Page 1

IEI Technology Corp.

User Manual

IOVU-572M Panel PC

MODEL:

IOVU-572M

Panel PC, 5.7" Touch Screen, 624 MHz Marvell XScale PXA310,

Fast Ethernet, 2 x USB, 802.11b/g Wireless, RS-232/422/485

RoHS Compliant, IP 64 Protection

Rev. 1.01 – 27 August, 2013

Page i

Page 2

Date Version Changes

27 August, 2013 1.01 Added Section 4.5.1: Wireless AP

13 February, 2012 1.00 Initial release

IOVU-572M Panel PC

Revision

Page ii

Page 3

IOVU-572M Panel PC

COPYRIGHT NOTICE

The information in this document is subject to change without prior notice in order to

improve reliability, design and function and does not represent a commitment on the part

of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or

consequential damages arising out of the use or inability to use the product or

documentation, even if advised of the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are

Copyright

reserved. No part of this manual may be reproduced by any mechanical, electronic, or

other means in any form without prior written permission of the manufacturer.

TRADEMARKS

All registered trademarks and product names mentioned herein are used for identification

purposes only and may be trademarks and/or registered trademarks of their respective

owners.

Page iii

Page 4

IOVU-572M Panel PC

Table of Contents

1 INTRODUCTION.......................................................................................................... 1

1.1 OVERVIEW.................................................................................................................. 2

1.2 BENEFITS ................................................................................................................... 2

1.3 FEATURES................................................................................................................... 3

1.4 TECHNICAL SPECIFICATIONS ...................................................................................... 3

1.5 CERTIFICATIONS......................................................................................................... 5

2 DETAILED SPECIFICATIONS .................................................................................. 6

2.1 FRONT PANEL............................................................................................................. 7

2.2 CONNECTOR PANEL.................................................................................................... 7

2.3 DIMENSIONS............................................................................................................... 9

2.4 POWER SUPPLY ........................................................................................................ 10

3 UNPACKING................................................................................................................11

3.1 ANTI-STATIC PRECAUTIONS...................................................................................... 12

3.2 UNPACKING PRECAUTIONS....................................................................................... 12

3.3 UNPACKING CHECKLIST ........................................................................................... 13

3.4 OPTIONAL ITEMS...................................................................................................... 14

4 INSTALLATION ......................................................................................................... 15

4.1 INSTALLATION PRECAUTIONS ................................................................................... 16

4.2 SD CARD INSTALLATION .......................................................................................... 16

4.3 EXTERNAL PERIPHERAL INTERFACE CONNECTORS................................................... 17

4.3.1 12 V~36 V DC T erminal Block......................................................................... 18

4.3.2 RS-232/422/485 Serial Port............................................................................. 18

4.3.2.1 Connecting the Serial Port........................................................................ 18

4.3.2.2 RS-232/422/485 Selection........................................................................ 19

4.3.2.3 Pinouts....................................................................................................... 22

4.3.3 USB Connectors............................................................................................... 22

4.3.4 Ethernet Connector.......................................................................................... 23

4.4 MOUNTING THE SYSTEM .......................................................................................... 25

Page iv

Page 5

IOVU-572M Panel PC

4.4.1 Wall Mounting.................................................................................................. 26

4.4.2 Panel Mounting................................................................................................ 28

4.4.3 Arm Mounting .................................................................................................. 30

4.4.4 Stand Mounting................................................................................................ 31

4.5 SOFTWARE................................................................................................................ 31

4.5.1 Wireless AP ...................................................................................................... 32

A CERTIFICATIONS .................................................................................................... 35

A.1 ROHS COMPLIANT.................................................................................................. 36

A.2 IP 64 COMPLIANT FRONT PANEL............................................................................. 36

B SAFETY PRECAUTIONS......................................................................................... 37

B.1 SAFETY PRECAUTIONS............................................................................................. 38

B.1.1 General Safety Precautions............................................................................. 38

B.1.2 Anti-static Precautions.................................................................................... 39

B.2 MAINTENANCE AND CLEANING PRECAUTIONS........................................................ 39

B.2.1 Maintenance and Cleaning.............................................................................. 39

B.2.2 Cleaning Tools................................................................................................. 40

B.2.3 Federal Communication Commission Interference Statement........................ 40

C HAZARDOUS MATERIALS DISCLOSURE......................................................... 43

C.1 HAZARDOUS MATERIALS DISCLOSURE TABLE FOR IPB PRODUCTS CER TIFIED AS

ROHS COMPLIANT UNDER 2002/95/EC WITHOUT MERCURY ....................................... 44

Page v

Page 6

IOVU-572M Panel PC

List of Figures

Figure 1-1: IOVU-572M ...................................................................................................................2

Figure 2-1: Front Panel ..................................................................................................................7

Figure 2-2: IOVU-572M Peripheral Connectors ...........................................................................7

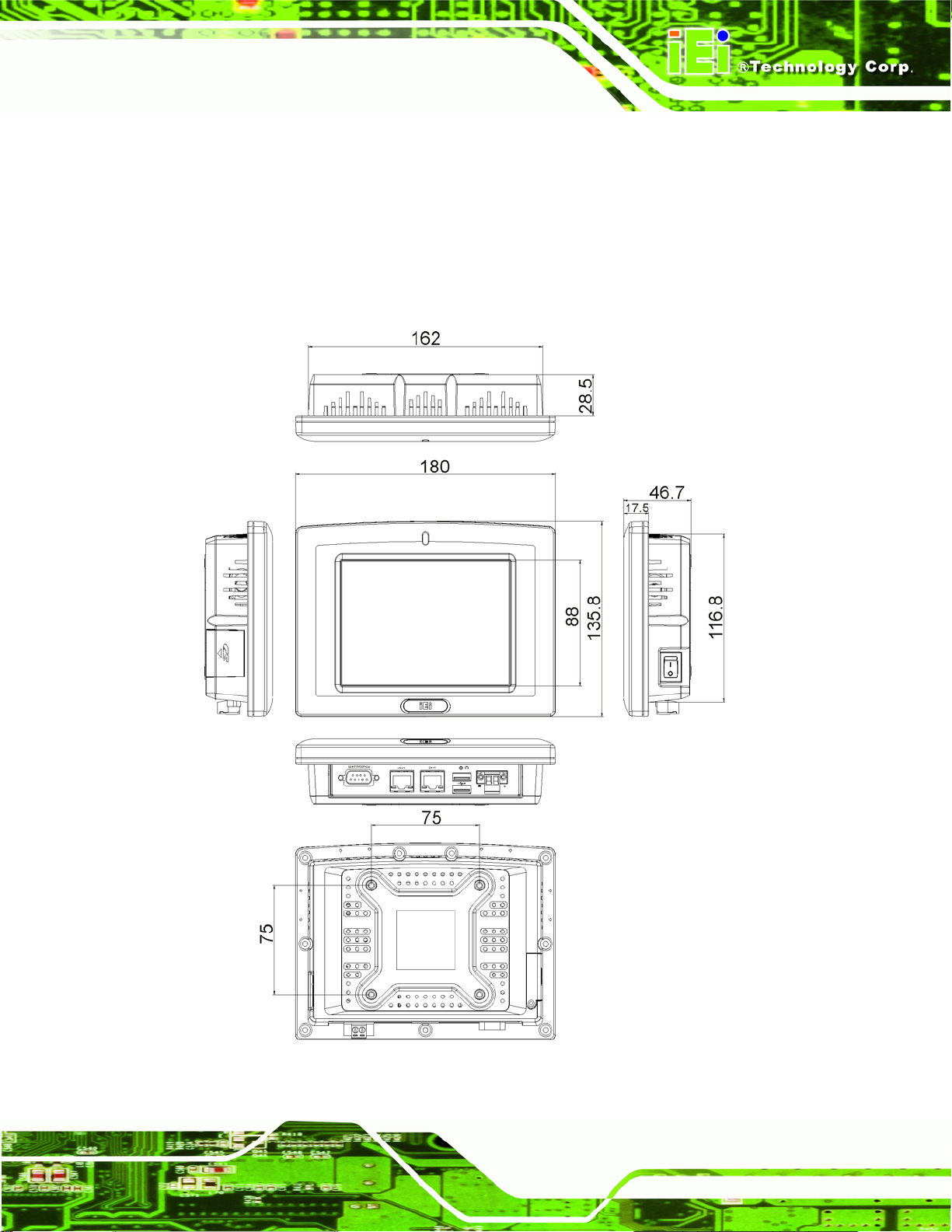

Figure 2-3: IOVU-572M Physical Dimensions (millimeters) .......................................................9

Figure 4-1: SD Card Installation..................................................................................................17

Figure 4-2: IOVU-572M Peripheral Connectors .........................................................................17

Figure 4-3: Power Terminal Block...............................................................................................18

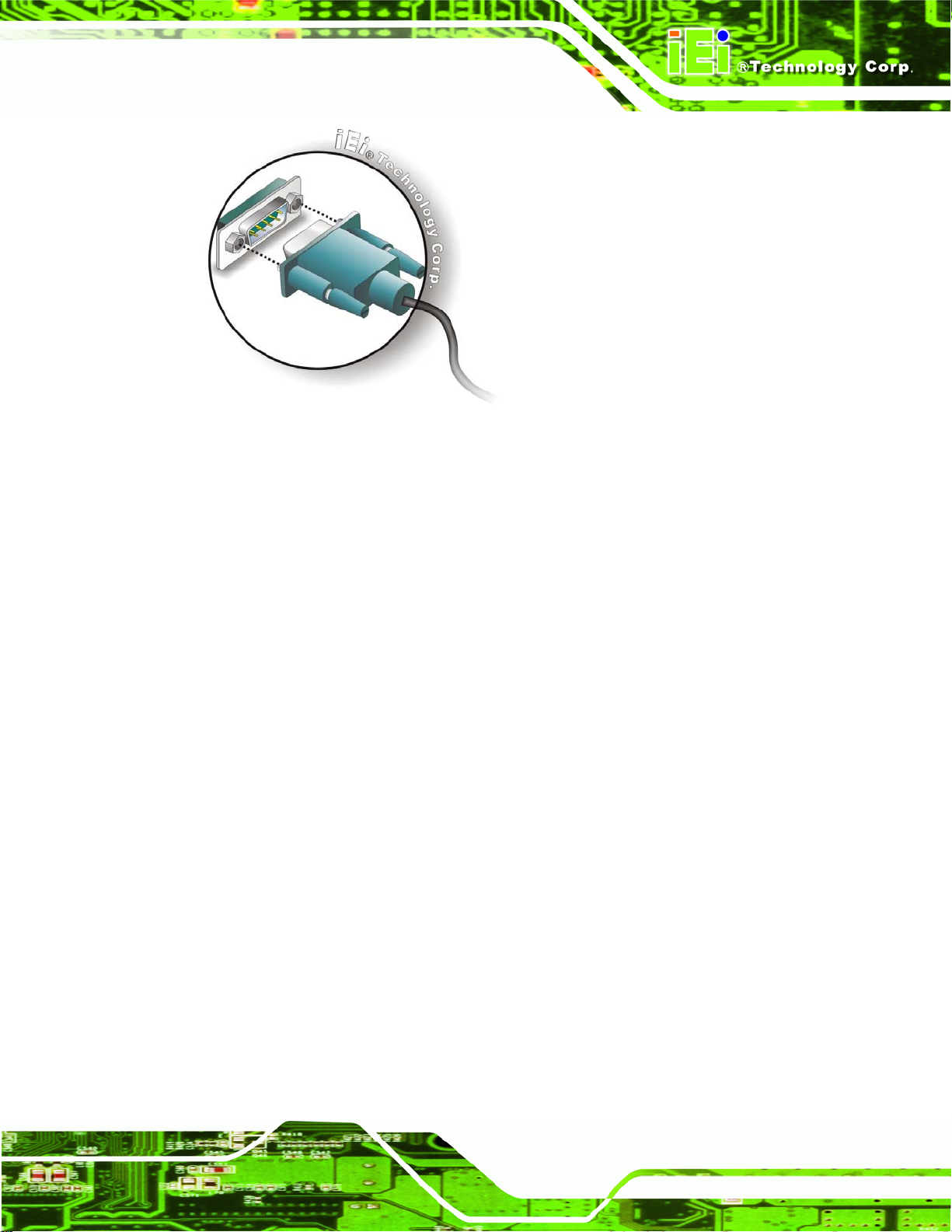

Figure 4-4: Serial Device Connector...........................................................................................19

Figure 4-5: Serial Port Mode Setting...........................................................................................20

Figure4-6: Confirm Serial Port Mode Setting.............................................................................20

Figure4-7: Confirmation Window................................................................................................21

Figure4-8: Restart.........................................................................................................................21

Figure 4–9: Serial Port Pinouts...................................................................................................22

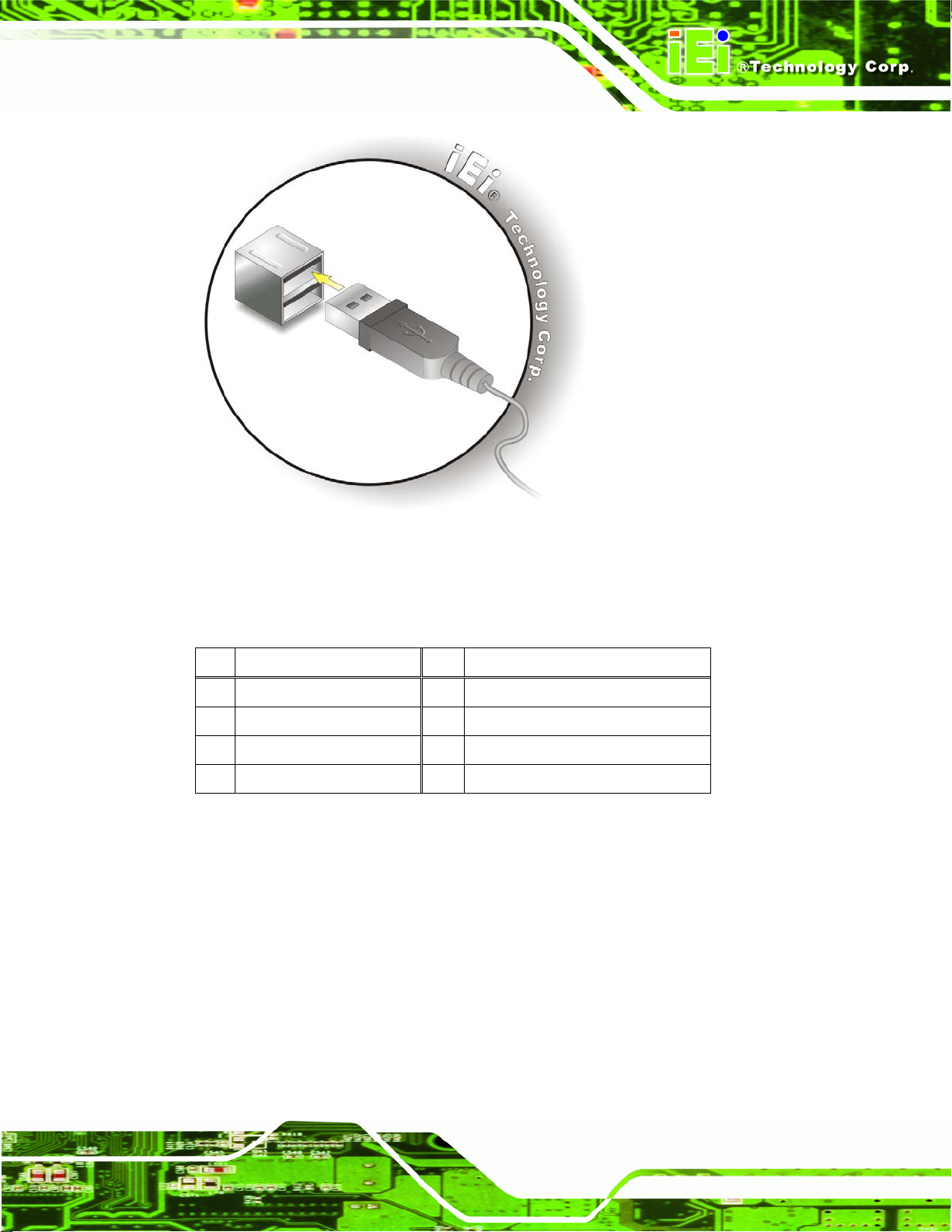

Figure 4-10: USB Connector........................................................................................................23

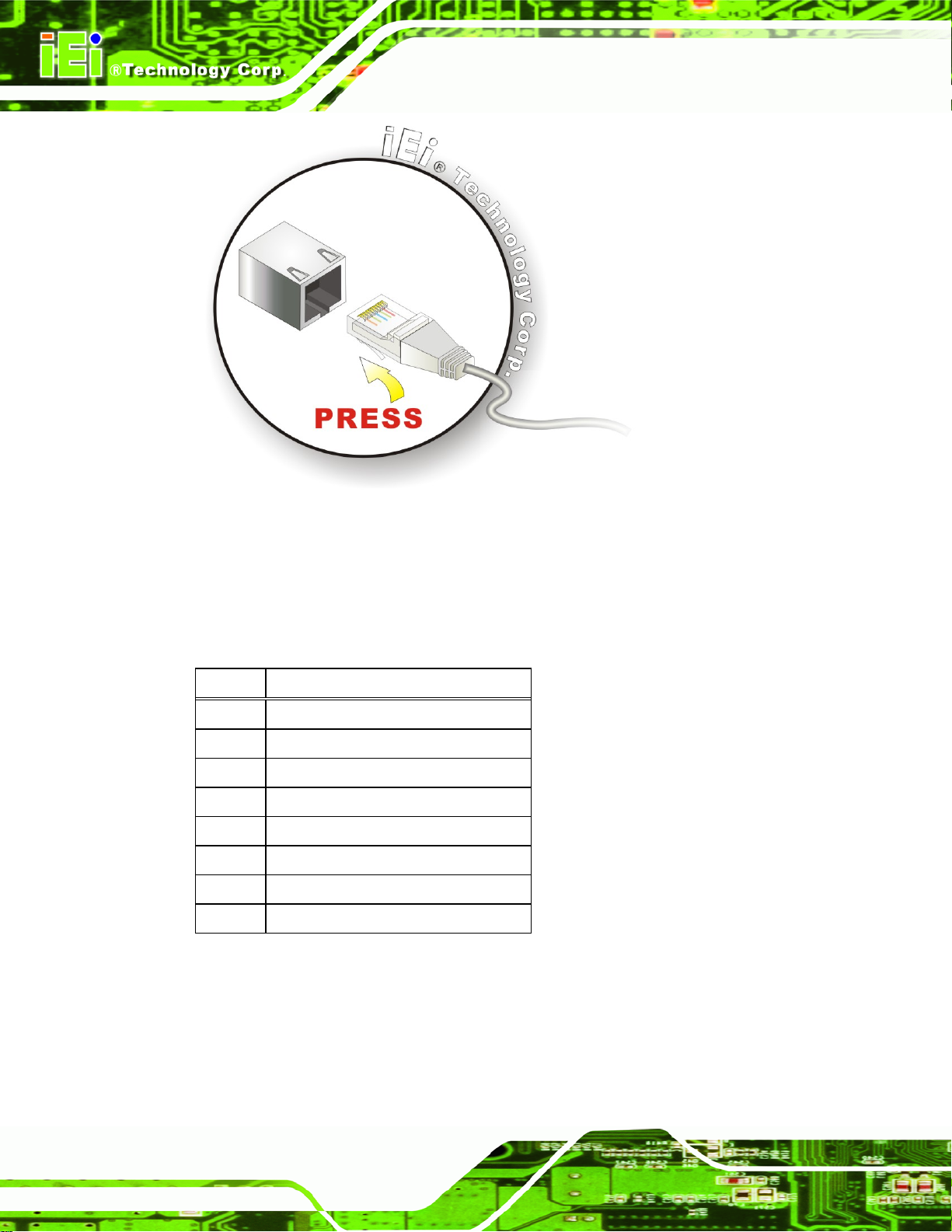

Figure 4-11: LAN Connection......................................................................................................24

Figure 4-12: Ethernet Connector.................................................................................................25

Figure 4-13: Wall-mounting Bracket...........................................................................................26

Figure 4-14: Chassis Support Screws........................................................................................27

Figure 4-15: Secure the IOVU-572M............................................................................................28

Figure 4-16: IOVU-572M Panel Opening (mm)...........................................................................29

Figure 4-17: Panel Mounting Clamp ...........................................................................................29

Figure 4-18: Tighten the Panel Mounting Clamp Screws.........................................................30

Figure 4-19: Stand Mounting.......................................................................................................31

Figure 4-20: Wireless AP .............................................................................................................32

Figure 4-21: Wireless Network Properties .................................................................................33

Figure 4-22: Wireless AP Connected..........................................................................................33

Figure 4-23: IP Information..........................................................................................................34

Page vi

Page 7

IOVU-572M Panel PC

List of Tables

Table 1-1: Technical Specifications..............................................................................................4

Table 3-1: Package List Contents...............................................................................................13

Table 3-2: Optional Items.............................................................................................................14

Table 4-1: External Interface Connectors...................................................................................17

Table 4-2: 12~36 V Power Connector Pinouts...........................................................................18

Table 4-3: Serial Port Pinouts......................................................................................................22

Table 4-4: USB Connector Pinouts.............................................................................................23

Table 4-5: Ethernet Connector Pinouts......................................................................................24

Table 4-6: Ethernet Connector LEDs..........................................................................................25

Page vii

Page 8

IOVU-572M Panel PC

Chapter

1

1 Introduction

Page 1

Page 9

1.1 Overview

Figure 1-1: IOVU-572M

IOVU-572M Panel PC

The IOVU-572M Panel PC comes with a 5.7" touch screen panel. It is powered by a

624 MHz Marvell XScale PXA310 processor and has 256 MB of SDRAM.

The IOVU-572M comes installed with Windows CE 6.0. The package also includes a

software development kit and documentation for easy operating system customization

according to needs.

The IOVU-572M is an extremely low power Panel PC. The system is fanless for quiet and

reliable operation

1.2 Benefits

Some of the IOVU-572M benefits include:

Customizable operating system to suit application needs.

Less downtime due to overheating because of the fanless design

Cost savings with low power consumption

Easy installation with a wide range of input voltages supported

Page 2

Solid-state storage and IP 64 protection of the front cover for handling tough

working environments

Page 10

IOVU-572M Panel PC

1.3 Features

The IOVU-572M features are listed below:

624 MHz Marvell XScale PXA310 processor

256 MB of SDRAM

Two Ethernet ports

Two USB ports

One RS-232/422/485 serial communication connection

Two built-in speakers

4-wire resistive touch panel

12-36 VDC input

RoHS compliant

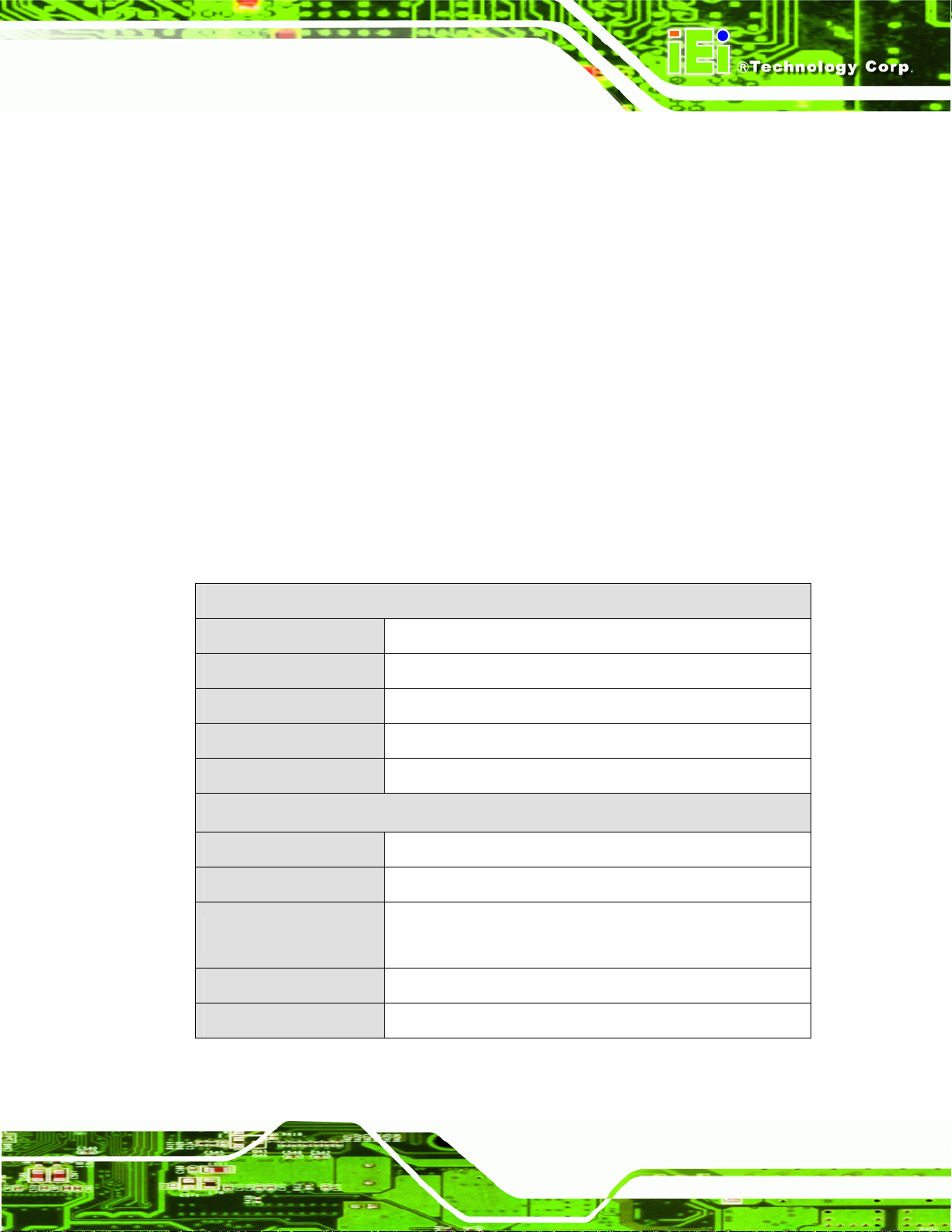

1.4 Technical Specifications

The IOVU-572M technical specifications are listed in Table 1-1.

System Specifications

CPU

Memory

Real-time Clock

Watchdog Timer

Reset

Display

Display Type

Display Size

Resolution

Brightness

624 MHz Marvell XScale PXA310 processor

256 MB of SDRAM

Battery backup RTC

Software programmable supports 1~255 sec. system reset

Reset button

TFT LCD screen

5.7"

640 x 480

262,000 colors

400 cd/m

2

Touch Panel

4-wired resistive touch panel

Page 3

Page 11

I/O and Communications

IOVU-572M Panel PC

Ethernet

Serial Ports

USB Interfaces

Audio

LED Function

Memory Socket

Power

Power Supply

Power Consumption

Environmental and Mechanical

Operating Temperature

Storage Temperature

2 x 10/100 Mb/s

1 x RS-232/422/485

2 x USB host connectors

2 x 1.5 Watt speakers

1 x Power ON/OFF LED on front panel

SD Card socket

12-36 VDC

12 W or less

Minimum: -10ºC (14°F)

Maximum: 60°C (140°F)

Minimum: -20ºC (-4°F)

Maximum: 70°C (158°F)

Humidity

Vibration

Front Panel Color

Physical Dimensions

Ingress Protection

Table 1-1: Technical Specifications

5%RH to 90%RH (non-condensing)

Operating Random Vibration Mode

1.Axes: 3 axs (Vertical / Transverse / Longitudinal).

2.10-500 Hz, 60min/axis.

3.Equivalent to Z:2.18 Grms X:1.6 Grms Y:1.96 Grms

Pantone Black C

180 mm x 135.8 mm x 46.7 mm

IP 64 compliant front panel

Page 4

Page 12

IOVU-572M Panel PC

1.5 Certifications

All IOVU-572M series models comply with the following international standards:

RoHS

IP 64

For a more detailed description of these standards, please refer to Appendix A.

Page 5

Page 13

IOVU-572M Panel PC

Chapter

2

2 Detailed Specifications

Page 6

Page 14

IOVU-572M Panel PC

2.1 Front Panel

The IOVU-572M front panel (Figure 2-1) comprises a 5.7" TFT WVGA 16-bit color touch

screen LCD in an ABS+PC plastic frame.

Figure 2-1: Front Panel

2.2 Connector Panel

All external peripheral interface connectors are located on the bottom panel of the

IOVU-572M . The peripheral interface connectors are shown in

Figure 2-2: IOVU-572M Peripheral Connectors

Figure 2-2.

Page 7

Page 15

External peripheral interface connectors on the IOVU-572M include:

1 x DC-IN bare wire terminal block

2 x RJ-45 LAN connectors

1 x RS-232/422/485 connector

2 x USB connectors

1 x Reset button

IOVU-572M Panel PC

Page 8

Page 16

IOVU-572M Panel PC

2.3 Dimensions

The physical dimensions of the IOVU-572M are shown in Figure 2-3 and listed below:

Width: 180 mm

Height: 135.8 mm

Depth: 46.7 mm

Figure 2-3: IOVU-572M Physical Dimensions (millimeters)

Page 9

Page 17

2.4 Power Supply

WARNING:

Whenever you need to remove a part for maintenance or upgrading,

switch off the power supply and unplug the power cord first.

The IOVU-572M has a terminal block connector on the bottom panel.

IOVU-572M Panel PC

Page 10

Page 18

IOVU-572M Panel PC

Chapter

3

3 Unpacking

Page 11

Page 19

3.1 Anti-static Precautions

WARNING:

Failure to take ESD precautions during installation may result in

permanent damage to the IOVU-572M and severe injury to the user.

Electrostatic discharge (ESD) can cause serious damage to electronic components,

including the IOVU-572M. Dry climates are especially susceptible to ESD. It is therefore

critical that whenever the IOVU-572M or any other electrical component is handled, the

following anti-static precautions are strictly adhered to.

Wear an anti-static wristband: Wearing a simple anti-static wristband can

help to prevent ESD from damaging the board.

IOVU-572M Panel PC

Self-grounding: Before handling the board touch any grounded conducting

material. During the time the board is handled, frequently touch any

conducting materials that are connected to the ground.

Use an anti-static pad: When configuring the IOVU-572M, place it on an

antic-static pad. This reduces the possibility of ESD damaging the

IOVU-572M.

3.2 Unpacking Precautions

When the IOVU-572M is unpacked, please do the following:

Follow the anti-static precautions outlined in Section

Make sure the packing box is facing upwards so the IOVU-572M does not fall

out of the box.

Make sure all the components shown in Section

3.1.

3.3 are present.

Page 12

Page 20

IOVU-572M Panel PC

3.3 Unpacking Checklist

NOTE:

If some of the components listed in the checklist below are missing,

please do not proceed with the installation. Contact the IEI reseller or

vendor you purchased the IOVU-572M from or contact an IEI sales

representative directly. To contact an IEI sales representative, please

send an email to sales@iei.com.tw.

The IOVU-572M is shipped with the following components:

Quantity Item and Part Number Image

1 IOVU-572M

1 Utility CD including SDK, utilities, and

technical documentation

1 Null modem cable

1 Touch pen

Table 3-1: Package List Contents

Page 13

Page 21

3.4 Optional Items

Item and Part Number Image

Panel mount kit

ALFPK-08

VESA 75 wall mount kit

AFLWK-07

LCD monitor/PPC stand kit for VESA 75, up to 5kg

STAND-A08-RS

IOVU-572M Panel PC

12V/5A DC 60W power adapter with bare wire,

90-264V AC input

63000-FSP060DBAB1555-RS

Table 3-2: Optional Items

Page 14

Page 22

IOVU-572M Panel PC

Chapter

4

4 Installation

Page 15

Page 23

4.1 Installation Precautions

During installation, be aware of the precautions below:

Read the user manual: The user manual provides a complete description of

the IOVU-572M, installation instructions and configuration options.

DANGER! Disconnect Power: Power to the IOVU-572M must be

disconnected during the installation process, or before any attempt is made to

access the rear panel. Electric shock and personal injury might occur if the

rear panel of the IOVU-572M is opened while the power cord is still

connected to an electrical outlet.

Qualified Personnel: The IOVU-572M must be installed and operated only

by trained and qualified personnel. Maintenance, upgrades, or repairs may

only be carried out by qualified personnel who are familiar with the associated

dangers.

IOVU-572M Panel PC

Air Circulation: Make sure there is sufficient air circulation when installing the

IOVU-572M. The IOVU-572M’s cooling vents must not be obstructed by any

objects. Blocking the vents can cause overheating of the IOVU-572M. Leave

at least 5 cm of clearance around the IOVU-572M to prevent overheating.

Grounding: The IOVU-572M should be properly grounded. The voltage feeds

must not be overloaded. Adjust the cabling and provide external overcharge

protection per the electrical values indicated on the label attached to the back

of the IOVU-572M.

4.2 SD Card Installation

The IOVU-572M supports a single SD card. To install the SD card, follow the steps below.

Step 1: Undo the SD card cover screw.

Step 2: Slide open the SD card cover.

Step 3: Slide the SD card into the slot. Replace the SD card slot cover and screw.

Step 0:

Page 16

Page 24

IOVU-572M Panel PC

Figure 4-1: SD Card Installation

4.3 External Peripheral Interface Connectors

Table 4-1 lists the external interface connectors on the IOVU-572M. Detailed descriptions

of the connectors can be found in the following table.

Connector Type

12-36 V DC bare wire power terminal Terminal Block

Ethernet connectors RJ-45 Jack connector

RS-232/422/485 Serial connector D-sub 9 Male connector

USB connectors Dual USB port

Table 4-1: External Interface Connectors

Figure 4-2: IOVU-572M Peripheral Connectors

Page 17

Page 25

4.3.1 12 V~36 V DC Terminal Block

The power terminal block connects to a 12~36 V DC power source.

CN Label: 12-36 V

IOVU-572M Panel PC

CN Type:

CN Location:

CN Pinouts:

Terminal block

Figure 4-2

See

Table 4-2 and Figure 4-3

See

Pin Description

1 12~36 V DC Power in

2 GND

Table 4-2: 12~36 V Power Connector Pinouts

Figure 4-3: Power Terminal Block

4.3.2 RS-232/422/485 Serial Port

This section outlines the usage and setup of the serial port on the rear I/O panel.

4.3.2.1 Connecting the Serial Port

The IOVU-572M has a single female DB-9 connector on the external peripheral interface

panel for a serial device. Follow the steps below to connect a serial device to the

IOVU-572M.

Step 1: Insert the serial connector. Insert the DB-9 connector of a serial device into

the DB-9 connector on the external peripheral interface. See

Page 18

Figure 4-4.

Page 26

IOVU-572M Panel PC

Figure 4-4: Serial Device Connector

Step 2: Secure the connector. Secure the serial device connector to the external

interface by tightening the two retention screws on either side of the connector.

4.3.2.2 RS-232/422/485 Selection

To select RS-232, RS-422, or RS-485 mode, please follow the directions below.

Step 1: Select "Start > Programs > IEI > IEI CEUTILITY.exe" to run IEI_CEUTILITY.exe

Step 2: Change serial port mode setting. Use the drop down menu in

select the desired mode setting.

Figure 4-5 to

Step 0:

Page 19

Page 27

IOVU-572M Panel PC

Figure 4-5: Serial Port Mode Setting

Step 3: Click "Save Registry" to save the changes.

Page 20

Figure

ٛ 4-6: Confirm Serial Port Mode Setting

Page 28

IOVU-572M Panel PC

Step 4: Confirm save changes. Click “Yes” to continue.

Figure

Step 5: Settings will take effect after th e system reboots. Click “Yes” to restart.

ٛ 4-7: Confirmation Window

Figure

ٛ 4-8: Restart

Page 21

Page 29

Step 0:

4.3.2.3 Pinouts

Serial port pinouts are shown below.

Pin RS-232 RS-422 RS-485

1 DCD RXD- DATA2 RX RXD+ DATA+

3 TX TXD-

4 DTR

5 GND GND GND

6 DSR

7 RTS TXD+

8 CTS

IOVU-572M Panel PC

9 RI

Table 4-3: Serial Port Pinouts

Figure 4–9: Serial Port Pinouts

4.3.3 USB Connectors

The external USB Series "A" receptacle connectors provide easier and quicker access to

external USB devices. Follow the steps below to connect USB devices to the IOVU-572M.

Step 1: Insert a USB Series "A" plug. Insert the USB Series "A" plug of a device into

the USB Series "A" receptacle on the external peripheral interface. See

Page 22

Figure 4-10. Step 1:

Page 30

IOVU-572M Panel PC

Figure 4-10: USB Connector

USB devices connect directly to the USB connectors on the external peripheral connector

panel.

Pin Description Pin Description

1 VCC 5 VCC

2 D1- 6 D23 D1+ 7 D2+

4 GND 8 GND

Table 4-4: USB Connector Pinouts

4.3.4 Ethernet Connector

There are two external RJ-45 LAN connectors. The RJ-45 connectors enable connection

to an external network. To connect a LAN cable with an RJ-45 connector, please follow

the instructions below.

Step 2: Align the connectors. Align the RJ-45 connector on the LAN cable with one of

the RJ-45 connectors on the IOVU-572M. See

Figure 4-11.

Page 23

Page 31

IOVU-572M Panel PC

Figure 4-11: LAN Connection

Step 3: Insert the LAN cable RJ-45 connector. Once aligned, gently insert the LAN

cable RJ-45 connector into the on-board RJ-45 connector. Step 0:

The Ethernet connector pinouts are shown below.

PIN DESCRIPTION

1 TPT+

2 TPT3 TPR+

4 LAN_GND

5 LAN_GND

6 TPR7 LAN_GND

8 LAN_GND

Table 4-5: Ethernet Connector Pinouts

Page 24

Page 32

IOVU-572M Panel PC

Figure 4-12: Ethernet Connector

The RJ-45 Ethernet connector has two status LEDs, one green and one yellow. The green

LED indicates activity on the port and the yellow LED indicates the port is linked

(

Table 4-6).

SPEED LED LINK LED

Status Description Status Description

GREEN ON: 100 MB

OFF: 10 MB

Table 4-6: Ethernet Connector LEDs

4.4 Mounting the System

WARNING!

When mounting the flat panel PC onto an arm, onto the wall or onto a

panel, it is better to have more than one person to help with the

installation to make sure the panel PC does not fall down and get

damaged.

Three methods of mounting the IOVU-572M are listed below.

Wall mounting

YELLOW ON: Linked

Flashing: Activity

Panel mounting

Arm mounting

The mounting methods are described below.

Page 25

Page 33

4.4.1 Wall Mounting

To mount the IOVU-572M onto the wall, please follow the steps below.

Step 1: Select the location on the wall for the wall-mounting bracket.

Step 2: Carefully mark the locations of the four screw holes in the bracket on the wall.

Step 3: Drill four pilot holes at the marked locations on the wall for the bracket retention

screws.

Step 4: Align the wall-mounting bracket screw holes with the pilot holes.

Step 5: Secure the mounting-bracket to the wall by inserting the retention screws into

IOVU-572M Panel PC

the four pilot holes and tightening them (

Figure 4-13: Wall-mounting Bracket

Step 6: Insert the four monitor mounting screws provided in the wall mounting kit into the

Figure 4-13).

Page 26

four screw holes on the real panel of the IOVU-572M and tighten until the screw

shank is secured against the rear panel (

Step 7: Align the mounting screws on the monitor rear panel with the mounting holes on

the bracket.

Figure 4-14).

Page 34

IOVU-572M Panel PC

Step 8: Carefully insert the screws through the holes and gently pull the monitor

downwards until the monitor rests securely in the slotted holes (

Ensure that all four of the mounting screws fit snuggly into their respective

slotted holes.

Figure 4-14).

NOTE:

In the diagram below the bracket is already installed on the wall.

Figure 4-14: Chassis Support Screws

Step 9: Secure the panel PC by fastening the retention screw of the wall-mounting

bracket. (

Figure 4-15). Step 9:

Page 27

Page 35

IOVU-572M Panel PC

Figure 4-15: Secure the IOVU-572M

4.4.2 Panel Mounting

The IOVU-572M can be mounted in a panel.

CAUTION:

When mounting the IOVU-572M take care to tighten the retention

screws or bolts until fully secure, but do not over tighten. Over

tightening the retention screws or bolts may cause them to become

stripped, rendering them useless.

To mount the IOVU-572M into a panel, please follow the steps below.

Page 28

Step 10: Select the position on the panel to mount the IOVU-572M.

Step 11: Cut out a section from the panel that corresponds to the rear panel dimensions

of the IOVU-572M. Take care that the panel section that is cut out is smaller than

Page 36

IOVU-572M Panel PC

the overall size of the frame that surrounds the IOVU-572M but just large

enough for the rear panel of the IOVU-572M to fit through (see

Figure 4-16: IOVU-572M Panel Opening (mm)

Step 12: Slide the IOVU-572M through the hole until the frame is flush against the panel.

Step 13: Insert the panel mounting clamps into the pre-formed holes along the edges of

the chassis, behind the frame.

Figure 4-16).

Figure 4-17: Panel Mounting Clamp

Step 14: Tighten the screws that pass through the panel mounting clamps until the plastic

caps at the front of all the screws are firmly secured to the panel (

Step 14:

Figure 4-18).

Page 29

Page 37

Figure 4-18: Tighten the Panel Mounting Clamp Screws

IOVU-572M Panel PC

4.4.3 Arm Mounting

The IOVU-572M is VESA (Video Electronics Standards Association) compliant and can be

mounted on an arm with a 75 mm interface pad. To mount the IOVU-572M on an arm,

please follow the steps below.

Step 15: The arm is a separately purchased item. Please correctly mount the arm onto

the surface it uses as a base. To do this, refer to the installation documentation

that came with the mounting arm.

NOTE:

When purchasing the arm please ensure that it is VESA compliant and

that the arm has a 75 mm interface pad. If the mounting arm is not

VESA compliant it cannot be used to support the IOVU-572M.

Page 30

Step 16: Once the mounting arm has been firmly attached to the surface, lift the

IOVU-572M onto the interface pad of the mounting arm.

Page 38

IOVU-572M Panel PC

Step 17: Align the retention screw holes on the mounting arm interface with those on the

IOVU-572M.

Step 18: Secure the IOVU-572M to the interface pad by inserting four retention screws

through the bottom of the mounting arm interface pad and into the IOVU-572M.

Step 0:

4.4.4 Stand Mounting

The IOVU-572M has Video Electronics Standards Association (VESA) standard mounting

holes tapped into the rear panel. The monitor stand mounting plate has a matching VESA

hole pattern. To mount the IOVU onto a stand, please follow the steps below.

Step 1: Line up the threaded holes on the monitor rear panel with the screw holes on the

Step 2: Secure the monitor to the stand with the supplied retention screws

Figure 4-19: Stand Mounting

4.5 Software

monitor stand mounting plate.

Figure 4-19).Step 2:

(

The IOVU-572M comes with a pre-installed Windows CE 6.0 operating system and a rich

software application development kit. For information about configuring the operating

system, adding remote management tools or additional software and drivers, refer to the

Page 31

Page 39

user manuals on IEI IOVU Utility CD that came with the IOVU-572M. The IOVU includes

the following software:

Standard Windows® CE 6.0 professional version license.

Optional Board Support Package (BSP) for customers to customize their own

Attached Software Development Kit (SDK) for embedded Visual C++ to

Built-in .NET Compact Framework support with related SDK

Free pre-installed utilities for configuring and diagnosing your IOVU-572M.

Free remote management tools installed in laptop for remotely configuring,

4.5.1 Wireless AP

IOVU-572M Panel PC

OS image.

program Windows CE application.

monitoring, and managing your IOVU-572M.

To select Wireless AP, please follow the instructions below.

Step 1: When turn on the power, Wireless AP start to search wireless base stations

around as shown below. (

Figure 4-20: Wireless AP

Figure 4-20).

Page 32

Step 2: Select your Internet connection and click Connect.

Step 3: The Wireless Network Properties screen appears. (

password into the Network key. Click OK.

Figure 4-21). Input the

Page 40

IOVU-572M Panel PC

Figure 4-21: Wireless Network Properties

Step 4: The soft AP configuration is finished. (

Figure 4-22).

Figure 4-22: Wireless AP Connected

Page 33

Page 41

Step 5: Click the IP Information tab to view the information of the Wireless AP Solo. If

the server function is enabled on the AP, the user can automatically get an IP

IOVU-572M Panel PC

address and a subnet mask. (

Figure 4-23: IP Information

Figure 4-23)

Page 34

Page 42

IOVU-572M Panel PC

Appendix

A

A Certifications

Page 35

Page 43

A.1 RoHS Compliant

All models in the IOVU series comply with the Restriction of Hazardous Materials (RoHS)

Directive. This means that all components used to build the industrial workstations and the

workstation itself are RoHS compliant.

The RoHS Directive bans the placing on the EU market of new electrical and electronic

equipment containing more than agreed levels of lead, cadmium, mercury, hexavalent

chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE)

flame retardants.

A.2 IP 64 Compliant Front Panel

The front panels on all models in the IOVU series have an ingress protection rating (IP) of

64, IP 64 or greater. The front panels are protected from dust particles and splashed

water.

IOVU-572M Panel PC

Page 36

Page 44

IOVU-572M Panel PC

B Safety Precautions

Appendix

B

Page 37

Page 45

B.1 Safety Precautions

WARNING:

The precautions outlined in this appendix should be strictly followed.

Failure to follow these precautions may result in permanent damage to

the IOVU-572M.

Please follow the safety precautions outlined in the sections that follow:

B.1.1 General Safety Precautions

Please ensure the following safety precautions are adhered to at all times.

IOVU-572M Panel PC

Make sure the power is turned off and the power cord is disco nnected

whenever the IOVU-572M is being installed, moved or modified.

Do not apply voltage levels that exceed the specified voltage range.

Doing so may cause fire and/or an electrical shock.

Electric shocks can occur if the IOVU-572M chassis is opened when the

IOVU-572M is running.

Do not drop or insert any objects into the ventilation openings of the

IOVU-572M.

If considerable amounts of dust, water, or fluids enter the IOVU-572M,

turn off the power supply immediately, unplug the power cord, and contact the

IOVU-572M vendor.

DO NOT:

o Drop the IOVU-572M against a hard surface.

o Strike or exert excessive force onto the LCD panel.

o Touch any of the LCD panels with a sharp object

o In a site where the ambient temperature exceeds the rated temperature

Page 38

Page 46

IOVU-572M Panel PC

B.1.2 Anti-static Precautions

WARNING:

Failure to take ESD precautions during the installation of the

IOVU-572M may result in permanent damage to the IOVU-572M and

severe injury to the user.

Electrostatic discharge (ESD) can cause serious damage to electronic components,

including the IOVU-572M. Dry climates are especially susceptible to ESD. It is therefore

critical that whenever the IOVU-572M is opened and any of the electrical components are

handled, the following anti-static precautions are strictly adhered to.

Wear an anti-static wristband: Wearing a simple anti-static wristband can

help to prevent ESD from damaging any electrical component.

Self-grounding: Before handling any electrical component, touch any

grounded conducting material. During the time the electrical component is

handled, frequently touch any conducting materials that are connected to the

ground.

Use an anti-static pad: When configuring or working with an electrical

component, place it on an antic-static pad. This reduces the possibility of ESD

damage.

Only handle the edges of the electrical component: When handling the

electrical component, hold the electrical component by its edges.

B.2 Maintenance and Cleaning Precautions

When maintaining or cleaning the IOVU-572M, please follow the guidelines below.

B.2.1 Maintenance and Cleaning

Prior to cleaning any part or component of the IOVU-572M, please read the details below.

Except for the LCD panel, never spray or squirt liquids directly onto any other

components. To clean the LCD panel, gently wipe it with a piece of soft dry

cloth or a slightly moistened cloth.

Page 39

Page 47

The interior of the IOVU-572M does not require cleaning. Keep fluids away

from the IOVU-572M interior.

Be cautious of all small removable components when vacuuming the

IOVU-572M.

Turn the IOVU-572M off before cleaning the IOVU-572M.

Never drop any objects or liquids through the openings of the IOVU-572M.

Be cautious of any possible allergic reactions to solvents or chemicals used

when cleaning the IOVU-572M.

Avoid eating, drinking and smoking within vicinity of the IOVU-572M.

B.2.2 Cleaning Tools

Some components in the IOVU-572M may only be cleaned using a product specifically

designed for the purpose. In such case, the product will be explicitly mentioned in the

cleaning tips. Below is a list of items to use when cleaning the IOVU-572M.

IOVU-572M Panel PC

Cloth – Although paper towels or tissues can be used, a soft, clean piece of

cloth is recommended when cleaning the IOVU-572M.

Water or rubbing alcohol – A cloth moistened with water or rubbing alcohol

can be used to clean the IOVU-572M.

Using solvents – The use of solvents is not recommended when cleaning the

IOVU-572M as they may damage the plastic parts.

Vacuum cleaner – Using a vacuum specifically designed for computers is

one of the best methods of cleaning the IOVU-572M. Dust and dirt can restrict

the airflow in the IOVU-572M and cause its circuitry to corrode.

Cotton swabs - Cotton swaps moistened with rubbing alcohol or water are

excellent tools for wiping hard to reach areas.

Foam swabs - Whenever possible, it is best to use lint free swabs such as

foam swabs for cleaning.

B.2.3 Federal Communication Commission Interference Statement

Page 40

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

Page 48

IOVU-572M Panel PC

must accept any interference received, including interference that may cause undesired

operation.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

FCC Caution: Any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate this equipment.

This transmitter must not be co-located or operating in conjunction with any other antenna

or transmitter.

FOR PORTABLE DEVICE USAGE (<20m from body/SAR neede d)

Radiation Exposure Statement:

The product comply with the FCC portable RF exposure limit set forth for an uncontrolled

environment and are safe for intended operation as described in this manual. The further

RF exposure reduction can be achieved if the product can be kept as far as possible from

the user body or set the device to lower output power if such function is available.

Page 41

Page 49

FOR MOBILE DEVICE USAGE (>20cm/low power)

Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance

20cm between the radiator & your body.

FOR COUNTRY CODE SELECTION USAGE (WLAN DEVICES)

Note: The country code selection is for non-US model only and is not available to all US

model. Per FCC regulation, all WiFi product marketed in US must fixed to US operation

channels only.

IOVU-572M Panel PC

Page 42

Page 50

IOVU-572M Panel PC

C Hazardous Materials

Appendix

C

Disclosure

Page 43

Page 51

IOVU-572M Panel PC

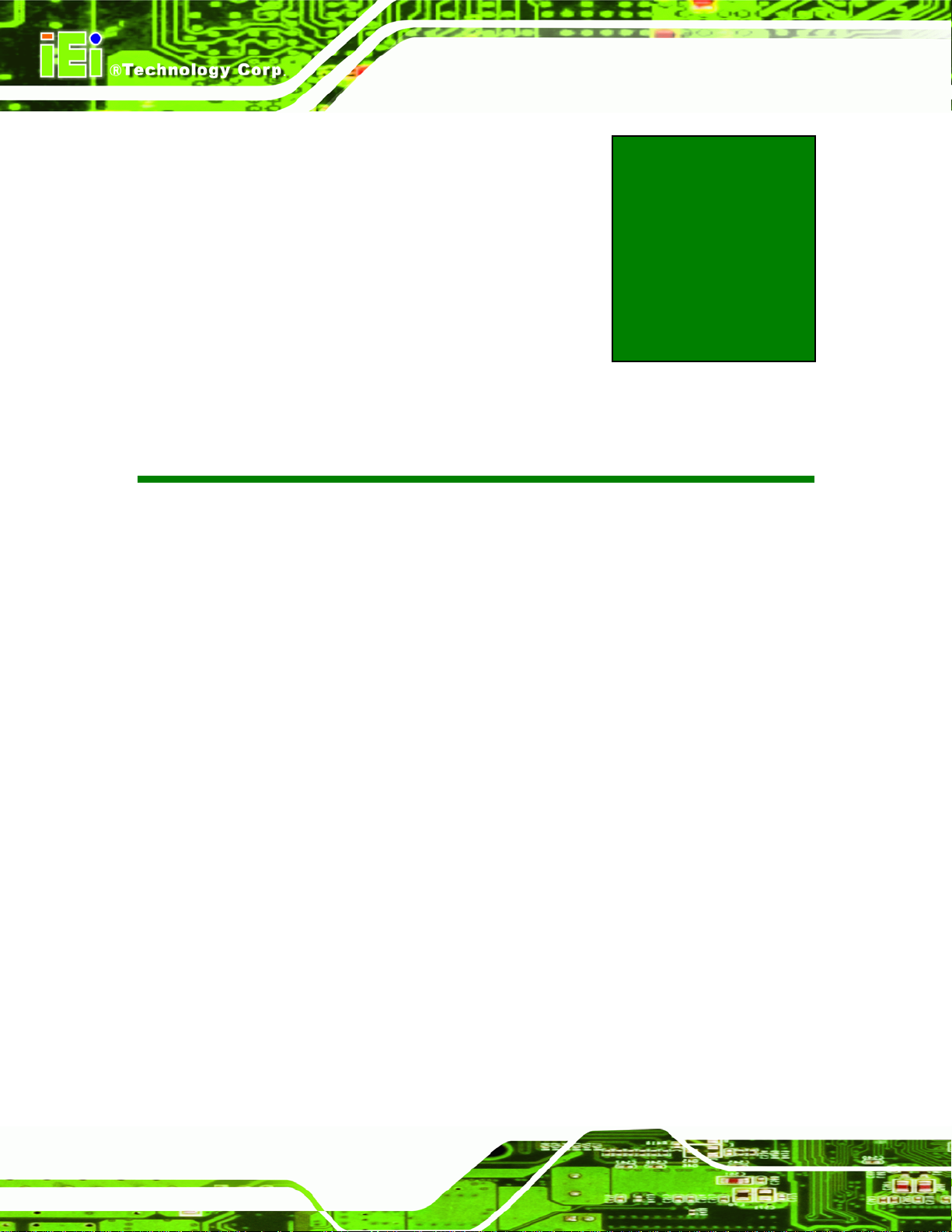

C.1 Hazardous Materials Disclosure Table for IPB Products

Certified as RoHS Compliant Under 2002/95/EC Without

Mercury

The details provided in this appendix are to ensure that the product is compliant with the

Peoples Republic of China (China) RoHS standards. The table below acknowledges the

presences of small quantities of certain materials in the product, and is applicable to China

RoHS only.

A label will be placed on each product to indicate the estimated “Environmentally Friendly

Use Period” (EFUP). This is an estimate of the number of years that these substances

would “not leak out or undergo abrupt change.” This product may contain replaceable

sub-assemblies/components which have a shorter EFUP such as batteries and lamps.

These components will be separately marked.

Please refer to the table on the next page.

Page 44

Page 52

IOVU-572M Panel PC

Toxic or Hazardous Substances and Elements Part Name

Housing

Display

Printed Circuit

Board

Metal

Fasteners

Cable

Assembly

Fan Assembly

Power Supply

Assemblies

Lead

(Pb)

X O O O O X

X O O O O X

X O O O O X

X O O O O O

X O O O O X

X O O O O X

X O O O O X

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(CR(VI))

Polybrominated

Biphenyls

(PBB)

Polybrominated

Diphenyl

Ethers

(PBDE)

Battery

O: This toxic or hazardous substance is contained in all of the homogeneous materials for the part is

below the limit requirement in SJ/T11363-2006

X: This toxic or hazardous substance is contained in at least one of the homogeneous materials for

this part is above the limit requirement in SJ/T11363-2006

O O O O O O

Page 45

Page 53

此附件旨在确保本产品符合中国 RoHS 标准。以下表格标示此产品中某有毒物质的含量符

合中国 RoHS 标准规定的限量要求。

本产品上会附有”环境友好使用期限”的标签,此期限是估算这些物质”不会有泄漏或突变”的

年限。本产品可能包含有较短的环境友好使用期限的可替换元件,像是电池或灯管,这些元

件将会单独标示出来。

有毒有害物质或元素 部件名称

IOVU-572M Panel PC

铅

(Pb)

壳体

显示

印刷电路板

金属螺帽

电缆组装

风扇组装

电力供应组装

电池

O: 表示该有毒有害物质在该部件所有物质材料中的含量均在 SJ/T11363-2006 标准规定的限量要求以下。

X: 表示该有毒有害物质至少在该部件的某一均质材料中的含量超出 SJ/T11363-2006 标准规定的限量要求。

X O O O O X

X O O O O X

X O O O O X

X O O O O O

X O O O O X

X O O O O X

X O O O O X

O O O O O O

汞

(Hg)

镉

(Cd)

六价铬

(CR(VI))

多溴联苯

(PBB)

多溴二苯

醚

(PBDE)

Page 46

Loading...

Loading...