IET Labs PRS-200 Operation Manual

♦ PRECISION INSTRUMENTS FOR TEST AND MEASUREMENT ♦

PRS-200 SERIES

High Precision

Manual or SCPI Programmable

Decade Resistance Substituters

(IEEE-488.2, RS232 or Ethernet)

Operation Manual

PRS200 IEEE.2 im/May 2015

IET LABS, INC.

Copyright 2015 IET Labs, Inc.

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

www.ietlabs.com

♦ PRECISION INSTRUMENTS FOR TEST AND MEASUREMENT ♦

IET LABS, INC.

TEL: (516) 334-5959 • (800) 899-8438 • FAX: (516) 334-5988

www.ietlabs.com

WARRANTY

We warrant that this product is free from defects in material and workmanship and, when properly used,

will perform in accordance with applicable IET speci cations. If within one year after original shipment,

it is found not to meet this standard, it will be repaired or, at the option of IET, replaced at no charge when

returned to IET. Changes in this product not approved by IET or application of voltages or currents greater

than those allowed by the speci cations shall void this warranty. IET shall not be liable for any indirect,

special, or consequential damages, even if notice has been given to the possibility of such damages.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

i

WARNING

OBSERVE ALL SAFETY RULES

WHEN WORKING WITH HIGH VOLTAGES OR LINE VOLTAGES.

Dangerous voltages may be present inside this instrument. Do not open the case

Refer servicing to quali ed personnel

HIGH VOLTAGES MAY BE PRESENT AT THE TERMINALS OF THIS INSTRUMENT

WHENEVER HAZARDOUS VOLTAGES (> 45 V) ARE USED, TAKE ALL MEASURES TO

AVOID ACCIDENTAL CONTACT WITH ANY LIVE COMPONENTS.

USE MAXIMUM INSULATION AND MINIMIZE THE USE OF BARE

CONDUCTORS WHEN USING THIS INSTRUMENT.

WHEN WORKING WITH HIGH VOLTAGES, POST WARNING SIGNS AND

Use extreme caution when working with bare conductors or bus bars.

KEEP UNREQUIRED PERSONNEL SAFELY AWAY.

CAUTION

DO NOT APPLY ANY VOLTAGES OR CURRENTS TO THE TERMINALS OF THIS

INSTRUMENT IN EXCESS OF THE MAXIMUM LIMITS INDICATED ON

THE FRONT PANEL OR THE OPERATING GUIDE LABEL.

ii

CONTENTS

WARRANTY ................................................................................................ i

WARNING .................................................................................................. ii

CAUTION ................................................................................................... ii

Chapter 1: INTRODUCTION ..................................................................... 1

Chapter 2: SPECIFICATIONS ................................................................... 3

2.1 Model Conguration and specications ............................................................3

2.2 General specications ........................................................................................4

Chapter 3: OPERATION ............................................................................ 7

3.1 Initial inspection and setup ................................................................................7

3.2 Connection .........................................................................................................7

3.2.1 General Considerations ............................................................................7

3.2.2 Electrical Considerations .........................................................................7

3.2.3 Four-Wire Kelvin Lead Connections .......................................................7

3.2.4 Thermal emf Considerations....................................................................7

3.3 Dial Setting ........................................................................................................8

3.4 Environmental Conditions .................................................................................8

3.5 Local Operation .................................................................................................8

3.6 Remote Operation ..............................................................................................8

Chapter 4: ETHERNET OPTION ............................................................. 10

4.1 Ethernet Programming .....................................................................................10

4.2 Network Setup ............................................................................................................. 10

4.3 Ethernet Test Keyboard ........................................................................... ....................10

4.4 Network Conguration ................................................................................................ 11

4.5 Web Browser Conguration ........................................................................................ 11

4.6 VXI Conguration Utility ........................................................................................... 13

4.7 Resetting Default Network Settings ............................................................................ 15

4.8 PRS Programming ....................................................................................................... 15

Chapter 5: IEEE INTERFACE OPTION ................................................... 16

5.1 Introduction .......................................................................................... 16

5.2 Capabilities ........................................................................................... 16

5.3 Address Switch and Communications Settings .......................................... 16

5.4 IEEE Option Operation .......................................................................... 17

5.5 GPIB Test Keyboard ........................................................................................17

iii

Chapter 6: SERIAL INTERFACE OPTION .............................................. 18

6.1 Introduction .......................................................................................... 18

6.2 Capabilities ........................................................................................... 18

6.3 Signal Interface and Communications Settings ......................................... 18

6.4 Serial Option Operation .......................................................................... 18

6.5 Serial Test Keyboard ........................................................................................19

Chapter 7: PROGRAMMING ................................................................... 20

7.1 Introduction .......................................................................................... 20

7.2 Command String Structure ..................................................................... 20

7.3 Advanced Programming Software Driver ................................................. 21

Chapter 8: MAINTENANCE .................................................................... 24

8.1 Verication of Performance .................................................................... 24

8.2 Calibration Interval ................................................................................ 24

APPENDIX A: SCPI COMMAND REFERENCE ...................................... 25

APPENDIX B: IEEE.2 COMMON COMMANDS ...................................... 27

iv

PRS-200 Series

Chapter 1

INTRODUCTION

The PRS Series (Figure 1.1) is a broad

line of high precision manual and programmable decade substituters. They provide direct

resistance substitution as well as RTD (Resistance Temperature Detector) simulation, in a

wide selection of ranges, tolerances and ratings.

The PRS substituter is a precision resistance source with excellent characteristics of

stability, temperature coefcient, and power

coefcient. High dynamic ranges are available, starting as low as 1 mΩ, and extending

to as many as 10 decades. These features

combined with a low virtually constant “zero

resistance” make for very versatile instruments.

The PRS Series features two optional

special settings. An “open circuit” and a “short

circuit”. These modes are useful for obtaining

reproducible transitions between settings, i.e.

break-before-make or to short between settings. The “short circuit” setting also provides

a reduced zero resistance.

Operation is both local using convenient

direct-reading front panel thumbwheel switches, and remote with optional Ethernet, RS-232,

or IEEE-488 interfaces. Both can provide an

optional extra “10” position for each decade.

currents are passed through them. This is most

often the case when only minute test currents

are drawn by digital multimeters and other test

instruments. Contact resistance remains low

and repeatable.

High-quality gold-plated tellurium-copper

ve-way binding posts serve to minimize the

thermal emf effects, which would produce errors in dc resistance measurements. All other

conductors within the instrument, as well as the

solder employed contain no metals or junctions

that could contribute to thermal emf problems.

With a resolution as low as 1 mΩ and

a maximum available resistance of over 100

MΩ, the PRS-202 Series may be used for

exacting precision measurement applications

requiring high accuracy, good stability, and low

zero resistance. They are suited for automatic

and manual calibration and testing, simulation

of RTD’S, programmable loads, and many

other laboratory and industrial applications.

The PRS Series may be rack mounted

to serve as components in measurement and

control systems.

The PRS Series employs very low resistance, low thermal emf relays with gold-clad

silver-alloy contacts. A special design keeps

contact resistance to a minimum. The gold

plating keeps the silver contacts from becoming tarnished when unused, or when only low

INTRODUCTION

Figure 1.1: High Precision Manual or Programmable

Decade Resistance Substituter

1

PRS-200 Series

This page is intentionally left blank.

2

INTRODUCTION

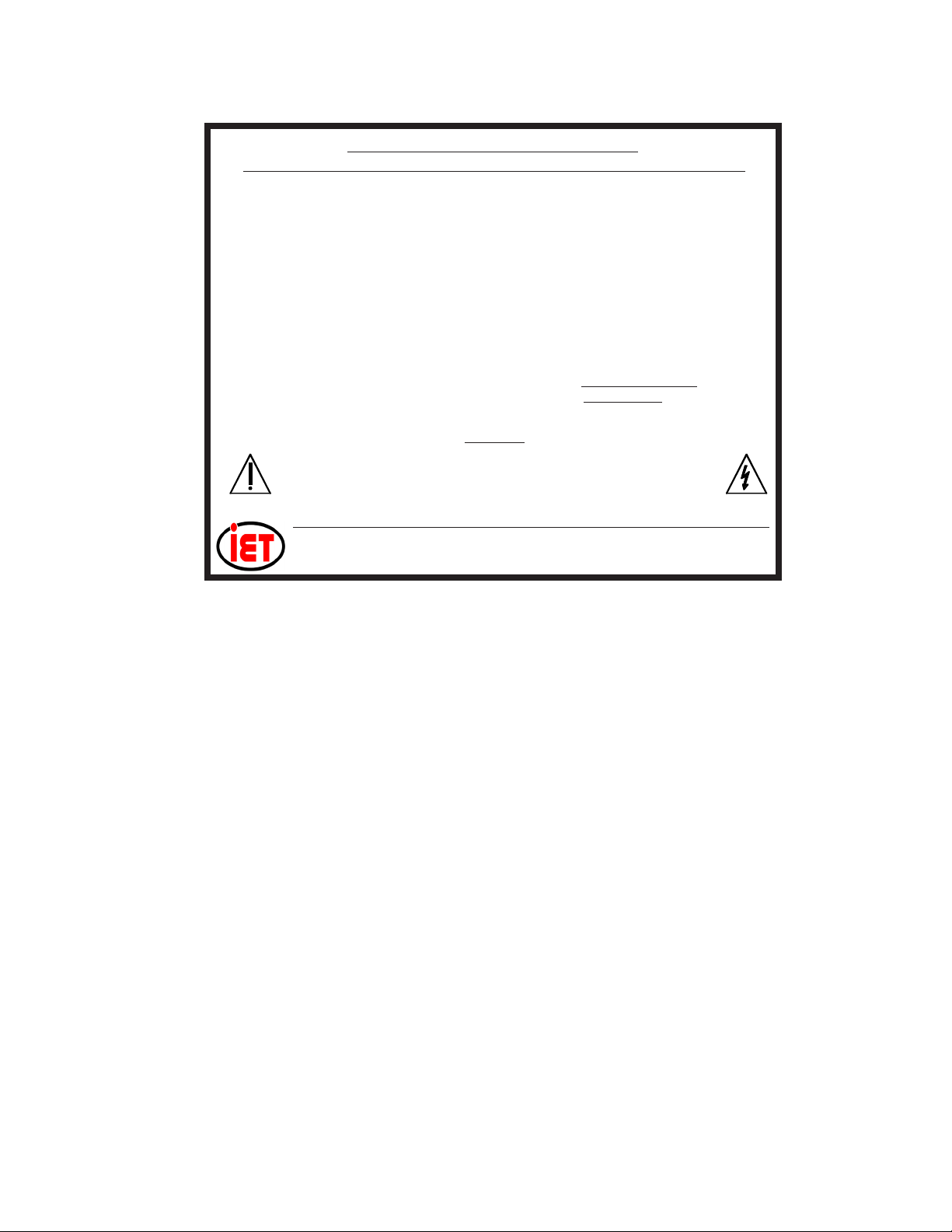

PRS SERIES OPERATING GUIDE

CONSULT INSTRUCTION MANUAL FOR PROPER INSTRUMENT OPERATION

Resistance Type: Metal film.

Range: 0 to 9,999,999 Ω, in 1 Ω steps.

Accuracy: ±(0.1% + 30 mΩ), after subtraction of zero setting resistance; traceable to NIST.

Zero Resistance: <450 mΩ, <410 mΩ, typical; <560 mΩ if OC (Open Circuit) option is pres-

ent; <20 mΩ, with SC (Short Circuit) option activated.

Maximum Load: 0.5 A, or 200 V (dc + peak ac), or 1 W/step, whichever applies rst.

Interface: IEEE-488.2-1987,SCPI 1994.0; front panel switch selects REMOTE or LOCAL

operation; “*IDN” for S/N, Model & REV; “CAL:DATe?” for last calibration date.

Ground: GND terminal on front panel is connected to both chassis and earth ground.

Operation: Unit should be allowed to stabilize for one hour. For maximum stability, allow unit

to warm-up over two hours and keep free from mechanical disturbances.

PRS-200 Series

POWER: 105-125 V, 50-60 Hz

FUSE: 0.25 A

WARNING

Observe all safety rules when working with high voltages or line voltages. Connect the shield to earth

ground in order to maintain the case at a safe voltage. Whenever hazardous voltages (>45 V) are used,

take all measures to avoid accidental contact with any live components: a) Use maximum insulation and

minimize the use of bare conductors. b) Remove power when adjusting switches. c) Post warning signs

and keep personnel safely away.

MODEL: PRS-201-1W-IEEE.2

SN: G2-XXXXXXX

IET LABS, INC. • Long Island, NY • info@ietlabs.com • (516) 334-5959 • (800) 899-8438

CAGE CODE: 62015 www.ietlabs.com

PRSBLBL/p27/PRS201-1W-IEEE.2/05-15

FIGURE 2.1 Typical OPERATING GUIDE Afxed to Unit

(Please see label afxed to your unit)

OPERATION

5

PRS-200 Series

Chapter 3

OPERATION

The GND terminal on all models is con-

nected to the case and to earth and chassis

grounds. This may be used as a shield terminal.

3.2.2 Electrical Considerations

The performance of the PRS is directly

affected by the quality of the connection to the

system under test. This is particularly true with

the precision series models having higher-accuracy and/or lower-impedance decades.

For optimum performance, contact resistance should be kept to a minimum by using

the most substantial mating connection possible, and by assuring that the connection is well

secured to the binding posts.

3.2.3 Four-Wire Kelvin Lead Connec-

tions

4-wire Kelvin leads minimize the effects

of contact resistance and approach ideal performance. The CURRENT and SENSE HI/

LO terminal pairs may be shorted together to

provide a 2-terminal connection in instances

where high accuracy is not a concern.

3.1 Initial inspection and setup

This instrument was tested and carefully

inspected before shipment. It should be in

proper electrical and mechanical order upon

receipt.

An OPERATING GUIDE is attached

to the case of the instrument to provide ready

reference to specications.

Mount the unit in a standard 19” rack if

the rack mount option is specied.

3.2 Connection

3.2.1 General Considerations

The PRS Series Decade unit is built in

3-terminal or 5-terminal versions. The binding

posts are standard laboratory type and readily

accept banana plugs, telephone tips, spade lugs,

alligator clips, and bare wire. Binding posts

are located on the front panel of the instrument

unless specically ordered with a Rear Output

option.

3.2.4 Thermal emf Considerations

The PRS Series uses high-quality, lowemf components. Thermal emf is primarily

attributable to the temperature difference

between the leads of the relay and the contacts

when temperature is applied to the coil. This

emf is of the order of 5 µV per relay, but is not

usually additive. The typical worst case is <15

µV.

6

The 3-terminal version posts are labeled

HI, LO, and GND. The HI and LO terminals

are connected to the ends of the internal imped-

ance being set.

5-terminal models provide four Kelvin

terminals consisting of a CURRENT and a

SENSE pair, each labeled HI and LO. These

minimize contact resistance.

OPERATION

Loading...

Loading...