Page 1

Supplementary device manual

AS-i controllere with Profibus DPV1

A

AC1355, AC1356

AC1365, AC1366

AS-i master profile: M4

Firmware: from version RTS 3.0 onwards

Target: from V.15 onwards

®

for CoDeSys

from version 2.3 onwards

7390702 / 01 08 / 2008

1

Page 2

2

As on: 14 Aug. 2008

© All rights reserved by ifm electronic gmbh.

No part of this manual may be reproduced and used

without ifm electronic's consent.

Page 3

Contents

1

On this manual .........................................................................................................................1-1

1.1 What do the symbols and formats stand for?................................................................ 1-1

1.2 What devices are described in this manual?................................................................. 1-2

1.3 How is this manual structured? ..................................................................................... 1-2

1.4 Overview: where is what? ............................................................................................. 1-3

2 Safety instructions................................................................................................................... 2-1

2.1 General.......................................................................................................................... 2-1

2.2 What previous knowledge is required? ......................................................................... 2-1

2.3 Functions and features.................................................................................................. 2-1

3 System requirements............................................................................................................... 3-1

3.1 Information concerning the device ................................................................................ 3-1

3.2 Information concerning the software ............................................................................. 3-1

3.3 Required accessories.................................................................................................... 3-1

4 Getting started.......................................................................................................................... 4-1

4.1 Connection .................................................................................................................... 4-1

4.2 Set up the AS-i master .................................................................................................. 4-1

4.3 Set up Profibus DPV1 ................................................................................................... 4-1

5 Function.................................................................................................................................... 5-1

5.1 Data management......................................................................................................... 5-1

5.2 Status LED for the fieldbus............................................................................................ 5-2

5.3 Which operating modes are there for the PLC in the controllere? ................................ 5-2

6 Menu..........................................................................................................................................6-1

6.1 Main menu [Quick Setup] .............................................................................................. 6-1

6.2 Main menu [Fieldbus Setup].......................................................................................... 6-2

7 Set-up ........................................................................................................................................ 7-1

7.1 Parameter setting of the controllere.............................................................................. 7-1

7.1.1 Parameter setting of slaves in the controllere.................................................. 7-1

7.1.2 Set the parameters of the fieldbus interface in the controllere......................... 7-1

7.2 Connect the controllere to the Profibus host ................................................................. 7-2

7.3 Parameter setting of the Profibus host.......................................................................... 7-2

7.3.1 Assigning the addresses of the inputs/outputs to the host "locations"............. 7-4

7.3.2 Assign PLC addresses to the Profibus modules ............................................ 7-11

7.3.3 Define Profibus DP modules .......................................................................... 7-13

3

Page 4

Device-specific Profibus DP parameters..................................................................... 7-25

7.4

7.4.1 Device-specific Profibus DP parameters (example)....................................... 7-25

7.4.2 Definitions in the GSD file............................................................................... 7-26

7.5 Finish set-up ................................................................................................................ 7-27

8 DP module 7: Command channel........................................................................................... 8-1

8.1 List of commands in module 7....................................................................................... 8-1

8.2 Module 7, command 1: read master flags.................................................................... 8-2

8.3 Module 7, command 2: change operating mode.......................................................... 8-3

8.4 Module 7, command 3: read current slave configuration ............................................. 8-4

8.5 Module 7, command 4: read projected slave configuration ......................................... 8-5

8.6 Module 7, command 5: change projected slave configuration..................................... 8-6

8.7 Module 7, command 6: read slave parameter.............................................................. 8-7

8.8 Module 7, command 7: change projected slave parameters ....................................... 8-8

8.9 Module 7, command 8: read LAS (list of active slaves) ............................................... 8-9

8.10 Module 7, command 9: read LDS (list of detected slaves) ........................................ 8-11

8.11 Module 7, command 10

8.12 Module 7, command 11

8.13 Module 7, command 13

8.14 Module 7, command 14

8.15 Module 7, command 15

8.16 Module 7, command 16

8.17 Module 7, command 19

8.18 Module 7, command 21

8.19 Module 7, command 22

8.20 Module 7, command 23

8.21 Module 7, command 62

8.22 Module 7, command 63

dec

dec

dec

dec

dec

dec

dec

dec

dec

dec

dec

dec

(0A

): read LPF (list of slaves with periphery fault)....... 8-12

hex

(0B

): read LPS (list of projected slaves) ...................... 8-13

hex

(0D

): read telegram error counter ................................ 8-14

hex

(0E

): read configuration error counter.......................... 8-15

hex

(0F

): read AS-i cycle counter ....................................... 8-16

hex

(10

): change current slave parameters........................ 8-17

hex

(13

): config. all ............................................................. 8-18

hex

(15

): save configuration in flash ................................... 8-19

hex

(16

): reset telegram error counter of a slave ............... 8-20

hex

(17

): address slave ...................................................... 8-21

hex

(3E

): operating mode "continuous command“ ............. 8-22

hex

(3F

): no operation command without function ............. 8-23

hex

9 DP module 12: Extended command channel ........................................................................ 9-1

9.1 List of extended commands in module 12..................................................................... 9-1

9.2 Data structure ................................................................................................................ 9-3

9.3 Error codes in the module 12 ........................................................................................ 9-5

9.4 CTT2 error code in module 12 ...................................................................................... 9-5

9.5 Module 12, extended command 0: no execution of a command ................................. 9-6

9.6 Module 12, extended command 1: write parameters to a connected AS-i slave......... 9-7

9.7 Module 12, extended command 3: adopt and store connected AS-i slaves in the

configuration ..................................................................................................................

9.8 Module 12, extended command 4: write LPS ............................................................ 9-11

9.9 Module 12, extended command 5: set the operating mode of the AS-i master......... 9-13

9.10 Module 12, extended command 6: readdress a connected AS-i slave...................... 9-15

9.11 Module 12, extended command 7: set the auto address mode of the AS-i master... 9-17

9.12 Module 12, extended command 9: change extended ID code 1 in the AS-i slave .... 9-18

4

9-9

Page 5

Module 12, extended command 10...20

9.13

directly to / from 3 AS-i slaves in each case ...............................................................

(0A...14

dec

): force analogue data transfer

hex

9-20

9.14 Module 12, extended command 21

AS-i slave with the profile 7.4 ......................................................................................

9.15 Module 12, extended command 26

9.16 Module 12, extended command 28

changing to the protected mode..................................................................................

9.17 Module 12, extended command 31

"Extended safety monitor protocol" in the "Safety at work" monitor............................

9.18 Module 12, extended command 33

of an AS-i slave with the profile S-7.4 .........................................................................

9.19 Module 12, extended command 34

of an AS-i slave with the profile S-7.4 .........................................................................

9.20 Module 12, extended command 35

of an AS-i slave with the profile S-7.4 .........................................................................

9.21 Module 12, acyclic command 36

dec

with CTT2 profile (S-7.5.5, S-7.A.5 or S-B.A.5) .........................................................

9.22 Module 12, acyclic command 37

dec

with CTT2 profile (S-7.5.5, S-7.A.5 or S-B.A.5) .........................................................

9.23 Module 12, acyclic command 38

dec

of an AS-i slave with CTT2 profile (S-7.5.5, S-7.A.5 or S-B.A.5) ...............................

9.24 Module 12, acyclic command 39

dec

of an AS-i slave with CTT2 profile (S-7.5.5, S-7.A.5 or S-B.A.5) ...............................

(15

dec

dec

dec

dec

dec

dec

dec

(24

(25

(26

(27

): read ID character string of an

hex

(1A

): read AS-i master version................... 9-28

hex

(1C

): deactivate the slave reset when

hex

(1F

): one-time execution of the

hex

(21

): read the diagnostic character string

hex

(22

): read parameter character string

hex

(23

): write parameter character string

hex

): standard read call of an AS-i slave

hex

): standard write call of an AS-i slave

hex

): manufacturer-specific read call

hex

): manufacturer-specific write call

hex

9-25

9-29

9-30

9-35

9-37

9-38

9-40

9-44

9-47

9-51

9.25 Module 12, extended command 50

of AS-i slaves 0(A)...15(A)...........................................................................................

9.26 Module 12, extended command 51

of AS-i slaves 16(A)...31(A).........................................................................................

9.27 Module 12, extended command 52

of the AS-i slaves 1B...15B..........................................................................................

9.28 Module 12, extended command 53

of the AS-i slaves 16B...31B........................................................................................

9.29 Module 12, extended command 54

connected AS-i slaves.................................................................................................

9.30 Module 12, extended command 55

9.31 Module 12, extended command 56

of the AS-i slaves 0(A)...15(A).....................................................................................

9.32 Module 12, extended command 57

of the AS-i slaves 16(A)...31(A)...................................................................................

9.33 Module 12, extended command 58

of the AS-i slaves 1B...15B..........................................................................................

9.34 Module 12, extended command 59

of the AS-i slaves 16B...31B........................................................................................

9.35 Module 12, extended command 96

flash memory of the controllere...................................................................................

dec

dec

dec

dec

dec

dec

dec

dec

dec

dec

dec

(32

): read current configuration

hex

(33

): read current configuration

hex

(34

): read current configuration

hex

(35

): read current configuration

hex

(36

): read current parameters of the

hex

(37

): read current AS-i slave lists............... 9-61

hex

(38

): read projected configuration

hex

(39

): read projected configuration

hex

(3A

): read projected configuration

hex

(3B

): read projected configuration

hex

(60

): save data non-volatilely in the

hex

9-55

9-56

9-57

9-58

9-59

9-63

9-64

9-65

9-66

9-67

9.36 Module 12, extended command 97

controllere....................................................................................................................

9.37 Module 12, extended command 102

controllere display........................................................................................................

9.38 Module 12, extended command 105

of the controllere..........................................................................................................

dec

dec

dec

(61

): carry out various settings in the

hex

(66

): retrieve the status of the

hex

(69

): read the device properties

hex

9-68

9-69

9-71

5

Page 6

Acyclic services for Profibus DPV1 ..................................................................................... 10-1

10

10.1 Description................................................................................................................... 10-1

10.2 Services for acyclic data transfer between DPM1 master and slave.......................... 10-2

10.3 Services for acyclic data transfer between DPM2 master and slave.......................... 10-2

10.4 DPV1 addresses in slot 0 for access via PLC............................................................. 10-3

10.5 Examples..................................................................................................................... 10-5

10.5.1 Examples DPV1 reading ................................................................................ 10-5

10.5.2 Examples DPV1 writing .................................................................................. 10-5

10.6 DPV1 error messages ................................................................................................. 10-5

10.6.1 DPV1 error code application........................................................................... 10-5

10.6.2 DPV1 error codes data access....................................................................... 10-5

10.6.3 DPV1 error codes device................................................................................ 10-6

10.6.4 DPV1 error codes application-specific ........................................................... 10-6

10.6.5 DPV1 function 58 "Reason codes" ................................................................. 10-6

11 The DPV1 command channel................................................................................................11-1

11.1 Overview of the commands in the DPV1 command channel...................................... 11-1

11.2 Syntax.......................................................................................................................... 11-2

11.3 DPV1 command 0

11.4 DPV1 command 1

11.5 DPV1 command 3

dec

dec

dec

(00

(01

(03

in the configuration ......................................................................................................

11.6 DPV1 command 4

11.7 DPV1 command 5

11.8 DPV1 command 6

11.9 DPV1 command 7

11.10 DPV1 command 9

dec

dec

dec

dec

dec

(04

(05

(06

(07

(09

AS-i slave ..................................................................................................................

11.11 DPV1 command 10...20

to / from 3 AS-i slaves in each case ..........................................................................

11.12 DPV1 command 21

dec

(15

profile S-7.4 ...............................................................................................................

11.13 DPV1 command 28

dec

(1C

protected mode..........................................................................................................

11.14 DPV1 command 31

dec

(1F

protocol" in the "Safety at Work" monitor ..................................................................

11.15 DPV1 command 33

dec

(21

the profile S-7.4 .........................................................................................................

): no execution of a command.......................................... 11-4

hex

): write parameters to a connected AS-i slave ................. 11-5

hex

): adopt and store currently connected AS-i slaves

hex

): change the list of projected AS-i slaves (LPS)............. 11-9

hex

): set the operating mode of the AS-i master ................ 11-11

hex

): readdress a connected AS-i slave ............................. 11-13

hex

): set the auto address mode of the AS-i master .......... 11-15

hex

): change the extended ID code 1 in the connected

hex

(0A...14

dec

): read ID string of an AS-i slave with the

hex

): deactivate the slave reset when changing to the

hex

): one-time execution of the "Extended safety monitor

hex

): read diagnosis string of an AS-i slave with

hex

): force analogue data transfer directly

hex

11-7

11-16

11-18

11-23

11-26

11-27

11-32

11.16 DPV1 command 34

the profile S-7.4 .........................................................................................................

11.17 DPV1 command 35

the profile S-7.4 .........................................................................................................

11.18 DPV1 command 36

CTT2 profile (S-7.5.5, S-7.A.5 or S-B.A.5)...............................................................

11.19 DPV1 command 37

CTT2 profile (S-7.5.5, S-7.A.5 or S-B.A.5)...............................................................

6

dec

dec

dec

dec

(22

): read the parameter string of an AS-i slave with

hex

(23

): write parameter string of an AS-i slave with

hex

(24

): acyclic standard read call of an AS-i slave with

hex

(25

): acyclic standard write call of an AS-i slave with

hex

11-34

11-36

11-38

11-42

Page 7

DPV1 command 38

11.20

of an AS-i slave with CTT2 profile (S-7.5.5, S-7.A.5 or S-B.A.5) ..............................

dec

(26

): acyclic manufacturer-specific read call

hex

11-45

11.21 DPV1 command 39

of an AS-i slave with CTTS profile (S-7.5.5, S-7.A.5 or S-B.A.5)..............................

11.22 DPV1 command 50

AS-i slaves 0(A)...15(A).............................................................................................

11.23 DPV1 command 51

AS-i slaves 16(A)...31(A)...........................................................................................

11.24 DPV1 command 52

AS-i slaves 1B...15B..................................................................................................

11.25 DPV1 command 53

AS-i slaves 16B...31B................................................................................................

11.26 DPV1 command 54

a connected AS-i slave..............................................................................................

11.27 DPV1 command 55

11.28 DPV1 command 56

the AS-i slaves 1(A)...15(A).......................................................................................

11.29 DPV1 command 57

the AS-i slaves 16(A)...31(A).....................................................................................

11.30 DPV1 command 58

the AS-i slaves 1B…15B ...........................................................................................

11.31 DPV1 command 59

the AS-i slaves 16B…31B .........................................................................................

dec

dec

dec

dec

dec

dec

dec

dec

dec

dec

dec

(27

): acyclic manufacturer-specific write call

hex

(32

): read current configuration of

hex

(33

): Read current configuration of

hex

(34

): read current configuration of

hex

(35

): read current configuration of

hex

(36

): read current parameters of

hex

(37

): read current AS-i slave lists ..................................... 11-59

hex

(38

): projected configuration of

hex

(39

): read projected configuration of

hex

(3A

): read projected configuration of

hex

(3B

): read projected configuration of

hex

11-49

11-53

11-54

11-55

11-56

11-57

11-61

11-62

11-63

11-64

11.32 DPV1 command 96

of the controllere........................................................................................................

11.33 DPV1 command 97

11.34 DPV1 command 102

11.35 DPV1 command 105

dec

dec

dec

dec

(60

): save data non-volatilely in the flash memory

hex

(61

): carry out various settings in the controller

hex

(66

): retrieve the status of the controller

hex

(69

): read the device properties of the controller

hex

11-65

............. 11-66

e

display .......... 11-67

e

......... 11-69

e

12 Additional functions...............................................................................................................12-1

12.1 AS-i diagnosis via Profibus DP.................................................................................... 12-1

12.1.1 Digital inputs ................................................................................................... 12-1

12.1.2 Digital outputs................................................................................................. 12-1

12.1.3 Extended device-specific Profibus DP diagnosis ........................................... 12-2

12.1.4 Diagnostic master flags (byte 10 / byte 36) .................................................... 12-3

12.2 Set the Profibus DP address on the controllere.......................................................... 12-4

12.3 Read fieldbus parameters ........................................................................................... 12-6

12.4 Store system parameters .......................................................................................... 12-10

13 Technical data ........................................................................................................................ 13-1

13.1 Basic functions ............................................................................................................ 13-1

13.2 Profibus DP interface .................................................................................................. 13-1

14 Troubleshooting..................................................................................................................... 14-1

14.1 List of errors................................................................................................................. 14-1

14.2 Hardware error, exception error .................................................................................. 14-2

7

Page 8

Terms, abbreviations.............................................................................................................15-1

15

16 Index........................................................................................................................................16-1

8

Page 9

On this manual

What do the symbols and formats stand for?

1 On this manual

In this chapter you will find an overview of the following points:

• What do the symbols and formats stand for?

• What devices are described in this manual?

• How is this manual structured?

1.1 What do the symbols and formats stand for?

The following symbols or pictograms depict different kinds of remarks in this manual:

DANGER

Death or serious irreversible injuries are to be expected.

WARNING

Death or serious irreversible injuries may result.

CAUTION

Slight reversible injuries may result.

NOTICE

Property damage is to be expected or possible.

NOTE

The "i" in the square gives important information to help you handle the product or this manual

correctly.

► … Request for action

> … Reaction of device or software

→ ...

stands for "see"

abc Cross-reference (Link)

[…] [Designation] of key, signalling lamp, button, menu item ....

For several menu items to be selected consecutively we write:

[1st step] > [2nd step] > [3rd step]

ABC DESIGNATION of parameters (inputs, outputs, flags, function blocks)

Abc

● LED lit

○ LED off

✶

1-1

Designation of files and directories are written in monospace font

LED flashes

Page 10

On this manual

What devices are described in this manual?

1.2 What devices are described in this manual?

This manual describes the AS-i device family controller

of ifm electronic gmbh.

e

• with AS-i master profile M4

• with AS-i version 3.0 masters

• with a firmware from version RTS 2.2 onwards

• with the target from V.15 onwards.

In the "programming manual CoDeSys

®

2.3" more information about the use of the programming

system "CoDeSys for Automation Alliance" is given. This manual can be downloaded free of charge

from ifm's website at:

www.ifm.com> Select country/language > [Service] > [Download] > [Bus system AS-interface]

→

Description of the Ethernet programming interface

→ Separate supplement to this device manual.

1.3 How is this manual structured?

This manual is a combination of different instruction types. It is for beginners and also a reference for

advanced users.

How to use this manual:

• To find a certain subject straight away, please use the table of contents at the beginning of this

manual.

• Using the table of keywords at the end of the manual you can quickly find the term you are

looking for.

• At the beginning of a chapter we will give you a brief overview of its contents.

• You can find the title of the current chapter in bold in the header of each page. Below is the

current title of the second order.

• You can find the chapter-related number of the page in the footer of each page.

Abbreviations and technical terms

→ Chapter

Terms, abbreviations at the end of the manual.

We reserve the right to make alterations which can result in a change of contents of the manual. You

can find the current version on ifm's website at:

www.ifm.com > Select country/language > [Service] > [Download] > [Bus system AS-interface]

→

Nobody is perfect. Send us your suggestions for improvements to this manual and you will receive a

little gift from us to thank you.

© All rights reserved by ifm electronic gmbh. No part of this manual may be reproduced and used

without ifm electronic's consent.

1-2

Page 11

On this manual

Overview: where is what?

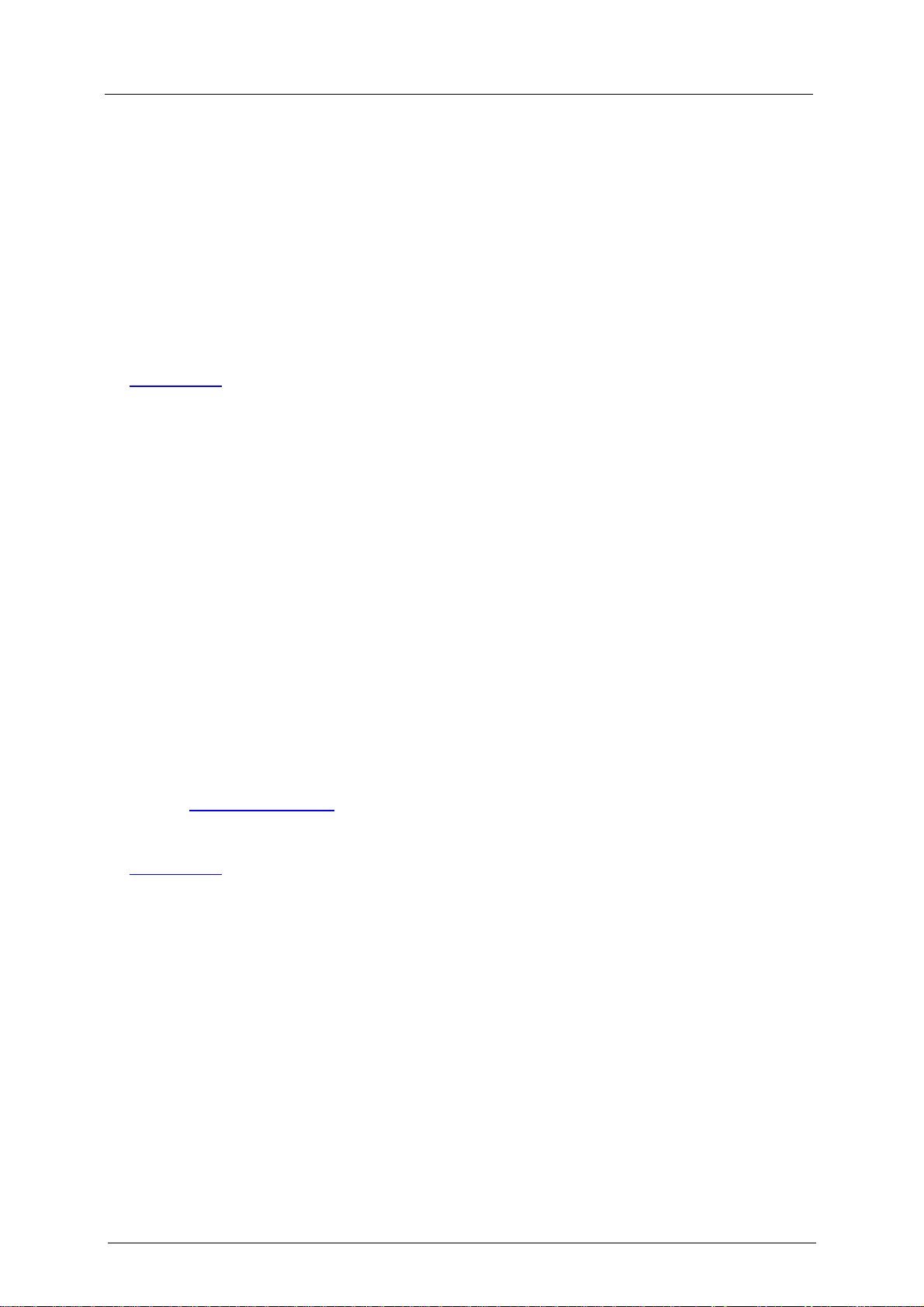

1.4 Overview: where is what?

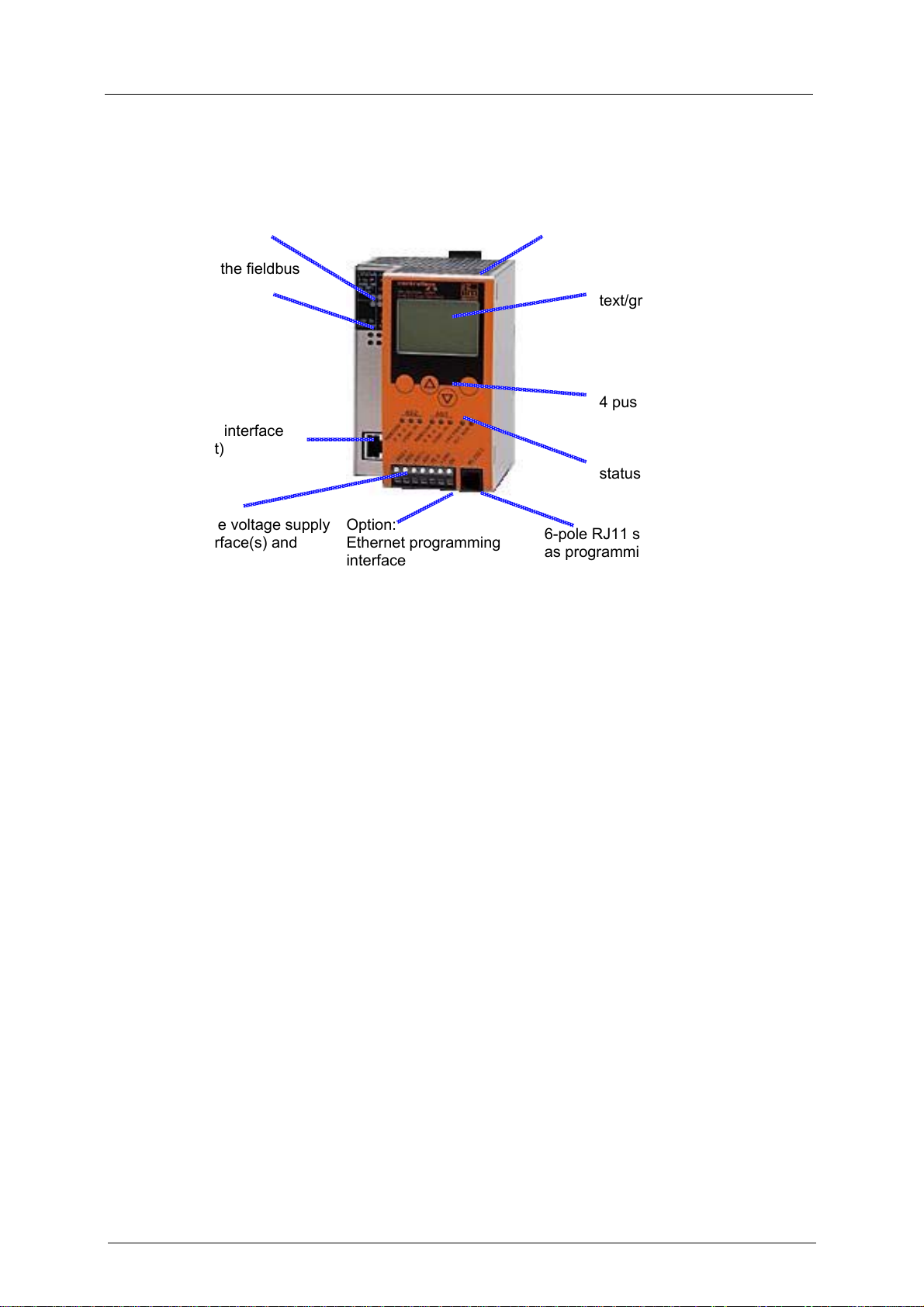

metal housing IP20 key to unlock the device from a rail

status LEDs of the fieldbus

interface

(option)

text/graphics display

4 pushbuttons

option: fieldbus interface

(here: Ethernet)

terminals for the voltage supply

24 V, AS-i interface(s) and

protective wire

Figure: overview controllere

Option:

Ethernet programming

interface

status LEDs

6-pole RJ11 socket of RS-232C

as programming interface

1-3

Page 12

On this manual

Overview: where is what?

1-4

Page 13

Safety instructions

General

2 Safety instructions

In this chapter you will find general safety instructions such as:

• General rules

• Required previous knowledge

• Safety instructions for mounting and installation

• When are you allowed to use this device and when not?

2.1 General

→ separate basic instructions of the device manual

No characteristics are warranted with the information, notes and examples provided in this manual.

The drawings, representations and examples imply no responsibility for the system and no applicationspecific particularities.

The manufacturer of the machine/equipment is responsible for ensuring the safety of the

machine/equipment.

WARNING

Property damage or bodily injury possible when the notes in this manual are not adhered to!

ifm electronic assumes no liability for this.

► The acting person must have read and understood the safety instructions and the corresponding

chapters of this manual before performing any work on or with this device.

► The acting person must be authorised to work on the machine/equipment.

2.2 What previous knowledge is required?

This manual is for persons with knowledge of control technology and PLC programming with IEC

61131-3 as well as the CoDeSys

Knowledge of the fieldbus Profibus DPV1 is a prerequisite.

Profibus user organisation →

Connection and parameter settings of the Profibus host → its manuals.

The manual is intended for persons authorised to install, connect and set up the controllere according

to the EMC and low voltage directives. The controllers must be installed and put into operation by a

qualified electrician.

In case of malfunctions or uncertainties please contact the manufacturer.

®

software.

http://www.profibus.com/

2.3 Functions and features

→ basic instructions of the device manual

2-1

Page 14

Safety instructions

Functions and features

2-2

Page 15

System requirements

Information concerning the device

3 System requirements

3.1 Information concerning the device

→ separate basic instructions of the device manual

3.2 Information concerning the software

→ separate basic instructions of the device manual

3.3 Required accessories

Basic functions → separate basic instructions of the device manual

For configuration and programming you also need:

• the software "CoDeSys for Automation Alliance ™" version 2.3 or higher (→ CD)

• in case of direct connection of the controllere to a PC with Ethernet interface (LAN):

a cross-over CAT5 Ethernet patch cable with RJ45 plug on both sides:

2 m art. no. EC2080

5 m art. no. E30112

• In case of connection of the controllere to a PC with Ethernet interface (LAN) via a hub or switch:

a common CAT5 Ethernet patch cable with RJ45 plug on both sides

• In case of direct connection of the controllere to a PC with serial interface:

Programming cable art. no. E70320

3-1

Page 16

System requirements

Required accessories

3-2

Page 17

Getting started

Connection

4 Getting started

4.1 Connection

► Connect the functional earth

► Connect the yellow AS-i cable for every master

► Connect the 24 V supply

► Connect the Profibus cable to the fieldbus master

4.2 Set up the AS-i master

► Connect the addressed AS-i slaves to the yellow AS-i cable

► Apply voltage

► If correctly addressed slaves are connected:

controllere menu [Config All] (→ basic manual)

► If no slave is connected:

controllere menu [Easy Startup](→ basic manual)

4.3 Set up Profibus DPV1

► Controllere menu "Fieldbus Setup": set the Profibus address

(→ page

► Copy the GSD file from the ifm CD (folder "gateway") to the suitable directory of the

corresponding fieldbus configuration program

► Define the I/O areas and the system behaviour in the fieldbus configuration program

► Save the configuration

► Transfer the configuration to the DPV1 master

► Start the DPV1 master

7-1, chapter ‘Set the parameters of the fieldbus interface in the controllere’)

4-1

Page 18

Getting started

Set up Profibus DPV1

4-2

Page 19

Function

Data management

5 Function

Basic functions → separate basic instructions of the device manual

Ethernet programming interface → separate complementary device manual

5.1 Data management

The controllere consists of different units:

AS-i master 1

text/graphics

display

fieldbus interface

Profibus DPV1

AS-i master 2

(optional)

CPU

PLC

Ethernet programming interface

(optional)

SRAM memory

RS-232C

flash memory

programming interface

This manual exclusively describes the following subject:

• The optional fieldbus interface Profibus DP operates independently and exchanges data with the

central system via a "Dual port RAM" interface .

For the AS-i controllers with Profibus interface the data management of Profibus DP is handled in the

operating system (firmware) of the device. A special driver in the PLC user program in the controllere

is not required. In the mode Run/Stop the digital and analogue output data is not transferred to the

outputs of the AS-i slaves. Therefore this data must be recopied in the PLC user program of the

controllere.

More information concerning the addresses and assignment to the Profibus modules → chapter

7,

Set-up.

5-1

Page 20

Function

Status LED for the fieldbus

5.2 Status LED for the fieldbus

For Profibus DP there is only one red LED [Bus Failure].

LED Description

● lights

○ off

✶

flashes 2 Hz

When response monitoring (watchdog) active:

no Profibus connection

When response monitoring (watchdog) active:

Profibus connection ok

OR: master switched off

OR: response monitoring (watchdog) deactivated

device error → message text in text/graphics display

5.3 Which operating modes are there for the PLC in the controllere?

Operating mode Description Behaviour via DPV1 / fieldbus

Run PLC program start

> The PLC program stored in the

controllere is processed.

> LED [PLC RUN] lit

Stop PLC program stop

> The PLC program stored in the

controllere is stopped.

> LED [PLC RUN] flashes

Via DPV1, data can be written to AS-i

slaves in the controllere application

program:

Mapping of the PLC address ranges

%IB4.512…%IB4.639

%IW4.320…%IW4.639

Gateway Controllere as gateway

> LED [PLC RUN] goes out

Fieldbus has exclusive write access for

the AS-i outputs.

DPV1 has no access here!

The timeouts for the analogue and

digital AS-i outputs only work in the

operating mode gateway. There is no

timeout monitoring for the other data

areas written via DPV1.

NOTE

During changes to the PLC program or to the slaves the PLC program should be stopped to avoid

malfunctions.

NOTE

In devices with Profibus and Ethernet programming interface, DPV1 is not considered as fieldbus but

as interface for operation and configuration.

5-2

Page 21

Menu

Main menu [Quick Setup]

6 Menu

NOTE

In this manual the menu texts are all in English.

Basic functions → separate basic instructions of the device manual

6.1 Main menu [Quick Setup]

Quick setting of the AS-i and fieldbus parameters, reading of the parameter data (password level 1

required). Details → page

Menu tree Explanation

12-6, chapter Read fieldbus parameters

Quick Setup

Fieldbus Setup

> Display of the current fieldbus address

► Change of the fieldbus address using the buttons [▲] or

[▼]

► After pressing [OK]:

> Controllere is set to the baud rate set in the Profibus DP

master.

► Always after pressing [OK]:

> Display of the data stored in the fieldbus master via the

data packets for communication with the AS-i controllere:

• Digital inputs in the fieldbus master of single or A slaves

on AS-i master 1

• Digital outputs in the fieldbus master to single or A slaves

on AS-i 1

• Digital inputs in the fieldbus master of single or A slaves

on AS-i master 2

• Digital outputs in the fieldbus master to single or A slaves

on AS-i 2

• Digital inputs in the fieldbus master of B slaves on AS-i

master 1

• Digital outputs in the fieldbus master to B slaves on AS-i 1

• Digital inputs in the fieldbus master of B slaves on AS-i

master 2

• Digital inputs in the fieldbus master of B slaves on AS-i

master 2

• Analogue multiplex inputs in the fieldbus master

• Analogue multiplex outputs in the fieldbus master

• Fieldbus data command channel

• Fieldbus data PLC inputs in the fieldbus master

• Fieldbus data PLC outputs in the fieldbus master

• Analogue inputs in the fieldbus master of AS-i master 1

• Analogue outputs in the fieldbus master on AS-i master 1

• Analogue inputs in the fieldbus master of AS-i master 2

6-1

Page 22

Menu

Main menu [Fieldbus Setup]

Menu tree Explanation

• Analogue outputs in the fieldbus master on AS-i master 2

• Fieldbus data diagnosis

• Fieldbus master command channel

• Digital inputs in the fieldbus master of single or A slaves

on AS-i master 1

(cycle starts again)

► Cancel with [ESC]

6.2 Main menu [Fieldbus Setup]

Setting of fieldbus parameters, reading of parameter data (password level 1 required).

Details → page

Menu tree Explanation

Fieldbus Setup > Display of the current fieldbus address

12-6, chapter Read fieldbus parameters

► Change of the fieldbus address using the keys [▲] / [▼]

► After pressing [OK]:

> Controllere is set to the baud rate set in the Profibus DP

master.

► Always after pressing [OK]:

> Display of the data stored in the fieldbus master via the

data packets for communication with the AS-i controllere:

• Digital inputs in the fieldbus master of single or A slaves

on AS-i master 1

• Digital outputs in the fieldbus master on single or A slaves

on AS-i master 1

• Digital inputs in the fieldbus master of single or A slaves

on AS-i master 2

• Digital outputs in the fieldbus master on single or A slaves

on AS-i master 2

• Digital inputs in the fieldbus master of B slaves on AS-i

master 1

• Digital outputs in the fieldbus master on B slaves on AS-i

master 1

6-2

• Digital inputs in the fieldbus master of B slaves on AS-i

master 2

• Digital outputs in the fieldbus master on B slaves on AS-i

master 2

• Analogue multiplex inputs in the fieldbus master

• Analogue multiplex outputs in the fieldbus master

• Fieldbus data command channel

• Fieldbus data PLC inputs in the fieldbus master

• Fieldbus data PLC outputs in the fieldbus master

• Analogue inputs in the fieldbus master of AS-i master 1

Page 23

Menu

Main menu [Fieldbus Setup]

Menu tree Explanation

• Analogue outputs in the fieldbus master on AS-i master 1

• Analogue inputs in the fieldbus master on AS-i master 2

• Analogue outputs in the fieldbus master on AS-i master 2

• Fieldbus data diagnosis

• Fieldbus master command channel

• Digital inputs in the fieldbus master of single or A slaves

on AS-i master 1

(cycle starts again)

► Cancel with [ESC]

6-3

Page 24

Menu

Main menu [Fieldbus Setup]

6-4

Page 25

Set-up

Parameter setting of the controllere

7 Set-up

This chapter shows you how to get the Profibus interface started quickly.

7.1 Parameter setting of the controllere

7.1.1 Parameter setting of slaves in the controllere

Set the parameters of the slaves in the AS-i controllere as described in the basic device manual.

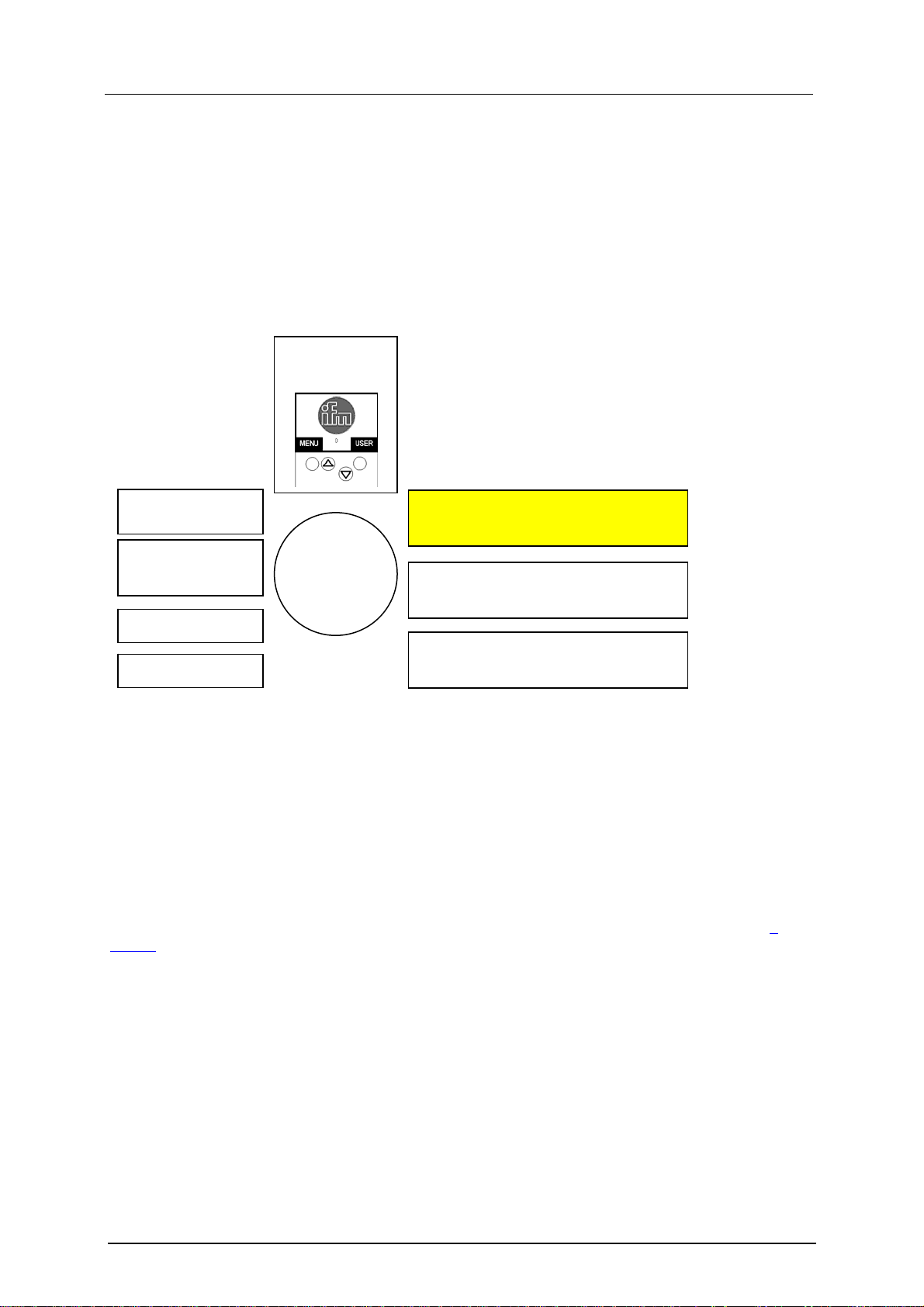

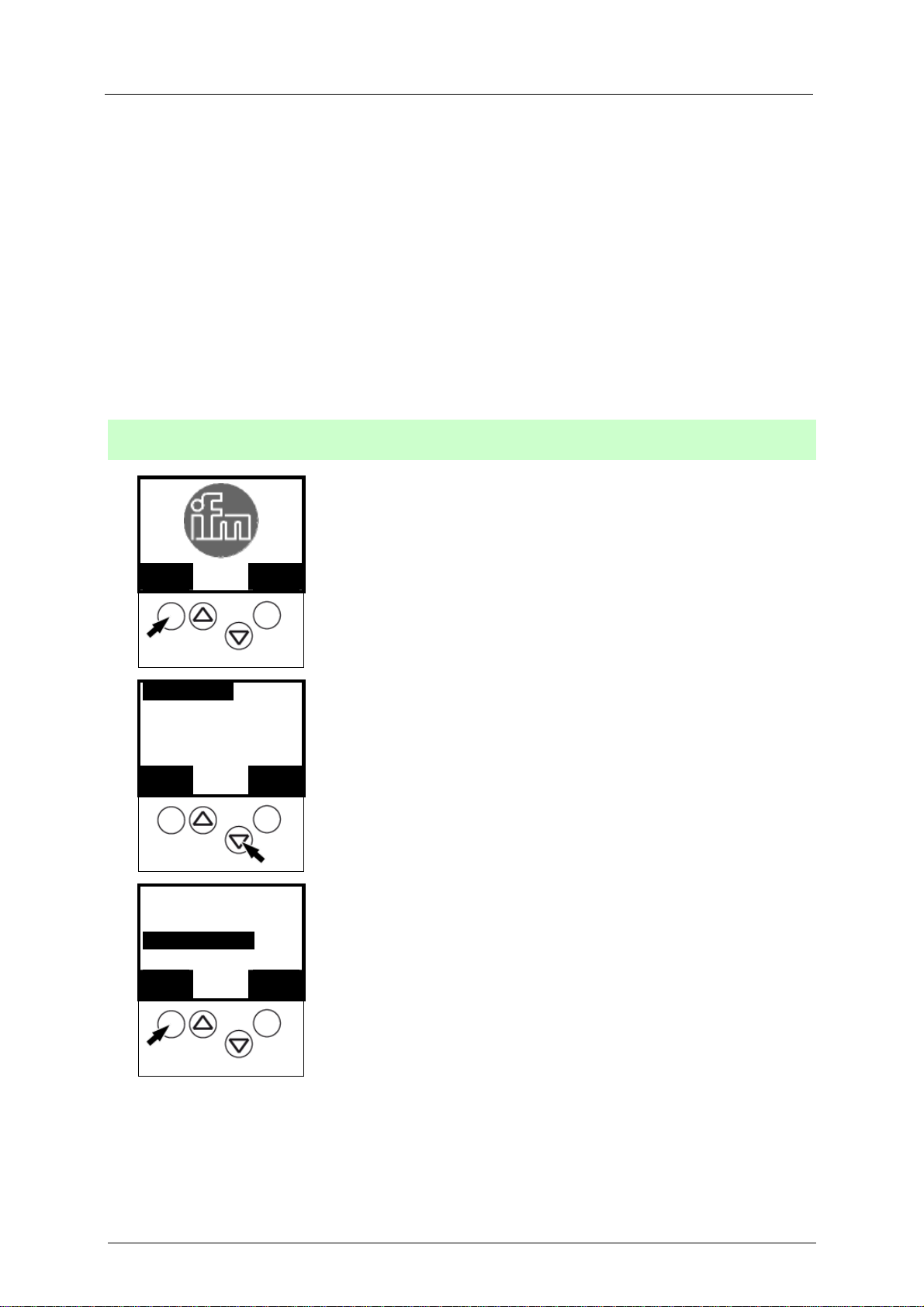

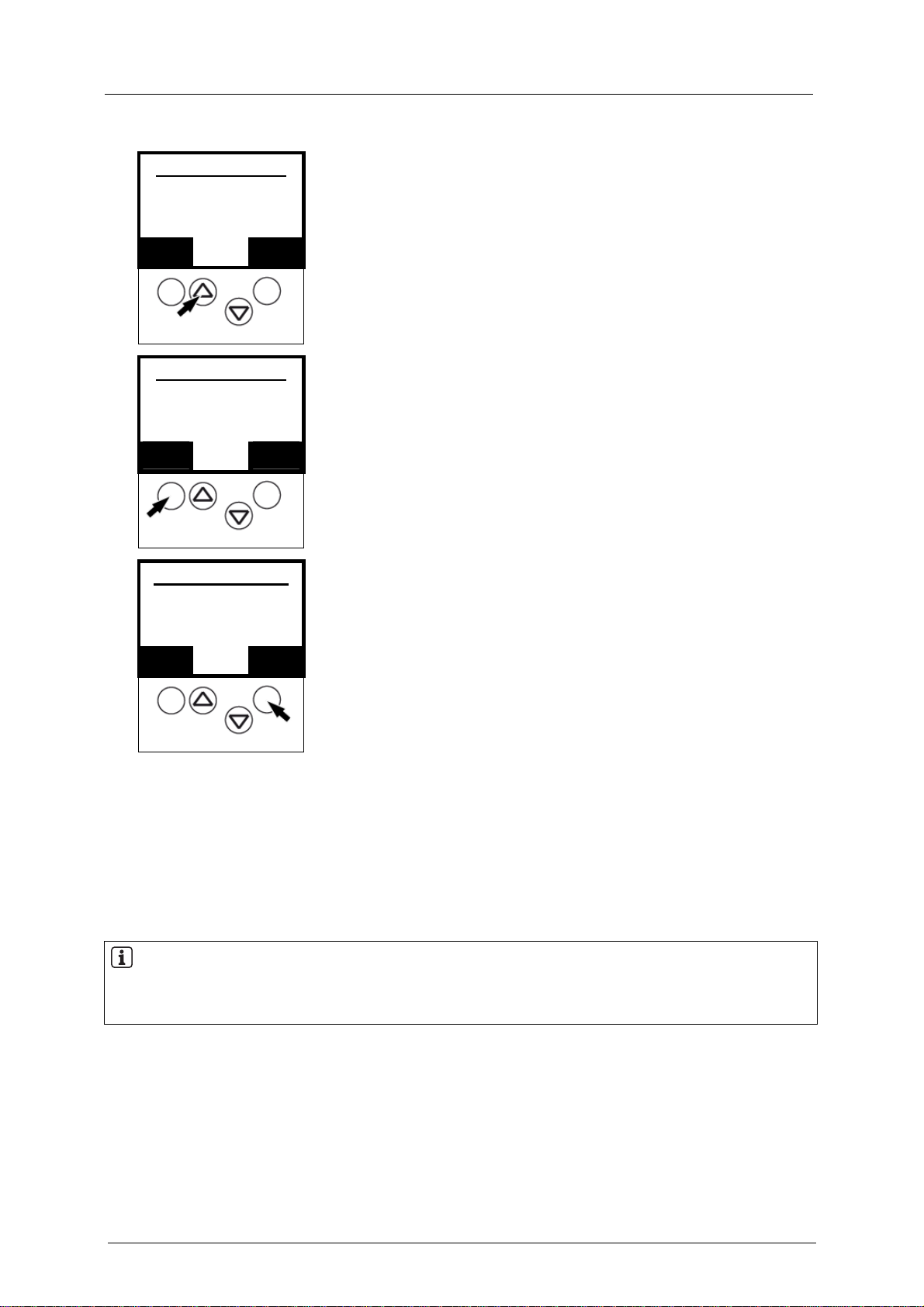

7.1.2 Set the parameters of the fieldbus interface in the controllere

[Menu] > [Fieldbus Setup] > Choose address > [OK]

1.

MMEENNUU

Quick Setup

2.

PLC Setup

Slave Lists

OOKK

Diagnostics

3.

Master Setup

Fieldbus Setup

OOKK

0

1

▲ ▼

1

▲ ▼

UUSSEERR

EESSCC

EESSCC

► Press [MENU]

► Scroll to [Fieldbus Setup] with [▼]

► Select [Fieldbus Setup] with [OK].

7-1

Page 26

Set-up

Connect the controllere to the Profibus host

Fieldbus Address

4.

0

OOKK

Fieldbus Address

5.

OOKK

Fieldbus Baudrate

6.

#### KBaud

OOKK

87

▲ ▼

32

87

▲ ▼

88

▲ ▼

► Scroll to the requested address with [▲] / [▼].

EESSCC

► Save the fieldbus address with [OK].

EESSCC

> If there is communication with the fieldbus master:

display of negotiated baud rate

► Acknowledge with [OK].

EESSCC

> If there is no communication with the fieldbus master:

display value not defined

► Cancel with [ESC].

7.2 Connect the controllere to the Profibus host

► Connect the Profibus cable to the controllere.

7.3 Parameter setting of the Profibus host

NOTE

Refer to the description of the Profibus interface on the host

(host = fieldbus master = in most cases higher-level PLC)

GSD file

(GSD = General Station Description) The GSD file ifm604D8.gsd on the ifm CD contains different

possible definitions (indications of lengths) for each of the 12 modules, adapted to the controllere. →

Hardware catalogue of the Profibus configuration software in the gateway folder.

► Copy this file to the suitable directory of the corresponding fieldbus configuration program (→ its

description).

7-2

Page 27

Set-up

Parameter setting of the Profibus host

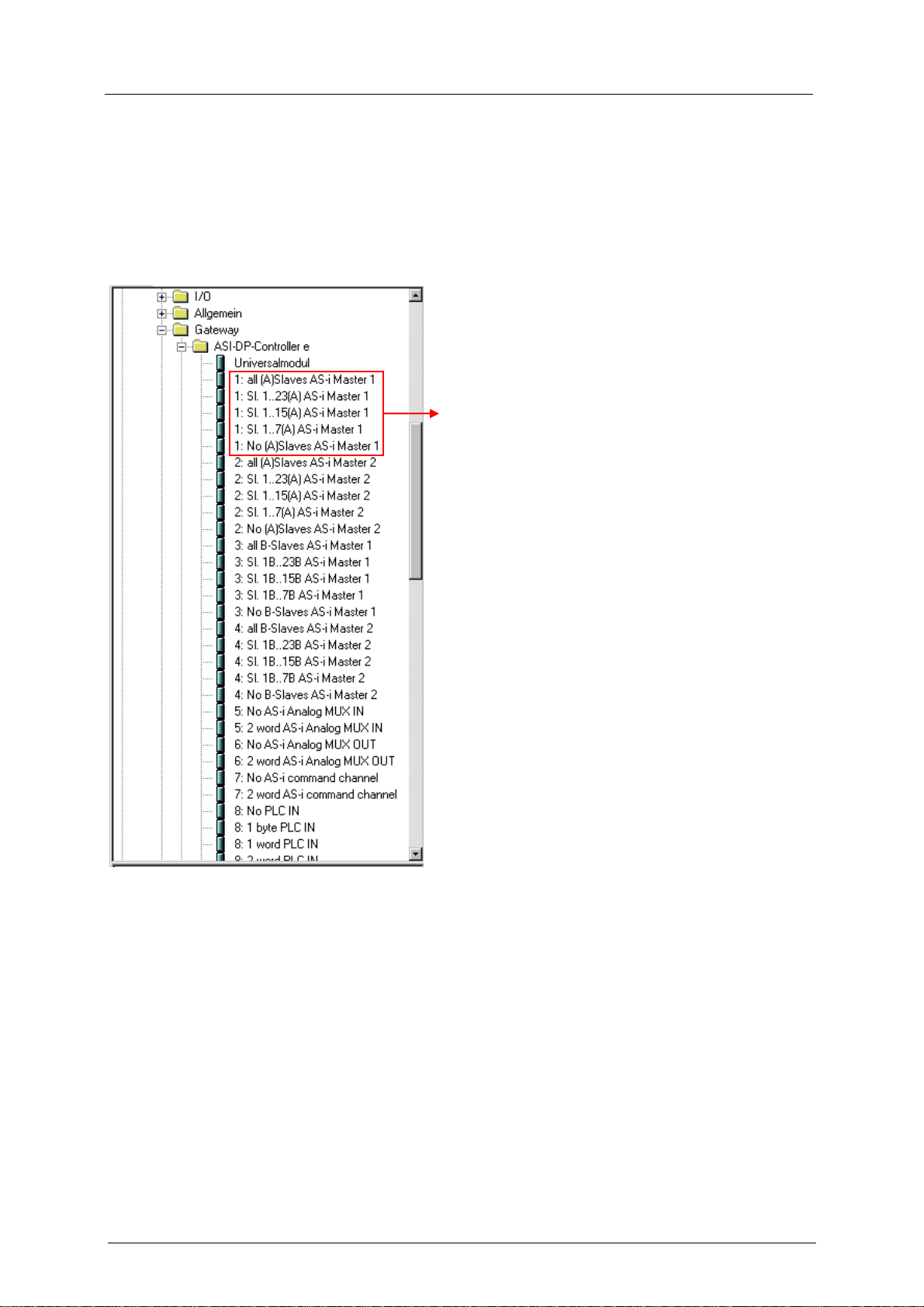

Programming software

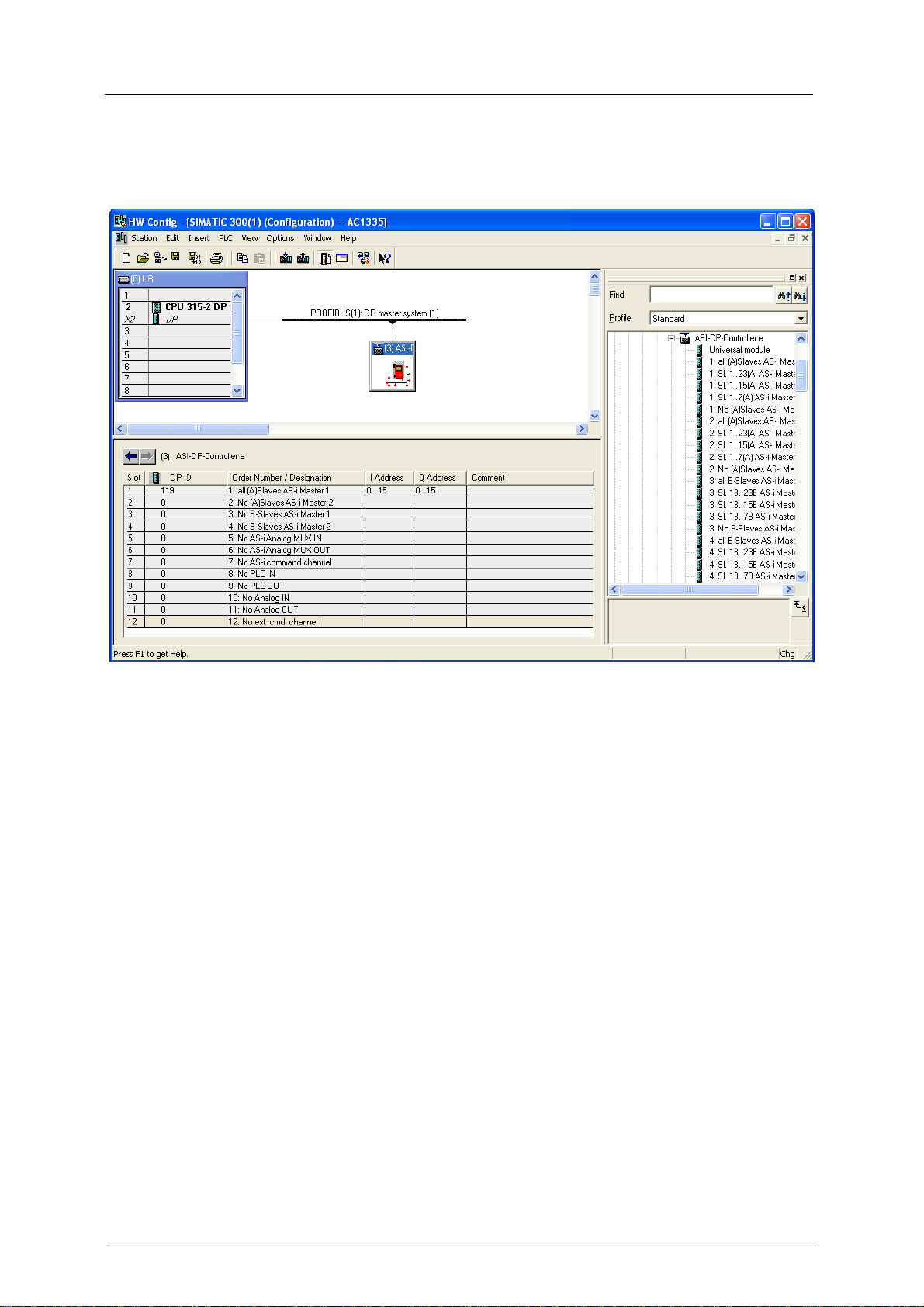

The data of the controllere or the connected AS-i systems to be transferred can be defined (by

indicating the length of up to 12 modules) in the programming software for the Profibus DP master

system (host).

You can select from these definitions for parameter setting in the host:

Example for module 1:

There is a choice of 5 entries:

• all single and A slaves on AS-i master 1

(length = 16 bytes)

• single and A slaves with the addresses

1(A)...23(A) on AS-i master 1

(length = 12 bytes)

• single and A slaves with the addresses

1(A)...15(A) on AS-i master 1

(length = 8 bytes)

• single and A slaves with the addresses

1(A)...7(A) on AS-i master 1

(length = 4 bytes)

• no single or A slaves on AS-i master 1

(length = 0 bytes)

If the parameters for a smaller number of slaves than indicated in the selection point are to be set, you

have created free reserve in the host.

Example:

5 single and/or A slaves are connected to the AS-i master 1.

You have selected on the host:

"single and A slaves with the addresses 1(A)...7(A) on AS-i master 1"

You have then created an address area reserve of 1 byte in the host which is not used for the time being. The first 3 bytes of the

reserved address area are used to exchange data.

7-3

Page 28

Set-up

Parameter setting of the Profibus host

7.3.1 Assigning the addresses of the inputs/outputs to the host "locations"

For Profibus DP, virtual locations in the host are assigned to the inputs/outputs addressed via AS-i.

NOTE

Addressing of CTT2 and CTT3 slaves → separate basic instructions of the device manual

and there → chapter "Use of analogue channels in the controllere depending on the slave profile"

and → chapter "Data distribution of slaves to the M4 controllere"

Digital inputs / outputs

st

example:

1

Siemens S7 with AS-i controllere as gateway. The digital inputs/outputs on the AS-i controllere are

assigned to the host as bytes 0...15.

In this constellation, how are the IEC addresses distributed to the inputs and outputs of the slaves? →

next page

7-4

Page 29

Set-up

Parameter setting of the Profibus host

Digital inputs and outputs of the slaves at start address 0

Start address Bits 7...4 Bits 3...0

(Slave 0) reserved for master flags Slave 1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Reserved Conf.

Err.

0 .7 0 .6 0 .5 0 .4 0 .3 0 .2 0 .1 0 .0

D3 D2 D1 D0 D3 D2 D1 D0

1 .7 1 .6 1 .5 1 .4 1 .3 1 .2 1 .1 1 .0

D3 D2 D1 D0 D3 D2 D1 D0

2 .7 2 .6 2 .5 2 .4 2 .3 2 .2 2 .1 2 .0

D3 D2 D1 D0 D3 D2 D1 D0

3 .7 3 .6 3 .5 3 .4 3 .3 3 .2 3 .1 3 .0

D3 D2 D1 D0 D3 D2 D1 D0

4 .7 4 .6 4 .5 4 .4 4 .3 4 .2 4 .1 4 .0

D3 D2 D1 D0 D3 D2 D1 D0

5 .7 5 .6 5 .5 5 .4 5 .3 5 .2 5 .1 5 .0

D3 D2 D1 D0 D3 D2 D1 D0

6 .7 6 .6 6 .5 6 .4 6 .3 6 .2 6 .1 6 .0

D3 D2 D1 D0 D3 D2 D1 D0

7 .7 7 .6 7 .5 7 .4 7 .3 7 .2 7 .1 7 .0

D3 D2 D1 D0 D3 D2 D1 D0

8 .7 8 .6 8 .5 8 .4 8 .3 8 .2 8 .1 8 .0

D3 D2 D1 D0 D3 D2 D1 D0

9 .7 9 .6 9 .5 9 .4 9 .3 9 .2 9 .1 9 .0

D3 D2 D1 D0 D3 D2 D1 D0

10 .7 10 .6 10 .5 10 .4 10 .3 10 .2 10 .1 10 .0

D3 D2 D1 D0 D3 D2 D1 D0

11 .7 11 .6 11 .5 11 .4 11 .3 11 .2 11 .1 11 .0

D3 D2 D1 D0 D3 D2 D1 D0

12 .7 12 .6 12 .5 12 .4 12 .3 12 .2 12 .1 12 .0

D3 D2 D1 D0 D3 D2 D1 D0

13 .7 13 .6 13 .5 13 .4 13 .3 13 .2 13 .1 13 .0

D3 D2 D1 D0 D3 D2 D1 D0

14 .7 14 .6 14 .5 14 .4 14 .3 14 .2 14 .1 14 .0

D3 D2 D1 D0 D3 D2 D1 D0

15 .7 15 .6 15 .5 15 .4 15 .3 15 .2 15 .1 15 .0

No Slave PF.Err D3 D2 D1 D0

Slave 2 Slave 3

Slave 4 Slave 5

Slave 6 Slave 7

Slave 8 Slave 9

Slave 10 Slave 11

Slave 12 Slave 13

Slave 14 Slave 15

Slave 16 Slave 17

Slave 18 Slave 19

Slave 20 Slave 21

Slave 22 Slave 23

Slave 24 Slave 25

Slave 26 Slave 27

Slave 28 Slave 29

Slave 30 Slave 31

7-5

Page 30

Set-up

Parameter setting of the Profibus host

nd

example:

2

Siemens S7 with AS-i controllere as gateway. The digital inputs/outputs on the AS-i controllere are

assigned to the host as bytes 65...80.

In this constellation, how are the IEC addresses distributed to the inputs and outputs of the slaves? →

next page

7-6

Page 31

Set-up

Parameter setting of the Profibus host

Digital inputs and outputs of the slaves at start address 65

Start address Bits 7...4 Bits 3...0

(Slave 0) reserved for master flags Slave 1

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Reserve

65 .7 65 .6 65 .5 65 .4 65 .3 65 .2 65 .1 65 .0

D3 D2 D1 D0 D3 D2 D1 D0

66 .7 66 .6 66 .5 66 .4 66 .3 66 .2 66 .1 66 .0

D3 D2 D1 D0 D3 D2 D1 D0

67 .7 67 .6 67 .5 67 .4 67 .3 67 .2 67 .1 67 .0

D3 D2 D1 D0 D3 D2 D1 D0

68 .7 68 .6 68 .5 68 .4 68 .3 68 .2 68 .1 68 .0

D3 D2 D1 D0 D3 D2 D1 D0

69 .7 69 .6 69 .5 69 .4 69 .3 69 .2 69 .1 69 .0

D3 D2 D1 D0 D3 D2 D1 D0

70 .7 70 .6 70 .5 70 .4 70 .3 70 .2 70 .1 70 .0

D3 D2 D1 D0 D3 D2 D1 D0

71 .7 71 .6 71 .5 71 .4 71 .3 71 .2 71 .1 71 .0

D3 D2 D1 D0 D3 D2 D1 D0

72 .7 72 .6 72 .5 72 .4 72 .3 72 .2 72 .1 72 .0

D3 D2 D1 D0 D3 D2 D1 D0

73 .7 73 .6 73 .5 73 .4 73 .3 73 .2 73 .1 73 .0

D3 D2 D1 D0 D3 D2 D1 D0

74 .7 74 .6 74 .5 74 .4 74 .3 74 .2 74 .1 74 .0

D3 D2 D1 D0 D3 D2 D1 D0

75 .7 75 .6 75 .5 75 .4 75 .3 75 .2 75 .1 75 .0

D3 D2 D1 D0 D3 D2 D1 D0

76 .7 76 .6 76 .5 76 .4 76 .3 76 .2 76 .1 76 .0

D3 D2 D1 D0 D3 D2 D1 D0

77 .7 77 .6 77 .5 77 .4 77 .3 77 .2 77 .1 77 .0

D3 D2 D1 D0 D3 D2 D1 D0

78 .7 78 .6 78 .5 78 .4 78 .3 78 .2 78 .1 78 .0

D3 D2 D1 D0 D3 D2 D1 D0

79 .7 79 .6 79 .5 79 .4 79 .3 79 .2 79 .1 79 .0

D3 D2 D1 D0 D3 D2 D1 D0

80 .7 80 .6 80 .5 80 .4 80 .3 80 .2 80 .1 80 .0

Conf.

Err.

NoSlave PF.Err D3 D2 D1 D0

Slave 2 Slave 3

Slave 4 Slave 5

Slave 6 Slave 7

Slave 8 Slave 9

Slave 10 Slave 11

Slave 12 Slave 13

Slave 14 Slave 15

Slave 16 Slave 17

Slave 18 Slave 19

Slave 20 Slave 21

Slave 22 Slave 23

Slave 24 Slave 25

Slave 26 Slave 27

Slave 28 Slave 29

Slave 30 Slave 31

7-7

Page 32

Set-up

Parameter setting of the Profibus host

Analogue inputs/outputs

1st example:

Siemens S7 with AS-i controllere as gateway.

The analogue inputs on the AS-i controllere are assigned to the host as bytes 256...287 (32 bytes = 16

words). The analogue outputs on the AS-i controllere are assigned to the host as bytes 256...271 (16

bytes = 8 words).

The order of the shown analogue slaves can be explicitly defined via parameters in the Profibus

configuration.

► To adapt the parameters, double-click on the controllere symbol.

► Change to the tab [Parameter Assignment] in the window which appears.

See figure:

7-8

Page 33

Set-up

Parameter setting of the Profibus host

In this constellation, how are the IEC addresses distributed to the inputs and outputs of the slaves?

The following tables show the correlation between start address and AS-i slave address (preset

parameters):

Analogue inputs

Start address [bytes] Slave address* Channel number

256 1

258 2

1

260 3

262

4

264 1

266 2

2

268 3

270

4

272 1

274 2

3

276 3

278

4

280 1

282 2

4

284 3

286

4

* The slave address can be freely assigned via the Profibus parameter data!

Analogue outputs

Start address [bytes] Slave address Channel number

256 1

258 2

1

260 3

262

4

264 1

266 2

2

268 3

270

4

* The slave address can be freely assigned via the Profibus parameter data!

7-9

Page 34

Set-up

Parameter setting of the Profibus host

Analogue inputs and outputs of the slaves at start address ###

SORRY - i n w o r k - SORRY

7-10

Page 35

Set-up

Parameter setting of the Profibus host

7.3.2 Assign PLC addresses to the Profibus modules

What are "Profibus modules"? These are entries in a parameter setting database of the programming

software for the Profibus DP master system (host). There you assign the individual "modules" to the

virtual "locations".

Locations are address areas for certain functions.

Modules are placeholders for certain address quantities within these areas.

The following IEC addresses are the designations for the PLC addresses in the controllere:

IEC address area

Description

from to

%IB1.1 %IB1.31 master 1, slaves 1A...31A, digital inputs

%IB2.1 %IB2.31 master 2, slaves 1A...31A, digital inputs

%IB11.1 %IB11.31 master 1, slaves 1B...31B, digital inputs

%IB12.1 %IB12.31 master 2, slaves 1B...31B, digital inputs

%IW21.1.x %IW21.31.x

%IW22.1.x %IW22.31.x

master 1, slaves 1...31,

analogue inputs x = channel*)

master 2, slaves 1...31,

analogue inputs x = channel *)

%IW0.0 %IW0.63 DP outputs for signal preprocessing

%IB0.128 %IB0.143

%IB0.144 %IB0.159

%IB0.160 %IB0.175

%IB0.176 %IB0.191

DP outputs for master1, slaves 1A...31A,

digital outputs

DP outputs for master1, slaves 1B...31B,

digital outputs

DP outputs for master2, slaves 1A...31A,

digital outputs

DP outputs for master 2, slaves 1B...31B,

digital outputs

Data flow

AS-i host

→

→

→

→

→

→

←

←

←

←

←

DP module

1 input

2 inputs

3 input

4 input

5 and 10

5 and 10

9

1 output

3 output

2 output

4 output

%IW0.96 %IW0.219

%IW0.224 %IW0.347

%IB0.704 %IB0.719

%IB0.720 %IB0.735

%IB0.736 %IB0.751

%IB0.752 %IB0.767

%QB1.1 %QB1.31

%QB2.1 %QB2.31

DP outputs for master 1, slaves 1...31,

analogue outputs

DP outputs for master 2, slaves 1...31,

analogue outputs

DP parameters for master 1, slaves

1A...31A, parameter data

DP parameters for master 1, slaves

1B...31B, parameter data

DP parameters for master 2, slaves

1A...31A, parameter data

DP parameters for master 2, slaves

1B...31B, parameter data

master 1, slaves 1A...31A,

digital outputs

master 2, slaves 1A...31A,

digital outputs

←

←

←

←

←

←

→

→

11

11

DP

parameters

DP

parameters

DP

parameters

DP

parameters

–

–

7-11

Page 36

Set-up

Parameter setting of the Profibus host

IEC address area

Description

from to

%QB11.1 %QB11.31

%QIB12.1 %QB12.31

%QW21.1.x %QW21.31.x

%QW22.1.x %QW22.31.x

master 1, slaves 1B...31B,

digital outputs

master 2, slaves 1B...31B,

digital outputs

master 1, slaves 1...31,

analogue outputs x = channel *)

master 2, slaves 1...31,

analogue outputs x = channel *)

%QW0.0 %QW0.63 signal preprocessing outputs for DP data

*) Channel numbers:

x = 0 → analogue channel 1

x = 1 → analogue channel 2

x = 2 → analogue channel 3

x = 3 → analogue channel 4

The following device behaviour is defined:

a) 1 channel per I/O slave

Word no. AS-i master no. Slave no. Channel

1 1

2 2

3 3

… …

30

31 1

32 2

33 3

… …

60

b) 2 channels per I/O slave

Word no. AS-i master no. Slave no. Channel

1 1

2

3 1

4

… …

59 1

60

1

30

2

30

1

1

2

30

Data flow

AS-i host

→

→

→

→

→

DP module

–

–

–

–

8

1

2

2

2

NOTE

All outputs will be reset when changing to the PLC operating mode "Stop"!

analogue outputs = 0,

digital outputs = FALSE

7-12

Page 37

Set-up

Parameter setting of the Profibus host

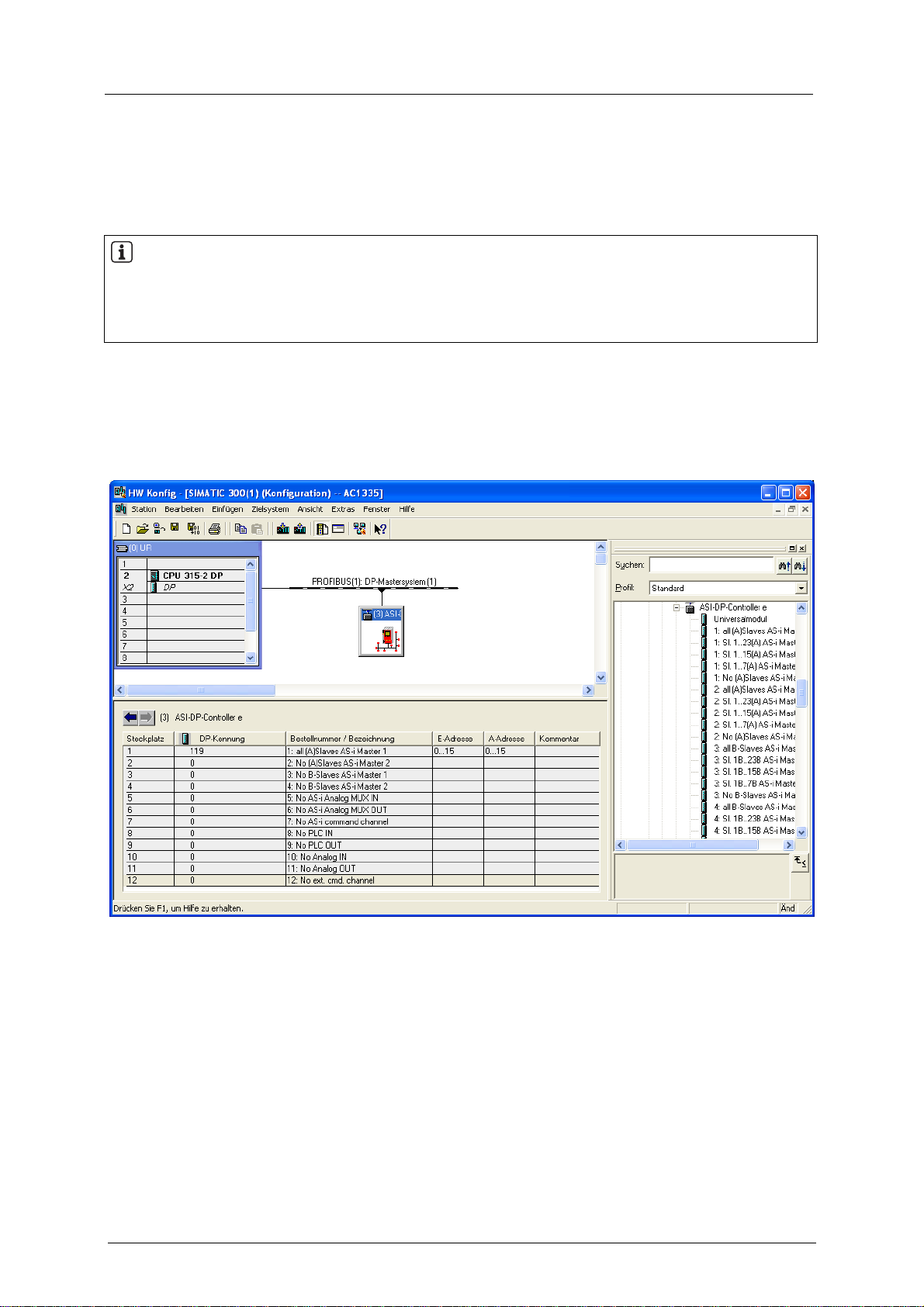

7.3.3 Define Profibus DP modules

The text of the different options of the modules always starts with the module number ( → photo page

7-3, section Programming software). So all options in the module list of the hardware catalogue

starting with "1:" are options of the first module in the device definition.

The first module for example defines the number of binary I/O data bytes of single or A slaves of AS-i

master 1 in the controllere which are to be transferred to the Profibus master via Profibus DP.

NOTE

The maximum data length of all 12 modules must not exceed 152 input bytes and 152 output bytes.

Example: Siemens S7

For the advanced Profibus DP user it is also possible to use length codes other than those indicated

as long as the maximum lengths of the modules are not exceeded.

7-13

Page 38

Set-up

Parameter setting of the Profibus host

Module 1: Binary inputs/outputs of single / A slaves of AS-i master 1

Contents Binary inputs and outputs of single or A slaves of AS-i master 1

Length 0...16 bytes I/O (if not used: length = 0)

Byte no. Bits 4...7 Bits 0...3

1 flags master 1 slave1(A)

2 slave2(A) slave3(A)

3 slave4(A) slave5(A)

4 slave6(A) slave7(A)

5 slave8(A) slave9(A)

6 slave10(A) slave11(A)

7 slave12(A) slave13(A)

8 slave14(A) slave14(A)

9 slave16(A) slave15(A)

10 slave18(A) slave19(A)

11 slave20(A) slave21(A)

12 slave22(A) slave23(A)

13 slave24(A) slave25(A)

14 slave26(A) slave27(A)

15 slave28(A) slave29(A)

16 slave30(A) slave31(A)

The flags in the first input byte contain status information of the AS-i master 1:

Bit 7 Bit 6 Bit 5 Bit 4

PLC running in the

controllere

Configuration error in

the AS-i circuit

AS-i master offline Periphery fault

The flags in the first output byte contain control information of the AS-i master 1:

Bit 7 Bit 6 Bit 5 Bit 4

Reserved Reserved

Reset of the stored

diagnostic data

Activate transfer of the

stored diagnostic data

If bit 4 of the control information is TRUE, the controllere transmits the stored periphery faults and

configuration errors in the device-specific diagnosis. The flags remain TRUE even if the fault is no

longer present. Bit 5 in the control information resets this information.

7-14

Page 39

Set-up

Parameter setting of the Profibus host

Module 2: Binary inputs/outputs of single / A slaves of AS-i master 2

Contents Binary inputs and outputs of single or A slaves of AS-i master 2

Length 0...16 bytes I/O (if not used: length = 0)

Byte no. Bits 4...7 Bits 0...3

1 flags master 2 slave1(A)

2 slave2(A) slave3(A)

3 slave4(A) slave5(A)

4 slave6(A) slave7(A)

5 slave8(A) slave9(A)

6 slave10(A) slave11(A)

7 slave12(A) slave13(A)

8 slave14(A) slave14(A)

9 slave16(A) slave15(A)

10 slave18(A) slave19(A)

11 slave20(A) slave21(A)

12 slave22(A) slave23(A)

13 slave24(A) slave25(A)

14 slave26(A) slave27(A)

15 slave28(A) slave29(A)

16 slave30(A) slave31(A)

The flags in the first input byte contain status information of AS-i master 2:

Bit 7 Bit 6 Bit 5 Bit 4

PLC running in the

controllere

Configuration error

in the AS-i circuit

No AS-i slave

detected

Periphery fault

The flags in the first output byte contain control information of the AS-i master 2:

Bit 7 Bit 6 Bit 5 Bit 4

Reserved Reserved

Reset of the stored

diagnostic data

Activate transfer of

the stored

diagnostic data

If bit 4 of the control information is TRUE, the controllere transmits the stored periphery faults and

configuration errors in the device-specific diagnosis. The flags remain TRUE even if the fault or error is

no longer present. Bit 5 in the control information resets this information.

7-15

Page 40

Set-up

Parameter setting of the Profibus host

Module 3: Binary inputs/outputs of B slaves of AS-i master 1

Contents Binary inputs and outputs of B slaves of the AS-i master 1

Length 0...16 bytes I/O (if not used: length = 0)

Byte no. Bits 4...7 Bits 0...3

1 reserved slave1B

2 slave2B slave3B

3 slave4B slave5B

4 slave6B slave7B

5 slave8B slave9B

6 slave10B slave11B

7 slave12B slave13B

8 slave14B slave14B

9 slave16B slave15B

10 slave18B slave19B

11 slave20B slave21B

12 slave22B slave23B

13 slave24B slave25B

14 slave26B slave27B

15 slave28B slave29B

16 slave30B slave31B

7-16

Page 41

Set-up

Parameter setting of the Profibus host

Module 4: Binary inputs/outputs of B slaves of AS-i master 2

Contents Binary inputs and outputs of B slaves of AS-i master 2

Length 0...16 bytes I/O (if not used: length = 0)

Byte no. Bits 4…7 Bits 0…3

1 reserved slave1B

2 slave2B slave3B

3 slave4B slave5B

4 slave6B slave7B

5 slave8B slave9B

6 slave10B slave11B

7 slave12B slave13B

8 slave14B slave14B

9 slave16B slave15B

10 slave18B slave19B

11 slave20B slave21B

12 slave22B slave23B

13 slave24B slave25B

14 slave26B slave27B

15 slave28B slave29B

16 slave30B slave31B

7-17

Page 42

Set-up

Parameter setting of the Profibus host

Module 5: Analogue inputs of AS-i master

Contents Multiplexed analogue inputs of AS-i master 1 and 2

Length 2-word consistent I/O ( if not used: length = 0)

DP master request (only 1 word)

Bit:

Word

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1st

Legend

MM 2 bits Master no. 1...2

X 1 bit Slave type 0 = single or A slave

SSSSS 5 bits Slave no. 1…31

CC 2 bits Channel no. 0...3

MM X SSSSS 0 0 0 0 0 0 CC

1 = B slave

dec

dec

Calculation of the more significant byte (MMXSSSSS):

(slave no.) + (master no. * 64

dec

) + (32

, if B slave)

dec

Controllere response (2 words, first word copy of the request):

Bit:

Word

2nd

Legend

MM 2 bits Master no. 1...2

X 1 bit Slave type 0 = single or A slave

SSSSS 5 bits Slave no. 1…31

E1 1 bits Error no. of the response 0 = ok

E2 1 bits Error no. of the response 0 = ok

E3 1 bits Error no. of the response 0 = ok

E4 1 bits Error no. of the response 0 = ok

CC 2 bits Channel no. 0...3

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1st

MM X SSSSS E4 E3 E2 E1 0 0 CC

Analogue value, INTEGER

1 = B slave

dec

1 = value invalid (of slave)

1 = overflow

1 = no analogue slave found

1 = protocol fault

dec

7-18

Page 43

Set-up

Parameter setting of the Profibus host

Module 6: Analogue outputs of AS-i master

Contents Multiplexed analogue outputs of AS-i master 1 and 2

Length 2-word consistent I/O (if not used: length = 0)

NOTE

If analogue outputs are also triggered in module 11, the value written in module 6 is overwritten with

the data of module 11.

DP master request (2 words)

Bit:

Word

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1st

2nd

Legend

MM 2 bits Master no. 1...2

X 1 bits Slave type 0 = single or A slave

SSSSS 5 bits Slave no. 1…31

V 1 bits Switch off the channel 1 = TRUE

CC 2 bits Channel no. 0…3

MM X SSSSS 0 0 0 V 0 0 CC

Analogue value, INTEGER

1 = B slave

dec

→ switch off the channel,

master transmits "invalid"

Calculation of the more significant byte (MMXSSSSS):

(slave no.) + (master no. * 64

dec

) + (32

, if B slave)

dec

Controllere response (2 words, copy of the request):

Bit:

Word

2nd

Legend

MM 2 bits Master no. 1...2

X 1 bits Slave type 0 = single or A slave

SSSSS 5 bits Slave no. 1…31

E1 1 bits Error no. of the response 0 = not used

E2 1 bits Error no. of the response 0 = ok

E3 1 bits Error no. of the response 0 = ok

E4 1 bits Error no. of the response 0 = ok

CC 2 bits Channel no. 0...3

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1st

MM X SSSSS E4 E3 E2 E1 0 0 CC

Analogue value, INTEGER

1 = B slave

dec

1 = protocol error (timeout)

1 = no analogue slave found

1 = protocol fault

7-19

Page 44

Set-up

Parameter setting of the Profibus host

Module 7: Command channel

Contents Command channel

→ page

8-1, chapter DP module 7: Command channel

Length 4-byte consistent I/O (if not used: length = 0)

IMPORTANT: For the query read only the required bytes. Unused bytes can

contain information of previous queries.

DP master request (4 bytes)

Bit

7 6 5 4 3 2 1 0

Byte

1

2

3

4

MM X SSSSS

→ Tables starting on the next page

→ Tables starting on the next page

Command no.

Calculation (MMXSSSSS):

(slave no.) + (master no. * 64

dec

) + (32

, if B slave)

dec

Controllere response (4 bytes, copy of the request)

Bit

7 6 5 4 3 2 1 0

Byte

1

2

3

4

Legend

D7 1 bit Error code 0 = no error occurred

D6 1 bit Command code 0 = command processed, buffer response valid

MM 2 bits Master no. 1...2

X 1 bit Slave type 0 = single or A slave

SSSSS 5 bits Slave no. 1…31

D7 D6 Command no.

MM X SSSSS

→ Tables starting on the next page

→ Tables starting on the next page

1 = error occurred during command processing

1 = command being processed, channel occupied

1 = B slave

dec

7-20

Page 45

Set-up

Parameter setting of the Profibus host

The commands are only executed if the command number (the first byte) changes. If the same

command is to be executed with different data several times (e.g. read slave lists), the operating mode

"continuous command" must first be selected for the data transfer. This is done with the command 62.

Overview of the commands in the DP module 7

Com

no.

1

2

3

4

5

6

7

8

Description Byte 2 Byte 3 Byte 4

► read master flags

> response:

► change operating mode

> response:

► read current slave configuration

> response:

► read projected slave configuration

> response:

► change projected slave

configuration

> response:

► read slave parameters

> response:

► change projected slave parameters

(default parameters)

> response:

► read LAS

> response:

MM000000

MM000000

MM000000

MM000000

MMXSSSSS

MMXSSSSS

MMXSSSSS

MMXSSSSS

MMXSSSSS

MMXSSSSS

MMXSSSSS

MMXSSSSS

MMXSSSSS

MMXSSSSS

MMXSSSSS

MMXSSSSS

0 –

master flags → page 8-2

AS-i master preset

operating mode

AS-i master current

operating mode

–

–

– –

slave configuration data

– –

slave configuration data

slave configuration data

slave configuration data

– –

projected

parameters

projected

parameters

projected

parameters

current parameters

–

–

– –

slave addresses from address group

► read LDS

MMXSSSSS

– –

9

> response:

► read LPF

MMXSSSSS

MMXSSSSS

slave addresses from address group

– –

10

> response:

► read LPS

MMXSSSSS

MMXSSSSS

slave addresses from address group

– –

11

slave addresses from address group

– –

12

> response:

MMXSSSSS

reserved – –

► read telegram error counter

MMXSSSSS

13

> response:

► read configuration error counter

MMXSSSSS

MM000000

error counter

– –

14

> response:

► read AS-i cycle counter

MM000000

MM000000

error counter

– –

15

> response:

MM000000

current count value of the cycle counter

7-21

Page 46

Set-up

Parameter setting of the Profibus host

Com

no.

16

17, 18

19

20

21

22

23

62

Description Byte 2 Byte 3 Byte 4

► change current slave parameters

> response:

MMXSSSSS

MMXSSSSS

parameters

reflected

parameters

–

–

reserved – – –

► config all

> response:

MM000000

MM000000

– –

status

–

reserved – – –

► save configuration in flash

> response:

► reset telegram error counter

> response:

► address slave

> response:

► operating mode "continuous

command“

> response: 0

MM000000

MM000000

MMXSSSSS

MMXSSSSS

– –

– –

– –

– –

MMXSSSSS 00XSSSSS

MMXSSSSS

0

– –

preset command

mode

current command

mode

–

0 = deactivate

1 = activate

0 = deactivated

1 = activated

63

► no operation command without

function

– – –

> response: – – –

7-22

Page 47

Set-up

Parameter setting of the Profibus host

Module 8: data transfer between Profibus DP master and PLC in the controllere

Contents Field for the data transfer between the Profibus DP master system and the PLC

functions in the controllere

Length 0...64-word inputs (if not used: length = 0)

Module 9: data transfer between PLC in the controllere and Profibus DP master

Contents Field for the data transfer between the PLC functions in the controllere and the

Profibus DP master system

Length 0...64-word outputs (if not used: length = 0)

Module 10: parallel analogue inputs

Contents

Parallel analogue inputs of up to 30 AS-i slaves, 1/2/4 words per AS-i slave; the

slave number and the number of analogue channels can be defined by Profibus

DP parameters.

Data length = 4 words (preset) All 4 channels of a total of up to 15 slaves on master 1 and 2 are

Data length = 2 words From slave 1 (of up to 30 slaves) on master 1 onwards, the channels 1

Data length = 1 word From slave 1 (of up to 30 slaves) on master 1 and 2 onwards, channel 1

transmitted.

Selection of the slaves to be transmitted via Profibus DP device

parameters (→ chapter

7-25)

page

and 2 are transmitted.

is transmitted.

Length 0...60-word inputs (if not used: length = 0)

Module 11: parallel analogue outputs

Contents

Parallel analogue outputs of up to 30 AS-i slaves, 1/2/4 words per AS-i slave; the

slave number and the number of analogue channels can be defined by Profibus

DP parameters.

Data length = 4 words (preset) All 4 channels on a total of up to 15 slaves on master 1 and 2

Data length = 2 words On slave 1 (up to 30 slaves) on master 1, the channels 1 and 2 are

Data length = 1 word On slave 1 (up to 30 slaves) on master 1 and 2 , channel 1 is

are transmitted.

Selection of the slaves to be transmitted via Profibus DP device

parameters (→ chapter

page

7-25)

transmitted.

transmitted.

Device-specific Profibus DP parameters,

Device-specific Profibus DP parameters,

Length 0...60-word outputs (if not used: length = 0)

NOTE

If analogue outputs are also triggered in module 6, the value written in module 6 is overwritten with

the data of module 11.

7-23

Page 48

Set-up

Parameter setting of the Profibus host

Module 12: Extended command channel

Contents Extended command channel

Length 2...18-word consistent inputs/outputs (if not used: length = 0)

NOTE

In some controllers larger consistent data fields cannot be processed in the direct I/O address area;

special function calls are then required.

7-24

Page 49

Set-up

Device-specific Profibus DP parameters

7.4 Device-specific Profibus DP parameters

With up to 100 bytes of the device-specific Profibus parameters the addresses of the analogue input

slaves and analogue output slaves to be transferred in parallel can be defined and the parameters of

the connected AS-i slaves can be set.

7.4.1 Device-specific Profibus DP parameters (example)

Byte

100

Parameter

[hex]

Description

1 80

2 00

fixed device parameters

3 00

4 00

5 AE fixed value: start of the analogue input addresses

6

…

20

42

…

slaves 2, 4, 6, 8,...30 of master 1

21 AA fixed value: start of the analogue output addresses

22

…

36

37

41

…

slaves 1, 3, 5, 7,...29 of master 1

2F bit 5 = TRUE activates the extended diagnosis of the AS-i system via Profibus DP

1F bit 4 = TRUE activates the AS-i parameter download

37

…

1F

…

predefined parameters of the AS-i slaves

FF

Slave addresses in the Profibus parameter bytes 6…20 and 22...36

Bit: 7 6 5 4 3 2 1 0

MM X SSSSS

Legend

MM 2 bits Master no. 1…2

X 1 bit Slave type 0 = single or A slave

1 = B slave

SSSSS 5 bits Slave no. 1…31

dec

Calculation of the more significant byte (MMXSSSSS):

(slave no.) + (master no. * 64

dec

) + (32

Examples: Master 1 Slave 3(A) 1*64 + 3

Master 2 Slave 5(A) 2*64 + 5 = 133

Master 1 Slave 1B 1*64 + 1 + 32

Master 1 Slave 28(A) 1*64 + 28

, if B slave)

dec

= 67

= 97

= 92

dec

= 85

dec

dec

dec

= 43

= 61

= 5C

hex

hex

hex

hex

7-25

Page 50

Set-up

Device-specific Profibus DP parameters

7.4.2 Definitions in the GSD file

The definitions in the GSD file (GSD = General Station Description) enable easy access to the device

parameters if this is supported by the configuration tool of the Profibus DP master:

Example

Siemens Step 7

Byte 37

Bit 5 = TRUE

If the parameter "Extended Profibus Diag." is set to "Enabled", the controllere transmits the extended

diagnostic data described in the next section. This data generates a DP request for a diagnosis in

case of an error state in the controllere. Therefore for a Siemens PLC OB82 must be programmed to