Operating Instructions

Compact Overfill Sensor, Float Type MAXIMAT VK C...

with integrated mesuring Transducer, DIBT Approval Z-65.11-355

:

Safety Precautions

• Installation, initial start-up and maintenance may only be

performed by trained personnel! All applicable European and

national regulations regarding installation of electrical

equipment must be adhered to.

• The device may only be connected to supply power which

complies with the specifications included in the technical data

and on the serial plate!

• The device must be disconnected from all sources of power

during installation and maintenance work!

• The device may only be operated under the conditions

specified in the operating instructions!

Functions Description

The MAXIMAT VK C... compact overfill sensor is used as a filllevel limit switch for permanently installed containers used for the

storage of non-flammable, water endangering liquids.

It is equipped with three different output circuits:

• A binary output for controlling a coupling relay, or the digital

input of a PLC

• A 0 to 20 mA current output for controlling an analogue input

channel, e.g. a programmed logic controller (PLC)

• Self-monitoring measuring circuit in combination with the

MAXIMAT SHR C... measuring transducer with 2-wire

connection

Note:

Only for liquids with density greater than 0.7g/cm³

The MAXIMAT VK C... compact overfill sensor is used also for oil,

emulsion and other non-conductive liquids.

Technical Data

Supply power

24 V DC ± 10%

With current limiting or 250 mA fuse recommended

Connected load

Approx. 3 W

Ambient temperature

-20 to +60

°

C

Container pressure

Atmospheric (0.8 to 1.1 bar)

Terminal housing

IP 65

Terminals

Screw terminals: IP 20

Max. wire cross-section: 2.5 mm²

Outputs

Binary output: +DO/-DO max. 20 mA / 24 V +AO / -AO

0 to 20 mA

Output for MAXIMAT SHR C... measuring transducer

DIP Switch

Operating Mode DIP1 DIP2 DIP3 DIP4

Binary output ON ON ON OFF

Current output/PLC OFF OFF OFF OFF

MAXIMAT SHR C OFF * OFF * OFF * OFF *

* Default setting

Note:

Be sure to examine the DIP switch settings before

switching supply power on!

Indicators

• Run = LED illuminated

Green LED on the connector PCB:

• Alarm / error = LED off

Measuring circuit for use with SHR C... transducer

Max. cable inductance: approx. 5 mH

Max. cable capacitance: approx. 0.5 µF

Measuring circuit cable length

Max. 300 m

Min. wire cross-section: 0.5 mm²

CE mark

In accordance with low-voltage directive (73/23/EWG),

EMC directive (89/336/EWG) and

• EN 50 082-2:1995

• EN 55 011 (class A):1998

DIBT Approval

Approval no. Z-65.11-355 for overfill sensors and leakage

sensors in accordance with WHG §19

Note:

The accompanying “General Building Supervisory Approval

no. Z-65.11-355” is an integral part of the operating

instructions and all stipulations contained therein must be

adhered to!

SU0213.DOC 06/03 © IER Eberhard Henkel GmbH Sheet 1

Operating Instructions: MAXIMAT VK C Compact Overfill Sensor, Float Type

Electrical connection:

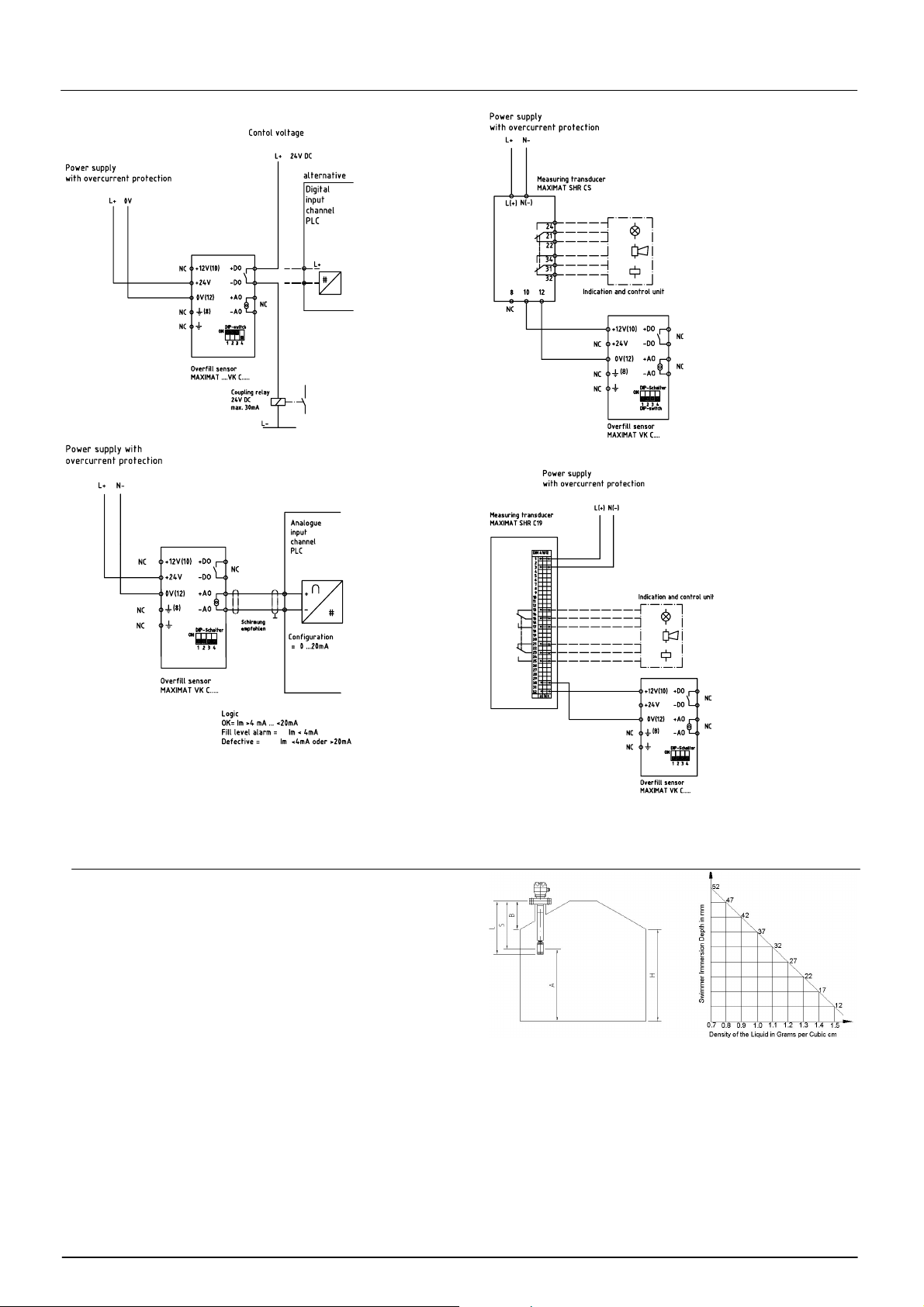

MAXIMAT VK C... binary output to coupling relay

MAXIMAT VK C... current output to PLC analogue input

Adjustment Instructions

The maximum allowable fill-level of any given tank can be

determined, for example, in accordance with TrbF 280 no.

2.2. Triggering level A is then calculated in accordance

with attachment 1, or the approval guidelines for overfill

inhibitors (ZG-ÜS). Dribbling quantities and switching delay

times must be taken into consideration. Switching delay

time can be adjusted at the MAXIMAT SHR C measuring

transducer within a range of 0.3 to 3 seconds.

Installation length L determines the fill-level monitor’s

triggering point.

Dimensions are calculated as follows:

H = tank height

A = triggering level

B = connector

E = immersion depth, table E

S = triggering point

L = H - A + B + E + 3

S = L - E – 3

MAXIMAT VK C... to MAXIMAT SHR CS measuring

transducer

MAXIMAT CK C… to MAXIMAT SHR C19 transducer

Guide tubes included with MAXIMAT VK.3L and

MAXIMAT VK.4L adjustable level monitors are supplied 50

mm longer than dimension L, so that the fill-level monitor

can be adapted to correspond to triggering level A during

installation. It is thus possible to readjust dimension L.

After the triggering point has been set, the locking screws

are tightened and sealed against tampering. Due to the

fact that this seal is not removed during periodic testing,

dimension L is always fixed, i.e. no readjustment is

necessary

SU0213.DOC 06/03 © IER Eberhard Henkel GmbH Sheet 2

Loading...

Loading...