Page 1

IEI MiniMax 3

Installation/Programming Manual

Document Number: 6055672

Revision: 1.0

Date: 01/23/07

Page 2

Table of Contents IEI MiniMax 3 Installation/Programming Manual

Table of Contents

Section 1: System Features and Specifications........................................................ 5

1.1 System Features...........................................................................................................................5

1.2 Specifications................................................................................................................................6

1.3 System Defaults............................................................................................................................6

1.4 Max 3 Door Control Module Diagram...........................................................................................7

1.5 Backplane Diagram.......................................................................................................................8

Section 2: Installation................................................................................................... 9

2.1 Check the Packing List..................................................................................................................9

2.2 Mount the Enclosure.....................................................................................................................9

2.3 Ground the Unit...........................................................................................................................10

2.4 Connect the RS-485 Cable from the Module to the Backplane..................................................11

2.5 Wire an Electric Door Lock to the Main Relay of the Max 3 Module.......................................... 12

2.5.1 Installing a Diode to Prevent Electrical Kickback from Lock – DC Locks Only................... 13

2.5.2 Installing an MOV to Prevent Electrical Kickback from Lock – AC Locks Only...................13

2.6 Connect a Secured Series Front End (SSFE) Reader to the Door Control Module...................14

2.7 Connect the Primary Wiegand Front End Reader (IN Reader).................................................. 15

2.8 Connecting a Secondary Wiegand Front End Reader (OUT Reader)........................................16

2.9 Wire a Request to Exit (REX) device and Door Contact.............................................................17

2.10 Wire the Alarm Shunt Relay......................................................................................................18

2.11 Wire the Door Ajar Relay..........................................................................................................19

2.12 Wire the Forced Door Relay......................................................................................................20

2.13 Network the MiniMax 3..............................................................................................................21

2.13.1 Connect the MiniMax 3 Backplane Directly to a PC..........................................................21

2.13.2 Connect Multiple Backplanes Together.............................................................................22

2.13.3 Connect the SEG-M to the MiniMax 3 (LAN/WAN Connection)........................................23

2.13.4 Connecting the SEG-1 to the MiniMax 3 (LAN/WAN Connection)....................................24

2.14 Installing a Tamper Switch........................................................................................................25

2.15 Complete Connections Between the 16.5 VAC Transformer and Backplane.......................... 26

2.16 Power up the System................................................................................................................27

Section 3: Programming............................................................................................ 28

3.1 Programming Methods................................................................................................................28

3.2 Entering Program Mode and Changing the Master Code...........................................................29

3.2.1 Entering Program Mode.......................................................................................................29

3.2.2 Changing the Master Code..................................................................................................29

3.2.3 Programming a Supervisor Code........................................................................................29

3.3 Changing the Door Number........................................................................................................30

3.4 Changing the Main Relay Time...................................................................................................30

3.5 Setting the Time and Date..........................................................................................................30

3.6 Programming Users....................................................................................................................31

3.6.1 User Types...........................................................................................................................31

3.6.2 Programming a “Code Only” User.......................................................................................32

3.6.3 Programming “Card Only” Users by Presentation..............................................................32

3.6.4 Programming 26-Bit “Card Only” Users without Presentation.............................................32

3.6.5 Programming “Code AND Card” Users...............................................................................33

3.6.6 Programming “Code or Card” Users....................................................................................33

3.6.7 Programming 26-Bit “Card Only” Users via Batch Entry without Presentation................... 33

Page 2 of 48 Document #: 6055672, Rev 1.0 D1c

Page 3

IEI MiniMax 3 Installation/Programming Manual Table of Contents

3.6.8 Programming Consecutive “Card Only” Users via Batch Entry by Presentation................ 34

3.6.9 Command 50 Quick Program Feature - “Code Only” or “Card Only”..................................34

3.7 Deleting Users.............................................................................................................................35

3.7.1 Delete a Single User............................................................................................................35

3.7.2 Delete a Block of Users.......................................................................................................35

3.8 Programming Extended Unlock Time.........................................................................................36

3.9 Programming Facility Code.........................................................................................................36

3.10 Programming User Lockout......................................................................................................36

3.11 Programming the Door Ajar Output Time.................................................................................37

3.12 Programming the Forced Door Time........................................................................................37

3.13 Using the Default Auto-Unlock Timezone.................................................................................38

3.13.1 Enable/Disable Timezones................................................................................................38

3.13.2 Enable/Disable Auto-Unlock..............................................................................................38

3.13.3 Enable/Disable First-In Auto-Unlock..................................................................................38

3.14 Programming Error Lockout......................................................................................................39

3.14.1 Setting the Error Lockout Threshold..................................................................................39

3.14.2 Setting the Error Lockout Duration....................................................................................39

3.15 Programming Wiegand LED Active State.................................................................................39

3.16 Programming Wiegand Sounder Active State..........................................................................40

3.17 Enable/Disable Control Module Audio Indicators..................................................................... 40

3.18 Reseting System Defaults and Erasing Memory......................................................................41

3.18.1 Resetting the Master Code and System Defaults Only.....................................................41

3.18.2 Erasing Entire Memory/Resetting System Defaults.......................................................... 41

3.18.3 Erasing the Transaction Event Log...................................................................................41

3.19 Programming Daylight Savings Time........................................................................................42

3.19.1 Enabling/Disabling Daylight Savings Time........................................................................42

3.19.2 Selecting Daylight Savings Time Format...........................................................................42

3.20 Programming Options Chart.....................................................................................................43

Section 4: Troubleshooting........................................................................................ 46

4.1 Troubleshooting Chart.................................................................................................................46

4.2 Keypad Self-Test.........................................................................................................................46

4.3 Front End Error Indicators...........................................................................................................46

4.4 Lithium Battery Replacement......................................................................................................47

Document #: 6055672, Rev 1.0 D1c Page 3 of 48

Page 4

List of Tables and Illustrations IEI MiniMax 3 Installation/Programming Manual

List of Tables

Table 1: System Features.......................................................................................................................5

Table 2: Specifications.............................................................................................................................6

Table 3: System Defaults........................................................................................................................6

Table 4: User Types..............................................................................................................................31

Table 5: Control Module Audio Indicators.............................................................................................40

Table 6: Programming Options Chart....................................................................................................43

Table 7: Troubleshooting Chart.............................................................................................................46

Table 8: Front End Error Indicators.......................................................................................................46

List of Illustrations

Figure 1: Max 3 Module Diagram............................................................................................................7

Figure 2: MiniMax 3 Backplane Diagram................................................................................................8

Figure 3: Connecting the GND Terminal from Transformer to the Backplane......................................10

Figure 4: RS-485 Connection from Max 3 Module to Backplane..........................................................11

Figure 5: Connecting Diode Across Strike............................................................................................13

Figure 6: Connecting Diode Across Maglock........................................................................................13

Figure 7: Connecting MOV Across Strike..............................................................................................13

Figure 8: Connect Secured Series Front End to DCM..........................................................................14

Figure 9: Connect Primary Wiegand Front End Reader to DCM..........................................................15

Figure 10: Connect Secondary Wiegand Front End Reader to DCM...................................................16

Figure 11: Wiring a REX Switch and Door Contacts.............................................................................17

Figure 12: Wiring the Alarm Shunt Relay..............................................................................................18

Figure 13: Wiring the Door Ajar Relay...................................................................................................19

Figure 14: Wiring the Forced Door Relay..............................................................................................20

Figure 15: Wiring MiniMax 3 Backplane to a PC...................................................................................21

Figure 16: Connecting Multiple Backplanes Together.......................................................................... 22

Figure 17: Connecting the SEG-M to the MiniMax 3.............................................................................23

Figure 18: Connecting the SEG-1 to the MiniMax 3..............................................................................24

Figure 19: Installing a Tamper Switch...................................................................................................25

Figure 20: Completing the Transformer Connections...........................................................................26

Figure 21: Plug on Detachable Keypad.................................................................................................28

Page 4 of 48 Document #: 6055672, Rev 1.0 D1c

Page 5

IEI MiniMax 3 Installation/Programming Manual Section 1: System Features and Specifications

Section 1: System Features and Specifications

The following section outlines the MiniMax 3 features, specifications and default settings.

1.1 System Features

Table 1: System Features

Feature Description/Details

Users 2000

Base Capacity Supports 1 Max 3 Module; Controls 1 Door

Additional Capability Network up to 64 doors with additional Max 3 modules

Communication Type

Audit Trail *2000 Event Transaction Log

Front End Support

Programming Max 3 Module supports keypad or PC programming

Auto-Unlock Time Zones

First-In Auto-Unlock Requires valid entry to initiate auto-unlock schedule.

Forced Door Alarm Relay/Timer

Alarm Zone Shunting Relay

Timed Egress Input

Non-Volatile EEPROM Memory

RS-485 Network; Connect via RS-232 to RS-485 Converter, USB to RS485 Converter

or LAN connection using SEG-M or SEG-1.

Each Max 3 Module supports either two Wiegand or Secured Series front End readers

for IN/OUT operation.

9:00 A.M. to 5:00 P.M. Monday-Friday

*Eight user definable time zones for auto-unlock or access control

*32 single day or block holidays

* Indicates feature available with PC software only.

Document #: 6055672, Rev 1.0 D1c Page 5 of 48

Page 6

Section 1: System Features and Specifications IEI MiniMax 3 Installation/Programming Manual

1.2 Specifications

The following table lists the Electrical, mechanical and environmental specifications.

Table 2: Specifications

Electrical

Power Supply

Current Requirements 110mA (backplane with module)

Front End 13.8 VDC, 300 mA (max. current draw)

Lock Output 13.8VDC or 16.5VAC, 600mA (max. current draw)

Aux 13.8VDC, 100mA (max. current draw)

Main Relay 12-24 VAC/DC, 2A (max. contact current)

Alarm Shunt, Door Ajar

and Forced Door Relays

REX/Door Loop Dry contact closure

Wiring Requirements

RS-485 Cable 24AWG, shielded, two twisted-pair telephone cable with a shunt capacitance of 16

Front End Cable Stranded wire with overall foil shield.

REX/Door Loop Cable Stranded wire with overall foil shield.

Mechanical

Enclosure Surface mount

Height 3.56” (9.04cm)

Width 11.29” (28.67 cm)

Length 11.31” (28.7 cm)

Material 19 gauge steel

Environmental

Temperature Tolerance

Recommended Use For indoor use only

16.5VAC 40VA or 50VA Class 2 Transformer (Revere # RT-G1640SL/M, Revere #

RT-G1650SL/M or Globtek, Inc. # DA-40-16.5G)

12-24VAC/DC, 1A (max. contact current)

pF/Ft (required only when using software)

-20°F to 130°F (-28°C to 54°C)

1.3 System Defaults

The following table lists the default settings for the Max 3 Door Control Module.

Table 3: System Defaults

Option Default Setting Option Default Setting

Master Code 1234 Main Relay Time 5 Seconds

Door Ajar Output Time 30 Seconds Forced Door Output Time 10 Seconds

Audio Keypress Feedback Enabled Visual Keypress Feedback Enabled

User Lockout Enabled User Lockout Type By Location

Time Zones Disabled Auto-Unlock Disabled

First-In Auto-Unlock Disabled User Timezone 24 Hours

Daylight Savings Time Enabled DST Format US

Wiegand LED State Active Low Wiegand Sounder State Active Low

Error Lockout Threshold 3 Attempts Error Lockout Duration 10 Seconds

Extended Unlock Time 10 Seconds Facility Code 11

Door Number 1

Auto-Unlock Time Zone

(Without software)

9 A.M to 5 P.M.; Monday

through Friday

Page 6 of 48 Document #: 6055672, Rev 1.0 D1c

Page 7

IEI MiniMax 3 Installation/Programming Manual Section 1: System Features and Specifications

1.4 Max 3 Door Control Module Diagram

The diagram below shows the component locations and terminal connections on the Max 3 Door Control Module.

Communication LEDs

RX = Receive Data

TX = Transmit Data

Figure 1: Max 3 Module Diagram

Document #: 6055672, Rev 1.0 D1c Page 7 of 48

Page 8

Section 1: System Features and Specifications IEI MiniMax 3 Installation/Programming Manual

1.5 Backplane Diagram

The diagram below shows the component locations and terminal connections on the Backplane.

Figure 2: MiniMax 3 Backplane Diagram

Notes:

The Max 3 communicates to the PC via an RS-485 connection. For this connection use TS3 on the far right, bottom of the backplane.

The module is then connected to the backplane via connector P1.

Port C is used for configuring the SEG-M, when it's plugged onto J2 on the backplane.

Page 8 of 48 Document #: 6055672, Rev 1.0 D1c

Page 9

IEI MiniMax 3 Installation/Programming Manual Section 2: Installation

Section 2: Installation

This section contains detailed procedures and wiring diagrams for installing the IEI MiniMax 3 Access Control System. This section is

presented in the order you should follow to install the unit. Not every section is necessary for every application.

The system must be installed within the protected area in accordance with the National Electrical Code (NFPA 70), local codes, and

the authority having jurisdiction. It should also be located in an area that is accessible for programming purposes. After the installation

is complete, the cabinet door should remain closed and locked to protect the contents.

Note: Programming commands are inserted into the installation procedures for your convenience. Programming should only be done

after all electrical connections are made and the system is powered up.

2.1 Check the Packing List

Open the box and inside is a metal enclosure. The metal enclosure has a removable lid, to give you easier access when wiring. Inside

the metal enclosure is:

• 1 Backplane mounted on standoffs

• 1 16.5VAC Transformer

• 1 Camlock with key

• 1 Hardware Pack containing:

• 1 Wire nuts (ORANGE)

• 4 Wall anchors (BLUE)

• 4 #8 1¼” sheet metal screws

• 1 Set of battery cables (BLACK AND RED)

• 1 Ground cables (BLACK wire with RED flush tab receptacle)

• 1 Max 3 Module

• 1 detachable keypad for programming (Pre-mounted to Max 3 Module)

• 1 Secured Series Software Package

• 1 MiniMax 3 Installation and Programming Manual

Note: MiniMax 3 System Kit contains additional components including proximity reader.

Please check the contents of the enclosure and verify all components on the packing list are present. Taking this inventory will

familiarize you with the components as well as ensure you have a complete kit.

2.2 Mount the Enclosure

The enclosure is designed to be wall mounted (surface mounted) using the supplied hardware. You must mount the enclosure on the

secure side of the door in a secured area such as a locked utility closet. Make sure it is accessible for programming and maintenance

purposes. Do not use the controller as access device to enter or exit through the door.

Mounting Procedure:

Unlock and open the metal enclosure. Notice that the enclosure lid opens from top to bottom so the enclosure lid forms a tabletop for a

convenient workspace.

1. Use the supplied wall anchors and sheet metal screws to secure the enclosure to the wall.

2. Drill 11/64’’ diameter holes for the wall anchors.

3. Tap the wall anchors into the wall until the outer flange is flush to the wall surface.

4. Insert the sheet-metal screws ¾ of the way into the anchors.

5. Hang the enclosure by aligning the slotted holes (cut into the rear of the cabinet) with the sheet-metal screws. Space between

slotted holes; on-center 9 11/16” Horizontally and 10 1/8” Vertically.

6. The enclosure should now be resting on the sheet-metal screws.

7. Tighten the sheet-metal screws until they are snug.

Document #: 6055672, Rev 1.0 D1c Page 9 of 48

Page 10

Section 2: Installation IEI MiniMax 3 Installation/Programming Manual

2.3 Ground the Unit

Grounding the system before making any electrical connections is imperative!

By grounding the system first you not only increase personal safety during installation, but you also protect the unit from damage due

to static discharge or any other transient voltage effects. We cannot stress enough the importance of completely grounding the unit

before making any connections or even touching the backplane (the large circuit board in the enclosure). Wire as shown and plug the

transformer into a grounded electrical socket.

Do not make any AC

Power connections

until Step 13 of the

installation.

Figure 3: Connecting the GND Terminal from Transformer to the Backplane

TOUCH THE GROUNDED METAL CABINET BEFORE TOUCHING THE BACKPLANE OR

THE MAX 3 DOOR CONTROL MODULE. THIS WILL REMOVE ANY STATIC CHARGE ON

YOUR PERSON. STATIC ELECTRICITY CAN DAMAGE THE ELECTRONIC COMPONENTS

USED ON THE CONTROLLERS.

Page 10 of 48 Document #: 6055672, Rev 1.0 D1c

Page 11

IEI MiniMax 3 Installation/Programming Manual Section 2: Installation

2.4 Connect the RS-485 Cable from the Module to the Backplane

The Max 3 Door Control Module requires an additional three position cable to make the RS-485 connection to the backplane. This

cable is connected from P5 on the upper right corner of the module to the three position connector underneath the module on the top

right of the backplane labeled P1. Simply plug one end of the cable into P5 and the other end into P1 on the backplane. The diagram

below illustrates how to connect the module to the backplane.

Figure 4: RS-485 Connection from Max 3 Module to Backplane

Document #: 6055672, Rev 1.0 D1c Page 11 of 48

Page 12

Section 2: Installation IEI MiniMax 3 Installation/Programming Manual

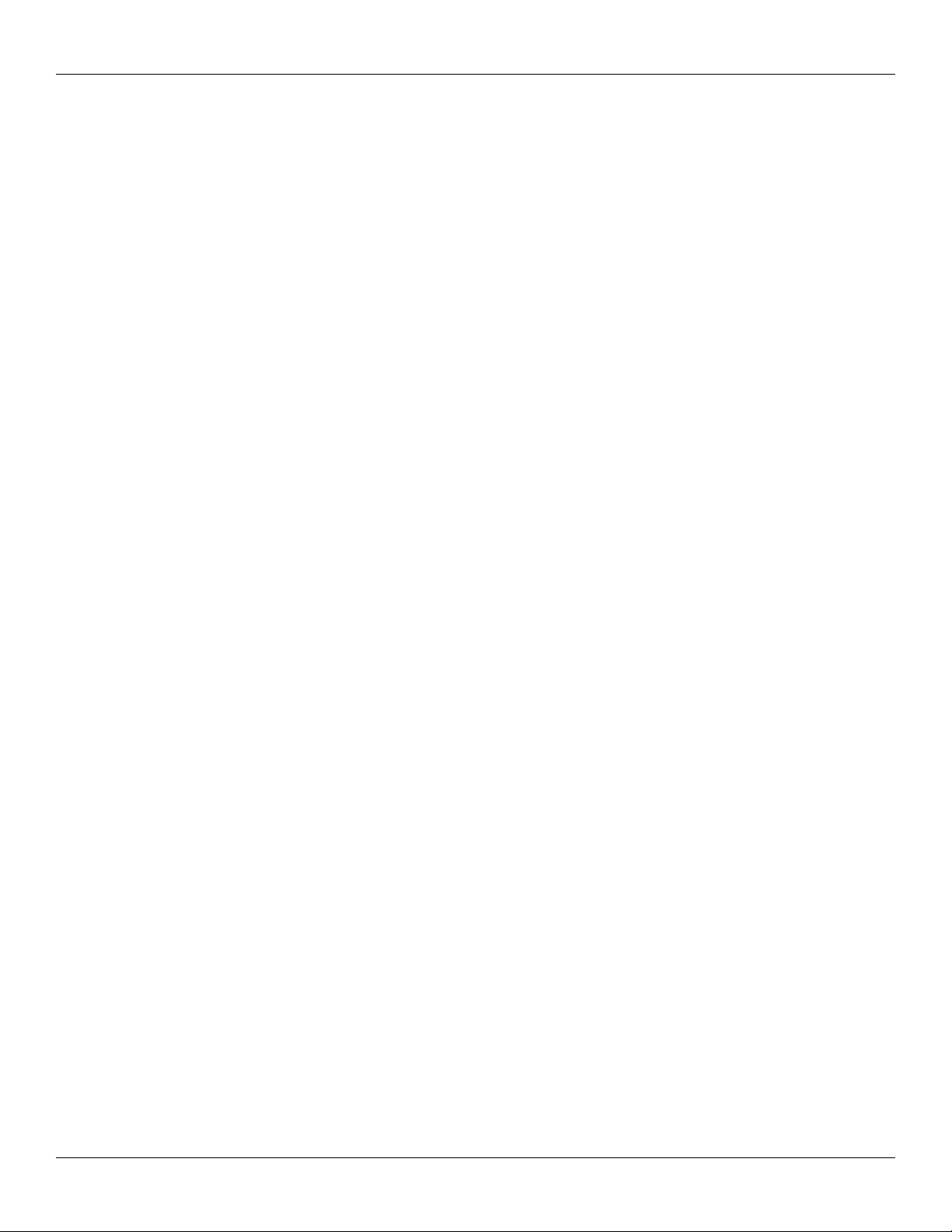

2.5 Wire an Electric Door Lock to the Main Relay of the Max 3 Module

The locking device is connected to terminal strip TS1 as shown in

the diagram on the right. The two diagrams below show how to

connect both a Maglock and an Electric Strike using an external

power supply.

For either locking device, positive voltage (V+) from an external

power source is connected to the relay common terminal (C).

When using a Maglock, connect the lock's positive side to the

normally closed (NC) terminal and the negative side to negative on

your power supply. When using an Electric Strike, connect the

lock's positive side to the normally open (NO) terminal and the

negative side to negative on your power supply.

NOTES:

You must use an external power supply to power your

lock.

The relay is a FORM C DRY CONTACT, which

means there is no output voltage on the relay contacts.

When using AC voltage, polarity does not matter.

Connecting a Maglock (Fail-Safe) Connecting an Electric Strike (Fail-Secure)

Programming the Main Relay Time:

The command sequence below is used to change the Main Relay time. The default value is 5 seconds.

Action Press

Enter Program Mode 99 # Master Code *

Program Main Relay Time

Exit Program Mode *

Page 12 of 48 Document #: 6055672, Rev 1.0 D1c

11 # time # 0 # **

(time = 1 to 99 seconds)

Page 13

IEI MiniMax 3 Installation/Programming Manual Section 2: Installation

2.5.1 Installing a Diode to Prevent Electrical Kickback from Lock – DC Locks Only

If your electric locking device does not come pre-installed with internal protection for electrical “kickback voltage” use the supplied

1N4004 diode for DC locks only. This “kickback voltage” could possibly damage the Max 3 control module and installing the diode

could help prevent this from happening. When installing the diode, connect it across the positive (V+) and negative (V-) of your

locking device. The diode is polarized, which means the cathode mark (silver band at one end) must be connected to the positive

connection as shown below. You must connect the diode as close as possible to the locking device for it to work properly.

Figure 6: Connecting Diode

Across Maglock

Figure 5: Connecting Diode Across Strike

2.5.2 Installing an MOV to Prevent Electrical Kickback from Lock – AC Locks Only

If your electric locking device does not come pre-installed with internal protection for electrical “kickback voltage” use the supplied

MOV for AC locks only. This “kickback voltage” could possibly damage the Max 3 control module and installing the MOV could

help prevent this from happening. When installing the MOV, connect it across the AC connection to your locking device. This device

is not polarized so it does not matter which direction you install it. You must connect the MOV as close as possible to the locking

device for it to work properly.

Figure 7: Connecting MOV Across

Strike

Document #: 6055672, Rev 1.0 D1c Page 13 of 48

Page 14

Section 2: Installation IEI MiniMax 3 Installation/Programming Manual

2.6 Connect a Secured Series Front End (SSFE) Reader to the Door Control Module

The Max 3 supports IEI Secured Series Front Ends, which include keypads, card readers and touch chip readers. These are connected

to to the Front End terminal strip TS5. You can connect up to two readers to each Door Control Module, for In/Out operation by

simply wiring them in parallel (both readers to the same four screw terminals). Each screw terminal is labeled with a wire color (black,

red, white/black and white yellow). These correspond to the color wire on the wire harness supplied with the front end reader.

You must use a four-conductor stranded cable with overall foil shield to connect the Front End to the Door Control Module. You also

must terminate the drain wire (the bare wire inside the foil shield), from the front end cable, to the fast-tab located on the Max 3

Backplane. There is a fast-tab located under each module on the lower edge of the backplane. They are labeled FT1, FT2, FT3 and

FT4. Connect the drain wire from the front ends connected to module one to FT1 and so on. IEI has included four ground cables and

wire-nuts to make this connection. Do not terminate the drain wire at the Front End Reader. Cut off the exposed drain wire and

wrap the insulation and the foil shield in electrical tape.

Note: The Max 3 Door Control Module must be configured to operate in Secured

Series Front End Mode. To do this, locate jumper JP2 above terminal strip TS7 and

place the jumper on both pins.

Wire Size vs. Cable Length Chart

Distance Wire Size

250 Feet 22 AWG

500 Feet 20 AWG

1000 Feet 18 AWG

Note: If you experience problems with

front end communications after connecting

a second keypad or reader, wiring a

separate ground wire from each keypad to

the black terminal on the Max 3 DCM may

solve the issue. If this does not fix the

problem contact IEI Technical Support.

Figure 8: Connect Secured Series Front End to DCM

Page 14 of 48 Document #: 6055672, Rev 1.0 D1c

Page 15

IEI MiniMax 3 Installation/Programming Manual Section 2: Installation

2.7 Connect the Primary Wiegand Front End Reader (IN Reader)

Wiegand readers are connected directly to the Front End Terminals on the Door Control Module. The primary reader (IN) should be

mounted on the exterior of the door and used to gain access into the secured area. The diagram and table below describe the

connections in detail. Please note that the Primary Wiegand Reader Data 0 wire is connected to DO PRI (Data 0 Primary) on terminal

strip TS5.

The LED connection is used to indicate status of the Main Relay and the Sounder connection is used to indicate various error

conditions. These are explained in more details in later sections.

You must use a four to six conductor stranded cable with overall foil shield to connect the Front End to the Door Control Module. You

also must terminate the drain wire (the bare wire inside the foil shield), from the front end cable, to the fast-tab located on the Max 3

Backplane. There is a fast-tab located under each module on the lower edge of the backplane. They are labeled FT1, FT2, FT3 and

FT4. Connect the drain wire from the front ends connected to module one to FT1 and so on. IEI has included four ground cables and

wire-nuts to make this connection. Do not terminate the drain wire at the Front End Reader. Cut off the exposed drain wire and

wrap the insulation and the foil shield in electrical tape.

IMPORTANT: The Max 3 Door Control Module must be configured to

operate in Wiegand Front End Mode. To do this, locate jumper JP2 above

terminal strip TS7 and place the jumper on one pin. This is the default

condition.

Primary Wiegand Reader Connections

Wiegand Reader DCM Terminal Strip

V- (Power) Black TS5

V+ (Power) RED TS5

Data 0 D0 PRI TS5

Data 1 D1 TS5

LED Control LED TS7

Sounder Control SND TS7

Note: The primary reader

records an IN event in the

transaction log.

Figure 9: Connect Primary Wiegand Front End

Reader to DCM

Document #: 6055672, Rev 1.0 D1c Page 15 of 48

Page 16

Section 2: Installation IEI MiniMax 3 Installation/Programming Manual

2.8 Connecting a Secondary Wiegand Front End Reader (OUT Reader)

The diagram below shows how to connect a secondary (out) reader to the Door Control Module. The secondary reader (OUT) should

be mounted on the interior side of the door and used to exit the secured area. Please note that the Secondary Wiegand Reader Data 0

wire is connected to DO SEC (Data 0 Secondary) on terminal strip TS7.

The LED connection is used to indicate status of the Main Relay and the Sounder connection is used to indicate various error

conditions. These are explained in more details in later sections.

You must use a four to six conductor stranded cable with overall foil shield to connect the Front End to the Door Control Module. You

also must terminate the drain wire (the bare wire inside the foil shield), from the front end cable, to the fast-tab located on the Max 3

Backplane. There is a fast-tab located under each module on the lower edge of the backplane. They are labeled FT1, FT2, FT3 and

FT4. Connect the drain wire from the front ends connected to module one to FT1 and so on. IEI has included four ground cables and

wire-nuts to make this connection. Do not terminate the drain wire at the Front End Reader. Cut off the exposed drain wire and

wrap the insulation and the foil shield in electrical tape.

IMPORTANT: The Max 3 Door Control Module must be configured to

operate in Wiegand Front End Mode. To do this, locate jumper JP2 above

terminal strip TS7 and place the jumper on one pin. This is the default

condition.

Secondary Wiegand Reader Connections

Wiegand Reader DCM Terminal Strip

V- (Power) Black TS5

V+ (Power) RED TS5

Data 0 D0 SEC TS7

Data 1 D1 TS5

LED Control LED TS7

Sounder Control SND TS7

Note: The secondary reader

records an OUT event in the

transaction log.

Figure 10: Connect Secondary Wiegand Front End

Reader to DCM

Page 16 of 48 Document #: 6055672, Rev 1.0 D1c

Page 17

IEI MiniMax 3 Installation/Programming Manual Section 2: Installation

2.9 Wire a Request to Exit (REX) device and Door Contact

Note: Use stranded wire with

overall foil shield for the

REX and Door Contact

cables. Connect the drain

with to the fast-tab on the

backplane.

Figure 11: Wiring a REX Switch and Door Contacts

Request to Exit (REX)

Door Switch Input

This is a normally open loop, when momentarily closed activates the Main Relay for the

length of time programmed in the Main Relay Time (command 11).

This is a normally closed loop that tells the Max 3 the door status. This is used for the Door

Ajar, Forced Door and Auto-Relock features.

Auto-Relock

Auto Re-lock refers to the feature that automatically locks the door one second after the door contact switch is opened. This allows

you to program a long unlock time, when required, without worrying about the door remaining open after the person has entered. No

programming is necessary for this feature, but it does require you connect a door contact switch as shown in the diagram above.

Remember you must remove jumper JP1 for the door contact input to operate.

Document #: 6055672, Rev 1.0 D1c Page 17 of 48

Page 18

Section 2: Installation IEI MiniMax 3 Installation/Programming Manual

2.10 Wire the Alarm Shunt Relay

The Alarm Shunt Relay is used when you are controlling access to a door that is monitored by an external alarm system. This relay

activates at the same time as the Main Relay (by either a valid code/card or REX) so you can bypass the existing alarm panel, as

shown in the diagram below. For this feature you must wire dedicated door contact to terminals TS6 (door contact switch input) as

shown below. The Alarm Shunt Relay remains energized until one second after the door contact switch input is closed. Remember you

must remove jumper JP1 for the door contact input to operate.

Figure 12: Wiring the Alarm Shunt Relay

Page 18 of 48 Document #: 6055672, Rev 1.0 D1c

Page 19

IEI MiniMax 3 Installation/Programming Manual Section 2: Installation

2.11 Wire the Door Ajar Relay

The Door Ajar Relay output alerts personnel that the door is being held, or propped open, after a valid access or REX. For this feature

to operate you must wire a dedicated door contact switch to the door terminals on TS6 (door contact switch input) as shown below.

Once the door contact switch input is opened, the Door Ajar timer begins. When the time reaches the time programmed in the Door

Ajar Time (command 44), the relay energizes and remains energized until the door contacts are closed. Remember you must remove

jumper JP1 for the door contact input to operate.

The diagram below shows how switch positive power (V+) to an alarm device. The Relay is rated to handle 1 Amp of current at either

12 or 24 Volts AC/DC. Alarm device(s) are not included with IEI equipment.

Figure 13: Wiring the Door Ajar Relay

Programming the Door Ajar Time:

The command sequence belows shows how to program the Door Ajar Time. The default value is 30 seconds.

Action Press

Enter Program Mode 99 # Master Code *

Program Door Ajar Time

Exit Program Mode *

Document #: 6055672, Rev 1.0 D1c Page 19 of 48

44 # time # 0 # **

(time = 10 to 990 seconds)

Page 20

Section 2: Installation IEI MiniMax 3 Installation/Programming Manual

2.12 Wire the Forced Door Relay

The Forced Door Relay Output alerts personnel that the door was opened without authorization. For this feature to operate you must

wire a dedicated door contact switch to the door terminals on TS6 (door contact switch input) as shown below. Remember you must

remove jumper JP1 for the door contact input to operate. If these door contacts are opened without a valid access or REX, the Forced

Door Relay energizes immediately. It remains energized until either a valid code is entered or card presented to the Front End Reader,

a valid code is entered on the Max 3 Module or the Forced Time (command 45) expires.

The diagram below shows how to switch positive power (V+) to an alarm device. The Relay is rated to handle 1 Amp of current at

either 12 or 24 Volts AC/DC. Alarm device(s) are not included with IEI equipment.

Figure 14: Wiring the Forced Door Relay

Programming the Forced Door Time:

The command sequence belows shows how to program the Forced Door Time. The default value is 10 seconds.

Action Press

Enter Program Mode 99 # Master Code *

Program Forced Door Time

45 # time # 0 # **

(time = 10 to 990 seconds)

Exit Program Mode *

Page 20 of 48 Document #: 6055672, Rev 1.0 D1c

Page 21

IEI MiniMax 3 Installation/Programming Manual Section 2: Installation

2.13 Network the MiniMax 3

The following section describes the various ways to connect the Max 3 to a personal computer (PC), as well as connecting more than

one Max 3 together. You can connect up to 64 Max 3 doors together on a single network.

IMPORTANT: When using the PC software to manage multiple doors you must

program a unique door number into each Door Control Module using the

following command: 43 # 0 # Door Number # ** (Door Number = 1 to 64). Refer

to section 3.3.

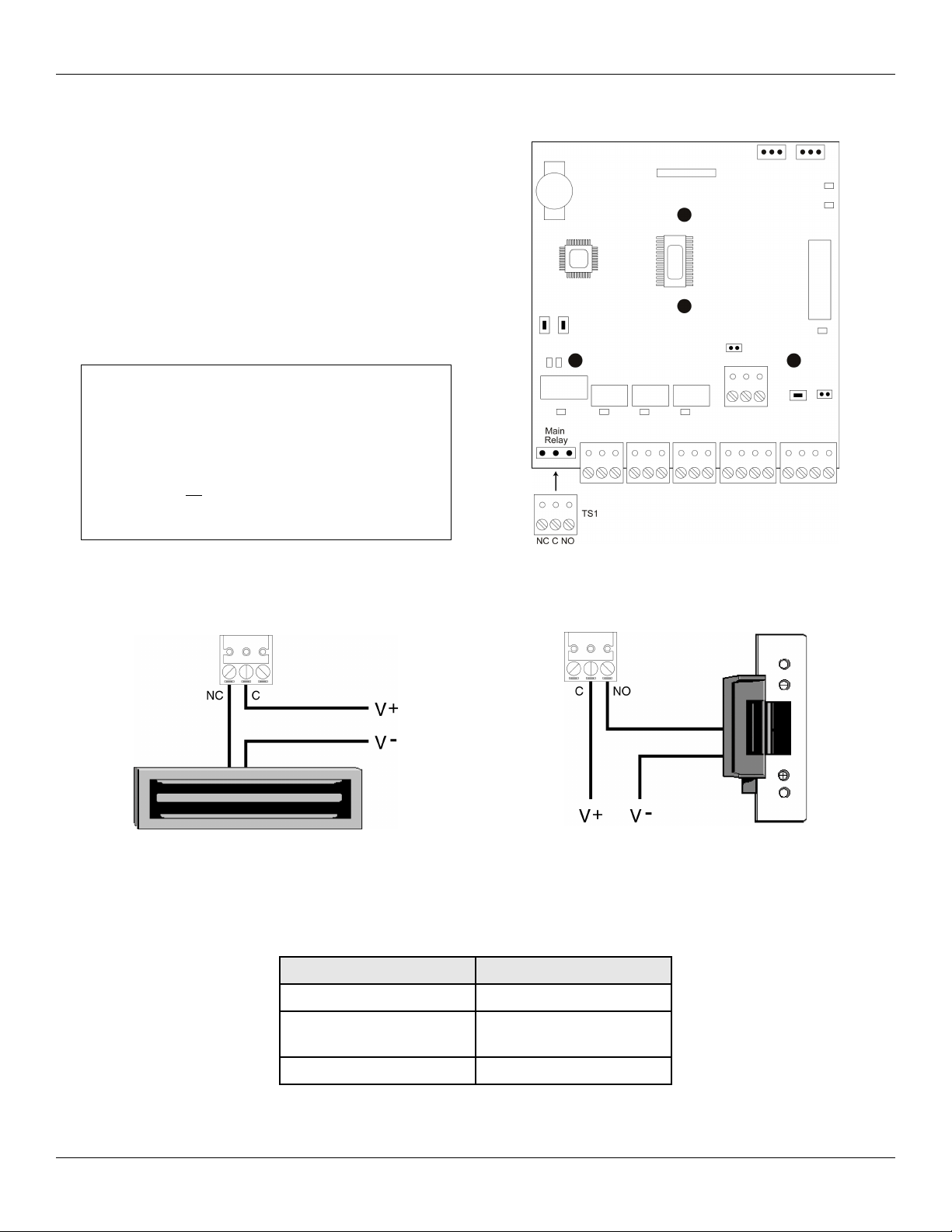

2.13.1 Connect the MiniMax 3 Backplane Directly to a PC

The Max 3 connects to a PC using RS-485 communications. However, a PC has either an RS-232 serial COM port or a USB port.

This means that in order to connect to a PC you must use either an RS-232 to RS-485 converter OR a USB to RS-485 converter. RS485 communications does have some significant advantages over other connection types, such as increased distance of up to 4000 feet

using the appropriate cable, the devices are wired in parallel which means if one unit goes off-line the rest are unaffected and

increased data transfer speed.

To make this connection, connect the Data A, Data B and GND terminals on TS3 (See below) to the same corresponding connections

on your converter. Then make the connection from the converter to your PC. Please refer to the instructions with your specific

converter for complete details on that device.

Note: The Max 3 Module must be connected to the backplane

using the wire harness described in section 2.4.

Note: The maximum

distance between the

backplane and the converter

is 4000 feet using 24AWG,

shielded, two twisted-pair

telephone cable with a shunt

capacitance of 16 pF/Ft.

Figure 15: Wiring MiniMax 3 Backplane to a PC

Document #: 6055672, Rev 1.0 D1c Page 21 of 48

Page 22

Section 2: Installation IEI MiniMax 3 Installation/Programming Manual

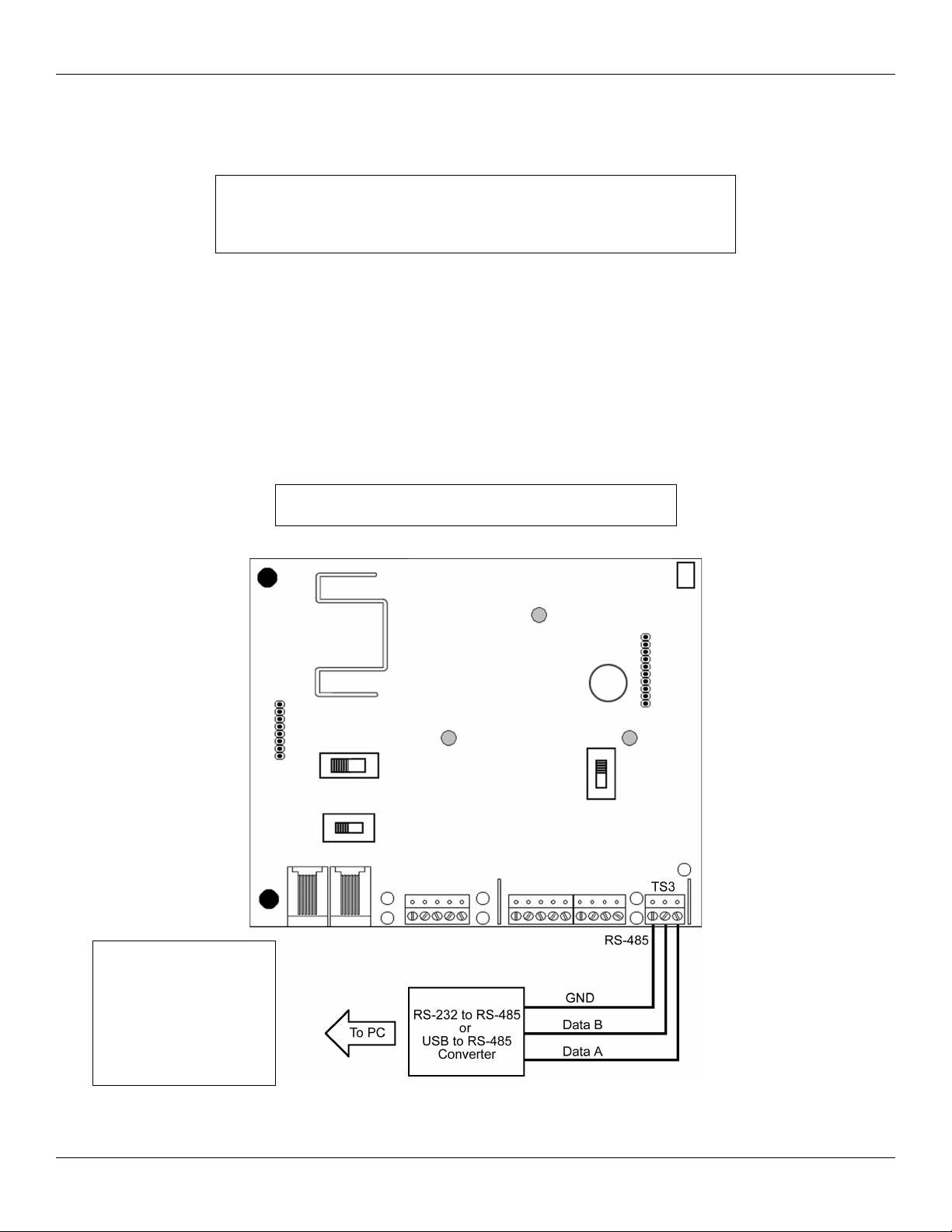

2.13.2 Connect Multiple Backplanes Together

The diagram below shows how to connect multiple backplanes together and then back to a PC. The units are wired in parallel, which

means you connect TS3 on both backplanes back to the RS-485 converter. You can either daisy-chain them or wire them all directly

back to the converter, depending what your installation requires. When connecting multiple backplanes, remember that each

backplane can be up to 4000 feet away from the converter. For example if your PC was centrally located with two units in either

direction at 4000 feet, the two backplanes would be 8000 feet apart. However, if you daisy-chain them, the last backplane in line, can't

be more than 4000 feet away. Below is an example of daisy-chaining backplanes together.

Note: The maximum

distance between any

backplane and the converter

is 4000 feet using 24AWG,

shielded, two twisted-pair

telephone cable with a shunt

capacitance of 16 pF/Ft.

Figure 16: Connecting Multiple Backplanes Together

Page 22 of 48 Document #: 6055672, Rev 1.0 D1c

Page 23

IEI MiniMax 3 Installation/Programming Manual Section 2: Installation

2.13.3 Connect the SEG-M to the MiniMax 3 (LAN/WAN Connection)

You can connect your MiniMax 3 to your LAN/WAN by using the SEG-M, Secured Ethernet Gateway. Follow the instructions below

and refer to the diagram.

The connection from the SEG-M to the MiniMax 3 requires you to plug the module onto the backplane connector J2 to power the unit.

You must also use the six-conductor wire harness from J1 on the SEG-M to P5 on the module and P1 on the backplane.

To connect additional backplanes to the system, simply connect TS3 on the first backplane to TS3 on the next backplane as shown

below. The SEG-M is only required on the first backplane of the system (up to 64 doors Max; if you require more doors an additional

SEG-M is required).

Figure 17: Connecting the SEG-M to the MiniMax 3

Note: The maximum

distance between the first

backplane with the SEG-M

and the next backplane is

4000 feet using 24AWG,

shielded, two twisted-pair

telephone cable with a shunt

capacitance of 16 pF/Ft.

Document #: 6055672, Rev 1.0 D1c Page 23 of 48

Page 24

Section 2: Installation IEI MiniMax 3 Installation/Programming Manual

2.13.4 Connecting the SEG-1 to the MiniMax 3 (LAN/WAN Connection)

You can also use the SEG-1 to connect your MiniMax 3 system to your LAN/WAN. Follow the instructions below and refer to the

diagram.

Run your RS-485 cable between terminal strip TS1 on the SEG-1 to TS3 on the backplane as shown in the diagram. You must also

connect the module to the backplane by connecting the supplied 3-conductor wire harness from P5 to the RS-485 connector

underneath the module on the backplane (P1).

To connect additional backplanes to the system, simply connect TS3 on the first backplane to TS3 on the next backplane as shown

below. The SEG-1 is only required on the first backplane of the system (up to 64 doors Max; if you require more doors an additional

SEG-1 is required).

Note: The maximum

distance between any

backplane and the SEG-1 is

4000 feet using 24AWG,

shielded, two twisted-pair

telephone cable with a shunt

capacitance of 16 pF/Ft.

Figure 18: Connecting the SEG-1 to the MiniMax 3

Page 24 of 48 Document #: 6055672, Rev 1.0 D1c

Page 25

IEI MiniMax 3 Installation/Programming Manual Section 2: Installation

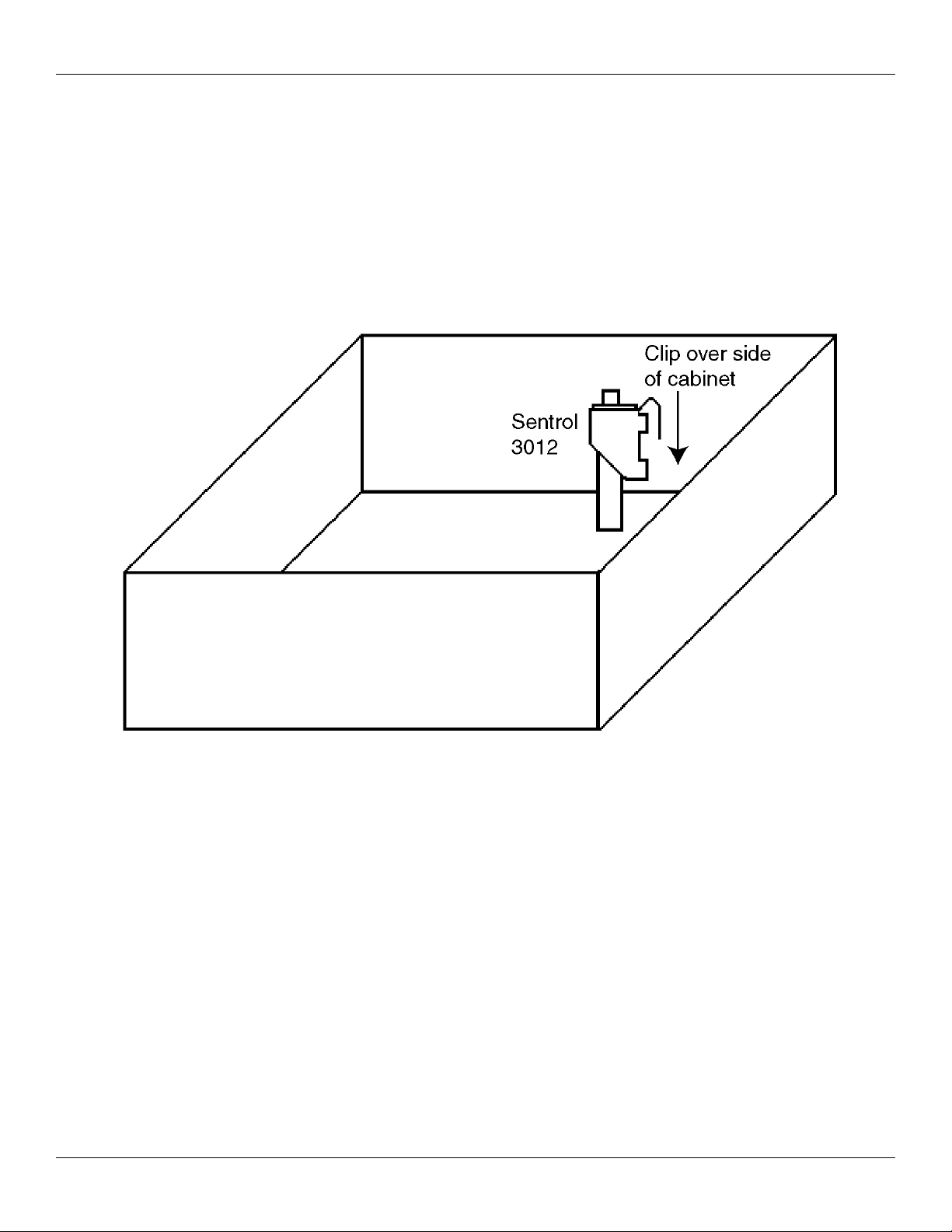

2.14 Installing a Tamper Switch

IEI recommends you install a tamper switch. The tamper switch must be mounted inside the locked cabinet and must activate if the

cabinet door is opened. The tamper switch must be wired to an alarm panel or other device that sounds an alarm and/or prevents

anyone from gaining access through the protected door.

IEI recommends using a Sentrol 3012 tamper switch (not provided).

To use this tamper switch, simply clip the switch on the side of the cabinet on the interior, then wire the leads to your alarm device

using the appropriate cable. See diagram below.

Figure 19: Installing a Tamper Switch

Document #: 6055672, Rev 1.0 D1c Page 25 of 48

Page 26

Section 2: Installation IEI MiniMax 3 Installation/Programming Manual

2.15 Complete Connections Between the 16.5 VAC Transformer and Backplane

Connect the 16.5 VAC Transformer (included with the MiniMax 3) to the Backplane at the terminals marked AC and EGND.

Provided with the Max 3 are Backup Battery Connection Cables. Connect these cables from your 12V battery (7AH Recommended)

to the Backplane at the terminals marked B+ and B-. Polarity is an issue! Be sure you know which battery terminals are positive and

negative BEFORE you connect your battery to the Backplane.

Figure 20: Completing the Transformer Connections

Page 26 of 48 Document #: 6055672, Rev 1.0 D1c

Page 27

IEI MiniMax 3 Installation/Programming Manual Section 2: Installation

2.16 Power up the System

Plug the transformer into a grounded 110 VAC electrical outlet. You should now have power to your system. Check the power status

by checking the following:

On the Backplane:

• LED 1 should be lit - This indicates that AC Power is present

• LED 3 should be lit - This indicates that DC Power is available on the Backplane

On the Max 3 Module:

• LED 1 should be lit - This indicates that the Max 3 Module is receiving power and functioning

• LED 4 should be lit - This indicates that the Front End Reader is receiving power

If the above requirements are met the system is now powered up and ready for programming and operation.

If the above requirements are not met see the Troubleshooting Section.

Document #: 6055672, Rev 1.0 D1c Page 27 of 48

Page 28

Section 3: Programming IEI MiniMax 3 Installation/Programming Manual

Section 3: Programming

This section contains the details of programming the Max 3 Door Control Module using the detachable keypad. If you are using the

PC software, this section may not apply, but you may find it useful to familiarize yourself with the various features available in the

Max 3. To see a complete list of programming commands refer to the programming options chart at the end of this section.

3.1 Programming Methods

There are two ways you can program the Max 3 Door Control Module. You can either program it using the detachable keypad or you

can program it using the PC software. Using the PC software gives you access to many more features than you would have

programming through the keypad only. This manual covers only programming through the keypad, although it does refer to features

that require the PC software to use to it's fullest extent.

The diagram below shows how to connect the detachable keypad to the Door Control Module. The keypad comes pre-installed on the

first module, but to program additional modules you must remove it and connect to the module you are programming.

Figure 21: Plug on Detachable Keypad

Page 28 of 48 Document #: 6055672, Rev 1.0 D1c

Page 29

IEI MiniMax 3 Installation/Programming Manual Section 3: Programming

3.2 Entering Program Mode and Changing the Master Code

The following sections explains how to enter program mode and change the master code. You also have the option to program a

supervisor user, which allows an additional person to add and delete users.

3.2.1 Entering Program Mode

The first step in programming the Max 3 Door Control Module is to place it into program mode by using the master code, which is

defaulted to 1234.

To place the unit in program mode, press: 99 # Master Code *

When the unit is in program mode the yellow LED flashes slowly.

When you are done programming, to exit program mode press the * key and the yellow LED stops flashing.

If at any point you make a programming error (either press a wrong key or perform a command the unit does not recognize), the unit

produces a program error by turning on the yellow LED solid. To clear a program error, simply press the * key.

Note: If you don't know the master code press the program button (SW1) on the main circuit board. Momentarily pushing this button

forces the unit into program mode. You then should change the master code immediately.

3.2.2 Changing the Master Code

The master code is stored in user memory location 1 and used to enter program mode. To change the master code use the following

programming sequence:

Action Command

Enter Program Mode 99 # master code *

Change Master Code 1 # new master code * new master code *

Exit Program Mode *

Note: Throughout the programming section the last step is to exit program mode. If you are going to program multiple users or

keypad options, you are not required to exit program mode after each command sequence. You may continue to the next programming

command without exiting program mode. When all your programming is complete, you can then exit program mode by pressing the *

key.

3.2.3 Programming a Supervisor Code

The following table shows how to program a supervisor code. User location 2 is reserved for the supervisor code. This user has access

to only user programming commands and can't change other system related options and parameters.

Action Command

Enter Program Mode 99 # master code *

Program a Supervisor Code Code 2 # new code * new code *

Exit Program Mode *

Document #: 6055672, Rev 1.0 D1c Page 29 of 48

Page 30

Section 3: Programming IEI MiniMax 3 Installation/Programming Manual

3.3 Changing the Door Number

Each Max 3 Door Control Module is assigned a door address or door number. The door number is used to identify each unit when

they are networked together. You can network up to 64 Max 3 Door Control Modules together. You must change the door number

when you are using the PC software. The default door number is 1. To change it, follow the instructions below.

Action Command

Enter Program Mode 99 # master code *

Change the Door Number 43 # 0 # Door Number # * *

Exit Program Mode *

3.4 Changing the Main Relay Time

The Main Relay is defaulted to operate for 5 seconds. Command 11 is used to reprogram this time. This time affects standard unlock

users (type 1). If you need to program the Main Relay to toggle, you must program a toggle user. See the user section for details on

user types.

Action Command

Enter Program Mode 99 # master code *

Change Main Relay Time 11 # unlock time * 0 * (1 to 255 seconds)

Exit Program Mode *

3.5 Setting the Time and Date

You must program the time and date into each Door Control Module in order for the timezone and transaction event log features to

work. Follow the instructions below to reprogram the time and date.

Action Command

Enter Program Mode 99 # master code *

Set the Time 41 # HHMM # 0 # **

(HH = Hours; MM = Minutes)

Time is in 24 hour format.

Set the Date 42 # MMDDYY # DOW # **

(MM = Month; DD = Day; YY = Year; DOW =

Day of Week: 1 = Sunday, 2 = Monday, 3 =

Tuesday, 4 = Wednesday, 5 = Thursday, 6 = Friday,

7 = Saturday)

Exit Program Mode *

Page 30 of 48 Document #: 6055672, Rev 1.0 D1c

Page 31

IEI MiniMax 3 Installation/Programming Manual Section 3: Programming

3.6 Programming Users

The following section describes in detail how to program users. Each Max 3 Door Control Module can store up to 2000 users. Each

user is stored in a unique position in the units memory. This is referred to as the user location. Codes can be from 1 to 6 digit in length

in any combination. If at any point while programming a code or a card you get a programming error (solid yellow LED), and you

know you are entering the command correctly, make sure that the code or card is not already programmed. If you are unsure try

entering that code or presenting that card outside of program mode and see if you are granted access. If so, you must use a different

code or card for that user.

Note: IEI recommends that, if you are not using software, you keep a list of all the

users you have programmed in the device, in case you need to modify or delete a

particular user later on.

3.6.1 User Types

The table below identifies and describes the four user types supported by the Max 3. The user type number is used in programming

commands in the subsequent sections where it indicates “user type.”

Table 4: User Types

User Type Name User Type Number Description

Toggle User 0 Toggle users are used to latch the Main Relay in the unlocked

position for an indefinite period of time. Entering the same (or

another) toggle code, re-locks the unit.

Standard Access 1 Normal access users are the default user type. This user type unlocks

the door for the duration of the Main Relay time set in command 11.

See section 3.4 for details.

Lockout User 3 A Lockout user is used to lock out other users from gaining access

through the door. Refer to section 3.10 for details on user lockout.

Extended Unlock User 4 Extended Unlock users operate like standard access users, except

they use a different unlock time programmed using command 32,

parameter 3. It is defaulted to 10 seconds. See section 3.8 for details.

Singe Use User 5 Single use users are allowed to gain access only once. After you enter

this code/card the user is deleted from memory.

Relock User 6 A Relock user is used to relock the door if it was toggled open or is in

auto-unlock. Once entered, the door relocks immediately.

Emergency User 7 An Emergency user is a special user that can't be locked out by a user

lockout code. This user also uses the extended unlock time. It is

defaulted to 10 seconds. See section 3.8 for details.

Document #: 6055672, Rev 1.0 D1c Page 31 of 48

Page 32

Section 3: Programming IEI MiniMax 3 Installation/Programming Manual

3.6.2 Programming a “Code Only” User

To program a “Code Only” use command 50. This user gains access by entering their code on the keypad. Refer to table 4 for details

on user types. Codes can be from 1 to 6 digit in length in any combination. The programming sequence is as follows:

Note: This programming command applies to Secured Series Front End Keypads only.

Action Command

Enter Program Mode 99 # master code *

Program User 50 # user type # user location # code * repeat code *

Exit Program Mode *

3.6.3 Programming “Card Only” Users by Presentation

To program a “Card Only” user by presentation (by presenting the card to the reader) use command 50. This user type gains access by

presenting their card to the front end reader. Refer to table 4 for details on user types. The programming sequence is as follows:

Action Command

Enter Program Mode 99 # master code *

Program User 50 # user type # user location # * * <present card>

Exit Program Mode *

3.6.4 Programming 26-Bit “Card Only” Users without Presentation

To program a 26-Bit “Card Only” user without presentation (without presenting the card to the front end reader) use command 51.

Refer to table 4 for details on user types. This command is useful, if you want to program a card, but you don't have the physical card

with you. When programming cards with this command, you must program the facility code, using command 32, parameter 2,

prior to programming users. The programming sequence to program cards is as follows:

Note: This programming command applies to Wiegand Front Ends only.

Action Command

Enter Program Mode 99 # master code *

Program User 51 # user type # user location # card number * card

number *

Exit Program Mode *

Page 32 of 48 Document #: 6055672, Rev 1.0 D1c

Page 33

IEI MiniMax 3 Installation/Programming Manual Section 3: Programming

3.6.5 Programming “Code AND Card” Users

When you are a combination “code and card” user you can present either your card/touch chip first at the front end reader or enter the

code first on the front end keypad. Codes can be from 1 to 6 digit in length in any combination. Refer to table 4 for details on user

types. After you either present your card or enter your code, the red and green LEDs alternate (if unit is equipped with LEDs). This

indicates that the unit is awaiting the second part of the combination before granting access. Once access is granted, the LED turns

solid green (if unit is equipped with LED) and the door unlocks. The programming sequence is as follows:

Note: This programming command applies to Secured Series Front End Keypads and Card Readers only.

Action Command

Enter Program Mode 99 # master code *

Program User 50 # user type # user location # code * repeat code *

<present card>

Exit Program Mode *

3.6.6 Programming “Code or Card” Users

To program a “Code OR Card” user use command 52. This type of user can use either their code or card to gain access. Codes can be

from 1 to 6 digit in length in any combination. Refer to table4 for details on user types. The programming sequence is as follows:

Note: This programming command applies to Secured Series Front End Keypads and Card Readers only.

Action Command

Enter Program Mode 99 # master code *

Program User 52 # user type # user location # code * repeat code *

<present card>

Exit Program Mode *

3.6.7 Programming 26-Bit “Card Only” Users via Batch Entry without Presentation

To program a 26-Bit “Card Only” user via batch entry without presentation (without presenting the card to the front end reader) use

command 57. “Batch entry” allows you to enter multiple, sequential 26-Bit format cards into the unit’s memory at one time. Up to

1,998 users can be added this way at one time. (User 1 is reserved for the Master code and user 2 is reserved for the supervisor). When

programming cards with this command, you must program the facility code, using command 32, parameter 2, prior to programming

users.

Note: This programming command applies to Wiegand Front Ends only.

Action Command

Enter Program Mode 99 # master code *

Program User 57 # number of users # starting user location # card

number * card number *

Exit Program Mode *

Document #: 6055672, Rev 1.0 D1c Page 33 of 48

Page 34

Section 3: Programming IEI MiniMax 3 Installation/Programming Manual

3.6.8 Programming Consecutive “Card Only” Users via Batch Entry by Presentation

To program consecutive “Card Only” user via batch entry by presentation (by presenting cards to the front end reader) use command

53. This command provides a simple method of programming a group of consecutive users by presenting the appropriate cards. Up to

1,998 users can be added this way at one time. Entering location 1 (master code) or location 2 (supervisor user) as the first card in the

sequence generates an error because the master and supervisor codes cannot be programmed as a “Card Only” user. The card loading

stops automatically once the current user location exceeds 2000. Pressing any key on the faceplate aborts the loading process.

Action Command

Enter Program Mode 99 # master code *

Program Users 53 # user type # starting user location # * * <present

card>, <present card>, ....

Exit Program Mode *

3.6.9 Command 50 Quick Program Feature - “Code Only” or “Card Only”

The Max 3 contains a quick method for programming standard access user type users that are usually programmed using command 50.

When using this method the 50 is not required in the command sequence.

Action Command

Enter Program Mode 99 # master code *

Program “Code Only” User user location # * code * repeat code *

Program “Card Only” User user location # * * <present card>

Exit Program Mode *

Page 34 of 48 Document #: 6055672, Rev 1.0 D1c

Page 35

IEI MiniMax 3 Installation/Programming Manual Section 3: Programming

3.7 Deleting Users

There are two methods for deleting users from the Max 3. You can either delete a single user or you can delete a block of consecutive

users. You must know the user locations for user(s) you wish to delete in order to do this.

3.7.1 Delete a Single User

To delete a single user, follow the steps below.

Action Command

Enter Program Mode 99 # master code *

Delete User user location # * *

Exit Program Mode *

3.7.2 Delete a Block of Users

You can delete a block of consecutive users using command 58. This command requires you enter the starting user location you want

the deletion to begin and how many users from that point you want to delete. You must enter each value twice to ensure that you've

entered the correct number. Every user from the starting location to the ending user location is deleted. For example if you want to

delete user 10 to user 25, enter 10 in the start user value and 15 in the number of users value.

To delete a block of users, follow the steps below.

Action Command

Enter Program Mode 99 # master code *

Delete Users 58 # start user # start user # number of users *

Exit Program Mode *

number of users *

Document #: 6055672, Rev 1.0 D1c Page 35 of 48

Page 36

Section 3: Programming IEI MiniMax 3 Installation/Programming Manual

3.8 Programming Extended Unlock Time

The extended unlock time is the time used by the extended unlock user type (type 4) and emergency users (type 7). This time is

defaulted to 10 seconds.

Action Command

Enter Program Mode 99 # master code *

Program Extended Unlock Time 32 # 3 # unlock time # * * (1 to 255 seconds)

Exit Program Mode *

3.9 Programming Facility Code

This command is used to set the facility code used when programming 26-bit wiegand cards using commands 51 and 57. When using

these commands, the controller takes the programmed facility code and builds the 26-bit card data to store in the user location. The

default value is 11.

Action Command

Enter Program Mode 99 # master code *

Program Facility Code 32 # 4 # facility # * * (0 to 255)

Exit Program Mode *

3.10 Programming User Lockout

User lockout is used to lock down the controller so users cannot gain entrance through the door. If a locked out user attempts to gain

access after a lockout code (user type 3) is entered the front end indicates an error condition. On a Secured Series Front End, the

yellow LED (if equipped) lights for 2 seconds. On a Wiegand Front End, the sounder activates for 2 seconds.

Note: The master code, supervisor user and emergency users can't be locked out.

User lockout locks out users by location. This means that any user in higher user location than the lockout user used to initiate lockout

does not gain access. For example if the lockout user is in user location 6, users from locations 7 through 2000 do not have access.

By default, user lockout is enabled. If you with to turn it off see the command below.

Action Command

Enter Program Mode 99 # master code *

Enable User Lockout 30 # 5 # 1 # * * (default)

Disable User Lockout 30 # 5 # 0 # * *

Exit Program Mode *

Page 36 of 48 Document #: 6055672, Rev 1.0 D1c

Page 37

IEI MiniMax 3 Installation/Programming Manual Section 3: Programming

3.11 Programming the Door Ajar Output Time

To program the Door Ajar Output time use command 44. You can program it from 10 to 990 seconds in 10 second increments. The

default value is 30 seconds, which means the output triggers if the door position switch is held open for 30 seconds. The command

sequence is as follows:

Action Command

Enter Program Mode 99 # master code *

Delete Users 44 # time # 0 # ** (10 to 990 Seconds)

Exit Program Mode *

3.12 Programming the Forced Door Time

To program the Forced Door output time use command 45. You can program it from 10 to 990 seconds in 10 second increments. The

default value is 10 seconds, which means the output triggers immediately after 10 seconds. The command sequence is as follows:

Action Command

Enter Program Mode 99 # master code *

Delete Users 45 # time # 0 # ** (10 to 990 Seconds)

Exit Program Mode *

Document #: 6055672, Rev 1.0 D1c Page 37 of 48

Page 38

Section 3: Programming IEI MiniMax 3 Installation/Programming Manual

3.13 Using the Default Auto-Unlock Timezone

The Max 3 Door Control Module contains a default Auto-Unlock timezone from 9:00 A.M. To 5:00 P.M. Software is not required for

this feature to work. First you must enable timezones and then enable auto-unlock timezones. If you want it to operate as a first-in

auto-unlock timezone you must also enable that feature.

Note: If you require additional timezones you must use the PC software.

3.13.1 Enable/Disable Timezones

Use the following command to enable or disable timezones.

Action Command

Enter Program Mode 99 # master code *

Enable Timezones 30 # 9 # 1 # * *

Disable Timezones 30 # 9 # 0 # * *

Exit Program Mode *

3.13.2 Enable/Disable Auto-Unlock

Use the following command to enable or disable auto-unlock.

Action Command

Enter Program Mode 99 # master code *

Enable Auto-Unlock 30 # 11 # 1 # * *

Disable Auto-Unlock 30 # 11 # 0 # * *

Exit Program Mode *

3.13.3 Enable/Disable First-In Auto-Unlock

Use the following command to enable or disable first-in auto-unlock.

Action Command

Enter Program Mode 99 # master code *

Enable First-In Auto-Unlock 30 # 12 # 1 # * *

Disable First-In Auto-Unlock 30 # 12 # 0 # * *

Exit Program Mode *

Page 38 of 48 Document #: 6055672, Rev 1.0 D1c

Page 39

IEI MiniMax 3 Installation/Programming Manual Section 3: Programming

3.14 Programming Error Lockout

Error lockout is used to prevent someone from attempting to gain access by guessing a code or presenting cards. When the number of

invalid attempts is reached (error lockout threshold), the unit locks out any attempt to enter a code or present a card for the time

programmed in the error lockout duration. When this occurs the yellow LED on a Secured Series Front End or the sounder on a

Wiegand Front End is turned on for the duration.

3.14.1 Setting the Error Lockout Threshold

To set the error lockout threshold use the following command. The default is 3 attempts.

Action Command

Enter Program Mode 99 # master code *

Program Error Lockout Threshold 32 # 0 # attempts # * * (1 to 50 attempts)

Exit Program Mode *

3.14.2 Setting the Error Lockout Duration

To set the error lockout duration use the following command. The default is 10 seconds.

Action Command

Enter Program Mode 99 # master code *

Program Error Lockout Time Duration 32 # 1 # time duration # * * (1 to 255 seconds)

Exit Program Mode *

3.15 Programming Wiegand LED Active State

This command is used to program the wiegand LED terminal active state, which controls the wiegand front end's LED to indicate

whether the door is locked or not. By default the wiegand LED terminals is high (13.8 Volts) and when a programmed card is

presented and is validated, the LED terminal goes low (Ground) when access is granted. This is known as active low. An active high

state is just the opposite. The LED terminal is low and goes high on a valid access.

Action Command

Enter Program Mode 99 # master code *

Set Wiegand LED Active State to Low 30 # 16 # 0 # * * (default)

Set Wiegand LED Active State to High 30 # 16 # 1 # * *

Exit Program Mode *

Document #: 6055672, Rev 1.0 D1c Page 39 of 48

Page 40

Section 3: Programming IEI MiniMax 3 Installation/Programming Manual

3.16 Programming Wiegand Sounder Active State

The wiegand sounder terminal (SND) is used to indicate an error condition on a wiegand front end by using the reader's sounder (if

available). When an access denied error condition such as user lockout, user disabled or bad timezone occurs the sounder terminal

changes state for 2 seconds, which generates a solid tone on the reader's sounder. When error lockout occurs, the terminal changes

state for the amount of time programmed for the error lockout duration (command 32, parameter 1). By default the sounder state is set

to active low. This means that the terminal is normally high (13.8 Volts) and goes low (Ground) on an error condition. Setting the sate

to an active high means the terminal is normally low (Ground) and does high (13.8 Volts) on error condition.

Action Command

Enter Program Mode 99 # master code *

Set Wiegand Sounder Active State to Low 30 # 17 # 0 # * * (default)

Set Wiegand Sounder Active State to High 30 # 17 # 1 # * *

Exit Program Mode *

3.17 Enable/Disable Control Module Audio Indicators

Control Module audio indicators refers the the sounds generated by the controller to indicate various conditions after a code is entered

or card is presented at the front end. This feature should be used mainly for troubleshooting purposes, since you wouldn't be able to

hear the audio indicators when the cabinet is closed. For instance, you may want to enable this to find out why someone is being

denied access.

Note: These audio alerts only occur on the control module not on the front end.

Action Command

Enter Program Mode 99 # master code *

Disable Audio Indicators 30 # 18 # 0 # * * (default)

Enable Audio Indicators 30 # 18 # 1 # * *

Exit Program Mode *

Table 5: Control Module Audio Indicators

Condition Sounder Indication

Invalid Code or Card 3 Very Rapid Beeps

User Lockout Activated Pair of Double Beeps

User Lockout Canceled Single Double Beep

Access Denied – User Disabled 1 Long Beep Followed by 1 short Beep

Access Denied – Bad Timezone 1 Long Beep Followed by 2 short Beeps

Access Denied – User Lockout 1 Long Beep Followed by 3 short Beeps

First-In Auto-Unlock Activated 4 Quick Beeps

Toggle Mode Activated 6 Quick Beeps

Page 40 of 48 Document #: 6055672, Rev 1.0 D1c

Page 41

IEI MiniMax 3 Installation/Programming Manual Section 3: Programming

3.18 Reseting System Defaults and Erasing Memory

There are two methods for deleting programmed information from the Max 3 Door Control Module. The first method is using

command 40, which resets the system defaults and the master code only. The second method is through command 46, which erases all

the memory in the unit, except the transaction log.

3.18.1 Resetting the Master Code and System Defaults Only

Entering command 40 erases everything from memory except the user list and transaction log and restores the default settings. This is

useful if the unit has experienced programming problems, or wish to delete earlier programming.

Action Command

Enter Program Mode 99 # master code *

Reset System Defaults 40 # 00000 # 00000 # * *

Exit Program Mode *

3.18.2 Erasing Entire Memory/Resetting System Defaults

Entering command 46 deletes everything from memory including the user list but not the transaction log and restores the default

settings. This is used as a last resort if you need to erase a specific user and do not have a programmed user list.

Action Command

Enter Program Mode 99 # master code *

Erase Entire Memory 46 # 00000 # 00000 # * *

Exit Program Mode *

3.18.3 Erasing the Transaction Event Log

If you need to erase the transaction event log use command 76. Once you've done this command the transaction log is erased

permanently.

Note: The PC software is required to view the transaction log.

Action Command

Enter Program Mode 99 # master code *

Erase Transaction Event Log 76 # 00000 # 00000 # * *

Exit Program Mode *

Document #: 6055672, Rev 1.0 D1c Page 41 of 48

Page 42

Section 3: Programming IEI MiniMax 3 Installation/Programming Manual

3.19 Programming Daylight Savings Time

The Max 3 Module supports Daylight Savings Time, which can be enabled or disabled by using the commands below. Daylight

Savings Time is enabled by default.

3.19.1 Enabling/Disabling Daylight Savings Time

The following chart shows how to enable or disable Daylight Savings Time.

Action Command

Enter Program Mode 99 # master code *

Enable Daylight Savings Time 30 # 13 # 1 # ** (default)

Disable Daylight Savings Time 30 # 13 # 0 # **

Exit Program Mode *

3.19.2 Selecting Daylight Savings Time Format

Below is the command to select which Daylight Savings Time format you wish to use, United States (US) or European. Below the

command is a chart containing the definition of the two formats. Please note that the Max 3 supports the US 2007 Daylight Saving

Time.

Action Command

Enter Program Mode 99 # master code *

Select US Daylight Savings Time Format 30 # 15 # 0 # ** (default)

Select European Daylight Savings Time Format 30 # 15 # 1 # **

Exit Program Mode *

US DST Format

Begins Second Sunday in March at 2:00 AM

End First Sunday in November at 2:00 AM

European DST Format

Begins Last Sunday in March at 2:00 AM

Ends Last Sunday in October at 2:00 AM

Page 42 of 48 Document #: 6055672, Rev 1.0 D1c

Page 43

IEI MiniMax 3 Installation/Programming Manual Section 3: Programming

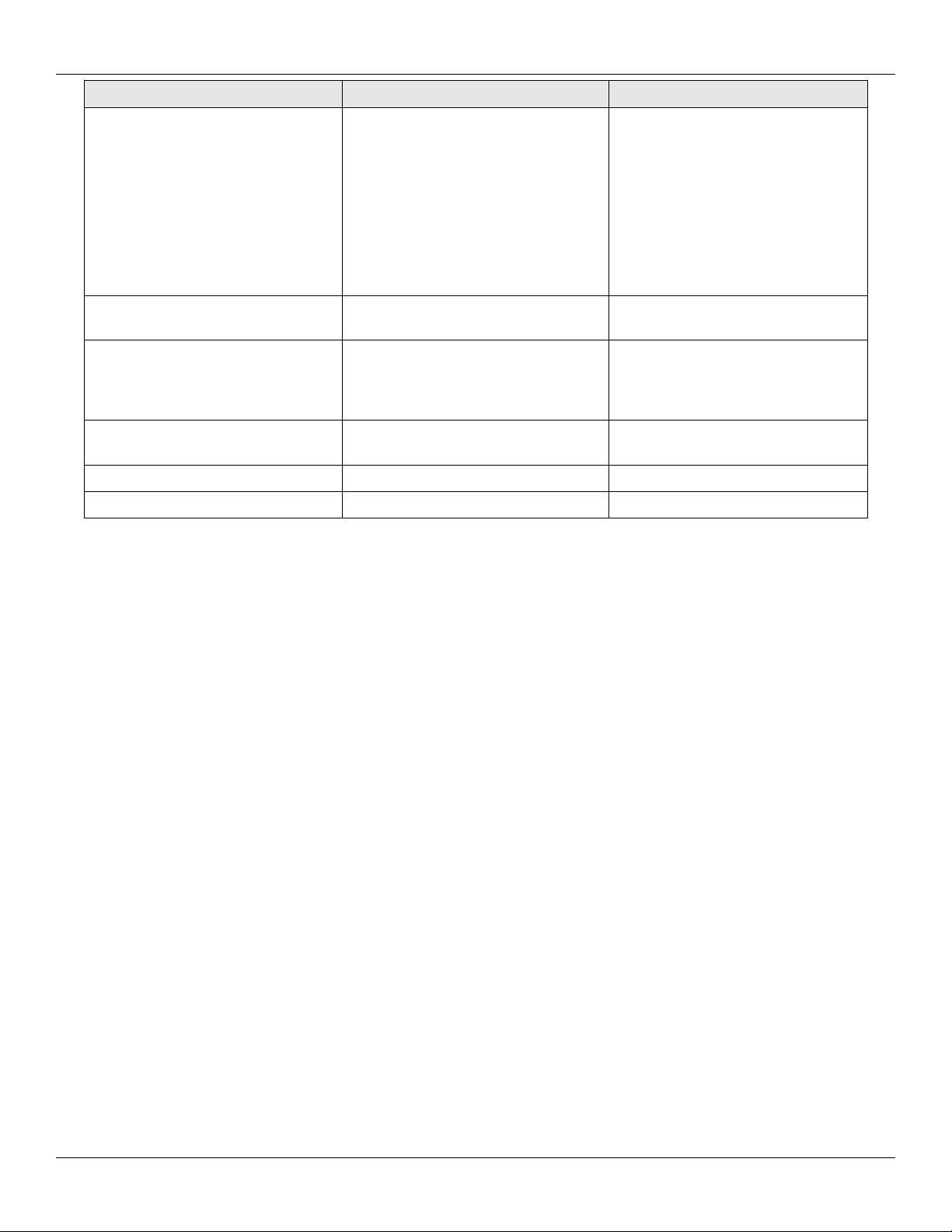

3.20 Programming Options Chart

The following chart is a complete list of programming commands available in the Max 3 Door Control Module. This chart is for quick

reference. Please refer to the preceding sections for complete details of each command. Defaults are in bold.

Table 6: Programming Options Chart

Action Desired Press Details

Enter Program Mode 99 # (Master Code)* Yellow LED blinks slowly

Change master code

Add Supervisor Code

Set Main Relay Time 11 # time # 0 # **

Set/clear standard option 30 # option # s/c # ** See Chart below

Option Set Clear

0 – Audio Keypress Feedback 0 = Disabled 1 = Enabled

1 – Visual Keypress Feedback 0 = Disabled 1 = Enabled

5 – User Lockout Enable 0 = Disabled 1 = Enabled

9 – Time Zone Select 0 = Disabled 1 = Enabled

11 – Auto-Unlock Select 0 = Disabled 1 = Enabled

12 – First-In Auto-Unlock 0 = Disabled 1 = Enabled

13 – Daylight Savings Time 0 = Disabled 1 = Enabled

15 – Daylight Savings Time Format 0 = US 1 = European

16 – WFE LED Output Select 0 = Active Low 1 = Active High

17 – WFE Sounder Output Select 0 = Active Low 1 = Active High

18 – Control Module Audio Indicators 0 = Disabled 1 = Enabled

1 # (new code) * (repeat code) *

Ex: 1 # 4321 * 4321 *

2 # (new code) * (repeat code) *

Ex: 1 # 6478 * 6478 *

Code-only operation

Code-only operation

Time =1-99 seconds (default = 5

seconds)

Change Platform Parameters 32 # parameter # value # ** See Chart Below

Parameter Value

0 – Error Lockout Threshold 1 – 50 Attempts (Default = 3)

1 – Error Lockout Duration 1-255 Sec. (Default = 10 Sec.)

3 – Extended User Unlock Time 1-255 Sec. (Default = 10 Sec.)

4 – Facility Code (For commands 51 & 57) 0 – 255 (Default = 11)

Set System Time 41 # hhmm # 0 # ** hhmm=hour/minute (24 Hour Format)

Set System Date 42 # mmddyy # dow # **

Set Door Number 43 # 0 # Door Number # **

Set Door Ajar Time 44 # time # 0 # **

Document #: 6055672, Rev 1.0 D1c Page 43 of 48

mmddyy=month, date, year; dow=day

of week, 1=Sunday

Time =door ajar time, to nearest 10’s

seconds, entered as 30-990;

(default=30 secs)

Page 44

Section 3: Programming IEI MiniMax 3 Installation/Programming Manual

Action Desired Press Details

Time =forced door time, to nearest 10’s

Set Forced Door Time 45 # time # 0 # **

Reset System Defaults Only 40 # 00000 # 00000 # ** Does not delete users

seconds, entered as 30-990;

(default=10 secs)

Delete Entire Memory and Reset

System Defaults

Program User – Code Only

Program User – Code AND Card

By Presenting Card