IFM Electronic AC1403, AC1404, AC1401, AC1402 Device Manual

>

7391120 / 01 09 / 2018

Device Manual

SmartPLC DataLine with Profinet device interface

AC1403

AC1404

Master profile: M4

Firmware: 4.3.1 or higher

English

>

SmartPLC DataLine with Profinet device interface

2

Contents

1 Preliminary note 5

1.1 Legal and copyright information ........................................................................................... 5

1.2 Purpose of the document ..................................................................................................... 5

1.3 Explanation of Symbols ....................................................................................................... 6

1.4 Overview: User documentation for AC1403/04 ................................................................... 7

1.5 Modification history .............................................................................................................. 7

2 Safety instructions 8

2.1 General safety instructions .................................................................................................. 8

2.2 Required background knowledge ........................................................................................ 8

2.3 Tampering with the unit ........................................................................................................ 8

3 System description 9

3.1 Intended use ......................................................................................................................10

3.1.1 Permitted use ................................................................................................ ............................. 10

3.1.2 Prohibited use ............................................................................................................................ 10

3.2 Information concerning the device .....................................................................................11

3.2.1 Overview .................................................................................................................................... 11

3.2.2 Operating elements .................................................................................................................... 12

3.2.3 Display elements ........................................................................................................................ 12

3.2.4 CODESYS SPS .......................................................................................................................... 12

3.2.5 Interfaces .................................................................................................................................... 13

3.2.6 Required accessories ................................................................................................................. 13

4 Operation 14

4.1 Control of the graphical user interface ...............................................................................14

4.1.1 Function keys ................................................................................................ ............................. 15

4.1.2 Arrow keys .................................................................................................................................. 15

4.2 Menu view ..........................................................................................................................16

4.2.1 Menu navigation ......................................................................................................................... 16

4.2.2 Navigation aids ........................................................................................................................... 17

4.3 Page view ...........................................................................................................................19

4.3.1 Navigate on a page .................................................................................................................... 19

4.3.2 Use navigation aids .................................................................................................................... 19

4.3.3 Description of the control elements ............................................................................................ 20

4.4 Remote access ..................................................................................................................32

4.4.1 General................................................................................................................................ ....... 32

4.4.2 Recommended browsers................................ ................................................................ ............ 32

4.4.3 Operating instructions ................................................................................................................ 33

5 Menu 36

5.1 Start screen ........................................................................................................................36

5.2 Menu functions ...................................................................................................................37

5.2.1 Additional functions .................................................................................................................... 37

5.3 Quick setup ........................................................................................................................38

5.3.1 Quick setup: Project AS-i networks ............................................................................................ 39

5.3.2 Quick setup: Configure the operating mode of the AS-i masters ................................................ 40

5.3.3 Quick setup: Configure the output access .................................................................................. 41

5.3.4 Quick setup: Access the device via QR code ............................................................................. 42

5.3.5 Quick setup: Configure the PROFINET interface ....................................................................... 42

5.3.6 Quick setup: Set the Konfigurationsschnittstelle 1 ...................................................................... 43

5.3.7 Quick setup: Set the configuration interface 2 ............................................................................ 44

SmartPLC DataLine with Profinet device interface

3

5.3.8 Quick setup: Address the AS-i slaves connected to AS-i Master 1 ............................................ 45

5.3.9 Quick setup: Address the AS-i slaves connected to AS-i Master 2 ............................................ 46

5.4 AS-i 1 / AS-i 2 .....................................................................................................................47

5.4.1 AS-i 1 / AS-i 2: Master setup ...................................................................................................... 48

5.4.2 AS-i 1 / AS-i 2: Diagnosis ........................................................................................................... 50

5.4.3 AS-i 1 / AS-i 2: AS-i slaves ......................................................................................................... 52

5.5 System ...............................................................................................................................58

5.5.1 System: Programmable Logic Controller (PLC) .......................................................................... 59

5.5.2 System: Information ................................................................................................................... 65

5.5.3 System: Setup ............................................................................................................................ 66

5.5.4 System: Diagnosis ...................................................................................................................... 79

5.6 Interfaces ...........................................................................................................................80

5.6.1 Interfaces: Konfigurationsschnittstelle 1 ..................................................................................... 81

5.6.2 Interfaces: Configuration interface 2 ........................................................................................... 83

5.6.3 Interfaces: PROFINET interface ................................................................................................. 84

5.7 ifm system solutions ...........................................................................................................90

5.7.1 Notes on ifm system solutions .................................................................................................... 91

5.7.2 Show information about installed ifm apps ................................................................................. 92

5.7.3 Install single/basic app ............................................................................................................... 93

5.7.4 Install multi app .......................................................................................................................... 94

5.7.5 Update ifm apps ......................................................................................................................... 95

5.7.6 Uninstall ifm apps ....................................................................................................................... 95

6 Setup 96

6.1 Connect the device to the periphery ..................................................................................96

6.1.1 EtherNet/IP interface .................................................................................................................. 96

6.1.2 Configuration interface ............................................................................................................... 96

6.2 zzStart screen 'Basic settings' ...........................................................................................97

6.2.1 Change the basic settings of the device ..................................................................................... 97

6.3 Update the firmware of the device .....................................................................................99

6.3.1 Behaviour of the settings upon firmware update ........................................................................ 99

6.3.2 Firmware update from SD card ................................................................................................ 100

6.3.3 Firmware update via the web interface ..................................................................................... 101

6.4 Connect and address AS-i slaves ....................................................................................103

6.5 Set up Profinet .................................................................................................................103

6.6 Set Ethernet configuration interfaces ...............................................................................104

6.7 Exchange AS-i slave ........................................................................................................104

7 Troubleshooting 105

7.1 Status LED .......................................................................................................................105

7.1.1 Status LED: Basic device ......................................................................................................... 105

7.1.2 Status LED: Fieldbus PROFINET ............................................................................................. 105

7.2 Start screen: Status LEDs ................................................................................................106

7.2.1 Status of the web interface ....................................................................................................... 106

7.2.2 Operating mode of the AS-i master .......................................................................................... 106

7.2.3 Control instance of the AS-i outputs ......................................................................................... 106

7.2.4 Fieldbus status ................................................................ ......................................................... 106

7.3 Online diagnosis function .................................................................................................107

7.3.1 Message types ......................................................................................................................... 107

7.3.2 Locate error sources ................................................................................................................ 107

7.4 Online Support Center (OSC) ..........................................................................................108

7.4.1 OSC: View current error messages .......................................................................................... 109

7.4.2 OSC: Show message history .................................................................................................... 110

8 Appendix 111

8.1 Approval tests / certifications ...........................................................................................111

8.2 Technical data ..................................................................................................................112

8.2.1 Housing .................................................................................................................................... 112

8.2.2 Power supply connections ........................................................................................................ 112

SmartPLC DataLine with Profinet device interface

4

8.2.3 Operation .................................................................................................................................. 112

8.2.4 Display elements ...................................................................................................................... 112

8.2.5 Interfaces .................................................................................................................................. 113

8.2.6 Programmable Logic Controller (PLC) ..................................................................................... 113

8.3 Address assignment in Ethernet networks ......................................................................114

8.4 Configuration interfaces: Connection concepts ...............................................................115

8.4.1 Direct connection ...................................................................................................................... 115

8.4.2 Connection via Ethernet network .............................................................................................. 116

8.5 AS-i master ......................................................................................................................117

8.5.1 Operating modes of the AS-i master ........................................................................................ 118

8.5.2 Master flags .............................................................................................................................. 120

8.6 AS-i slaves .......................................................................................................................121

8.6.1 Profiles of AS-i slaves............................................................................................................... 122

8.7 Fieldbus Profinet ..............................................................................................................131

8.7.1 Fieldbus parameters ................................................................................................................. 131

8.7.2 Parameter data ......................................................................................................................... 132

8.7.3 Cyclic data ................................................................................................................................ 135

8.7.4 Acyclic data .............................................................................................................................. 151

8.7.5 I&M data ................................ ................................................................................................... 157

8.7.6 Fieldbus alarms ........................................................................................................................ 159

8.8 OSC messages ................................................................................................................170

8.8.1 OSC messages: System .......................................................................................................... 170

8.8.2 OSC messages: AS-i 1 / AS-i 2 ................................................................................................ 171

9 Index 172

SmartPLC DataLine with Profinet device interface

5

1 Preliminary note

Content

Legal and copyright information ............................................................................................................... 5

Purpose of the document ......................................................................................................................... 5

Explanation of Symbols ............................................................................................................................ 6

Overview: User documentation for AC1403/04 ........................................................................................ 7

Modification history ................................................................................................................................... 7

>

33203

1.1 Legal and copyright information

33117

© All rights reserved by ifm electronic gmbh. No part of this manual may be reproduced and used

without the consent of ifm electronic gmbh.

All product names, pictures, companies or other brands used on our pages are the property of the

respective rights owners:

AS-i is the property of the AS-International Association, (→ www.as-interface.net)

CAN is the property of the CiA (CAN in Automation e.V.), Germany (→ www.can-cia.org)

CODESYS™ is the property of the 3S – Smart Software Solutions GmbH, Germany

(→ www.codesys.com)

DeviceNet™ is the property of the ODVA™ (Open DeviceNet Vendor Association), USA

(→ www.odva.org)

EtherNet/IP® is the property of the → ODVA™

EtherCAT® is a registered trade mark and patented technology, licensed by Beckhoff Automation

GmbH, Germany

IO-Link® (→ www.io-link.com) is the property of the → PROFIBUS Nutzerorganisation e.V.,

Germany

ISOBUS is the property of the AEF – Agricultural Industry Electronics Foundation e.V.,

Deutschland (→ www.aef-online.org)

Microsoft® is the property of the Microsoft Corporation, USA (→ www.microsoft.com)

PROFIBUS® is the property of the PROFIBUS Nutzerorganisation e.V., Germany

(→ www.profibus.com)

PROFINET® is the property of the → PROFIBUS Nutzerorganisation e.V., Germany

Windows® is the property of the → Microsoft Corporation, USA

>

1.2 Purpose of the document

This document applies to devices of the type "SmartSPS DataLine mit Profinet-Device-Schnittstelle

(art. no.: AC1403/04)

It is part of the device and contains information about the correct handling of the product.

► Read this document before using the device.

► Keep this document during the service life of the device.

41760

SmartPLC DataLine with Profinet device interface

6

>

WARNING!

Death or serious irreversible injuries may result.

CAUTION!

Slight reversible injuries may result.

NOTICE!

Property damage is to be expected or may result.

Important note

Non-compliance can result in malfunction or interference

Information

Supplementary note

► ...

Request for action

> ...

Reaction, result

→ ...

"see"

abc

Cross-reference

123

0x123

0b010

Decimal number

Hexadecimal number

Binary number

[...]

Designation of pushbuttons, buttons or indications

1.3 Explanation of Symbols

34171

SmartPLC DataLine with Profinet device interface

7

>

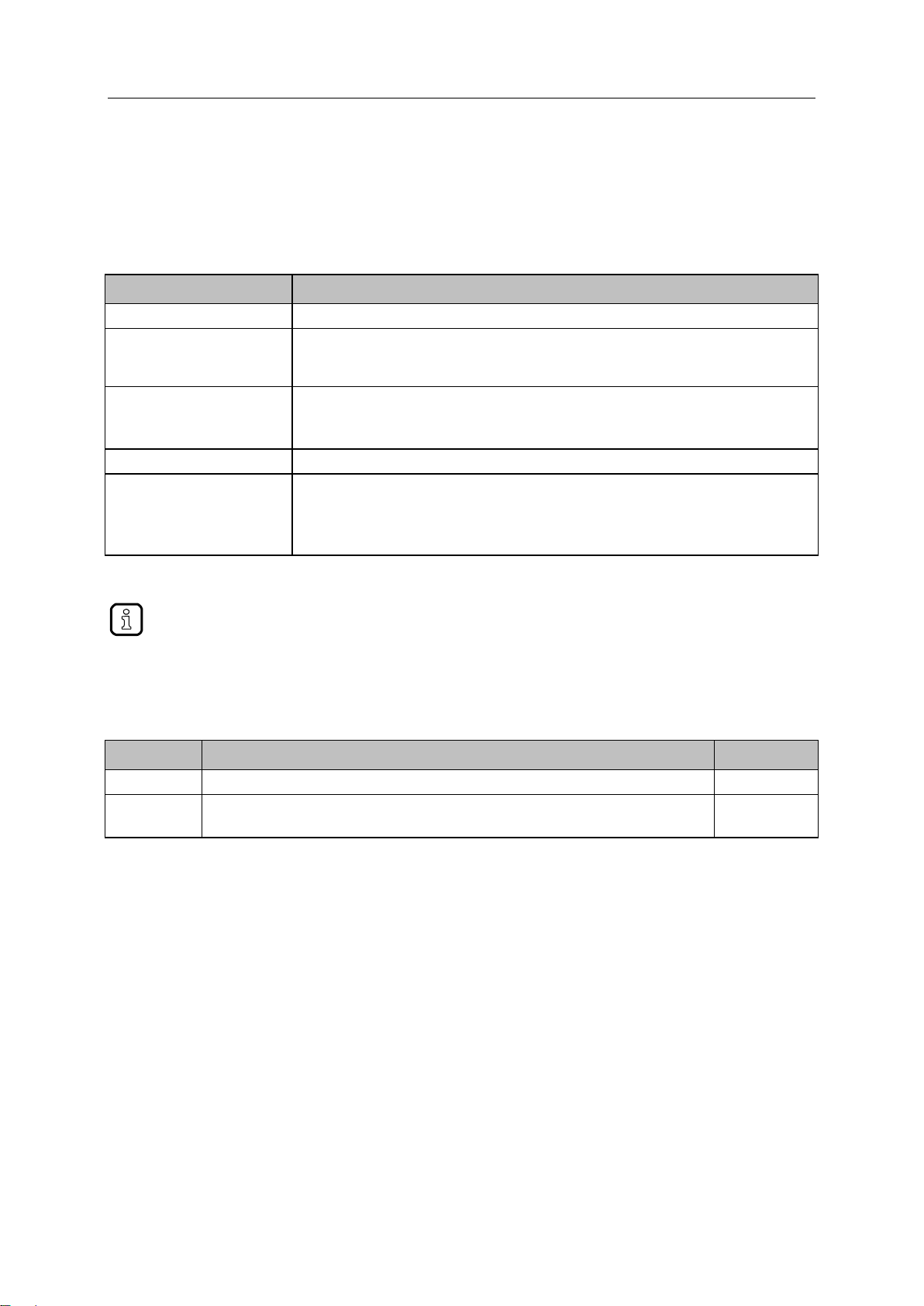

Document

Content / Description

Data sheet

Technical data of the device as a table

Operating instructions *

Notes on mounting and electrical installation of the device

Set-up, description of the operating and display elements, maintenance information, scale

drawing

Device manual

Notes on operation of the device via GUI and web interface

Error elimination

Description of the fieldbus data

Supplement device manual

Description of the acyclic data sets and the command interface

Programming manual

Creation of a project with the device using CODESYS

Configuration of the device using CODESYS

Programming of the SPS of the device

Description of the device-specific CODESYS function libraries

The user can download all documents from the ifm website.

Version

Topic

Date

00

New creation of document

12 / 2017

01

Update to Firmware 4.3.1

Changed: Restore device configuration

09 / 2018

1.4 Overview: User documentation for AC1403/04

41793

ifm electronic provides the following user documentation for the models of the device class "SmartSPS

DataLine mit Profinet-Device-Schnittstelle":

*... The operating instructions are supplied with the device.

>

1.5 Modification history

34492

SmartPLC DataLine with Profinet device interface

8

2 Safety instructions

Content

General safety instructions ....................................................................................................................... 8

Required background knowledge ............................................................................................................. 8

Tampering with the unit ............................................................................................................................ 8

WARNING!

Tampering with the unit.

> In case of non-compliance:

Possible affects on safety of operators and machinery

Expiration of liability and warranty

► Do not open the devices!

► Do not insert any objects into the devices!

► Prevent metal foreign bodies from penetrating!

>

28333

2.1 General safety instructions

41415

Read this document before setting up the product and keep it during the entire service life.

Only use the product for its intended purpose.

If the operating instructions or the technical data are not adhered to, personal injury and/or damage to

property may occur.

Improper or non-intended use may lead to malfunctions of the device, to unwanted effects in the

application or to a loss of the warranty claims.

The manufacturer assumes no liability for any consequences caused by tampering with the device or

incorrect use by the operator.

► Observe these operating instructions.

► Adhere to the warning notes on the product.

>

2.2 Required background knowledge

41648

This document is intended for specialists. Specialists are people who, based on their relevant training

and experience, are capable of identifying risks and avoiding potential hazards that may be caused

during operation or maintenance of the product.

For programming these people should also have knowledge of control technology experience in PLC

programming to IEC 61131-3.

The document contains information about the correct handling of the product.

>

2.3 Tampering with the unit

33190

SmartPLC DataLine with Profinet device interface

9

3 System description

Content

Intended use ...........................................................................................................................................10

Information concerning the device .........................................................................................................11

28392

SmartPLC DataLine with Profinet device interface

10

>

Content

Permitted use .........................................................................................................................................10

Prohibited use .........................................................................................................................................10

3.1 Intended use

>

36928

3.1.1 Permitted use

36762

The device is designed for operation in the control cabinet.

The device may only be used for the following purposes:

as AS-i master in 1 or 2 AS-i networks to control the data exchange to the sensor/actuator level

as gateway between the AS-i network and a higher-level controller (PROFINET-Controller = Host;

e.g. PLC) via the fieldbus interface

as Programmable Logic Controller (PLC) for program-based parameter setting, control and

regulation of the AS-i slaves connected to the device

as EtherCAT master (software extension)

as fieldbus slave (software extension)

>

3.1.2 Prohibited use

34228

The device may not be used beyond the limits of the technical data (→ Technical data (→ S. 112))!

SmartPLC DataLine with Profinet device interface

11

>

Content

Overview .................................................................................................................................................11

Operating elements ................................................................................................................................12

Display elements ....................................................................................................................................12

CODESYS SPS ......................................................................................................................................12

Interfaces ................................................................................................................................................13

Required accessories .............................................................................................................................13

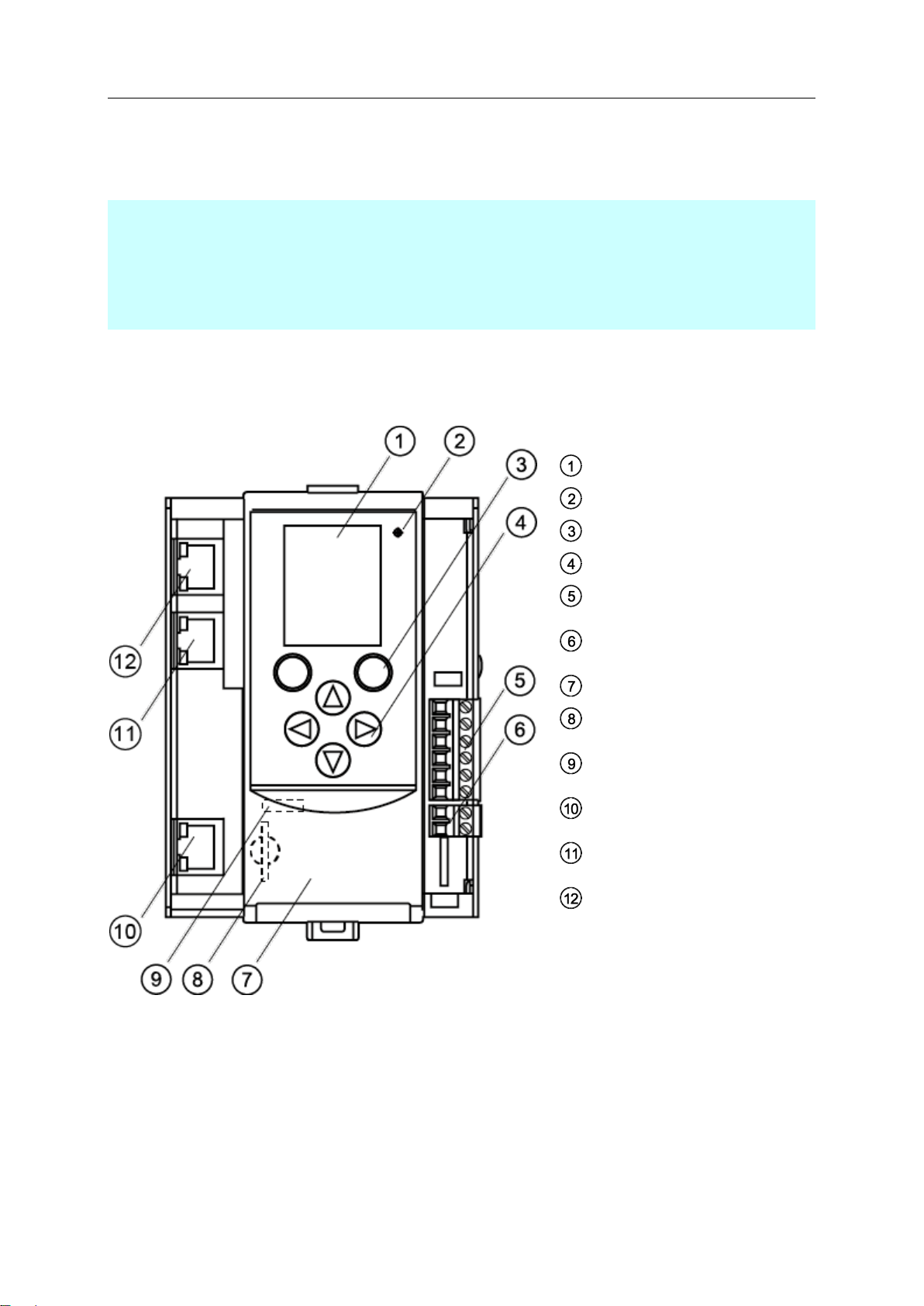

Legend:

Display

Status LED (H1)

2 function keys

4 arrow keys

Connector (X1) for

AS-i 1, AS-i 2, functional earth

Connector (X2) for AUX

(here with AUX jumper)

Front flap

Slot for SD card (behind the front

flap)

Ethernet configuration interface 1

(X3) (behind the front flap)

Ethernet configuration interface 2

(X8) with status LED (H6, H7)

PROFINET interface 2 (X7) with

status LED (H4, H5)

PROFINET interface 1 (X6) with

status LED (H2, H3)

3.2 Information concerning the device

>

3.2.1 Overview

36905

36757

SmartPLC DataLine with Profinet device interface

12

>

For information about the programming of the device-internal SPS with CODESYS, please

refer to the programming manual:

→ www.ifm.com > product page > [Downloads]

3.2.2 Operating elements

The device provides the following operating elements.

>

Arrow and function keys

Below the display is the key panel with two function keys and four arrow keys. The operator controls

the Graphical User Interface (GUI) of the device with the keys.

Operating notes: → Operation (→ S. 14)

>

3.2.3 Display elements

The device provides the following display elements:

>

Display

The display is used to display the Graphical User Interface (GUI) of the device.

Operating notes: → Operation (→ S. 14)

Technical data: → Technical data (→ S. 112)

>

36790

36959

36917

36894

Status LEDs

36784

The device features the following status LEDs which display the current status of system components.

Meaning of the LED colours and flashing frequencies: → Status LED (→ S. 105)

>

3.2.4 CODESYS SPS

36953

The device features a Programmable Logic Controller (PLC). The PLC can run the following

application types:

Applications that have been created with the IEC 61131-3 compliant programming software

"CODESYS Development System" (from version V3.5 SP9 Patch 7 Hotfix 3)

System solutions that have been provided by ifm electronic

Technical data: → Programmable Logic Controller (PLC) (→ S. 113)

SmartPLC DataLine with Profinet device interface

13

>

3.2.5 Interfaces

The device provides the following interfaces:

>

Ethernet configuration interfaces

The configuration interface 1 (X3) is behind the front flap of the device.

The configuration interface 2 (X8) is underneath the PROFINET interface (X6/X7).

The user can access the following functions via both interfaces:

web interface for device configuration and diagnostics

Programming of the device-internal SPS and the fail-safe PLC with CODESYS

Operation as additional fieldbus interface

Possible network topologies: → Configuration interfaces: Connection concepts (→ S. 115)

Technical data: → Technical data (→ S. 112)

>

PROFINET fieldbus interface

The device communicates with the higher-level control instance of the PROFINET network via the

PROFINET interface (X6/X7).

Notes regarding connetion concepts: → Configuration interfaces: Connection concepts (→ S. 115)

Technical data: → Technical data (→ S. 112)

>

36927

36913

36925

SD card slot

The SD card slot (X5) is located behind the front flap of the device. The following actions can be

performed with an SD card:

update the firmware of the device

save/restore the device configuration

Technical data: → Technical data (→ S. 112)

>

3.2.6 Required accessories

To be able to operate the device in a sensible way you need the following accessories (not supplied

with the device):

Depending on the selected voltage supply ( Operating instructions) you need:

a power supply for the 24 V power supply (e.g. art. no. DN3011)

for each AS-i master one AS-i power supply each (e.g. art. no. AC1236)

a data decoupling module AC1250 (accessory, optional)

AS-i slaves.

36761

36764

SmartPLC DataLine with Profinet device interface

14

4 Operation

Content

Control of the graphical user interface ...................................................................................................14

Menu view...............................................................................................................................................16

Page view ...............................................................................................................................................19

Remote access .......................................................................................................................................32

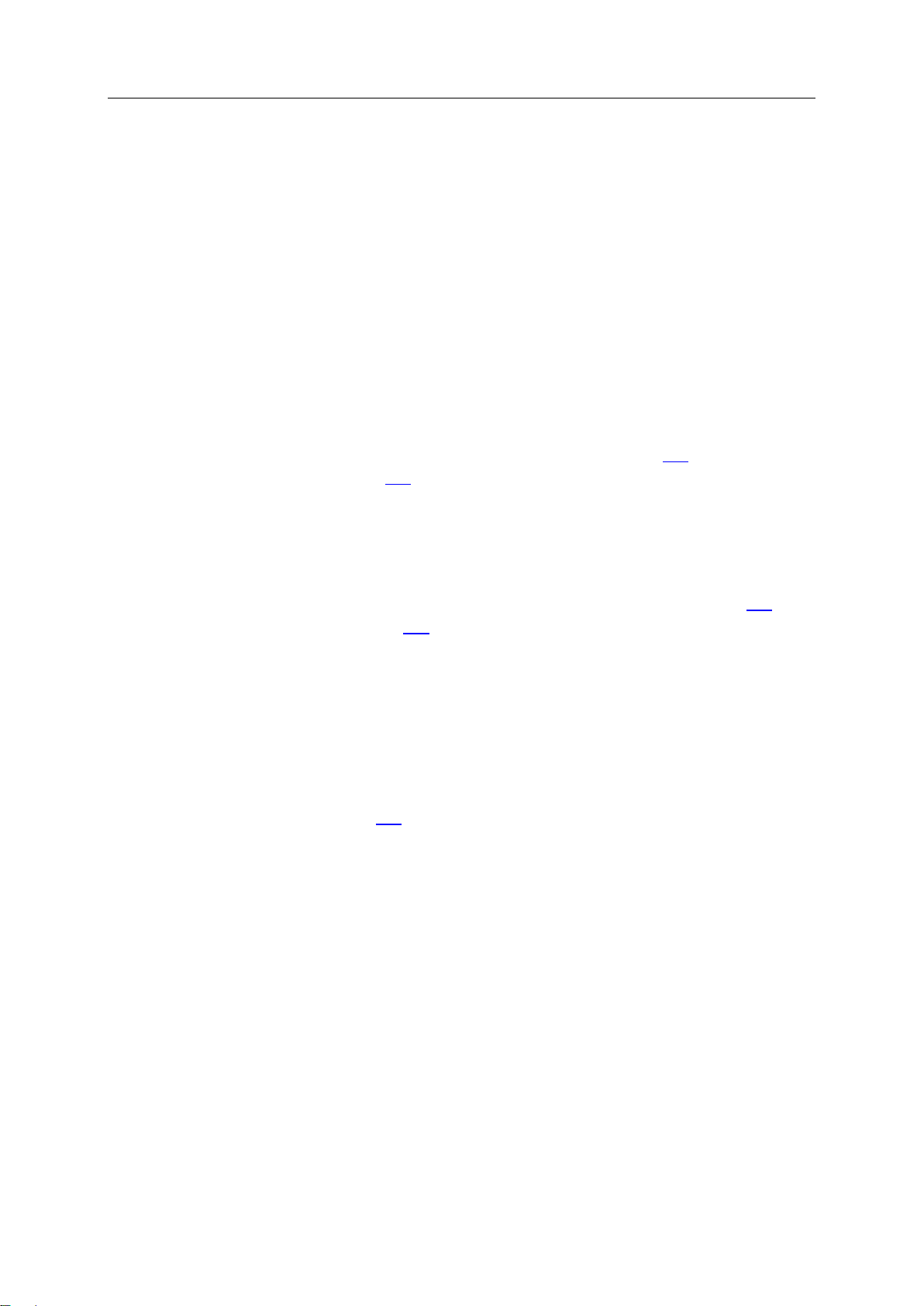

Legend:

Label left function key

Navigation compass

Label right function key

Right function key

Left function key

[] arrow key

[] arrow key

[] arrow key

[] arrow key

>

4.1 Control of the graphical user interface

Below the display is the key panel with six membrane keys. The operator controls the graphical user

interface of the device with these keys. The key panel is closely linked to the navigation status bar.

41713

41568

SmartPLC DataLine with Profinet device interface

15

>

The two function keys allow the operator to trigger specified

actions (e.g. tick a checkbox). The function of the function keys

changes depending on the context.

The two text fields in the navigation status bar are

associated with the function keys located directly below the

display. They indicate the action that will be triggered if the

function key is pressed in the current work step. If the function

key is not labelled, it means that it has no function in the

present situation.

Example (→ figure):

► The left function key triggers the action [Select].

► The right function key triggers the action [Back].

The fourarrow keys [], [], [] and [] can be used for

navigation and selection.

The navigation compass shows which of the four arrow keys

can be used in the respective work step.

Examples:

All arrow keys are active and will trigger a device

response when pressed.

Only the arrow keys [] and [] are active and will

trigger a device response when pressed.

4.1.1 Function keys

>

4.1.2 Arrow keys

41476

7091

SmartPLC DataLine with Profinet device interface

16

>

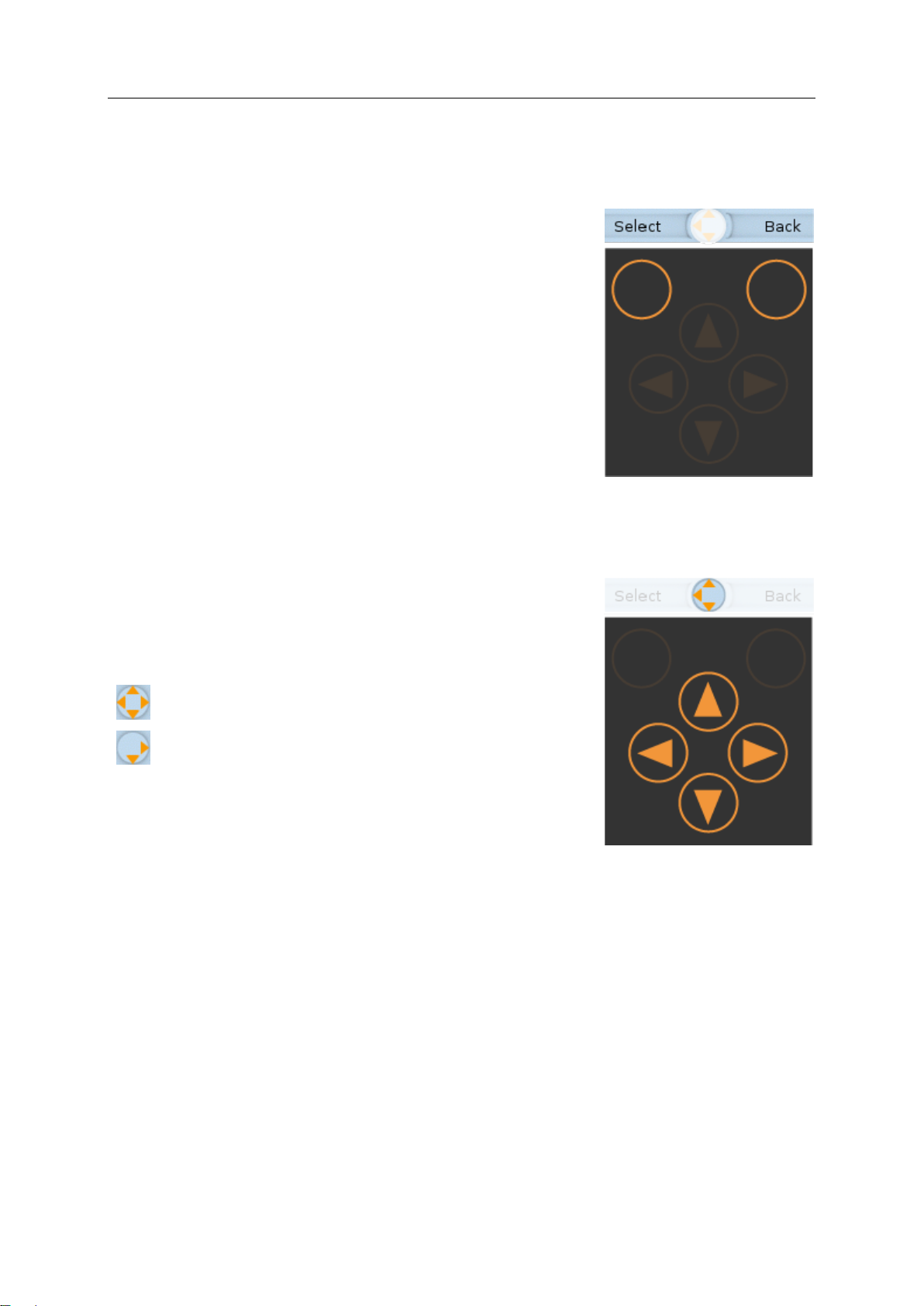

Legend:

Info bar

Main navigation bar

Subnavigation bar 1

Subnavigation bar 2

Selected menu item (focus)

Navigation status bar with

labelling of the function keys

navigation compass

Long texts are displayed as scrolling text in the info bar.

4.2 Menu view

41755

The menu view allows the user to select the menu page with the required control or display function.

>

4.2.1 Menu navigation

41756

The central operating elements in the menu view are the three navigation bars. They reflect the

menu structure of the device software. Each navigation bar represents a menu level. The symbols in a

navigation bar represent the submenus and menu items.

Rules for menu navigation:

► Use [] / [] to navigate within a menu level.

> The selected symbol has the focus (= orange frame).

> If the selected symbol has a submenu, the corresponding subnavigation bar will automatically

appear.

► Use [] to go one menu level down.

► Use [] to go one menu level up.

At th

e lowest menu level:

► Press [Select] function key to go to the page of the selected menu item (→Page view (→ S. 19)).

In the main navigation bar:

► Press [Back] function key to return to the start screen (→Start screen (→ S. 36)).

SmartPLC DataLine with Profinet device interface

17

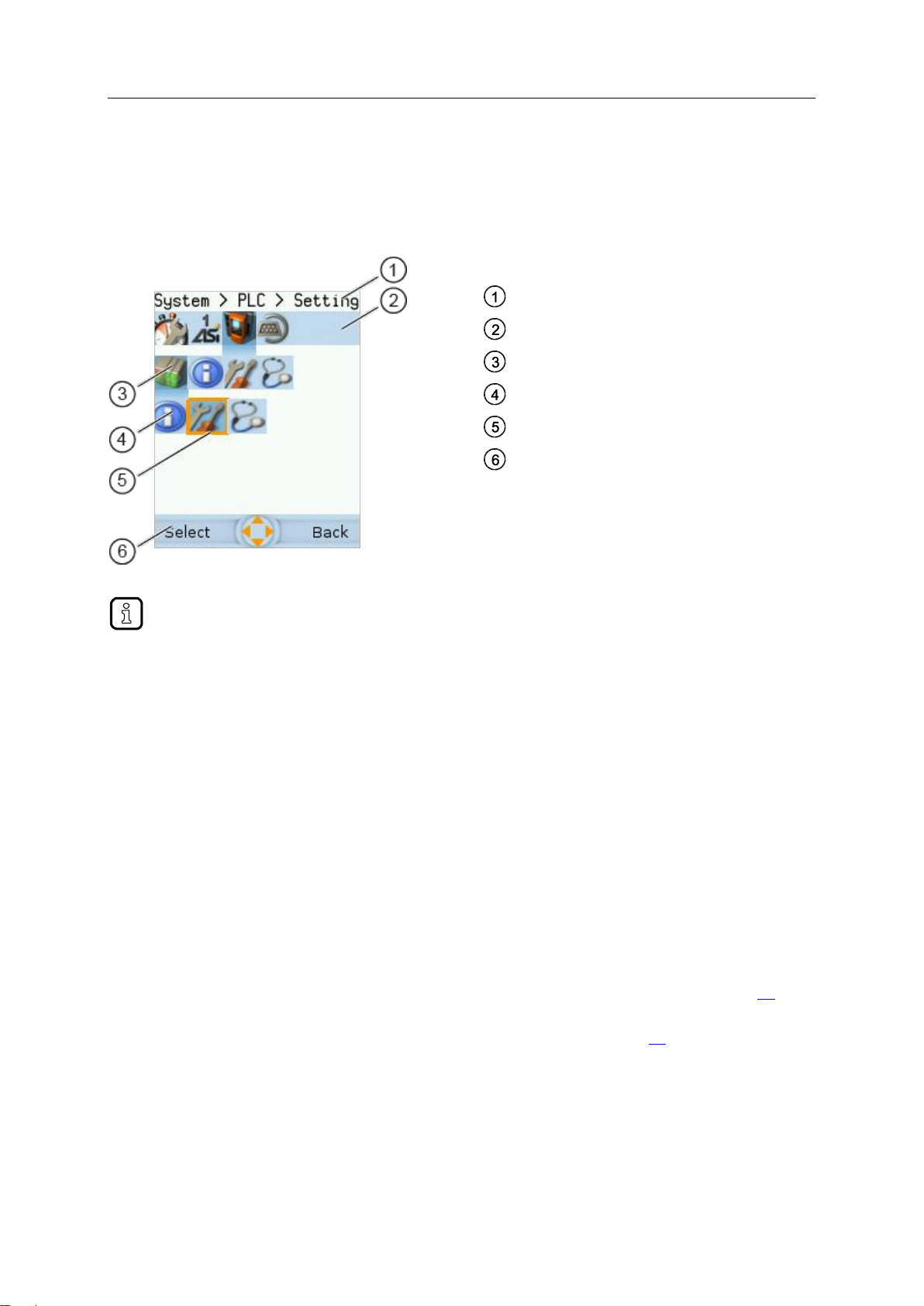

>

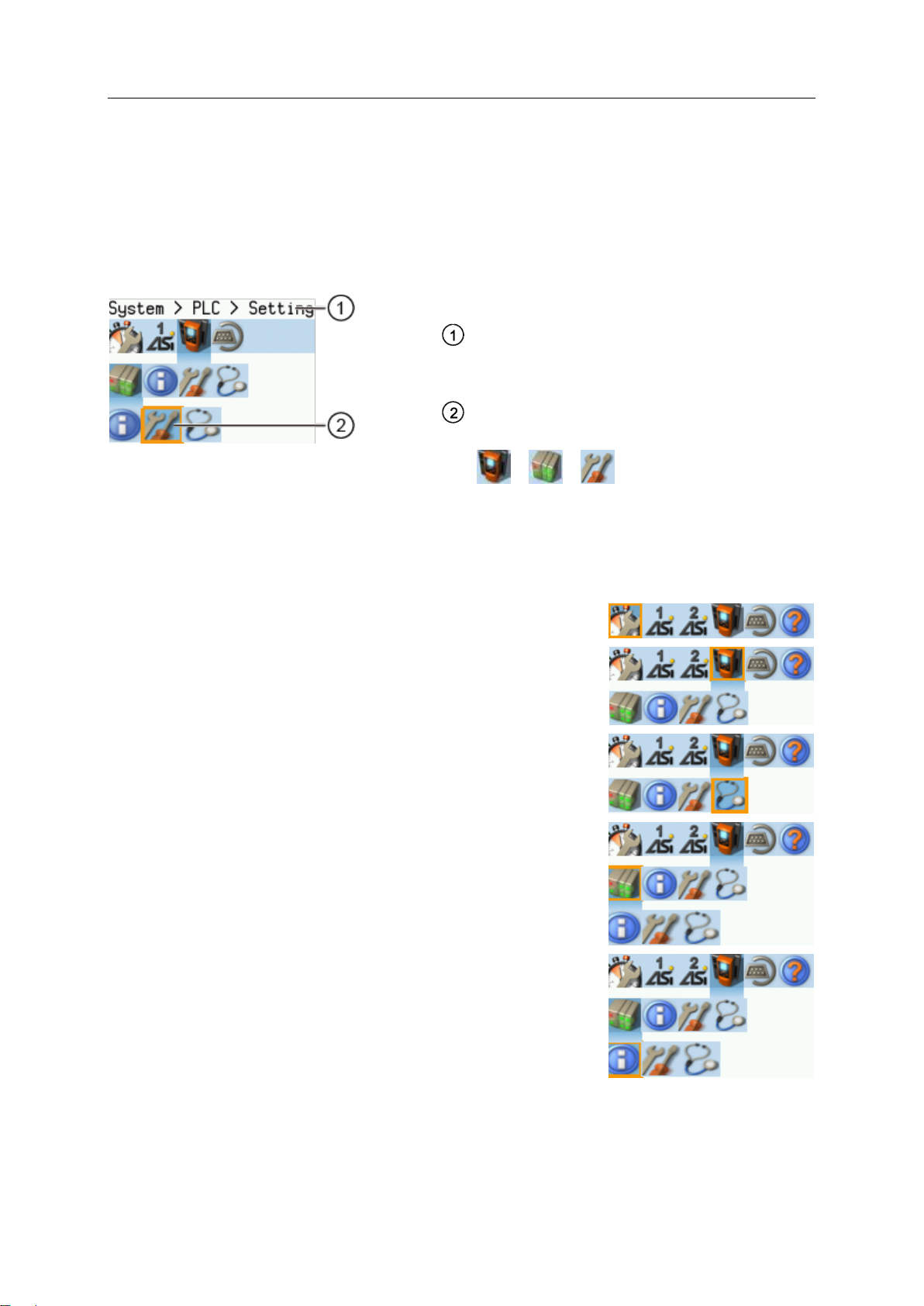

Legend:

Info bar

Navigation path to the focused menu element:

[System] > [PLC] > [Setup]

Menu element with focus

Navigation path to the focused menu element:

> >

1.

> Initial position when accessing the menu screen

2.

► Use [] to select the [System] menu symbol.

> The focus is on the [System] menu symbol.

> The first subnavigation bar appears.

3.

► Use [] to change to the first subnavigation barh.

> The focus is on the [Diagnosis] menu symbol.

4.

► Use [] to select the [PLC] menu symbol.

> The focus is on the [PLC] menu symbol.

> The second subnavigation bar appears.

5.

► Use [] to change to the second subnavigation bar.

> The focus is on the [Information] menu symbol.

4.2.2 Navigation aids

The following screen elements help you navigate through the menu:

> The info bar shows the navigation path of the selected menu symbol.

> The navigation compass shows which navigation steps are possible from the current position.

>

Example

To access the menu page containing the setting options for the device-internal PLC:

41748

41499

SmartPLC DataLine with Profinet device interface

18

6.

► Use [] to select the [Settings] menu symbol.

> The focus is on the [Settings] menu symbol.

► Press the [Select] function key to go to the page view

of the [Settings] menu item.

> The page shows the setting options for the

device-internal PLC.

SmartPLC DataLine with Profinet device interface

19

>

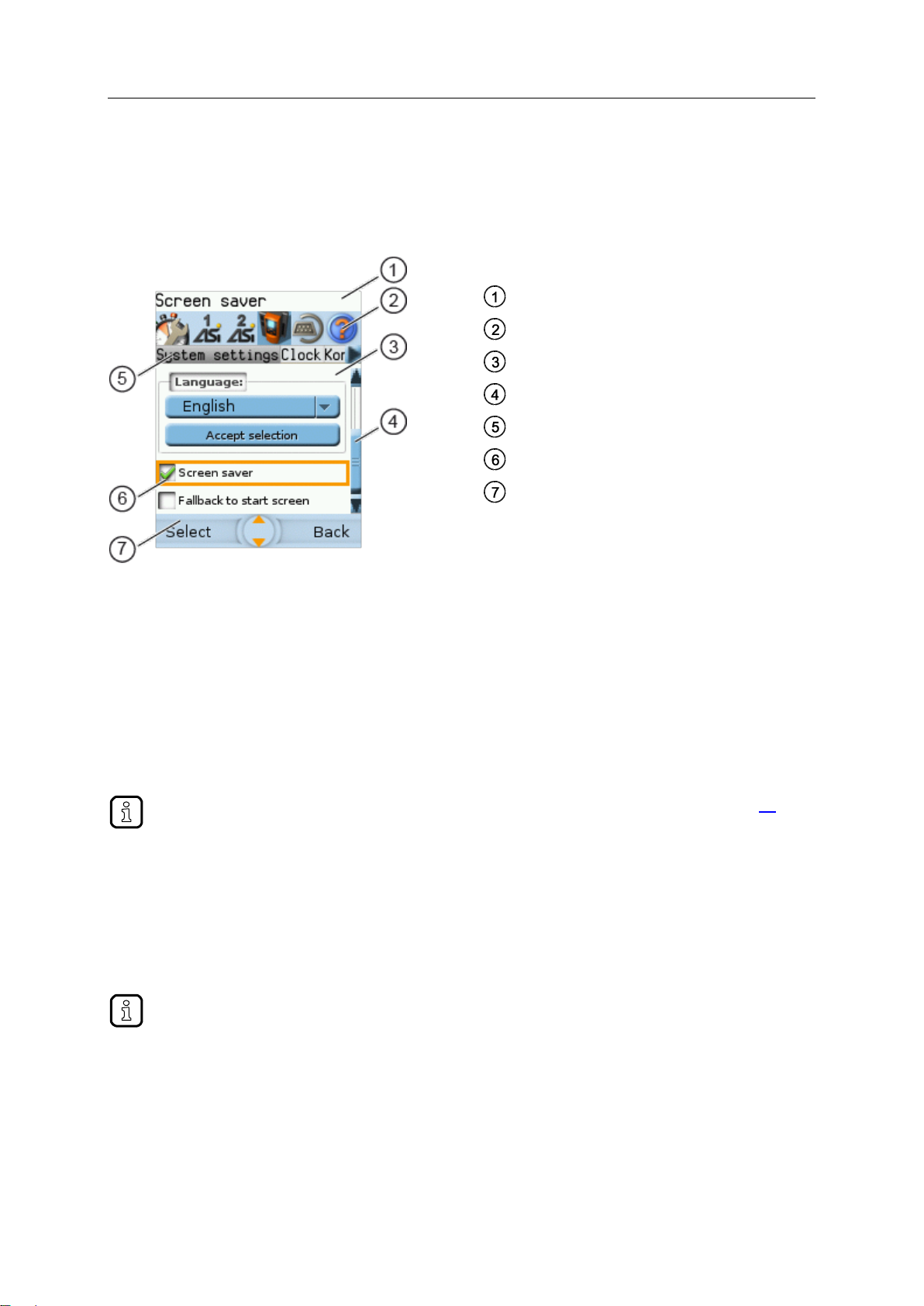

Legend:

Info bar

Main navigation bar

Page

Scroll bar

Tab menu

Page element with focus

Navigation status bar with

labelling of function keys

navigation compass

Rules for using the different control elements: →Description of the control elements (→ S. 20)

Long texts are displayed as scrolling text in the info bar.

4.3 Page view

The page view allows the user to select and execute a requested function.

>

41786

4.3.1 Navigate on a page

The page contains elements, that allow the operator to control the device or access information.

For page navigation, the following basic rules apply:

► Use the arrow keys [] / [] to change between the different page elements.

> The selected element is marked (= orange frame).

► Use the [Back] function key to return to the tab menu / menu view.

>

4.3.2 Use navigation aids

The following aids offer navigation users additional orientation:

> The info bar shows detailed information about the selected element (focus).

> The active menu symbol in the main navigation bar has a dark background.

> A scroll bar appears on the right side of the screen if the elements do not fit on the page.

> The navigation compass shows the navigation options in the active work step.

> The text fields in the navigation status bar show the current assignment of the function keys.

41749

41678

SmartPLC DataLine with Profinet device interface

20

>

Content

Tab menu/Tab ........................................................................................................................................21

Button .....................................................................................................................................................22

Checkbox ................................................................................................................................................22

List ..........................................................................................................................................................23

Slave selector .........................................................................................................................................24

Confirmation message ............................................................................................................................29

Numerical field ........................................................................................................................................30

Binary field ..............................................................................................................................................31

4.3.3 Description of the control elements

A page consists of different control elements.

41586

SmartPLC DataLine with Profinet device interface

21

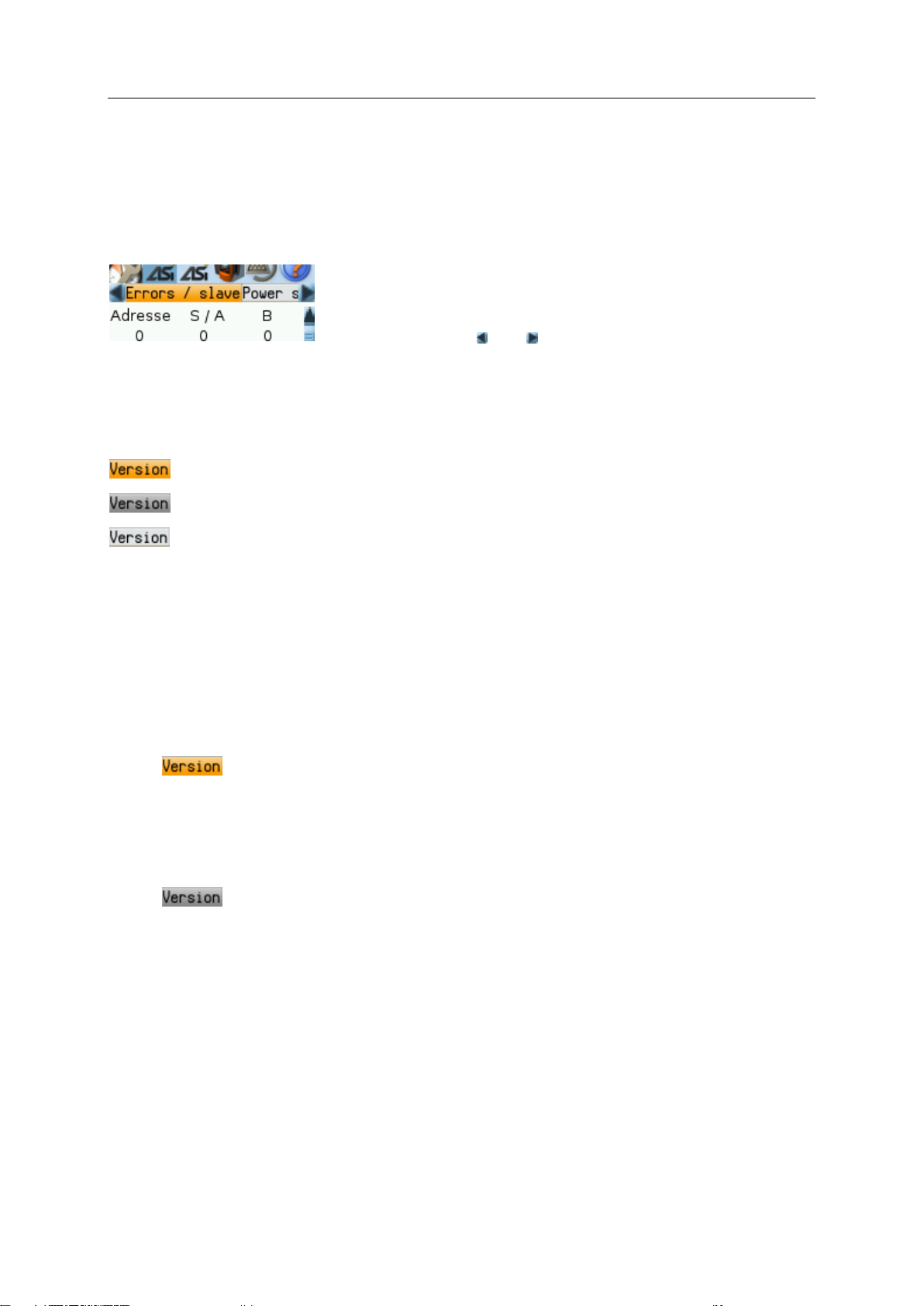

>

> The focused tab has an orange background

> The info bar displays the name of the active tab (in this

example: Errors / slave).

> The symbols and indicate that there are more tabs on

the left and right sides of the visible tab.

> The page shows the control elements that belong to the

currently selected tab.

=

Tab has the focus

=

Tab is active

=

Tab is inactive

Tab menu/Tab

A tab menu groups together the different functions of a menu page. A tab menu consists of at least

two tabs. A tab combines related functions.

Example:

Tabs can have the following background colours:

Use:

1 Select the menu item

► Go to the menu item with the tab menu.

> The tab menu appears.

> The focus is on the left-hand tab.

2 Select a tab

► Use [] / [] arrow key to select the desired tab.

> The focus (orange background) moves to the selected tab:

> The page shows the functions of the selected tab.

3 Activate the menu page

► Press [Select] arrow key to go to the page that belongs to the active tab.

> When going to the page, the tab menu remains visible.

> The background colour of the active tab turns grey.

4 Carry out the desired functions

► Use [] to select and execute the desired function.

5 Change to tab menu

► Press [Back] function key to change to the tab menu.

> The focus (orange background) moves to the active tab.

41675

SmartPLC DataLine with Profinet device interface

22

>

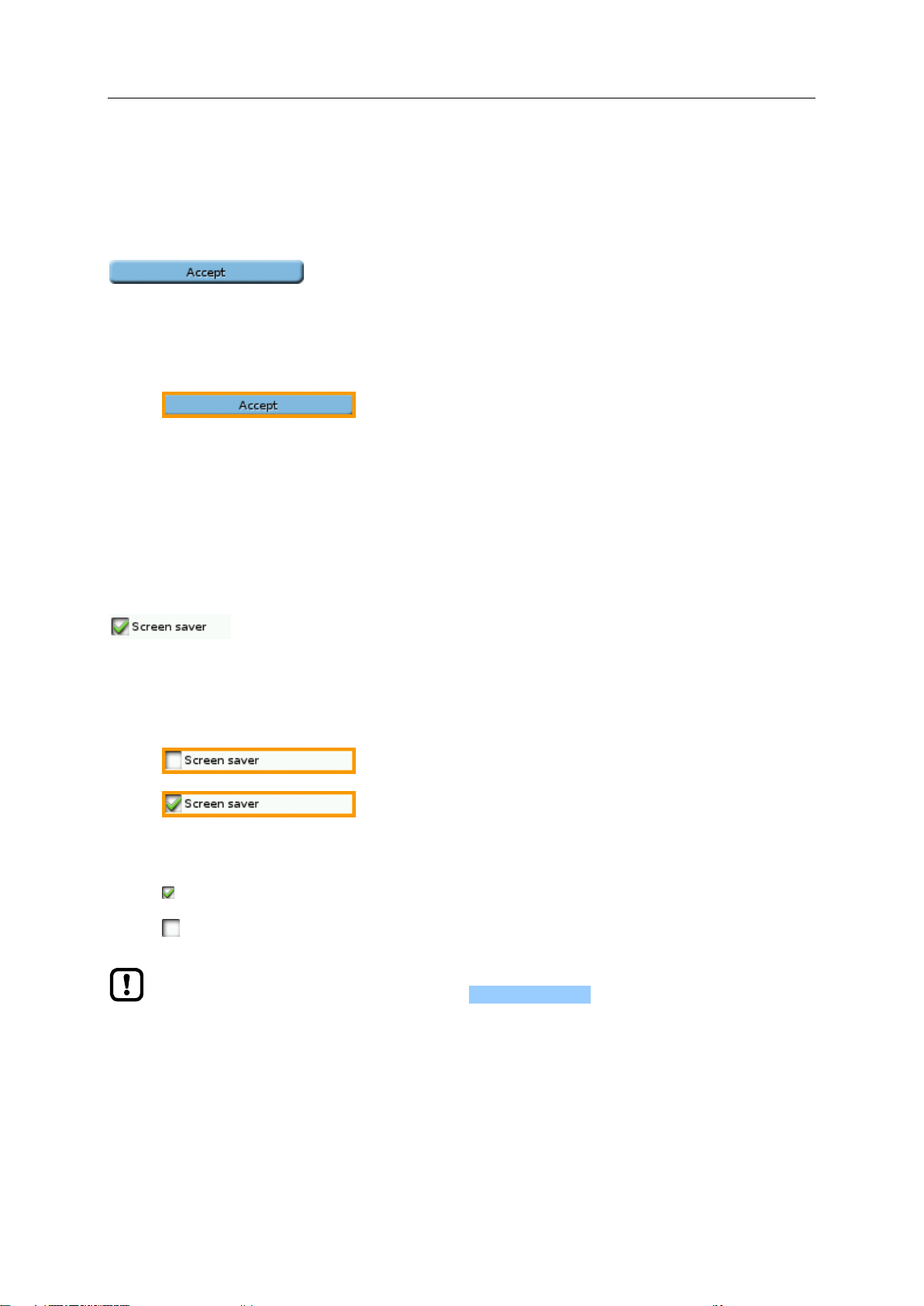

The setting or clearing of a checkbox is not always immediately effective. Often the change

must be confirmed by clicking a button (e.g. [Accept selection])!

Button

41536

A button allows the operator to carry out a specified action once. The caption on the button describes

the action.

Example:

Use:

1 Select a button

► Use the arrow keys [] / [] to select a button.

> The selected button gets an orange frame:

2 Activate the button

► Use [Select] function key to activate the selected button.

> The function is executed.

>

Checkbox

41600

A checkbox permits the user to activate/deactivate a parameter. A checkbox control element consists

of a checkbox and a caption.

Example:

Use:

1 Select a checkbox

► Use [] / [] arrow key to select the checkbox

> The focus (orange frame) moves to the selected checkbox

OR:

2 Check/uncheck a checkbox

► Use [Select] function key to check/uncheck the selected checkbox.

> The status change is indicated:

= checkbox is checked

OR:

= checkbox is unchecked

SmartPLC DataLine with Profinet device interface

23

>

= list without caption

= list with caption

The set value will not always become effective immediately. Often the change must be

confirmed by clicking a button (e.g. [Accept selection])!

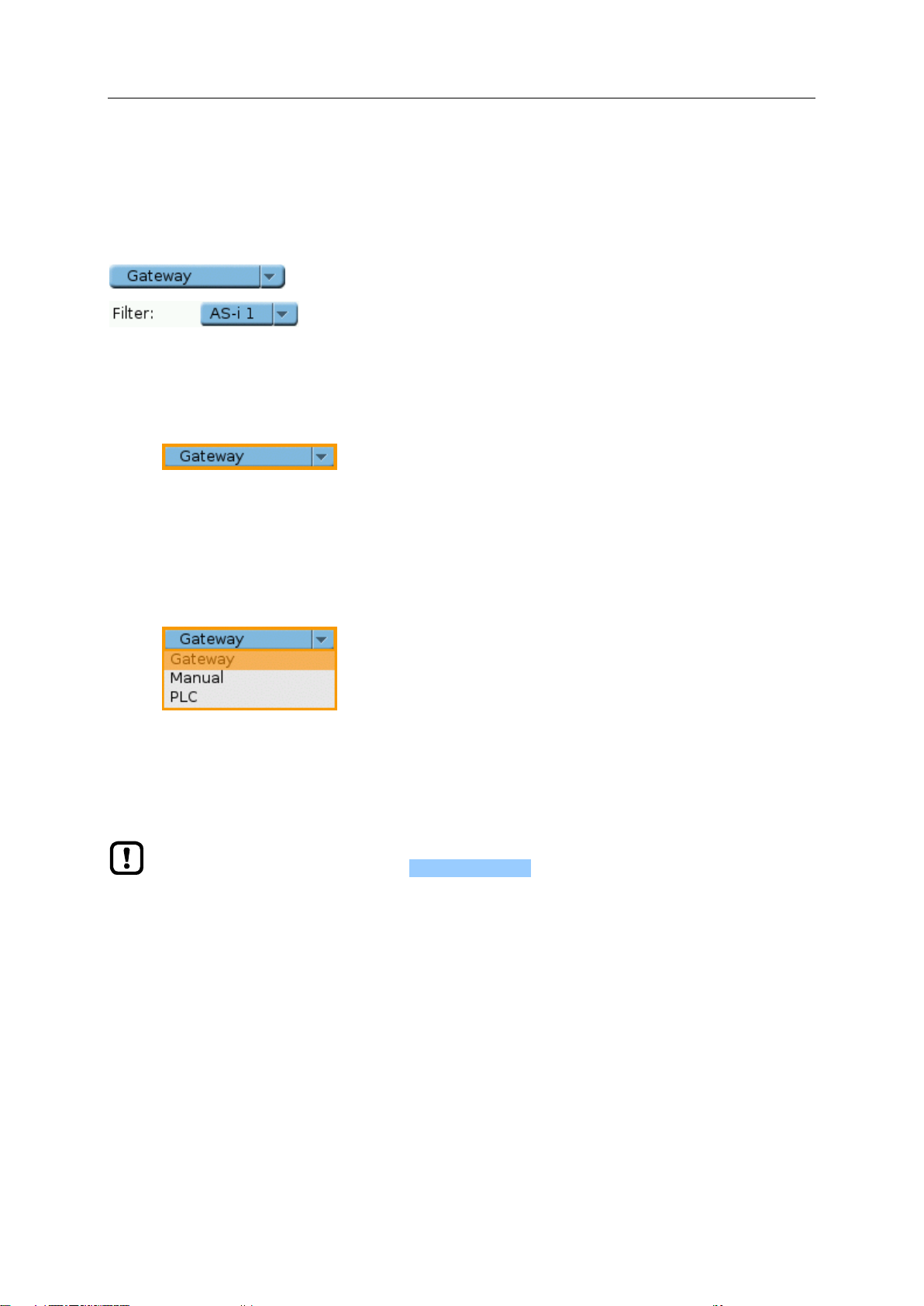

List

41484

A list provides a set of defined values. The operator can select precisely one value from this set (= 1 of

n selection).

Examples:

Use:

1 Select a list

► Use [] / [] arrow key to select the list.

> The focus (orange frame) moves to the selected list.

> The list shows the active value: (in this exampleGateway).

2 Activate the list

► Use [Select] function key to open the list.

> The opened list shows the selectable values.

3 Select a value

► Use [] / [] arrow key to select the desired value from the list.

> The background colour of the selected value turns orange.

4 Apply the selected value

► Use [Select] function key to apply the selected value.

OR:

Use [Back] function key to quit and close the list.

> The list shows the selected value.

SmartPLC DataLine with Profinet device interface

24

>

Content

Overview of slave states .........................................................................................................................25

Overview of free slave addresses ..........................................................................................................27

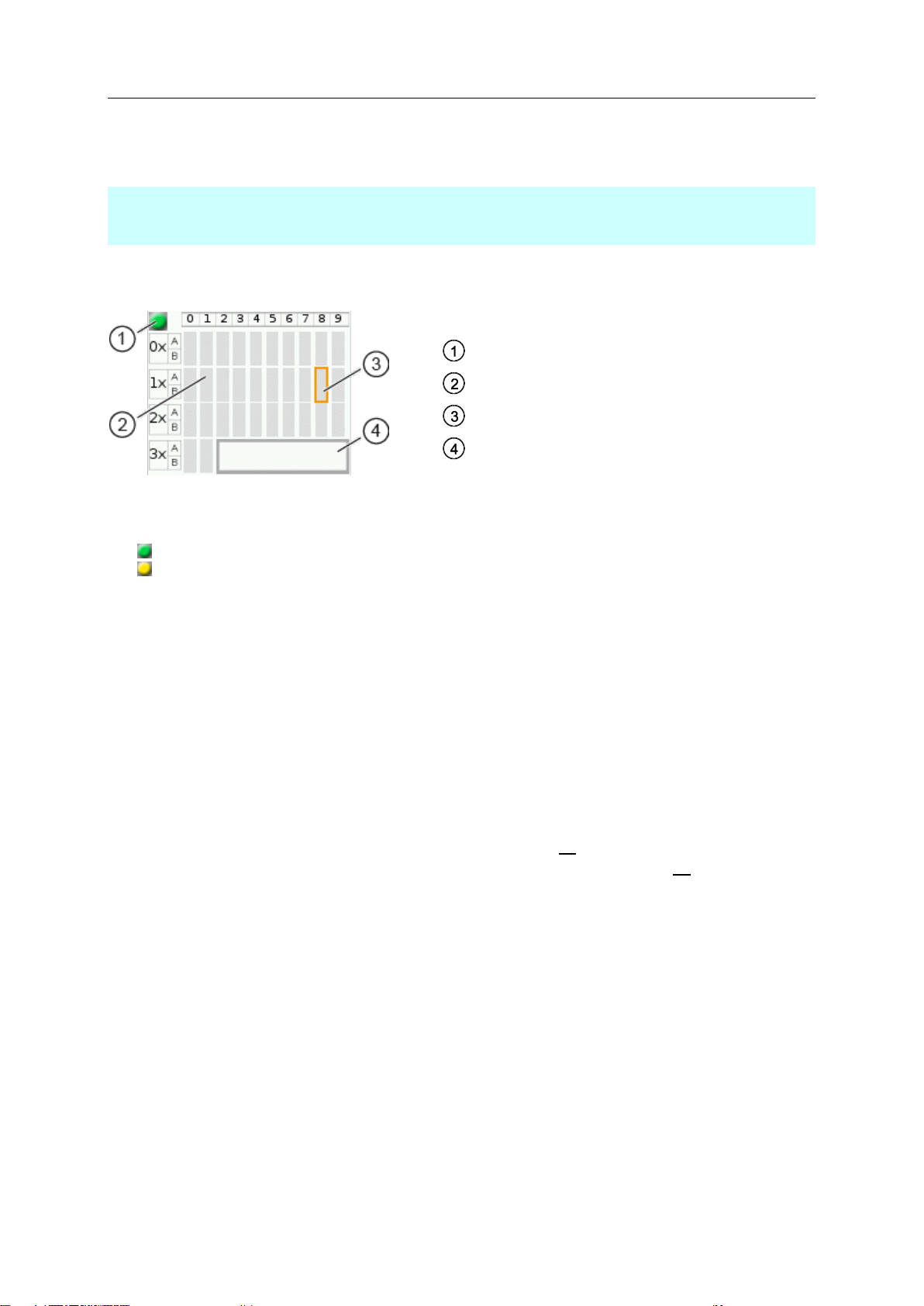

Legend:

Indicator of AS-i master operating mode

AS-i address symbol

Highlighted AS-i address (focus)

Status message of highlighted AS-i address

Slave selector

The slave selector is used to select an AS-i slave or an AS-i address.

> The status LED indicates the active operating mode of the AS-i master:

= AS-i master in protected mode

= AS-i master in projection mode

> Every field represents an AS-i address. An AS-i address can be occupied by:

– a single slave symbol

– an A/B slave pair symbol

> The row and column headers help to locate the AS-i address.

Example: address of the field selected in the picture

– row header: 1x (= tens digit of the AS-i address)

– column header: 8 (= units digit of the AS-i address)

– type of slave: single slave (= symbol fully occupies the address field)

– resulting AS-i address: 18

> The symbol of the A/B slave pair appears when an A or B slave is used on this address.

The slave selector is used in the following overviews:

Overview of slave states (→ Overview of slave states (→ S. 25))

Overview of free slave addresses (→ Overview of free slave addresses (→ S. 27))

41653

SmartPLC DataLine with Profinet device interface

25

>

> The slave selector shows an overview of the slaves in the

selected AS-i network.

> The symbol colour signals the slave status. Meaning of

symbols and colours:

→ Slave status: colour code + symbols (→ S. 26)

> The text field displays the status of the selected AS-i slave.

Possible status messages:

Slave active

Not projected (= configuration error)

Double address (= double address error)

Periphery (= periphery fault)

Overview of slave states

Use:

1 Select an AS-i slave

► Use the arrow keys [], [], [] and [] to select the desired AS-i slave.

> The focus (= orange frame) is on the selected AS-i slave.

> The info bar shows the address of the selected AS-i slave.

> The text field shows a status message about the selected AS-i slave.

2 Activate the selected AS-i slave

► Use [Select] function key to activate the selected AS-i slave and go to the next menu page.

OR:

Use [Back] function key to cancel and leave the slave selector.

41728

SmartPLC DataLine with Profinet device interface

26

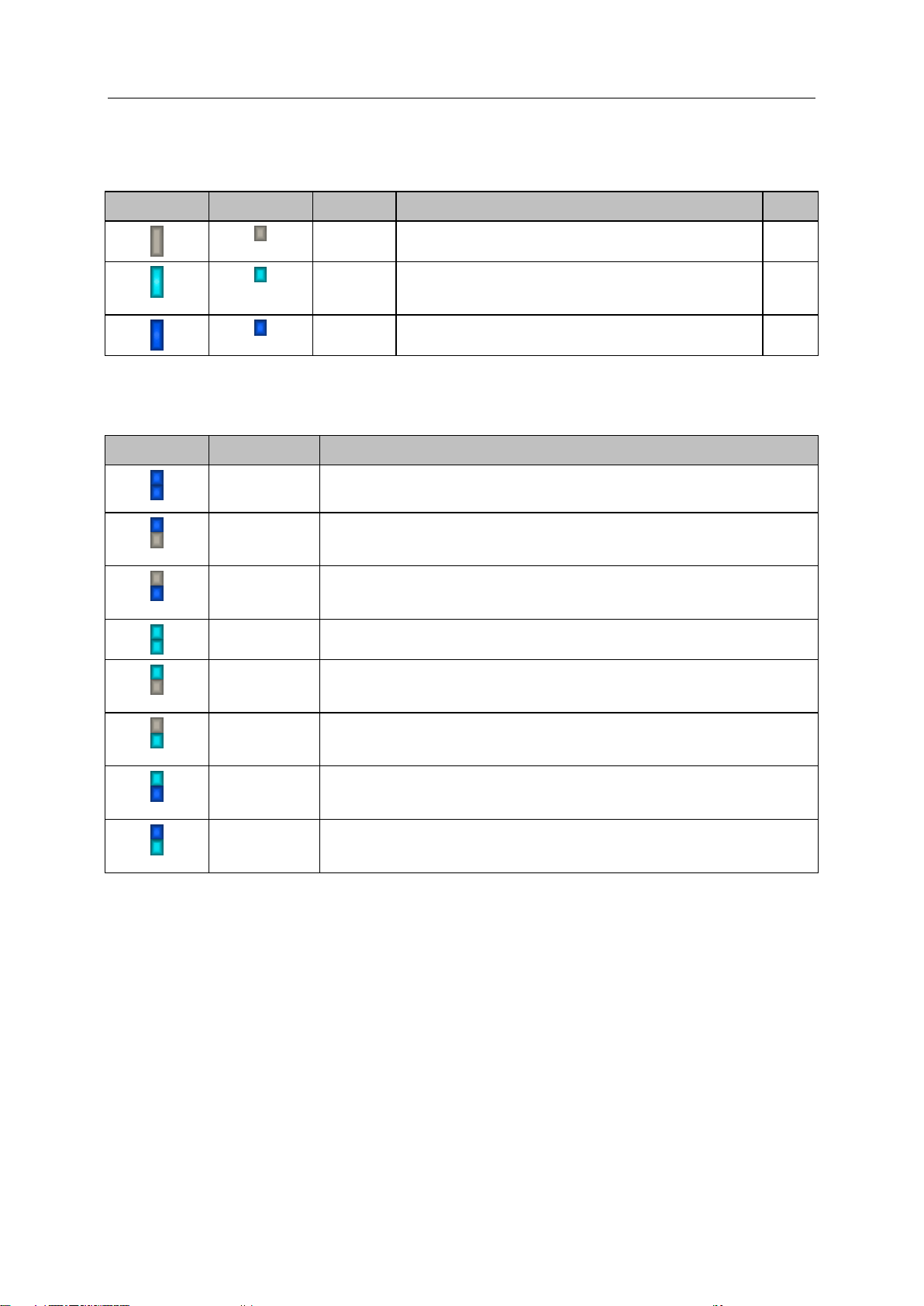

>

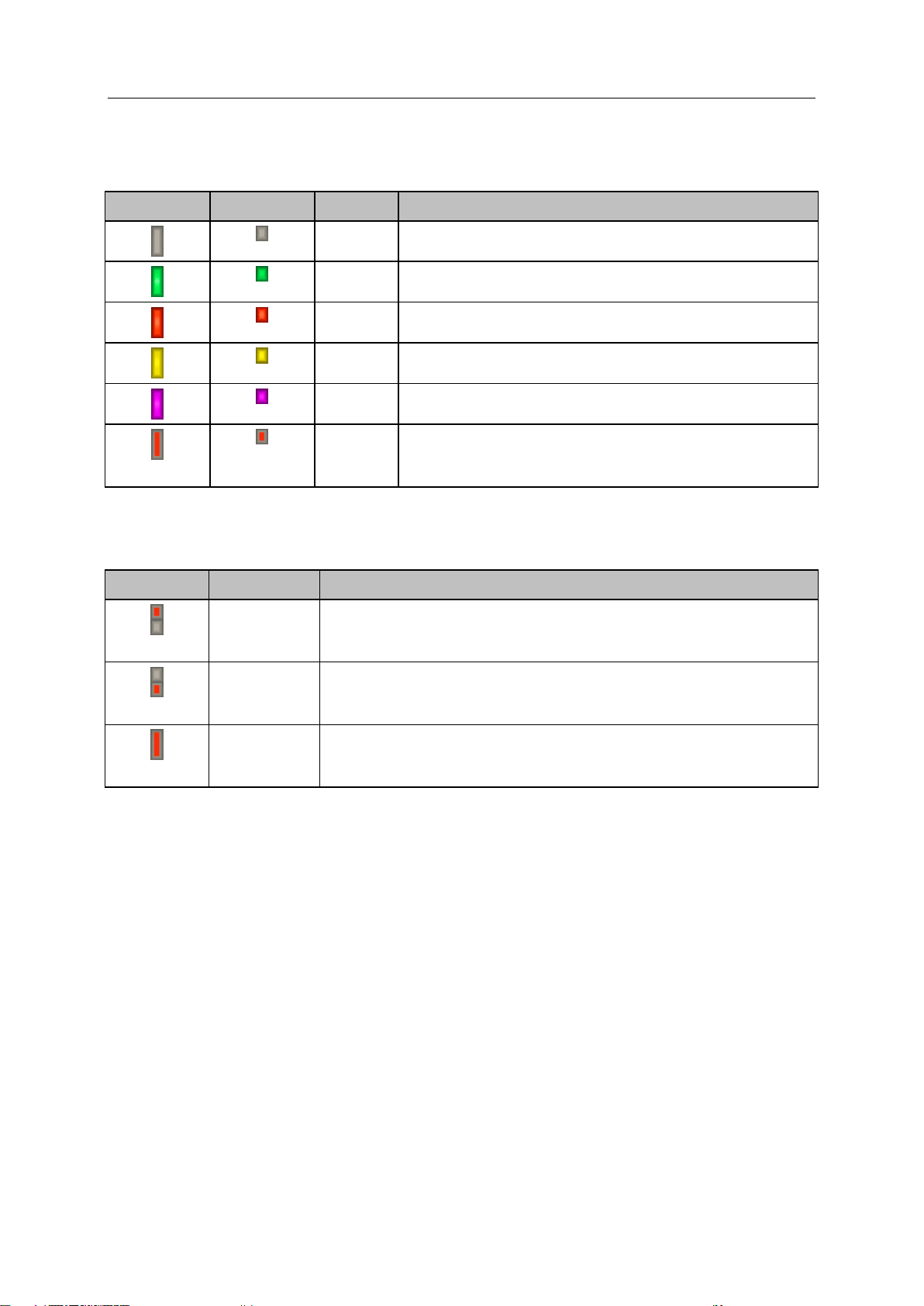

Single slave

A/B slave

Colour

Meaning

grey

No slave found:

slave address is neither in the LPS nor in the LDS

green

Slave is activated ( in LAS)

red

Configuration error type 1:

slave is projected (in LPS) but was not found (in LDS)

yellow

Slave signals a peripheral fault

pink

Several slaves have the same address (double address error)

grey red

Configuration error type 2:

the found slave (in LDS) is not projected (in LPS)

the found slave has another profile than projected

Symbol

Colour

Meaning

grey red

grey

Configuration error type 2:

Single slave is projected (in LPS) but was not found (in LDS).

Instead, a new A slave with the same address was installed.

grey

grey red

Configuration error type 2:

Single slave is projected (in LPS) but was not found (in LDS).

Instead, a new B slave with the same address was installed.

grey red

Configuration error type 2:

A or B slave is projected (in LPS) but was not found (in LDS).

Instead, a new single slave with the same address was installed.

Slave status: colour code + symbols

>

Meaning of the colour combinations (example: configuration error type 2)

41652

41741

SmartPLC DataLine with Profinet device interface

27

>

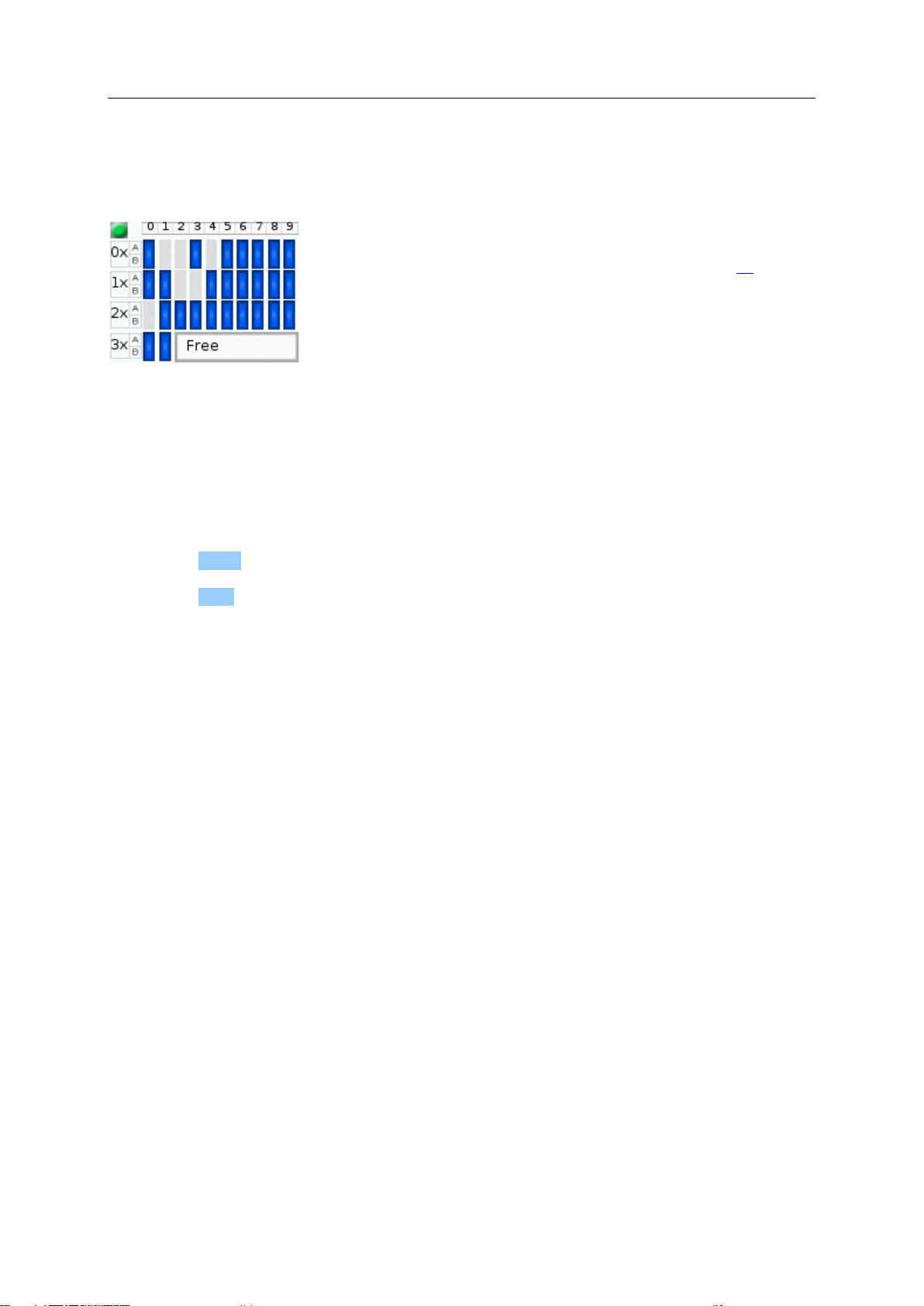

> The symbol colour indicates the state of the AS-i address.

Meaning of symbols and colours:

→ Free slave addresses: colour code + symbols (→ S. 28)

> The text field displays the status of the selected AS-i slave.

Possible status messages:

Free

Missing slave

Overview of free slave addresses

In this overview, the slave selector shows the free and occupied AS-i addresses.

Use:

1 Select the AS-i address

► Use the arrow keys [], [], [] and [] to select the desired AS-i address.

> The focus (= orange frame) is on the selected AS-i address.

> The info bar displays the selected AS-i address.

> The text field shows a status message for the selected AS-i address.

2 Activate the selected AS-i address

► Press [Select] function key to activate the selected AS-i address and go to the next menu page.

OR:

Press [Back] function key to cancel and leave the slave selector.

41729

SmartPLC DataLine with Profinet device interface

28

>

Single slave

A/B slave

Colour

Meaning

Prio.

grey

Slave address is already used.

--

turquoise

Address is free according to LDS (= no slave found), however:

address already belongs to a stored projection (= application

profile).

1

blue

Address is free according to LDS (= no slave found).

Address is not used in a stored projection (= application profile).

2

Symbol

Colour

Meaning

blue

blue

Slave to be addressed is an A/B slave:

A and B addresses are free.

blue

grey

Slave to be addressed is an A/B slave:

– A address is free.

– B address is used.

grey

blue

Slave to be addressed is an A/B slave:

– A address is used.

– B address is free.

turquoise

turquoise

Slave to be addressed is an A/B slave:

A and B addresses are free, but already used in a stored projection.

turquoise

grey

Slave to be addressed is an A/B slave:

– A address is free, but already used in a stored projection.

– B address is used.

grey

turquoise

Slave to be addressed is an A/B slave:

– A address is used.

– B address is free, but already used in a stored projection.

turquoise

blue

Slave to be addressed is an A/B slave:

– A address is free, but already used in a stored projection.

– B address is free.

blue

turquoise

Slave to be addressed is an A/B slave:

– A address is free

– B address is free, but already used in a stored projection.

Free slave addresses: colour code + symbols

>

Meaning of the colour combinations

41493

41736

SmartPLC DataLine with Profinet device interface

29

>

> Action: Change AS-i slave address from 1a to 1b

> Confirmation message shows:

Action (= Change AS-i address)

Slave address prior to change

Slave address after change

> The operator has the following input options:

[Select] function key

[Back] function key

Confirmation message

The confirmation message is a security prompt. It appears when important changes are made to the

system settings. The confirmation message shows the changes made. For the changes to become

effective, they first need to be acknowledged by the operator.

Example:

Use:

1 Change the settings

► Change the system settings.

> The confirmation message appears.

2 Confirm the message

► Press [Select] function key to confirm the changes and apply the new value.

OR:

Press [Back] function key to reject the changes and continue to use the old value.

> The page displays the valid settings.

41606

SmartPLC DataLine with Profinet device interface

30

>

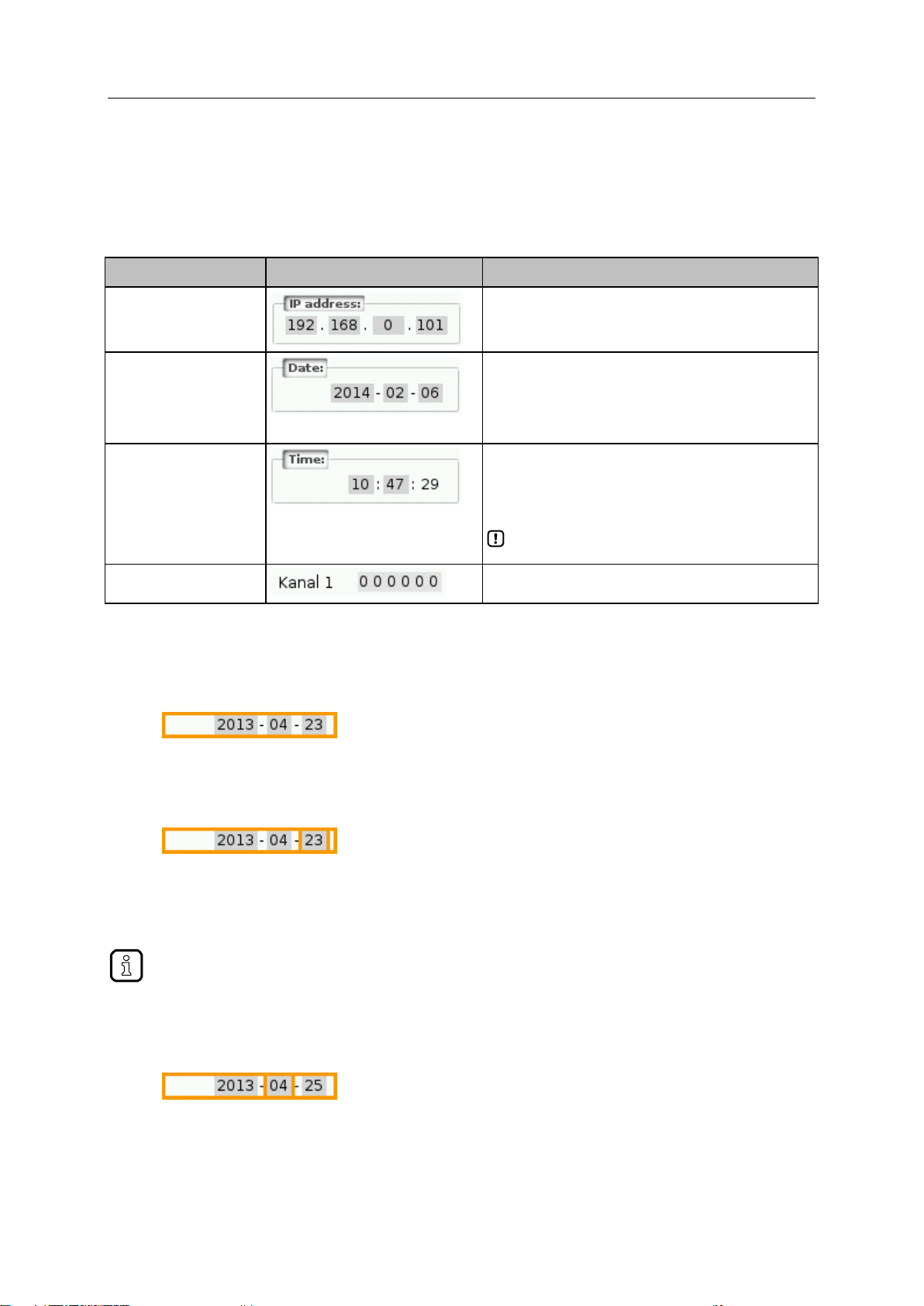

Control element

Example

Meaning

IP address

Entry of an IP address (IPv4) in [w.x.y.z] format

w | x | y | z = network segments (value range: 0... 255)

Date Date entry in [yyyy-mm-ss] format

yyyy = year (value range: 0000 ... 9999)

mm = month (value range: 01 ... 12)

dd = day (value range: 01 ... 31)

Time

Time entry in [hh:mm:ss] format

hh = hours (value range: 00 ... 12)

mm = minutes (value range: 00 .... 59)

ss = seconds (value range: 00 ... 59)

The numerical field for seconds (ss) cannot be

edited!

Analogue value

Entry of an analogue output value

Value range (per numerical field): 0 ... 9

Press and hold the arrow key [] / [] to rapidly move through larger value ranges.

Numerical field

The numerical field allows the operator to enter integer values. The value range is context-specific.

Numerical fields are part of the following GUI elements:

41720

Use (using the example of the numerical date field):

1 Select a numerical field

► Use [] / [] arrow key to select the date control element.

> The focus (= orange frame) is on the selected date control element.

> The date control element displays the current date

2 Activate the editing mode

► Press [Select] function key to enter the editing mode.

> The focus (orange frame) is on the right element

3 Set the desired value

► Use [] / [] arrow key to increment the desired value.

> The segment displays the new value.

4 Select the next segment

► Use the arrow key [] / [] to mark the segment to be edited.

> The focus (orange frame) moves to the marked segment

► Optional: Repeat steps 3 and 4 until all segments have the desired values.

Loading...

Loading...