IFM Electronic AC412S Device Manual

>

7391190 / 03

Device Manual

SmartPLC SafeLine

with PROFIBUS slave interface

AC412S

Master profile: M4

Firmware: 4.3.2

English

>

04 / 2019

SmartPLC SafeLine with PROFIBUS slave interface

2

Contents

1 Preliminary note 6

1.1 Legal and copyright information ........................................................................................... 6

1.2 Purpose of the document ..................................................................................................... 6

1.3 Explanation of Symbols ....................................................................................................... 7

1.4 Overview: User documentation for AC4S ............................................................................ 8

1.5 Modification history .............................................................................................................. 8

2 Safety instructions 9

2.1 General safety instructions .................................................................................................. 9

2.2 Required background knowledge ........................................................................................ 9

2.3 Tampering with the unit ........................................................................................................ 9

3 System description 10

3.1 Intended use ......................................................................................................................11

3.1.1 Permitted use ............................................................................................................................. 11

3.1.2 Prohibited use ............................................................................................................................ 11

3.2 Information concerning the device .....................................................................................12

3.2.1 Overview .................................................................................................................................... 12

3.2.2 Operating elements .................................................................................................................... 13

3.2.3 Display elements ........................................................................................................................ 13

3.2.4 Interfaces .................................................................................................................................... 14

3.2.5 Type label ................................................................................................................................... 16

3.2.6 Required accessories ................................................................................................................. 16

3.3 Hardware ............................................................................................................................17

3.3.1 Safety architecture ..................................................................................................................... 18

3.3.2 Operating states of AC412S ....................................................................................................... 22

3.3.3 Monitoring and securing mechanisms ........................................................................................ 23

3.3.4 Error detection and processing ................................................................................................... 23

3.4 Software .............................................................................................................................26

3.4.1 Software modules of the device ................................................................................................. 26

3.4.2 Safety functions .......................................................................................................................... 26

3.4.3 Certified software components for safe applications .................................................................. 27

4 Mounting 28

4.1 Install device ......................................................................................................................28

5 Electrical connection 29

5.1 Wiring .................................................................................................................................29

5.2 Connect the supply voltage ................................................................................................29

5.2.1 Standard configuration: 24 V power supply and AS-i power supply/supplies ............................. 30

5.3 Connect devices to local I/O interface ...............................................................................31

5.3.1 Supported connection types ....................................................................................................... 31

5.3.2 Supported device types .............................................................................................................. 32

5.3.3 Connect sensors / actuators ....................................................................................................... 43

6 Operation 44

6.1 Control of the graphical user interface ...............................................................................44

6.1.1 Function keys ............................................................................................................................. 45

6.1.2 Arrow keys .................................................................................................................................. 45

SmartPLC SafeLine with PROFIBUS slave interface

3

6.2 Menu view ..........................................................................................................................46

6.2.1 Menu navigation ......................................................................................................................... 46

6.2.2 Navigation aids ........................................................................................................................... 47

6.3 Page view ...........................................................................................................................49

6.3.1 Navigate on a page .................................................................................................................... 49

6.3.2 Use navigation aids .................................................................................................................... 49

6.3.3 Description of the control elements ............................................................................................ 50

6.4 Remote access ..................................................................................................................62

6.4.1 General....................................................................................................................................... 62

6.4.2 Recommended browsers............................................................................................................ 62

6.4.3 Operating instructions ................................................................................................................ 63

7 Menu 66

7.1 Start screen ........................................................................................................................66

7.2 Menu functions ...................................................................................................................67

7.2.1 Additional functions .................................................................................................................... 67

7.3 Quick setup ........................................................................................................................68

7.3.1 Quick setup: Project AS-i networks ............................................................................................ 69

7.3.2 Quick setup: Configure the operating mode of the AS-i masters ................................................ 70

7.3.3 Quick setup: Configure the output access .................................................................................. 71

7.3.4 Quick setup: Access the device via QR code ............................................................................. 71

7.3.5 Quick setup: Configure the PROFIBUS interface ....................................................................... 72

7.3.6 Quick setup: Set the Konfigurationsschnittstelle ......................................................................... 73

7.3.7 Quick setup: Address the AS-i slaves connected to AS-i Master 1 ............................................ 75

7.3.8 Quick setup: Address the AS-i slaves connected to AS-i Master 2 ............................................ 76

7.4 AS-i 1 / AS-i 2 .....................................................................................................................77

7.4.1 AS-i 1 / AS-i 2: Master setup ...................................................................................................... 78

7.4.2 AS-i 1 / AS-i 2: Diagnosis ................................................................................................ ........... 80

7.4.3 AS-i 1 / AS-i 2: AS-i slaves ......................................................................................................... 82

7.5 System ...............................................................................................................................88

7.5.1 System: Programmable Logic Controller (PLC) .......................................................................... 89

7.5.2 System: Information ................................................................................................................... 95

7.5.3 System: Setup ............................................................................................................................ 96

7.5.4 System: Diagnosis .................................................................................................................... 108

7.6 Interfaces .........................................................................................................................109

7.6.1 Interfaces: Konfigurationsschnittstelle ...................................................................................... 110

7.6.2 Interfaces: PROFIBUS interface ............................................................................................... 114

7.7 Safety ...............................................................................................................................120

7.7.1 Safety: Status of the fail-safe slaves at AS-i Master 1 .............................................................. 121

7.7.2 Safety: Status of the fail-safe slaves at AS-i Master 2 .............................................................. 125

7.7.3 Safety: Local IOs ...................................................................................................................... 126

7.7.4 Safety: FSoE ............................................................................................................................ 130

7.7.5 Safety: System ......................................................................................................................... 131

7.8 ifm system solutions .........................................................................................................132

7.8.1 Notes on ifm system solutions .................................................................................................. 132

7.8.2 Show information about installed ifm apps ............................................................................... 134

7.8.3 Install single/basic app ............................................................................................................. 135

7.8.4 Install multi app ........................................................................................................................ 136

7.8.5 Update ifm apps ....................................................................................................................... 137

7.8.6 Uninstall ifm apps ..................................................................................................................... 137

8 Setup 138

8.1 Install device ....................................................................................................................138

8.2 Connect the device to the periphery ................................................................................138

8.2.1 PROFIBUS interface ................................................................................................................ 138

8.2.2 Configuration interface ............................................................................................................. 138

8.2.3 Install devices on the local I/O interface ................................................................................... 139

8.3 Install devices on the local I/O interface ..........................................................................139

8.4 Start screen 'Basic settings' .............................................................................................140

8.4.1 Change the basic settings of the device ................................................................................... 140

SmartPLC SafeLine with PROFIBUS slave interface

4

8.5 Notes on the firmware update ..........................................................................................142

8.6 Connect and address AS-i slaves ....................................................................................142

8.7 Set the Profibus interface .................................................................................................143

8.8 Setup of the configuration interface .................................................................................143

8.9 Replace standard AS-i slave ............................................................................................144

8.10 Replace safe AS-i slave ...................................................................................................144

9 Troubleshooting 145

9.1 Status LED .......................................................................................................................145

9.1.1 Status LED: Basic device ......................................................................................................... 145

9.2 Start screen: Status LEDs ................................................................................................146

9.2.1 Status of the web interface ....................................................................................................... 146

9.2.2 Operating mode of the AS-i master .......................................................................................... 146

9.2.3 Control instance of the AS-i outputs ......................................................................................... 146

9.3 Online diagnosis function .................................................................................................147

9.3.1 Message types ......................................................................................................................... 147

9.3.2 Locate error sources ................................................................................................................ 147

9.4 Online Support Centre (OSC) ..........................................................................................148

9.4.1 OSC: Display current messages .............................................................................................. 149

9.4.2 OSC: Show message history .................................................................................................... 150

9.5 Availability of the fail-safe PLC ........................................................................................151

9.6 Display diagnostic protocol ..............................................................................................151

10 Appendix 152

10.1 Technical data ..................................................................................................................153

10.1.1 Environmental conditions ......................................................................................................... 153

10.1.2 Safety classification .................................................................................................................. 153

10.1.3 Power supply connections ........................................................................................................ 153

10.1.4 Electrical data ........................................................................................................................... 154

10.1.5 Display elements ...................................................................................................................... 154

10.1.6 Housing .................................................................................................................................... 154

10.1.7 Interfaces .................................................................................................................................. 155

10.1.8 AS-interface .............................................................................................................................. 155

10.1.9 Programmable Logic Controller (PLC) ..................................................................................... 156

10.2 Address assignment in Ethernet networks ......................................................................157

10.3 Configuration interface: connection concepts ..................................................................158

10.3.1 Direct link .................................................................................................................................. 158

10.3.2 Connection via Ethernet network .............................................................................................. 158

10.4 AS-i master ......................................................................................................................159

10.4.1 Operating modes of the AS-i master ........................................................................................ 160

10.4.2 Master flags .............................................................................................................................. 162

10.5 AS-i slaves .......................................................................................................................163

10.5.1 Profiles of AS-i slaves............................................................................................................... 164

10.6 Fieldbus Profibus .............................................................................................................173

10.6.1 Fieldbus parameters ................................................................................................................. 173

10.6.2 Device-specific parameters ...................................................................................................... 174

10.6.3 Cyclic data ................................................................................................................................ 178

10.6.4 Acyclic data .............................................................................................................................. 202

10.6.5 I&M data ................................................................................................................................... 209

10.6.6 Fieldbus alarms ........................................................................................................................ 212

10.7 OSC messages ................................................................................................................221

10.7.1 OSC messages: System .......................................................................................................... 221

10.7.2 OSC messages: AS-i 1 / AS-i 2 ................................................................................................ 222

10.7.3 OSC messages: Safety module ............................................................................................... 223

10.7.4 OSC messages: Safety PLCopen function blocks .................................................................... 238

11 Index 239

SmartPLC SafeLine with PROFIBUS slave interface

5

SmartPLC SafeLine with PROFIBUS slave interface

6

1 Preliminary note

Content

Legal and copyright information ............................................................................................................ 6

Purpose of the document ...................................................................................................................... 6

Explanation of Symbols ......................................................................................................................... 7

Overview: User documentation for AC4S ............................................................................................. 8

Modification history ................................................................................................................................ 8

>

33203

1.1 Legal and copyright information

33117

© All rights reserved by ifm electronic gmbh. No part of this manual may be reproduced and used

without the consent of ifm electronic gmbh.

All product names, pictures, companies or other brands used on our pages are the property of the

respective rights owners:

AS-i is the property of the AS-International Association, (→ www.as-interface.net)

CAN is the property of the CiA (CAN in Automation e.V.), Germany (→ www.can-cia.org)

CODESYS™ is the property of the 3S – Smart Software Solutions GmbH, Germany

(→ www.codesys.com)

DeviceNet™ is the property of the ODVA™ (Open DeviceNet Vendor Association), USA

(→ www.odva.org)

EtherNet/IP® is the property of the → ODVA™

EtherCAT® is a registered trade mark and patented technology, licensed by Beckhoff Automation

GmbH, Germany

IO-Link® (→ www.io-link.com) is the property of the → PROFIBUS Nutzerorganisation e.V.,

Germany

ISOBUS is the property of the AEF – Agricultural Industry Electronics Foundation e.V.,

Deutschland (→ www.aef-online.org)

Microsoft® is the property of the Microsoft Corporation, USA (→ www.microsoft.com)

PROFIBUS® is the property of the PROFIBUS Nutzerorganisation e.V., Germany

(→ www.profibus.com)

PROFINET® is the property of the → PROFIBUS Nutzerorganisation e.V., Germany

Windows® is the property of the → Microsoft Corporation, USA

>

1.2 Purpose of the document

This document applies to devices of the type "SmartPLC AC4S with PROFIBUS" interface" (art. no.:

AC412S) with the firmware version 4.3.2.

These instructions describe the following topics:

Mounting and electrical connection of AC412S

Installation of additional devices (sensors, actuators) to the local I/O interface

Operation and configuration of the device via the menu (GUI and web interface)

Command channels, cyclic and acyclic data records

Error diagnostics and troubleshooting

42287

SmartPLC SafeLine with PROFIBUS slave interface

7

1.3 Explanation of Symbols

WARNING!

Death or serious irreversible injuries may result.

CAUTION!

Slight reversible injuries may result.

NOTICE!

Property damage is to be expected or may result.

Important note

Non-compliance can result in malfunction or interference

Information

Supplementary note

► ...

Request for action

> ...

Reaction, result

→ ...

"see"

abc

Cross-reference

123

0x123

0b010

Decimal number

Hexadecimal number

Binary number

[...]

Designation of pushbuttons, buttons or indications

34171

SmartPLC SafeLine with PROFIBUS slave interface

8

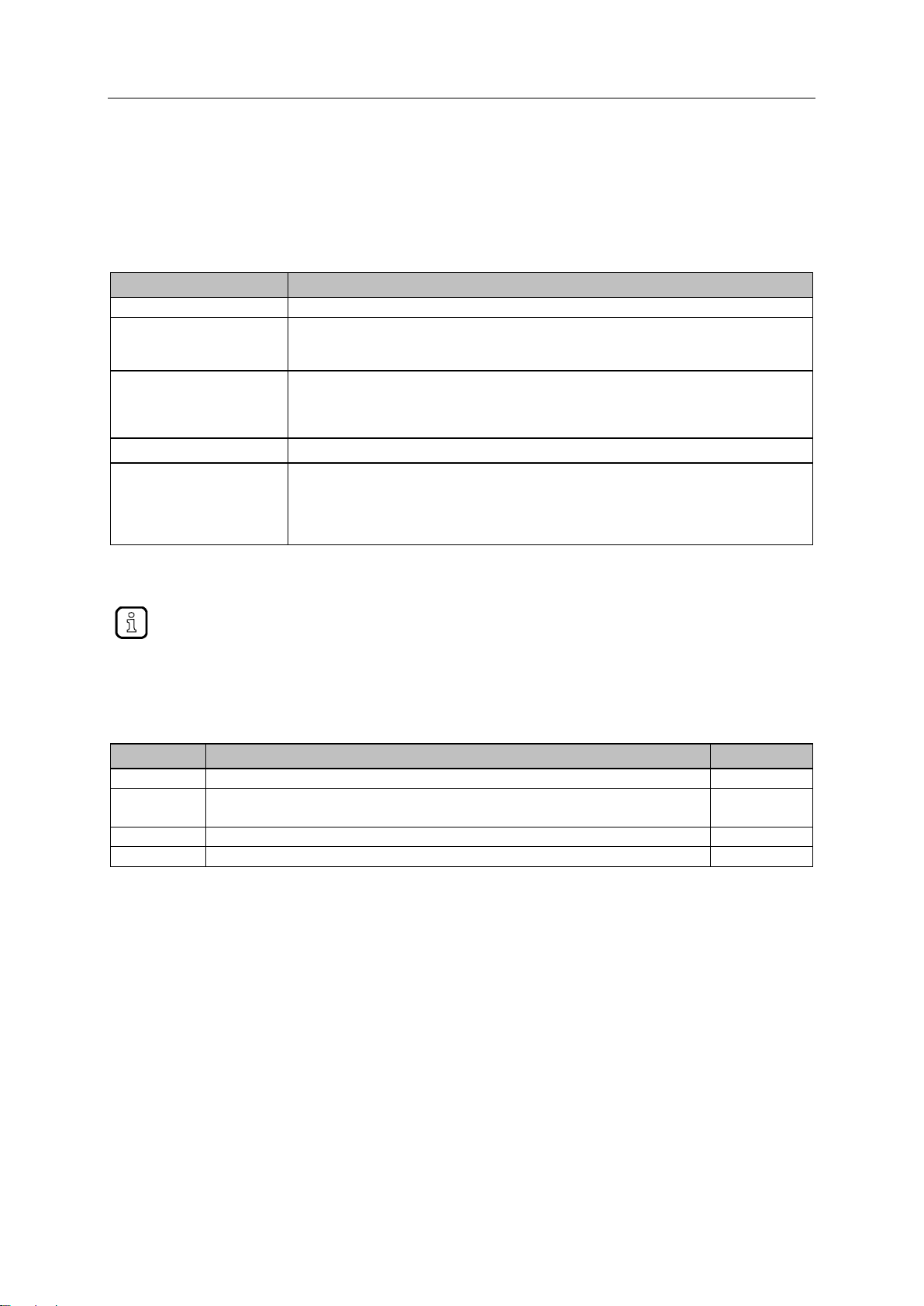

1.4 Overview: User documentation for AC4S

Document

Content / Description

Data sheet

Technical data of AC412S as a table

Operating instructions *

Notes on mounting and electrical installation of the AC412S

Set-up, description of the operating and display elements, maintenance information, scale

drawing

Device manual

Notes on operation of AC412S via GUI and web interface

Description of the cyclic and acyclic data records, fieldbus parameters and command

interface

Error description

Supplement device manual

Description of the acyclic data sets and the command interface

Programming manual

Creation of a project with the device using CODESYS

Configuration of the device using CODESYS

Programming of the Standard-SPS of the device

Programming of the fail-safe PLC of the device

Description of the device-specific CODESYS function libraries

All documents can be downloaded from ifm's website.

Version

Topic

Date

00

New creation of document

12 / 2017

01

Update to firmware 4.3.1

Changed: Restore device configuration

09 / 2018

02

Deleted: chapter 5.2.2 „Device supply via a joint power supply”

01 / 2019

03

Update to firmware 4.3.2

42309

ifm electronic provides the following user documentation for the models of the device class "Fail-safe

SmartPLC AC4S":

Legend:

*... The operating instructions are supplied with the device.

>

1.5 Modification history

34492

04 / 2019

SmartPLC SafeLine with PROFIBUS slave interface

9

2 Safety instructions

Content

General safety instructions .................................................................................................................... 9

Required background knowledge .......................................................................................................... 9

Tampering with the unit ......................................................................................................................... 9

WARNING!

Tampering with the unit.

> In case of non-compliance:

Possible affects on safety of operators and machinery

Expiration of liability and warranty

► Do not open the devices!

► Do not insert any objects into the devices!

► Prevent metal foreign bodies from penetrating!

>

28333

2.1 General safety instructions

41415

Read this document before setting up the product and keep it during the entire service life.

Only use the product for its intended purpose.

If the operating instructions or the technical data are not adhered to, personal injury and/or damage to

property may occur.

Improper or non-intended use may lead to malfunctions of the device, to unwanted effects in the

application or to a loss of the warranty claims.

The manufacturer assumes no liability for any consequences caused by tampering with the device or

incorrect use by the operator.

► Observe these operating instructions.

► Adhere to the warning notes on the product.

>

2.2 Required background knowledge

41648

This document is intended for specialists. Specialists are people who, based on their relevant training

and experience, are capable of identifying risks and avoiding potential hazards that may be caused

during operation or maintenance of the product.

For programming these people should also have knowledge of control technology experience in PLC

programming to IEC 61131-3.

The document contains information about the correct handling of the product.

>

2.3 Tampering with the unit

33190

SmartPLC SafeLine with PROFIBUS slave interface

10

3 System description

Content

Intended use ........................................................................................................................................ 11

Information concerning the device ...................................................................................................... 12

Hardware ............................................................................................................................................. 17

Software .............................................................................................................................................. 26

This chapter describes the structure and the components of the system.

42275

SmartPLC SafeLine with PROFIBUS slave interface

11

3.1 Intended use

Content

Permitted use ...................................................................................................................................... 11

Prohibited use ...................................................................................................................................... 11

>

3.1.1 Permitted use

AC412S can assume the following functions:

AS-i master in 2 separate AS-i networks

Fail-safe programmable logic controller (PLC) and standard PLC for acquiring, processing and

providing safe and non-safe data of the connected AS-i slaves and the channels of the local I/O

interface

Gateway for the transmission of standard control and user data between a higher-level

PROFIBUS controller and the slaves in the AS-i networks

>

3.1.2 Prohibited use

The device may not be used beyond the limits of the technical data (→ Technical data (→ S. 153))!

36928

42316

34228

SmartPLC SafeLine with PROFIBUS slave interface

12

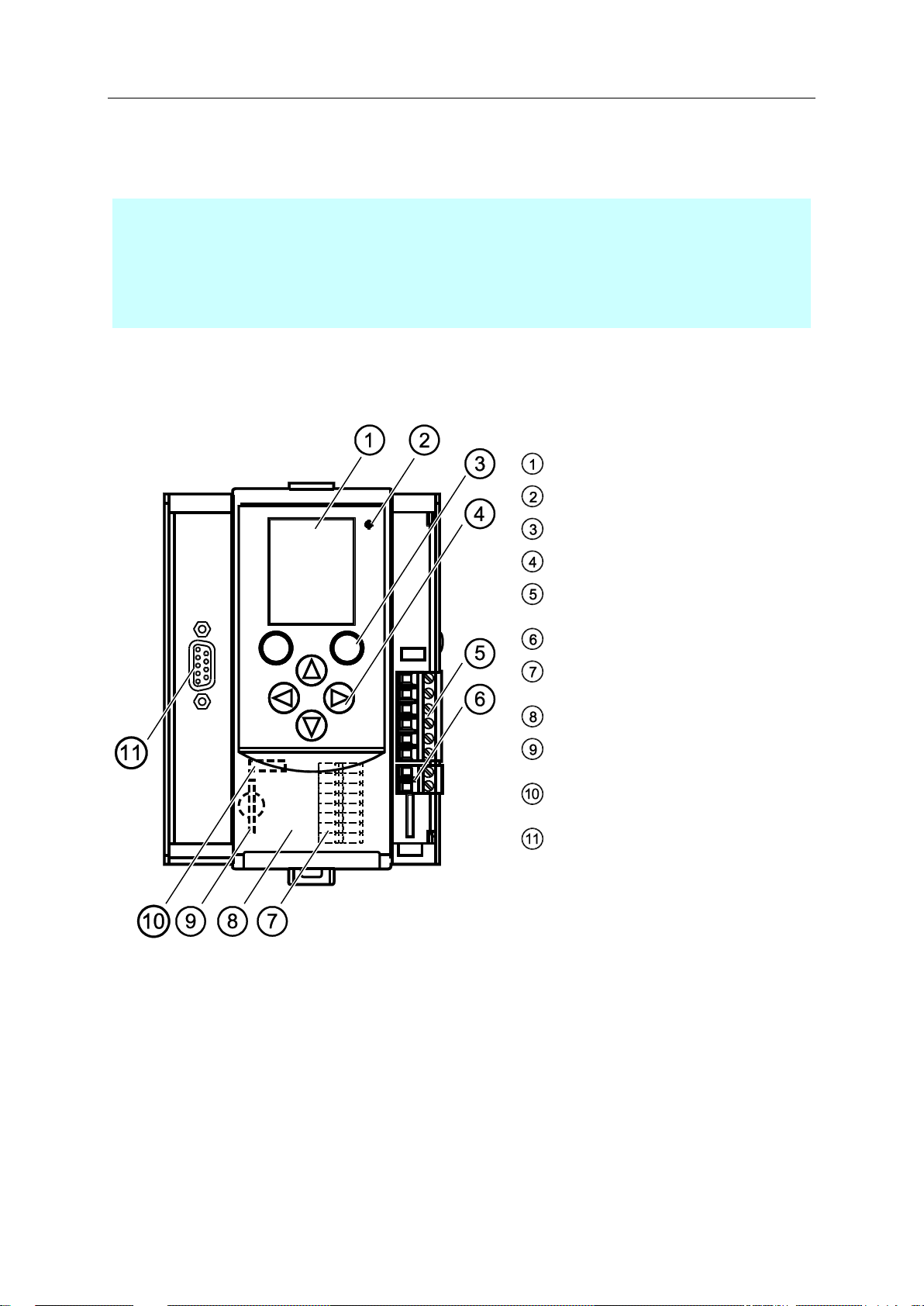

3.2 Information concerning the device

Content

Overview .............................................................................................................................................. 12

Operating elements ............................................................................................................................. 13

Display elements ................................................................................................................................. 13

Interfaces ............................................................................................................................................. 14

Type label ............................................................................................................................................ 16

Required accessories .......................................................................................................................... 16

Legende:

Display

Status-LED (H1)

2 Funktionstasten

4 Pfeiltasten

Anschlussstecker (X1) für

AS-i 1, AS-i 2, Funktionserde

Anschlussstecker (X2) für AUX

Lokale Ein- und Ausgänge (X4)

(hinter der Frontklappe)

Frontklappe

Steckplatz für SD-Karte (X5)

(hinter der Frontklappe)

Ethernet-Konfigurationsschnittstelle (X3)

(hinter der Frontklappe)

PROFIBUS-Schnittstelle (X6)

>

3.2.1 Overview

36905

42308

SmartPLC SafeLine with PROFIBUS slave interface

13

3.2.2 Operating elements

36790

The device provides the following operating elements.

>

Arrow and function keys

36959

Below the display is the key panel with two function keys and four arrow keys. The operator controls

the Graphical User Interface (GUI) of the device with the keys.

Operating notes: → Operation (→ S. 44)

>

3.2.3 Display elements

36917

The device provides the following display elements:

>

Display

36894

The display is used to display the Graphical User Interface (GUI) of the device.

Operating notes: → Operation (→ S. 44)

Technical data: → Technical data (→ S. 153)

>

Status LEDs

36784

The device features the following status LEDs which display the current status of system components.

Meaning of the LED colours and flashing frequencies: → Status LED (→ S. 145)

SmartPLC SafeLine with PROFIBUS slave interface

14

3.2.4 Interfaces

Content

Ethernet configuration interface .......................................................................................................... 14

Local input/output interface ................................................................................................................. 14

SD card slot ......................................................................................................................................... 15

PROFIBUS fieldbus interface .............................................................................................................. 15

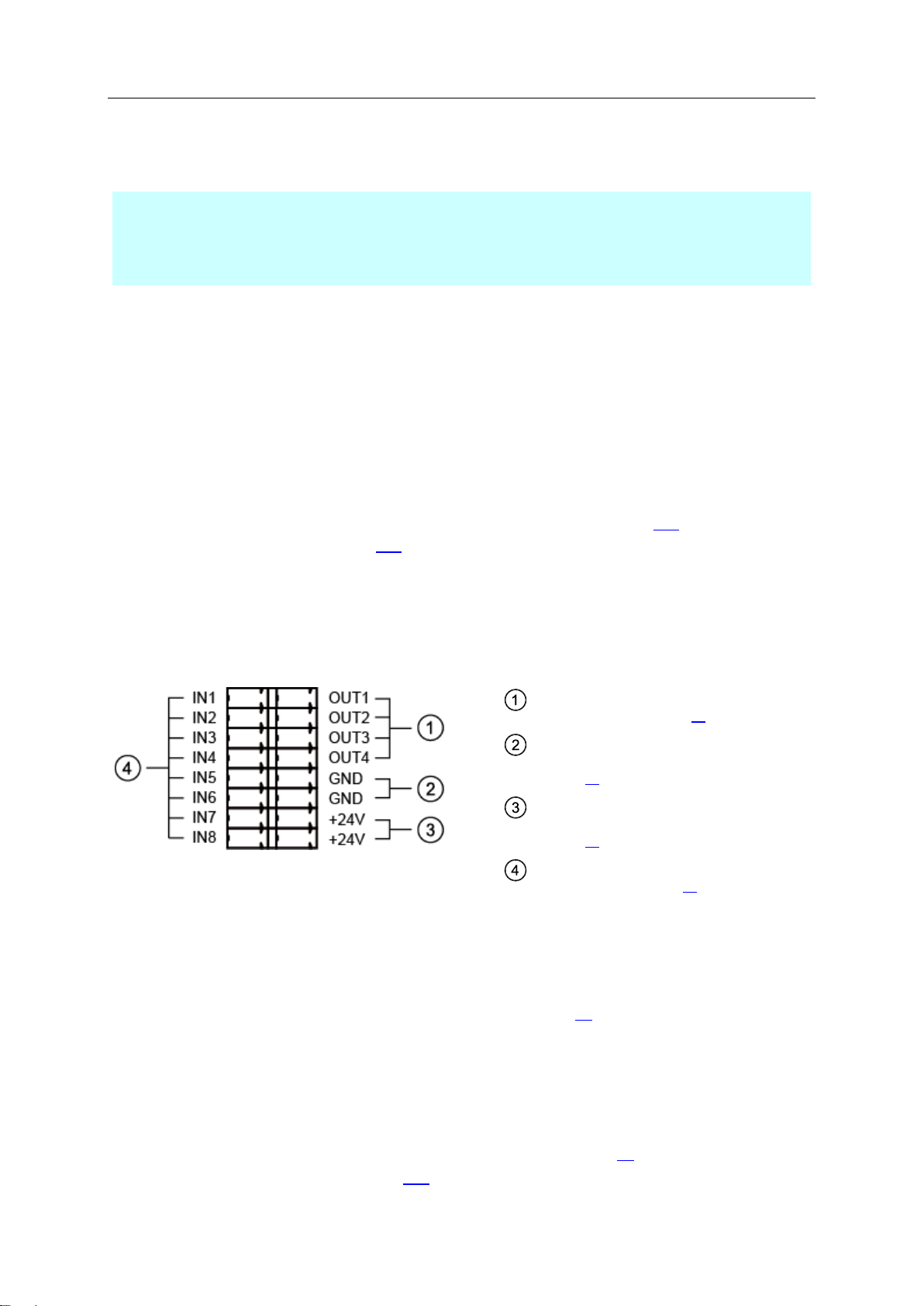

4x output channels (OUT1 .... OUT4)

→ Local outputs (→ S. 15)

2x voltage ground GND

→ Voltage source / voltage ground

(→ S. 14)

2x voltage source +24V

→ Voltage source / voltage ground

(→ S. 14)

8x input channels (IN1 ... IN8)

→ Local inputs (→ S. 14)

AC412S has the following interfaces.

>

Ethernet configuration interface

The configuration interface (X3) is located behind the front flap of the device. It allows the user to

access the following device functions:

web interface for device configuration and diagnosis

programming of the device-internal Standard-SPS and the fail-safe PLC using CODESYS

Configuration as fieldbus interface

Possible network topologies: → Configuration interface: connection concepts (→ S. 158)

Technical data: → Technical data (→ S. 153)

>

Local input/output interface

The local input/output interface (X4) is behind the front flap of the device. Safe and non-safe

peripherals without AS-i interface can be connected to the local inputs and outputs.

Connections of the local I/O interface:

42306

42193

42303

>

Voltage source / voltage ground

+24V and GND are used as voltage supply for the safety IO PCB of the safety module of AC412S.

Notes on the electrical connection: → Electrical connection (→ S. 29)

>

Local inputs

The local I/O interface provides 8 input channels for the connection of devices (e.g. sensors, switches,

light curtains). Each input channel can be used as safe or standard input. Configuration is effected via

the programming system CODESYS.

Connection of peripherals: → Connect devices to local I/O interface (→ S. 31)

Technical data: → Technical data (→ S. 153)

>

42272

42304

SmartPLC SafeLine with PROFIBUS slave interface

15

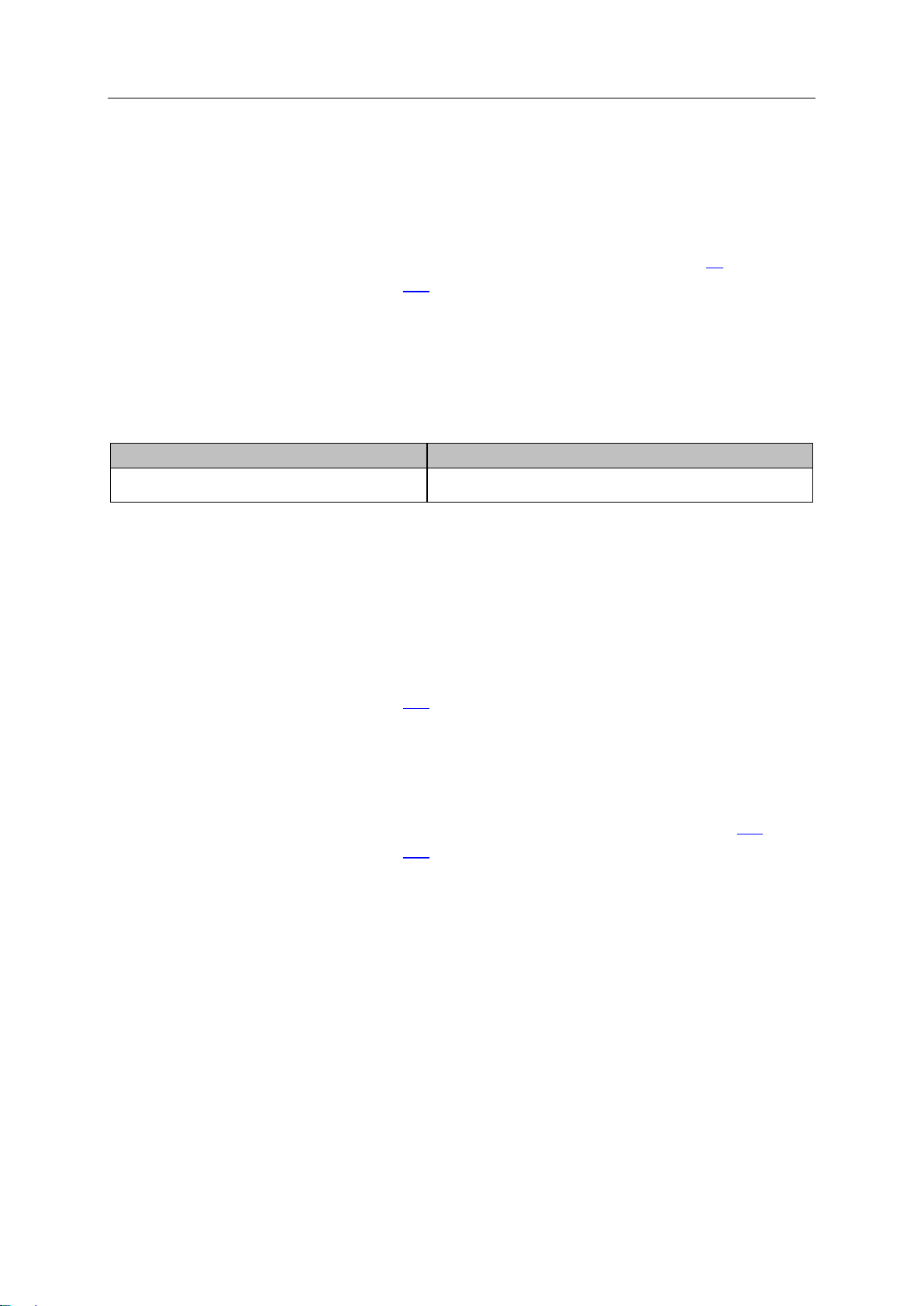

Local outputs

Min. configuration

Max. configuration

8 non-safe inputs

4 non-safe outputs

4 safe inputs, 2 channels (SIL3)

4 safe outputs, 1 channel (SIL3)

42291

The local I/O interface provides 4 output channels for the connection of devices (e.g. actuators,

relays). Each output channel can be used as safe or standard output. Configuration is effected via the

programming system CODESYS.

Notes on the connection of peripherals: → Connect devices to local I/O interface (→ S. 31)

Technical data: → Technical data (→ S. 153)

>

Possible combinations of input and output channels

42315

The inputs IN1...IN8 can be configured both as safe and non-safe inputs.

The outputs OUT1...OUT4 can be configured both as safe and non-safe outputs.

This permits the following minimum or maximum input and output combinations:

>

SD card slot

42194

The SD card slot (X5) is located behind the front flap of the device. The following actions can be

performed with an SD card:

Save and restore the device configuration

Storage medium for access to Standard-SPS

Technical data: → Technical data (→ S. 153)

>

PROFIBUS fieldbus interface

The device communicates with the higher-level control instance of the PROFIBUS network via the

PROFIBUS interface (X6).

Notes regarding connetion concepts: → Configuration interface: connection concepts (→ S. 158)

Technical data: → Technical data (→ S. 153)

41428

SmartPLC SafeLine with PROFIBUS slave interface

16

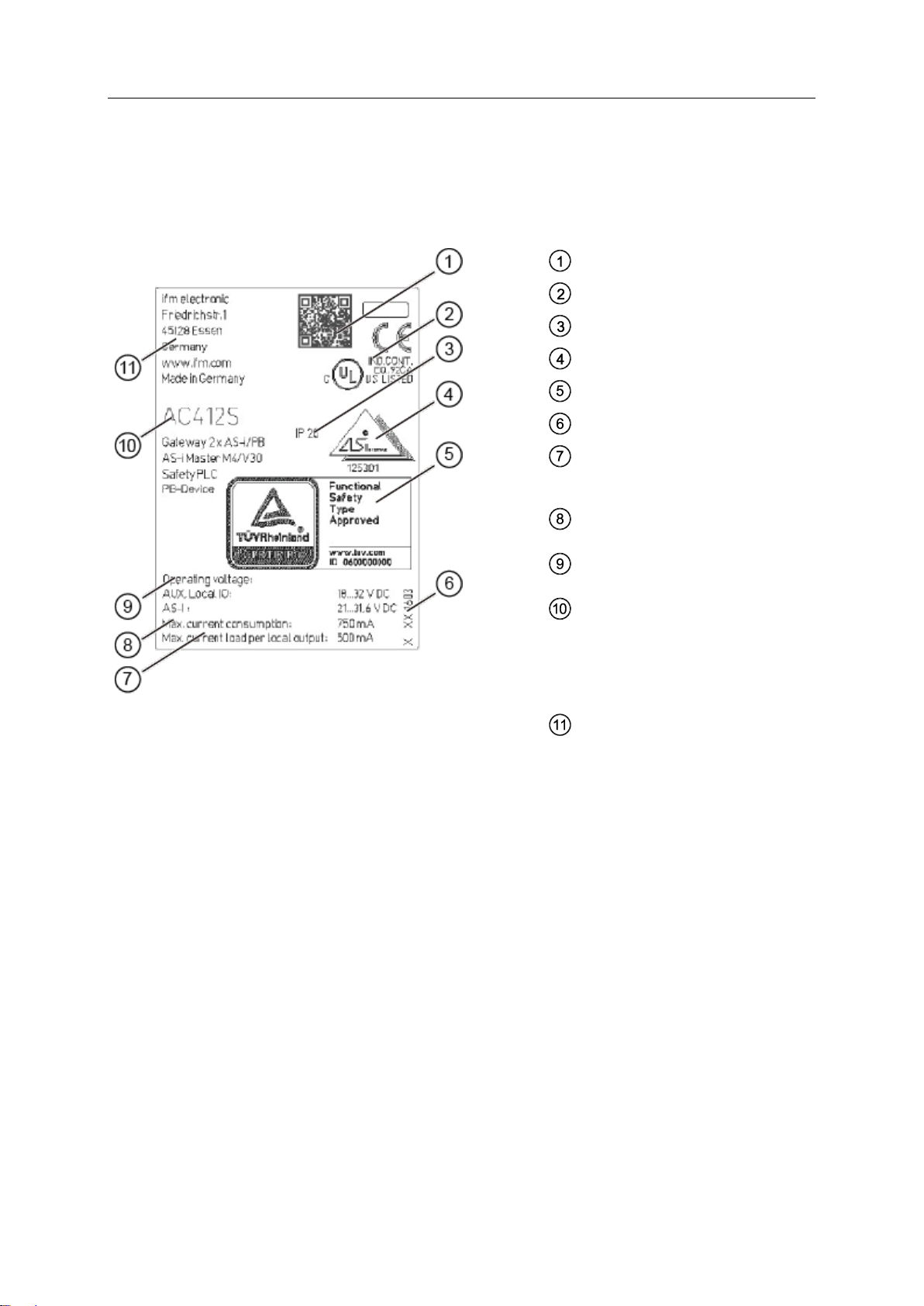

3.2.5 Type label

QR code for product website

CE/cULus marking

Protection class

AS-i certification

TÜV certification

Hardware version

Operating voltage for

– Aux / local IO PCB

– AS-i

max. current consumption of the

device

max. load per output channel of the

local I/O interface

Type designation incl. device

functionality

– number of AS-i fieldbus gateways

– classification of the AS-i masters

– fail-safe PLC

– fieldbus

Manufacturer identification

The type label is on the right housing side of the device. It provides the following information:

42274

>

3.2.6 Required accessories

To be able to operate the device in a sensible way you need the following accessories (not supplied

with the device):

Depending on the selected voltage supply ( Operating instructions) you need:

a power supply for the 24 V power supply (e.g. art. no. DN3011)

for each AS-i master one AS-i power supply each (e.g. art. no. AC1236)

a data decoupling module AC1250 (accessory, optional)

Fail-safe and standard AS-i slaves

Fail-safe and standard devices for connecting with the local I/O interface

42259

SmartPLC SafeLine with PROFIBUS slave interface

17

3.3 Hardware

Content

Safety architecture............................................................................................................................... 18

Operating states of AC412S .............................................................................................................. 22

Monitoring and securing mechanisms ................................................................................................. 23

Error detection and processing ........................................................................................................... 23

42223

SmartPLC SafeLine with PROFIBUS slave interface

18

3.3.1 Safety architecture

Content

System architecture ............................................................................................................................. 18

Process safety time ............................................................................................................................. 21

The reachable characteristic safety values of the automation system implemented with

AC412S depend on the following components:

Safety classification of the peripherals installed at the local I/O interface (→Supported device

types (→ S. 32))

Safety classification of the installed safe AS-i slaves

>

42266

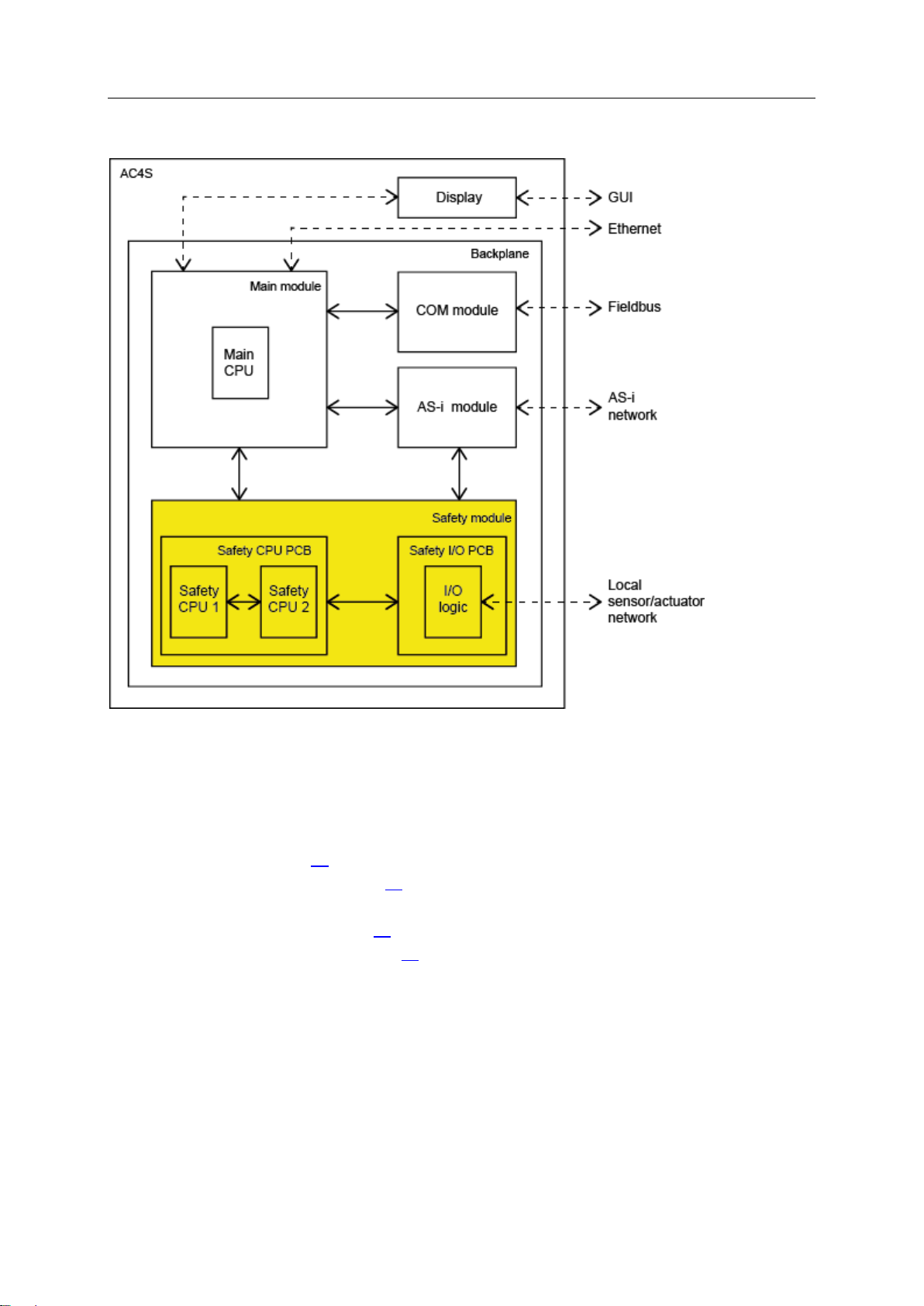

System architecture

42268

The hardware structure of the safety module of AC412S corresponds to the implementation to DIN EN

ISO 13849-1:2008, IEC 62061:2010 and IEC61508:2010 with a two-channel architecture with

hardware fault tolerance (HFT = 1).

The device achieves the following characteristic safety values:

SIL 3 / SIL CL 3 referred to IEC 61508:2010 and IEC 62061:2010

Performance Level e EN ISO 13849-1:2008)

Category 4 (EN ISO 13849-1:2008)

SmartPLC SafeLine with PROFIBUS slave interface

19

AC412S has the following system architecture:

>

Main module

42292

The main module is the central component of AC412S. It contains the recovery system and the

firmware of the device and controls the communication between the individual system components via

the backplane. The main module has interfaces to the following components:

Display (→ Display (→ S. 19))

COM module (→ COM module (→ S. 20))

Ethernet configuration interface

AS-i module (→ AS-i module (→ S. 20))

Safety module (→ Safety module (→ S. 20))

>

Display

42230

The display is the graphic user interface of AC412S via which the user can configure and diagnose the

device. The display exchanges the resulting data with the main module.

SmartPLC SafeLine with PROFIBUS slave interface

20

COM module

42210

The COM module provides the PROFIBUS functionality of AC412S. This comprises the PROFIBUS

connection and the necessary firmware. The COM module receives the fieldbus data from the main

module via an interface and transfers it to the fieldbus. Simultaneously it receives data from the

fieldbus and transfers it to the main module for further processing.

>

AS-i module

42242

The AS-i module provides the AS-i functionality of AC412S such as receiving, evaluating and

transmitting AS-i telegrams without any logical preprocessing. It contains 2 AS-i masters controlling 2

separate AS-i circuits.

The following number of AS-i slaves can be connected to each AS-i master:

up to 62 non safe AS-i slaves or

up to 31 safe AS-i input slaves or

up to 15 AS-i control slaves to control safe AS-i output slaves

The AS-i module exchanges the data of the safe AS-i slaves with the safety module via the backplane.

All AS-i data is provided to the main module for representation on the display.

>

Safety module

42251

The safety module contains the safety-related hardware of AC412S. The architecture of the safety

module provides the following structural features:

1oo2 hardware architecture (1 out of 2 architecture)

2-channel structure with separate diagnostics in both channels

2-channel safe inputs selectable

1-channel and 2-channel safe outputs selectable

Built-in tests on both safe processing units (safety CPU 1/2)

Hardware failure tolerance (HFT) = 1

The safety module consists of the following components:

Safety CPU PCB with 2 processors for the control technology signal processing (safety CPU1/2)

Safety I/O PCB with a separate voltage supply for the local I/O interface

Both PCBs are separated from each other galvanically. They are supplied from separate voltage

sources.

Both safety CPUs have separate watchdogs and reset circuits. They are interconnected via cross

communication.

Both PCBs are interconnected via a serial interface for bidirectional data exchange.

The safety module has interfaces to the main module and the AS-i module.

SmartPLC SafeLine with PROFIBUS slave interface

21

Process safety time

► When setting up the safety function, also take into account the process safety time of the

application!

► Take into account other potential delays caused by upstream and downstream

components (sensors, actuators) for time-related considerations. These times extend the

response time for safety-related faults.

► Process safety time of the other components of the safety function: the manufacturers’

data sheets

In the following cases a single fault cannot lead to a hazardous situation:

if the safe state is assumed

if the fault detection and the reaction to the fault happen within the process safety time

42313

The process safety time depends on the source and the objective of the request, the signal processing

and the transmission length.

If the safety time is shorter than the process safety time required by the safety function of the plant, a

single fault can in the worst case lead to a faulty output signal for a short time but not to a loss of the

safety function.

A loss of the safety function can only occur if the faulty signal cannot be corrected within the process

safety time.

SmartPLC SafeLine with PROFIBUS slave interface

22

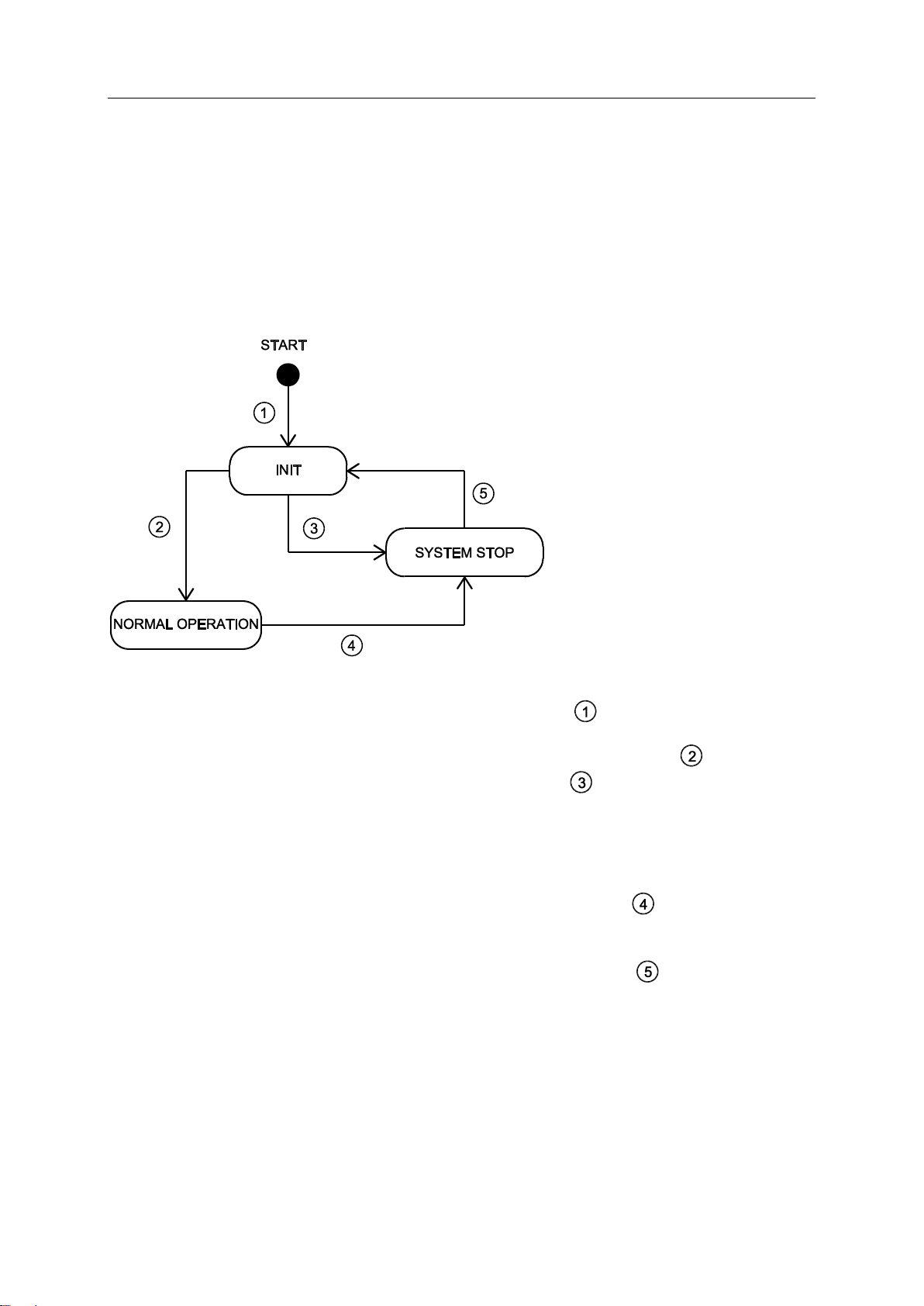

3.3.2 Operating states of AC412S

AC412S has the following operating states:

INIT

NORMAL OPERATION

SYSTEM STOP

Below the state chart:

42321

INIT

After the start the device automatically goes into the INIT state ( ). In the INIT state the device

undergoes the different hardware and integration tests (PBIT = Power-up Built-In Test). If the PBIT

test is successfully passed, the device takes the state NORMAL OPERATION ( ). If the PBIT

test is not passed, the device passes into the SYSTEM STOP ( ).

NORMAL OPERATION

In NORMAL OPERATION the device of Standard-SPS and the fail-safe PLC provides a working

environment. The states and the operation modes of the PLC applications are valid (see

programming manual). Simultaneously and irrespective of the processing of the PLC applications

the device continuously undergoes different hardware tests (CBIT = continuous built-in test). If this

CBIT test is not passed, the device goes into the SYSTEM STOP state ( ).

SYSTEM STOP

In SYSTEM STOP the device is in the safe state. To leave the SYSTEM STOP state the operator

has to carry out a power-on reset. The device changes to the INIT state ( ).

SmartPLC SafeLine with PROFIBUS slave interface

23

3.3.3 Monitoring and securing mechanisms

>

System start / power on reset

When the voltage supply has been applied, the safety module of AC412S automatically undergoes a

power-on built-in test (PBIT). The PBIT consists of the following routines:

Test and installation of the safety-relevant hardware modules

Test of the program, configuration and user data in SDRAM (CRC test)

If at least one of these partial tests is failed, the system reacts as follows:

The safety module goes into the safe state

The transition from the fail-safe PLC to the safe operation is prevented

An error message is provided in the online support centre (OSC) of the device

>

Normal operation

During normal operation the safety module of AC412S continuously undergoes a continuous built-in

test (CBIT). The CBIT detects accidental hardware errors. It monitors all safety-relevant hardware

modules. The CBIT consists of the following routines:

Monitor the safety-relevant hardware modules with the required DC

Monitor all diagnostic data that is relevant for the safe functions

Monitor the program process

Depending on the error class the device triggers certain measures (→Error classes (→ S. 23)).

>

42296

42276

42297

3.3.4 Error detection and processing

>

Error classes

AC412S recognises the following error classes:

>

Fatal error

The following errors are classified as fatal errors:

error in the device (temperature exceeded, soiling)

error in the channels

Response to fatal errors:

The safety module goes into the safe state (→Safe state (→ S. 25))

42221

42218

42222

SmartPLC SafeLine with PROFIBUS slave interface

24

Serious error

42252

Following errors are classified as serious errors:

Errors occurring in the periphery which do not affect the processing logic of the device

Response to serious errors:

The safety module goes into the safe state (→Safe state (→ S. 25))

>

Exception errors

42225

An exception error occurs when the device software is in a non foreseen state.

Response to exception errors:

The safety module goes into the safe state (→Safe state (→ S. 25))

>

Scheduling errors

42254

The following errors are classified as scheduling errors:

Errors in the correct processing of the different tasks in the course of which the operating system

cannot make a task change any more so that the watchdog is triggered.

Response to scheduling errors:

All output channels of the local I/O interface go into the default state (= switched off)

All safe output slaves stop sending code sequences

Restart disable of the fail-safe PLC

>

Error message

AC412S signals occurring errors via the following mechanisms:

status LED (→Status LED (→ S. 145))

online support Centre (→Online Support Centre (OSC) (→ S. 148))

42224

SmartPLC SafeLine with PROFIBUS slave interface

25

Safe state

All non safety-relevant functions of the basic device continue to be available in the safe state.

42258

The safety module of AC412S is always in the safe state. Exceptions are the following operating

states of the fail-safe PLC:

debug operation

download operation

safe operation

If a fatal, serious or exception error occurs during these operating states, the safety module of

AC412S goes into the safe state.

The safe state is characterised by the following features:

All safe output channels of the local I/O interface are already power-free

All safe AS-i control slaves have stopped sending code sequences

the fail-safe PLC is in the STOP mode

the cyclic data transfer between safety module and basic device is interrupted

the data packages of the safe cross communication between the two safety CPUs are filled with

zero sequences and marked as "invalid"

the basic device detects that the safety module is in the safe state and provides this information in

the OSC and on the PROFIBUS and configuration interface

>

Reset error

All error states (→Error classes (→ S. 23)) can only be exited using one of the following measures.

► Reboot the device (power-on reset)

42257

SmartPLC SafeLine with PROFIBUS slave interface

26

3.4 Software

Content

Software modules of the device .......................................................................................................... 26

Safety functions ................................................................................................................................... 26

Certified software components for safe applications ........................................................................... 27

Software modules

Description

Recovery system

Environment for the firmware installation

Firmware

Firmware of AC412S

CODESYS standard runtime system

(Standard-SPS)

Runtime environment for the execution of CODESYS applications to IEC 61131

CODESYS safety runtime system (failsafe PLC)

Certified runtime environment for the execution of safe CODESYS applications

Standard application

CODESYS application for Standard-SPS

Safe application

CODESYS application for fail-safe PLC (= safety function)

The user is responsible for setting the safe function of the application (= safe application). If

necessary, he must also obtain an approval from the supervisory and test organisations

according to the national regulations.

AC412S provides the programmer with a safe environment which is suited for the execution

of a safe application to SIL3. The user is responsible for programming the safe application.

>

3.4.1 Software modules of the device

AC412S has the following software modules:

>

3.4.2 Safety functions

AC412S provides the following safety functions:

Freely programmable fail-safe PLC

Safe reading of local digital inputs and linking via the fail-safe PLC

Safe control of local digital outputs via the fail-safe PLC

Safe reading of safe AS-i input slaves and linking via the fail-safe PLC

Control of safe AS-i output slaves via the fail-safe PLC

Safe data transfer between min. 2 AC412S

Safe data transfer from and to EtherCAT slaves (FSoE)

42280

42281

42262

SmartPLC SafeLine with PROFIBUS slave interface

27

3.4.3 Certified software components for safe applications

Information about device-specific software components and about how to program StandardSPS and the fail-safe PLC: → Programming manual fail-safe SmartPLC AC4S"

42207

To program safe applications for AC412S ifm electronic provides certified software components for the

programming environment CODESYS safety 3.5. In addition, the user can use the function libraries

supplied with CODESYS safety.

SmartPLC SafeLine with PROFIBUS slave interface

28

4 Mounting

Content

Install device ...................................................................................................................................... 28

Ensure a condensation-free environment. Avoid excessive dust, vibration and shock. The air

circulation through the vents must not be impeded. Installation in environments with ionising

radiation is not permitted.

Avoid installation in direct vicinity of frequency inverters or other interfering sources.

>

34058

4.1 Install device

42302

The device must only be installed, connected and put into operation by a qualified electrician as the

safe function of the device and machinery is only guaranteed when installation is correctly carried out.

The installation and connection must comply with the applicable national and international standards.

Responsibility lies with the person installing the device.

► Fix the device onto a 35 mm raised rail.

► Vertical installation (upright).

► Adhere to a minimum distance of 30 mm between the ventilation holes (perforated sheet) and

other parts.

► Maximum operating distance: 2000 m above sea level

► The protection rating of the device is IP 20. The installation must take place in a control cabinet

with at least IP 54 protection.

► Lay the cables in a cable duct.

► Keep the installation space of the device free from electrically-conductive particles.

SmartPLC SafeLine with PROFIBUS slave interface

29

5 Electrical connection

Content

Wiring .................................................................................................................................................. 29

Connect the supply voltage ................................................................................................................. 29

Connect devices to local I/O interface ................................................................................................. 31

The device must be connected by a qualified electrician.

► Disconnect power before connecting the device.

► Observe the national and international regulations for the installation of electrical

equipment.

► Connect the device as indicated on the terminals.

► Ensure an electrical connection between the AC412S (X1, terminal FE) and the ground

of the installation.

Terminal X1

Pin

Description

AS-i 2 +

1

AS-i + for AS-i line 2

AS-i 2 -

2

AS-i - for AS-i line 2

AS-i 1 +

3

AS-i + for AS-i line 1

AS-i 1 -

4

AS-i - for AS-i line 1

FE

5

Functional earth

6

Not connected

Terminal X2

Pin

Description

24 V

1

+24 V device supply

GND

2

GND

Terminal X4

Pin

Description

1...8

IN1...IN8

9...12

OUT1...OUT4

13,14

GND 15,16

+24 V power supply Safe-IO module

Terminal X3, X8

Configuration interfaces

Socket X6

EtherCAT interface 2 (OUT)

Socket X7

EtherCAT interface 1 (IN)

5.1 Wiring

42226

42273

A fixed terminal assignment is mandatory for the fail-safe inputs (IN 1...8) → Connect sensors / actuators

(→ S. 43)

>

5.2 Connect the supply voltage

Supply the device with one of the following versions.

42212

SmartPLC SafeLine with PROFIBUS slave interface

30

>

Power must be applied simultaneously to the Safe_IO module (terminal X4) and to the

device supply (terminal X2).

24 V device supply

Connect the pins 24 V and 0 V of terminal X2 to a 24 V DC power supply (18...32 V

SELV/PELV).

24 V Safe-IO power supply

Connect the pins 24 V and GND of terminal X4 to a 24 V DC power supply (18...32 V

SELV/PELV).

5.2.1 Standard configuration: 24 V power supply and AS-i power supply/supplies

42279

► Connect the supply voltage inputs of the device to the power supply intended for this purpose.

AS-i bus 1

Connect the AS-i 1+ and AS-i 1- pins of terminal X1 to the AS-i power supply (e.g. AC1254) of the

first AS-i bus.

AS-i bus 2

Connect the AS-i 2+ and AS-i 2- pins of terminal X1 to the AS-i power supply (e.g. AC1254) of the

second AS-i bus.

► Ensure a low-resistance connection of the symmetry point of the device (terminal X1, pin 5 FE) to

the ground of the installation.

► For the 24 V power supply (device, Safe-IO), select a power supply which supplies an output

current of at least 3 A.

► The cable length of the DC supply between power supply and AC412S is to be limited to max. 3

m.

The power supplies used must meet the standard DIN EN 60950-1 for SELV/PELV.

Loading...

Loading...