IFB EXECUTIVE PLUS WTEX+B Operating Manual

EXECUTIVE PLUS

USE ONLY GENUINE IFB SPARES & ACCESSORIES

* Company shall not be responsible for defects arising due to usage of spurious parts and accessories

OPERATING MANUAL

Advancing the science of washing

IFB Industries Limited, Plot No. IND - 5, Sector - 1, East Calcutta Township, Calcutta - 700 078

Visit us at www.ifbappliances.com

ALSO FROM IFB

CLOTHES DRYER

CAPACITY - 5.5KG

MICROWAVE OVEN

CAPACITY - 17 to 30 LITERS

DISHWASHER

CAPACITY - 12 PLACE SETTING

Customer Care

Dial

1860 425 5678 - BSNL & MTNL Callers

3900 4321 - Other Callers

or email

customerservice@ifbglobal.com

s

Dea

r

C

u

to

mer

m

he

i na i

o

A

wa

r

welco

me

to t

nt

er

t

onal

family

f

B t g a hi g

I

F

‘

umble

wa

sh’ technolo

y

b

sed

wa

s

n machin

e

owners.

ur

s

m is t y

Yo

wa hin

g

ac

hin

e,

ru

l goin

g

to

be

your

e

o n

r s e o

fre

d m

m

achi

e. It requ

i es

ju

t 30 s cond

s of y

ur

time in

l

i

ic

ti

m

.

oad

ng

the

fab

r s an

d set ng

the

pr

ogra me

o

to e

to

ple

s

T

hereafter

, y u are

tally

fr

e

do

wh

at yo

u

a e.

do n y

up

This

wa

shi

ng

m

achine es

ot need our

s

er

visio

n

o

s

o

e

n

qanym

re This

washing

m

achine

i

m

d

lle

d

o

the

un

i

ue

s

pt u e

o

d

s

‘tum

ble

wa

h’ co

nce

for s p

ri

r

fab

ric

ca

re

an

wa

h

performances.

A

o

l

i s

y

u read

thi

s

man

ua yo

u

w ll

understand

wh

at this

wa h

d

s

in

g

m

achine

ca

n o

for

yo

u.

fu

n, a

nt

a

t

r a tFor

an

y ther infor

m

atio

ple se

co

c

you

ne re

s

ede

lear or

I

F

B

sSer

vi

c

Cen

tre

.

3

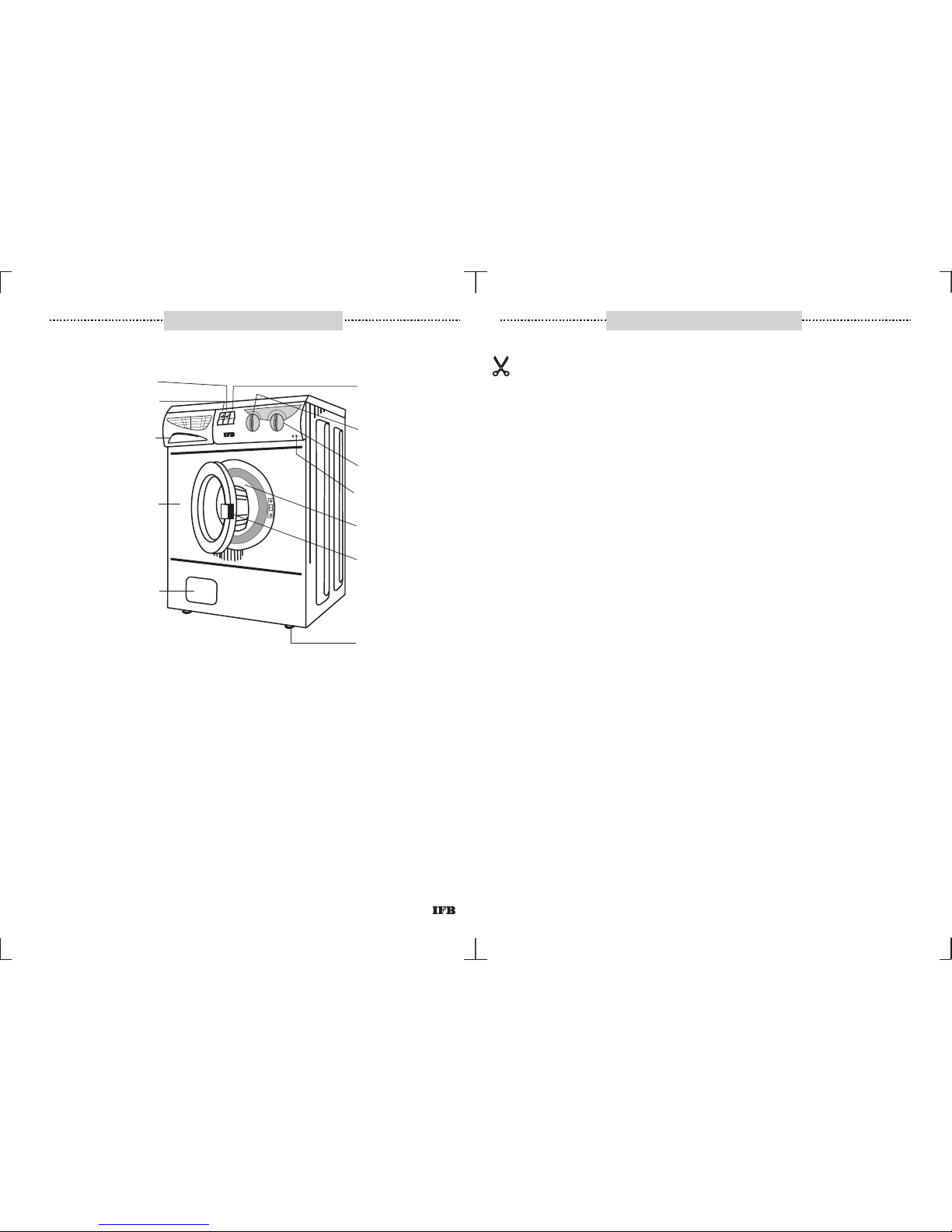

KNOW YOUR MACHINE

INSTALLATION 7

qPre Installation

qUnpacking

qSetting Up

qWater Inlet

qWater Outlet

q Electrical Connection

USING YOUR MACHINE 11

q Control Panel

qEnviromental protection / conservation issues

qBefore using your machine for the first time

qAutomatic Detergent Dispenser Tray

qSelector Buttons

qOn/Off Switch with Temperature Selector Knob

qProgramme Selector Knob

qIndicator Lamp

qKinds of Wash Programmes

qProgramme Selection

qProgramme Selection Chart

OPERATION 22

qSorting of Garments

qLoading the Machine

qDetergent to be used and Quantity

qFabric Conditioner

qTreatment of Stains

qWash Load Guide

qInternational Washing Symbols

qProgramme Run

qSwitching Off the Machine

qCheck Points

MAINTENANCE 27

qFluff Filters

qDrum

qSieves

qFrost Protection

qDraining During Emergencies

FAULT DIAGNOSIS 29

qWhy does it happen?

SAFETY PRECAUTIONS 30

TECHNICAL DATA 32

6

CONTENTS

5

MODEL : EXECUTIVE PIUS

DEALER’S NAME :

CUSTOMER’S NAME :

ADDRESS :

PIN CODE :

TEL. NO. (Resi.) (Off.)

E-MAIL :

MOTOR SR. NO. :

DATE OF PURCHASE :

SR. NO. WTEX+B

SERVICE STATION COPY

INSTALL THE MACHINE ONLY IF EARTHING IS PROPER

ADVANTAGES OF TUMBLE WASH

MOST EFFECTIVE CLEANING AS THE CLOTHES PASS

THROUGH SOAPY WATER AND ALSO FALL ON SOAP

SOLUTION IMPROVING WETTING OF CLOTHES.

qRESEMBLES THE THUMPING AND RUBBING ACTION OF

GENTLE HAND WASH.

qUSES LESS WATER COMPARED TO TUB TYPE TOP LOADERS.

qLESS WATER MEANS LESS DETERGENT AND ELECTRICITY

CONSUMPTION.

qWASHING IS EFFECTIVE BY DETERGENCY, SOAKING,

HEATING, TUMBLING AND SQUEEZING.

qGIVES BETTER DRYING EFFECT BY SPINNING.

q

5

0

0

6

E

F

D

C

G

B

H

A

TE E

RA U

REM

P T

E

A U

RT M

PE

R T

E

50

60

EXECUTIVE Plus

As

a

1

2

a

a

a

a

5

a

Asa

2

a a

a

a

5

a

As

2

a

a

a

a

5

a

a

A

s

2a

a

5

a

a

a

5

a

Spin Speed

Selector Button

On/Off Switch

with Temperature

Selector Knob

Programme

Selector Knob

Indicator Lamps

Porthole Door

Spin Cancel Button

Water Plus Button

Detergent Tray

(with Programme

Selection Chart)

Special powder

coated Galvanised

steel Cabinet

Fluff Filter Door

Adjustable Feet

for Levelling

Interlocking Door

Lock Handle

KNOW YOUR MACHINE

6

..........................................................................................

INSTALLATION REPORT

IFB WASHING MACHINE

Model : __________________ Serial No. : ______________Customer’s Name : __________________

_________________________________________________Tel. No. ___________________________

Address :___________________________________________________________________________

__________________________________________________________________________________

Installation Check Points

Machine Delivered on : __________________ Machine Installed on :_______________

1. Any Major transit damage to the machine observed Yes No

2. Condition of Earthing/Plug Point (16 Amp.

230V AC with MCB or other automatic short circuit

protection devices. )good

If poor, customer has been advised, to correct the same Yes No

3. User Manual Delivered Yes No

4. Inform user of need to keep drain hose

straight & maximum height of draining. Yes No

5. Warranty term explained Yes No

6. Machine levelling procedure &

importance explained Yes No

7. Detergents and bleach recommendation

revelent DD tray chambers explained Yes No

8. Basic wash demo given Yes No

9. Trouble shooting explained Yes No

10.Check following for proper order :

a. Inlet Hose Yes No

b. DD Tray Yes No

c. Ratmesh fitted ( If applicable ) Yes No

d. Drain hose Yes No

11.Do’s and Don't’s explained Yes No

12.Display function explained ( If applicable ) Yes No

13.Procedure for cleaning rubber sleave / coin trap Yes No

14.Program selection, Programs & buttons options

( other knob ) explaind Yes No

15.Indicator lamp/Status LED function ( if Applicable ) Yes No

16.Buzzer function ( if Applicable ) Yes No

Installed by :_______________________ Signature : ________________________________

Customer’s response

1. The installation person was courteous & Helpful. Yes No

2. I would describe my experience

with installation as Unacceptable Satisfactory

Non Satisfactory Very Satisfactory

I certify that the above information & checks have been done to my satisfaction & I am fully satisfied with

the installation of the washing machine.

Customer’s Signature________________Date :__________________ Time : ____________

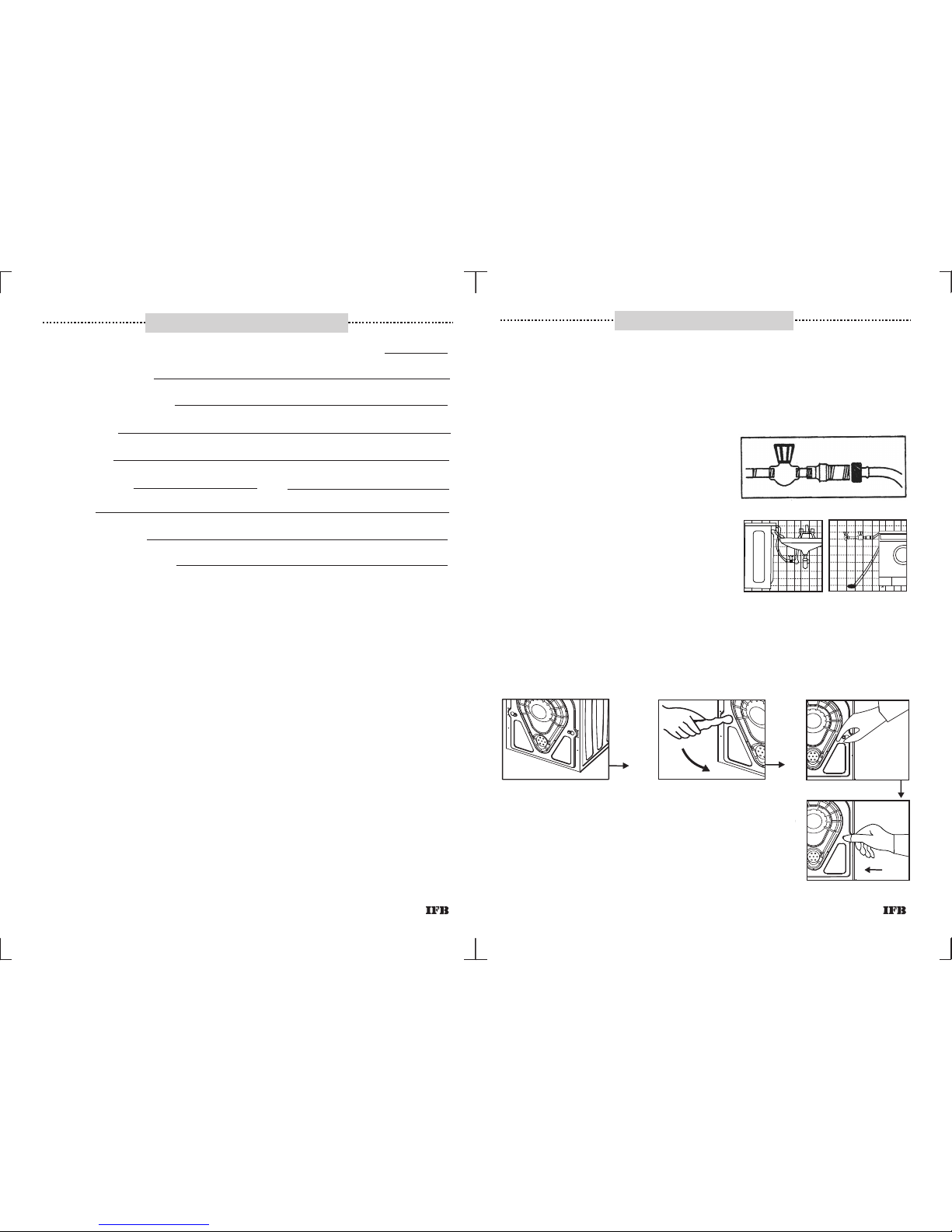

WATER INLET

DRAIN

PIPE

WATER INLET

DRAIN

PIPE

WATER

SUPPLY

STOP

LOCK

REDUCER

MACHINE

WATER

INLET

1/2

3/4

1. Remove Carton.

2. Remove top packing cover.

3. Remove side packing and plastic jacket.

4. Remove packing from the bottom of the

motor

5. Place the machine at the site at which it is to be

Installed, and put the rat mesh.

Unpacking

INSTALLATION

Pre Installation

1. It is mandatory to have a 16 amp. 3-pin 230V AC, 50Hz

electrical point with a 16 amp. MCB or Automatic short

circuit protection device within 1 meter of the machine.

Make sure it has proper earthing.

2. Fixed plumbing is recommended

for the machine. The water inlet

of th e machine h as a collar

with3/4”parallel internal threads.

The water supply point with an

ex t ernal 3/ 4 ” p aral l e l t hre a d

should be available within1 meter

of the machine’s location.

3. Two options on the water inlet and

drain pipe connection are shown.

In case these possibilities do not

exist for the drain pipe, please

arrange an additional length of

pipe.

4. Please inform our service centre for installation and demonstration

of the machine once the points mentioned above have been

completed.

7

MODEL : EXECUTIVE PIUS SR. NO. WTEX+B

DEALER’S NAME :

CUSTOMER’S NAME :

ADDRESS :

PIN CODE :

TEL. NO. (Resi.) (Off.)

E-MAIL :

MOTOR SR. NO. :

DATE OF PURCHASE :

CUSTOMER COPY

34

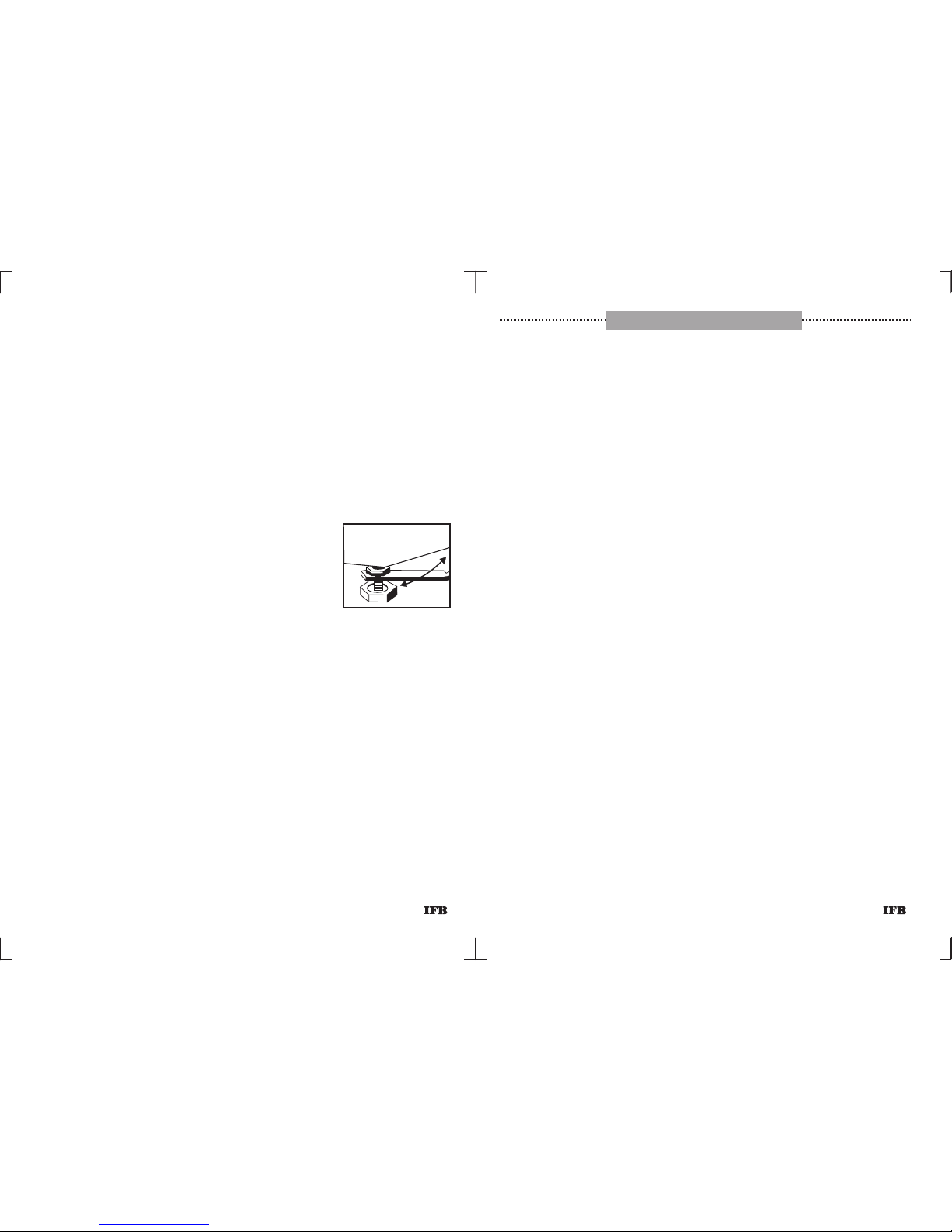

Setting Up

The machine should be levelled properly on the

floor. However, it can be installed on any suitable

platform or trolley, as desired.

Install machine in a room with adequate

ventilation. Avoid a room with no windows. The

back of the machine should be at least 4 inches

(100 mm) away from the wall.

1. Do not place the machine on slanting, uneven,

unstable surface.

2. Level the machine by using the adjustable screws provided at the

bottom for levelling.

3. Loosen securing nut. Adjust the screw to change level. Tighten

securing nut to ensure that screw is locked into place.

4. Make sure that the machine rests on all four feet on a level

surface, at all times, to avoid vibrations during operation

5. Machine should be leveled again in case it is moved to a new site.

6. Machine is provided with ventilating openings on the base. Hence it

is always recommended to put the machine on the floor after

removing the carpet.

7. In countries where there are areas which may be subjected to

infestation by cockroaches or other insects etc, pay attention to

keep the appliance & surrounding in clean condition at at all times

any damage which be caused by cockroaches etc will not be

covered by the appliance guratantee.

6. Remove transit bolts.

7. Insert plastic caps provided into holes vacated and press till they

click into place.

8. Keep transit bolts carefully. They will be required in case you need to

shift the machine again.

9. For shifting and re-installation at a new site, please get in touch with

our ser vice personnel.

10. Keep packaging material carefully. It comes handy while shifting

residence.

11. PLEASE DO NOT OPERATE THE MACHINE TILL TRANSIT BOLTS

HAVE BEEN REMOVED.

8

Dimensions (DxWxH) : 56 cm x 60 cm x 85 cm

Weight : 57 kgs

Capacity : 5 Kg. of dry clothes (cotton)*

Programmes : 18 Wash Care Programmes

Selector Buttons : Water Plus, Spin Cancel, Spin

Speed Selector

Spin Speed : 600 to 800 rpm

Heater Rating : 1.9Kw

Drum : Stainless Steel

0

Temperature Selection : Cold to 90 C

Drain Pump Rating : 30 Watts

Water Consumption : 45 litres for standard wash.

Power Consumption : 0.25 unit for cold wash

0

Cotton Wash Programme : 1.2 - 1.5 unit hot wash at 60 C

Connected Load : 2.35 KW Max.

Programme Duration : 30 to 95 minutes

Power supply : 220 - 240 V, Single Phase, 50 Hz

2

Water Pressure : 1 bar ( 1.03 kg/cm ) - 10 bar ( 10.3

2

kg/cm )

Specifications are subject to change without Prior notice.

*Capacity depends on size, texture and combination of clothes

Depending on water pressur e, Water hardness, Water in let

Temperature, Quantity and type of textile, Detergents used, Degree of

soiling, Ambient condition, selected additional functions & power supply

fluctuations the actual values given on or with the machine can deviate

from the declared standard values, as they are tested according to the

laboratory conditions

TECHNICAL DATA

33

Loading...

Loading...