IFM Electronic AC2630, AC2636, AC2637, AC2638, AC2631 Device Manual

...

Device manual

Field modules DP

AC2630 / AC2631 / AC2634

AC2636 / AC2637 / AC2638

UK

7390983 / 00 03 / 2013

Field modules DP

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3 Documentation� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1 Firmware and hardware status� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

3�1�1 Downward compatibility � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4 Connections � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�1 Fieldbus connection � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�2 Fieldbus termination � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�3 Nominal current consumption of modules connected to PROFIBUS-DP� � 7

4�4 Connection to a Siemens PLC type S7-300� � � � � � � � � � � � � � � � � � � � � � � � 8

4�4�1 Importing the GSD file � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�5 Selection of modules as slaves � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

5 Data mapping of the modules� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

5�1 Data mapping: Stand-alone and extension modules � � � � � � � � � � � � � � � � 13

5�1�1 Digital input modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

5�1�2 Digital output modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

5�1�3 Digital combined modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

5�1�4 Analogue input modules� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

5�1�5 Analogue output modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

6 Error handling and diagnosis � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

6�1 Error handling via LEDs � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

6�1�1 Flash codes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

6�1�2 Diagnostic LEDs for PROFIBUS � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

6�1�3 Error causes� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

6�2 Error diagnosis via software � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

6�2�1 General structure of the diagnostic messages� � � � � � � � � � � � � � � � � 18

6�2�2 Diagnostic message of the stand-alone modules � � � � � � � � � � � � � � 19

7 ifm Profibus DP modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

7�1 General technical information� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

7�2 Supply voltage � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

7�2�1 Operating voltage � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

7�2�2 Load voltage � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

7�3 Nominal current consumption of the modules � � � � � � � � � � � � � � � � � � � � � 22

7�4 Electrical isolation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

7�4�1 Digital modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

7�4�2 Analogue modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

7�5 Incoming line and power supply � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 22

7�5�1 Power loss of power cable � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

7�6 Start-up behaviour of the modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

7�7 Scale drawing� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

8 Devices� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

2

Field modules DP

8�1 Technical data � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

8�2 Digital stand-alone modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

8�2�1 AC2630 FieldModuleDP 4x2DI M12 � � � � � � � � � � � � � � � � � � � � � � � � 25

8�2�2 AC2631 FieldModuleDP 2x2DI 2x2DO M12 � � � � � � � � � � � � � � � � � � 25

8�3 Analogue input modules � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

8�3�1 AC2638 FieldModuleDP 4AI (V) M12� � � � � � � � � � � � � � � � � � � � � � � � 25

8�3�2 AC2636 FieldModuleDP 4AI (C) M12 � � � � � � � � � � � � � � � � � � � � � � � 26

8�3�3 AC2634 FieldModuleDP 4AI (PT100) M12 � � � � � � � � � � � � � � � � � � � 29

8�3�4 AC2637 FieldModuleDP 4AO (C) M12� � � � � � � � � � � � � � � � � � � � � � � 32

UK

This document is the original instructions�

3

Field modules DP

1 Preliminary note

This document applies to devices of the "Field modules DP" (art� no: AC26xx)�

These instructions are part of the device�

This document is intended for specialists� These specialists are people who are

qualified by their appropriate training and their experience to see risks and to

avoid possible hazards that may be caused during operation or maintenance of

the device� The document contains information about the correct handling of the

device�

Read this document before use to familiarise yourself with operating conditions,

installation and operation� Keep this document during the entire duration of use of

the device�

Adhere to the safety instructions�

Symbols

►

Instructions

> Reaction, result

[…] Designation of keys, buttons or indications

→ Cross-reference

Important note

Non-compliance can result in malfunction or interference�

Information

Supplementary note

Warning signs used

WARNING

Warning of serious personal injury�

Death or serious irreversible injuries may result�

CAUTION

Warning of personal injury�

Slight reversible injuries may result�

NOTE

Warning of damage to property�

4

Field modules DP

2 Safety instructions

These instructions contain texts and figures concerning the correct handling of the

device and must be read before installation or use�

Observe the operating instructions� Non-observance of the instructions, operation

which is not in accordance with use as prescribed below, wrong installation or

incorrect handling can seriously affect the safety of operators and machinery�

► Prepare installation

► Disconnect the power supply of the device�

► Ensure that devices cannot be accidentally restarted�

► Verify safe isolation from the supply�

► Earth and short circuit�

► Cover or enclose adjacent units that are live�

UK

► Follow the specific mounting instructions of the device�

► Only suitably qualified personnel in accordance with EN 50 110-1/-2 (VDC

0105 part 100) is permitted to work on this device/system�

► Before installation and before touching the device ensure that you are free of

electrostatic charge�

► The funtional earth (FE) must be connected to the protective earth (PE) or to

the potential equalisation� The system installer is responsible for implementing

this connection�

► Connecting cables and signal lines must be installed in such a manner that

inductive or capacitive interference do not impair the automatic functions�

► Install automation equipment and related operating elements in such a way that

they are protected against unintentional operation�

► Suitable safety hardware and software measures should be implemented for

the I/O interface so that a line or wire breakage on the signal side does not

result in undefined states in the automation device�

► Ensure a reliable electrical isolation of the low voltage for the 24 V supply�

Only use power supplies compliant with IEC 60 364-4-41 or HD 384�4�41 S2

(VDE 0100 part 410) �

► Fluctuations or deviations of the mains voltage from the rated value must not

exceed the tolerance limits specified in the technical data, otherwise this may

cause malfunction and dangerous operation�

► E-stop devices to IEC/EN 60 204-1 must be effective in all operating modes of

the automation device� Unlatching the e-stop devices must not cause restart�

5

Field modules DP

► Devices that are designed for mounting in housings or control cabinets must

only be operated and controlled after they have been installed with the housing

closed� Desktop or portable units must only be operated and controlled in

enclosed housings�

► Measures should be taken to ensure the proper restart of programs interrupted

after a voltage dip or failure� This should not cause dangerous operating states

even for a short time� If necessary, an emergency stop must be carried out�

► Wherever faults in the automation system may cause personal injuries or

damage to property, external measures must be implemented to ensure a safe

operating state in the event of a fault or malfunction (e�g� by means of separate

limit switches, mechanical interlocks etc�)

► The electrical installation must be carried out in accordance with the relevant

regulations (e�g� with regard to cable cross-sections, fuses, PE)�

► All work relating to transport, installation, commissioning and maintenance

must only be carried out by qualified personnel� (IEC 60 364 or HD 384 or

DIN VDE 0100 and national work safety regulations have to be observed)�

► All shrouds and doors must be kept closed during operation�

3 Documentation

This documentation relates to the hardware and firmware status at the time of

editing this manual� The features of the devices are continuously developed further

and improved�

3.1 Firmware and hardware status

3.1.1 Downward compatibility

The modules are downward compatible� Older modules cannot, however,

feature the same characteristics as new module versions� However, existing

characteristics have been retained so that older modules can always be replaced

with the new ones�

The documentation describes the differences between the modules�

The firmware and hardware status of the modules can be taken from the version

number printed on the side of the module� The version number can be identified by

the prefix "D"�

6

Firmware and hardware status

21

12

Indication on module Declaration Example

D� kkjjxyzu D�22011501

kk Calendar week Week 22

jj Year of the year 2001

Field modules DP

x Firmware bus board Firmware bus, version 1

y Hardware bus board Hardware, version 5

z Firmware I/O board Firmware I/O, 0 (no firmware needed for

this board)

u Hardware I/O board Hardware I/O, version 1

4 Connections

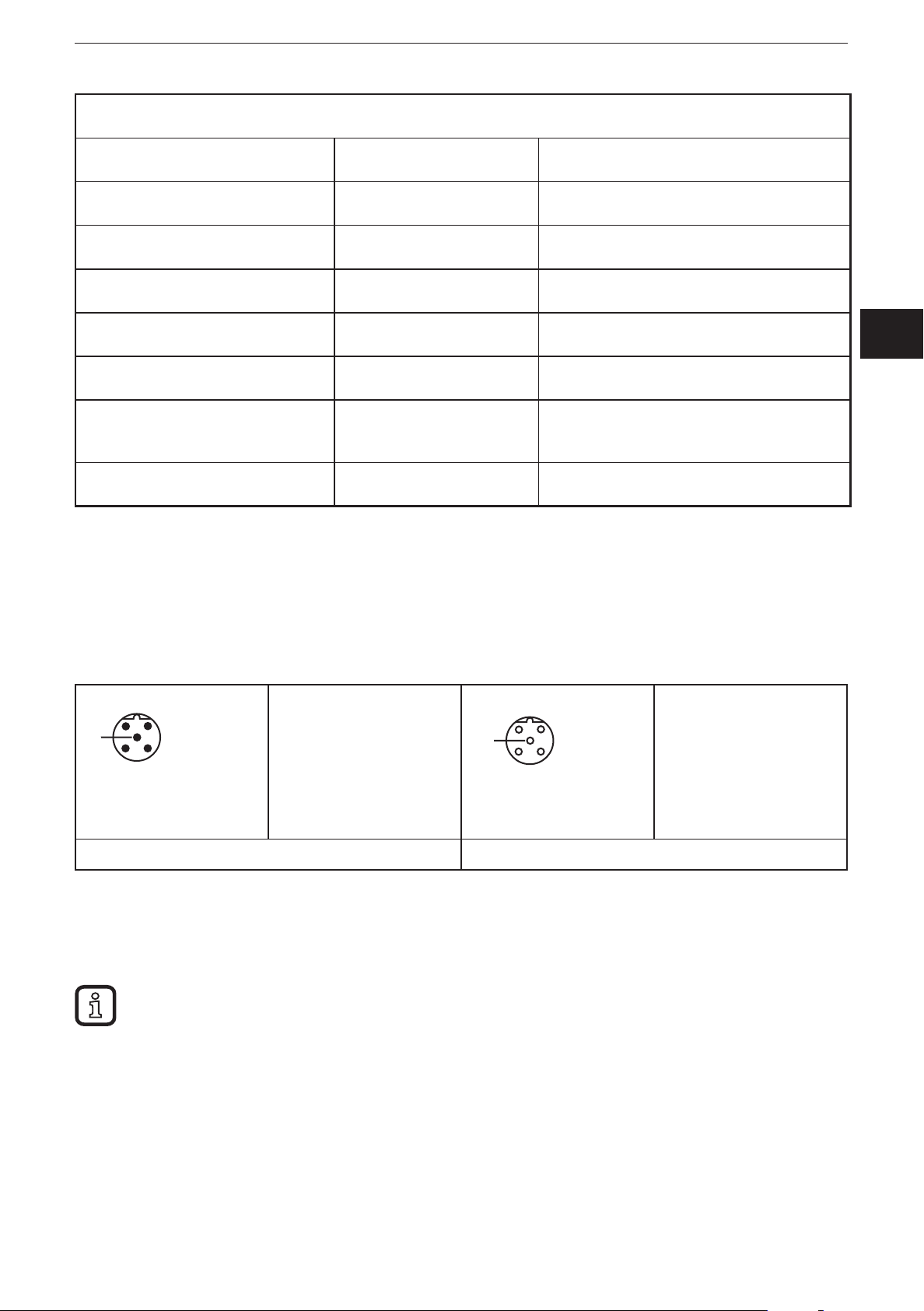

4.1 Fieldbus connection

The fieldbus connection is established using reverse-keyed M12x1 connectors�

1: not connected

5

3

4

2: line A

3: GND

4: line B

5: shield (also on

coupling nut)

5

4

3

1: 5 V DC

2: line A

3: GND

4: line B

5: shield (also on

coupling nut)

UK

M12 connector for the in-coming bus line M12 connector for the outgoing bus line

4.2 Fieldbus termination

The bus is terminated using an external terminating resistor� The modules are not

capable of fieldbus termination�

4.3 Nominal current consumption of modules connected to PROFIBUSDP

It is important to consider the current consumption of the individual modules for

power-feed, module protection and assessment of the voltage drop on the power

cable�

Chapter 7 contains a table with the nominal current consumption of the modules�

The bus termination must be accomplished externally using a connector with integrated terminating

resistor (E12315) as passive terminating resistor�

7

Field modules DP

4.4 Connection to a Siemens PLC type S7-300

In order to describe the connection of the modules to an S7-300 type Siemens

controller, the software package "SIMATIC Manager" version 5�5 with Service

Pack 2 from the company Siemens is used�

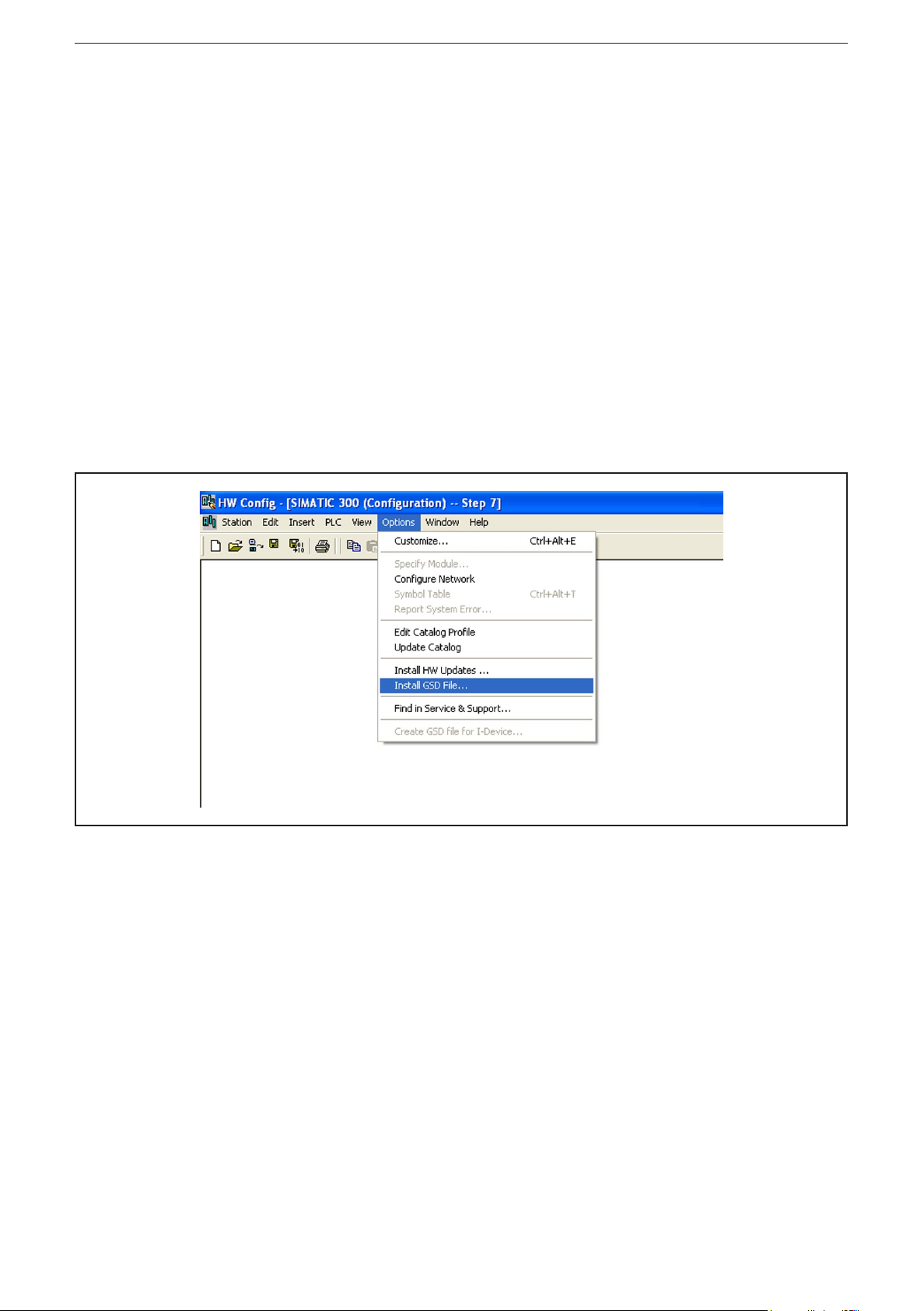

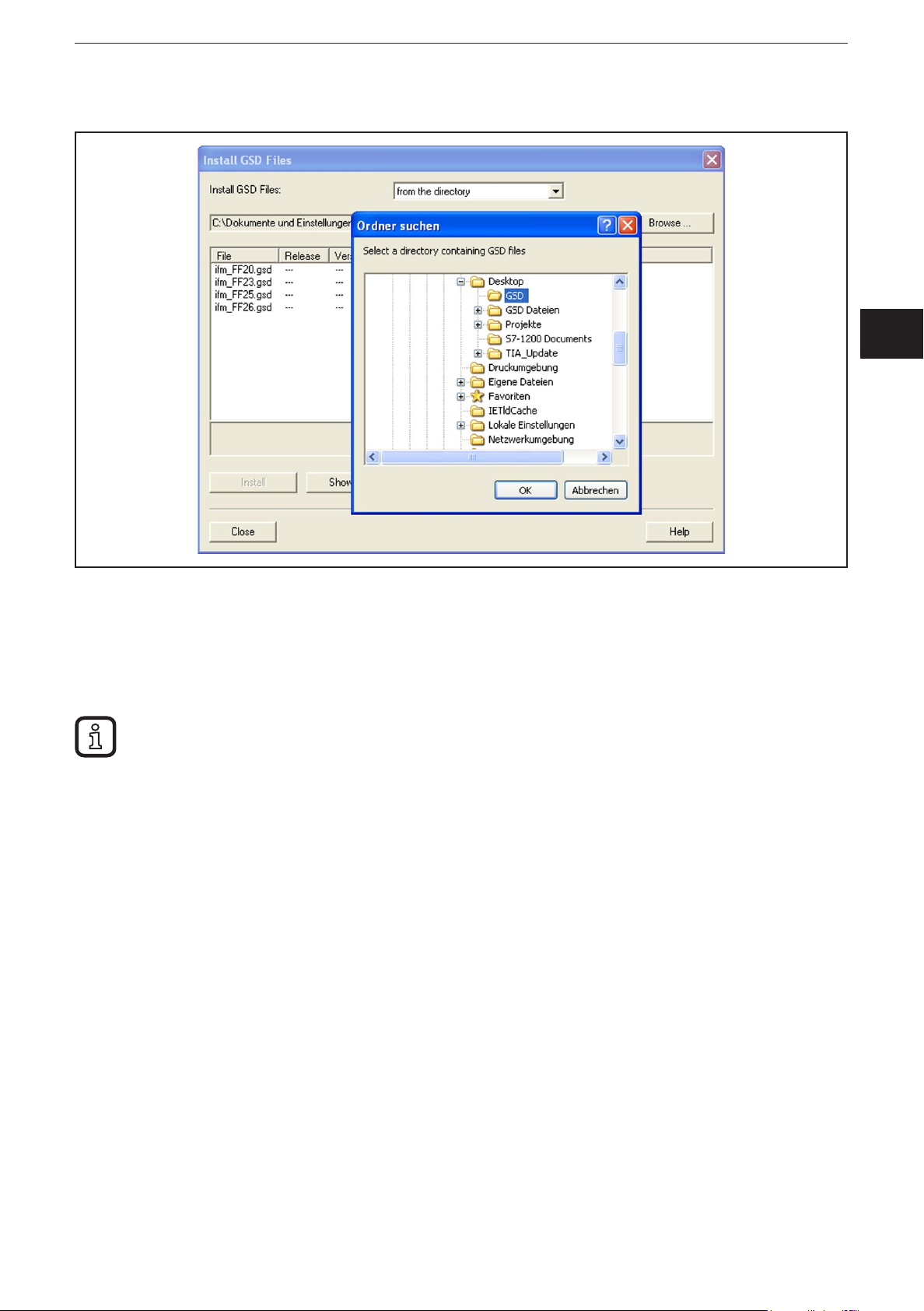

4.4.1 Importing the GSD le

Prior to initial configuration of the system in the hardware configurator of the

software, the GSD files must be imported into the software�

Start the software and proceed as follows to import the above GSx files:

► Open new or existing project�

► Open hardware configurator

Copy the required GSx file to the software via menu item [Options] → [Install GSD

File���]�

Importing a GSD file

8

► Select the GSD file from the according source directory�

Field modules DP

UK

Selecting the GSD file from the directory

After correct import and an update of the hardware catalogue via [Options]

→ [Update Catalog] the modules will be displayed as separate entries in the

hardware catalogue�

The exact configuration procedure can be found in the operating manual which is supplied together

with the software�

9

Field modules DP

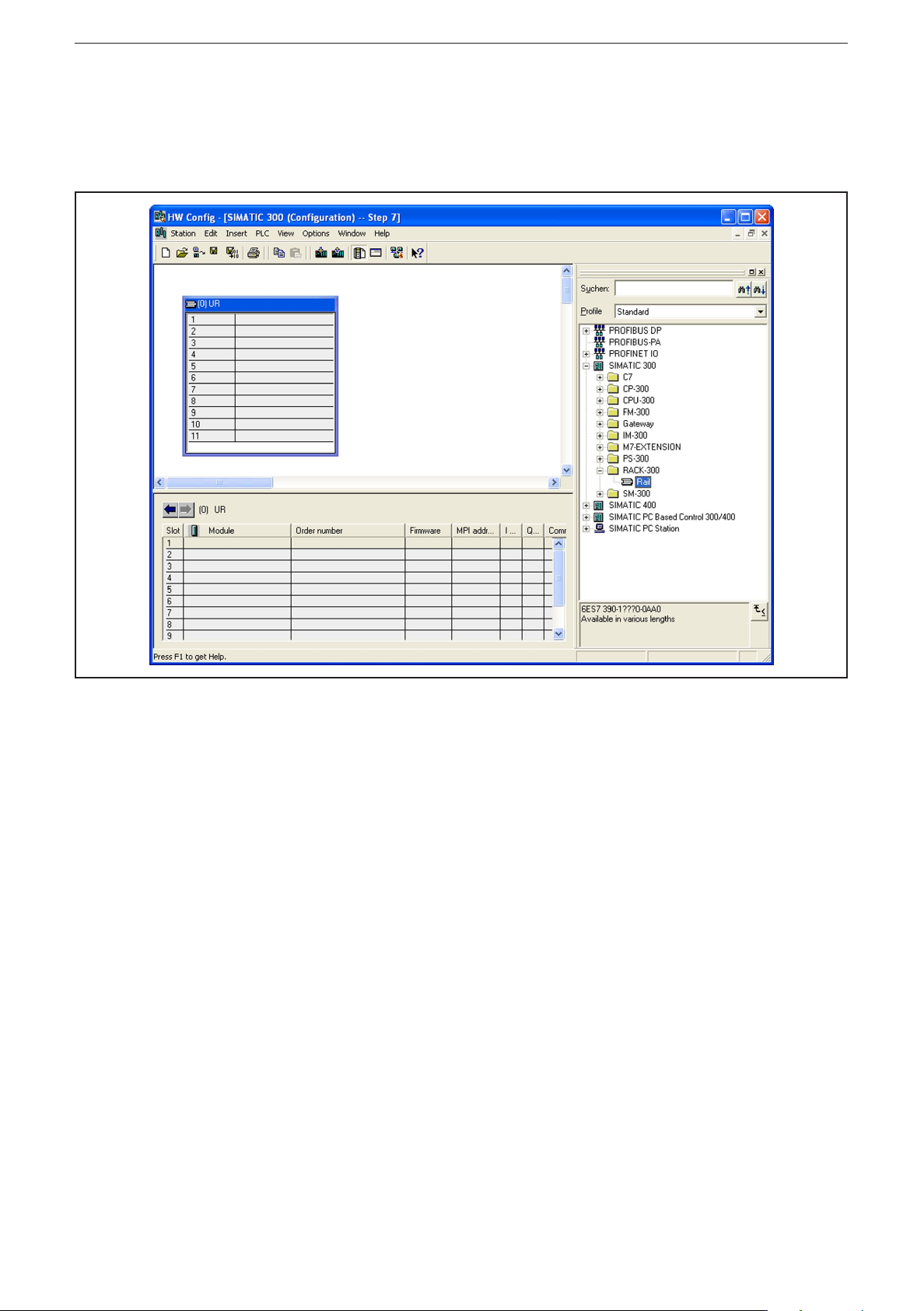

Selecting a CPU

First, select a module rack� In this example, rack 300 is selected under

[SIMATIC 300] → [RACK 300]

Selecting the module rack

Then the CPU type is determined�

10

Field modules DP

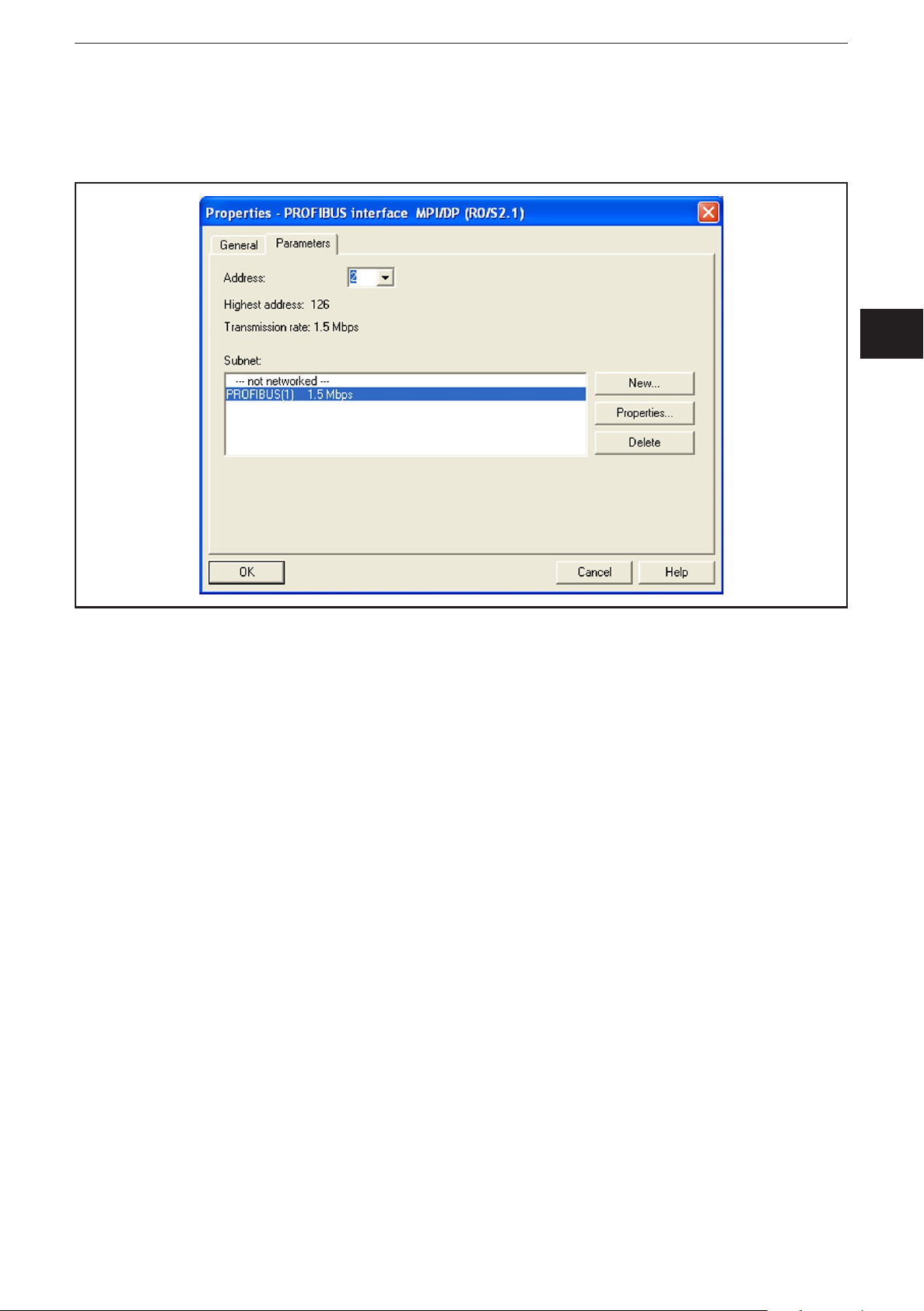

Enter the PROFIBUS address of the CPU in the dialogue box and select the

subnet [PROFIBUS]�

Use the button [Properties] to further define the subnet�

UK

Selecting the subnet

11

Loading...

Loading...