Page 1

ECW-281BB6 Embedded System

ECW-281BB6 Embedded System

Page 1

Page 2

ECW-281BB6 Embedded System

Date Version Changes

June 2007 1.00 Initial release

ECW-281BB6 Embedded System

Revision

Page 2

Page 3

ECW-281BB6 Embedded System

COPYRIGHT NOTICE

The information in this document is subject to change without prior notice in order to

improve reliability, design and function and does not represent a commitment on the part

of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or

consequential damages arising out of the use or inability to use the product or

documentation, even if advised of the possibility of such damages.

Copyright

This document contains proprietary information protected by copyright. All rights are

reserved. No part of this manual may be reproduced by any mechanical, electronic, or

other means in any form without prior written permission of the manufacturer.

TRADEMARKS

IBM PC is a registered trademark of International Business Machines Corporation.

INTEL® is a registered trademark of INTEL® Corporation. Other product names

mentioned herein are used for identification purposes only and may be trademarks and/or

registered trademarks of their respective owners.

Page 3

Page 4

ECW-281BB6 Embedded System

Packing List

NOTE:

If any of the components listed in the checklist below are missing, please do not

proceed with the installation. Contact the IEI reseller or vendor you purchased

the ECW-281BB6 from or contact an IEI sales representative directly. To

contact an IEI sales representative, please send an email to

The items listed below should all be included in the ECW-281BB6 package.

1 x ECW-281BB6 embedded system

1 x Power cord

2 x Mounting brackets

1 x DIN mount kit

1 x Screw set

1 x Thermal pad for HDD

1 x Mini jumper set

4 x Foot pads

1 x QIG

1 x Driver and manual CD

1 x Power Adaptor (for WD models only)

1 x Wall mount kit (optional)

sales@iei.com.tw.

Page 4

Page 5

ECW-281BB6 Embedded System

SAFETY PRECAUTIONS

1. Prior to installing, moving and modifying the embedded system, make sure

that the unit’s power is turned off and the power cord is disconnected.

2. Do not apply voltage levels that exceed the specified voltage range. Doing so

may cause fire or an electrical shock.

3. Electric shock can occur if the embedded system is opened. Do not drop or

insert any objects into any openings of the embedded system.

4. Only qualified engineers from certified system integrators or VARs are

allowed to make necessary modifications to the embedded system.

5. If considerable amounts of dust, water, or fluids enter the embedded system,

Precautions

turn off the power supply immediately, unplug the power cord, and contact the

vendor.

6. Explosions may occur with installations in environments where flammable

gases are present.

7. Fault-tolerant and failsafe designs should be implemented with the use of the

embedded system on transportation vehicles, ships, safety/security devices,

or medical devices not related to life-support functions. Users/integrators

should take responsibility for adequate levels of reliability and safety.

8. Preventive designs should be implemented so as to avoid communications

faults between the embedded system and the devices it controls.0.

HANDLING PRECAUTIONS

1. Do not drop the embedded system against a hard surface.

2. Do not strike or exert excessive force onto the embedded system.

3. Avoid exposing the embedded system to direct sunlight, dust, or chemical

vapors.

4. Condensation might form inside the embedded system chassis if exposed to

sudden changes in temperature.

5. Carefully route the power cord so that people cannot step on it. Do not place

anything over the power cord.

Page 5

Page 6

6. If the equipment should be left unused for an extended period of time,

disconnect it from the power source to avoid damage by transient

over-voltage.

7. If any of the following situations arises, get the equipment checked by service

personnel:0.

ECW-281BB6 Embedded System

o The power cord or plug is damaged.

o Liquid has penetrated into the equipment.

o The equipment has been exposed to moisture.

o The equipment does not work properly, or the user cannot get it to work

according to the user manual.

o The equipment has been dropped and damaged.

o The equipment shows obvious signs of breakage.

WARNING!

Any changes or modifications made to the equipment that are not

expressly approved by the relevant standards could void the authority

to operate the equipment.

MAINTENANCE AND CLEANING

Note the following precautions before beginning to clean the embedded system.

When cleaning any single part or component of the computer, please read and

understand the details below fully.

Never spray or squirt liquids directly onto any computer component. To clean

the device, please rub it with a piece of dry and soft cloth or a slightly

moistened cloth.

Page 6

The interior of the embedded system does not require cleaning. Keep fluids

away from the embedded system and the interior of it.

Turn the system off before cleaning the embedded system.

Never drop any objects through the openings of the embedded system or get

the circuit board damp or wet.

Page 7

ECW-281BB6 Embedded System

Be cautious of any cleaning solvents or chemicals used when cleaning the

embedded system as some individuals may be allergic to the ingredients.

Avoid any eating, drinking or smoking near the embedded system.

CLEANING TOOLS

Below is a list of items to use while cleaning the computer or computer peripherals. Please

keep in mind that some components in the computer may only be cleaned using a product

designed for cleaning that component, if this is the case it will be mentioned in the

cleaning tips.

Cloth - A piece of cloth is the best tool to use when rubbing up a component.

Although paper towels or tissues can be used on most hardware as well, it is

recommended to rub it with a piece of cloth.

Water or rubbing alcohol – Moisten a piece of cloth a bit with some water or

rubbing alcohol and rub it on the computer. Unknown solvents may be harmful

to the plastics parts.

Vacuum cleaner - Removing the dust, dirt, hair, cigarette particles, and other

particles out of a computer can be one of the best methods of cleaning a

computer. Over time these items can restrict the airflow in a computer and

cause circuitry to corrode.

Cotton swabs - Cotton swabs moistened with rubbing alcohol or water are

excellent tools for wiping hard to reach areas in the keyboard, mouse, and

other locations.

Foam swabs - Whenever possible it is better to use lint free swabs such as

foam swabs.

ESD PRECAUTIONS

Observe all conventional anti-ESD methods while handling the components contained

within the embedded system should the need arise to remove any of the chassis panels.

The use of a grounded wrist strap and an anti-static work pad is recommended. Avoid dust

and debris or other static-accumulating materials in the work area.

Page 7

Page 8

ECW-281BB6 Embedded System

Table of Contents

1 INTRODUCTION................................................................................................... 19

1.1 ECW-281BB6 EMBEDDED SYSTEM OVERVIEW ...................................................... 20

1.1.1 ECW-281BB6 Benefits..................................................................................... 20

1.1.2 ECW-281BB6 Features.................................................................................... 20

1.2 ECW-281BB6 MODEL VARIATIONS......................................................................... 21

1.3 TECHNICAL SPECIFICATIONS .................................................................................... 21

1.4 POWER MODULE SPECIFICATIONS............................................................................ 23

1.4.1 Power Module Options.................................................................................... 23

1.4.2 Power Module Specifications .......................................................................... 24

1.5 POWER ADAPTER..................................................................................................... 25

2 MECHANICAL DESCRIPTION.......................................................................... 27

2.1 ECW-281BB6 MECHANICAL OVERVIEW ................................................................ 28

2.2 PHYSICAL DIMENSIONS............................................................................................ 28

2.2.1 ECW-281BB6 Dimensions............................................................................... 28

2.2.2 Motherboard Dimensions ................................................................................ 29

2.2.3 Power Module Dimensions.............................................................................. 30

2.3 EXTERNAL OVERVIEW ............................................................................................. 31

2.3.1 Front Panel...................................................................................................... 31

2.3.2 Rear Panel ....................................................................................................... 31

2.3.3 Bottom Surface................................................................................................. 32

2.4 INTERNAL OVERVIEW............................................................................................... 33

3 SYSTEM COMPONENTS .................................................................................... 35

3.1 ECW-281BB6 EMBEDDED SYSTEM MOTHERBOARD .............................................. 36

3.1.1 ECW-281BB6 Embedded System Motherboard............................................... 36

3.1.2 WAFER-8522 Motherboard Overview............................................................. 36

3.1.3 CPU Support.................................................................................................... 37

3.1.4 Intel® Celeron® M............................................................................................ 37

3.2 PERIPHERAL INTERFACE CONNECTORS .................................................................... 38

3.2.1 Peripheral Interface Connectors ..................................................................... 38

Page 8

Page 9

ECW-281BB6 Embedded System

3.2.2 External Interface Panel Connectors............................................................... 38

3.3 INTERNAL PERIPHERAL CONNECTORS...................................................................... 39

3.3.1 AT Power Connector........................................................................................ 39

3.3.2 ATX Power Connector ..................................................................................... 40

3.3.3 Audio Connector .............................................................................................. 41

3.3.4 IDE Connector................................................................................................. 42

3.3.5 LED Connector................................................................................................ 44

3.3.6 Power Button Connector.................................................................................. 45

3.3.7 Reset Button Connector ................................................................................... 46

3.3.8 Serial Port Connector (RS-232/422/485) ........................................................ 47

3.3.9 Serial Port Connector (COM 3, COM 4, COM 5 and COM 6)....................... 48

3.3.10 Internal USB Connectors............................................................................... 49

3.4 EXTERNAL PERIPHERAL INTERFACE CONNECTORS .................................................. 50

3.4.1 External Peripheral Interface Connector Overview........................................ 50

3.4.2 RJ-45 Ethernet Connector ............................................................................... 51

3.4.3 Serial Port Connector (COM1) ....................................................................... 52

3.4.4 USB Combo Ports............................................................................................ 53

3.4.5 VGA Connector................................................................................................ 53

3.5 WAFER-8522 MOTHERBOARD ON-BOARD JUMPERS.............................................. 55

3.5.1 Clear CMOS Jumper........................................................................................ 55

3.5.2 COM Port Setting Jumper ............................................................................... 57

3.5.3 LCD Voltage Selection ..................................................................................... 58

3.5.4 LCD Resolution Selection................................................................................ 59

3.6 CONNECTOR MAPPINGS ........................................................................................... 60

3.6.1 Power Connector............................................................................................. 61

3.6.2 ATX Mode Connector....................................................................................... 61

4 INSTALLATION .................................................................................................... 63

4.1 ANTI-STATIC PRECAUTIONS...................................................................................... 64

4.2 INSTALLATION PROCEDURE...................................................................................... 64

4.2.1 Installation Procedure Overview..................................................................... 64

4.2.2 Unpacking........................................................................................................ 65

4.2.3 Bottom Surface Removal.................................................................................. 67

4.2.4 Configure the Jumper Settings......................................................................... 67

4.2.5 IDE Hard Drive Installation............................................................................ 68

Page 9

Page 10

4.2.6 Mounting the System with Mounting Brackets................................................. 70

4.2.7 Mounting the System with Wall Mount Kit....................................................... 71

4.2.8 DIN Mounting.................................................................................................. 73

4.2.9 Cable Connections........................................................................................... 75

4.3 POWER-ON PROCEDURE .......................................................................................... 76

4.3.1 Installation Checklist....................................................................................... 76

4.3.2 Terminal Block Pinouts.................................................................................... 76

4.3.3 Power-on Procedure........................................................................................ 77

5 BIOS SETTINGS.................................................................................................... 79

5.1 INTRODUCTION ........................................................................................................ 80

5.1.1 Starting Setup................................................................................................... 80

5.1.2 Using Setup...................................................................................................... 80

5.1.3 Getting Help..................................................................................................... 81

5.1.4 Unable to Reboot After Configuration Changes.............................................. 81

ECW-281BB6 Embedded System

5.1.5 BIOS Menu Bar................................................................................................ 81

5.2 MAIN ....................................................................................................................... 82

5.3 ADVANCED............................................................................................................... 83

5.3.1 CPU Configuration.......................................................................................... 84

5.3.2 IDE Configuration........................................................................................... 86

5.3.2.1 IDE Master, IDE Slave............................................................................. 89

5.3.3 Super IO Configuration.................................................................................... 93

5.3.4 Hardware Health Configuration...................................................................... 99

5.3.5 MPS Configuration ........................................................................................ 100

5.3.6 T rusted Computing......................................................................................... 101

5.3.7 USB Configuration......................................................................................... 102

5.3.7.1 USB Mass Storage Device Configuration............................................... 104

5.4 BOOT ..................................................................................................................... 106

5.4.1 Boot Settings Configuration........................................................................... 106

5.4.2 Boot Device Priority...................................................................................... 108

5.4.3 Removable Drives.......................................................................................... 109

5.5 SECURITY................................................................................................................110

5.6 CHIPSET ..................................................................................................................112

5.6.1 NorthBridge Configuration.............................................................................112

5.6.2 SouthBridge Configuration.............................................................................117

Page 10

Page 11

ECW-281BB6 Embedded System

5.7 POWER KEY ............................................................................................................118

5.8 EXIT....................................................................................................................... 120

6 DRIVER INSTALLATION.................................................................................. 123

6.1 AVAILABLE SOFTWARE DRIVERS............................................................................ 124

6.2 CHIPSET DRIVER INSTALLATION............................................................................. 124

6.3 REALTEK AUDIO DRIVER INSTALLATION ............................................................... 127

6.4 INTEL GRAPHICS MEDIA ACCELERATOR DRIVER ................................................... 130

6.5 LAN DRIVER INSTALLATION ................................................................................. 132

7 TROUBLESHOOTING AND MAINTENANCE .............................................. 135

7.1 ECW-281BB6 SYSTEM MAINTENANCE OVERVIEW .............................................. 136

7.2 SYSTEM TROUBLESHOOTING.................................................................................. 136

7.2.1 The System Doesn’t Turn On.......................................................................... 136

7.2.2 The System Doesn’t Boot Up.......................................................................... 137

7.2.3 More Troubleshooting.................................................................................... 138

7.3 COMPONENT REPLACEMENT PROCEDURE.............................................................. 138

7.3.1 SO-DIMM Replacement................................................................................. 139

A IEI EMBEDDED SYSTEM SERIES.................................................................. 143

A.1 IEI EMBEDDED SYSTEM SERIES............................................................................ 144

A.1.1 Overview........................................................................................................ 144

A.1.2 IEI Embedded System Series......................................................................... 144

A.1.3 IEI Embedded System Series Variations........................................................ 145

A.2 EMBEDDED SYSTEM SOLUTIONS........................................................................... 145

A.2.1 AMD® Geode® LX800 500MHz Solutions..................................................... 145

A.2.2 AMD® Geode® GX466 333MHz Solutions.................................................... 146

A.2.3 VIA® LUKE® 1GHz Solutions ....................................................................... 146

A.2.4 VIA® MARK® 800MHz Solutions.................................................................. 147

A.2.5 Intel® Celeron® M 1.5GHz Solutions ............................................................ 147

A.2.6 Intel® Pentium® M 1.6GHz Solutions............................................................ 148

A.2.7 Intel® Socket 479 Pentium®/Celeron® M 2GHz Solutions ............................ 149

A.2.8 LGA 775 Intel® Pentium® 4/ Pentium® D Solutions ..................................... 149

A.2.9 Intel® Socket 479 Core Duo/Solo Solutions.................................................. 149

B BIOS MENU OPTIONS....................................................................................... 151

Page 11

Page 12

B.1 BIOS CONFIGURATION OPTIONS........................................................................... 152

C WATCHDOG TIMER.......................................................................................... 155

D ADDRESS MAPPING.......................................................................................... 159

D.1 IO ADDRESS MAP ................................................................................................. 160

D.2 1ST MB MEMORY ADDRESS MAP ......................................................................... 161

D.3 IRQ MAPPING TABLE............................................................................................ 161

D.4 DMA CHANNEL ASSIGNMENTS............................................................................. 161

INDEX............................................................................................................................ 163

ECW-281BB6 Embedded System

Page 12

Page 13

ECW-281BB6 Embedded System

Figure 1-1: ECW-281BB6 WAFER Series Embedded System ................................20

Figure 1-2: Power Adapter .........................................................................................25

Figure 2-1: ECW-281BB6 Dimensions (mm).............................................................29

Figure 2-2: WAFER SBC Dimensions (mm)..............................................................30

Figure 2-3: Power Module Dimensions (mm)...........................................................30

Figure 2-4: ECW-281BB6 Front Panel.......................................................................31

Figure 2-5: ECW-281BB6 Rear Panel ........................................................................32

Figure 2-6: Bottom Surface........................................................................................33

Figure 2-7: Internal Overview.....................................................................................34

List of Figures

Figure 3-1: WAFER-8522 Jumper and Connector Locations..................................36

Figure 3-2: AT Power Connector Location...............................................................40

Figure 3-3: ATX Power Connector Location.............................................................41

Figure 3-4: Audio Connector Pinouts .......................................................................42

Figure 3-5: IDE Device Connector Location.............................................................43

Figure 3-6: LED Connector Locations.......................................................................45

Figure 3-7: Power Button Connector Location........................................................46

Figure 3-8: Reset Button Connector Locations.......................................................46

Figure 3-9: Serial Port Connector Location..............................................................47

Figure 3-10: RS-232 Serial Port Connector Location ..............................................48

Figure 3-11: Internal USB Connector Location........................................................50

Figure 3-12: WAFER-8522 On-board External Interface Connectors.....................51

Figure 3-13: LAN Connector ......................................................................................51

Figure 3-14: Serial Port Pinout Locations.................................................................53

Figure 3-15: VGA Connector......................................................................................54

Figure 3-16: Jumpers..................................................................................................55

Figure 3-18: JP2 Clear CMOS Jumper.......................................................................57

Figure 3-19: COM Port Setting Jumper Location.....................................................58

Figure 3-20: LCD Voltage Selection Jumper Location............................................59

Page 13

Page 14

Figure 3-21: LCD Resolution Jumper Location........................................................60

Figure 4-1: Bottom Surface Retention Screws.........................................................67

Figure 4-2: Hard Drive Bracket ..................................................................................68

Figure 4-3:HDD Bracket Retention Screws ..............................................................68

Figure 4-4: HDD Retention Screws............................................................................69

Figure 4-5: HDD Thermal Pad ....................................................................................70

Figure 4-6: Mounting Bracket Retention Screws.....................................................71

Figure 4-7: Wall-mounting Bracket............................................................................72

Figure 4-8: Mount the Embedded System................................................................73

Figure 4-9: DIN Rail Mounting Bracket......................................................................74

Figure 4-10: Screw Locations ....................................................................................74

Figure 4-11: Mounting the DIN RAIL..........................................................................75

Figure 4-12: Secure the Assembly to the DIN Rail...................................................75

ECW-281BB6 Embedded System

Figure 4-13: Terminal Block Pinouts.........................................................................76

Figure 4-14: Power Button .........................................................................................77

Figure 6-1: InstallShield Wizard Preparation Screen............................................ 124

Figure 6-2: Welcome Screen................................................................................... 125

Figure 6-3: License Agreement............................................................................... 125

Figure 6-4: Readme Information............................................................................. 126

Figure 6-5: Restart the Computer........................................................................... 126

Figure 6-6: Audio Driver Install Shield Wizard Starting ....................................... 127

Figure 6-7: Audio Driver Setup Preparation.......................................................... 127

Figure 6-8: Audio Driver Welcome Screen............................................................ 128

Figure 6-9: Audio Driver Software Configuration................................................. 128

Figure 6-10: Audio Driver Digital Signal ................................................................ 129

Figure 6-11: Audio Driver Installation Begins....................................................... 129

Figure 6-12: Audio Driver Installation Complete................................................... 130

Figure 6-13: GMA Driver Installation Welcome Screen........................................ 131

Page 14

Figure 6-14: GMA Driver License Agreement........................................................ 131

Figure 6-15: GMA Driver Installing Notice............................................................. 132

Figure 6-16: GMA Driver Installation Complete .................................................... 132

Figure 6-17: LAN License Agreement.................................................................... 133

Page 15

ECW-281BB6 Embedded System

Figure 6-18: Select the Driver Directory ................................................................ 133

Figure 6-19: LAN Driver Configuration .................................................................. 134

Figure 7-1: SO-DIMM Cover Plate........................................................................... 139

Figure 7-2: SO-DIMM Removal................................................................................ 140

Figure 7-3: SO-DIMM Thermal Bracket Retention Screws................................... 140

Figure 7-4: SO-DIMM Installation............................................................................ 141

Page 15

Page 16

ECW-281BB6 Embedded System

List of Tables

Table 1-1: Model Variations........................................................................................21

Table 1-2: Technical Specifications ..........................................................................22

Table 1-3: ECW-281BB6 Power Module Options .....................................................23

Table 1-4: DC-to-DC Power Module Specifications.................................................24

Table 1-5: Power Adapter Specifications..................................................................26

Table 3-1: Supported Processor................................................................................37

Table 3-2: Peripheral Interface Connectors..............................................................38

Table 3-3: Rear Panel Connectors.............................................................................39

Table 3-4: AT Power Connector Pinouts ..................................................................40

Table 3-5: ATX Power Connector Pinouts................................................................41

Table 3-6: Audio Connector Pinouts.........................................................................42

Table 3-7: IDE Connector Pinouts.............................................................................44

Table 3-8: LED Connector Pinouts............................................................................45

Table 3-9: Power Button Connector Pinouts............................................................46

Table 3-10: Reset Button Connector Pinouts...........................................................47

Table 3-11: RS-232/422/485 Serial Port Connector Pinouts....................................48

Table 3-12: RS-232 Serial Port Connector Pinouts..................................................49

Table 3-13: Internal USB Connector Pinouts ...........................................................50

Table 3-14: RJ-45 Ethernet Connector Pinouts........................................................51

Table 3-15: RJ-45 Ethernet Connector LEDs............................................................52

Table 3-16: RS-232 Serial Port (COM 1) Pinouts......................................................52

Table 3-17: USB Connector Pinouts..........................................................................53

Table 3-18: VGA Connector Pinouts .........................................................................54

Table 3-19: Jumpers....................................................................................................55

Page 16

Table 3-21: JP2 Clear CMOS Jumper Settings.........................................................56

Table 3-22: COM Port Setting Jumper Settings.......................................................57

Table 3-23: LCD Voltage Selection Jumper Settings...............................................58

Table 3-24: LCD Resolution Jumper Settings..........................................................60

Page 17

ECW-281BB6 Embedded System

Table 3-25: Motherboard Power Connector Mapping..............................................61

Table 3-26: Motherboard Power Connector Mapping..............................................61

Table 4-1: Package List Contents..............................................................................66

Table 5-1: BIOS Navigation Keys...............................................................................81

Page 17

Page 18

ECW-281BB6 Embedded System

List of BIOS Menus

Menu 1: Main ....................................................................................................82

Menu 2: Advanced ....................................................................................................84

Menu 3: CPU Configuration .......................................................................................85

Menu 4: IDE Configuration.........................................................................................86

Menu 5: IDE Master and IDE Slave Configuration ...................................................90

Menu 6: Super IO Configuration................................................................................94

Menu 7: Hardware Health Configuration ..................................................................99

Menu 8: MPS Configuration.................................................................................... 100

Menu 9: Trusted Computing ................................................................................... 101

Menu 10: USB Configuration .................................................................................. 102

Menu 11: USB Mass Storage Device Configuration.............................................. 104

Menu 12: Boot ................................................................................................. 106

BIOS Menu 13: Boot Settings Configuration......................................................... 107

Menu 14: Boot Device Priority Settings................................................................. 109

Menu 15: Removable Drives ................................................................................... 110

Menu 16: Security ................................................................................................. 111

Menu 17: Chipset ................................................................................................. 112

Menu 18:NorthBridge Chipset Configuration........................................................ 113

Menu 19:SouthBridge Chipset Configuration....................................................... 117

Menu 20:Power ................................................................................................. 119

Menu 21:Exit ................................................................................................. 120

Page 18

Page 19

ECW-281BB6 Embedded System

Chapter

1

1 Introduction

Page 19

Page 20

ECW-281BB6 Embedded System

1.1 ECW-281BB6 Embedded System Overview

Figure 1-1: ECW-281BB6 WAFER Series Embedded System

There are four WAFER-8522 Intel® Celeron® M based embedded solutions in the

ECW-281BB6 series. All fanless motherboards have been optimized

applications that require minimum installation space. The WAFER series boards support a full

range of functions for an AT/ATX-compatible industrial computer.

subsystems are all capable of supporting one 2.5” hard disk drive.

ECW-281BB6 embedded

for multimedia

1.1.1 ECW-281BB6 Benefits

The ECW-281BB6 embedded system has the following benefits:

Easy installation saves installation time

Complete integration saves solution development time and cost

Secure storage with one IDE hard drive supported

Compact size saves space

Powerful preinstalled Intel® Celeron M CPU and motherboard ensures

rigorous processing needs can be met

1.1.2 ECW-281BB6 Features

Page 20

The ECW-281BB6 has the following features

RoHS compliant design

Fanless system

Built-in DC-to-DC power converter

Page 21

ECW-281BB6 Embedded System

Intel® Celeron M 1GHz Zero Cache CPU supported

Dual GbE LAN for high speed network applications

One IDE hard drive supported

Wall mount and DIN mount supported.

1.2 ECW-281BB6 Model Variations

There are four models in the ECW-281BB6 embedded system series. Two models have a

preinstalled 512MB DDR memory module and the other two models have a 1GB DDR

memory module preinstalled. Another distinctive is that two models support a DC 12V

input and the other two models supports 9V ~ 36V DC input. The four models are listed in

Table 1-1 below.

ECW-281BB6 CPU Memory Power

/512MB

/1GB

-WD/512MB

-WD/1GB

Table 1-1: Model Variations

Intel® Celeron M 1GHz zero cache 512MB DDR 12V DC input

Intel® Celeron M 1GHz zero cache 1GB DDR 12V DC input

Intel® Celeron M 1GHz zero cache 512MB DDR 9V~36V DC input

Intel® Celeron M 1GHz zero cache 1GB DDR 9V~36V DC input

1.3 Technical Specifications

The specifications for the Intel based embedded systems are listed below.

ECW-281BB6

CPU

System Chipset

System Memory

Intel® ULV Celeron® M 1GHz zero cache CPU

Intel® 852GM + ICH4

512MB/1GB 200-pin SO-DIMM DDR 266MHz SDRAM

Ethernet

Display

Dual 10/100/1000Base-T RTL8110SC

CRT integrated in Intel® 852GM

Page 21

Page 22

ECW-281BB6 Embedded System

USB

Serial Port

Audio

Storage

Chassis Construction

Power Supply

Operating Shock

Operating Vibration

4 x USB 2.0 supported (two in front panel, two in rear panel)

5 x RS-232

1 x RS-232/422/485 (selectable)

1 x Audio out

One 2.5” IDE hard drive supported

Aluminum Alloy

Internal DC-to-DC power converter, input voltage:

12V DC or 9V – 36V (WD)

External power adapter, input voltage:

90V AC ~ 264V AC @ 47Hz ~ 63Hz, 55W

1G, 5Hz~500Hz, random operation (HDD)

MIL-STD-810F 514.5C-1

Operating temperature

Color

Weight (Net/Gross)

Dimensions (D x W x H)

EMC

Table 1-2: Technical Specifications

0ºC ~ 50ºC

Black

2.1kg/3.9kg

132mm x 229mm x 64mm

FCC Class A, CE

Page 22

Page 23

ECW-281BB6 Embedded System

1.4 Power Module Specifications

1.4.1 Power Module Options

The ECW-281BB6 embedded system supports either a 12V DC input or a 9V~36V DC

input. The input support depends on the power module installed in the system. The two

power modules are listed in

Embedded System Power Module DC Input

ECW-281BB6/512MB

ECW-281BB6/1GB

ECW-281BB6-WD/512MB

ECW-281BB6-WD/1GB

Table 1-3: ECW-281BB6 Power Module Options

Table 1-3:

IDD-12250A 12V DC input

IDD-12250A 12V DC input

IDD-936260A 9V~36V DC input

IDD-936260A 9V~36V DC input

Page 23

Page 24

1.4.2 Power Module Specifications

The specifications for the IDD-12250A and IDD-936260A are shown in Table 1-4.

Model Name: IDD-12250A IDD-936260A

ECW-281BB6 Embedded System

Input

Output:

12V

5V

5VSB

Max. Total Output:

Performance Characteristics:

Noise & Ripple:

Line Regulation:

Load Regulation

Efficiency:

Dimensions:

12VDC 9VDC~36VDC

5A (pass thru.) 3A (Max.)

10A (Max.) 10A (Max.)

0.5A (Max.) 0.5A (Max.)

50W+60W (12V pass thru.) 60W

< 240mV < 240mV

< 20mV < 20mV

<60mV <60mV

Up to 90% Up to 90%

40mm x 100mm 40mm x 100mm

Page 24

Weight:

Operating Temperature:

Table 1-4: DC-to-DC Power Module Specifications

46g 58g

-40°C~85°C -40°C~85°C

Page 25

ECW-281BB6 Embedded System

1.5 Power Adapter

The ECW-281BB6 series models are shipped with a 55W power adapter.

Figure 1-2: Power Adapter

The specifications for the adapter are listed in

Nominal

Regulation

Output

Protection

Time Hold Up

Ripple/Noise

Min.

Max.

Short Circuit

Over-Voltage

12.0V

11.52V – 12.48V

120mV

0A

4.58A

Output can be shorted without damage and

auto-recovery

Upper Trip Limit: 15V+/-1.5V

10ms

Table 1-5:

Input

Min.

Nominal

90V

115V ~ 230V

Page 25

Page 26

ECW-281BB6 Embedded System

Environment

Max.

Frequency

Inrush Current

Steady Current

Efficiency

Temperature

Relative Humidity

264V

47Hz ~ 63Hz

80A Max. (cold start at 25ºC)

1.3Arms Max.

80% (typical)

Operating 0ºC ~ 40ºC

Storage -25ºC ~ 65ºC

Operating

(non-condensing)

Storage

(non-condensing)

Operating: 1G, 5Hz~500Hz, random vibration,

0% ~ 95%

0% ~ 95%

Vibration

Shock

MTBF

Reliability

Leakage Current

Table 1-5: Power Adapter Specifications

30mins/axis, 3 direction

Storage: 2G, 5Hz~500Hz, random vibration,

30mins/axis, 3 direction

Operating: 10G, 11ms, Half-sine wave

Storage: 20G, 11ms, Half-sine wave

100,000 hours of continuous operation at 25ºC

0.5mA max @264V

Page 26

Page 27

ECW-281BB6 Embedded System

Chapter

2

2 Mechanical

Description

Page 27

Page 28

ECW-281BB6 Embedded System

2.1 ECW-281BB6 Mechanical Overview

The ECW-281BB6 RoHS compliant, Intel® Celeron® M fanless embedded system

features industrial grade components that offer longer operating life, high shock/vibration

resistance and endurance over a wide temperature range. The ECW-281BB6 combines

these features in an aluminum enclosure designed for space critical applications that

require low power consumption. Featuring two LAN, four USB, six serial communication

ports, as well as audio, and VGA, the ECW-281BB6 offers system integrators and

developers the best selection of robust and high performance computing system platforms.

An internal bracket supports one 2.5” IDE hard drives.

2.2 Physical Dimensions

The physical dimensions of the ECW-281BB6 embedded systems are listed below.

2.2.1 ECW-281BB6 Dimensions

The dimensions of the ECW-281BB6 are listed below and shown in Figure 2-1.

Height: 64.00mm

Width: 229.00mm

Length: 132.00mm

Page 28

Page 29

ECW-281BB6 Embedded System

Figure 2-1: ECW-281BB6 Dimensions (mm)

2.2.2 Motherboard Dimensions

The WAFER series dimension are listed below and shown in Figure 2-2.

Length: 145.00mm

Width: 102.00mm

Page 29

Page 30

ECW-281BB6 Embedded System

Figure 2-2: WAFER SBC Dimensions (mm)

2.2.3 Power Module Dimensions

The power module dimensions are listed below and shown in Figure 2-3.

Length: 100.00mm

Width: 40.00mm

Figure 2-3: Power Module Dimensions (mm)

Page 30

Page 31

ECW-281BB6 Embedded System

2.3 External Overview

2.3.1 Front Panel

The ECW-281BB6 front panel contains:

2 x USB port connectors

1 x HDD LED indicator

1 x Power button

An overview of the front panel is shown in

Figure 2-4 below.

Figure 2-4: ECW-281BB6 Front Panel

2.3.2 Rear Panel

The rear panel of the ECW-281BB6 provides access to the following external I/O

connectors.

2 x USB port connectors

2 x RJ-45 Ethernet connector

1 x VGA connector

1 x RS-232/422/485 serial port

5 x RS-232 serial ports

1 x Speaker out

1 x 3-pin terminal block

1 x 12V DC power jack

Page 31

Page 32

An overview of the rear panel is shown in Figure 2-5.

ECW-281BB6 Embedded System

Figure 2-5: ECW-281BB6 Rear Panel

2.3.3 Bottom Surface

WARNING:

Never remove the bottom access panel from the chassis while power is still

being fed into the system. Before removing the bottom access panel, make

sure the system has been turned off and all power connectors unplugged.

The bottom surface of the ECW-281BB6 contains the retention screw holes for the VESA

MIS-D 100 wall-mount kit, two-side mounting brackets and DIN mount bracket.

Page 32

Page 33

ECW-281BB6 Embedded System

Figure 2-6: Bottom Surface

2.4 Internal Overview

The ECW-281BB6 internal components are listed below:

1 x IEI WAFER motherboard (preinstalled)

1 x IEI power module (preinstalled)

1 x SO-DIMM module (preinstalled)

1 x Hard drive bracket and IDE cable support one IDE hard disk

All the components are accessed by removing the bottom surface.

Page 33

Page 34

ECW-281BB6 Embedded System

Figure 2-7: Internal Overview

Page 34

Page 35

ECW-281BB6 Embedded System

Chapter

3

3 System Components

Page 35

Page 36

ECW-281BB6 Embedded System

3.1 ECW-281BB6 Embedded System Motherboard

3.1.1 ECW-281BB6 Embedded System Motherboard

NOTE:

The jumpers and connectors shown in the section below are those jumpers

and connectors that are relevant to the configuration and installation of the

embedded system. For a complete list of jumpers and connectors on the

WAFER-8522 motherboard, please refer to the WAF E R-8522 user manual.

The ECW-281BB6 models have a WAFER-8522 motherboard installed in the system. The

following sections describe the relevant connectors and jumpers on the motherboard.

3.1.2 WAFER-8522 Motherboard Overview

The locations of the WAFER-8522 jumpers and connectors used on the ECW-281BB6 are

shown in

Figure 3-1 below.

Page 36

Figure 3-1: WAFER-8522 Jumper and Connector Locations

Page 37

ECW-281BB6 Embedded System

3.1.3 CPU Support

NOTE:

The ECW-281BB6 has a preinstalled 1GHz Celeron M CPU on-board. If

the CPU fails, the motherboard has to be replaced. Please contact the

IEI reseller or vendor you purchased the ECW-281BB6 from or contact

an IEI sales representative directly. To contact an IEI sales

representative, please send an email to

The ULV Intel® Celeron® M processor is installed on the WAFER-8522 motherboard.

Specifications for the processors are listed in

Family Architecture Cache Clock Speed FSB

ULV Intel® Celeron® M 90 nm 512 KB L2 1.0 GHz 400 MHz

Table 3-1: Supported Processor

sales@iei.com.tw.

Table 3-1 below:

3.1.4 Intel® Celeron® M

The (ULV) Intel® Celeron® M processor comes with the following features:

Intel® Streaming SIMD Extensions accelerates 3D graphics performance,

video decoding/encoding, and speech recognition.

Advanced power management features

Compatible with IA-32 software.

Advanced branch prediction and data prefetch logic

Page 37

Page 38

3.2 Peripheral Interface Connectors

Section 3.2.1 lists all the peripheral interface connectors seen in Section 3.1.2.

3.2.1 Peripheral Interface Connectors

Table 3-2 shows a list of the peripheral interface connectors on the WAFER-8522.

ECW-281BB6 Embedded System

Detailed descriptions of these connectors can be found in Section

Connector Type Label

AT power connector 4-pin wafer connector CN5

ATX power connector 3-pin wafer connector CN8

Audio connector 10-pin box header CN4

IDE Interface connector 44-pin box header IDE1

LED connector 6-pin header CN3

Power button connector 2-pin wafer connector CN7

Reset button connector 2-pin wafer connector CN6

RS-232/422/485 serial port connector 14-pin header COM2

RS-232 serial port connector

40-pin header CN9

3.3.

(COM3~COM6)

USB connector 8-pin header USB1

Table 3-2: Peripheral Interface Connectors

3.2.2 External Interface Panel Connectors

Table 3-3 lists the rear panel connectors on the WAFER-8522. Detailed descriptions of

these connectors can be found in Section

Page 38

3.4.

Page 39

ECW-281BB6 Embedded System

Connector Type Label

Ethernet connectors RJ-45 connector LAN1, LAN2

RS-232 serial port connector DB-9 connector COM1

USB ports USB port J2

VGA port connector 15-pin female VGA1

Table 3-3: Rear Panel Connectors

3.3 Internal Peripheral Connectors

Internal peripheral connectors are found on the motherboard and are only accessible

when the motherboard is outside of the chassis. This section has complete descriptions of

all the internal, peripheral connectors on the WAFER-8522.

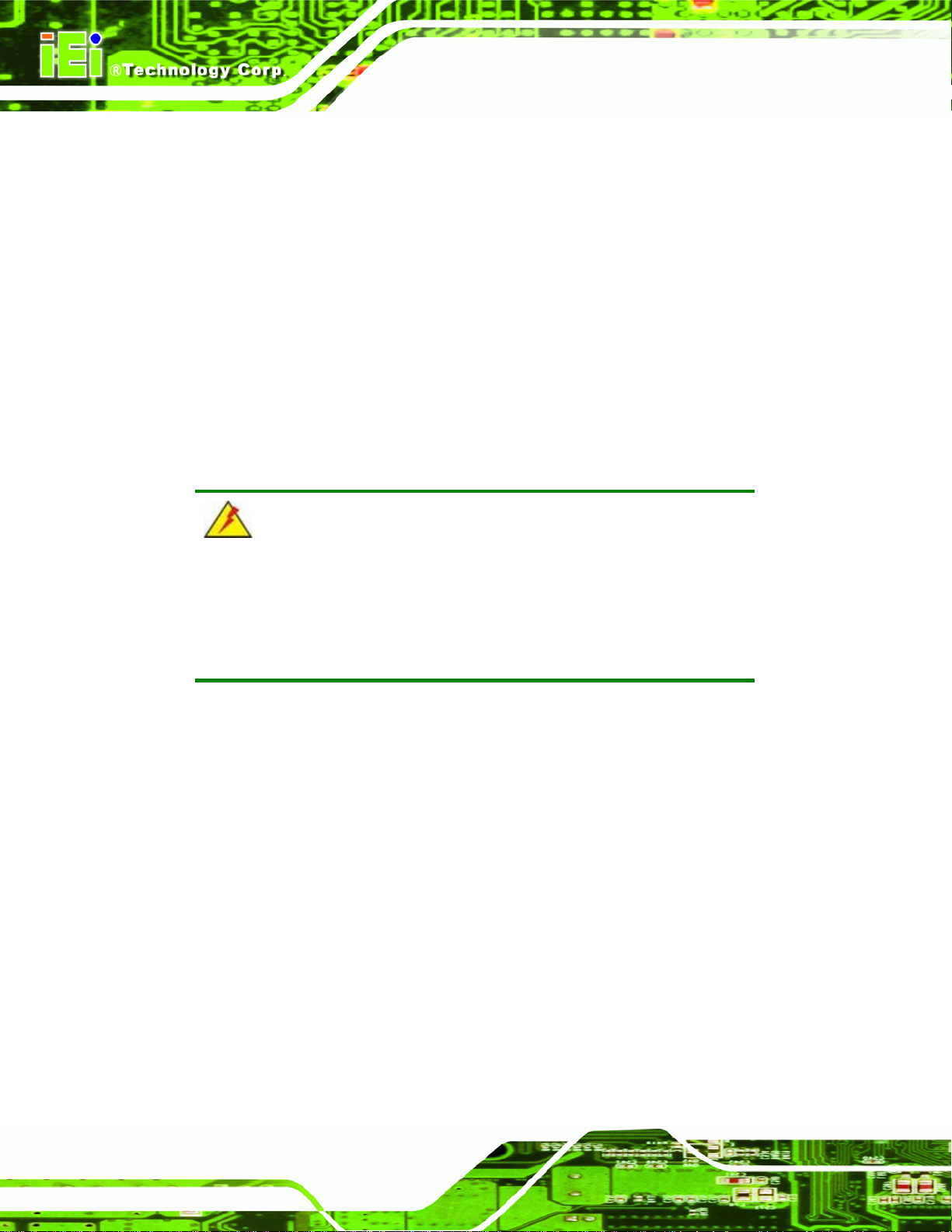

3.3.1 AT Power Connector

CN Label: CN5

CN Type:

CN Location: See

CN Pinouts: See Table 3-4

The 4-pin AT power connector is connected to an AT power supply.

4-pin wafer connector (1x4)

Figure 3-2

Page 39

Page 40

ECW-281BB6 Embedded System

Figure 3-2: AT Power Connector Location

PIN NO. DESCRIPTION

1 +12V

2 GROUND

3 GROUND

4 +5V

Table 3-4: AT Power Connector Pinouts

3.3.2 ATX Power Connector

CN Label: CN8

CN Type:

CN Location: See

CN Pinouts: See Table 3-5

The 3-pin ATX power connector is connected to an ATX power supply.

3-pin wafer connector (1x3)

Figure 3-3

Page 40

Page 41

ECW-281BB6 Embedded System

Figure 3-3: ATX Power Connector Location

PIN NO. DESCRIPTION

1 +5V_SB

2 GROUND

3 PS_ON

Table 3-5: ATX Power Connector Pinout s

3.3.3 Audio Connector

CN Label: CN4

CN Type:

CN Location: See

CN Pinouts: See Table 3-6

The 10-pin audio connector is connected to speakers the output of audio signals from the

system.

10-pin box header (2x5)

Figure 3-4

Page 41

Page 42

ECW-281BB6 Embedded System

Figure 3-4: Audio Connector Pinouts

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1 LINEOUT_R 2 LINEIN_R

3 GROUND 4 GROUND

5 LINEOUT_L 6 LINEIN_L

7 GROUND 8 GROUND

9 MIC1IN 10 MIC2IN

Table 3-6: Audio Connector Pinouts

3.3.4 IDE Connector

CN Label: IDE1

CN Type:

CN Location: See

CN Pinouts: See Table 3-7

One 44-pin IDE device connector on the WAFER-8522 supports connectivity to two hard

disk drives.

44-pin box header (2x22)

Figure 3-5

Page 42

Page 43

ECW-281BB6 Embedded System

Figure 3-5: IDE Device Connector Location

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1 RESET# 2 GROUND

3 DATA 7 4 DATA 8

5 DATA 6 6 DATA 9

7 DATA 5 8 DATA 10

9 DATA 4 10 DATA 11

11 DATA 3 12 DATA 12

13 DATA 2 14 DATA 13

15 DATA 1 16 DATA 14

Page 43

Page 44

17 DATA 0 18 DATA 15

19 GROUND 20 N/C

21 DMARQ 22 GROUND

23 IOW# 24 GROUND

25 IOR# 26 GROUND

27 IORDY 28 BALE

29 DMACK# 30 GROUND

31 INTERRUPT 32 N/C

33 SA1 34 PDIAG

35 SA0 36 SA2

37 HDC CS0# 38 HDC CS1#

39 HDD ACTIVE# 40 GROUND

41 +5V 42 +5V

43 GROUND 44 N/C

ECW-281BB6 Embedded System

Table 3-7: IDE Connector Pinouts

3.3.5 LED Connector

CN Label: CN3

CN Type:

CN Location: See

CN Pinouts: See Table 3-8

The LED connector connects to an HDD indicator LED and a power LED on the system

chassis to inform the user about HDD activity and the power on/off status of the system.

6-pin header (1x6)

Figure 3-6

Page 44

Page 45

ECW-281BB6 Embedded System

Figure 3-6: LED Connector Locations

PIN NO. DESCRIPTION

1 +5V

2 GROUND

3 +5V

4 GROUND

5 HDLED+

6 HDLED-

Table 3-8: LED Connector Pinouts

3.3.6 Power Button Connector

CN Label: CN7

CN Type:

CN Location: See

CN Pinouts: See Table 3-9

The power button connector is connected to a power switch on the system chassis to

2-pin wafer connector (1x2)

Figure 3-7

enable users to turn the system on and off.

Page 45

Page 46

ECW-281BB6 Embedded System

Figure 3-7: Power Button Connector Location

PIN NO. DESCRIPTION

1 Button+

2 Button-

Table 3-9: Power Button Connector Pinouts

3.3.7 Reset Button Connector

CN Label: CN6

CN Type:

CN Location: See

2-pin wafer connector (1x2)

Figure 3-8

CN Pinouts: See Table 3-10

The reset button connector is connected to a reset switch on the system chassis to enable

users to reboot the system when the system is turned on.

Page 46

Figure 3-8: Reset Button Connector Locations

Page 47

ECW-281BB6 Embedded System

PIN NO. DESCRIPTION

1 RESET#

2 GROUND

Table 3-10: Reset Button Connector Pinouts

3.3.8 Serial Port Connector (RS-232/422/485)

CN Label: COM2

CN T ype:

CN Location: See

14-pin header (2x7)

Figure 3-9

CN Pinouts: See Table 3-11

The serial port connectors connect to RS-232, RS-422 or RS-485 serial port device.

Figure 3-9: Serial Port Connector Location

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1 DCD 2 DSR

3 RXD 4 RTS

5 TXD 6 CTS

7 DTR 8 RI

9 GND 10 GND

11 (RS422/485) TX+ 12 (RS422/485) TX13 (RS422) RX+ 14 (RS422) RX-

Page 47

Page 48

ECW-281BB6 Embedded System

Table 3-11: RS-232/422/485 Serial Port Connector Pinouts

3.3.9 Serial Port Connector (COM 3, COM 4, COM 5 and COM 6)

CN Label: CN9

CN T ype:

CN Location: See

40-pin header (2x20)

Figure 3-10

CN Pinouts: See Table 3-12

The 40-pin serial port connector contains the following four serial ports, COM 3, COM 4,

COM 5 and COM 6. All four serial ports are RS-232 serial communications channels. The

serial port locations are specified below.

COM 3 is located on pin 1 to pin 10

COM 4 is located on pin 11 to pin 20

COM 5 is located on pin 21 to pin 30

COM 6 is located on pin 31 to pin 40

Page 48

Figure 3-10: RS-232 Serial Port Connector Location

Page 49

ECW-281BB6 Embedded System

PIN NO. DESCRIPTION

1 DCD_COM3 2 DSR_COM3

3 RXD_COM3 4 RTS_COM3

5 TXD_COM3 6 CTS_COM3

7 DTR_COM3 8 RI_COM3

9 GND 10 GND

11 DCD_COM4 12 DSR_COM4

13 RXD_COM4 14 RTS_COM4

15 TXD_COM4 16 CTS_COM4

17 DTR_COM4 18 RI_COM4

19 GND 20 GND

21 DCD_COM5 22 DSR_COM5

23 RXD_COM5 24 RTS_COM5

25 TXD_COM5 26 CTS_COM5

27 DTR_COM5 28 RI_COM5

29 GND 30 GND

IN NO.DESCRIPTION

31 DCD_COM6 32 DSR_COM6

33 RXD_COM6 34 RTS_COM6

35 TXD_COM6 36 CTS_COM6

37 DTR_COM6 38 RI_COM6

39 GND 40 GND

Table 3-12: RS-232 Serial Port Connector Pinouts

3.3.10 Internal USB Connectors

CN Label: USB1

CN T ype:

CN Location: See

CN Pinouts: See Table 3-13

8-pin header (2x4)

Figure 3-11

Page 49

Page 50

ECW-281BB6 Embedded System

One 2x4 pin connector provides connectivity to two USB 2.0 ports. The USB ports are

used for I/O bus expansion.

Figure 3-11: Internal USB Connector Location

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1 VCC 2 GROUND

3 DATA0- 4 DATA0+

5 DATA0+ 6 DATA07 GROUND 8 VCC

Table 3-13: Internal USB Connector Pinouts

3.4 External Peripheral Interface Connectors

3.4.1 External Peripheral Interface Connector Overview

The WAFER-8522 external peripheral interface connectors are listed below and shown in

Figure 3-12:

2 x RJ-45 Ethernet connector

1 x Serial communications port

2 x USB combo ports

Page 50

1 x VGA port

Page 51

ECW-281BB6 Embedded System

Figure 3-12: WAFER-8522 On-board External Interface Connectors

3.4.2 RJ-45 Ethernet Connector

CN Label: LAN1 and LAN2

CN Type:

CN Location: See

RJ-45

Figure 3-12

CN Pinouts: See Table 3-14

The RJ-45 Ethernet connector on the WAFER-8522 provides connectivity to a GbE

Ethernet connection between the WAFER-8522 and a Local Area Network (LAN) through

a network hub.

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1 TX0+ 5 TX2-

2 TX0- 6 TX13 TX1+ 7 TX3+

4 TX2+ 8 TX3-

Table 3-14: RJ-45 Ethernet Connector Pinouts

Figure 3-13: LAN Connector

Page 51

Page 52

The RJ-45 Ethernet connector has two status LEDs, one green and one yellow. The green

LED indicates activity on the port and the yellow LED indicates the port is linked. See

Table 3-15.

SPEED LED ACT/LINK LED

STATUS DESCRIPTION STATUS DESCRIPTION

OFF 10Mbps connection OFF No link

ORANGE 100Mbps connection YELLOW Linked

GREEN 1Gbps connection BLINKING Data Activity

Table 3-15: RJ-45 Ethernet Connector LEDs

3.4.3 Serial Port Connector (COM1)

CN Label: COM1

ECW-281BB6 Embedded System

CN Type:

CN Location: See

DB-9 connector

Figure 3-12

CN Pinouts: See Table 3-16 and Figure 3-14

The 9-pin DB-9 COM 1 serial port connector is connected to RS-232 serial

communications devices.

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1 DCD 6 DSR

2 RXD 7 RTS

3 TXD 8 CTX

4 DTR 9 RI

5 GND

Table 3-16: RS-232 Serial Port (COM 1) Pinouts

Page 52

Page 53

ECW-281BB6 Embedded System

Figure 3-14: Serial Port Pinout Locations

3.4.4 USB Combo Ports

CN Label: J2

CN Type:

CN Location: See

CN Pinouts: See Table 3-17

The two USB combo ports provide connectivity to USB devices. The USB port support

both USB 1.1 and USB 2.0.

PIN NO. DESCRIPTION PIN NO. DESCRIPTION

1 USBVCC0 5 USBVCC1

2 USBP0- 6 USBP13 USBP0+ 7 USBP1+

4 USBGND0 8 USBGND1

Table 3-17: USB Connector Pinouts

USB Combo port

Figure 3-12

3.4.5 VGA Connector

CN Label: VGA1

CN Type:

CN Location: See

CN Pinouts: See Figure 3-15 and Table 3-18

DB15

Figure 3-12

Page 53

Page 54

ECW-281BB6 Embedded System

The standard 15-pin female DB15 VGA connector connects to a CRT or LCD monitor

directly.

PIN DESCRIPTION PIN DESCRIPTION

1 RED 9 +5V

2 GREEN 10

3 BLUE 11

4 NC 12

5 GROUND 13

6 +5V 14

7 GROUND 15

8 GROUND

GROUND

NC

DDCDAT

HSYNC

VSYNC

DDCCLK

Table 3-18: VGA Connector Pinouts

Page 54

Figure 3-15: VGA Connector

Page 55

A

ECW-281BB6 Embedded System

3.5 WAFER-8522 Motherboard On-board Jumpers

NOTE:

jumper is a metal bridge used to close

an electrical circuit. It consists of two or

three metal pins and a small metal clip

(often protected by a plastic cover) that

slides over the pins to connect them. To

CLOSE/SHORT a jumper means

connecting the pins of the jumper with

the plastic clip and to OPEN a jumper

means removing the plastic clip from a

jumper.

The WAFER-8522 motherboard has several onboard jumpers (Table 3-19).

Description Label Type

Clear CMOS JP2 2-pin header

COM port select JP4 3-pin header

LCD voltage select JP5 3-pin header

LCD panel resolution select JP1 8-pin header

Figure 3-16: Jumpers

Table 3-19: Jumpers

3.5.1 Clear CMOS Jumper

Jumper Label: JP2

Jumper Type:

Jumper Settings: See

Jumper Location: See Figure 3-17

2-pin header

Table 3-20

Page 55

Page 56

ECW-281BB6 Embedded System

If the WAFER-8522 fails to boot due to improper BIOS settings, the CMOS can be cleared

using the battery connector. Disconnect the battery from the connector for a few seconds

then reconnect the battery. The CMOS should be cleared.

If the “CMOS Settings Wrong” message is displayed during the boot up process, the fault

may be corrected by pressing the F1 to enter the CMOS Setup menu. Do one of the

following:

Enter the correct CMOS setting

Load Optimal Defaults

Load Failsafe Defaults.

After having done one of the above, save the changes and exit the CMOS Setup menu.

The clear CMOS jumper settings are shown in

Clear CMOS Description

Open Keep CMOS Setup Default

Short Clear CMOS Setup

Table 3-20.

Table 3-20: JP2 Clear CMOS Jumper Settings

The location of the clear CMOS jumper is shown in Figure 3-17 below.

Page 56

Page 57

ECW-281BB6 Embedded System

Figure 3-17: JP2 Clear CMOS Jumper

3.5.2 COM Port Setting Jumper

Jumper Label: JP4

Jumper Type:

Jumper Settings: See

Jumper Location: See Figure 3-18

The JP4 jumper sets the communication protocol used by the second serial

communications port (COM 2) as RS-232, RS-422 or RS-485. The COM Port Setting

jumper selection options are shown in

JP4 Description

Short 1-2 RS-232 Default

Short 2-3 RS-422/485

Table 3-21: COM Port Setting Jumper Settings

The COM Port Setting jumper location is shown in Figure 3-18 below.

3-pin header

Table 3-21

Table 3-21.

Page 57

Page 58

Figure 3-18: COM Port Setting Jumper Location

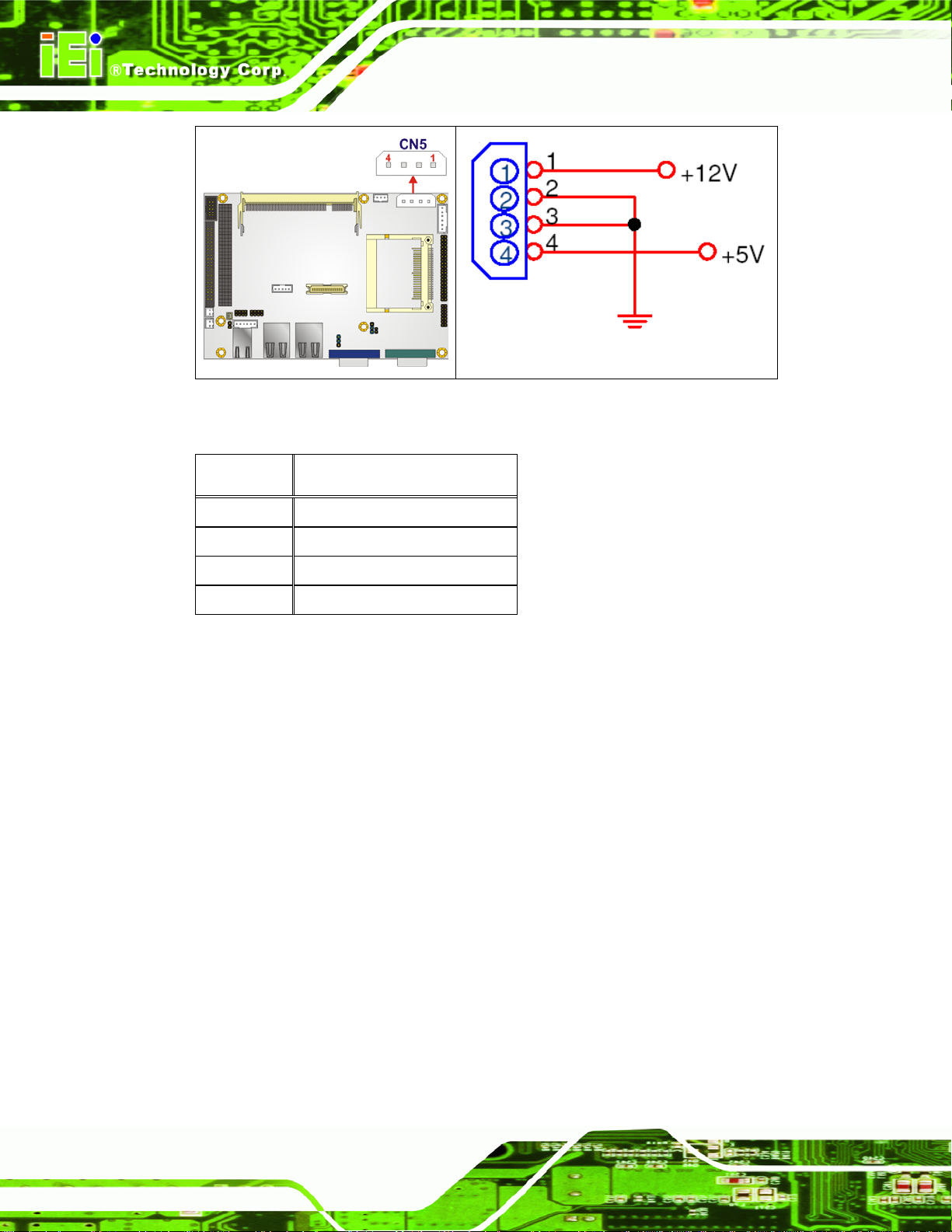

3.5.3 LCD Voltage Selection

ECW-281BB6 Embedded System

WARNING:

Permanent damage to the screen and WAFER-8522 may occur if the

wrong voltage is selected with this jumper. Please refer to the user

guide that came with the monitor to select the correct voltage.

Jumper Label: JP5

Jumper Type:

Jumper Settings: See

Jumper Location: See Figure 3-19

The LCD Voltage Selection jumper allows the LCD screen voltage to be set. The LCD

Voltage Selection jumper settings are shown in

3-pin header

Table 3-22

Table 3-22.

Page 58

AT Power Select Description

Short 1-2 +5V LVDS

Short 2-3 +3.3V LVDS Default

Table 3-22: LCD Voltage Selection Jumper Settings

Page 59

ECW-281BB6 Embedded System

The LCD Voltage Selection jumper location is shown in Figure 3-19.

Figure 3-19: LCD Voltage Selection Jumper Location

3.5.4 LCD Resolution Selection

Jumper Label: JP1

Jumper Type:

Jumper Settings: See

8-pin header

Table 3-23

Jumper Location: See Figure 3-20

Use the LCD Resolution jumper to select the resolution of the LCD. The LCD Resolution

settings are shown in

7-8 5-6 3-4 1-2

Open Open Open Open For BIOS Setting

Open Open Open Short Type 0: 640x480 18-bit

Open Open Short Open Type 1: 800x600 18-bit

Open Open Short Short Type 2: 1024x768 18-bit

Open Short Open Open Type 3: 1280x1024 48-bit

Table 3-23.

PIN NO.

Description

Open Short Open Short Type 4: 1400x1050 48-bit

Open Short Short Open Type 5: 1400x1050 36-bit

Open Short Short Short Type 6: 1600x1200 48-bit

Page 59

Page 60

Short Open Open Open Type 7: 1280x768 18-bit

Short Open Open Short Type 8: 1600x1050 48-bit

Short Open Short Open Type 9: 1920x1200 36-bit

Short Open Short Short Type 10: 1024x768 24-bit

Short Short Open Open Type 11: Reserved

Short Short Open Short Type 12: Reserved

Short Short Short Open Type 13: Reserved

Short Short Short Short Type 14: Reserved

ECW-281BB6 Embedded System

Table 3-23: LCD Resolution Jumper Settings

The LCD resolution jumper location is shown in Figure 3-20.

Figure 3-20: LCD Resolution Jumper Location

3.6 Connector Mappings

This section describes how the connectors on the motherboard and power module are

connected to different components within the system. When performing maintenance

operations on the system it is imperative that the correct connections are made.

Page 60

Page 61

ECW-281BB6 Embedded System

3.6.1 Power Connector

The connector mapping for the power module output power connector and the

motherboard input power connector are shown in

Table 3-24.

WAFER-8522 Power Module

CN5: Power CN4: Output Power

Pin 1 Pin 4

Pin 2 Pin 3

Pin 3 Pin 2

Pin 4 Pin 1

Table 3-24: Motherboard Power Connector Mapping

3.6.2 ATX Mode Connector

The connector mapping for the ATX mode connector on the motherboard and power

module are shown in

WAFER-8522 Power Module

Table 3-25.

CN8: PS-ON CN7: ATX Mode

Pin 1 Pin 1

Pin 2 Pin 2

Pin 3 Pin 3

Table 3-25: Motherboard Power Connector Mapping

Page 61

Page 62

ECW-281BB6 Embedded System

THIS PAGE IS INTENTIONALLY LEFT BLANK

Page 62

Page 63

ECW-281BB6 Embedded System

Chapter

4

4 Installation

Page 63

Page 64

4.1 Anti-static Precautions

WARNING:

If the following anti-static precautions are not followed, a user may be

injured and the system irreparably damaged.

Electrostatic discharge (ESD) can cause serious damage to electronic components,

including the WAFER series motherboard and the power module. (Dry climates are

especially susceptible to ESD.) It is therefore critical that whenever the ECW-281BB6 is

opened and any electrical component handled, the following anti-static precautions are

strictly adhered to.

ECW-281BB6 Embedded System

Wear an anti-static wristband: - Wearing a simple anti-static wristband can

help to prevent ESD from damaging the board.

Self-grounding:- Before handling the board, touch any grounded conducting

material. During the time the board is handled, frequently touch any

conducting materials that are connected to the ground.

4.2 Installation Procedure

4.2.1 Installation Procedure Overview

To properly install the ECW-281BB6, the following steps must be followed. Detailed

descriptions of these instructions are listed in the sections that follow.

Step 1: Unpacking

Step 2: Configure the jumper settings

Step 3: Install the IDE hard disk drive (HDD)

Page 64

Step 4: Mount the ECW-281BB6

Step 5: Connect the front panel peripheral connectors

Page 65

ECW-281BB6 Embedded System

Step 6: Power the system upStep 0:

4.2.2 Unpacking

After the ECW-281BB6 is received make sure the following components are included in

the package. If any of these components are missing, please contact the ECW-281BB6

reseller or vendor where it was purchased or contact an IEI sales representative

immediately.

Quantity Item Image

1 ECW-281BB6 embedded system

1 Power cord

2 Mounting brackets

1 DIN mount kit

1 Screw set

4 Foot pad

1 Thermal pad for HDD

Page 65

Page 66

1 Mini jumper pack

ECW-281BB6 Embedded System

1 Quick installation guide

1 Driver and manual CD

1 Power Adaptor (for WD models only)

1 Wall mount kit (optional)

Table 4-1: Package List Contents

Page 66

Page 67

ECW-281BB6 Embedded System

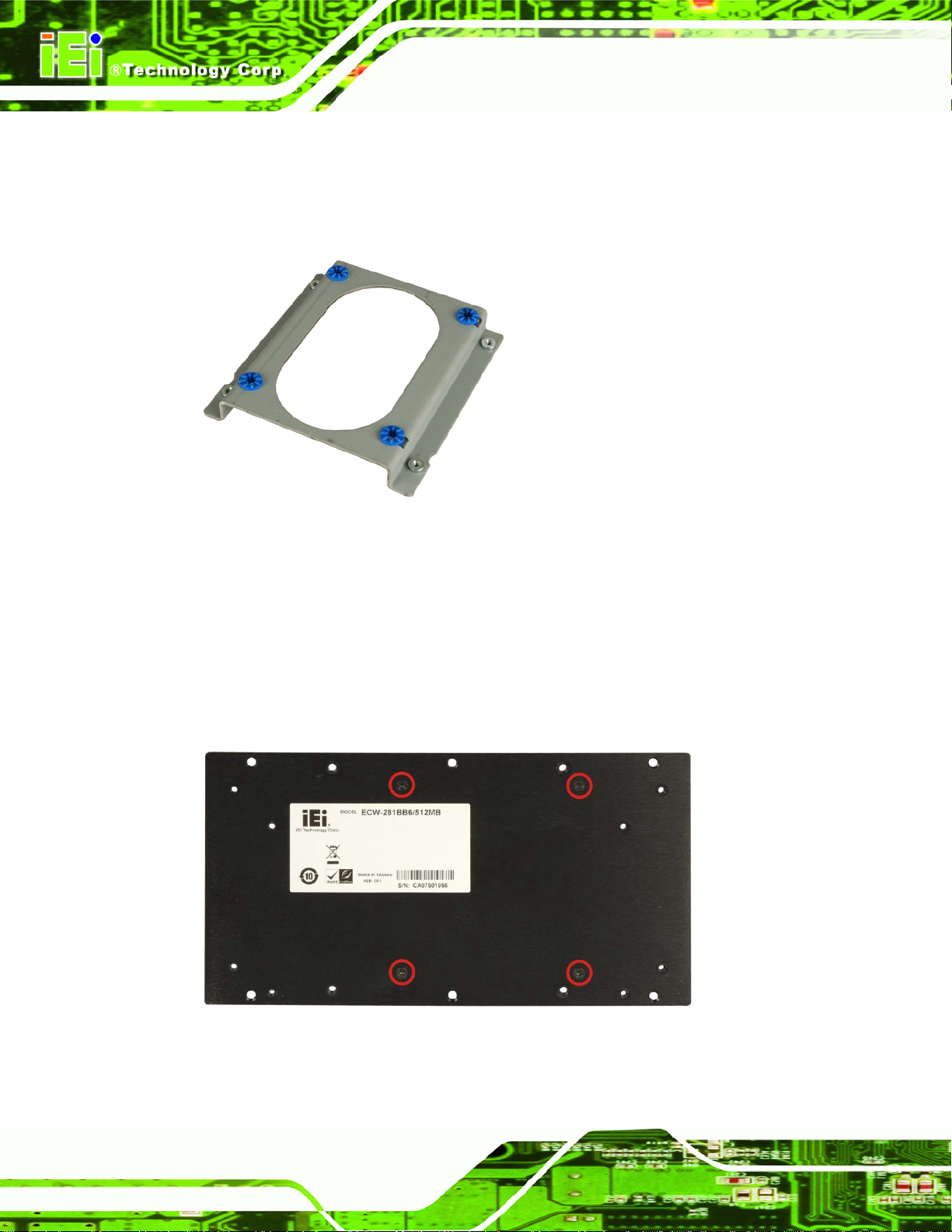

4.2.3 Bottom Surface Removal

Before the jumper settings can be configured and the hard disk drive can be installed, the

bottom surface must be removed. To remove the bottom surface, please follow the steps

below:

Step 1: Remove the bottom surface retention screws. The bottom surface is secured to

the chassis with six retention screws (

removed.

Figure 4-1). All six screws must be

Figure 4-1: Bottom Surface Retention Screws

Step 2: Gently remove the bottom surface from the ECW-281BB6. Step 0:

4.2.4 Configure the Jumper Settings

To configure the jumper settings, please follow the steps below.

Step 1: Remove the bottom surface. See Section

Step 2: Locate the jumper settings on the embedded motherboard. See Chapter

Step 3: Make the jumper settings in accordance with the settings described and defined

in Chapter

3.Step 0:

4.2.3.

3.

Page 67

Page 68

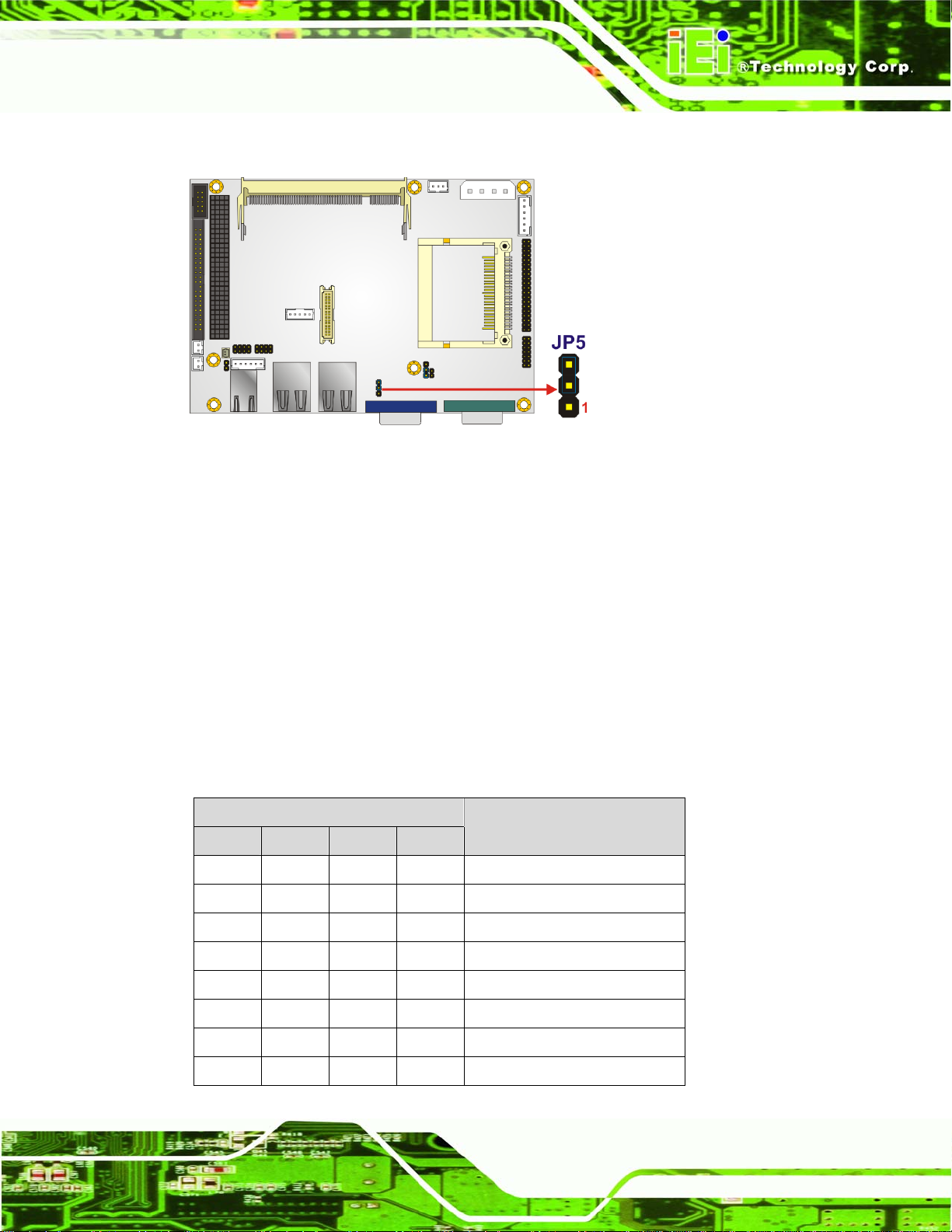

4.2.5 IDE Hard Drive Installation

One 2.5” IDE hard drive supported. The IDE drive is installed into a hard drive bracket

ECW-281BB6 Embedded System

attached on the inside of the bottom panel (

Figure 4-2).

Figure 4-2: Hard Drive Bracket

To install the hard drive into the system, please follow the steps below.

Step 1: Remove the bottom surface See Section

4.2.3.

Step 2: Remove the hard drive bracket from the bottom surface by removing the four

retention screws that secure the bracket to the bottom surface. (

Figure 4-3)

Figure 4-3:HDD Bracket Retention Screws

Page 68

Page 69

ECW-281BB6 Embedded System

Step 3: Place the HDD into the bracket.

Step 4: Align the retention screw holes in the HDD with those in the bottom of the

bracket.

Step 5: Secure the HDD with the bracket by inserting four retention screws into the

bottom of the bracket (

Figure 4-4).

Figure 4-4: HDD Retention Screws

Step 6: Locate the breather hole of the HDD. Cut off the corresponding area of the

breather hole from the thermal pad.

Step 7: Adhere the thermal pad to the HDD. Make sure there is no obstacle covering the

breather hole (

CAUTION:

Make sure the breather hole of the HDD is not covered. Covering the breather

hole may cause damage to the HDD.

Figure 4-5).

Page 69

Page 70

ECW-281BB6 Embedded System

Figure 4-5: HDD Thermal Pad

Step 8: Replace the HDD bracket onto the bottom surface by aligning the four retention

screw holes in the HDD bracket with those in the back of the bottom surface.

Step 9: Reinsert the four previously removed retention screws.

Step 10: Connect the IDE cable connector in the ECW-281BB6 to the HDD.

Step 11: Replace the bottom surface to the bottom panel by reinserting the six previously

removed retention screws. Step 0:

4.2.6 Mounting the System with Mounting Brackets

To mount the embedded system onto a wall or some other surface using the two mounting

brackets, please follow the steps below.

Step 1: Turn the embedded system over.

Step 2: Align the two retention screw holes in each bracket with the corresponding

retention screw holes on the sides of the bottom surface.

Page 70

Step 3: Secure the brackets to the system by inserting two retention screws into each

bracket.

Page 71

ECW-281BB6 Embedded System

Figure 4-6: Mounting Bracket Retention Screws

Step 4: Drill holes in the intended installation surface.

Step 5: Align the mounting holes in the sides of the mounting brackets with the predrilled

holes in the mounting surface.

Step 6: Insert four retention screws, two in each bracket, to secure the system to the

wall. Step 0:

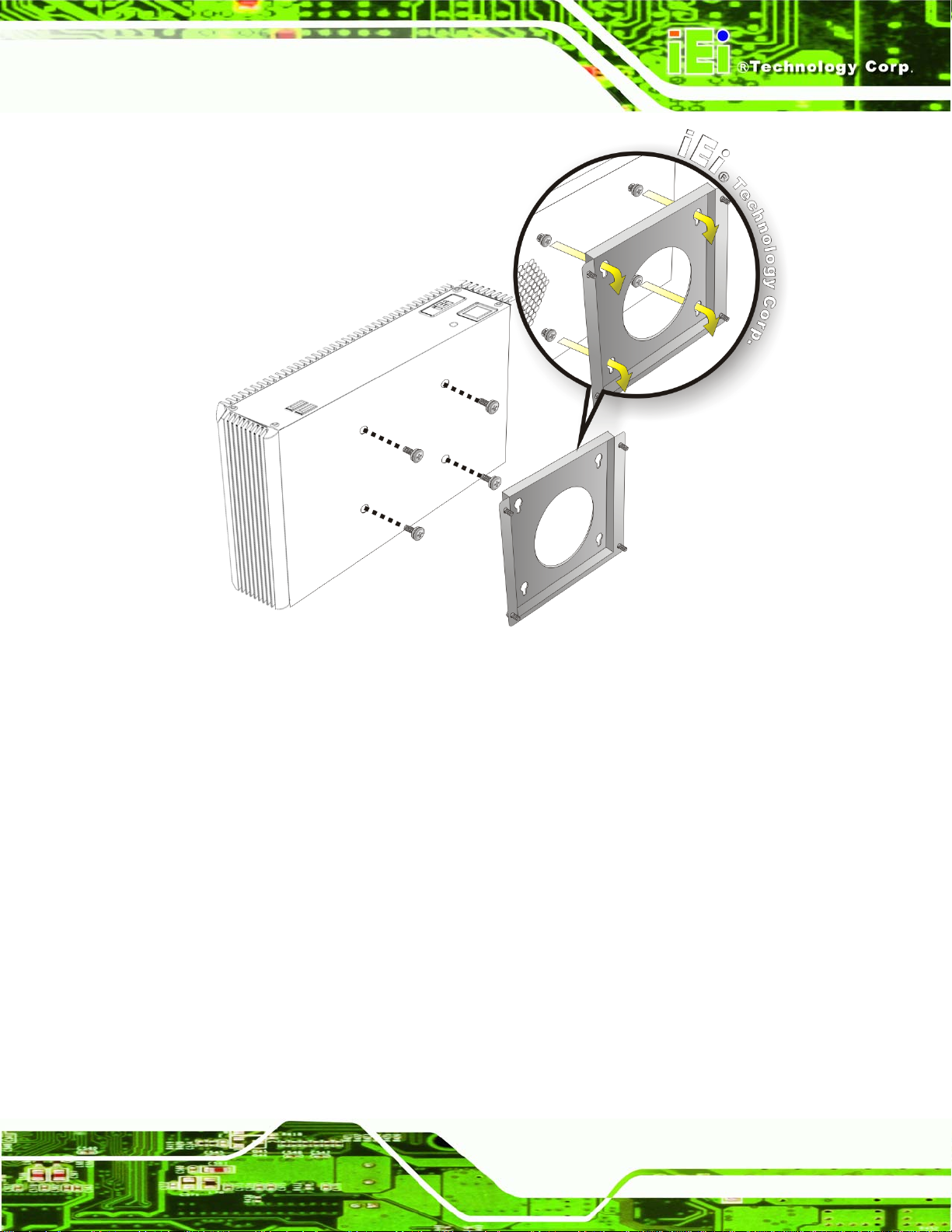

4.2.7 Mounting the System with Wall Mount Kit

To mount the embedded system onto a wall using the VESA MIS-D 100 wall mount kit,

please follow the steps below.

Step 1: Select the location on the wall for the wall-mounting bracket.

Step 2: Carefully mark the locations of the four bracket screw holes on the wall.

Step 3: Drill four pilot holes at the marked locations on the wall for the bracket retention

screws.

Step 4: Align the wall-mounting bracket screw holes with the pilot holes.

Step 5: Secure the mounting-bracket to the wall by inserting the retention screws into

the four pilot holes and tightening them (

Figure 4-7).

Page 71

Page 72

ECW-281BB6 Embedded System

Figure 4-7: Wall-mounting Bracket

Step 6: Insert the four monitor mounting screws provided in the wall mounting kit into the

four screw holes on the bottom panel of the system and tighten until the screw

shank is secured against the bottom panel (

Step 1: Align the mounting screws on the ECW-281BB6 bottom panel with the mounting

holes on the bracket.

Step 2: Carefully insert the screws through the holes and gently pull the monitor

downwards until the ECW-281BB6 rests securely in the slotted holes (

). Ensure that all four of the mounting screws fit snuggly into their respective

4-8

slotted holes.

Figure 4-8).

Figure

NOTE:

In the diagram below the bracket is already installed on the wall.

Page 72

Page 73

ECW-281BB6 Embedded System

Figure 4-8: Mount the Embedded System

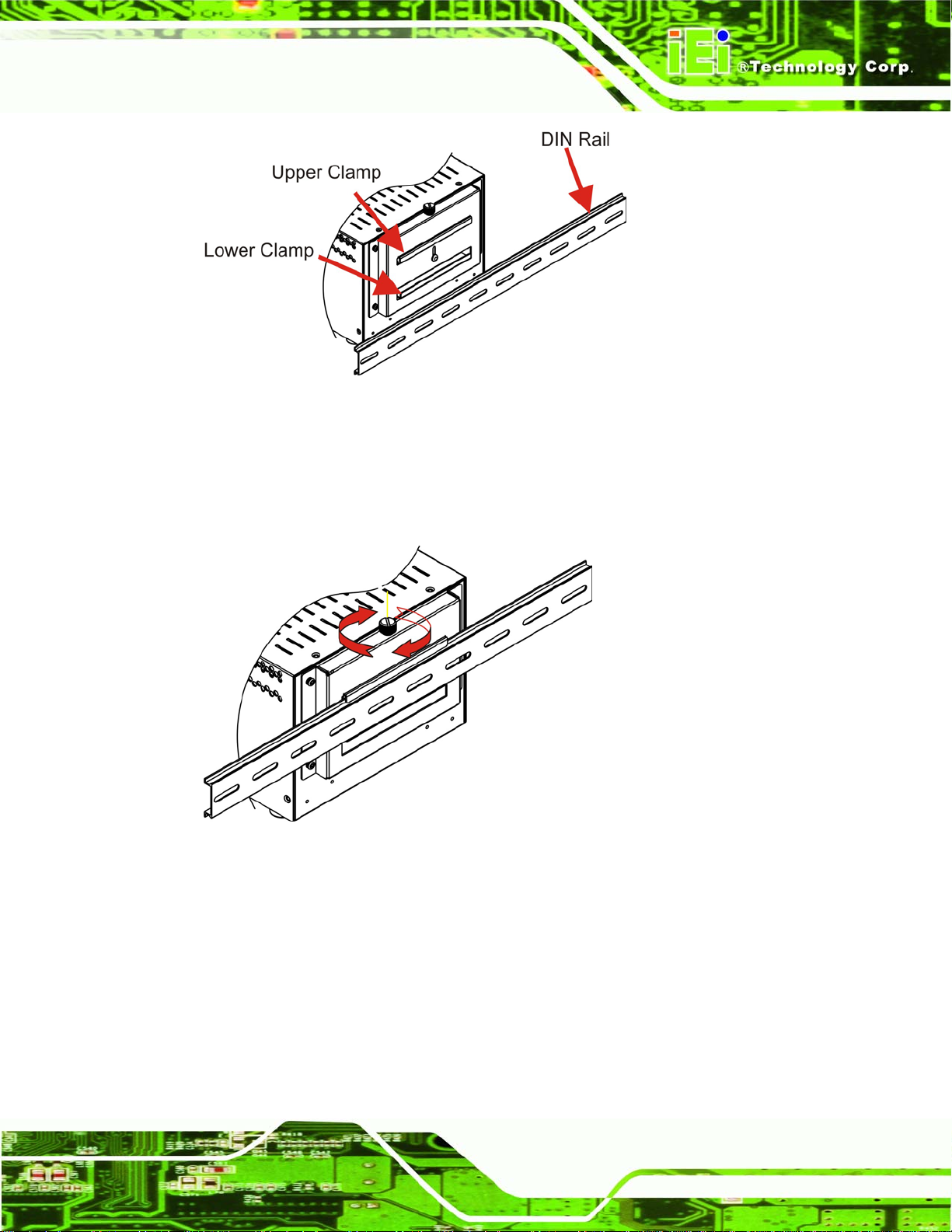

4.2.8 DIN Mounting

To mount the ECW-281BB6 embedded system onto a DIN rail, please follow the steps

below.

Step 3: Attach the DIN rail mounting bracket to the bottom panel of the embedded

system. Secure the bracket to the embedded system with the supplied retention

screws (

Figure 4-9).

Page 73

Page 74

ECW-281BB6 Embedded System

Figure 4-9: DIN Rail Mounting Bracket

Step 4: Make sure the inserted screw in the center of the bracket is at the lowest

position of the elongated hole (

Figure 4-10).

Figure 4-10: Screw Locations

Step 5: Place the DIN rail flush against the back of the mounting bracket making sure

the edges of the rail are between the upper and lower clamps (

Figure 4-11).

Page 74

Page 75

ECW-281BB6 Embedded System

Figure 4-11: Mounting the DIN RAIL

Step 6: Secure the DIN rail to the mounting bracket by turning the top screw clockwise.

This draws the lower clamp up and secures the embedded system to the DIN

Figure 4-12).Step 0:

rail (

Figure 4-12: Secure the Assembly to the DIN Rail

4.2.9 Cable Connections

Once the system has been mounted on the wall, the following connectors can be

connected to the system.

VGA cable connector

Serial port connectors

RJ-45 connectors

Page 75

Page 76

USB devices can be connected to the system.

ECW-281BB6 Embedded System

The cable connection locations are shown in

4.3 Power-On Procedure

4.3.1 Installation Checklist

WARNING:

Make sure a power supply with the correct input voltage is being fed into

the system. Incorrect voltages applied to the system may cause damage to

the internal electronic components and may also cause injury to the user.

To power on the embedded system please make sure of the following:

The bottom surface panel is installed

All peripheral devices (VGA monitor, serial communications devices etc.) are

Figure 2-5.

connected

The power cables are plugged in

The system is securely mounted

4.3.2 Terminal Block Pinouts

The terminal block pinouts are shown in Figure 4-13.

Figure 4-13: Terminal Block Pinouts

Page 76

Page 77

ECW-281BB6 Embedded System