Page 1

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc. 1 August 14, 2019

Description

The ZMOD4510 Evaluation Kit (EVK) is designed for evaluating

IDT’s ZMOD4510 Gas Sensor Module for Total Outdoor Air Quality

(OAQ). The sensor module is optimized for the detection of trace

atmospheric gases, including nitrogen oxides (NOx) and ozone

(O3) and reporting an Air Quality Index (AQI) based on the standard

of the US Environmental Protection Agency (EPA).

IDT’s Gas Sensor Evaluation Software allows Windows®-based

operating systems to communicate with the ZMOD4510 EVK via a

USB connection on the user’s computer, which functions as a

master. The software and additional related documentation is

available on the IDT website.

The EVK’s Communication Board (HiCom) handles the interface

between the user’s computer and the ZMOD4510 module mounted

on the ZMOD4510 Sensor Board (i.e., daughter board). Note: Only

one Communication Board with one Sensor Board can be

connected to the computer at a time.

The ZMOD4510 Evaluation Kit uses an FTDI controller on the

Communication Board to handle the USB protocol, translate

communications, and synchronize communications with the I2C

interface. The Sensor Board includes a decoupling capacitor.

The Communication Board has devices mounted on both sides.

The components on the top side generate a stable supply voltage.

A potentiometer can be used to adjust the internal supply voltage

in the typical range from 1.7V to 3.6V. Alternatively, the user’s

external supply voltage can be used. The intensity of the adjacent

LED is proportional to the supply voltage.

ZMOD4510 Evaluation Kit

Features

User-friendly EVK expedites configuration and evaluation of

the ZMOD4510 Total Outdoor Air Quality Sensor

Operates with IDT provided software; either with executable

ZMOD4510 GUI or alternatively with firmware programming

examples for Windows® and Linux®

The modular design of the EVK allows simple connection of

Sensor Boards for different gas sensor derivatives and easy

integration with other sensor products via the I2C interface.

The required Gas Sensor Evaluation Software is available for

free download on the IDT website, which also provides

background information on outdoor air quality and sensor

programming.

Additional pins provided to measure power consumption,

supply voltage, and the GPIO trigger for an external device

The bill of materials (BOM) and schematics for the

ZMOD4510 Communication Board and Sensor Board are

included in this document.

ZMOD4510-EVK Contents

HiCom Communication Board

Sensor Board with ZMOD4510 Gas Sensor Module

3.0m Type-B USB to Micro-USB Cable

USB Cable to Computer

HiCom Communication Board

ZMOD4510

Sensor Board

ZMOD4510

Page 2

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc. 2 August 14, 2019

Important Notes

Disclaimer

Integrated Device Technology, Inc. and its affiliated companies (herein referred to as “IDT”) shall not be liable for any damages arising out of defects resulting from

(i) delivered hardware or software

(ii) non-observance of instructions contained in this manual and in any other documentation provided to the user, or

(iii) misuse, abuse, use under abnormal conditions, or alteration by anyone other than IDT.

TO THE EXTENT PERMITTED BY LAW, IDT HEREBY EXPRESSLY DISCLAIMS AND USER EXPRESSLY WAIVES ANY AND ALL WARRANTIES, WHETHER

EXPRESS, IMPLIED, OR STATUTORY, INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A

PARTICULAR PURPOSE, STATUTORY WARRANTY OF NON-INFRINGEMENT, AND ANY OTHER WARRANTY THAT MAY ARISE BY REASON OF USAGE

OF TRADE, CUSTOM, OR COURSE OF DEALING.

Restrictions in Use

IDT’s ZMOD4140 Evaluation Kit, consisting of the HiCom Communication Board, ZMOD4510 Sensor Board, and the ZMOD4510 Evaluation Software, is designed

for evaluation purpose only. IDT’s ZMOD4510 Evaluation Kit must not be used for calibration, test, qualification, production or usage in safety-critical or life-

protecting applications.

Important Equipment Warning: Ensure the correct connection of all cables. Supplying the board using the wrong

polarity could result in damage to the board and/or the equipment. Check that all jumpers have been placed as

specified in this document.

Contents

1. Setup ............................................................................................................................................................................................................4

1.1 Required or Recommended User Equipment ......................................................................................................................................4

1.2 User Computer Requirements .............................................................................................................................................................4

1.2.1 Computer Requirements ......................................................................................................................................................4

1.3 Software Installation and Setup ...........................................................................................................................................................4

1.4 EVK Hardware Connections and Initial Power-up ...............................................................................................................................5

2. Usage Guide .................................................................................................................................................................................................8

2.1 Measurement Control Block ................................................................................................................................................................8

2.2 Signal Analysis Block ..........................................................................................................................................................................9

2.3 Plot Visualization Block .......................................................................................................................................................................9

3. Schematics .................................................................................................................................................................................................10

4. Bill of Materials (BOM) ................................................................................................................................................................................13

5. Board Layout ..............................................................................................................................................................................................15

6. Ordering Information ...................................................................................................................................................................................17

7. Revision History ..........................................................................................................................................................................................17

!

Page 3

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc. 3 August 14, 2019

List of Figures

Figure 1. Initial Display after Installation of the Gas Sensor Evaluation Software ..............................................................................................5

Figure 2. Jumper Settings, LEDs, and Connectors on Top Side of ZMOD4510 Communication Board ............................................................6

Figure 3. Jumper Settings, Connections, and Test Points on Communication Board for the Internal or External Supply Voltage .....................7

Figure 4. Initial Display for the ZMOD4510 Start-up ...........................................................................................................................................8

Figure 5. Communication Board Schematic – Page 1 ......................................................................................................................................10

Figure 6. Communication Board Schematic – Page 2 ......................................................................................................................................11

Figure 7. Sensor Board Schematic ...................................................................................................................................................................12

Figure 8. HiCom Communication Board Layout – Top Layer ...........................................................................................................................15

Figure 9. HiCom Communication Board Layout – Bottom Layer ......................................................................................................................15

Figure 10. Sensor Board Layout – Top Layer .....................................................................................................................................................16

Figure 11. Sensor Board Layout – Bottom Layer ...............................................................................................................................................16

List of Tables

Table 1. Evaluation Kit Connection Descriptions ...............................................................................................................................................6

Table 2. Signal Analysis Block User Options ....................................................................................................................................................9

Table 3. Communication Board BOM ..............................................................................................................................................................13

Table 4. Sensor Board BOM ...........................................................................................................................................................................15

Page 4

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc. 4 August 14, 2019

1. Setup

1.1 Required or Recommended User Equipment

By default, the internal supply voltage for powering the Sensor Board is generated from the USB voltage supplied by the user’s computer via

the USB cable. If there is a need for currents higher than the defined USB standard (usually 500mA at 5V), an external voltage supply source

can be used instead of the internally generated voltage supply provided on the Communication Board.

The external supply only powers the sensor modules, and not the communication board itself. The supply must meet the following requirements:

Voltage – 1.7V to 3.6V

Current must meet the user’s specifications – The minimum is 30mA for electronics with additional current needed for each gas sensor

module of approximately 11mA (with a 1.8V voltage supply).

1.2 User Computer Requirements

1.2.1 Computer Requirements

A Windows-based computer is required for interfacing with the EVK and configuring the ZMOD4510. The user must have administrative rights

on the computer to download and install the Gas Sensor Evaluation Software.

The computer must meet the following requirements:

1GB RAM

Hard drive with at least 250MB free space

1 USB port

Windows Vista

®

/Windows 7®/Windows 8®/Windows 10®

Internet access for initial download of the drivers and software

Important: Before installing and activating the software, assemble and connect the hardware for the kit to the user’s computer according to

steps 1 through 3 in “EVK Hardware Connections and Initial Power-up.”

1.3 Software Installation and Setup

Before using the Gas Sensor Evaluation Software, the USB drivers for the FTDI device must be installed. Download the drivers and

corresponding installation guides from the FTDI website (www.ftdichip.com). The drivers will not affect the operation of any other USB

peripherals. The kit does not need to be connected during installation of the drivers.

Complete the following procedure to download and install the ZMOD4510 Evaluation Software with the kit connected:

1. Download the ZMOD4510 Gas Sensor Evaluation Software zip file at www.IDT.com/ZMOD4510-EVK.

2. Create a folder on the user’s computer for the software (e.g., C:\Program Files (x86)\IDT Software). Extract the contents of the

downloaded zip file into this folder.

3. Double-click on the extracted executable file Gas_Sensor_Evaluation.bat to start the software each time the program is used and

select the ZMOD4510 – Outdoor Air Quality option. Figure 1 shows the initial display after execution.

Page 5

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc. 5 August 14, 2019

Figure 1. Initial Display after Installation of the

Gas Sensor Evaluation

Software

1.4 EVK Hardware Connections and Initial Power-up

To set up the EVK hardware before using the software, complete the following procedure:

1. Refer to Figure 2, Figure 3, and Table 1 to determine the correct jumper settings for the ZMOD4510 Communication Board depending on

whether an external supply or the internal voltage supply on the board is used.

If the internal voltage supply is used, ensure that the jumper is across the pins labeled “int” on the K2 connector.

If using an external supply, ensure that the jumper is across the pins labeled “ext” on the K2 connector. In this case, without

connecting the external supply to the Communication Board, verify that the external voltage supply setting does not exceed the

voltage supply specifications (i.e., a minimum of 1.7V and a maximum of 3.6V) as per the ZMOD4510 Datasheet. With the external

supply off, connect the external voltage to the 2-pin “+ - V ext” header adjacent to the K2 jumper with the orientation indicated in

Figure 3. Note: If this option is used, adjustments of the external voltage are not possible on either the Communication Board or the

Sensor Board for adjusting an external voltage supply.

2. Install the ZMOD4510 Sensor Board on the 14-pin connector on the Communication Board, taking care to ensure the proper orientation

of the Sensor Board as shown on page 1.

3. Insert the micro-USB cable into the X1 connector on the Communication Board and connect it to a free USB port on the user’s computer.

If the external voltage supply has been selected, turn on the external supply and verify that the D3 LED adjacent to the potentiometer is

on (see Figure 2). Note: The intensity of the green D3 LED is proportional to the supply voltage.

4. Activate the software as described in “Software Installation and Setup”.

5. If the internal voltage is used, the Gas Sensor Evaluation Software activates the internal voltage after the sensor has been started. Use

the metal potentiometer to the left of the K2 connector to adjust the VDD supply voltage in the typical range from 1.7V to 3.6V as

measured across the V_TGT and GND pins available on the K3 connector as shown in Figure 3. Its initial adjustment on delivery

provides a voltage of VDD ≈ 2.0V. Once a measurement has been started by the software, the green D3 LED adjacent to K2 will light

with an intensity proportional to the voltage supply that was set using the potentiometer.

6. Verify that the red D1 LED is on, which indicates that the kit is properly connected and powered (see Figure 2).

The Communication Board provides the additional K3 and Modul1 connectors for the following optional uses as described in Table 1. To make

use of any of these options, contact IDT for further instructions (see contact information on last page).

Extra measurement options (e.g., current consumption to determine the power requirements of the ZMOD4510)

Connections for additional sensors (e.g., IDT humidity sensor HS3001)

Page 6

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc. 6 August 14, 2019

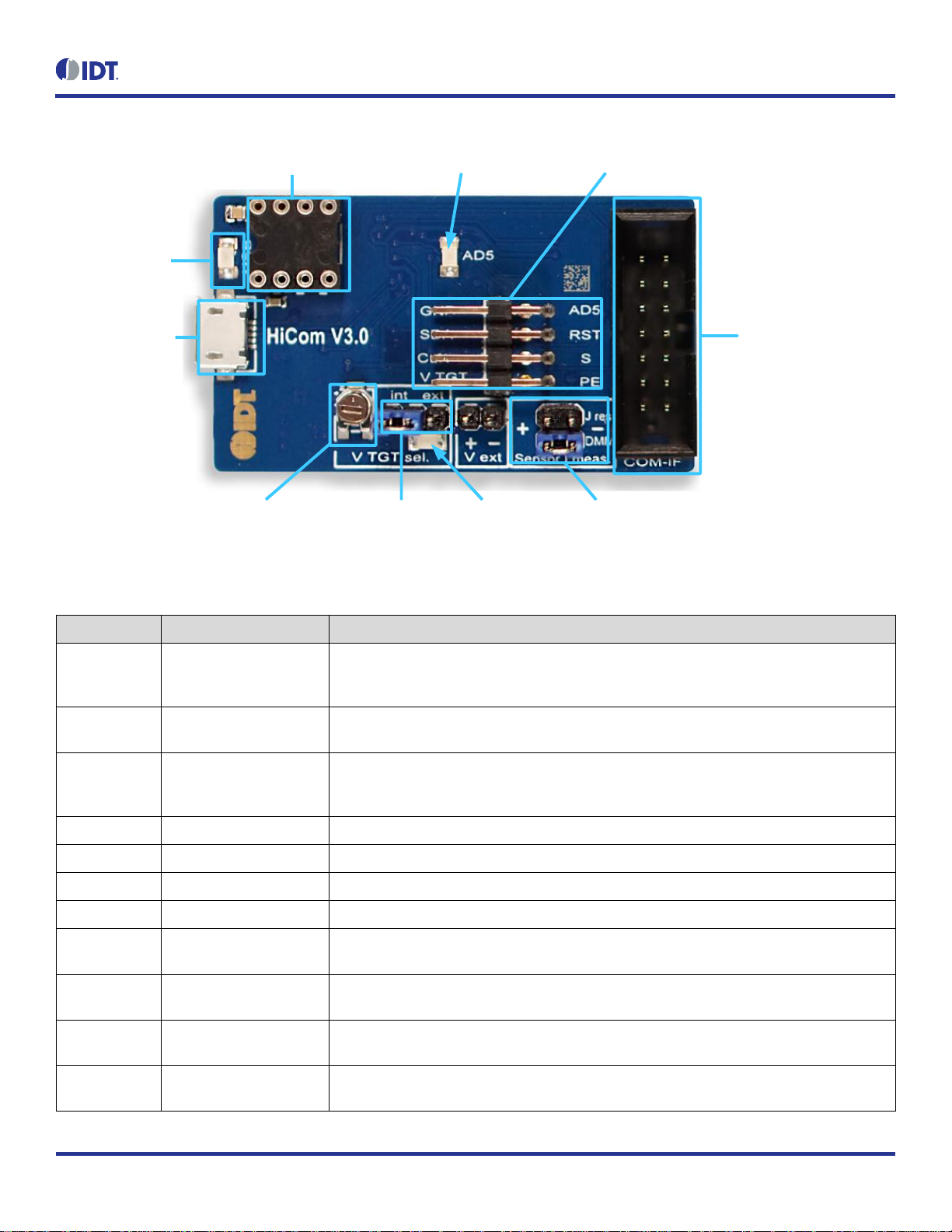

Figure 2. Jumper Settings, LEDs, and Connectors on Top Side of ZMOD4510 Communication Board

Select Internal or

External Supply for

Sensor Board (K2)

Potentiometer for

Setting Supply

Voltage (R19)

Current Measurement

Direct or Shunt Resistor (K1)

14-Pin Connector for

Sensor Board (K4)

8-Pin, 2-Row Connector (K3)

Micro USB B-Type

Connector (X1)

Status LED (D1)

External Sensor Socket (Modul1) AD5 Status LED (D2)

Internal Supply

Status LED (D3)

Table 1. Evaluation Kit Connection Descriptions

Connector

Type

Description

K1

4-pin, 2-row header

This jumper can be used to break the supply voltage line to measure the current consumption of

a connected Sensor Board. Important: During normal operation, ensure that a jumper is on the

“DMM” position as shown in Figure 2.

K2

3-pin header

This jumper selects either the internal or external voltage supply. For the proper position for the

jumper, see Figure 3.

K3

8-pin, 2-row right-angle

header

This connector can be used to connect the ZMOD4510 in different configurations or to measure

the communication lines and voltages on the ZMOD4510 Sensor Board. AD5 is a GPIO pin that

can be controlled via the software.

K4

14-pin connector

This is the connector for installing the ZMOD4510 Sensor Board on the Communication Board.

K5

2-pin header

This is the connector for an optional external voltage supply (see Figure 3).

D1

Status LED

This LED lights if the Communication Board is powered correctly (see Figure 2).

D2/AD5

Status LED

This LED lights if the trigger pin is set by the software (see Figure 2).

D3

Status LED

This LED will light with an intensity proportional to the internal voltage supply that was set using

the potentiometer (see Figure 2).

X1

Micro-USB B-type

This is the micro-USB cable connector for connecting the Communication Board to the user’s

computer.

R19

Potentiometer

This potentiometer adjusts the internal supply voltage. The internal supply voltage can be

adjusted by rotating the potentiometer with a small screwdriver.

Modul1

DIL socket

This socket can be used to add external components (e.g., a humidity sensor) to the

Communication Board. For further instructions, contact IDT.

Page 7

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc. 7 August 14, 2019

Figure 3. Jumper Settings, Connections, and Test Points on Communication Board for the Internal

or External Supply Voltage

K2 Jumper:

If using the internal supply, set

the jumper to the intposition

If using an external supply, set

the jumper to the extposition

V ext + External Positive Supply K5

V ext – External Negative Supply K5

V_TGT pin on K3 (Bottom)

GND pin on K3 (Bottom)

GPIO (AD5) on K3 (Top)

Page 8

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc. 8 August 14, 2019

2. Usage Guide

When the Gas Sensor Evaluation Software with the ZMOD4510 – Outdoor Air Quality option is started, the initial window is displayed as shown

in Figure 4.

The initial display consists of three blocks:

Measurement Control

Signal Analysis

Plot Visualization

Figure 4. Initial Display for the ZMOD4510 Start-up

Measurement Control

Signal Analysis

Plot Visualization

2.1 Measurement Control Block

The “Measurement” area of the display allows users to start the ZMOD4510’s gas measurements. When the “start sensor” button is clicked,

the button name changes to “stop sensor” and the measurement starts running continuously with the given sample time (the default is 1 minute).

The results will be saved in a comma separated file (CSV), which is user-selected via the file and path selection dialog when the sensor is

started.

A comment (e.g., “Start test”) can be added to the data entry by adding a text string to the “Add comment to next measurement” field and then

clicking the “ok” button. If a measurement is already in progress, the comment will be added to the next measurement. The comments will be

displayed in the plot and will be saved in the CSV result file. This facilitates tracking the user’s experimental investigations. Below this entry

field, a small window with a log field shows all events logged.

Page 9

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc. 9 August 14, 2019

2.2 Signal Analysis Block

Table 2. Signal Analysis Block User Options

Display Section

Button/Action

Description

Display

The “clear memory” button will delete all current data from the plots (memory). The data

in the measurement file will remain.

If measurements are acquired simultaneously for multiple ZMOD4510 gas sensors, the

measurement results file can contain data from different sensors. In the “Sensor” dropdown menu, the user can choose a sensor to display by selecting the unique sensor

identification number.

The drop-down menu adjacent to the “show” button provides options for selecting the

time period for showing the recent history or the complete data. Click the “show” button

to apply new settings to the plots.

Algorithm Result

The first 10 measurements of the algorithm will be taken for sensor stabilization. During

this time, the “Algorithm Result” section will indicate the completion progress. Note that

this does not cover the full stabilization of the sensor module. Recommendation: The

ZMOD4510 has a sample time of 1 minute for these 10 measurements resulting in 10

minutes for the initialization measurements.

After the stabilization measurements, the “Air Quality Index” (AQI) is shown in six

categories:

0 to 50 Good Air Quality

51 to 100 Moderate Air Quality

101 to 150 Unhealthy Air Quality for Sensitive Groups

151 to 200 Unhealthy Air Quality

201 to 300 Very Unhealthy Air Quality

> 300 Hazardous Air Quality

2.3 Plot Visualization Block

The lower half of the display provides a visualization of the data. This plot shows the AQI based on the standard of the US Environmental

Protection Agency (EPA). For additional information, including application notes, white papers and blogs, visit www.idt.com/ZMOD4510.

Page 10

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc.

10

August 14, 2019

3. Schematics

Figure 5. Communication Board Schematic – Page 1

Page 11

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc.

11

August 14, 2019

Figure 6. Communication Board Schematic – Page 2

Page 12

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc.

12

August 14, 2019

Figure 7. Sensor Board Schematic

Page 13

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc.

13

August 14, 2019

4. Bill of Materials (BOM)

Table 3. Communication Board BOM

Position

Name

Value

Package

1

C3

10µF/16V

0805

2

C5

100nF

0603

3

C6

10nF

0805

4

C7

100nF

0603

5

C8

100nF

0603

6

C9

10µF/16V

0805

7

C10

10µF/16V

0805

8

C11

10µF/16V

0805

9

C12

100nF

0603

10

C13

100nF

0603

11

C14

100nF

0603

12

C15

100nF

0603

13

C16

100nF

0603

14

C17

10µF/16V

0805

15

C18

27pF

0603

16

C19

27pF

0603

17

C20

10µF/16V

0805

18

C21

10µF/16V

0805

19

C22

100nF

0603

20

C23

100nF

0603

21

C24

10µF/16V

0805

22

C25

100nF

0603

23

C26

100nF

0603

24

C27

10µF/16V

0805

25

C28

100nF

0603

26

C29

10µF/16V

0805

27

C30

100nF

0603

28

C31

220nF

0805

29

D1

LED 1206RT

1206-DIODE

30

D2

LED 1206GN

1206-DIODE

31

D3

LED 1206GN

1206-DIODE

32

D4

SD0805S040S0R1-SCHOTTKY

0805-DIODE

33

IC1

LP38692-adj

SOT-223-5

Page 14

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc.

14

August 14, 2019

Position

Name

Value

Package

34

IC2

LP38692-adj

SOT-223-5

35

IC3

93LC46B

SOT23-6

36

IC4

FT2232HL

LQFP64

37

IC6

SN74LVC1T45

SOT23-6

38

IC8

SN74LVC2T45DCT

SSOP8_0,65

39

K1

I_meas

2X02

40

K2

Select

1X03

41

K3

K2X4

2X04-90

42

K4

K2X7

LH-14

43

K5

V_EXT

1X02

44

L1

10µH

1210

45

L2

10µH

1210

46

L3

10µH

1210

47

Modul1

Honeywell480-3652-1-ND

DIL8 SMD Socket

48

Q1

12.00MHz

QUARZ-ABM3

49

R1

1kΩ

0805

50

R2

1kΩ

0805

51

R3

1.6kΩ

0805

52

R4

12kΩ

0805

53

R5

47kΩ

0805

54

R6

2.2kΩ

0805

55

R7

10kΩ

0805

56

R8

1kΩ

0805

57

R13

51Ω

0805

58

R15

51Ω

0805

59

R16

10Ω

0805

60

R17

1kΩ

0805

61

R18

470Ω

0805

62

R19

2.0kΩ

TRIMMER-3142 SERIES

63

R20

1kΩ

0805

64

R21

10kΩ

0805

65

R22

2.0kΩ

0805

66

R23

2.0kΩ

0805

67

X1

USB-micro-B-5pol-SMD-Bu

USB-MICRO_TYPB_AMTEK

Page 15

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc.

15

August 14, 2019

Table 4. Sensor Board BOM

Designator

Quantity

Manufacturer

Manufacturer Part Number

C1 2 Taiyo Yuden

LMK105BJ104KV-F

U1

1

IDT

ZMOD4510

X1

1

Sullins

SFH11-PBPC-D07-ST-BK

5. Board Layout

Figure 8. HiCom Communication Board Layout – Top Layer

Figure 9. HiCom Communication Board Layout – Bottom Layer

Page 16

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc.

16

August 14, 2019

Figure 10. Sensor Board Layout – Top Layer

Figure 11. Sensor Board Layout – Bottom Layer

Page 17

ZMOD4510 Evaluation Kit User Manual

© 2019 Integrated Device Technology, Inc.

17

August 14, 2019

6. Ordering Information

Orderable Part Number

Description

ZMOD4510-EVK-HC

ZMOD4510 Evaluation Kit including the ZMOD4510 Sensor Board, HiCom Communication Board (USB Interface)

and Micro-USB Cable. The Gas Sensor Evaluation Software is available for download free of charge on

www.IDT.com/ZMOD4510-EVK

7. Revision History

Revision Date

Description of Change

August 14, 2019

Initial release.

Corporate Headquarters

6024 Silver Creek Valley Road

San Jose, CA 95138

www.IDT.com

Sales

1-800-345-7015 or 408-284-8200

Fax: 408-284-2775

www.IDT.com/go/sales

Tech Support

www.IDT.com/go/support

DISCLAIMER Integrated Devic e Technology, Inc. (IDT) and its affiliated companies (herein referred to as “IDT”) reserve the right to modify the products and/or specifications described herein at an y time,

without notice, at IDT's sole discretion. Performanc e specifications and operating parameters of the described products ar e determined in an independent s tate and are not guarantee d to perform the same

way when installed in customer products . The information contained herein is provided without repres entation or warranty of a ny kind, whether express or implied, including, but not limited to, the suitability

of IDT's products for any particular purpose, an implied warranty of merchantability, or non-infringem ent of the intellectual property rights of others. This document is presented only as a guide and does not

convey any license under intellectual property rights of IDT or any third parties.

IDT's products are not i ntended for use in applicati ons involving extreme environmental conditions or in life support systems or similar devices where the failure or malfunction of an IDT product can be

reasonably expected to significantly affect the health or safety of users. Anyone using an IDT product in such a mann er does so at their own risk, absent an express, written agreement by IDT.

Integrated Device Technology, IDT and the IDT logo are trademarks or registered trademarks of IDT and its subsidiaries in the United States and other countries. Other tr ademarks used herei n are the

property of IDT or their respective third party owners. For datasheet type definitions and a glossary of common terms, visit www.idt.com/go/glossary. All contents of this document are copyright of Integrated

Device Technology, Inc. All rights reserved.

Loading...

Loading...