Mac Mini Model A1347 Teardown

Mac Mini Model A1347 Teardown

Step 1 -

Well folks, after much clamor, it seems the engineers at

Apple have finally included an HDMI port in an actual

Apple product.

Notable Tech Specs:

2.4 or 2.66 GHz Intel Core 2 Duo processor

2 GB of RAM (expandable up to 8 GB)

NVIDIA GeForce 320M graphics processor with

256MB of shared DDR3 SDRAM (the same as

the most recent MacBook)

HDMI port with support for up to 1920-by-1200

resolution

AirPort Extreme 802.11n Wi-Fi wireless

networking

SD card slot

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 1 of 13

Mac Mini Model A1347 Teardown

Step 2

Step 3

Departing from previous generations, the Mini's unibody

top enclosure is machined from a single block of

aluminum.

Measuring 1.4 x 7.7 x 7.7 inches and weighing only 3

lbs, this is truly one for the books.

Contents of box:

Mac Mini

HDMI to DVI adapter

Power cord

The black logo and other accents match quite nicely

with the styling of Apple's iPad and recent iMacs.

Congrats, Mini, you're no longer the black sheep of the

family!

The model number for this new unit is A1347.

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 2 of 13

Mac Mini Model A1347 Teardown

Step 4

The Mini's new port layout is indeed surprising:

Step 5

In comparison to the Mac Mini model A1176, the Mid

2010 is thinner and wider.

There is a definite difference in height between the Mid

2010 and previous iterations.

AC power in

Built-in 10/100/1000BASE-T ethernet

Firewire 800

HDMI

Mini DisplayPort

Four USB 2.0 ports, down one from the previous

Mac Mini

SD card slot

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 3 of 13

Mac Mini Model A1347 Teardown

Step 6

With a simple counter-clockwise twist, the black access

plate can be removed for easy RAM and fan access.

Gone are the days of the putty knife...you

will be missed old friend...

Step 7

Much like many other new Apple products, removing

the RAM is quite feasible this time around.

This little guy comes with two SO-DIMM slots capable

of supporting up to 8GB of RAM.

Our base unit came strapped with two gigs of RAM.

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 4 of 13

Mac Mini Model A1347 Teardown

Step 8

After removing two screws, the fan can be lifted out to

access its power connector.

The connectors inside this machine look pretty

consistent with those found in Apple's current product

lineup. Nothing too new here.

All three fan screws are isolated with rubber dampers; a

feature not seen on older apple machines. Low noise

and vibration are big selling points for Apple these

days, and the new Mini's idle emission of 14 dB is a

testament to those design goals.

Step 9

Like previous generations, the new Mini is cooled by a

single brushless fan.

The extremely high blade density of the blower pushes

a good amount of air while keeping noise at a minimum.

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 5 of 13

Mac Mini Model A1347 Teardown

Step 10

The Wi-Fi antenna plate is held in place by four screws.

After a good deal of wiggling, the antenna plate can be

slid out from under the lip of the outer case.

Step 11

The top Wi-Fi antenna connector is hidden underneath

the antenna plate near the hard drive connector.

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 6 of 13

Mac Mini Model A1347 Teardown

Step 12

Removing the cowling gives access to various

connectors on the logic board:

Hard drive flex cable

Optical drive flex cable (in the server model, this

is where the second hard drive flex cable is)

Thermal sensor cables

Infrared board cable

Step 13

Behold, iFixit's specialized Mac Mini Mid 2010 logic

board removal tool!

There are two blind holes in the case of the Mini that

are meant for the ends of Apple's u-shaped logic board

removal tool.

Being the shadetree mechanics that we are, we

decided to circumvent the special Apple tool in favor of

something that works just fine while keeping extra

dollars out of Mr. Jobs' pockets.

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 7 of 13

Mac Mini Model A1347 Teardown

Step 14

Before completely sliding out the logic board assembly,

the power supply connector must be disconnected.

After disconnecting the power cable, the logic board

assembly slides right out.

Step 15

The top and bottom of the logic board and I/O frame

assembly.

In using unibody construction, Apple had to get creative

with the placement of the antennas. Two auxiliary

antennas are the square steel components seen at

both ends of the I/O frame.

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 8 of 13

Mac Mini Model A1347 Teardown

Step 16

Two screws secure the speaker assembly to the logic

board.

The Mini's 3/8" woofer dome won't be popping ear

drums anytime soon.

Step 17

Next to where the speaker was located, we find the

AirPort Extreme card.

The Mac Mini Mid 2010 has 802.11n Wi-Fi wireless

networking, as well as Bluetooth 2.1 with Enhanced

Data Rate technology.

After disconnecting the remaining two antenna

connectors and its data cable, the AirPort card can be

easily removed from the logic board.

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 9 of 13

Mac Mini Model A1347 Teardown

Step 18

A couple of spring-loaded T8 Torx screws secure the

oddly shaped heat sink to the processors.

In keeping with its space saving design, the fins

directing air toward the vent hole are slanted to allow

for better fan placement.

Step 19

The I/O frame is held to the logic board by a few T6

Torx screws.

The two I/O bezel antennas are more visible in this

picture. The long antenna wires are grounded

periodically along their length, presumably for better

signal transmission to the important part - the antennas

themselves.

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 10 of 13

Mac Mini Model A1347 Teardown

Step 20

The bare logic board.

The brains of the unit feature:

Other notable chips include:

Intel P8600 2.4 GHz Core 2 Duo processor

NVIDIA GeForce 320M graphics processor with

256MB of shared DDR3 SDRAM

Broadcom BCM57765 integrated gigabit ethernet

and memory card reader controller

Cirrus 4206ACNZ audio controller

Delta LFE9249-R discrete LAN filter

Step 21

The Mac Mini comes with either a 320GB or 500GB

SATA hard drive.

Sadly, there's only one hard drive in our non-server

model.

Need more storage? Only time will tell if this Mac Mini

is as

recommend just getting the server edition.

easily modified as its predecessor. For now, we

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 11 of 13

Mac Mini Model A1347 Teardown

Step 22

The new Mini's power supply churns out a minuscule 7

Amps at 12V. Compare that to the 25.8 Amps at 12V

cranked out by the

Like its iMac cousin, the Mac Mini finally says goodbye

to external AC adapters.

Holy capacitors! Fingertips beware.

iMac Intel 27".

Step 23

The optical drive bay drive simply slides out of the

aluminum unibody housing.

Well what do we have here? Is this a new optical drive?

Why yes it is!

The optical drive is 12.5 mm thick, giving everyone a

glimmer of hope for a sweet Blu Ray installation...

Hitachi-LG Data Storage (HLDS) Super Multi

DVD Rewriter model GA32N

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 12 of 13

Mac Mini Model A1347 Teardown

Step 24

Due to popular demand, we've added

photos of the IR sensor/receiver.

The IR sensor/receiver is located on the optical drive

near the top right edge.

Step 25

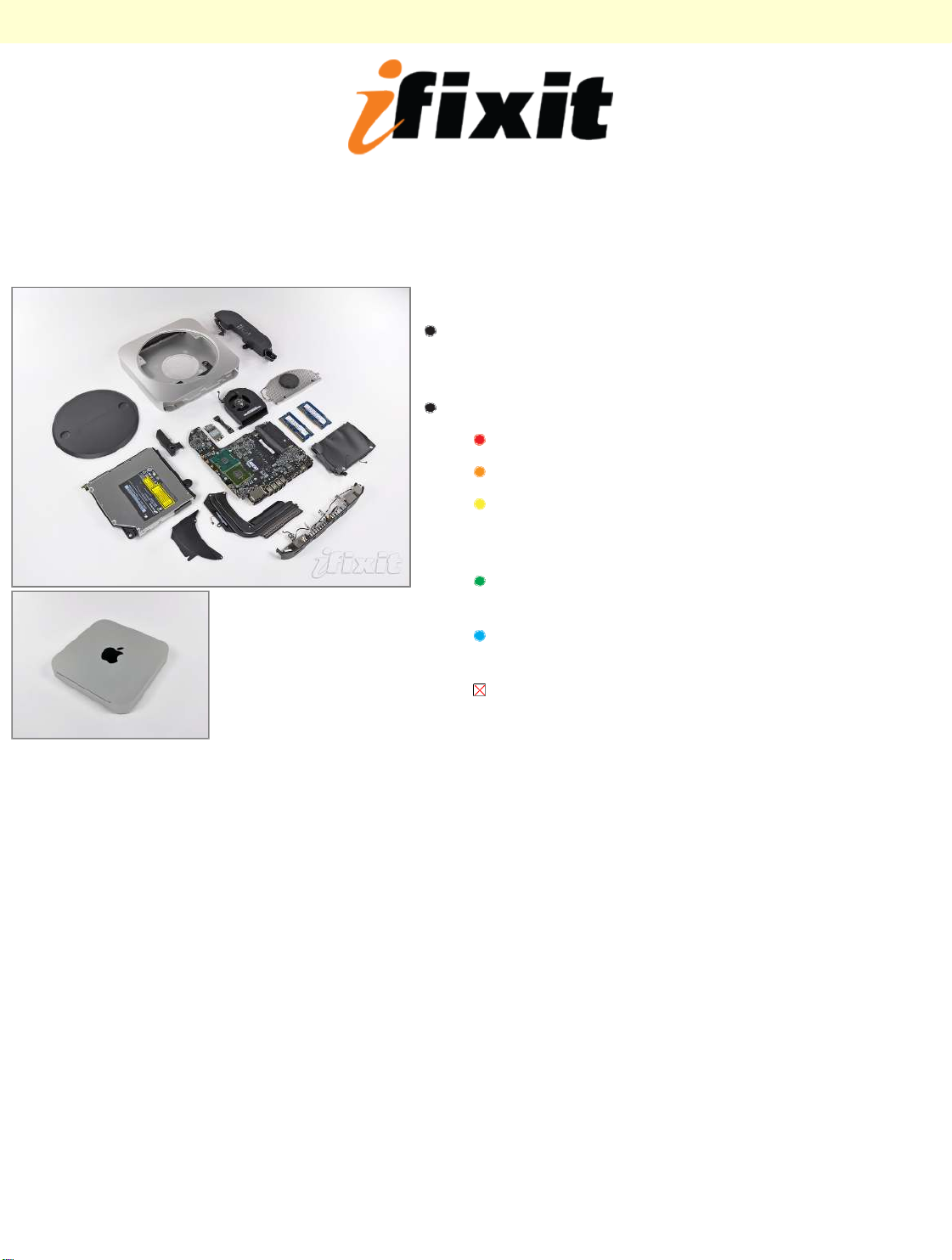

The remainders of the Mac Mini Mid 2010.

Macminicolo took apart the server version of the new

Mini. Check it out if you want to see how Apple stashed

the second hard drive.

Thanks for following iFixit during this historic moment.

Until next time!

© 2010 iFixit — CC BY-NC-SA www.iFixit.com Page 13 of 13

Loading...

Loading...