Page 1

Original Programming Manual

CabinetController

CR0301

Runtime system V05

CODESYS® > V2.3.9.33 (< V 3.0)

English

7391083_01_UK 2016-04-21

1

Page 2

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Contents

Contents

1 About this manual 4

1.1 Copyright .............................................................................................................................. 4

1.2 Overview: documentation modules for ecomatmobile devices ............................................ 5

1.3 CODESYS programming manual ........................................................................................ 5

1.4 What do the symbols and formats mean? ........................................................................... 6

1.5 How is this documentation structured? ................................................................................ 7

1.6 History of the instructions (CR030n) .................................................................................. 8

2 Safety instructions 9

2.1 Please note! ......................................................................................................................... 9

2.2 What previous knowledge is required? ..............................................................................10

2.3 Start-up behaviour of the controller....................................................................................10

2.4 Notes: serial number ..........................................................................................................11

2.5 Notes: TEST inputs ............................................................................................................11

3 System description 12

3.1 Information about the device ..............................................................................................12

3.2 Hardware description .........................................................................................................12

3.2.1 Hardware structure ..................................................................................................................... 13

3.2.2 Monitoring concept ..................................................................................................................... 15

3.2.3 Inputs (technology) ..................................................................................................................... 17

3.2.4 Outputs (technology) .................................................................................................................. 21

3.2.5 Note on wiring ............................................................................................................................ 24

3.2.6 Safety instructions about Reed relays ........................................................................................ 24

3.2.7 Status LED ................................................................................................................................. 25

3.3 Interface description ...........................................................................................................26

3.3.1 Serial interface ........................................................................................................................... 26

3.3.2 CAN interfaces ........................................................................................................................... 27

3.4 Software description ..........................................................................................................28

3.4.1 Software modules for the device ................................................................................................ 28

3.4.2 Programming notes for CODESYS projects ............................................................................... 31

3.4.3 Operating states ......................................................................................................................... 35

3.4.4 Operating modes ........................................................................................................................ 39

3.4.5 Performance limits of the device ................................................................................................ 41

4 Configurations 42

4.1 Set up the runtime system .................................................................................................42

4.1.1 Reinstall the runtime system ...................................................................................................... 43

4.1.2 Update the runtime system ......................................................................................................... 44

4.1.3 Verify the installation .................................................................................................................. 44

4.2 Set up the programming system ........................................................................................45

4.2.1 Set up the programming system manually ................................................................................. 45

4.2.2 Set up the programming system via templates ........................................................................... 47

4.3 Function configuration of the inputs and outputs ...............................................................48

4.3.1 Configure inputs ......................................................................................................................... 49

4.3.2 Configure outputs ....................................................................................................................... 52

4.4 Note on wiring ....................................................................................................................54

4.5 Safety instructions about Reed relays ...............................................................................54

2

Page 3

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Contents

5 ifm function elements 55

5.1 ifm libraries for the device CR0301 ....................................................................................55

5.1.1 Bibliothek ifm_CR0301_V05yyzz.LIB ......................................................................................... 56

5.1.2 Library ifm_CR0301_CANopenMaster_V04yynn.LIB ................................................................. 58

5.1.3 Library ifm_CR0301_CANopenSlave_V04yynn.LIB ................................................................... 58

5.1.4 Library ifm_CAN1_EXT_Vxxyyzz.LIB ......................................................................................... 59

5.1.5 Bibliothek ifm_J1939_1_Vxxyyzz.LIB ......................................................................................... 59

5.2 ifm function elements for the device CR0301 ....................................................................60

5.2.1 Function elements: CAN layer 2 ................................................................................................. 60

5.2.2 Function elements: CANopen master ......................................................................................... 76

5.2.3 Function elements: CANopen slave ........................................................................................... 86

5.2.4 Function elements: CANopen SDOs .......................................................................................... 94

5.2.5 Function elements: SAE J1939 .................................................................................................. 99

5.2.6 Function elements: serial interface ........................................................................................... 111

5.2.7 Function elements: Optimising the PLC cycle via processing interrupts .................................. 116

5.2.8 Function elements: processing input values ............................................................................. 122

5.2.9 Function elements: adapting analog ue val ues ......................................................................... 127

5.2.10 Function elements: counter functions for frequency and period measurement ........................ 130

5.2.11 Function elements: PWM functions .......................................................................................... 140

5.2.12 Function elements: controllers .................................................................................................. 149

5.2.13 Function elements: softwar e reset ............................................................................................ 158

5.2.14 Function elements: measuring / setting of time ........................................................................ 160

5.2.15 Function elements: saving, rea ding and conv ert ing data in the memory .................................. 163

5.2.16 Function elements: data access and data check ...................................................................... 170

6 Diagnosis and error handling 177

6.1 Diagnosis .........................................................................................................................177

6.2 Fault .................................................................................................................................177

6.3 Reaction in case of an error .............................................................................................178

6.4 Reaction in case of a system error ..................................................................................178

6.5 CAN / CANopen: errors and error handling .....................................................................178

7 Appendix 179

7.1 System flags .....................................................................................................................179

7.1.1 System flags: CAN ................................................................................................................... 180

7.1.2 System flags: error flags ........................................................................................................... 180

7.1.3 System flags: status LED ......................................................................................................... 181

7.1.4 System flags: voltages.............................................................................................................. 181

7.1.5 System flags: inputs and outputs .............................................................................................. 182

7.1.6 System flags: system ............................................................................................................... 182

7.2 Address assignment and I/O operating modes ................................................................183

7.2.1 Addresses / variables of the I/Os .............................................................................................. 183

7.2.2 Possible operating modes inp uts/o utpu t s ................................................................................. 187

7.3 Error tables .......................................................................................................................190

7.3.1 Error flags ................................................................................................................................. 190

7.3.2 Errors: CAN / CANopen............................................................................................................ 190

8 Glossary of Terms 191

9 Index 204

10 Notizen • Notes • Notes 208

11 ifm weltweit • ifm worldwide • ifm à l’échelle internationale 213

3

Page 4

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

History of the instructions (CR030n) ................................................................................................... 8

About this manual Copyright

1 About this manual

Copyright ............................................................................................................................................... 4

Overview: documentation modules for ecomatmobile devices ............................................................. 5

CODESYS programming manual .......................................................................................................... 5

What do the symbols and formats mean? ............................................................................................. 6

How is this documentation structured? ................................................................................................. 7

>

1.1 Copyright

6088

© All rights reserved by ifm electronic gmbh. No part of this manual may be reproduced and used

without the consent of ifm electronic gmbh.

All product names, pictures, companies or other brands used on our pages are the property of the respective rights owners:

• AS-i is the property of the AS-International Association, (→ www.as-interface.net

• CAN is the property of the CiA (CAN in Automation e.V.), Germany (→ www.can-cia.org)

• CODESYS™ is the property of the 3S – Smart Software Solutions GmbH, Germany (→ www.codesys.com)

• DeviceNet™ is the property of the ODVA™ (Open DeviceNet Vendor Association), USA (→ www.odva.org)

• EtherNet/IP® is the property of the →ODVA™

®

• IO-Link

(→ www.io-link.com) is the property of the →PROFIBUS Nutzerorganisation e.V., Germany

• ISOBUS is the property of the AEF – Agricultural Industry Electronics Foundation e.V., Deutschland

(→ www.aef-online.org)

• Microsoft® is the property of the Microsoft Corporation, USA (→ www.microsoft.com)

• PROFIBUS® is the property of the PROFIBUS Nutzerorganisation e.V., Germany (→ www.profibus.com)

• PROFINET® is the property of the →PROFIBUS Nutzerorganisation e.V., Germany

®

• Windows

is the property of the →Microsoft Corporation, USA

)

202

4

Page 5

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

About this manual Overview: documentation modules for ecomatmobile devic es

>

1.2 Overview: documentation m odules for ecomatmobile devices

The documentation for ecomatmobile devices consists of the following modules:

1. Data sheet

Contents Technical data in a table

Source → www.ifm.com > select your country > [Data sheet search] > CR0301 > [Technical data in PDF format]

2. Installation instructions / operating instructions

Contents Instructions for installation, electrical installation, (commissioning*), technical data

Source The instructions are supplied with the device

They are also found on ifm's homepage:

→ www.ifm.com

3. Programming manual + online help

Contents Description of the configuration and the functions of the device software

Source → www.ifm.com > select your country > [Data sheet search] > CR0301 > [Operating instructions]

4. System manual "Know-how ecomatmobile"

> select your country > [Data sheet search] > CR0301 > [Operating instructions]

17405

Contents Know-how about the following topics:

• Overview Templates and demo programs

• CAN, CANopen

• Control outputs

• User flash memory

• Visualisations

• Overview of the files and libraries used

Source → www.ifm.com > select your country > [Data sheet search] > CR0301 > [Operating instructions]

5. System manual "The ISOBUS in the ifm controller"

Contents Description of the configuration and the functions of the ISOBUS software in the device

Source → www.ifm.com > select your country > [Data sheet search] > CRnnnn > [Operating instructions]

thereby "CRnnnn" stands for the articel numbers of the devices which are pre-installed with ISOBUS

*) The descriptions in brackets are only included in the instructions of certain devices.

>

1.3 CODESYS programming manual

17542

In the additional "Programming Manual for CODESYS V2.3" you obtain more details about the use of

the programming system.

This manual can be downloaded free of charge from ifm's website:

→ www.ifm.com

You also find manuals and online help for ecomatmobile at:

→ ecomatmobile DVD "Software, tools and documentation"

> Select your country > [Service] > [Download] > [Systems for mobile machines]

5

Page 6

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

About this manual What do the sy m bols and formats mean?

>

1.4 What do the symbols and formats mean?

The following symbols or pictograms illustrate the notes in our instructions:

WARNING

Death or serious irreversible injuries may result.

CAUTION

Slight reversible injuries may result.

NOTICE

Property damage is to be expected or may result.

Important notes concerning malfunctions or disturbances

Other remarks

► ... Request for action

203

> ... Reaction, result

→ ... "see"

abc Cross-reference

123

0x123

0b010

[...] Designation of pushbuttons, buttons or indications

Decimal number

Hexadecimal number

Binary number

6

Page 7

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

About this manual How is this documentation structured?

>

1.5 How is this documentation str uctured?

This documentation is a combination of different types of manuals. It is for beginners and also a

reference for advanced users. This document is addressed to the programmers of the applications.

How to use this manual:

• Refer to the table of contents to select a specific subject.

• Using the index you can also quickly find a term you are looking for.

• At the beginning of a chapter we will give you a brief overview of its contents.

• Abbreviations and technical terms → Appendix.

In case of malfunctions or uncertainties please contact the manufacturer at:

→ www.ifm.com

We want to become even better! Each separate section has an identification number in the top right

corner. If you want to inform us about any inconsistencies, indicate this number with the title and the

language of this documentation. Thank you very much for your support!

We reserve the right to make alterations which can result in a change of contents of the

documentation. You can find the current version on ifm's websi te at:

→ www.ifm.com

> Select your country > [Contact].

> Select country > [Data sheet search] > (Article no.) > [Operating instructions]

204

1508

7

Page 8

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

About this manual History of t he instructions (CR030n)

>

1.6 History of the instructions (CR030n)

9181

What has been changed in this manual? An overview:

Date Theme Change

2010-09-09 PID2 (FB) parameters of the inputs corrected

2010-11-10 Terminating resistors correction in topic 1244

2011-02-14 TIMER_READ_US (FB) conversion of max. counter value corrected

2011-04-05 Memory POUs FRAMREAD, FRAMWRITE,

FLASHREAD, FLASHWRITE

2011-04-13 CANopen overview new: CANopen tables in the appendix

2011-04-14 CR0303 several corrections: - device has an own hydraulic library

2011-05-24 CR0303: memory FBs FRAMREAD, FRAMWRITE permitted values of the parameters SRC, DST

2012-01-09 Memory modules FRAMREAD, FRAMWRITE Swapped parameters SRC, DST in the table

2012-10-04 diverse corrections

2013-06-24 various new document structure

2014-04-28 Various function blocks More precise description of the function block input

2014-06-30 Name of the documentation "System manual" renamed as "Programming manual"

2014-07-18 CR0303: Error flag Wrong: ERROR_A_INx

2014-07-31 FB PHASE Description of parameters of outputs C, ET corrected

2014-08-26 Description of inputs, outputs highside / lowside replaced by positive / negative

2015-01-13 Structure of documentation for error codes, system

flags

2015-03-10 Available memory Description improved

2015-05-26 FB J1939_x_GLOBAL_REQUEST More precise description

2015-06-10 Various function blocks Description of the FB input CHANNEL corrected

>

permitted values of the parameters SRC, LEN, DST

- some system flags do not exist

- IEC addresses of in- and outputs

- configuration of the inputs

- set the status LED in the application program

corrected

"Permissible values"

CHANNEL

Correct: ERROR_Ix

switching

• error flags:

now only in the appendix, chapter System flags

• CAN / CANopen errors and error handling:

now only in the system manual "Know-How"

• error codes, EMCY codes:

now in the appendix, chapter Error tables

8

Page 9

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Notes: TEST inputs ............................................................................................................................. 11

Safety instructions Please note!

2 Safety instructions

Please note! ........................................................................................................................................... 9

What previous knowledge is required? ............................................................................................... 10

Start-up behaviour of the controller ..................................................................................................... 10

Notes: serial number ........................................................................................................................... 11

>

213

2.1 Please note!

214

11212

No characteristics are warranted with the information, notes and examples provided in this manual.

With the drawings, representations and examples given no responsibility for the system is assumed

and no application-specific particularities are taken into account.

► The manufacturer of the machine/equipment is responsible for ensuring the safety of the

machine/equipment.

► Follow the national and international regulations of the country in which the machine/installation is

to be placed on the market!

WARNING

Non-observance of these instructions can lead to property damage or personal injury.

ifm electronic gmbh does not assume any liability in this regard.

► The acting person must have read and understood the safety instructions and the corresponding

chapters in this manual before working on and with this device.

► The acting person must be authorised to work on the machine/equipment.

► The acting person must have the qualifications and training required to perform this work.

► Adhere to the technical data of the devices!

You can find the current data sheet on ifm's homepage at:

→ www.ifm.com

in PDF format]

► Note the installation and wiring information as well as the functions and features of the devices!

→ supplied installation instr uc tions or on ifm's homepage:

→ www.ifm.com

instructions]

► Please note the corrections and notes in the release notes for the existing documentation,

available on the ifm website:

→ www.ifm.com

instructions]

> Select your country > [Data sheet search] > (article number.) > [Technical data

> Select your country > [Data sheet search] > (article number.) > [Operating

> Select your country > [Data sheet search] > (article number.) > [Operating

5020

NOTICE

The driver module of the serial interface can be damaged!

Disconnecting or connecting the serial interface while live can cause undefined states which damage

the driver module.

► Do not disconnect or connect the serial interface while live.

9

Page 10

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Safety instructions What previous k nowledge is required?

>

2.2 What previous knowledge is required?

215

This document is intended for people with knowledge of control technology and PLC programming

with IEC 61131-3.

To program the PLC, the people should also be familiar with the CODESYS software.

The document is intended for specialists. These specialists are people who are qualified by their

training and their experience to see risks and to avoid possible hazards that may be caused during

operation or maintenance of a product. The document contains information about the correct handling

of the product.

Read this document before use to familiarise yourself with operating conditions, installation and

operation. Keep the document during the entire duration of use of the device.

Adhere to the safety instructions.

>

2.3 Start-up behaviour of the controller

6827

15233

11575

WARNING

Danger due to unintentional and dangerous start of machine or plant sections!

► When creating the program, the programmer must ensure that no unintentional and dangerous

start of machines or plant sections after a fault (e.g. e-stop) and the following fault elimination can

occur!

Realise restart inhibit.

► In case of an error, set the outputs concerned to FALSE in the program!

A restart can, for example, be caused by:

• voltage restoration after power failure

• reset after watchdog response because of too long a cycle time

• error elimination after an E-stop

To ensure a safe behaviour of the controller:

► Monitor the voltage supply in the application program.

► In case of an error switch off all relevant outputs in the application program.

► Monitor actuators which can cause hazardous movements in the application program (feedback).

► Monitor relay contacts which can cause hazardous movements in the application program

(feedback).

► If necessary, ensure that welded relay contacts in the application project cannot trigger or continue

hazardous movements.

10

Page 11

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Safety instructions Notes: serial number

>

2.4 Notes: serial number

20780

► In the user's production facility, draw a diagram of the controller network in the machine. Enter the

serial number of each controller installed into the network diagram.

► Before downloading a software component, read out this serial number and check the network

diagram to make sure that you are accessing the right controller.

>

2.5 Notes: TEST inputs

20781

► The TEST inputs of all the controllers in the machine should be wired individually and marked

clearly so that they can be properly allocated to the controllers.

► During a service access only activate the TEST input of the controller to be accessed.

>

11

Page 12

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Software description ............................................................................................................................ 28

Status LED .......................................................................................................................................... 25

System description Information ab o ut the dev ic e

3 System description

Information about the device ............................................................................................................... 12

Hardware description........................................................................................................................... 12

Interface description ............................................................................................................................ 26

>

3.1 Information about the device

This manual describes of the ecomatmobile family for mobile machines of ifm electronic gmbh:

• CabinetController: CR0301, CR0302

>

3.2 Hardware description

Hardware structure .............................................................................................................................. 13

Monitoring concept .............................................................................................................................. 15

Inputs (technology) .............................................................................................................................. 17

Outputs (technology) ........................................................................................................................... 21

Note on wiring ...................................................................................................................................... 24

Safety instructions about Reed relays ................................................................................................. 24

975

1310

14081

12

Page 13

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Available memory ................................................................................................................................ 14

System description Hardware des cription

>

3.2.1 Hardware structure

Conditions ............................................................................................................................................ 13

Prinziple block diagram ....................................................................................................................... 13

>

Conditions

The device does not start until sufficient voltage is applied to the supply connection VBBs.

A voltage > 10 V is deemed sufficient.

Permissible operating voltage → data sheet

>

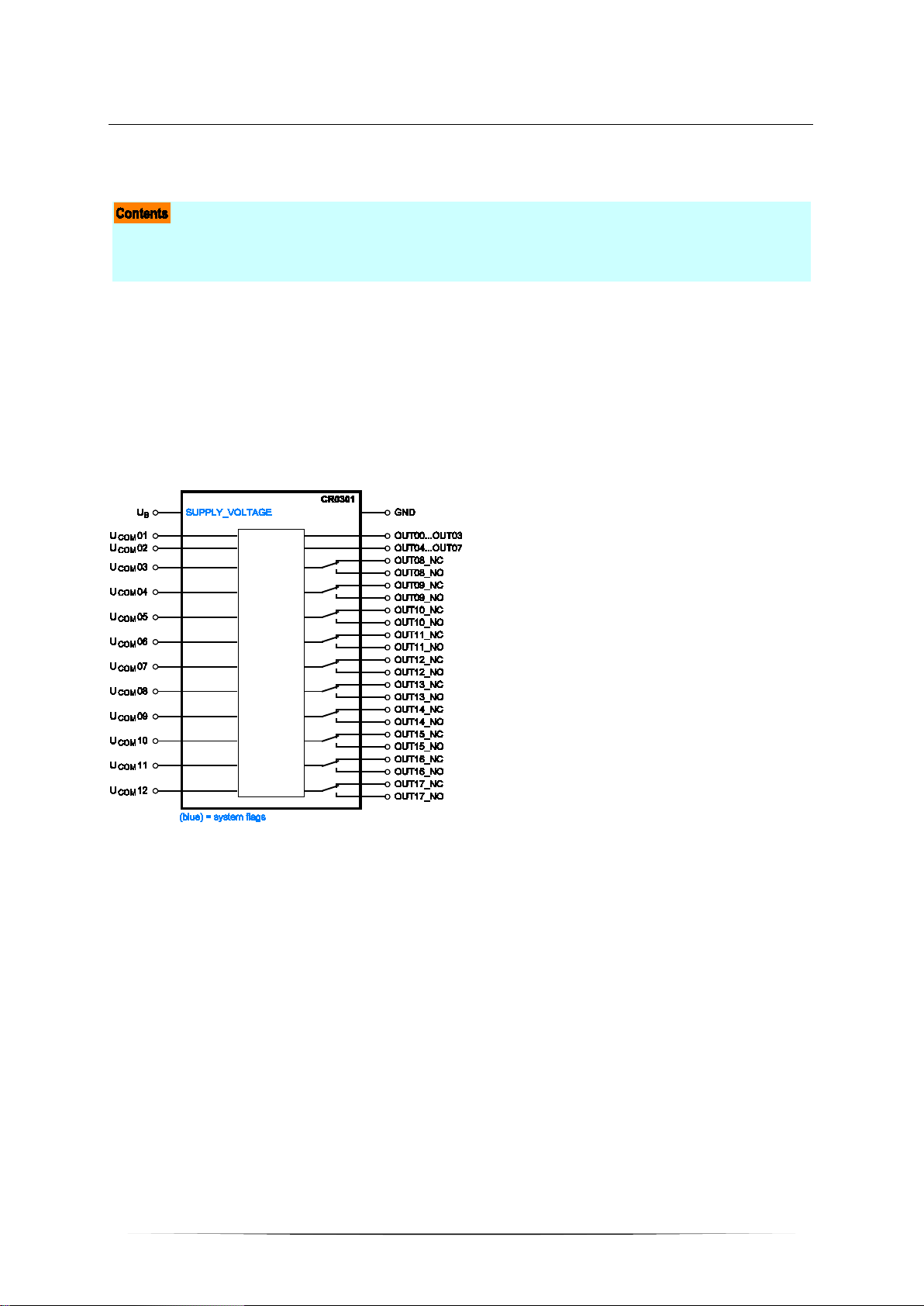

Prinziple block diagram

15332

19971

20848

Figure: Block diagram of the supply

13

Page 14

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Hardware des cription

>

Available memory

>

FLASH-Speicher

13736

14024

FLASH memory (non-volatile, slow memory)

512 kByte

overall existing in the device

Thereof the following memory areas are reserved for ...

maximum size of the application program 192 kByte

data other than the application program

48 kByte

user can write data such as files, bitmaps, fonts

data other than the application program

read data with FLASHREAD (→ page 167

) or write data with FLASHWRITE

16 kByte

(→ page 168)

(files: 128 bytes less for header)

The remaining rest of the memory is reserved for system internal purposes.

>

SRAM

SRAM (volatile, fast memory)

overall existing in the device

SRAM indicates here all kinds of volatile and fast memories.

Thereof the following memory areas are reserved for ...

data reserved by the application program 48 kByte

The remaining rest of the memory is reserved for system internal purposes.

>

256 kByte

18705

EEPROM

EEPROM (non-volatile, slow memory)

overall existing in the device

Thereof the following memory areas are reserved for ...

variables in the application program, declared as VAR_RETAIN 256 Byte

remanent memory freely available to the user

Access is made via E2READ (→ page 165) and E2WRITE (→ page 166)

4 kByte

3 840 Byte

3957

14

Page 15

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

One-time mechanisms ........................................................................................................................ 16

System description Hardware des cription

>

3.2.2 Monitoring conce pt

The controller monitors the supply voltages and the system error flags.

Depending on the status...

• the controller switches off completely

> the program stops

> the outputs become currentless and change to logic "0"

> the status LED goes out

>

Monitoring and securing mechanisms

After application of the supply voltage................................................................................................. 15

If runtime system / application is running ............................................................................................ 16

If the TEST pin is not active ................................................................................................................ 16

For the these devices the following monitoring activities are automatically carried out:

>

19973

3926

After application of the supply voltage

After application of the supply voltage (controller is in the boot loader) the following tests are carried

out in the device:

> RAM test (one-time)

> supply voltage

> system data consistency

> CRC of the boot loader

> if exists and is started: CRC of the runtime system

> if exists and is started: CRC of the application program

> memory error:

• If the test is running: flag ERROR_MEMORY = TRUE

(can be evaluated as from the first cycle).

• If the test is not running: red LED is lit.

3927

15

Page 16

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Hardware des cription

>

If runtime system / application is running

then the following tests are cyclically carried out:

> Triggering of the watchdog (100 ms)

Then continuous program check watchdog

> Continuous temperature check

In case of a fault: system flag ERROR_TEMPERATURE = TRUE

> Continuous voltage monitoring

In case of a fault: system flag ERROR_POWER = TRUE or ERROR_VBBR = TRUE

> Continuous CAN bus monitoring

> Continuous system data monitoring:

- program loaded

- operating mode RUN / STOP,

- runtime system loaded,

- node ID,

- baud rate of CAN and RS232.

> In the operating mode RUN:

Cyclical I/O diagnosis:

- short circuit,

- wire break,

- overload (current) of the inputs and outputs,

- cross fault (only for SafetyController).

>

3928

If the TEST pin is not active

> Write protection for system data in FRAM ¹), e.g.:

• runtime system loaded,

• calibration data.

Implemented via hardware and software.

> Write protection for application program (in the flash memory)

> DEBUG mode

¹) FRAM indicates here all kinds of non-volatile and fast memories.

>

One-time mechanisms

> CRC monitoring during download or upload.

> It must be checked that the runtime system and the application are assigned to the same device.

3929

3930

16

Page 17

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Input group IN12...IN15 ....................................................................................................................... 20

System description Hardware des cription

>

3.2.3 Inputs (tec hnol ogy)

Analogue inputs ................................................................................................................................... 17

Binary inputs ........................................................................................................................................ 18

Input group ANALOG0...7 ................................................................................................................... 19

Input group IN00...IN07 ....................................................................................................................... 19

Input group IN08...IN11 / FRQ00...FRQ03 .......................................................................................... 19

>

14090

Analogue inputs

2426

The analogue inputs can be configured via the application program. The measuring range can be set

as follows:

• current input 0...20 mA

• voltage input 0...10 V

• voltage input 0...32 V

The voltage measurement can also be carried out ratiometrically (0...1000 ‰, adjustable via f unction

blocks). This means potentiometers or joysticks can be evaluated without additional reference voltage.

A fluctuation of the supply voltage has no influence on this measured value.

As an alternative, an analogue channel can also be evaluated binarily.

In case of ratiometric measurement the connected sensors should be supplied with VBBs of the

device. So, faulty measurements caused by offset voltage are avoided.

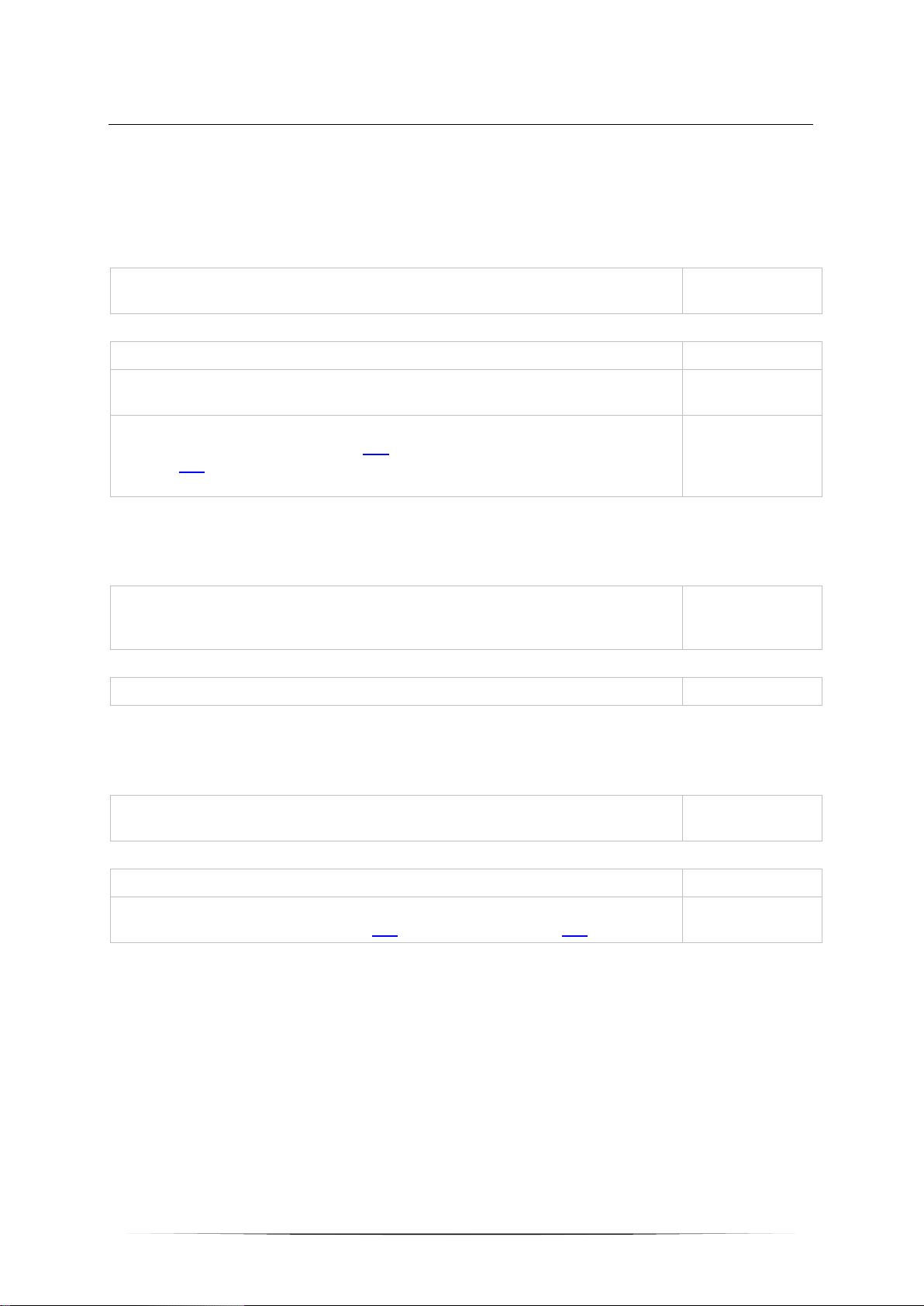

In = pin multifunction input n

(CR) = device

(1) = input filter

(2) = analogu e current measuring

(3a) = binary -input plus switching

(3b) = binary -input minus switching

(4a) = analog ue voltage meas ur ing 0. .. 10 V

(4b) = analog ue voltage measuring 0.. .32 V

(5) = voltage

(6) = reference voltage

8971

Figure: principle block diagram multifunction input

17

Page 18

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Hardware des cription

>

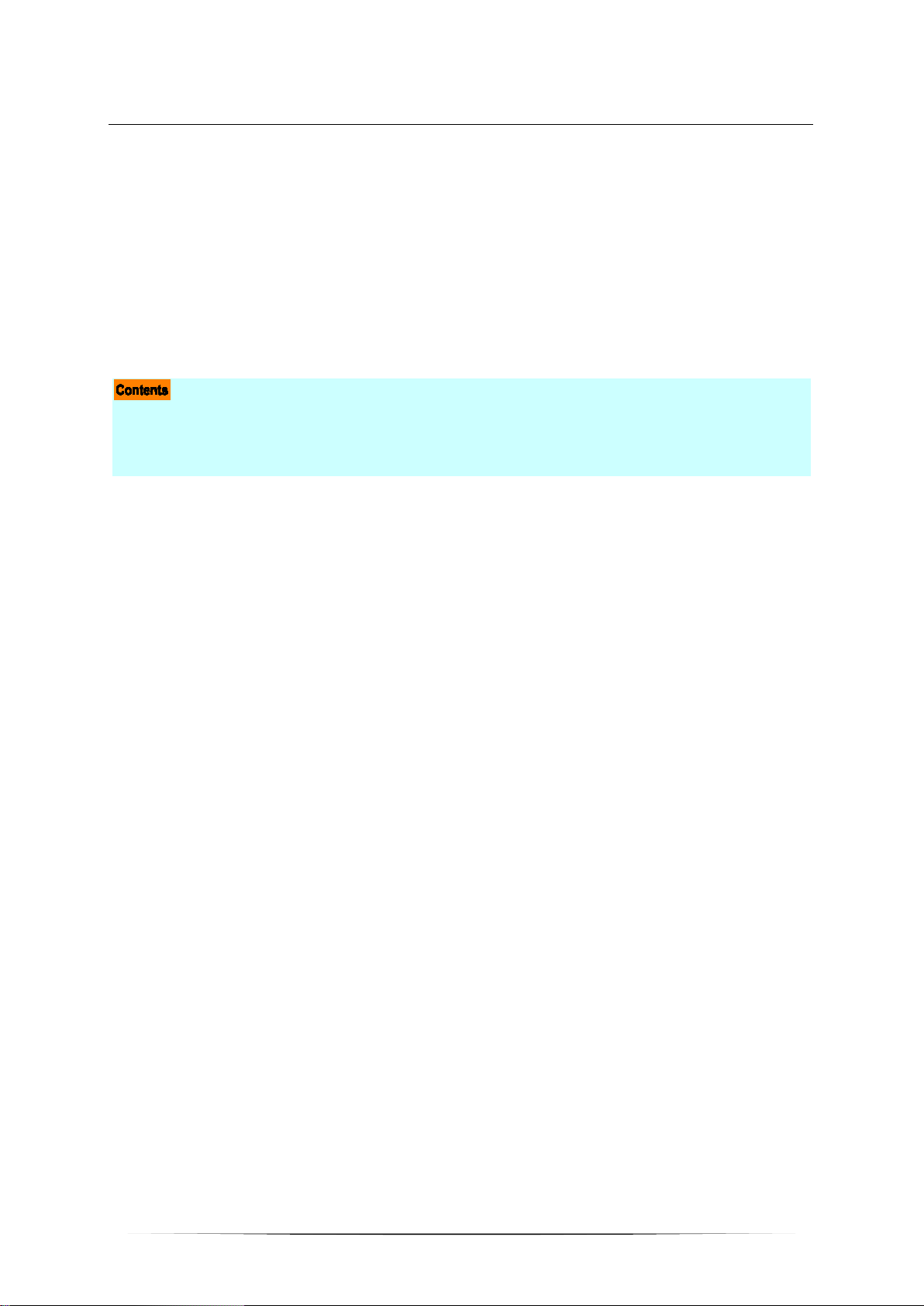

Binary inputs

The binary input can be operated in following modes:

• binary input plus switching (BL) for positive sensor signal

• binary input minus switching (BH) for negative sensor signal

Depending on the device the binary inputs can configured differently. In addition to the protective

mechanisms against interference, the binary inputs are internally evaluated via an analogue stage.

This enables diagnosis of the input signals. But in the application software the switching signal is

directly available as bit information

In = pin binary-input n

(CR) = device

(1) = input filter

(2a) = input minus switchi ng

(2b) = input plus switching

(3) = voltage

1015

7345

Figure: basic circuit of binary input minus switching / plus switching for negative and positive sensor signals

In = pin binary input n

(S) = sensor

Basic circuit of binary input plus switching (BL)

for positive sensor signal:

Input = open signal = low (GND)

For some of these inputs (→ data sheet) the potential can be selected to which it will be switched.

Basic circuit of binary input minus switching (BH)

for negative sensor signal:

Input = open signal = high (supply)

In = pin binary input n

(S) = sensor

18

Page 19

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Hardware des cription

>

Input group ANALOG0...7

20856

These inputs are a group of multifunction channels.

These inputs can be used as follows (each input separately configurable):

• analogue input 0...20 mA

• analogue input 0...10 V

• analogue input 0...32 V

• voltage measurement ratiometric 0...1000 ‰ von 32 V

• binary input plus switching (BL) for positive sensor signal (with/without diagnosis)

→ chapter Possible operating modes inputs/outputs (→ page 187

All inputs show the same behaviour concerning function and diagnosis.

► Configuration of each input is made via the application program:

• configuration byte ANALOGxy_MODE

• FB INPUT_ANALOG (→ page 123

) > input MODE

If the analogue inputs are configured for current measurement, the device switches to the safe voltage

measurement range (0...32V DC) and the corresponding error bit in the flag byte ERROR_A_INx is set

when the final value (> 23 mA) is exceeded.

> When the value is again below the limit value, the input automatically switches back to the current

measurement range.

>

)

Input group IN00...IN07

19976

These inputs are a group of multifunction channels.

These inputs can be used as follows (each input separately configurable):

• binary input plus switching (BL) for positive sensor signal (with/without diagnosis)

→ chapter Possible operating modes inputs/outputs (→ page 187

)

► Configuration of each input is made via the application program :

• configuration byte INxx_MODE

Sensors with diagnostic capabilities to NAMUR can be evaluated.

>

Input group IN08...IN11 / FRQ00...FRQ03

19979

These inputs are a group of multifunction channels.

These inputs can be used as follows (each input separately configurable):

• binary input plus switching (BL) for positive sensor signal (with/without diagnosis)

• fast input for e.g. incremental encoders and frequency or interval measurement

→ chapter Possible operating modes inputs/outputs (→ page 187

Sensors with diagnostic capabilities to NAMUR can be evaluated.

► Configuration of each input is made via the application program:

• configuration byte INxx_MODE

• Fast inputs with the following FBs:

FAST_COUNT (→ page 131) Counter block for fast input pulses

FREQUENCY (→ page 132) Measures th e frequency of the signal arriving at the selected channel

INC_ENCODER (→ page 133) Up/down counter function for the evaluation of encoders

PERIOD (→ page 135) Measures the frequency and the cycle period (cycle time) in [µs] at the indicated ch annel

PERIOD_RATIO (→ page 137) Measures the frequency and the cycle period (cycle time) in [ µ s] during th e indicated p eriods at

PHASE (→ page 139) Reads a pair of channels with fast inputs and compares the phase position of the signals

the indicate d channel. In addition, the mark-to-space ratio is indicated in [‰].

)

19

Page 20

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Hardware des cription

>

Input group IN12...IN15

These inputs are a group of multifunction channels.

These inputs can be used as follows (each input separately configurable):

• binary input plus switching (BL) for positive sensor signal

• binary input minus switching (BH) for negative sensor signal

→ chapter Possible operating modes inputs/outputs (→ page 187

Sensors with diagnostic capabilities to NAMUR can be evaluated.

All inputs show the same behaviour concerning function and diagnosis.

Detailed description → chapter Address assignment inputs / outputs

► Configuration of each input is made via the application program:

• inputs IN12+IN13 via configuration byte IN12_13_MODE

• inputs IN14+IN15 via configuration byte IN14_15_MODE

)

20858

20

Page 21

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Output group OUT11...OUT17 ............................................................................................................ 23

System description Hardware des cription

>

3.2.4 Outputs (technology)

Binary outputs ...................................................................................................................................... 21

PWM outputs ....................................................................................................................................... 22

Output group OUT00...OUT03 ............................................................................................................ 22

Output group OUT04...OUT07 ............................................................................................................ 23

Output group OUT08...OUT10 ............................................................................................................ 23

>

Binary outputs

The following operating modes are possible for the device outputs (→ data sheet):

• binary output, plus switching (BH), short-circuit proof, overload protected

Qn = pin output n

(L) = load

Basic circuit of output plus switching (BH)

for positive output signal

14093

19986

15451

21

Page 22

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Hardware des cription

>

PWM outputs

The following operating modes are possible for the device outputs (→ data sheet):

• PWM output, plus switching (BH) without diagnostic function

Qn = pin output n

(L) = load

Basic circuit of output plus switching (BH)

for positive output signal

>

Output group OUT00...OUT03

These outputs are a group of multifunction channels.

These outputs provide several function options (each output separately configurable):

• binary output, plus switching (BH), short-circuit proof, overload protected

• analogue output with Pulse Width Modulation (PWM)

→ chapter Possible operating modes inputs/outputs (→ page 187

► Configuration of each output is made via the application program:

PWM outputs: selectively

→ FB PWM (→ page 141

)

→ FB PWM100 (→ page 145)

→ FB PWM1000 (→ page 147)

)

14095

15451

20860

► For the limit values please make sure to adhere to the data sheet!

22

Page 23

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Hardware descripti on

>

Output group OUT04...OUT07

These outputs are a group of channels with a single specified function.

These outputs have the following fixed setting:

• binary output, plus switching (BH), short-circuit proof, overload protected

→ chapter Possible operating modes inputs/outputs (→ page 187

► For the limit values please make sure to adhere to the data sheet!

>

)

Output group OUT08...OUT10

These outputs are a group of channels with a single specified function.

These outputs have the following fixed setting:

• binary output with relay (change-over contacts)

• The outputs have no current measurement, no overload detection.

► For the limit values please make sure to adhere to the data sheet!

>

Output group OUT11...OUT17

These outputs are a group of channels with a single specified function.

These outputs have the following fixed setting:

• binary output with relay (change-over contacts)

• The outputs have no current measurement, no overload detection.

20863

20865

20867

► For the limit values please make sure to adhere to the data sheet!

23

Page 24

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Hardware des cription

>

3.2.5 Note on wiring

1426

The wiring diagrams (→ installation instructions of the devices, chapter "Wiring") describe the standard

device configurations. The wiring diagram helps allocate the input and output channels to the IEC

addresses and the device terminals.

The individual abbreviations have the following meaning:

A Analogue input

BH Binary high side input: minus switching for negative sensor signal

BL Binary low side input: plus switching for positive sensor signal

CYL Input period measurement

ENC Input encoder signals

FRQ Frequency input

H bridge Output with H-bridge function

PWM

PWMi PWM output with current measurement

IH Pulse/counter input, high side: minus switching for negative sensor signal

IL Pulse/counter input, low side: plus switching for positive sensor signal

R Read back channel for one output

Binary high side output: plus switching for posit i ve output signal

Binary low side output: minus switching for negative output signal

Pulse-width modulated signal

Allocation of the input/output channels: → Catalogue, mounting instructions or data sheet

>

3.2.6 Safety instructions about Reed relays

For use of non-electronic switches please note the following:

Contacts of Reed relays may be clogged (reversibly) if connected to the device inputs without

series resistor.

► Remedy: Install a series resistor for the Reed relay:

Series resistor = max. input voltage / permissible current in the Reed relay

Example: 32 V / 500 mA = 64 Ohm

► The series resistor must not exceed 5 % of the input resistance RE of the device input (→ data

sheet). Otherwise, the signal will not be detected as TRUE.

Example:

RE = 3 000 Ohm

⇒ max. series resistor = 150 Ohm

7348

24

Page 25

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Hardware des cription

>

3.2.7 Status LED

The operating states are indicated by the integrated status LED (default setting).

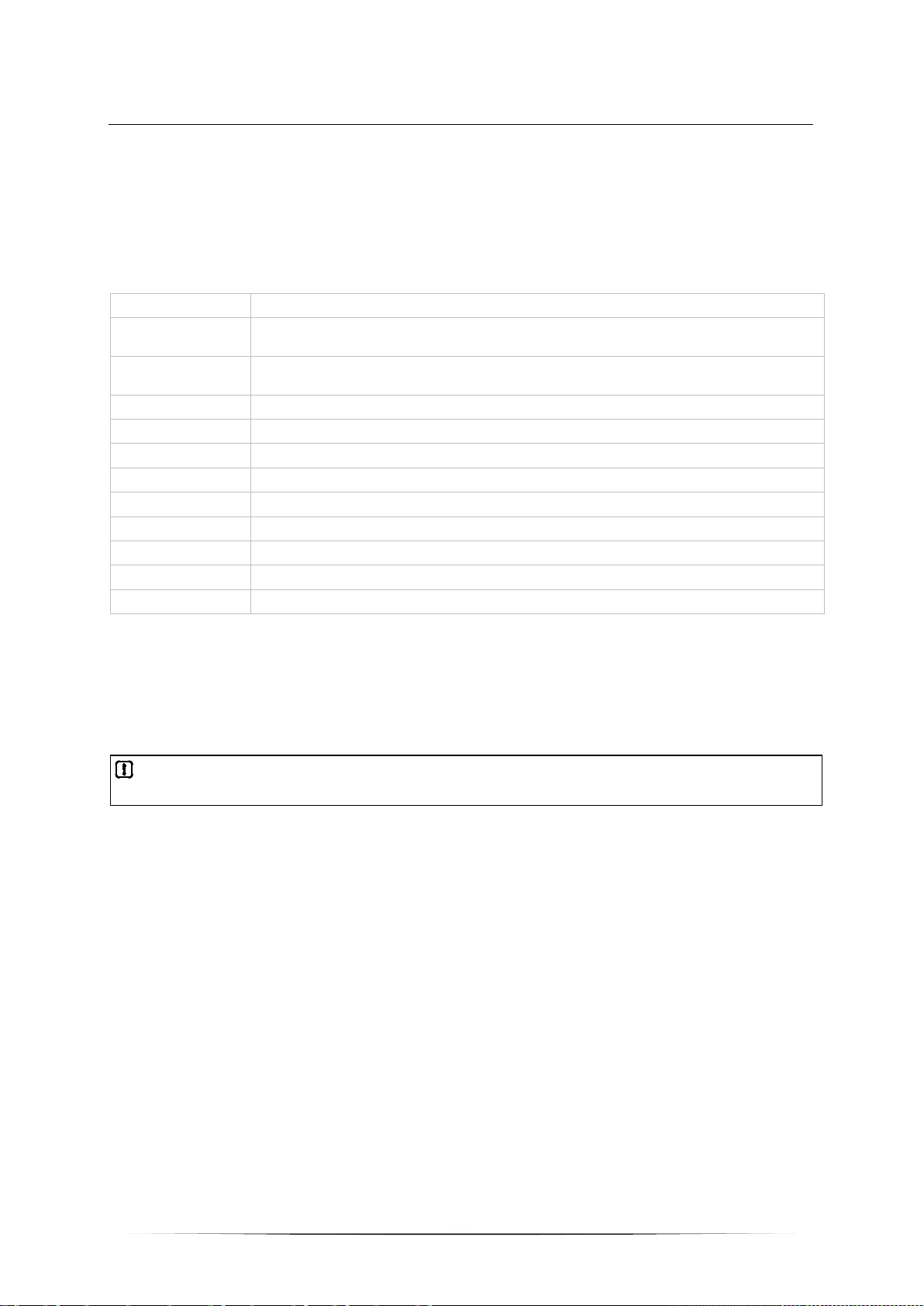

LED colour Display Description

Permanently off No operat i ng voltage

Off

Briefly on Initialisation or reset checks

Orange

(time frame = 200 ms)

Flashing with 5 Hz TEST=TRUE: no runtim e system loaded

Green

(time frame = 200 ms)

Flashing with 2 Hz Application = RUN

Green

(time frame = 200 ms)

Permanently on Appl i cation = STOP

Green

Flashing with 2 Hz Application = RUN with error

Red

(time frame = 200 ms)

Briefly on FATAL ERROR

Red

(time frame = 200 ms)

Permanently on

Red

TEST=TRUE: Application = STOP and FATAL ERROR

TEST=FALSE: ERROR STOP / SYSTEM STOP

1437

The status LED can be changed by the programming system for the operating states STOP and RUN.

To do so, the following system variable is used:

LED_MODE Flashing frequency from the data structure "LED_MODES"

permissible: LED_2HZ, LED_1HZ, LED_05HZ, LED_0HZ (constant)

If the flashing mode is changed in the application program, the default setting table is no longer

valid.

25

Page 26

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

CAN interfaces .................................................................................................................................... 27

System description Interface description

>

3.3 Interface description

Serial interface ..................................................................................................................................... 26

>

3.3.1 Serial interface

This device features a serial interface.

The serial interface can generally be used in combination with the following functions:

• program download

• debugging

• free use of the application

NOTE

The serial interface is not available to the user by default, because it is used for program download

and debugging.

The interface can be freely used if the user sets the system flag bit SERIAL_MODE=TRUE.

Debugging of the application program is then only possible via one of the 4 CAN interfaces.

Connections and data → data sheet

14098

14099

12998

26

Page 27

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Available CAN interfaces and CAN protocols ..................................................................................... 27

System description Interface description

>

3.3.2 CAN interfaces

Connections and data → data sheet

>

Available CAN interfaces and CAN protocols

The following CAN interfaces and CAN protocols are available in this ecomatmobile device:

14101

20872

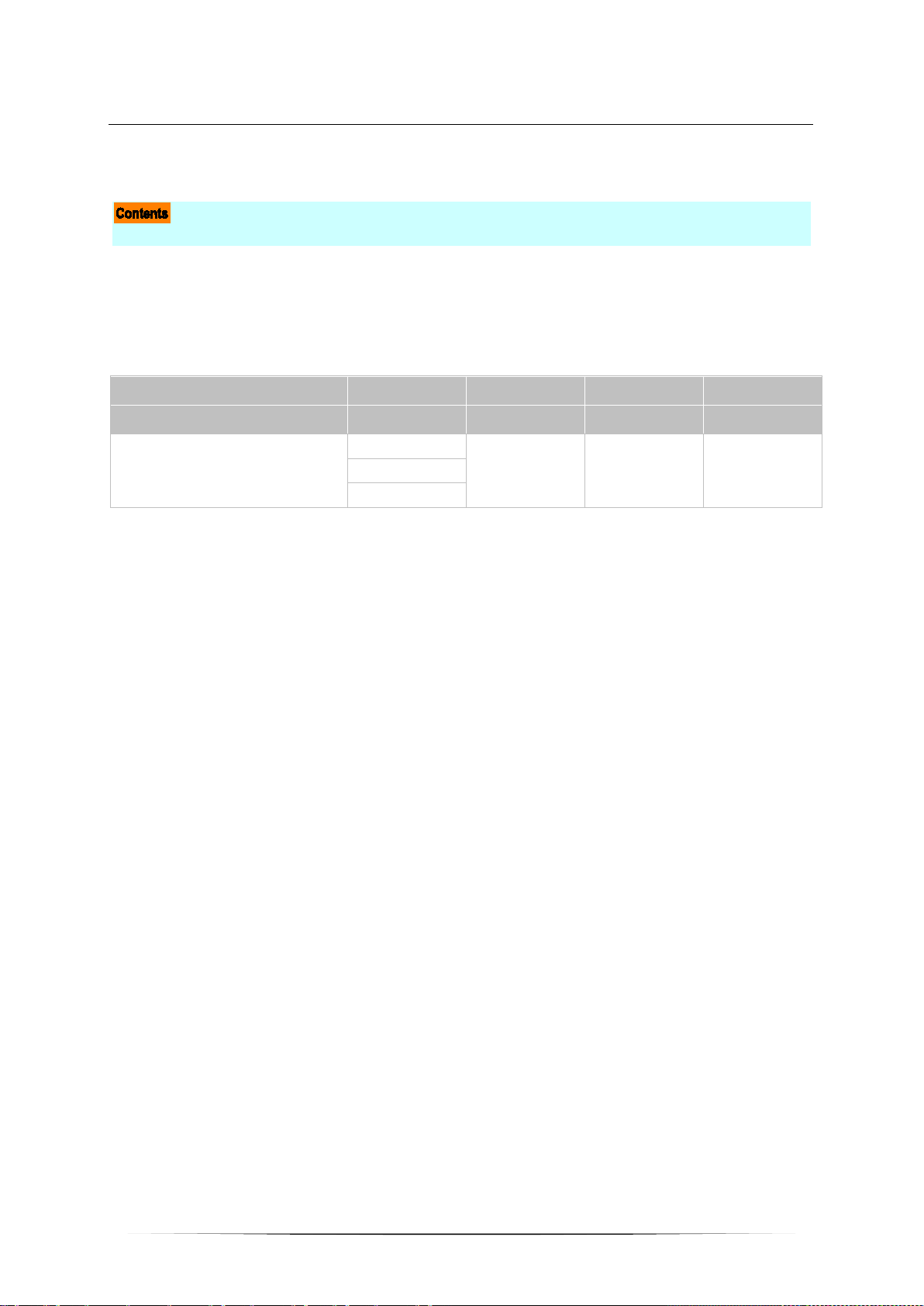

CAN interface

Default download ID

CAN protocols

Standard baud rate = 125 kBit/s

CAN 1 CAN 2 CAN 3 CAN 4

ID 127 ID 126 ID 125 ID 124

CAN Layer 2

CANopen

Interface does not

exist

Interface does not

exist

Interface does not

SAE J1939

exist

27

Page 28

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Performance limits of the device ......................................................................................................... 41

Libraries ............................................................................................................................................... 30

System description Software descripti o n

>

3.4 Software description

Software modules for the device ......................................................................................................... 28

Programming notes for CODESYS projects ....................................................................................... 31

Operating states .................................................................................................................................. 35

Operating modes ................................................................................................................................. 39

>

3.4.1 Software modules for the device

Bootloader ........................................................................................................................................... 29

Runtime system ................................................................................................................................... 29

Application program............................................................................................................................. 29

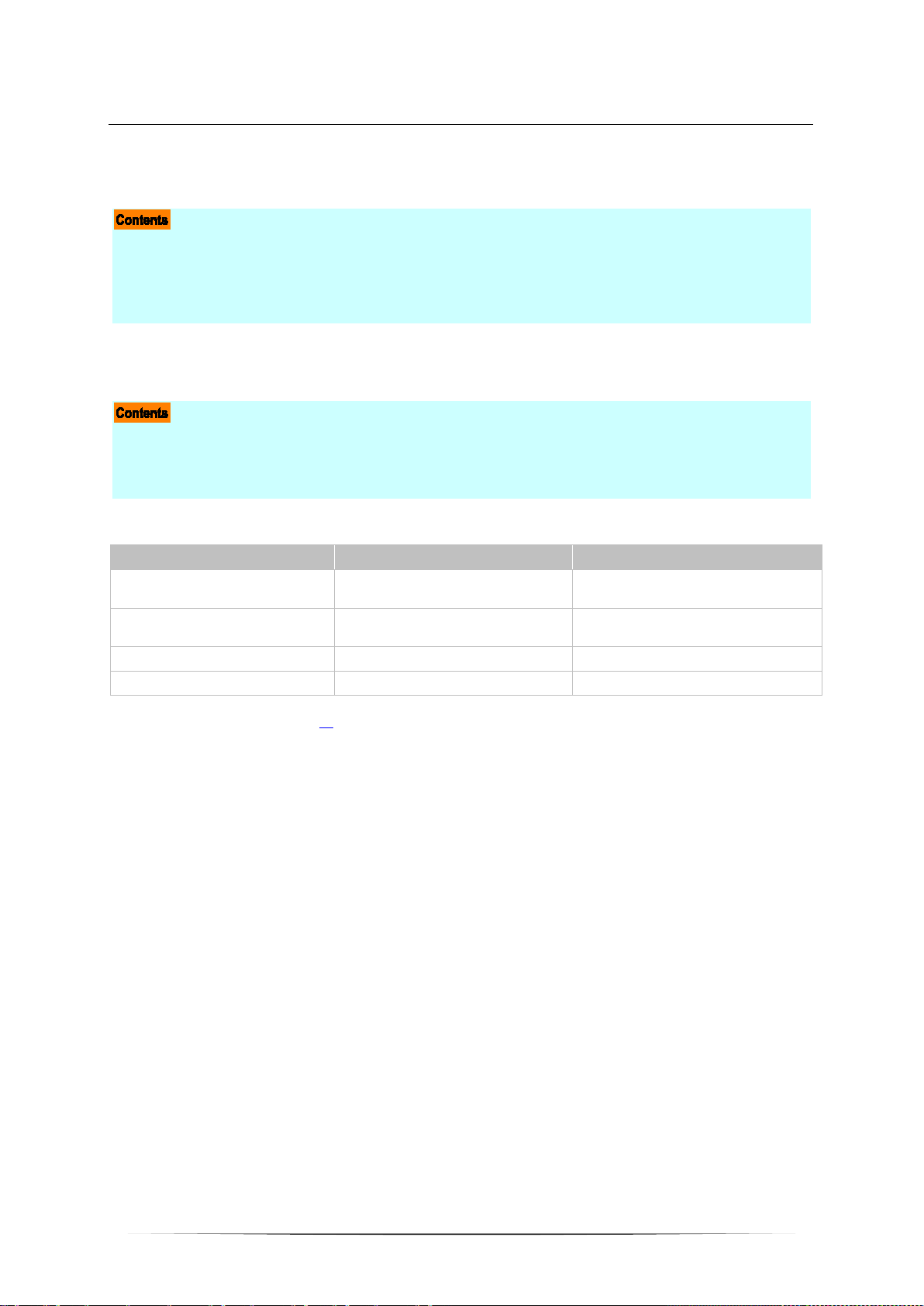

The software in this device communicates with the hardware as below:

software module Can user change the module? By means of what tool?

Application program

with libraries

Runtime system *)

Bootloader no --(Hardware) no ---

*) The runtime system version number must correspond to the target version number in the CODESYS target system setting.

→ chapter Set up the target (→ page 45

Below we describe this software module:

)

yes

Upgrade yes

Downgrade yes

CODESYS,

MaintenanceTool

MaintenanceTool

14107

14110

28

Page 29

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Software description

>

Bootloader

14111

On delivery ecomatmobile controllers only contain the boot loader.

The boot loader is a start program that allows to reload the runtime system and the application

program on the device.

The boot loader contains basic routines...

• for communication between hardware modules,

• for reloading the operating system.

The boot loader is the first software module to be saved on the device.

>

Runtime system

14112

Basic program in the device, establishes the connection between the hardware of the device and the

application program.

On delivery, there is normally no runtime system loaded in the controller (LED flashes green at 5 Hz).

Only the bootloader is active in this operating mode. It provides the minimum functions for loading the

runtime system, among others support of the interfaces (e.g. CAN).

Normally it is necessary to download the runtime system only once. Then, the application program can

be loaded into the controller (also repeatedly) without affecting the runtime system.

The runtime system is provided with this documentation on a separate data carrier. In addition, the

current version can be downloaded from the website of ifm electronic gmbh:

→ www.ifm.com

>

> Select your country > [Service] > [Download]

Application program

14118

Software specific to the application, implemented by the machine manufacturer, generally containing

logic sequences, limits and expressions that control the appropriate inputs, outputs, calculations and

decisions.

8340

WARNING

The user is responsible for the reliable function of the application programs he designed. If necessary,

he must additionally carry out an approval test by corresponding supervisory and test organisations

according to the national regulations.

29

Page 30

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Software descripti o n

>

Libraries

20880

ifm electronic offers several libraries (*.LIB) to match each device containing program modules for

the application program. Examples:

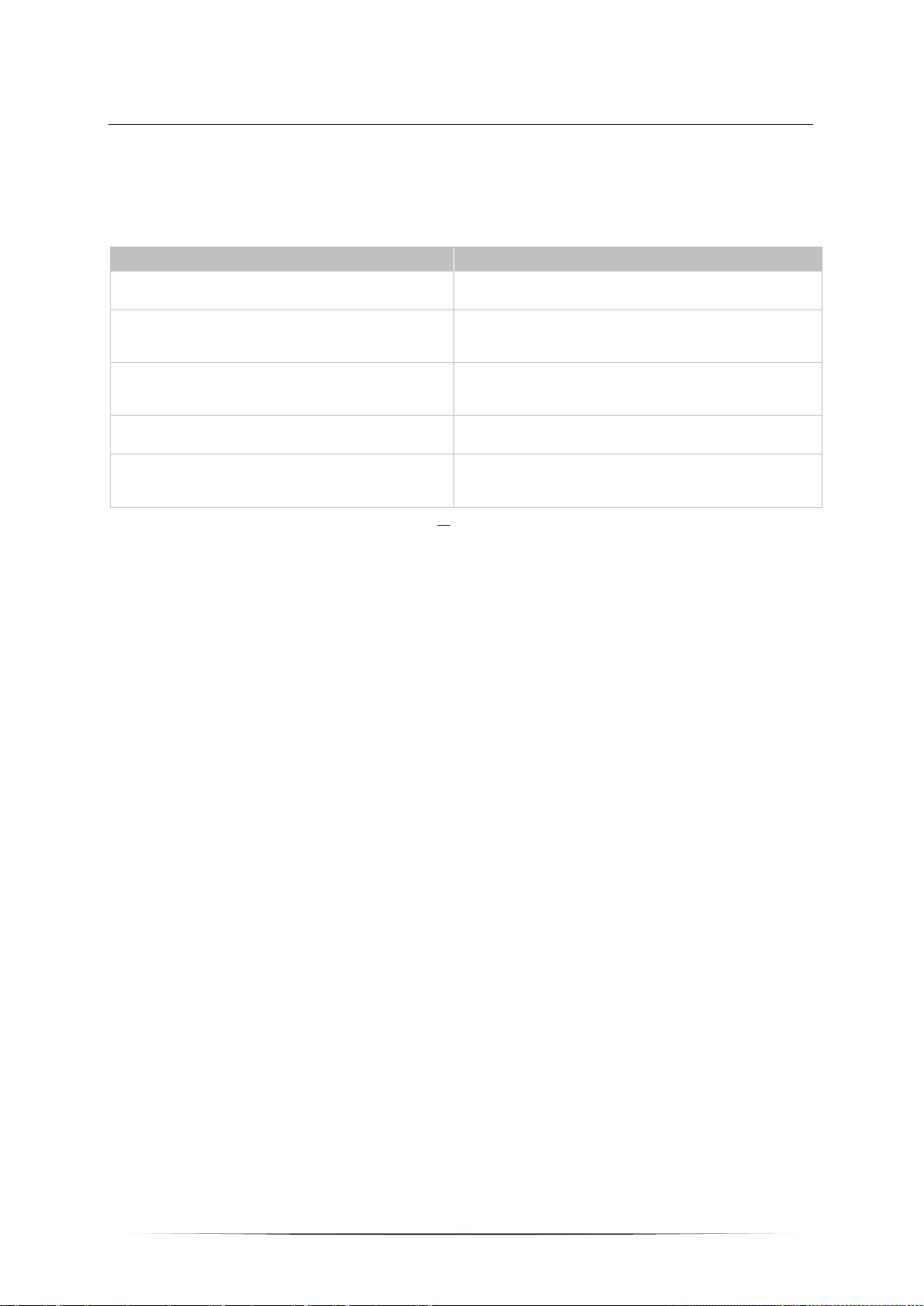

Library Usage

ifm_CR0301_Vxxyyzz.LIB Device-specific library

ifm_CR0301_CANopenMaster_Vxxyyzz.LIB (optional)

ifm_CR0301_CANopenSlave_Vxxyyzz.LIB (optional)

ifm_CAN1_EXT_Vxxyyzz.LIB (optional)

ifm_CR0301_J1939_1_Vxxyyzz.LIB (optional)

Details: → chapter ifm libraries for the device CR0301 (→ page 55)

Must always be contained in the application program!

if the CAN interface of the device is to be operated as a

CANopen master

if the CAN interface of the device is to be operated as a

CANopen-Slave

if the CAN interface of the device is to operate on 29 bits

if theCAN interface of the device is to communicate with a motor

control

30

Page 31

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Using ifm downloader .......................................................................................................................... 34

System description Software descripti o n

>

3.4.2 Programming notes for CODESYS projects

FB, FUN, PRG in CODESYS .............................................................................................................. 31

Calculations and conversions in the application program ................................................................... 32

Note the cycle time! ............................................................................................................................. 32

Creating application program .............................................................................................................. 33

Save boot project................................................................................................................................. 34

Here you receive tips how to program the device.

► See the notes in the CODESYS programming manual

→ www.ifm.com

→ ecomatmobile DVD "Software, tools and documentation".

>

FB, FUN, PRG in CODESYS

In CODESYS we differentiate between the following types of function elements:

FB = function block

• An FB can have several inputs and several outputs.

• An FB may be called several times in a project.

• An instance must be declared for each call.

• Permitted: Call FB and FUN in FB.

FUN = function

• A function can have several inputs but only one output.

• The output is of the same data type as the function itself.

PRG = program

• A PRG can have several inputs and several outputs.

• A PRG may only be called once in a project.

• Permitted: Call PRG, FB and FUN in PRG.

> select your country > [Data sheet search] > CR0301 > [Operating instructions]

7426

8473

NOTE

Function blocks must NOT be called in functions!

Otherwise: During execution the application program will crash.

All function elements must NOT be called recursively, nor indirectly!

An IEC application must contain max. 8,000 function elements!

Background:

All variables of functions...

• are initialised when called and

• become invalid after return to the caller.

Function blocks have 2 calls:

• an initialisation call and

• the actual call to do something.

Consequently that means for the FB call in a function:

• every time there is an additional initialisation call and

• the data of the last call gets lost.

31

Page 32

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Software descripti o n

>

Calculations and conversions in the application program

20779

NOTE

If the following elements are required in the application program:

• mathematical functions (e.g. ATAN),

• calculations,

• conversions (e.g. REAL_TO_BYTE),

then the following applies to the values at the inputs and outputs of the corresponding operators:

► Strictly observe the admissible value range in each individual case!

> Otherwise, this may cause an FPU error in the controller.

Examples:

20777

The value of the target format that can max. represented is exceeded.

Example:

REAL_TO_INT (12345678.3)

> INT is limited to -32768...+32767 (only integers)

An existing real number is obviously in the value range of the target format.

In reality, however, the number is outside the target format (because of the internal representation of

the real number).

Example:

DW := REAL_TO_DWORD (4294967295.0);

> The most accurate representation of 4294967295 in REAL is 4.294967296E9

> Therefore the value exceeds the max. permissible value of the target format by 1.

> DWORD is limited to 0...4294967295.

>

20778

Note the cycle time!

For the programmable devices from the controller family ecomatmobile numerous functions are

available which enable use of the devices in a wide range of applications.

As these units use more or fewer system resources depending on their complexity it is not always

possible to use all units at the same time and several times.

NOTICE

Risk that the device acts too slowly!

Cycle time must not become too long!

► When designing the application program the above-mentioned recommendations must be

complied with and tested.

► If necessary, the cycle time must be optimised by restructuring the software and the system set-

up.

8006

32

Page 33

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Software descripti o n

>

Creating application program

The application program is generated by the CODESYS programming system and loaded in the

controller several times during the program development for testing:

In CODESYS: [Online] > [Login] > load the ne w progra m.

For each such download via CODESYS the source code is translated again. The result is that each

time a new checksum is formed in the controller memory. This process is also permissible for safety

controllers until the release of the software.

8007

Graphics: Creation and distribution of the software

33

Page 34

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Software descripti o n

>

Save boot project

Always save the related boot project together with your application project in the device. Only then

will the application program be available after a power failure in the device.

NOTE

Note: The boot project is slightly larger than the actual program.

However: Saving the boot project in the device will fail if the boot project is larger than the available

IEC code memory range. After power-on the boot project is deleted or invalid.

► CODESYS menu [Online] > [Create boot project]

This is necessary after each change!

> After a reboot, the device starts with the boot project last saved.

> If NO boot project was saved:

• The device remains in the STOP operation after reboot.

• The application program is not (no longer) available.

• The LED lights green.

>

7430

Using ifm downloader

8008

The ifm downloader serves for easy transfer of the program code from the programming station to the

controller. As a matter of principle each application software can be copied to the controllers using the

ifm downloader. Advantage: A programming system with CODESYS licence is not required.

Here you will find the current ifm downloader (min. V06.18.26):

ecomatmobile DVD "Software, tools and documentation" under the tab 'R360 tools [D/E]'

34

Page 35

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

SYSTEM STOP state .......................................................................................................................... 38

System description Software descripti o n

>

3.4.3 Operating states

Operating states: runtime system is not available ............................................................................... 35

Operating states: application program is not available ....................................................................... 36

Operating states: application program is available ............................................................................. 37

Bootloader state .................................................................................................................................. 38

INIT state (Reset) ................................................................................................................................ 38

STOP state .......................................................................................................................................... 38

RUN state ............................................................................................................................................ 38

After power on the ecomatmobile device can be in one of five possible operating states:

• BOOTLOADER

• INIT

• STOP

• RUN

• SYSTEM STOP (after ERROR STOP)

>

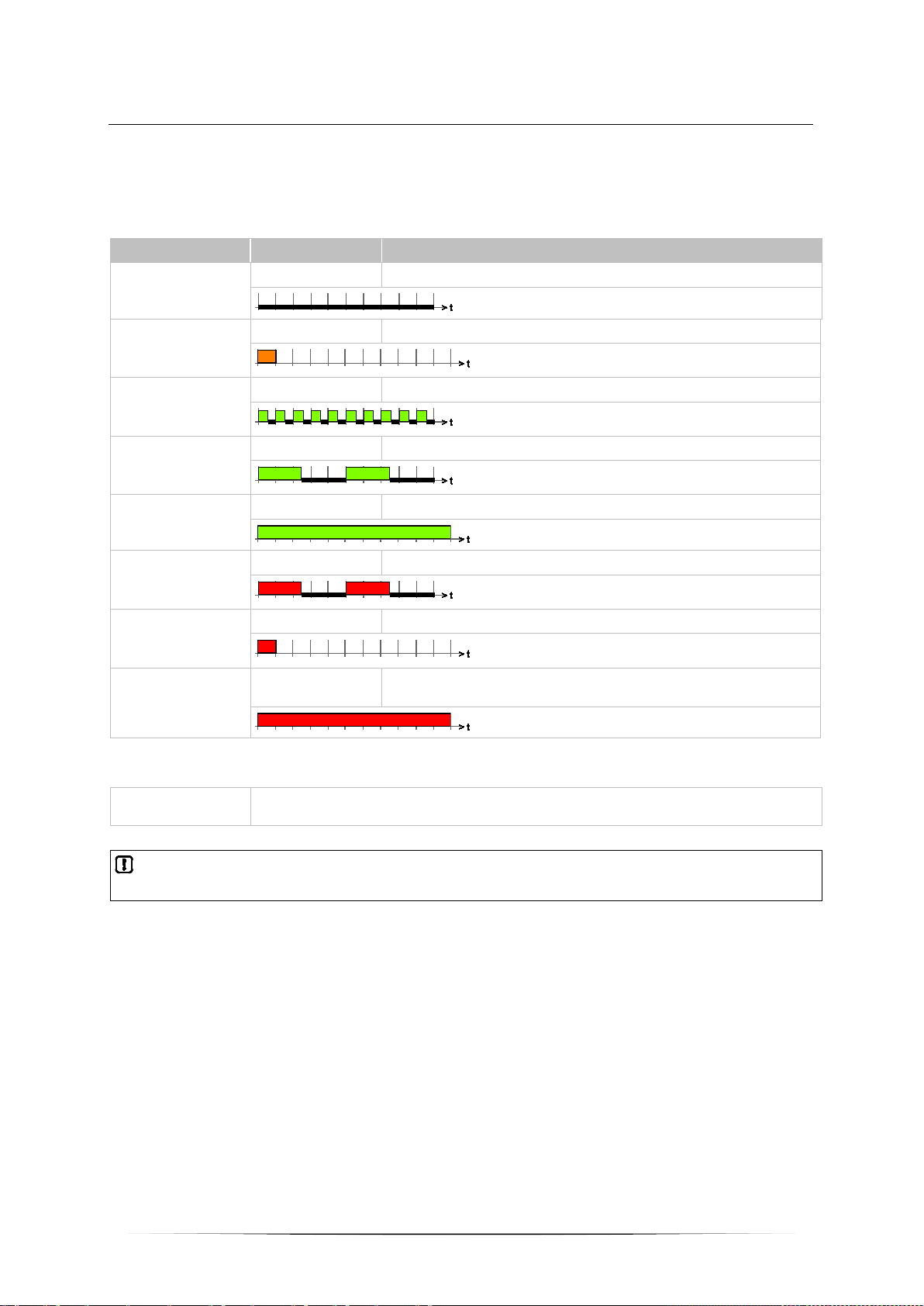

Operating states: runtime system is not available

14120

19217

Figure: operating states (here: runtime system is not available)

35

Page 36

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Software descripti o n

>

Operating states: application program is not available

19218

Figure: operating states (here: application program is not available)

36

Page 37

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Software descripti o n

>

Operating states: application program is available

19219

Figure: operating states (here: application program is available)

37

Page 38

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Software descripti o n

>

Bootloader state

No runtime system was loaded. The ecomatmobile controller is in the boot loading state. Before

loading the application software the runtime system must be downloaded.

> The LED flashes green (5 Hz).

>

INIT state (Reset)

Premise: a valid runtime system is installed.

This state is passed through after every power on reset:

> The runtime system is initialised.

> Various checks are carried out, e.g. waiting for correctly power supply voltage.

> This temporary state is replaced by the RUN or STOP state.

> The LED lights yellow.

Change out of this state possible into one of the following states:

• RUN

• STOP

>

1080

1076

STOP state

This state is reached in the following cases:

• From the RESET state if:

• no program is loaded or

• the last state before the RESET state was the STOP state

• From the RUN state by the STOP command

• only for the operating mode = Test (→ chapter TEST mode)

> The LED lights green.

>

RUN state

This state is reached in the following cases:

• From the RESET state if:

• the last state before the RESET state was the RUN state

• From the STOP state by the RUN command

• only for the operating mode = Test (→ chapter TEST mode)

> The LED flashes green (2 Hz).

>

SYSTEM STOP state

The ecomatmobile controller goes to this state if a non tolerable error (ERROR STOP) was found.

This state can only be left by a power-off-on reset.

> The LED lights red.

1078

1077

19222

38

Page 39

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

NOTICE

System description Software descripti o n

>

3.4.4 Operating modes

1083

Independent of the operating states the ecomatmobile controller can be operated in different modes.

>

TEST mode

20876

NOTICE

Loss of the stored software possible!

In the test mode there is no protection of the stored runtime system and application software.

14892

NOTE

> Connect the TEST connection to the supply voltage only AFTER you have connected the OPC

client!

This operating mode is achieved by applying a high level (supply voltage) to the test input

(→ installation instructi ons, c hapter " wiring ").

The controller can now receive commands via one of the interfaces in the RUN or STOP mode and,

for example, communicate with the programming system.

Only in the TEST mode, the software can be downloaded to the controller.

The state of the application program can be queried via the flag TEST.

Summary Test input is active:

• Programming mode is enabled

• Software download is possible

• Status of the application program can be queried

• Protection of stored software is not possible

Zerstörung des EEPROMs möglich!

Der Test-Eingang darf nicht permanent aktiviert werden, weil sonst die zulässigen Schreibzyklen im

EEPROM überschritten we rden.

>

Notes: TEST inputs

► The TEST inputs of all the controllers in the machine should be wired individually and marked

clearly so that they can be properly allocated to the controllers.

► During a service access only activate the TEST input of the controller to be accessed.

20781

39

Page 40

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

System description Software descripti o n

>

SERIAL_MODE

1085

The serial interface is available for the exchange of data in the application. Debugging the application

software is then only possible via the CAN interface.

This function is switched off as standard (FALSE). Via the flag SERIAL_MODE the state can be

controlled and queried via the application program or the programming system.

→ chapter Function elements: serial interface (→ page 111

>

)

DEBUG mode

1086

If the input DEBUG of SET_DEBUG (→ page 174) is set to TRUE, the programming system or the

downloader, for example, can communicate with the controller and execute some special system

commands (e.g. for service functions via the GSM modem CANremote).

In this operating mode a software download is not possible because the test input (→ chapter TEST

mode) is not connected to supply voltage.

40

Page 41

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

NOTICE

System description Software descripti o n

>

3.4.5 Performance limits of the device

Note the limits of the device! → Data sheet

>

Above-average stress

The following FBs, for example, utilise the system resources above average:

Function block Above average load

FREQUENCY,

PERIOD,

PERIOD_RATIO,

PHASE

CAN interface High baud rate (> 250 kbits) with a high bus load

PWM,

PWM100,

PWM1000

INC_ENCODER Many encoder channels at the same time

The FBs listed above as examples trigger system interrupts. This means: each activation prolongs the

cycle time of the application program.

Use of several measuring channels with a high input frequency

Many PWM channels at the same time. In particular the channels as from 4

are much more time critical

7358

20878

1509

Risk that the controller works too slowly! Cycle time must not become too long!

► When the application program is designed the above-mentioned recommendations must be

complied with and tested. If necessary, the cycle time must be optimised by restructuring the

software and the system set-up.

>

Watchdog behaviour

In this device, a watchdog monitors the program runtime of the CODESYS application.

If the maximum watchdog time (100...200 ms) is exceeded:

> the device performs a reset and reboots

>

1490

41

Page 42

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Safety instructions about Reed relays ................................................................................................. 54

Verify the installation ........................................................................................................................... 44

Configurations Set up the runtime system

4 Configurations

Set up the runtime system ................................................................................................................... 42

Set up the programming system ......................................................................................................... 45

Function configuration of the inputs and outputs ................................................................................ 48

Note on wiring ...................................................................................................................................... 54

The device configurations described in the corresponding installation instructions or in the Appendix

(→ page 179

requested specifications of most applications.

Depending on the customer requirements for series use it is, however, also possible to use other

device configurations, e.g. with resp ec t to the inputs /o utputs and ana lo gue chan n els.

>

4.1 Set up the runtime system

Reinstall the runtime system ............................................................................................................... 43

Update the runtime system ................................................................................................................. 44

) to this documentation are used for standard devices (stock items). They fulfil the

1016

14091

42

Page 43

ifm Programming Manual ecomatmobile CabinetController (CR0301) Runtime System V05 2016-04-21

Configurations Set up the runtime system

>

4.1.1 Reinstall the runtime system

14092

2733

On delivery of the ecomatmobile device no runtime system is normally loaded (LED flashes green at

5 Hz). Only the bootloader is active in this operating mode. It provides the minimum functions for

loading the runtime system (e.g. RS232, CAN).

Normally it is necessary to download the runtime system only once. The application program can then

be loaded to the device (also several times) without influencing the runtime system.

The runtime system is provided with this documentation on a separate data carrier. In addition, the

current version can be downloaded from the website of ifm electronic gmbh at:

→ www.ifm.com

> Select your country > [Service] > [Download]

2689

NOTE

The software versions suitable for the selected target must always be used:

• runtime system (ifm_CR0301_Vxxyyzz.H86),

• PLC configuration (ifm_CR0301_Vxx.CFG),

• device library (ifm_CR0301_Vxxyyzz.LIB ) and

• the further files.

V

xx: 00...99

yy: 00...99

zz: 00...99

version

target version number

release number

patch number

The basic file name (e.g. "CR0301") and the software version number "xx" (e.g. "02") must always

have the same value! Otherwise the device goes to the STOP mode.

The values for "yy" (release number) and "zz" (patch number) do not have to match.

4368

The following files must also be loaded: