady state

Test temperature 40°C / 93% RH,

Test duration: 21 days

EN 60068-2-52 Salt spray test

Severity level 3 (motor vehicle)

only with installed EC0401 or EC0402 cover

Mechanical tests ISO 16750-3 Test VII; vibration, random

Mounting location: vehicle body

EN 60068-2-6 Vibration, sinusoidal

10...500 Hz; 0.72 mm/10 g; 10 cycles/axis

ISO 16750-3 Bumps

30 g/6 ms; 24,000 shocks

Note The EC declaration of conformity and approvals can be found at:

www.ifm.com → data sheet search → CR0403 → More information

Wiring

A B C D E F N2 P/N1

8 poles 4 poles 6 poles

VBB

S

IN0

IN1

GND

GND

IN2

IN3

VBB

S

VBB

S

IN4

IN5

GND

GND

IN6

IN7

VBB

S

VBB

S

IN8

IN9

GND

GND

IN10

IN11

VBB

S

OUT0

GND

OUT1

GND

OUT2

GND

OUT3

GND

OUT4

GND

OUT5

GND

OUT6

GND

OUT7

GND

OUT8

GND

OUT9

GND

OUT10

GND

OUT11

GND

VBB

S

GND

CAN2_H

CAN2_L

VBB

S

VBB

1

VBB

2

GND

CAN1_H

CAN1_L

Abbreviations A = analogue

B

H

= binary high side

B

L

= binary low side

FRQ = frequency/pulse inputs

PWM = pulse width modulation

VBB

S

= supply sensors/module

VBB

1

= supply OUT 0...7

VBB

2

= supply OUT 8...11

Page 27

UK

BasicController / BasicController

plus

27

8.3 CR0411

Control systems

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0411 / page 1

CR0411

18

A B C D E F

N2

P/N1

25,5

127

163

145

12,5

8,5

6,5

10,5

79,7

112

LED

8,5

Mobile controller

BasicController

plus

8 inputs

8 outputs

2 CAN interfaces

Programming

to IEC 61131-3

8...32 V DC

Technical data Modular control system

Usable as CANopen master or intelligent I/O module

Mechanical data

Housing plastic housing (black)

Dimensions (H x W x D)

without cover

with EC0401 cover

with EC0402 cover and BasicDisplay

CR0451

163 x 112 x 25.5 mm

163 x 112 x 68 mm

163 x 112 x 73.4 mm

Installation xing by means of 4 M4 screws to DIN 912 or DIN 7984 and 4 tubular rivets to

DIN 7340 (tubular rivets are supplied)

Connection AMP blade male terminals 6.3 mm, to be clipped into place and thus vibration-

resistant, protected against reverse polarity

contacts AMP timer, CuZn pre-tin-plated

core cross-section 0.5...2.5 mm²

Inputs

Outputs

Operating voltage , CAN bus

2 x 8-pole

2 x 8-pole

1 x 6-pole, 1 x 4-pole

Protection IP 20 (with cover and cable seal IP 54)

Operating/storage temperature -40...85° C / -40...85° C

Weight 0.30 kg

Electrical data

Operating voltage 8...32 V DC

Current consumption 45 mA (at 24 V DC)

Overvoltage

Undervoltage detection

Undervoltage shutdown

36 V for t ≤ 10 s

if U

B

≤ 7.8 V

if U

B

≤ 7.0 V

Processor Freescale PowerPC, 50 MHz

Memory (total) 592 Kbytes RAM / 1536 Kbytes Flash / 1 Kbyte FRAM

Memory allocation see BasicController

plus

system manual

www.ifm.com → Data sheet search → e.g. CR0411 → Additional data

Device monitoring Undervoltage monitoring

Watchdog function

Checksum test for program and system

Excess temperature monitoring

Page 28

BasicController / BasicController

plus

28

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0411 / page 2

CR0411 Technical data

Control systems

CAN interfaces 1/2

Baud rate

Communication pro le

CAN interface 2.0 A/B, ISO 11898

20 Kbits/s...1 Mbit/s (default CAN1: 250 Kbits/s, CAN2: 250 Kbits/s)

CANopen, CiA DS 301 version 4, CiA DS 401 version 1.4

or SAE J 1939 or free protocol

Software/programming

Programming system CODESYS version 2.3 (IEC 61131-3)

Inputs 8 (con gurable)

Con gurations

Number Description

4 digital for positive/negative sensor signals

analogue (0...10/32 V DC, 0...20 mA, ratiometric)

frequency (≤ 30 kHz)

B

L/BH

A

FRQ

4 digital for positive sensor signals

resistance measurement (0.016...30 kΩ)

B

L

R

positive sensor signals have diagnostic capabilities

Outputs 8 (con gurable)

Con gurations

Number Description

4 positive switching (high side)

PWM output (20…250 Hz), 2.5 A,

current-controlled, 0.02…2.5 A, diagnosis

B

H

PWM

PWM-I

4 positive switching (high side)

negative switching (low side), 4 A

PWM output (20…250 Hz), 4 A, diagnosis

current-controlled, 0.02…4 A, diagnosis

H-bridge function

B

H

B

L

PWM

PWM-I

H bridge

Status LED two-colour LED (red/green)

Operating states (preset)

Colour Status Description

– permanently off no operating voltage

orange 1 x on initialisation or reset checks

green 5 Hz no operating system loaded

2 Hz application running (RUN)

permanently on application stopped (STOP)

Red 10 Hz application stopped (STOP with error)

5 Hz application stopped due to undervoltage

permanently on system error (fatal error)

Abbreviations A

B

H

B

L

FRQ

H

PWM

PWM-I

R

VBB

S

VBB

1

VBB

2

Analogue

Binary high side

Binary low side

Frequency/pulse inputs

H-bridge function

Pulse width modulation

Pulse width modulation, current-controlled

Resistor input

Supply sensors/module

supply OUT 0...3

supply OUT 4...7

Page 29

UK

BasicController / BasicController

plus

29

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0411 / page 3

CR0411 Technical data

Control systems

Input characteristics

Analogue inputs (A, B

L/BH

, FRQ)

Connection A: 02, 03, 06, 07

IN0...IN3

can be con gured as...

● Voltage inputs

Input voltage 0...10 V or 0...32 V

Resolution 12 bits

Accuracy ± 1% FS

Input resistance 65.6 kΩ (0...10 V), 50.7 kΩ (0...32 V)

Input frequency ≤ 500 Hz

● current inputs, with diagnostic capability

Input current 0...20 mA

Resolution 12 bits

Accuracy ± 1% FS

Input resistance 400 Ω

Input frequency ≤ 500 Hz

At a current of > 23 mA the input is switched to the voltage input!

● Voltage inputs, 0...32 V, ratiometric

Function (U

IN

÷ UB) x 1000 ‰

Value range 0...1000 ‰

Input resistance 50.7 kΩ

● Binary voltage inputs for positive sensor signals

Switch-on level > 0.7 U

B

Switch-off level < 0.3 U

B

Input resistance 3.2 kΩ

Input frequency 50 Hz

Diagnosis wire break > 0.95 U

B

Diagnosis short circuit < 1 V

● Binary voltage inputs for negative sensor signals

Switch-on level > 0.7 UB

Switch-off level < 0.3 UB

Input resistance 3.2 kΩ

Input frequency 50 Hz

● Frequency inputs

Input resistance 3.2 kΩ

Input frequency ≤ 30 kHz

Switch-on level > 0.35...0.48 U

B

Switch-off level < 0.29 U

B

Digital/resistor inputs (BL, R)

Connection B: 02, 03, 06, 07

IN4…IN7

can be con gured as…

● Binary voltage inputs for positive sensor signals

Switch-on level > 0.7 U

B

Switch-off level < 0.3 U

B

Input resistance 3.2 kΩ

Input frequency 50 Hz

Diagnosis wire break > 0.95 U

B

Diagnosis short circuit < 1 V

● Resistor input

Measuring current < 2.0 mA

Input frequency 50 Hz

Measuring range 0.016…30 kΩ

Accuracy ± 2 % FS: 16 Ω...3 kΩ

± 5 % FS: 3...15 kΩ

± 10 % FS: 15...30 kΩ

Diagnosis > 31 kΩ

Diagnosis short circuit to VBB

Page 30

BasicController / BasicController

plus

30

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0411 / page 4

CR0411 Technical data

Control systems

Output characteristics

Digital outputs

(B

H

, PWM, PWM-I)

Connection D: 01, 03, 05, 07

OUT0…OUT3

● Semiconductor outputs, positive-switching (high side)

Short-circuit proof and overload protected

Diagnosis via current feedback (wire break / overload)

Diagnosis via voltage feedback, pullup resistance can be deactivated (wire

break/ short circuit)

Switching voltage 5.5...32 V DC

Switching current ≤ 2.5 A

Load resistance ≥ 4.8 Ω (at 12 V DC)

≥ 9.6 Ω (at 24 V DC)

● PWM outputs

Output frequency 20...250 Hz

Pulse/pause ratio 1…1000 ‰

Switching current ≤ 2.5 A

● Current-controlled output

Output frequency 20...250 Hz

Control range 0.02…2.5 A

Setting resolution 1 mA

Control resolution 2 mA

Max. ambient temperature in PWM mode: ≤ 70 °C

Max. switch-on current ≤ 24 A

Digital outputs

(B

H/L

, PWM, PWM-I, H)

Connection E: 01, 03, 05, 07

OUT4…OUT7

● Semiconductor outputs, positive-switching (high side),

negative switching (low side), short-circuit and overload protection

Diagnosis via current feedback (wire break / overload)

Diagnosis via voltage feedback, pullup resistance can be deactivated (wire

break/ short circuit)

Switching voltage 5.5...32 V DC

Switching current ≤ 4 A

Max. clamp energy < 3 J (at 25°C)

Load resistance ≥ 3 Ω (at 12 V DC)

≥ 6 Ω (at 24 V DC)

● PWM outputs

Output frequency 20...250 Hz

Pulse/pause ratio 1…1000 ‰

Switching current ≤ 4 A

● current-controlled output

Output frequency 20...250 Hz

Control range 0.02…4 A

Setting resolution 1 mA

Control resolution 2 mA

Max. ambient temperature in PWM mode: ≤ 70 °C

Max. switch-on current ≤ 24 A (high side)

≤ 16 A (low side)

Free wheel diodes Free wheel diodes for the deactivation of inductive loads are integrated

Overload protection

(valid for all outputs)

≤ 5 minutes (at 100% overload)

Short-circuit strength

(valid for all inputs and outputs)

≤ 5 minutes (contacts +VBB/GND)

Total current per output supply VBB

1

or

VBB

2

≤ 8 A

Page 31

UK

BasicController / BasicController

plus

31

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0411 / page 5

CR0411 Technical data

Control systems

Total summation current of the output

supply VBB

1

and VBB

2

(continuous current load)

≤ 12 A

Test standards and regulations

CE marking EN 61000-6-2 Electromagnetic compatibility (EMC)

Noise immunity

EN 61000-6-4 Electromagnetic compatibility (EMC)

Emission standard

E1 marking UN/ECE-R10 Emission standard

Immunity with 100 V/m

Electrical tests ISO 7637-2 Pulse 1, severity level: IV; function state C

Pulse 2a, severity level: IV; function state A

Pulse 2b, severity level: IV; function state C

Pulse 3a, severity level: IV; function state A

Pulse 3b, severity level: IV; function state A

Pulse 4, severity level: IV; function state B

Pulse 5, severity level: III; function state C

(data valid for the 24 V system)

Pulse 4, severity level: III; function state C

(data valid for the 12 V system)

Climatic tests EN 60068-2-30 Damp heat, cyclic

Upper temperature 55°C, number of cycles: 6

EN 60068-2-78 Damp heat, steady state

Test temperature 40°C / 93% RH,

Test duration: 21 days

EN 60068-2-52 Salt spray test

Severity level 3 (vehicle)

Only with installed EC0401 or EC0402 cover

Mechanical tests ISO 16750-3 Test VII; Vibration, random

Mounting location: vehicle body

EN 60068-2-6 Vibration, sinusoidal

10...500 Hz; 0.72 mm/10 g; 10 cycles/axis

ISO 16750-3 Bumps

30 g/6 ms; 24,000 shocks

Tests for railway applications EN 50121-3-2 Electromagnetic compatibility (EMC)

EN 50155 clause 12.2 Electronic equipment used on rolling stock

Note The EC declaration of conformity and approvals can be found at:

www.ifm.com → Data sheet search → CR0411 → More information

Page 32

BasicController / BasicController

plus

32

ifm electronic gmbh • Friedrichstraße 1 • 45128 Essen

We reserve the right to make technical alterations without prior notice! 24.10.2014CR0411 / page 6

CR0411 Technical data

Control systems

Wiring

A B C D E F N2 P/N1

8 poles 4 poles 6 poles

VBB

S

IN0

IN1

GND

GND

IN2

IN3

VBB

S

VBB

S

IN4

IN5

GND

GND

IN6

IN7

VBB

S

OUT0

GND

OUT1

GND

OUT2

GND

OUT3

GND

OUT4

GND

OUT5

GND

OUT6

GND

OUT7

GND

VBB

S

GND

CAN2_H

CAN2_L

VBB

S

VBB

1

VBB

2

GND

CAN1_H

CAN1_L

C/F = not used

Abbreviations A

B

H

B

L

FRQ

H

PWM

PWM-I

R

VBB

S

VBB

1

VBB

2

Analogue

Binary high side

Binary low side

Frequency/pulse inputs

H-bridge function

Pulse width modulation

Pulse width modulation, current-controlled

Resistor input

Supply sensors/module

Supply OUT 0...3

Supply OUT 4...7

Page 33

UK

BasicController / BasicController

plus

33

9 Maintenance, repair and disposal

9.1 Maintenance

The device does not contain any components that need to be maintained by the

user�

9.2 Cleaning the housing surface

► Disconnect the device�

► Clean the device from dirt using a soft, chemically untreated and dry cloth�

► In case of heavy dirt, use a damp cloth�

The following agents are not suited for cleaning the device:

chemicals dissolving plastics such as methylated spirit, benzine, thinner,

alcohol, acetone or ammonia�

Micro-fibre cloths without chemical additives are recommended�

9.3 Repair

► The device must only be repaired by the manufacturer�

Observe the safety instructions (→ 2.4 Tampering with the device)

9.4 Disposal

► Dispose of the device in accordance with the national environmental

regulations�

10 Approvals/standards

Test standards and regulations (→ 8 Technical data)

The EC declaration of conformity and approvals can be found at:

www.ifm.com → Data sheet search → e.g. CR0401 → Approvals

Loading...

Loading...