IFM Electronic AL1300, AL1900 Operating Instructions Manual

Operating Instructions

IO-Link Master with PROFINET interface

DataLine

4 Ports

IP 65 / IP 66 / IP 67

AL1300

IO-Link: 1.1.2

ifm firmware: 2.1.28 or higher

LR DEVICE: 1.3.1.x or higher

English

7391152 / 01 05 / 2018

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Content

Table of Contents

1 Preliminary note 5

1.1 Legal and copyright information ........................................................................................... 5

1.2 Purpose of the document ..................................................................................................... 5

1.3 Symbols and styles used ..................................................................................................... 6

1.4 Modification history .............................................................................................................. 6

2 Safety instructions 7

2.1 General ................................................................................................................................ 7

2.2 Required background knowledge ........................................................................................ 7

2.3 Safety symbols on the device .............................................................................................. 7

2.4 Tampering with the unit ........................................................................................................ 8

3 Intended use 9

3.1 Permitted use ....................................................................................................................... 9

3.2 Prohibited use ...................................................................................................................... 9

4 Function 10

4.1 Communication, parameter setting, evaluation .................................................................11

4.1.1 IO-Link ........................................................................................................................................ 11

4.1.2 PROFINET ................................................................................................................................. 11

4.1.3 Internet of Things (IoT) ............................................................................................................... 11

4.1.4 Parameter setting ....................................................................................................................... 11

4.1.5 Visual indication ......................................................................................................................... 12

4.2 Digital inputs .......................................................................................................................12

4.3 IO-Link supply ....................................................................................................................12

5 Mounting 13

5.1 Mount the device ................................................................................................................13

6 Electrical connection 14

6.1 Remarks .............................................................................................................................14

6.2 PROFINET ports ................................................................................................................15

6.3 IoT port ...............................................................................................................................15

6.4 IO-Link ports .......................................................................................................................16

6.4.1 Input circuit ................................................................................................................................. 17

6.4.2 IO-Link circuits ............................................................................................................................ 17

6.5 Connect the device ............................................................................................................18

7 Operating and display elements 19

7.1 Overview ............................................................................................................................19

7.2 LED indicators ....................................................................................................................20

7.2.1 Status LEDs ............................................................................................................................... 20

7.2.2 Ethernet interface ....................................................................................................................... 20

7.2.3 IoT port ....................................................................................................................................... 21

7.2.4 Voltage supply ............................................................................................................................ 21

7.2.5 IO-Link ports (Class A) ............................................................................................................... 21

2

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Content

8 Configuration 22

8.1 LR DEVICE ........................................................................................................................23

8.1.1 Remarks ..................................................................................................................................... 24

8.1.2 IoT: Configure access rights ....................................................................................................... 25

8.1.3 IoT: Configure IP settings ........................................................................................................... 26

8.1.4 IoT: Configure the interface to the LR SMARTOBSERVER ....................................................... 27

8.1.5 Fieldbus: Configure the PROFINET port .................................................................................... 27

8.1.6 IO-Link ports: Activate data transfer to the LR SMARTOBSERVER .......................................... 28

8.1.7 IO-Link ports: Configure operating mode.................................................................................... 29

8.1.8 IO-Link ports: Set the device validation and data storage .......................................................... 30

8.1.9 Firmware: Reset device to factory settings ................................................................................. 31

8.1.10 Firmware: Reboot the device ...................................................................................................... 31

8.1.11 Configure IO-Link devices .......................................................................................................... 32

8.2 PROFINET .........................................................................................................................33

8.2.1 Install GSD file ............................................................................................................................ 34

8.2.2 Add the IO-Link master to the PROFINET network .................................................................... 35

8.2.3 Configure access rights .............................................................................................................. 37

8.2.4 Configure IO-Link ports .............................................................................................................. 38

8.2.5 Configure the PROFINET port .................................................................................................... 39

8.2.6 Configure IO-Link devices .......................................................................................................... 39

8.2.7 Read and write data cyclically .................................................................................................... 40

8.2.8 PROFINET: Read & write device information ............................................................................. 40

8.2.9 PROFINET: Programmers' notes ................................ ............................................................... 41

8.3 IoT Core .............................................................................................................................43

8.3.1 Configure IoT interface ............................................................................................................... 44

8.3.2 Configure the fieldbus interface .................................................................................................. 44

8.3.3 Configure IO-Link ports .............................................................................................................. 45

8.3.4 Configure IO-Link devices .......................................................................................................... 45

8.3.5 Set application identification ....................................................................................................... 45

8.3.6 Read / write cyclic process data ................................................................................................. 46

8.3.7 Read diagnostic data .................................................................................................................. 46

8.3.8 Control IO-Link master ............................................................................................................... 46

8.3.9 Read device information ................................ ................................................................ ............. 47

8.3.10 Read information about IO-Link devices .................................................................................... 47

8.3.11 Examples .................................................................................................................................... 48

8.3.12 Programmers' notes ................................................................................................................... 52

9 Operation 56

9.1 Firmware update ................................................................................................................56

9.2 Web interface: Read device and diagnostic information....................................................57

9.3 Replace IO-Link device ......................................................................................................58

10 Maintenance 59

11 Factory settings 60

12 Accessories 61

13 Appendix 62

13.1 Technical data ....................................................................................................................63

13.1.1 Application .................................................................................................................................. 63

13.1.2 Electrical data ............................................................................................................................. 63

13.1.3 Inputs / outputs ........................................................................................................................... 63

13.1.4 Inputs.......................................................................................................................................... 64

3

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Content

13.1.5 Outputs ................................................................ ................................................................ ....... 64

13.1.6 Interfaces .................................................................................................................................... 64

13.1.7 Operating conditions .................................................................................................................. 65

13.1.8 Approvals / tests ......................................................................................................................... 65

13.1.9 Mechanical data ......................................................................................................................... 65

13.1.10 Electrical connection .................................................................................................................. 66

13.2 PROFINET .........................................................................................................................67

13.2.1 Parameter data ........................................................................................................................... 67

13.2.2 Cyclic data .................................................................................................................................. 70

13.2.3 Acyclic data ................................................................................................................................ 72

13.3 ifm IoT Core .......................................................................................................................75

13.3.1 Overview: IoT profile .................................................................................................................. 76

13.3.2 Overview: IoT types .................................................................................................................... 79

13.3.3 Overview: IoT services ............................................................................................................... 80

14 Index 87

4

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Preliminary note Legal and copyright information

1 Preliminary note

Legal and copyright information ............................................................................................................... 5

Purpose of the document ......................................................................................................................... 5

Symbols and styles used .......................................................................................................................... 6

Modification history ................................................................................................................................... 6

>

14801

1.1 Legal and copyright information

1631

© All rights reserved by ifm electronic gmbh. No part of this manual may be reproduced and used

without the consent of ifm electronic gmbh.

All product names, pictures, companies or other brands used on our pages are the property of the

respective rights owners:

AS-i is the property of the AS-International Association, (→ www.as-interface.net)

CAN is the property of the CiA (CAN in Automation e.V.), Germany (→ www.can-cia.org)

CODESYS™ is the property of the 3S – Smart Software Solutions GmbH, Germany

(→ www.codesys.com)

DeviceNet™ is the property of the ODVA™ (Open DeviceNet Vendor Association), USA

(→ www.odva.org)

EtherNet/IP® is the property of the →ODVA™

EtherCAT® is a registered trade mark and patented technology, licensed by Beckhoff Automation

GmbH, Germany

IO-Link® (→ www.io-link.com) is the property of the →PROFIBUS Nutzerorganisation e.V.,

Germany

ISOBUS is the property of the AEF – Agricultural Industry Electronics Foundation e.V.,

Deutschland (→ www.aef-online.org)

Microsoft® is the property of the Microsoft Corporation, USA (→ www.microsoft.com)

PROFIBUS® is the property of the PROFIBUS Nutzerorganisation e.V., Germany

(→ www.profibus.com)

PROFINET® is the property of the →PROFIBUS Nutzerorganisation e.V., Germany

Windows® is the property of the →Microsoft Corporation, USA

>

1.2 Purpose of the document

This document is only for device types "IO-Link master - PROFINET gateway (DataLine) 4 port IP 65 /

IP 66 / IP 67" (art. no.: AL1300).

It is part of the device and contains information about the correct handling of the product.

► Read this document before using the device.

► Keep this document during the service life of the device.

22044

5

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Preliminary note Symbols and styles used

>

WARNING

Death or serious irreversible injuries may result.

CAUTION

Slight reversible injuries may result.

NOTICE

Property damage is to be expected or may result.

Important note

Non-compliance can result in malfunction or interference

Information

Supplementary note

► ...

Request for action

> ...

Reaction, result

→ ...

"see"

abc

Cross-reference

123

0x123

0b010

Decimal number

Hexadecimal number

Binary number

[...]

Designation of pushbuttons, buttons or indications

Version

Topic

Date

00

New creation of document

11 / 2017

01

Update to firmware 2.1.26

Correction: example for IoT service getdatamulti

Added: enable/disable transmission of events (Feldbus)

05 / 2018

1.3 Symbols and styles used

15989

>

1.4 Modification history

6

6922

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Safety instructions General

2 Safety instructions

General ..................................................................................................................................................... 7

Required background knowledge ............................................................................................................. 7

Safety symbols on the device ................................................................................................................... 7

Tampering with the unit ............................................................................................................................ 8

The plant manufacturer is responsible for the safety of the plant in which the device is

installed.

If the device is used in a way that is not intended by the manufacturer, the protection

supported by the device may be impaired.

Non-observance of the instructions, operation which is not in accordance with use as

prescribed below, wrong installation or incorrect handling can affect the safety of operators

and machinery.

► Observe these operating instructions.

► Adhere to the warning notes on the product.

General warning

Observe instructions in chapter "Electrical connection" (→ Electrical connection (→ p. 14))!

>

2.1 General

22068

>

2.2 Required background knowledge

22046

This document is intended for specialists. Specialists are people who, based on their relevant training

and experience, are capable of identifying risks and avoiding potential hazards that may be caused

during operation or maintenance of the product.

The document contains information about the correct handling of the product.

>

213

2.3 Safety symbols on the device

15021

7

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Safety instructions Tampering with the unit

>

WARNING

Tampering with the units can affect the safety of operators and machinery!

Tampering with the units is not allowed.

In case of non-compliance our liability and warranty expire.

► Do not open the devices!

► Do not insert any objects into the devices!

► Prevent metal foreign bodies from penetrating!

2.4 Tampering with the unit

11242

8

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Intended use Permitted use

3 Intended use

Permitted use ........................................................................................................................................... 9

Prohibited use ........................................................................................................................................... 9

>

3.1 Permitted use

The IO-Link master serves as a gateway between intelligent IO-Link devices and the fieldbus. The

device is designed for use without a control cabinet in the plant construction.

>

3.2 Prohibited use

The device may not be used beyond the limits of the technical data (→ Technical data (→ p. 63))!

18761

22052

22053

9

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Function Prohibited use

4 Function

Communication, parameter setting, evaluation ......................................................................................11

Digital inputs ...........................................................................................................................................12

IO-Link supply .........................................................................................................................................12

7482

10

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Function Communication, parameter setting, evaluation

>

IO-Link ....................................................................................................................................................11

PROFINET..............................................................................................................................................11

Internet of Things (IoT) ...........................................................................................................................11

Parameter setting ...................................................................................................................................11

Visual indication ......................................................................................................................................12

4.1 Communication, parameter setting, evaluation

>

7485

4.1.1 IO-Link

7773

The device offers the following IO-Link functions:

IO-Link master (IO-Link revision 1.0 and 1.1)

4 IO-Link ports for connection of IO-Link devices

Provision of process data of the connected IO-Link devices for LR SMARTOBSERVER monitoring

software (→ www.ifm.com)

>

4.1.2 PROFINET

2259

The device offers the following PROFINET functions:

Provision of the functions of a Profinet RT Device (Class B)

2 port switch for access to the PROFINET interface (X21/X22)

Gateway for transmission of the process and parameter data between the connected IO-Link

devices and the higher-level PROFINET controller

>

4.1.3 Internet of Things (IoT)

8355

The device has an Ethernet port (X23) for Internet-of-Things applications. The interface allows

separate access from IT networks to parameters, process and monitoring data of the IO-Link master

and the connected IO-Link devices. Different protocols (e.g. TCP/IP JSON) are supported.

>

4.1.4 Parameter setting

The device provides the following configuration options:

Parameter setting of the IO-Link master of the AL1300 with LR DEVICE parameter setting

software, PROFINET projection software or ifm IoT-Core services.

Parameter setting of the connected IO-Link devices (sensors, actuators) with LR DEVICE

parameter setting software, PROFINET projection software or ifm IoT-Core services

Storage of parameter sets of the connected IO-Link devices for automatic recovery (data storage)

7284

11

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Function Digital inputs

>

4.1.5 Visual indication

The device has the following visual indicators:

Status and error indication of the gateway, of the PROFINET connection and of the system

Status display of the voltage supply

Status and activity display of the Ethernet connection

Status, error and short circuit/overload indication of the IO-Link ports

>

4.2 Digital inputs

The device has 4 additional digital inputs (type 2 according to EN 61131-2).

The digital inputs are on pin 2 of the IO-Link ports X01 ... X04.

All inputs refer to the potential of the device supply (pin 3).

>

4.3 IO-Link supply

The device has 4 supplies for IO-Link devices.

The IO-Link ports X01...X04 are ports class A.

Every supply provides short circuit monitoring.

The device ensures fire protection for the connected IO-Link devices by providing a power-restricted

circuit at the IO-Link ports (according to IEC61010-1 and Class 2 according to UL1310).

7772

7584

7623

12

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Mounting Mount the device

5 Mounting

Mount the device ....................................................................................................................................13

► Disconnect the system from power before installation.

► For installation choose a flat mounting surface.

► Please observe the maximum tightening torque.

>

5.1 Mount the device

► Fix the unit to the mounting surface using 2 M5 mounting screws and washers.

Tightening torque: 1.8 Nm

► Ground the unit via the two mounting screws of the upper mounting lugs.

22016

15540

13

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Electrical connection Remarks

6 Electrical connection

Remarks .................................................................................................................................................14

PROFINET ports ....................................................................................................................................15

IoT port ...................................................................................................................................................15

IO-Link ports ...........................................................................................................................................16

Connect the device .................................................................................................................................18

A qualified electrician must connect the unit.

► Observe the national and international regulations for the installation of electrical

equipment.

Device is only suitable for operation on SELV/PELV voltages.

► Observe the information concerning IO-Link circuits (→ IO-Link circuits (→ p. 17))!

The device contains components that can be damaged or destroyed by electrostatic discharge

(ESD).

► Observe the required safety measures against electrostatic discharge!

The IP rating depends on the individual protection ratings of the unit, the applied connection

elements and the corresponding protective covers.

► For UL applications: For connecting the device and the IO-Link devices use UL certificated

cables of category CYJV or PVVA with a minimum temperature rating of 100°C.

► Depending on the mounting conditions, cables must be provided with a strain relief to

avoid unacceptable loads on the mounting points and M12 connections.

► Make sure that the M12 connection parts are correctly seated and mounted correctly. The

specified protection rating can not be guaranteed if this is not observed.

Wiring: → Technical data (→ p. 63)

The communication interfaces are seperated from the device supply according to EN61010-1

considering basis isolation as secondary circuit with maximum 30 V DC derived from the

applied voltage up to 300 V of overvoltage category II. The communication interfaces are

designed for a network environment 0 according to IEC TR62102.

>

6.1 Remarks

22017

18076

14

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Electrical connection PROFINET ports

>

► Connect the device via the M12 socket X21 and/or X22 to the

PROFINET network

(e.g. PROFINET PLC, additional PROFINET device)

Tightening torque: 0.6...0.8 Nm

► To connect the devices, use M12 connectors with protection rating

IP 65 / IP 66 / IP 67 or higher (→ Accessories (→ p. 61)).

► Cover the unused sockets with M12 protective caps (art no.

E73004).

Tightening torque 0.6...0.8 Nm

► Connect the device via the M12 socket X23 to the IT network (e.g.

laptop/PC with installed LR DEVICE parameter setting software,

laptop/PC with installed LR SMARTOBSERVER monitoring

software)

Tightening torque: 0.6...0.8 Nm

► To connect the devices, use M12 connectors with protection rating

IP 65 / IP 66 / IP 67 or higher (→ Accessories (→ p. 61)).

► Cover the unused sockets with M12 protective caps (art no.

E73004)

Tightening torque 0.6...0.8 Nm

6.2 PROFINET ports

>

17849

6.3 IoT port

11029

15

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Electrical connection IO-Link ports

>

Ports X01...X04: For use as IO-Link port class A:

► Connect the connector of the IO-Link devices with the M12 sockets

X01 ... X04.

Tightening torque: 0.6...0.8 Nm

Maximum cable length per IO-Link interface: 20 m

► For the connection, use M12 connectors with protection rating IP 65

/ IP 66 / IP 67 or higher (→ Accessories (→ p. 61)).

Ports X01...X04: For use as IO-Link port class B:

► Connect the connector of the IO-Link devices via the adapter with

the M12 sockets X01 ... X04.

Tightening torque: 0.6...0.8 Nm

► To connect the devices, use M12 connectors with protection rating

IP 65 / IP 66 / IP 67 or higher (→ Accessories (→ p. 61)).

► Cover the unused sockets with M12 protective caps (art no.

E73004).

Tightening torque 0.6...0.8 Nm

6.4 IO-Link ports

22684

16

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Electrical connection IO-Link ports

>

The connected IO-Link devices may only be supplied via the AL1300.

Exception: Connection of IO-Link devices to ports X01...X04 via suitable connection

technology for port class B operation (→ IO-Link ports (→ p. 16)):

The external supply for port class B operation must be galvanically separeted from the circuit

of the AL1300 by assuring basic isolation (according to EN61010-1, secondary circuit with

maximum 30 V DC derived from applied voltage up to 300 V of overvoltage category II)!

The isolation must be done both for IO-Link devices and for the connection technology.

NOTICE

Risk of material damage

If the requirements of galvanic separation of the circuits are not observed, the fire protection of the

device can not be assured.

► Observe the requirements of the electrical connection of IO-Link devices for port class B

operation!

6.4.1 Input circuit

18629

The inputs of the ports X01...X04 (pin 2) provide a type 2 behaviour according to standard EN61131-2,

the connected electronics must be rated for this electrically.

>

6.4.2 IO-Link circuits

11616

The IO-Link interfaces of the device meet the requirements of the IO-Link specification 1.0 to 1.1.2.

Further information: → Technical data (→ p. 63)

17

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Electrical connection Connect the device

>

► Disconnect power.

► Connect the unit via M12 socket X31 to 24 V DC

(20...30 V SELV/PELV; according to EN61010-1, secondary circuit

with maximum 30 V DC derived from applied voltage up to 300 V

of overvoltage category II).

Tightening torque: 0.6...0.8 Nm

Maximum cable length: 25 m

► To connect the device , use M12 connectors with protection rating

IP 65 / IP 66 / IP 67 or higher (→ Accessories (→ p. 61)).

If the port X01...X04 will be used as IO-Link ports Class B:

► Connect adapter for Port Class B operation to 24 V DC

(20...30 V SELV/PELV; according to EN61010-1, secondary circuit

with maximum 30 V DC derived from applied voltage up to 300 V

of overvoltage category II) (→ IO-Link ports (→ p. 16))

Tightening torque: 0.6...0.8 Nm

When using connectors longer than 25 m keep in mind the voltage drop as well as the

required minimum voltage supply of the AL1300.

6.5 Connect the device

2580

18

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Operating and display elements Overview

7 Operating and display elements

Overview .................................................................................................................................................19

LED indicators ........................................................................................................................................20

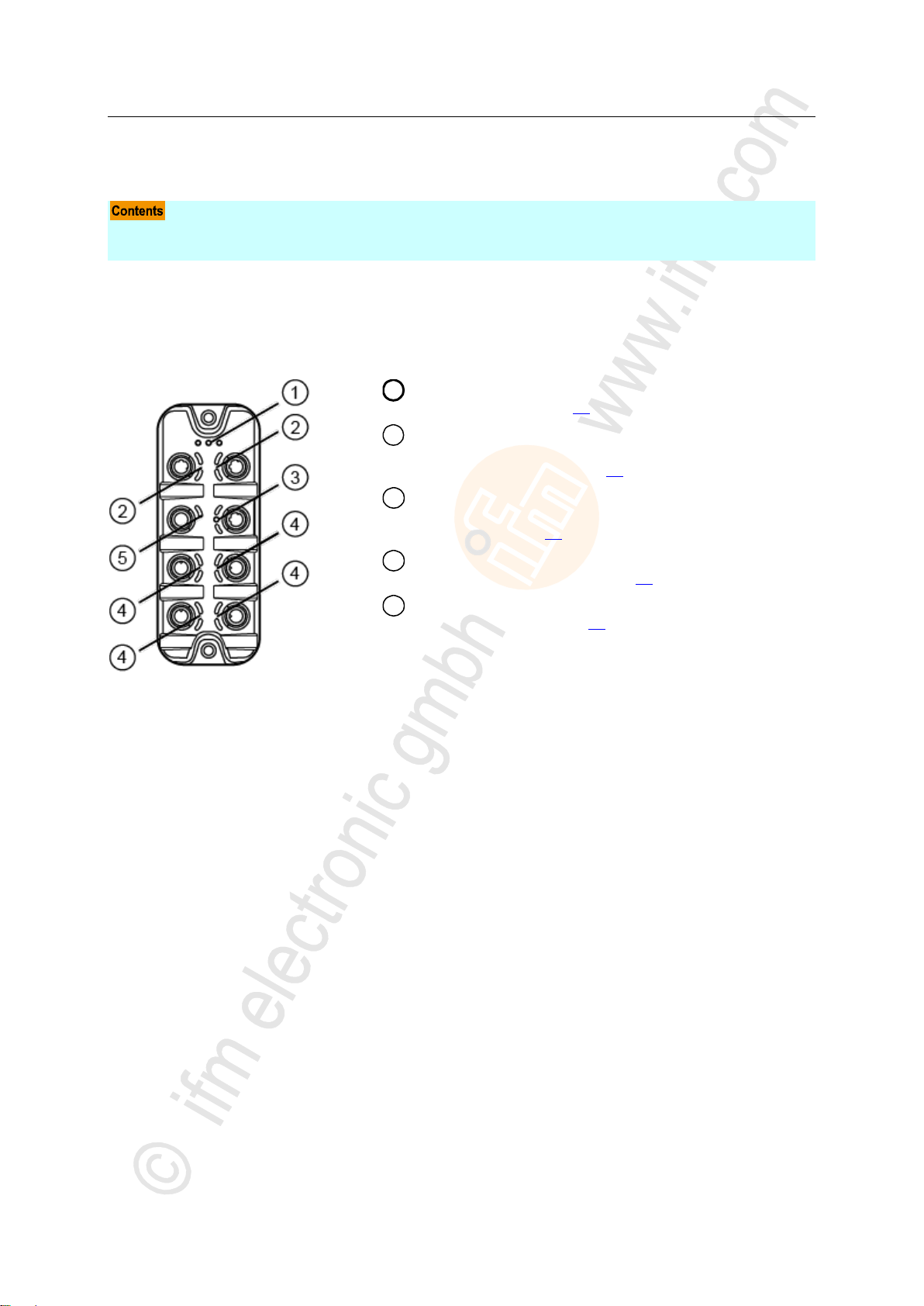

1

RDY, BF and SF status LEDs

→ Status LEDs (→ p. 20)

2

LNK and ACT status LEDs of the PROFINET

interfaces 1 (X21) and 2 (X22)

→ Ethernet interface (→ p. 20)

3

LNK, ACT status-LEDs and IoT LED of the IoT

interface (X23)

→ IoT port (→ p. 21)

4

IOL and DI status-LEDs of the IO-Link port (X01...X04)

→ IO-Link ports (Class A) (→ p. 21)

5

PWR status LED of the voltage supply (X31)

→ Voltage supply (→ p. 21)

>

7.1 Overview

5440

17857

19

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Operating and display elements LED indicators

>

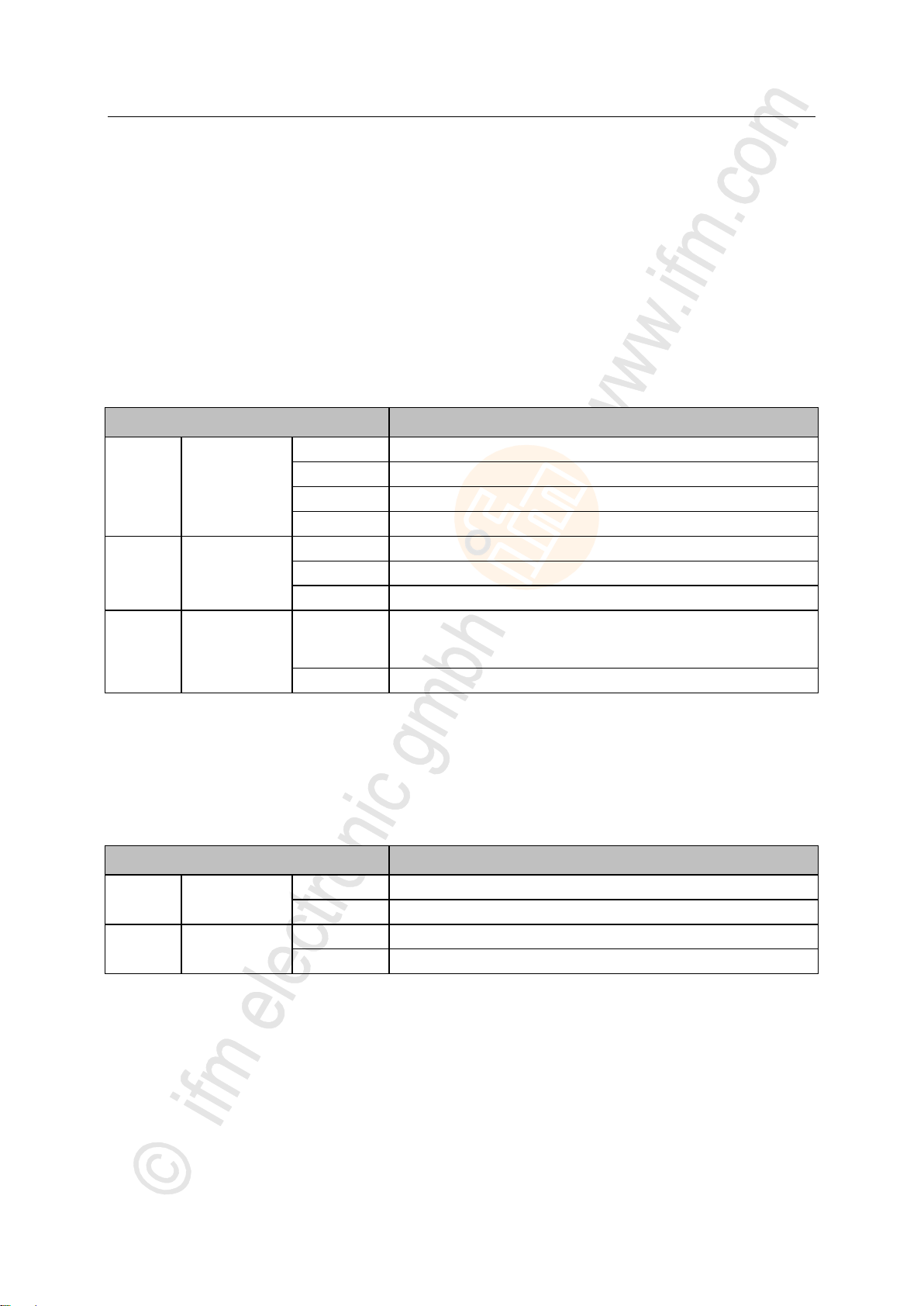

Status LED

Description

RDY

green

on

Gateway functions properly

flashes 1 Hz

Error

flashes 5 Hz

Firmware update

off

Gateway does not function; Unit reboots

BF

red

on

Bus error

flashes 1 Hz

No connection to the PROFINET controller

off

error-free

SF

red

on

Error in gateway

At least 1 IO-Link device sends warning / alarm (temperature,

over/under current, over/under voltage, shortcut)

off

error-free

Status LED

Description

LNK

green

on

Ethernet connection established

off

No Ethernet connection

ACT

yellow

flashes

Data is transmitted via the Ethernet interface.

off

No data transmission

7.2 LED indicators

The device only has the following LED indicators:

>

7.2.1 Status LEDs

The RDY LED shows the status of the gateway.

The BF LED (Bus Failure) shows the status of the PROFINET connection.

The SF LED (System Failure) shows the status of the system.

22024

22034

>

7.2.2 Ethernet interface

Each Ethernet interface (X21, X22) has 2 LEDs (LNK and ACT). The LEDs indicate the status of the

Ethernet connection.

22027

20

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Operating and display elements LED indicators

>

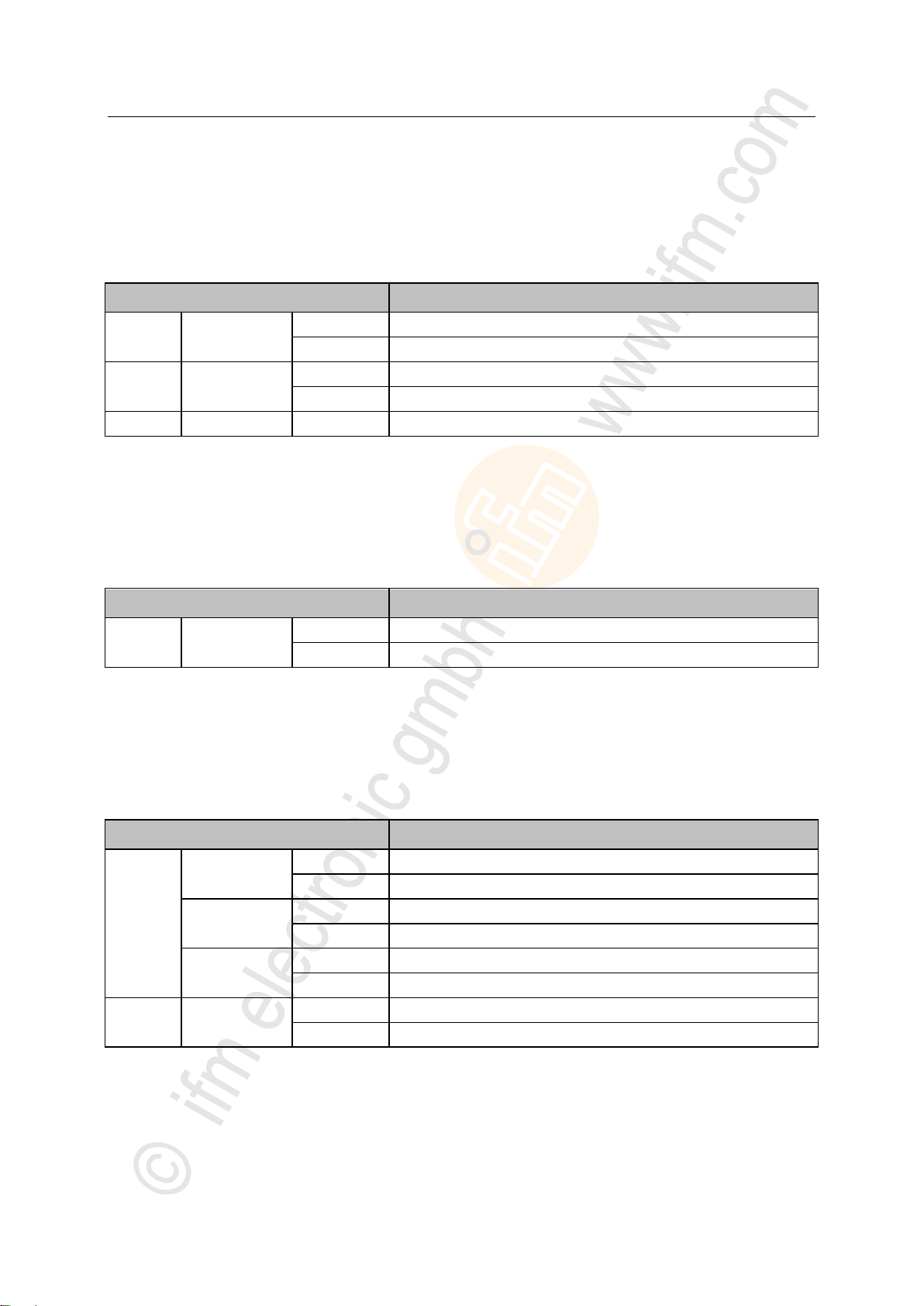

Status LED

Description

LNK

green

on

Ethernet connection established

off

No Ethernet connection

ACT

yellow

flashes

Data is transmitted via the Ethernet interface.

off

No data transmission

IoT

green

flashes

Device identification active

Status LED

Description

US

green

on

The supply voltage Us is applied.

off

No supply voltage is applied or the applied supply voltage is too low.

Status LED

Description

IOL

yellow

on

Interface configured as DI/DO: pin 4 (C/Q) =ON

off

Interface configured as DI/DO: pin 4 (C/Q) = OFF

green

on

IO-Link transmission functions properly

flashes 1 Hz

Interface configured as IO-Link, but no IO-Link transmission

red

on

Short circuit or overload in supply voltage

flashes 1 Hz

Transmission error

DI

yellow

on

Digital input: pin 2 (DI) = ON

off

Digital input : pin 2 (DI) = OFF

7.2.3 IoT port

7722

The IoT port (X23) has the 3 LNK, ACT and IoT LEDs. The LEDs indicate the status of the Ethernet

connection and the device identification.

>

7.2.4 Voltage supply

22026

The interface for voltage supply (X31) has the LED that is marked as US. The LED indicates the status

of the voltage supply.

>

7.2.5 IO-Link ports (Class A)

Each IO-Link port Class A (X01 ... X04) has 2 LEDs marked as IOL and DI. The LEDs indicate the

status of the IO-Link port.

22029

21

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Configuration LED indicators

8 Configuration

LR DEVICE .............................................................................................................................................23

PROFINET..............................................................................................................................................33

IoT Core ..................................................................................................................................................43

22367

22

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Configuration LR DEVICE

>

Remarks .................................................................................................................................................24

IoT: Configure access rights ...................................................................................................................25

IoT: Configure IP settings .......................................................................................................................26

IoT: Configure the interface to the LR SMARTOBSERVER ..................................................................27

Fieldbus: Configure the PROFINET port ................................................................................................27

IO-Link ports: Activate data transfer to the LR SMARTOBSERVER .....................................................28

IO-Link ports: Configure operating mode ...............................................................................................29

IO-Link ports: Set the device validation and data storage ......................................................................30

Firmware: Reset device to factory settings ............................................................................................31

Firmware: Reboot the device..................................................................................................................31

Configure IO-Link devices ......................................................................................................................32

8.1 LR DEVICE

On delivery, the AL1300 is configured with the factory settings (→ Factory settings (→ p. 60)).

Required software: LR DEVICE (1.3.1.x or higher) (art.-no.: QA0011/QA0012)

22822

23

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Configuration LR DEVICE

>

Offline parameter setting ........................................................................................................................24

VPN connection ......................................................................................................................................24

Further information about offline parameter setting: → Operating instructions LR DEVICE

An active VPN connection blocks the access of the parameter setting software LR DEVICE to

the PROFINET interface of the AL1300.

► Deactivate the VPN connection in order to be able to access the AL1300 with the LR

DEVICE.

8.1.1 Remarks

>

22369

Offline parameter setting

22405

The AL1300 supports the offline parameter setting. In this context, the user creates and stores a

configuration for the IO-Link master and the connected IO-Link devices without being connected to the

AL1300 (OFFLINE mode). The configuration created in this way can be stored as a file (*.lrp) and

loaded to the AL1300 and activated at a later date.

>

VPN connection

22762

24

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Configuration LR DEVICE

>

Name

Description

Possible values

[Access Rights]

The access rights to the

parameter data, process data

and the event/diagnostic

messages of the IO-Link master

as well as the connected IO-Link

devices

[PROFINET + IoT]

PROFINET and IoT Core have read

and write access rights to parameters

and process data

PROFINET and <IoT Core> have read

access rights to events/alarms

[PROFINET + IoT

(read-only)]

PROFINET has read and write access

rights to parameters and process data

PROFINET has read access rights to

events/alarms

IoT Core only has read access rights to

parameters, process data and

events/alarms

[IoT only]

IoT Core has read and write access

rights to parameters and process data

IoT has read access rights to

events/alarms

PROFINET has no access rights

Parameter [Access Rights]:

Different parameter settings in the PROFINET projection software and the IoT applications

can result in undesired system behaviour. The set values of the PROFINET projection

software apply.

Changes of the parameter [Access Rights] are only effective after restarting the device.

To activate the changed access rights:

► Firmware: Reboot the device (→ p. 31)

8.1.2 IoT: Configure access rights

16555

The access rights define which instance may read and / or write the parameter data, process data and

event/diagnostic messages.

In order to configure the access rights to the IO-Link master:

► Select [IoT] menu.

> The menu page shows the current settings.

► Set the following parameters as required:

► Save changed values on the device.

25

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Configuration LR DEVICE

>

To configure the IP settings with DHCP, a DHCP server has to be active in the IT network. If

no DHCP server can be reached in the IT network, an IP address is automatically assigned to

the IoT port with the Zeroconfig protocol (address range: → Factory settings).

Name

Description

Possible values

[DHCP]

Activate/deactivate the DHCP client of the

device

[Static IP]

IP settings were set by the user

[DHCP]

IP settings are set by a DHCP

server in the network.

[IP address]*

IP address of the IoT port

Factory setting: 169.254.X.X

[Subnet mask]*

Subnet mask of the Ethernet network

Factory setting: 255.255.0.0

[Default gateway IP address]*

IP address of the network gateway

Factory setting: 0.0.0.0

[MAC address]

MAC address of the IoT port

The value is firmly set.

8.1.3 IoT: Configure IP settings

17713

For access to the IO-Link master via the IT infrastructure the user has to set the IP settings of the IoT

port.

To configure the IP settings of the IoT port:

► Select [IoT] menu.

> The menu page shows the current settings.

► Set the following parameters as required:

* ... can only be edited if parameter [DHCP] = [Static IP]

► Save changed values on the device.

26

ifm Operating Instructions IO-Link Master with PROFINET interface DataLine 4 Ports IP 65 / IP 66 / IP 67 (AL1300) 05 / 2018

Configuration LR DEVICE

>

Name

Description

Possible values

[IP address

LR SMARTOBSERVER]

IP address of the PC on which the

LR SMARTOBSERVER is installed.

Factory setting: 255.255.255.255

[Port

LR SMARTOBSERVER]

Port number that is used to send process data to

the LR SMARTOBSERVER

0

...

65535

Factory setting:: 35100

[Interval

LR SMARTOBSERVER]

Cycle time for the transfer of the process data to

the LR SMARTOBSERVER (value in

milliseconds)

[Off]

no transfer

500

...

2147483647

500 ms

...

2147483647 ms

[Application Tag]

Source identifier of the IO-Link master in the

structure of the LR SMARTOBSERVER

(String32)

Factory setting: AL1300

After changing the parameter [Port LR SMARTOBSERVER] or [Application Tag], it may take

120 seconds before the device establishes a new TCP connection.

To prevent the delay:

► Reboot the device after the parameter change.

Parameter

Description

Possible values

[IP address]

IP address of the PROFINET port

Factory setting: 0.0.0.0

[Subnet mask]

Subnet mask of the IP network

Factory setting: 0.0.0.0

[Default gateway IP address]

IP address of the gateway

Factory setting: 0.0.0.0

[Profinet name]

Name of the device in the PROFINET network

e.g. al1xxx

[MAC address]

MAC address of the device

The value is firmly set.

8.1.4 IoT: Configure the interface to the LR SMARTOBSERVER

16552

To enable data transfer between the device and the LR SMARTOBSERVER monitoring software, the

LR SMARTOBSERVER monitoring software interface has to be configured.

► Select [IoT] menu.

> The menu page shows the current settings.

► Set the following parameters as required:

► Save changed values on the device.

>

8.1.5 Fieldbus: Configure the PROFINET port

The PROFINET ports X21/X22 have to be configured via the PROFINET for access to the device.

To set the IP properties of the fieldbus port:

► Select [Fieldbus] menu.

> The menu page shows the current settings.

► Set the following parameters as required:

► Save changed values on the device.

16581

27

Loading...

Loading...