Thermal Imaging Integrated Network Camera

User Manual

IV-THM42F25

12000 Ford, Suite110, Dallas, TX 75234

Tel: 972-247-1203 Fax: 972-247-1291

www.idview.com

Thermal Imaging Integrated Network Camera

User Manual

Precautions

Issue V1.0 (2014-01-10) i

Precautions

Precautions

Fully understand this document before using this device, and strictly observe rules in

this document when using this device. If you install this device in public places,

provide the tip "You have entered the area of electronic surveillance" in an eyecatching place. Failure to correctly use electrical products may cause fire and severe

injuries. To prevent accidents, carefully read the following context:

Symbols

This document may contain the following symbols whose meanings are described

accordingly.

Symbol

Description

It alerts you to fatal dangers which, if not avoided, may

cause deaths or severe injuries.

It alerts you to moderate dangers which, if not avoided,

may cause minor or moderate injuries.

It alerts you to risks. Neglect of these risks may cause

device damage, data loss, device performance

deterioration, or unpredictable results.

It provides a tip that may help you resolve problems or

save time.

It provides additional information.

To prevent electric shocks or other dangers, keep power plugs dry and clean.

Strictly observe installation requirements when installing the device. The

manufacturer shall not be held responsible for device damage caused by users' nonconformance to these requirements.

Precautions

Thermal Imaging Integrated Network Camera

User Manual

ii

Issue V1.0 (2014-01-10)

Strictly conform to local electrical safety standards and use power adapters that are

marked with the LPS standard when installing and using this device. Otherwise,

this device may be damaged.

Use accessories delivered with this device. The voltage must meet input voltage

requirements for this device.

If this device is installed in places with unsteady voltage, ground this device to

discharge high energy such as electrical surges in order to prevent the power supply

from burning out.

When this device is in use, ensure that no water or any liquid flows into the device.

If water or liquid unexpectedly flows into the device, immediately power off the

device and disconnect all cables (such as power cables and network cables) from

this device.

Do not place the thermal imaging camera and unpackaged products at a radiation

source with a high intensity regardless of whether the device is in the normal

power-on state, for example, the sun, laser, and electric arc welder, and place the

thermal imaging camera and unpackaged products against objects with a high heat

source, for example, the sun. Otherwise, the accuracy of the thermal imaging

camera will be affected. In addition, the detector in the thermal imaging camera

may be permanently damaged.

If this device is installed in places where thunder and lightning frequently occur,

ground the device nearby to discharge high energy such as thunder strikes in order

to prevent device damage.

Unless otherwise specified in the user manual, do not use the thermal imaging

camera in an environment with the temperature lower than -10C (+14F) or higher

than 50C (+122F). Otherwise, the images displayed by the thermal imaging

camera are abnormal and the device may be damaged if working beyond the

temperature range for a long period.

During the outdoor installation, prevent the morning or evening sunlight incidence

to the lens of the thermal imaging camera. The sun shade must be installed and

adjusted according to the angle of the sunlight illumination.

Avoid heavy loads, intensive shakes, and soaking to prevent damages during

transportation and storage. The warranty does not cover any device damage that is

caused during secondary packaging and transportation after the original packaging

is taken apart.

This device is a static sensitivity device. Improper static may damage the thermal

imaging camera. ESD protection measures and reliable grounding must be well

prepared for device installation and uninstallation.

Protect this device from fall-down and intensive strikes, keep the device away from

magnetic field interference, and do not install the device in places with shaking

surfaces or under shocks.

Thermal Imaging Integrated Network Camera

User Manual

Precautions

Issue V1.0 (2014-01-10) iii

Use a soft and dry cloth to clean the device body. In case that the dirt is hard to

remove, use a dry cloth dipped in a small amount of mild detergent and gently wipe

the device, and then dry it again. Pay special attention to the front window of the

thermal imaging camera because this is precision optics. If the front window has

water spots, use a clean and soft cloth moistened with water and wipe it. If the front

window needs further cleaning, use a soft cloth dampened with isopropyl alcohol

or detergent. Improper cleaning can cause damage to the device.

The lens window of the thermal imaging camera is designed to be applicable to an

outdoor environment. The window is coated with durable coating material, but may

require frequent cleaning. When you found lens image degradation or excessive

accumulation of pollutants, you should clear up the window in a timely manner.

Exercise caution when you use this device in severe sandstorm (such as deserts) or

corrosive environments (such as offshore). Improper use may cause surface coating

off.

Do not jam the ventilation opening. Follow the installation instructions provided in

this document when installing the device.

Keep the device away from heat sources such as radiators, electric heaters, or other

heat equipment.

Keep the device away from moist, dusty, extremely hot or cold places, or places

with strong electric radiation.

If the device is installed outdoors, take insect- and moisture-proof measures to

avoid circuit board corrosion that can affect monitoring.

Remove the power plug if the device is idle for a long time.

Before unpacking, check whether the fragile sticker is damaged. If the fragile

sticker is damaged, contact customer services or sales personnel. The manufacturer

shall not be held responsible for any artificial damage of the fragile sticker.

Special Announcement

All complete products sold by the manufacturer are delivered along with nameplates,

operation instructions, and accessories after strict inspection. The manufacturer shall

not be held responsible for counterfeit products.

This manual may contain misprints, technology information that is not accurate enough,

or product function and operation description that is slightly inconsistent with the

actual product. The manufacturer will update this manual according to product function

enhancement or changes and regularly update the software and hardware described in

this manual. Update information will be added to new versions of this manual without

prior notice.

This manual is only for reference and does not ensure that the information is totally

consistent with the actual product. For consistency, see the actual product.

Contents

Thermal Imaging Integrated Network Camera

User Manual

iv

Issue V1.0 (2014-01-10)

Contents

1 Product Overview .................................................................................................... 1

1.1 Thermal Imaging Principles and Advantages ................................................................. 1

1.2 Device Structure ............................................................................................................. 1

1.3 Cable Connection ........................................................................................................... 3

1.4 Functions and Features ................................................................................................... 4

2 Device Dimensions ................................................................................................. 5

3 Installation ................................................................................................................ 6

3.1 Preparations .................................................................................................................... 6

3.2 Installation Mode............................................................................................................ 7

3.3 Installation Procedure ..................................................................................................... 7

4 Quick Configuration ............................................................................................. 11

4.1 Login and Logout .......................................................................................................... 11

4.2 Main page layout .......................................................................................................... 12

4.3 Browsing Video ................................................................................................ ............ 13

4.3.2 Download the right control in the Internet Explorer......................................... 15

4.3.3 In the Google, Firefox, or Safari browsers watch real-time video .................... 16

4.4 Setting Local Network Parameters ............................................................................... 16

5 Parameter Setting ................................................................................................... 20

5.1 Sensor Configuration Interface ..................................................................................... 20

5.2 Setting Images .............................................................................................................. 20

5.3 FEC Mode .................................................................................................................... 22

5.4 DNR ............................................................................................................................. 24

5.5 Lens Control ................................................................................................................. 25

6 Technical Specifications ....................................................................................... 26

A Hazardous Substance Declaration ..................................................................... 29

Thermal Imaging Integrated Network Camera

User Manual

1 Product Overview

Issue V1.0 (2014-01-10) 1

1 Product Overview

1.1 Thermal Imaging Principles and Advantages

For any object, as long as its temperature is above the absolute zero (-273.15°C),

although the object does not give out light, it can radiate infrared. The infrared is also

known as thermal radiation. A temperature change occurs when the infrared radiated by

objects at different temperatures is absorbed by the infrared thermal detector, and

thereby generating an electrical effect. An electrical signal is amplified and processed

to obtain a thermal image corresponding to the distribution of heat on the surface of the

object, that is, infrared thermal imaging.

Applicable to any light environment

Traditional cameras rely on the natural or ambient light for imaging. However, the

infrared thermal imaging camera can clearly image the object with the infrared heat

radiation of the object without relying on any light. The infrared thermal camera is

applicable to any light environment and is free from glare impact. It can clearly

detect and find the target as well as identify the camouflaged and hidden target in

both day and night. Therefore, it achieves real 24-hour surveillance.

Monitoring the temperature field of the target heat distribution

The infrared thermal camera can display the temperature field of the object and

change the surface temperature distribution of the object that cannot be directly

seen by human eyes to the thermal image representing the surface temperature

distribution of the object. By monitoring the temperature field, you can

immediately identify the temperature abnormality, thereby preventing potential

risks caused by the temperature, such as fire.

Providing the cloud penetration capability

Atmosphere, dust, and clouds can absorb visible light and near infrared, but are

clear to the thermal infrared for 3 to 5 microns (medium wave infrared region) and

8 to 14 micron (long wave infrared). Therefore, it is difficult for the conventional

cameras to capture clear images under dense clouds, while the thermal imaging

camera is able to effectively penetrate the atmosphere and clouds to capture clear

images.

1.2 Device Structure

Figure 1-1 shows the rear panel of the thermal imaging integrated network camera. For

details about the interfaces, see Table 1-1.

1 Product Overview

Thermal Imaging Integrated Network Camera

User Manual

2

Issue V1.0 (2014-01-10)

Figure 1-1 Appearance and interfaces of the thermal imaging integrated network camera

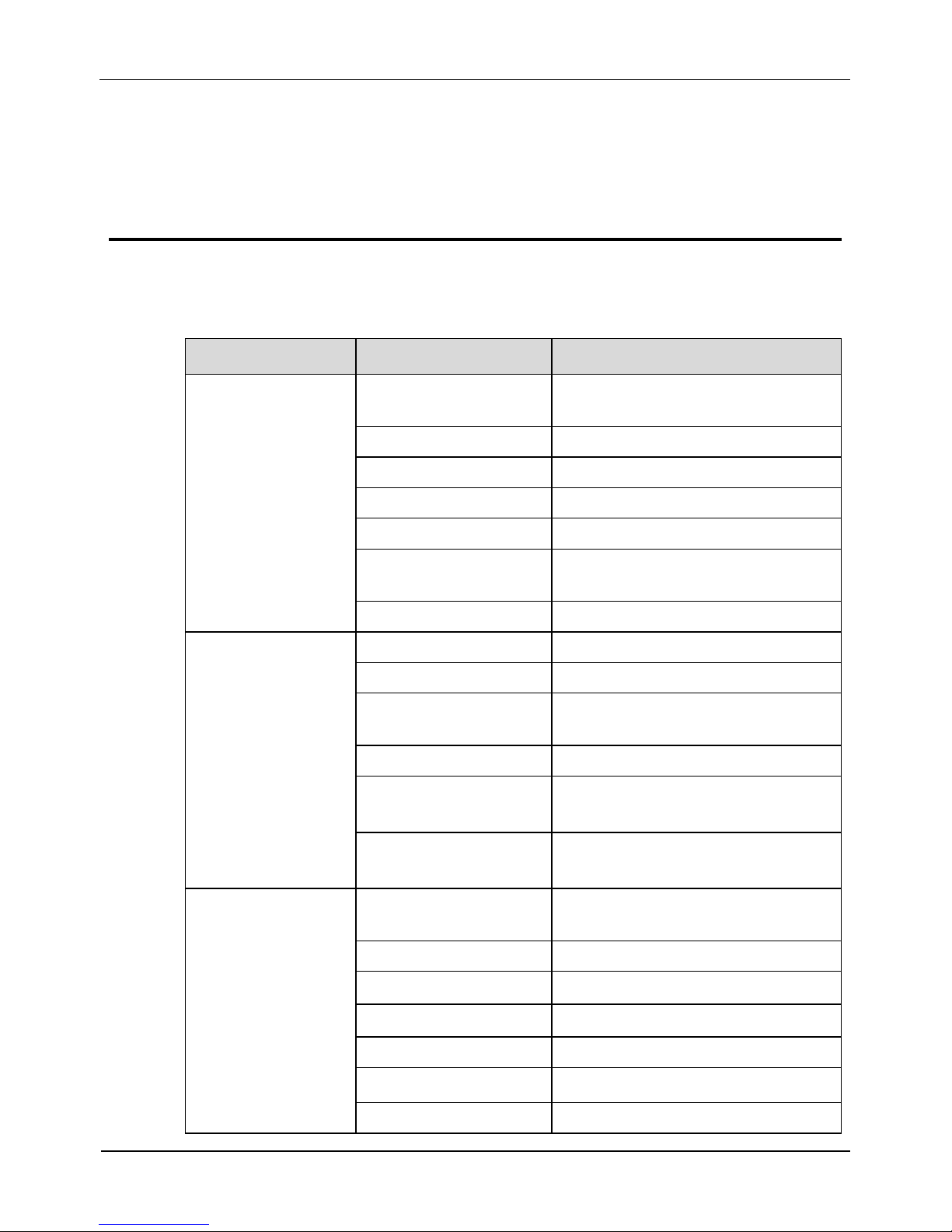

Table 1-1 Interfaces

No.

Physical Interface

Connection

1

Reset button

(RESET)

The configuration resumes to the factory settings

after you press the reset button for 3s. The default

value is 192.168.0.120.

2

Network indicator

Network connection indicator

3

Video output

(VOUT)

It outputs the analog video signals and can be

connected to the TV monitor to view analog

videos.

4

SD card indicator

The SD indicator has the following states:

OFF: The SD card is not inserted.

ON: The SD card is inserted.

5

SD card slot

It houses the SD card.

Note:

When you install the SD card, ensure that the

SD card is not in the write-protection state and

then insert the SD card in the SD card slot.

When you remove the SD card, ensure that the

SD card is not in the write-protection state.

Otherwise, the data may be lost or the SD card

may be damaged.

When hot plugging the SD card, stop recording

and then perform the corresponding operation.

Thermal Imaging Integrated Network Camera

User Manual

1 Product Overview

Issue V1.0 (2014-01-10) 3

1.3 Cable Connection

Figure 1-2 the multi-connector combination cable of the thermal imaging integrated

network camera. For details about the multi-connector combination cable, see Table 1-

2.

Figure 1-2 Multi-connector combination cable

Table 1-2 Multi-connector combination cable

ID

Core of Cable

Functions

Connection

1

Orange

Alarm output 1

negative

Connects to the alarm output

device.

White injected

with black

Alarm output 2

negative

Yellow

Alarm output 1

White injected

with blue

Alarm output 2

gray

Alarm input negative

Connects to the alarm input

device.

Purple

Alarm input 1

Blue

Alarm input 2

2 Network interface

Connects to the standard

Ethernet cable.

3 - Audio input port (cable

input)

Inputs the audio signal and

receives the analog audio

1 Product Overview

Thermal Imaging Integrated Network Camera

User Manual

4

Issue V1.0 (2014-01-10)

ID

Core of Cable

Functions

Connection

signals from the sound pick-up

device.

4 - Audio output

Connects to the external audio

device such as the voice box.

5

Brown

RS485RS+

RS485 interface, connects to

the external pan&tilts.

White

RS485RS-

6 - DC12V (2A)

Power interface, connects to

the 12 V DC power supply.

1.4 Functions and Features

Using the uncooled infrared focal plane sensor

Detecting the infrared wavelength ranging from 8 um to 14 um

420x315 pixels

High thermal sensitivity, reaching 50 mK

Supporting dedicated lens for 8/15/25/35/50 mm focal distance (optional)

Supporting pseudo color mode switching: black hot/white hot/rainbow/ironbow

Supporting the DVE image enhancement

Supporting noise reduction and mirroring

Supporting four coding algorithms, that is, H.264 BP, MP, HP, and MJPEG, and

high compatibility

Outputting three code streams in real time, and satisfying local storage and network

transmission of the video

1-channel audio input and 1-channel audio output, supporting bidirectional voice

talkback

Supporting the local storage of the Micro SD card (the maximum capacity is 32 GB)

and effectively resolving the video loss problem caused by network failure

Supporting NAS storage

Providing software and hardware watchdogs and automatic fault recovery

Linked heat dissipation structure of the metal enclosure

3-axis rotational adjustment structure facilitating installation and adjustment

DC 12 V/POE power supply

Thermal Imaging Integrated Network Camera

User Manual

2 Device Dimensions

Issue V1.0 (2014-01-10) 5

2 Device Dimensions

Figure 2-1 shows the dimensions of the thermal imaging integrated network camera.

Figure 2-1 Dimensions (unit: mm)

3 Installation

Thermal Imaging Integrated Network Camera

User Manual

6

Issue V1.0 (2014-01-10)

3 Installation

3.1 Preparations

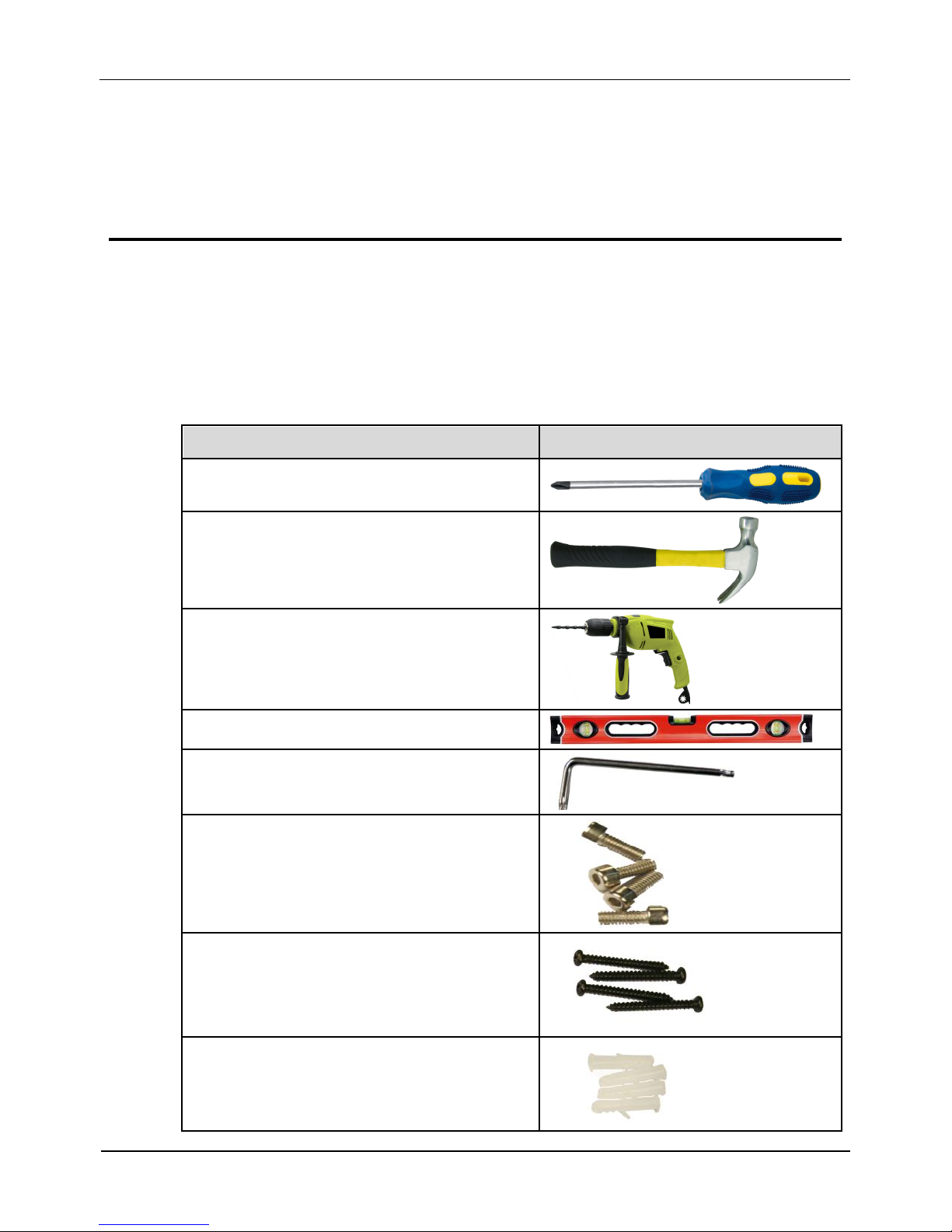

You may need the tools and accessories shown in Table 3-1 during the installation (you

need to prepare the tools by yourself, and the accessories are in the package of the

camera).

Table 3-1 Installation tools

Tools

Appearance

Phillips screwdriver (prepare by yourself)

Claw hammer (prepare by yourself)

Hammer drill (prepare by yourself)

Spirit level (prepare by yourself)

T15 ring spanner (delivered with the

camera)

Stainless hexagon socket head cap screw

(delivered with the camera)

Self-tapping screw (delivered with the

camera)

Inflatable colloidal particle (delivered with

the camera)

Thermal Imaging Integrated Network Camera

User Manual

3 Installation

Issue V1.0 (2014-01-10) 7

3.2 Installation Mode

The thermal imaging integrated camera can be installed on the ceiling or the wall. You

can select the appropriate installation according to your requirements. If the camera

needs to be installed on the cement wall, you need to install the expansion screws (the

mounting holes of the screws must be consistent with that of the support), and then

install the support.

NOTE

The wall where the support is mounted must be able to withstand at least three times of the

total weight of the support and the camera.

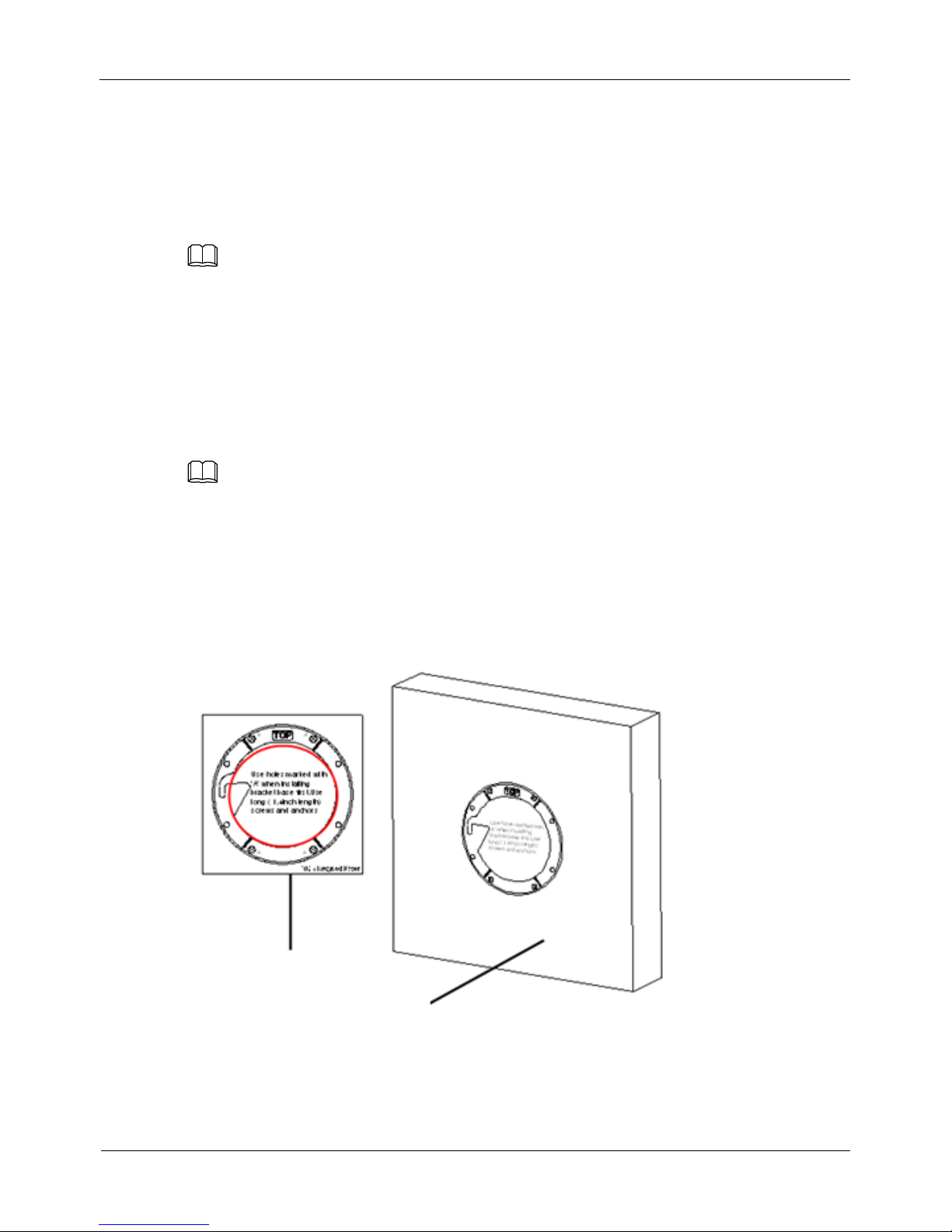

3.3 Installation Procedure

Step 1 Remove the installation location labels delivered with the camera. Stick the installation

location labels on the ceiling or the wall, as shown in Figure 3-1.

NOTE

If the installation uses the back leading mode, pouch a leading-out hole on the ceiling or

the wall, as shown in the area highlighted in red in Figure 3-1. (This manual uses the

back leading mode as an example.)

If the installation uses the side leading mode, lead the multi-connector combination cable

from the side notch on the bottom of the camera.

Figure 3-1 Installation location label

Location label

Wall

Step 2 According to the location hole positions shown in the installation location label, punch

four location holes with diameter 5 mm on the ceiling or the wall.

3 Installation

Thermal Imaging Integrated Network Camera

User Manual

8

Issue V1.0 (2014-01-10)

Step 3 Fix the installation base on the wall, as shown in Figure 3-2.

Figure 3-2 Fixing base

Step 4 Hang the integrated camera into the base along the guide slots and rotate it to a certain

angle to facilitate cable connection, as shown in Figure 3-3.

Figure 3-3 Hanging the integrated camera into the base

Step 5 Connect and conceal the cables for the integrated camera. After the cable connection is

complete, rotate the integrated camera to align at the installation base, as shown in

Figure 3-4.

Thermal Imaging Integrated Network Camera

User Manual

3 Installation

Issue V1.0 (2014-01-10) 9

Figure 3-4 Aligning at the base

Step 6 Fix the integrated camera to the installation base, as shown in Figure 3-5.

Figure 3-5 Fixing the integrated camera to the installation base

Step 7 Align the focusing fixture at the lens grooves, clamp a proper position, grasp the handle

portion of the fixture, and focus along the direction of arrows, as shown in Figure 3-6.

3 Installation

Thermal Imaging Integrated Network Camera

User Manual

10 Issue V1.0 (2014-01-10)

Figure 3-6 Focusing

Focusing fixture

Step 8 Adjust the surveillance angle, as shown in Figure 3-7, and then fix the screws.

Figure 3-7 Adjusting the surveillance angle

1. Loosen the screws 1, and adjust the part 1 along the arrow direction.

The adjustment angle is 360 degrees.

1. Loosen the screws 2, and adjust the part 2 along the arrow direction.

The adjustment angle is 90 degrees.

1. Loosen the screws 3, and adjust the part 3 along the arrow direction.

The adjustment angle is 360 degrees.

Screws 1Screws 2Screws 3

----End

Thermal Imaging Integrated Network Camera

User Manual

4 Quick Configuration

Issue V1.0 (2014-01-10) 11

4 Quick Configuration

4.1 Login and Logout

You must use Internet Explorer 6 or a later version to access the web management

system; otherwise, some functions may be unavailable.

Login system

Step 1 Open the Internet Explorer, enter the IP address of IP camera (default value:

192.168.0.120) in the address box, and press Enter.

The login page is displayed, as shown in Figure 4-1.

Figure 4-1 Login page

Step 2 Input the User and password.

The default name is admin. The default password is admin. Change the password when

you log in the system for first time to ensure system security.

You can change the system display language on the login page.

Step 3 Click Login.

4 Quick Configuration

Thermal Imaging Integrated Network Camera

User Manual

12 Issue V1.0 (2014-01-10)

The main page is displayed.

----End

logout

To logout of system, click Sign out in the upper right corner of the main page, the login

page is display after you log out of the system.

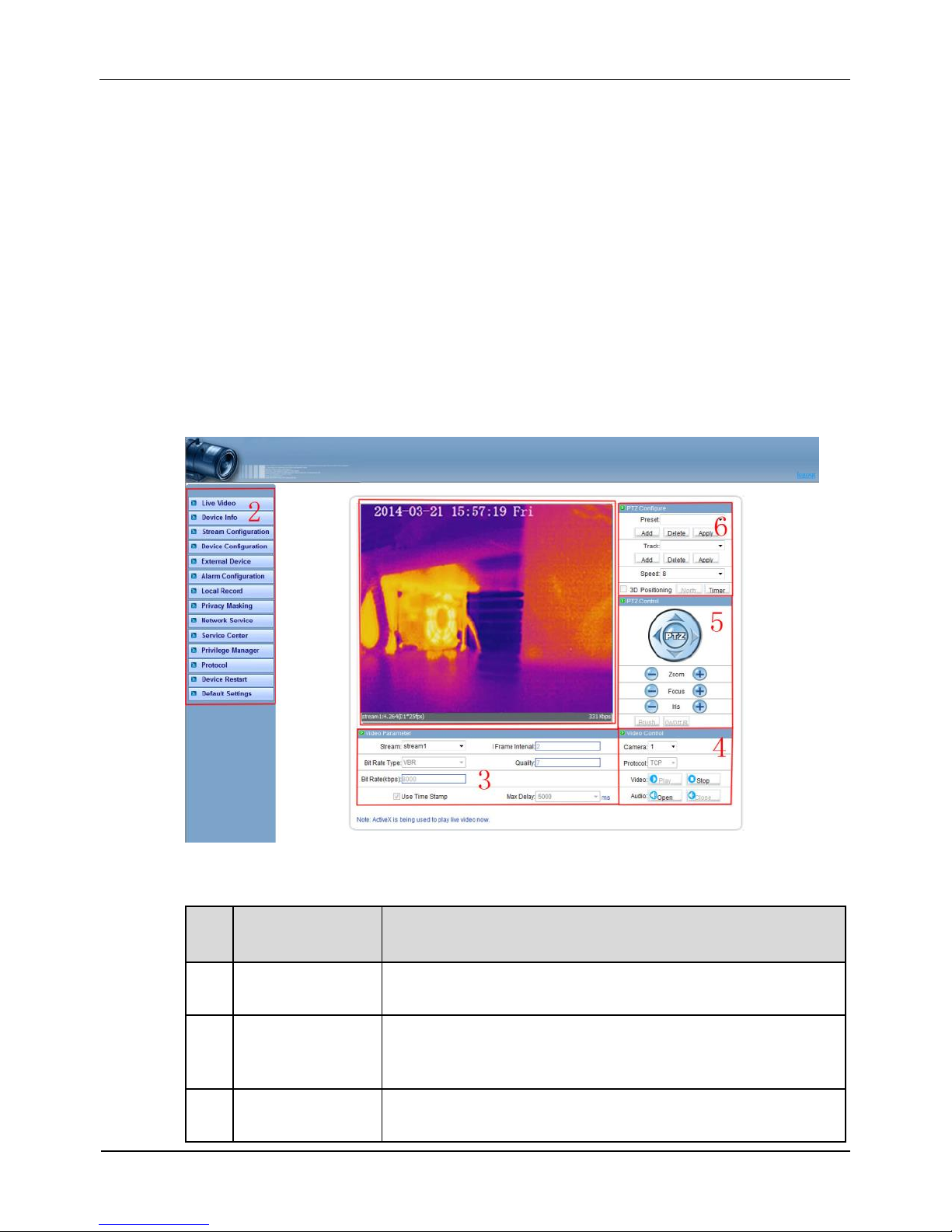

4.2 Main page layout

On the main page, you can view real-time video, set parameter, Video parameter, Video

control, PTZ control, PTZ Configure and log out of the system. Figure 4-2 is shown the

main page layout. Table 4-1 lists the elements on the main page layout.

Figure 4-2 Main page layout

Table 4-1 Elements on the main page

N

O.

Element

Description

1

Real-time video

area

Real-time videos are displayed in this area, You can also

set sensor parameters.

2

Menu area

You can choose a menu to set device parameters,

including the device information, audio and video streams,

alarm setting, and privacy mask function.

3

Video area

Video parameters, such as the I frame interval, bit rate

type, bit rate, and quality, are display.

Thermal Imaging Integrated Network Camera

User Manual

4 Quick Configuration

Issue V1.0 (2014-01-10) 13

N

O.

Element

Description

4

Video control

area

You can perform the following operation in this area:

Switch between cameras.

Start or stop playing Videos.

Start or stop playing audio.

Enable or disable the intercom function

5

PTZ control

You can control the camera direction, zoom in or out, and

change the focal length and aperture for a dome camera or

a camera connected to an external PTZ.

NOTE

Currently the automatic aperture adjustment function is not

support.

6

PTZ

configuration

area

you can perform the following operation in this area:

Add, delete, and invoke the presents and tacks.

Adjust the PTZ rotation speed.

Enable or disable 3D position.

Set the direction to due north.

Set the PTZ timer.

NOTE

PTZ timer function as a time trigger. When it is activated,

the PTZ rotates according to presents and tracks as

scheduled.

The PTZ timer use the time set in camera. Ensure the time is

correct.

This function is available only to a camera with PTZ or

camera connected to external PTZ.

4.3 Browsing Video

User can browse the real-time video in the web management system.

Preparation

To ensure the real-time video can be play properly, you must perform the following

operation when you log in to the web for the first time:

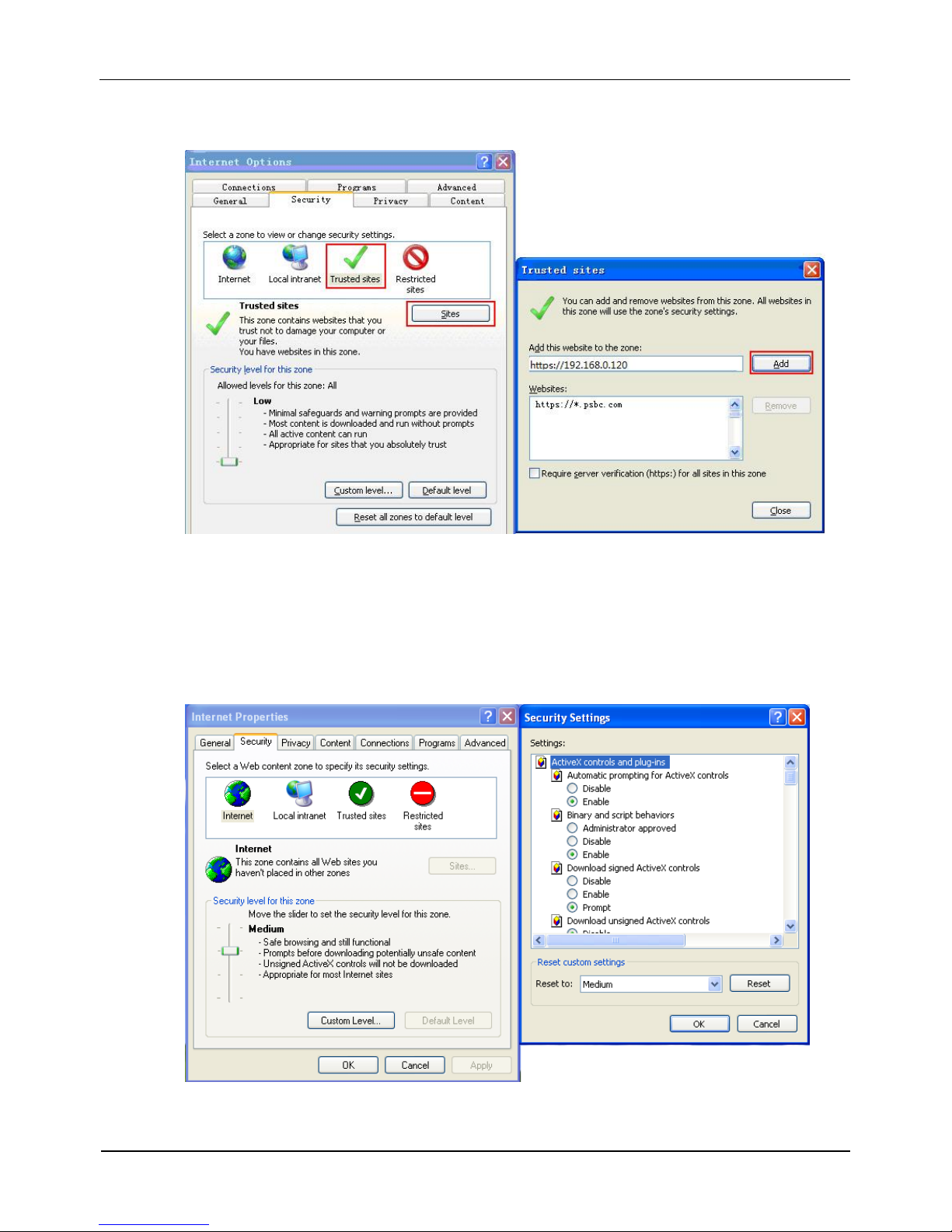

Step 1 Open the Internet Explorer. Choose Tools > Internet options > Security > Trusted

sites > Sites.

4 Quick Configuration

Thermal Imaging Integrated Network Camera

User Manual

14 Issue V1.0 (2014-01-10)

In the display dialog box, click Add, as shown in Figure 4-3.

Figure 4-3 Adding the a trusted site

Step 2 In the Internet Explorer, choose Tool > Internet Options > Security > Customer level,

and set Download unsigned ActiveX control and initialize and script ActiveX controls

not marked as safe for scripting under ActiveX controls and plug-ins to Enable, as

shown in Figure 4-4.

Figure 4-4 Configuring ActiveX control and plug-ins

Step 3 Download and install the player control as prompted.

Thermal Imaging Integrated Network Camera

User Manual

4 Quick Configuration

Issue V1.0 (2014-01-10) 15

The login page is display when the control is loaded.

4.3.2 Download the right control in the Internet Explorer

Preparation

User uses the Internet Explorer browse video.

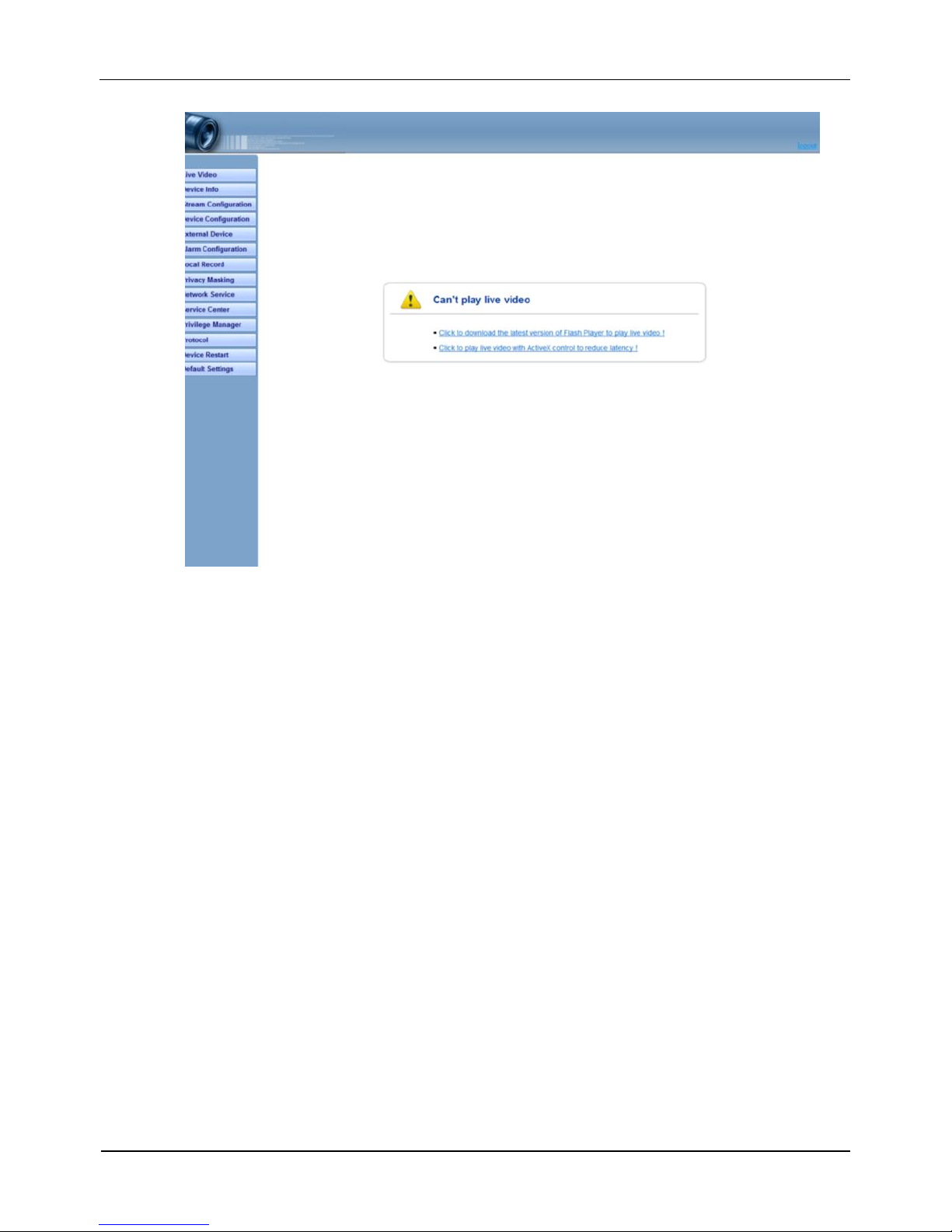

Real-time video page pop-ups the message “clicks to play live video with ActiveX

control to reduce latency” as shown in Figure 4-5.

Figure 4-5 Change the ActiveX

Click the message, jump to download ActiveX control interface, once downloading is

complete, you can watch more fluent video screen.

Unable to display video picture, and need to download and install the control

Preparation

User uses the IE Explorer browse video.

Real-time video page pop-up the message “click to download the latest version of

Flash Play live video” and “click to play video with ActiveX control to reduce

latency” as shown in Figure 4-6.

4 Quick Configuration

Thermal Imaging Integrated Network Camera

User Manual

16 Issue V1.0 (2014-01-10)

Figure 4-6 Download control tips

Click the message “click to play live video with ActiveX control to reduce latency”,

jump download Adobe Flash Player Plugin control interface, once downloading is

complete, you can watch video screen.

Click the message “click to download the latest version of Flash Play live video”, jump

to download ActiveX control interface, once downloading is complete, you can watch

more fluent video screen.

4.3.3 In the Google, Firefox, or Safari browsers watch real-time

video

Google, Firefox, and Safari browsers only support Adobe Flash Player Plugin to play

video. When Adobe Flash Plugin control version is too low, browser will automatically

clew you to download the latest control.

4.4 Setting Local Network Parameters

Description

Local network parameters include:

IP protocol

IP address

Subnet mask

Thermal Imaging Integrated Network Camera

User Manual

4 Quick Configuration

Issue V1.0 (2014-01-10) 17

Default gateway

Dynamic Host Configuration Protocol (DHCP)

Preferred Domain Name System (DNS) server

Alternate DNS server

Procedure

Step 1 Choose Device Configuration > Local Network.

The Local Network page is displayed, as shown in Figure 4-7.

Figure 4-7 Local Network page

Step 2 Set the parameters according to Table 4-2.

Table 4-2 Local network parameters

Parameter

Description

Setting

IP Protocol

IPv4 is the IP protocol that uses

an address length of 32 bits.

[Setting method]

Select a value from the

drop-down list box.

[Default value]

IPv4

4 Quick Configuration

Thermal Imaging Integrated Network Camera

User Manual

18 Issue V1.0 (2014-01-10)

Parameter

Description

Setting

Device obtain an

IP address

automatically

The device automatically

obtains the IP address from the

DHCP server.

[Setting method]

Click the option button.

NOTE

To query the current IP

address of the device, you

must query it on the

platform based on the

device name.

DHCP IP

IP address that the DHCP server

assigned to the device.

N/A

IP Address

Device IP address that can be

set as required.

[Setting method]

Enter a value manually.

[Default value]

192.168.0.120

Subnet Mask

Subnet mask of the network

adapter.

[Setting method]

Enter a value manually.

[Default value]

255.255.255.0

Default Gateway

This parameter must be set if

the client accesses the device

through a gateway.

[Setting method]

Enter a value manually.

[Default value]

192.168.0.1

Preferred DNS

Server

IP address of a DNS server.

[Setting method]

Enter a value manually.

[Default value]

192.168.0.1

Alternate DNS

Server

IP address of a domain server.

If the preferred DNS server is

faulty, the device uses the

alternate DNS server to resolve

domain names.

[Setting method]

Enter a value manually.

[Default value]

192.168.0.2

Step 3 Click OK.

If the message "Network Parameter Updated" is displayed, click OK. The system

saves the settings. The message "Set network params success, Please login system

again" is displayed. Use the new IP address to log in to the web management

system.

If the message "Invalid IP Address", "Invalid Subnet Mask", "Invalid default

gateway", "Invalid primary DNS", or "Invalid space DNS" is displayed, set the

parameters correctly.

Thermal Imaging Integrated Network Camera

User Manual

4 Quick Configuration

Issue V1.0 (2014-01-10) 19

If you set only the Subnet Mask, Default Gateway, Preferred DNS Server, and

Alternate DNS Server parameters, you do not need to log in to the system again.

You can click Reset to set the parameters again if required.

----End

5 Parameter Setting

Thermal Imaging Integrated Network Camera

User Manual

20 Issue V1.0 (2014-01-10)

5 Parameter Setting

5.1 Sensor Configuration Interface

Operation Procedure

Step 1 On the Internet Explorer interface or the client software interface, select and right-click

the surveillance image to the set, as shown in Figure 5-1.

Figure 5-1 Sensor configuration

Step 2 Choose Sensor Configuration. The Sensor Configuration dialog box is displayed.

5.2 Setting Images

Figure 5-2 shows the image setting interface.

Figure 5-2 Image setting interface

Thermal Imaging Integrated Network Camera

User Manual

5 Parameter Setting

Issue V1.0 (2014-01-10) 21

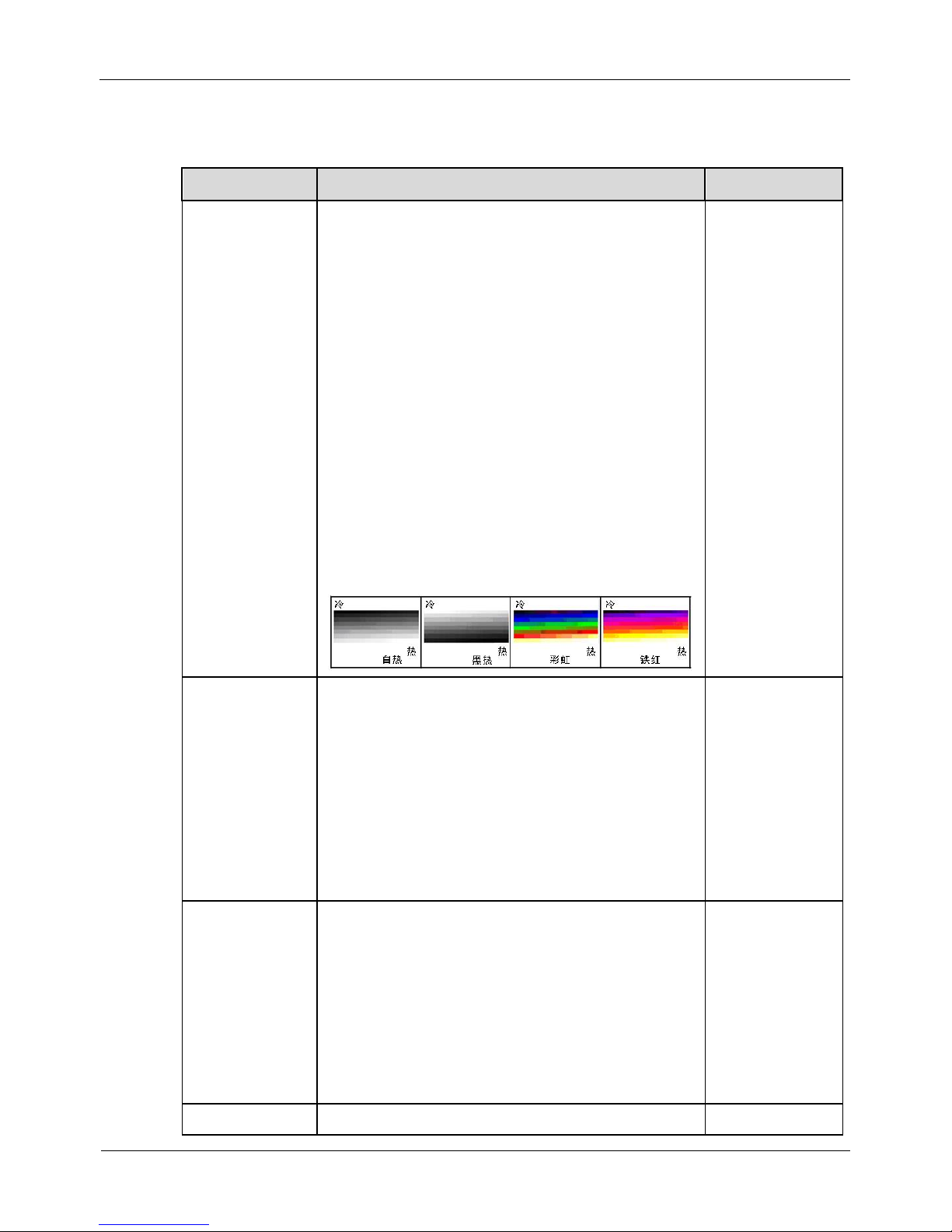

Table 5-1 lists the image setting parameters.

Table 5-1 Image setting parameters

Parameter

Description

Setting

Polarity/LUT

The temperatures of the temperature fields

detected by the thermal imaging camera are

separately mapped to values ranging from 0 to

255 by the algorithm. In the black/white display

mode, this range is converted to the grayscale

tones. For example, 0 indicates completely

black, and 255 indicates completely white. The

temperature field of the scene is converted to

images by using the grayscale ranging from 0 to

255. Different polarity modes can be converted

to different display images. The most common

setting is white hot (a hotter object is displayed

brighter than a colder object) or black hot (a

hotter object is displayed darker than a colder

object). The difference between two modes lies

in that the temperatures corresponding to the

darker one and the lighter one are reversed.

Other modes include rainbow and ironbow.

[How to set]

Select from the

drop-down list

box.

[Default value]

White hot

Dynamic DVE

The sharpness of normal thermographic images

is lower than the visible light and it is difficult to

use the normal thermographic images to identify

the original images of the targets. The image

enhancement and edge processing technology

can be used to get better recognition and

distinguishing effects. The dynamic DVE is

classified into six levels, ranging from 0 to 6.

You can set the DVE according to an actual

requirement.

[How to set]

Select by

dragging the

slider.

[Default value]

Level 1

Contrast

The contrast indicates a contrast between light

and dark images. The higher the value, the

greater the contrast, the darker the dark place,

and the brighter the bright place; the smaller the

value, the smaller the contrast, and the smaller

the difference between bright and dark. The

contrast classified into four levels, ranging from

1 to 4. You can set the contrast according to an

actual requirement.

[How to set]

Select by

dragging the

slider.

[Default value]

Level 4

Mirror

Providing the selection of image pixel locations.

[How to set]

5 Parameter Setting

Thermal Imaging Integrated Network Camera

User Manual

22 Issue V1.0 (2014-01-10)

Parameter

Description

Setting

Off: the image is not flipped.

Horizontal: the image is flipped left and right.

Vertical: the image is flipped up and down.

Horizontal + vertical: the image is rotated at 180

degree.

Select from the

drop-down list

box.

[Default value]

Off

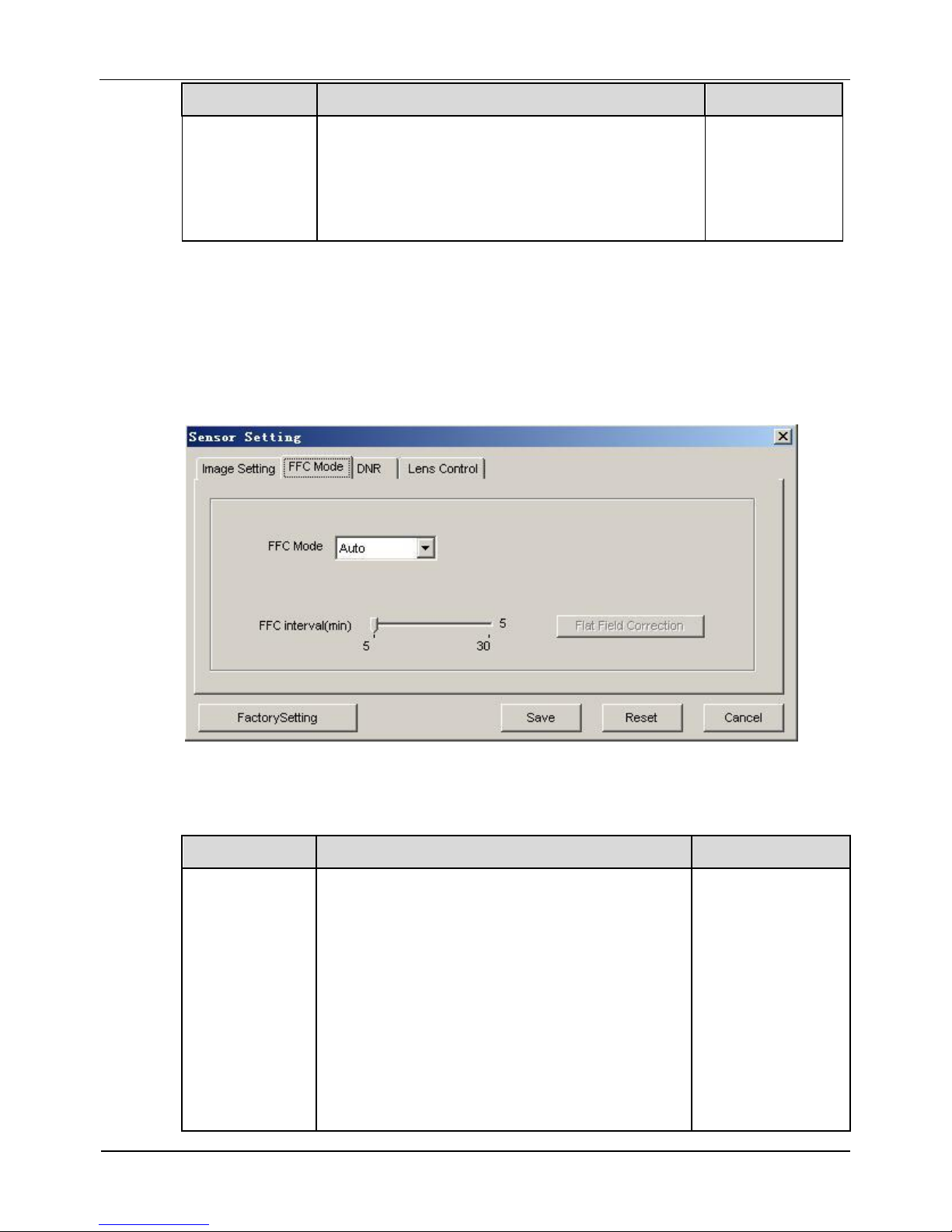

5.3 FEC Mode

Figure 5-3 shows the FFC mode interface.

Figure 5-3 FFC mode interface

Table 5-2 lists the parameters on the FFC mode interface.

Table 5-2 Parameters on the FFC mode interface

Parameter

Description

Setting

FFC Mode

The internal of the thermal imaging camera

may comprise the mechanical action correction

mechanism that can periodically improve the

image quality. This component is called flat

field correction (FFC). When controlling the

FFC, the FFC shields the sensor array, so that

each portion of the sensor can collect uniform

temperature fields (flat field). By means of

FFC, the camera can update the correction

coefficients to output more uniform images.

Throughout the FFC process, the video image

is frozen for two seconds and a static-frame

[How to set]

Select from the

drop-down list

box.

[Default value]

Automatic

Thermal Imaging Integrated Network Camera

User Manual

5 Parameter Setting

Issue V1.0 (2014-01-10) 23

Parameter

Description

Setting

image is displayed. After the FFC is complete,

the image is automatically recovered. Repeated

FFC operations can prevent the grainy and

image degradation problems. The FFC is

especially important when the temperature of

the camera changes. For example, after the

camera is powered on or the ambient

temperature is changed, you should

immediately perform the FFC.

Auto: In the Automatic FFC mode, the camera

performs FFC whenever its temperature

changes by a specified amount or at the end of

a specified period of time (whichever comes

first). When this mode is selected, the FFC

interval (minutes) ranges from 5 to 30 minutes.

The temperature change of the camera is based

on the temperatures collected by the internal

temperature probe. The temperature of the

camera sharply changes when the camera is

powered on. The FFC is relatively frequent,

which is normal.

Manual: In the manual FFC mode, the camera

does not automatically perform the FFC based

on the temperature change or the specified

period. You can press the Do FFC button to

select the manual FFC mode. When you feel

that the image is obviously degraded but the

automatic FFC is not performed, you can use

the manual FFC function to check whether the

image quality can be improved.

External: In the external FFC mode, the

internal mechanical action correction

mechanism is disabled. The uniform source

(black body) is placed in front of the camera.

This feature is useful if there are lens or lens

mount non uniformities that are not corrected

by an internal FFC. The camera will not

perform an FFC process on startup if the saved

state of the camera is External mode FFC.

Many customers have found that the palm of

their hand or a table is an adequate uniform

source to perform an External FCC.

FFC interval

(min)

In the automatic FFC mode, the FFC interval

ranges from 5 to 30 minutes.

[How to set]

Select by

dragging the

slider.

5 Parameter Setting

Thermal Imaging Integrated Network Camera

User Manual

24 Issue V1.0 (2014-01-10)

Parameter

Description

Setting

[Default value]

5

Flat Field

Correction

Manual: In the manual or external FFC mode,

the camera does not automatically perform the

FFC based on the temperature change or the

specified period. You can press the Do FFC

button.

-

5.4 DNR

Figure 5-4 shows the DNR interface.

Figure 5-4 DNR interface

Table 5-3 lists the DNR parameters.

Table 5-3 Parameters on the DNR interface

Parameter

Description

Setting

3DNR

Decrease the image

noise.

[How to set]

Select from the drop-down list box.

[Default value]

Off

2DNR

Decrease the image

noise.

[How to set]

Select from the drop-down list box.

[Default value]

On

Thermal Imaging Integrated Network Camera

User Manual

5 Parameter Setting

Issue V1.0 (2014-01-10) 25

5.5 Lens Control

Figure 5-5 shows the lens control interface.

Figure 5-5 Lens control interface

The electrical focusing lens can be controlled and adjusted.

6 Technical Specifications

Thermal Imaging Integrated Network Camera

User Manual

26 Issue V1.0 (2014-01-10)

6 Technical Specifications

Table 6-1 lists the specifications of the thermal imaging integrated camera.

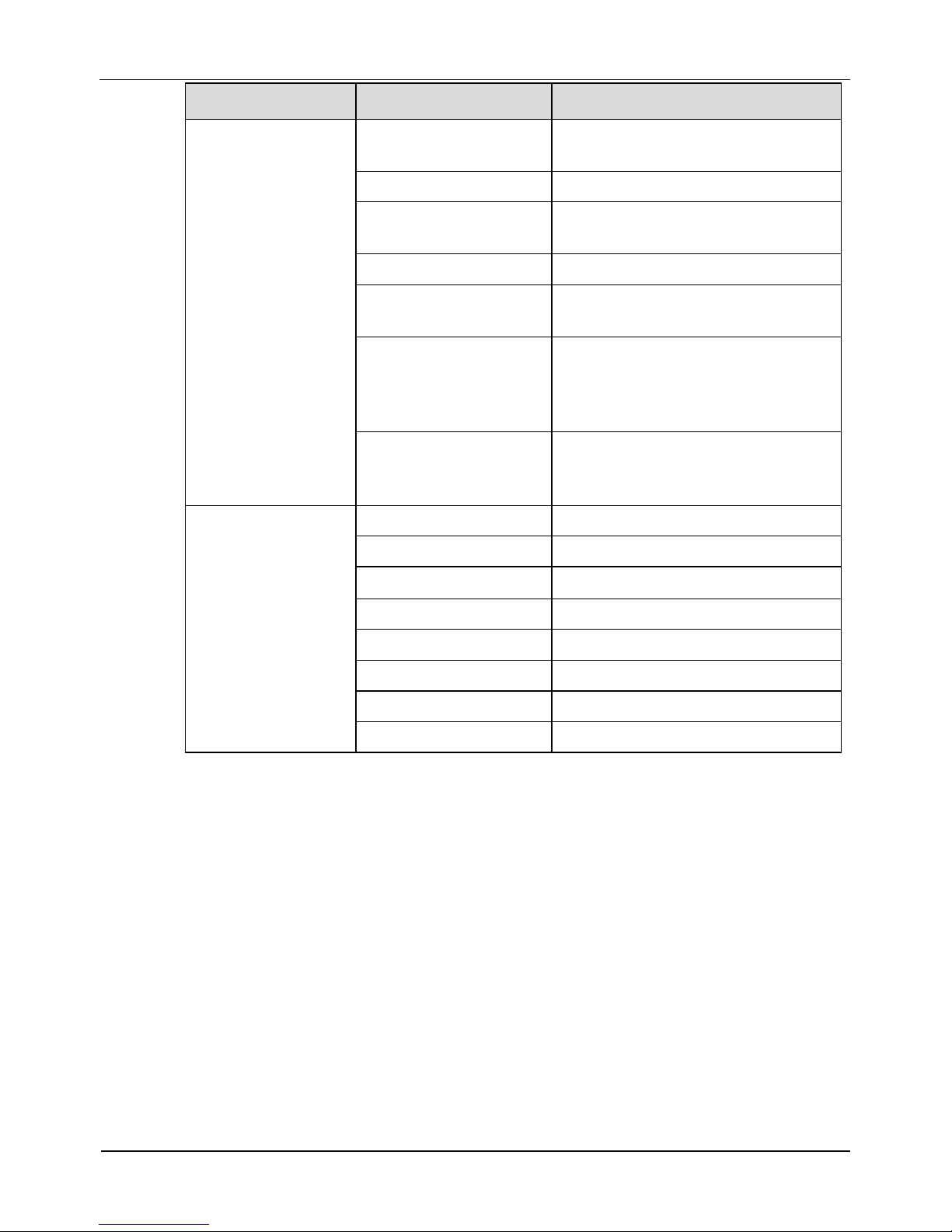

Table 6-1 Technical specifications

Type

Parameter

Description

Detector

performance

Detector type

Uncooled infrared focal plane

sensor

Sensing mode

Microbolometer

Pixel

420x315

Pixel spacing

25 um

Response waveband

8-14 um

Thermal sensitivity

NETD

50 mK

Frame frequency

50/60 Hz

Video features

Prime lens

8/15/25/35/50mm (optional)

Focusing mode

Manual

Field angle

75.4ox54.4o/, 39.7ox29.8o/,

23.7ox17.9o/, 17ox12.8o/11.9ox9o

F value

1.0

Recognition distance

(Human body)

60/110/180/250/350 meters

Recognition distance

(Vehicle)

120/200/350/500/650 meters

Function features

Polarity LUT

Black hot/white

hot/rainbow/ironbow

DVE

Levels 0 to 6

FFC

Auto/manual/external

DNR

Available, 2D/3D

Contrast

Levels 1 to 4

Mirror

Available

OSD display

Available

Thermal Imaging Integrated Network Camera

User Manual

6 Technical Specifications

Issue V1.0 (2014-01-10) 27

Type

Parameter

Description

Imaging feature

Output resolution

D1/CIF

Frame rate

30 fps

Coding features

Video compression

format

H.264BP/MP/HP/MJPEG

Audio compression

format

G711, AMR, and RAW_PCM

Multiple code streams

Support

Bit rate control

CBR/VBR

Adjustment of code

stream range

50 Kb to 4 Mb

Network features

Network protocol

IPv4/v6, RTSP/RTP/RTCP,

TCP/UDP, HTTP, DHCP, DNS,

FTP, DDNS, PPPOE, SMTP, and

SIP

Storage

communication

protocol

CIFS and NFS

WEB management

Embedded WEB service, remote

browsing and configuration over IE

browser

Remote upgrade and

maintenance

Support

Integration

Supporting the international

standard Onvif and the third-party

protocol

Maximum user access

amount

Simultaneous access of 10 users to

the maximum

Interface features

Network interface

RJ-45 and 10/100Base-T

Audio interface

1-channel audio input and 1channel audio output, supporting

bidirectional voice talkback

Alarm interface

2-channel alarm input and 2channel alarm output

Analog video output

interface

BNC, 75Ohm

Pan&tilts control

interface

RS485

SD card connector

Micro SD card/HCSD card, 32 GB

to the maximum

6 Technical Specifications

Thermal Imaging Integrated Network Camera

User Manual

28 Issue V1.0 (2014-01-10)

Type

Parameter

Description

System function

features

Intelligent alarm

Mobile detection alarm, I/O alarm,

and disk alarm

Heartbeat mechanism

Support

Storage

Local storage, NAS storage, and

SD card storage

Privacy mask

5 areas with configurable size

Character display

Time, date, channel No., channel

name and user-defined characters

Security

Password protection, multi-level

user group management, userdefine permissions, and one-key

reset

Reliability

Providing software and hardware

watchdogs and automatic fault

recovery

Physical features

Power supply

DC 12 V/POE

Power consumption

5 W

Operating temperature

-10C to +50C

Operating humidity

RH90% MAX (no condensation)

Protection class

IP66

Installation mode

Wall and ceiling

Dimensions

φ110×388 mm

Weight

About 1900g (25mm lens)

Thermal Imaging Integrated Network Camera

User Manual

Error! Use the Home tab to apply 标题 7 to

the text that you want to appear here.Error!

Use the Home tab to apply 标题 7 to the text

that you want to appear here.

Issue V1.0 (2014-01-10) 29

A Hazardous Substance Declaration

Component

Hazardous Substance or Element

Plumbum

(Pb)

Mercury

(Hg)

Cadmium

(Cd)

Hexavalent

Chromium

(Cr6+)

Polybrominated

Biphenyls (PBB)

Polybrominated

Diphenyl Ethers

(PBDE)

Structural

part

× ○ ○ ○ ○

○

Board/circuit

module

× ○ ○ ○ ○

○

Cable

connector

× ○ ○ ○ ○

○

Accessories

× ○ ○ ○ ○

○

○: indicates that the concentration of the hazardous substance in all homogeneous substances of the

component is within the limit specified in SJ/T 11363-2006 Requirements for Concentration

Limits for Certain Hazardous Substances in Electronic Information Products.

×: indicates that the concentration of the hazardous substance in at least one homogeneous substance

of the component exceeds the limit specified in SJ/T 11363-2006 Requirements for Concentration

Limits for Certain Hazardous Substances in Electronic Information Products.

101-300-0211-01

Loading...

Loading...