Page 1

IDT

Tsi620 Evaluation Board

User Manual

60D7000_MA001_03

August 7, 2009

6024 Silver Creek Valley Road San Jose, California 95138

Telephone: (408) 284-8200 • FAX: (408) 284-3572

Printed in U.S.A.

©2009 Integrated Device Technology, Inc.

Page 2

Integrated Device Technology, Inc. ("IDT") reserves the right to make changes to its products or specifications at any time, without notice, in order to improve design or

performance. IDT does not assume responsibility for use of any circuitry described herein other than the circuitry embodied in an IDT product. Disclosure of the information

herein does not convey a license or any other right, by implication or otherwise, in any patent, trademark, or other intellectual property right of IDT. IDT products may

contain errata which can affect product performance to a minor or immaterial degree. Current characterized errata will be made available upon request. Items identified

herein as "reserved" or "undefined" are reserved for future definition. IDT does not assume responsibility for conflicts or incompatibilities arising from the future definition

of such items. IDT products have not been designed, tested, or manufactured for use in, and thus are not warranted for, applications where the failure, malfunction, or

any inaccuracy in the application carries a risk of death, serious bodily injury, or damage to tangible property. Code examples provided herein by IDT are for illustrative

purposes only and should not be relied upon for developing applications. Any use of such code examples shall be at the user's sole risk.

Copyright © 2009 Integrated Device Technology, Inc.

All Rights Reserved.

The IDT logo is registered to Integrated Device Technology, Inc. IDT and CPS are trademarks of Integrated Device

Technology, Inc.

.

“Accelerated Thinking” is a service mark of Integrated Device Technology, Inc.

GENERAL DISCLAIMER

Page 3

Contents

1. Board Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Board Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 Baseband Processing Data Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.2 Board Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.3 Board Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Board Hardware Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.1 sRIO Switching and PrPMC Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.2 FPGA Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.3.3 DSP Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.3.4 System Management Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.3.5 Clocking Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.3.6 Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.3.7 JTAG Port and I2C Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.4 PCB Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.4.1 PCB Form Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.5 Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1.5.1 DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1.5.2 Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1.5.3 Push Button and Toggle Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1.6 Board Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1.6.1 JTAG and FPGA Programming Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1.6.2 Communication Interface Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1.6.3 SMA Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1.6.4 MISC Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1.7 LEDs and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1.7.1 Power Good Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1.7.2 AMC MMC LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1.7.3 LED Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1.7.4 Tri-color LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1.7.5 SFP Optical Transceiver LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1.7.6 GPIO LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3

2. Board Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.1 PMC Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.1.1 Running the Software Using Ramdisk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.1.2 Running the Software Using NFS Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.1.3 Installing the PMC Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.1.4 Modifying the PMC Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.2 FPGA Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.2.1 Installing the FPGA Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.2.2 Running the FPGA Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 4

4

2.2.3 FPGA Hardware Load Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.2.4 Software Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.3 DSP Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.3.1 Installing the DSP Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.3.2 Running the DSP Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.3.3 DSP Hardware Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.4 PMC/DSP/FPGA Software Execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 5

About this Document

This document discusses the functional characteristics of the Tsi620 evaluation board. It describes the

board’s key specifications, system architecture, and hardware implementation approaches. In addition,

it discusses the board’s configuration options, connectors, and LEDs.

The next version of this document will explain how the board’s software can be used to test the board’s

PMC, FPGA, and DSP capabilities.

Terms

AIF Antenna Interface

AMC Advanced Mezzanine Card

BB Baseband

5

bps Bit per second

BW Bandwidth (Usually means row data including encryption and service)

CPRI Common Public Radio Interface

DDR2 Double Data Rate 2 SDRAM

DFT Design for Testing

DSP Digital Signal Processor

EVB Evaluation Board

H/W Hardware

I/F Interface

LE Logic Element (FPGA programmable logic unit)

MMC MicroTCA AMC module management controller

OBSAI Open Base Station Air Interface

RF Radio Frequency

S/W Software

SFP Small Form Factor Pluggable

SPI Serial Peripheral Interface

SRIO Serial RapidIO

PrPMC Processor PMC

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 6

6

Revision History

60D7000_MA001_03, Formal, August 2009

There are no technical changes to this document.

60D7000_MA001_02, Formal, November 2008

This version was updated to include information about the software on the Tsi620 evaluation board

(see “Board Software”).

60D7000_MA001_01, Preliminary, June 2008

This is the first version of the Tsi620 Evaluation Board Manual.

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 7

1. Board Hardware

This section discusses the following topics:

• “Overview” on page 7

• “Board Architecture” on page 7

• “Board Hardware Functional Description” on page 12

• “PCB Characteristics” on page 30

• “Configuration Options” on page 31

1.1 Overview

This chapter discusses the functional characteristics of the Tsi620 evaluation board. It describes the

board’s key specifications, system architecture, and hardware implementation approaches.

7

The Tsi620 evaluation board serves the following purposes:

• To demonstrate the Tsi620’s potential application in a typical wireless baseband processing system

• To provide a hardware platform for customers to assess the Tsi620’s major features and to evaluate

the performance of the device in a real wireless base station system

• To function as a design reference for customer’s Tsi620 hardware development

1.2 Board Architecture

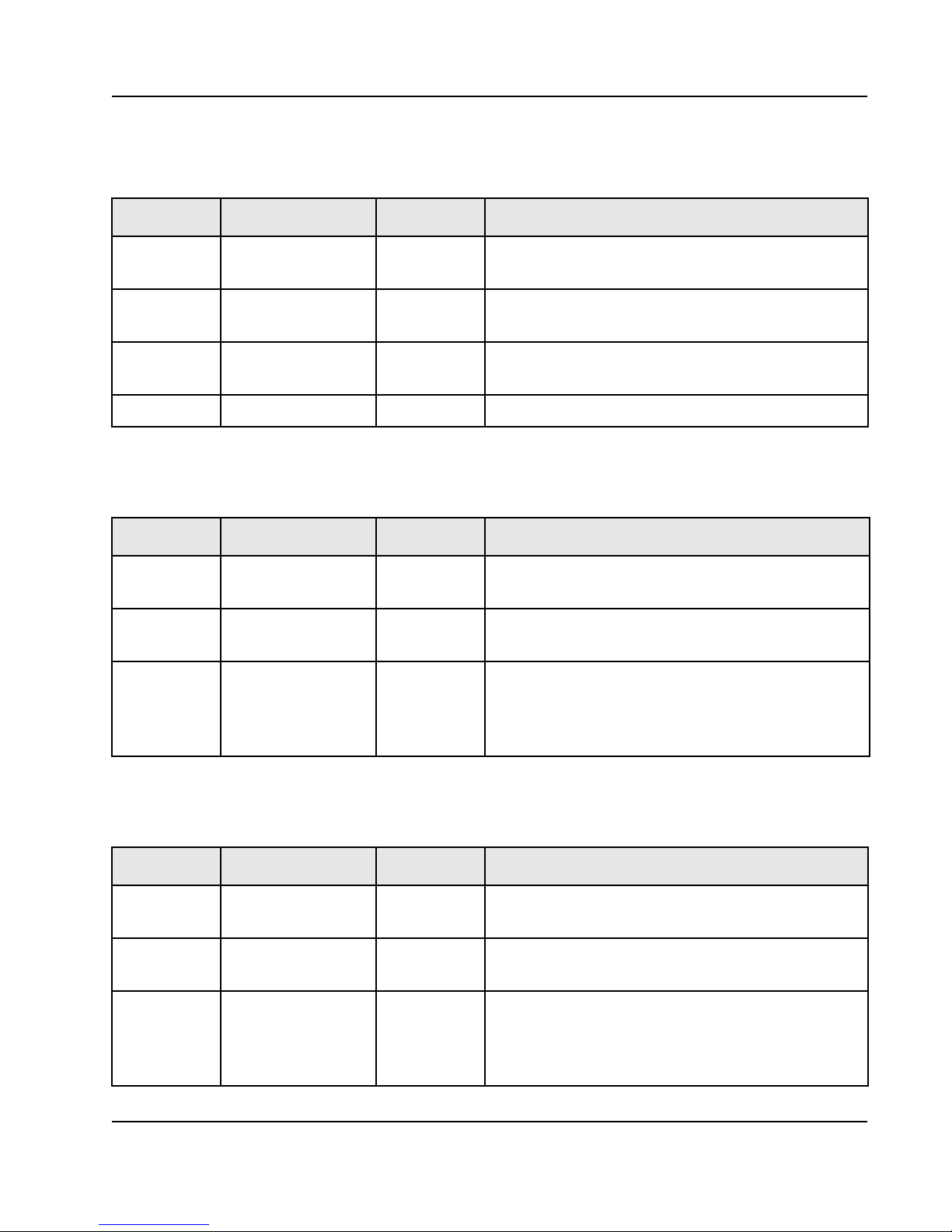

1.2.1 Baseband Processing Data Flow

The Tsi620 evaluation board can function as a baseband processing module in a wireless base station

application. The board can connect to an RF module with OBSAI/CPRI links. It is assumed that the

board will be functioning in an MicroTCA chassis with AMC-sRIO backplane, which provides

networking and system management interconnection.

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 8

8

AMC Finger Connector

Tsi620

SRIO Swi tch

SFP

Cage

SFP

Cage

TCI6488

DSP

BB Processing

Stratix3

FPGA

BB Processing

PrPMC Connector

AMC Vertical Connector

DDR2 256MB

x4 SRIO

PCI 32b/66M

‘XGMII

DDR2 32b/614M

x2 SRIO

RJ45

x1 SGMI I

1000BaseT

1x OBSAI/CPRI

1x OBSAI/CPRI

768Mb-BW

3Gb-BW

10Gb-BW

5Gb-BW

10Gb-BW

1Gb-BW

10Gb-BW

PowerPC

Processor

RF

Module

OBSAI/CPRIx4

RJ45

4x 768Mb-BW

RJ45

x4 SRIO

x1 SGMII

1x OBSAI/C PRI

3Gb-BW

RJ45

100BaseTx1 MII

Figure 1: Baseband Processing Data Flow

The major baseband processing engine on the evaluation board is a TI triple-core DSP TCI6488 with

3-GHz processing capability. Altera’s Stratix3 FPGA with up to 150K LE functions as the DSP

accelerator of the baseband data processing. Two antenna OBSAI/CPRI links provide the interface to

an RF module through SFP optical transceiver over optical cable. The low-speed OBSAI link with

780 Mbps is directly connected to the FPGA, and another high-speed OBSAI with up to 3 Gbps is fed

directly into the DSP antenna interface. One OBSAI/CPRI link is also supported between the AMC

backplane at port 17 and the DSP antenna interface.

The Tsi620 functions as the central traffic hub to provide high-bandwidth data flow of the AMC

backplane, FPGA, DSP, and PrPMC module. The processed data can be transmitted to the AMC sRIO

backplane through the Tsi620 sRIO switch. Both upstream and downstream data flow can be

implemented. The data transfer between the DSP and FPGA is through the Tsi620 using two 1x sRIO

links so that the FPGA can function as a powerful accelerator to assist DSP baseband processing. The

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

on-board PrPMC connector, which can function as the system management host and Ethernet

networking interface, supports all standard PrPMC modules.

Intergrated Device Technology

www.idt.com

Page 9

1.2.2 Board Specification

1.2.2.1 Baseband Processing Engine

• TI TCI6488 DSP

— Triple 1-GHz core fixed-point DSP with enhanced baseband processing capability

— 64-KB L1 cache, 3-MB L2 cache, and 64-KB L3 ROM

— External 256 MB, 32-bit DDR2 SDRAM at 614 M DDR speed

— External 4 MB serial Flash through the McBSP/SPI interface

— One OBSAI/CPRI link from the SPF connector

— One OBSAI/CPRI link from the AMC backplane port 17

— OBSAI speed: 768 Mbps, 1536 Mbps, 3072 Mbps

— CPRI speed: 614.4 Mbps, 1228.8 Mbps, 2457.6 Mbps

— Four OBSAI/CPRI links to the FPGA support OBSAI at 768 Mbps or CPRI at 614.4 Mbps

— One GigE SGMII port to RJ45 connector

— Dual x1 sRIO ports to Tsi620 sRIO switch with 5 Gb bandwidth

9

•Altera Stratix3 FPGA

— EP3SL150, 488 IOs, 780 FBGA 29 x 29 mm

— 150K LE

— 9.4-Mb embedded RAM

— XGMII-like Interface to sRIO switch with 10 Gb bandwidth

— One OBSAI/CPRI link to SFP port supports OBSAI at 768 Mbps or CPRI at 614.4 Mbps

— Four OBSAI/CPRI links to DSP supports OBSAI at 768 Mbps or CPRI at 614.4 Mbps

— One 10/100BaseT Ethernet to RJ45 connector

— System clocking synchronization interface and management

1.2.2.2 Antenna Interface

• Supports OBSAI/CPRI protocols on antenna interface

• Two OBSAI/CPRI links through the SFP connectors

• One OBSAI/CPRI link from AMC port 17

• Low-speed OBSAI/CPRI link to FPGA supports OBSAI at 786 Mbps and CPRI at 614.4 Mbps

• High-speed OBSAI/CPRI link to DSP supports OBSAI up to 3072 Mbps and CPRI up to

2457.6 Mbps

• Supports system frame synchronization through SMA connectors or AMC backplane

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 10

10

1.2.2.3 sRIO Fabric

• Tsi620 functions as the central hub to provide high-bandwidth data traffic of backplane, FPGA,

DSP, and PrPMC

• Tsi620 sRIO switch with dedicated PCI Interface and RIO XGMII port

• 4x sRIO link to AMC-sRIO backplane with 10-Gb bandwidth

• 4x sRIO link to AMC vertical slot for AMC to AMC connection in stand-alone mode

• 32-bit, 66-MHz PCI interface to PrPMC module

• XGMII-like 4x RIO port to FPGA with 10-Gb bandwidth

• Dual 1x sRIO links to DSP with 5-Gb bandwidth

1.2.2.4 Ethernet Network Interface

• GigE RJ45 port to DSP SGMII EMAC for external network connection

• PrPMC module can bridge between the external Ethernet network and Tsi620’s sRIO switch

• Supports AMC backplane port 0 GigE (1000Base-BX) to RJ45 to facilitate system management

networking connection

• 10M/100M Base-T RJ45 to Stratix3 FPGA

1.2.2.5 Board Form Factor

• Single width, full height, and custom length AMC card (73.8W x 350L x 29H mm)

• Supports a standard PrPMC module on the extension segment

• Available vertical AMC connector for another AMC card in stand-alone operation mode

• Front panel connectors: 2 x SFP cages, 2xRJ45(GigE), and 1xMINI-USB

• Additional connectors: RJ45 (100BaseT) and 12V DC input barrel plug

• Supports DSP emulation port and FPGA JTAG port on board

• AMC physical Hot Swap function with the manual toggle switch

1.2.2.6 Design for Testing Features

• 4x sRIO to AMC vertical connector for stand-alone operation

• USB based JTAG port on Tsi620 for the internal register access

• Tsi620 on-die scope support with standard JTAG port (Wiggler)

• 60-pin DSP emulator connector for DSP development

• Single JTAG header for both Altera FPGA and Actel FPGA programming and debugging

• GPIO signal network of Tsi620, FPGA, and DSP

• Two LED-display attached to FPGA

• LEDs, DIP switches, and test points, for testing support

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 11

1.2.2.7 Clocking Distribution

• On-board clock generation and distribution for sRIO domain, GigE domain, and OBSAI domain

• On-board clock generation and distribution for FPGA, DSP, and Tsi620

• SMT connectors for the base station system frame synchronization

• AMC backplane system clocking synchronization

1.2.2.8 Board System Controller

• Actel Flash-based FPGA, AFS600-FBGA256

• Board reset control

• Power sequence control and monitoring

• Board status report

• AMC MMC support

• Multiple voltage interface conversion

1.2.2.9 Power Management

11

• Meets AMC.0 specification for power management

• 12V power supply from AMC finger connector

• 12V@5A DC input connector for stand-alone operation

• 60W maximum power consumption including PrPMC module

• 3.3V@100mA for AMC management power

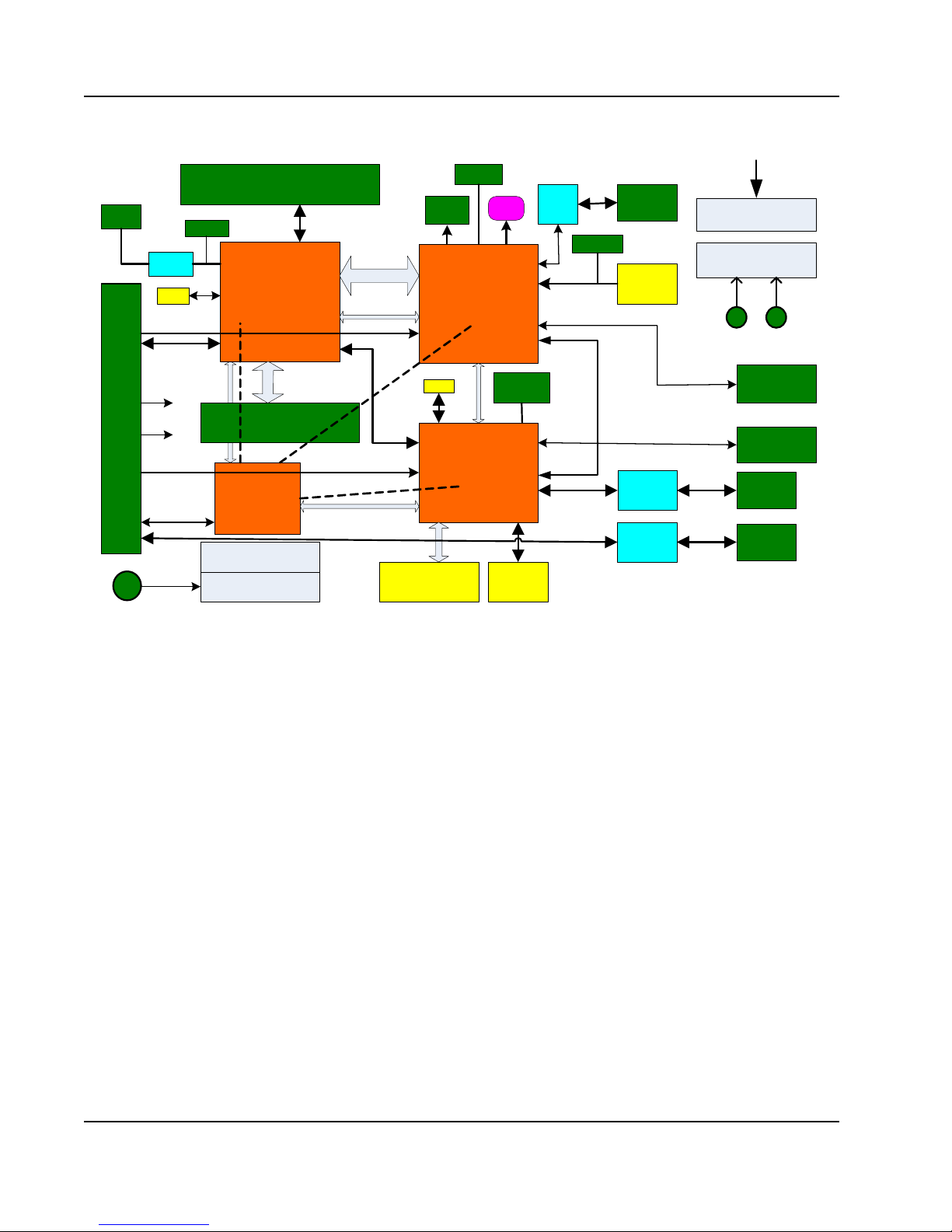

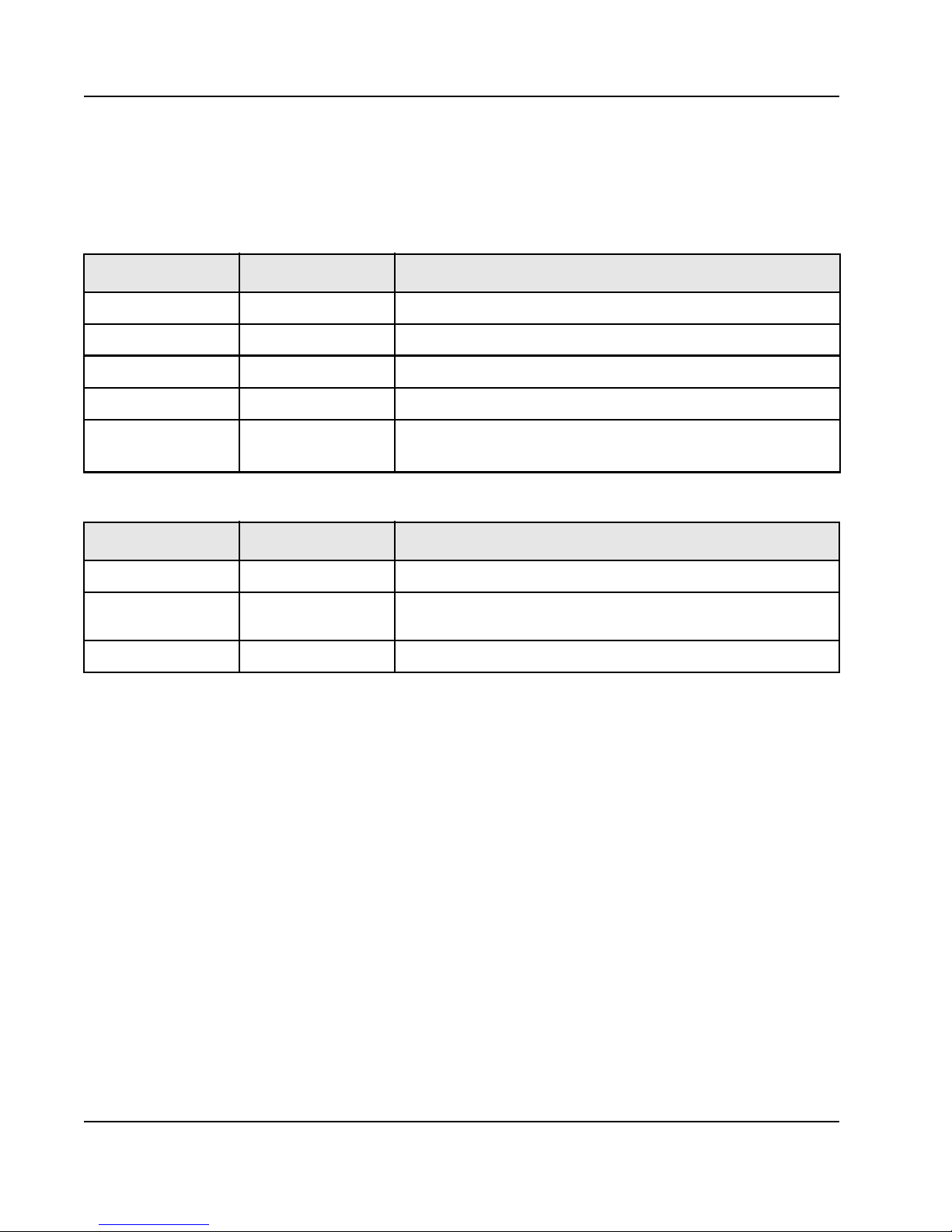

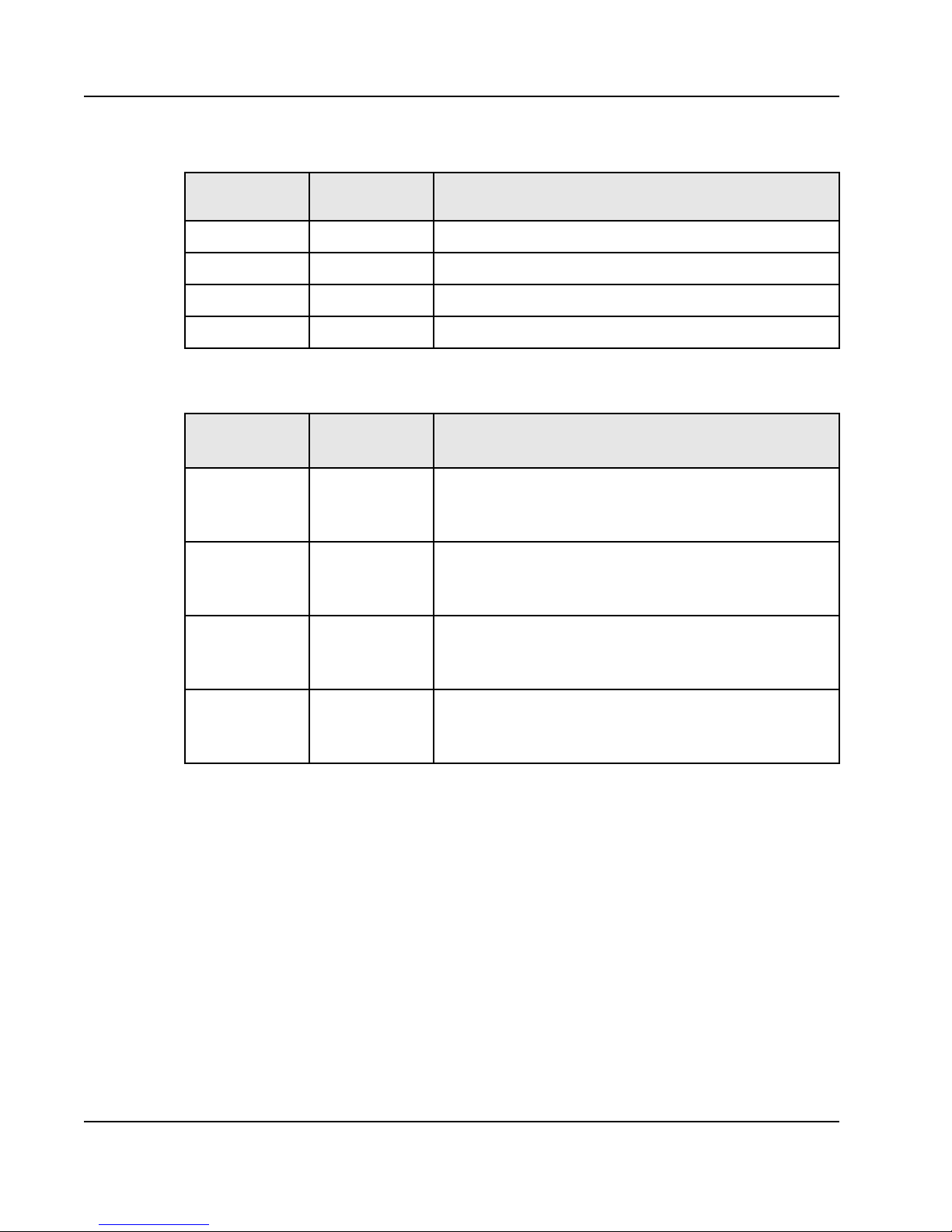

1.2.3 Board Architecture

Figure 2 displays the architecture of the Tsi620 evaluation board. The board includes the following

functional blocks; each block’s architectural features are discussed in the next section (see “Board

Hardware Functional Description”):

• sRIO switching and PrPMC module

• Stratix3 FPGA block

• TCI6488 DSP block

• GigE interface

• Clocking distribution

• Power management

• System controller

• AMC backplane and front panel connectors

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 12

12

AMC Finger Connector

Tsi620

SRIO Switch

SFP

Cage

SFP

Cage

TCI6488

DSP

Stratix3

FPGA

PrPMC Connector

AMC Ver tical Connector

DDR2 256MB

DSP

Emulator

x4 SRIO

x4 SRIO

PCI 32b/66M

‘XGMII

DDR2 32b/614M

x2 SRIO

OBSAI/CPRI

RJ45

x1 SGMI I

1000BaseT

OBSAI/CPRI (High Speed)

OBSAI /CPRI ( Low Sp eed)

POWER

Management

USB

SGMII

PHY

SPROM

SFLASH

4MB

CLOCK Management

RESET Contr ol

SPI

I2C

USB--

JTAG

Sync_SMA

PushButton

GPIO x 16

I2C

4x OBSAI/CPRI

Low Speed

AFS600

System

Controller

+12V@5A

Power Monitor

JTAG

RJ45

SGMII

PHY

x1 1000BASE- BX

LED

DIS

MMC

SYSCLK

JTAG

+12V

3.3V_MP

Mictor

AIF Port 1x OBSAI/CPRI

High Speed

MII

PHY

RJ45

100BaseT

Header

GPIO x6

GPIO x6

GPIO x4

Figure 2: Evaluation Board Architecture

1.3 Board Hardware Functional Description

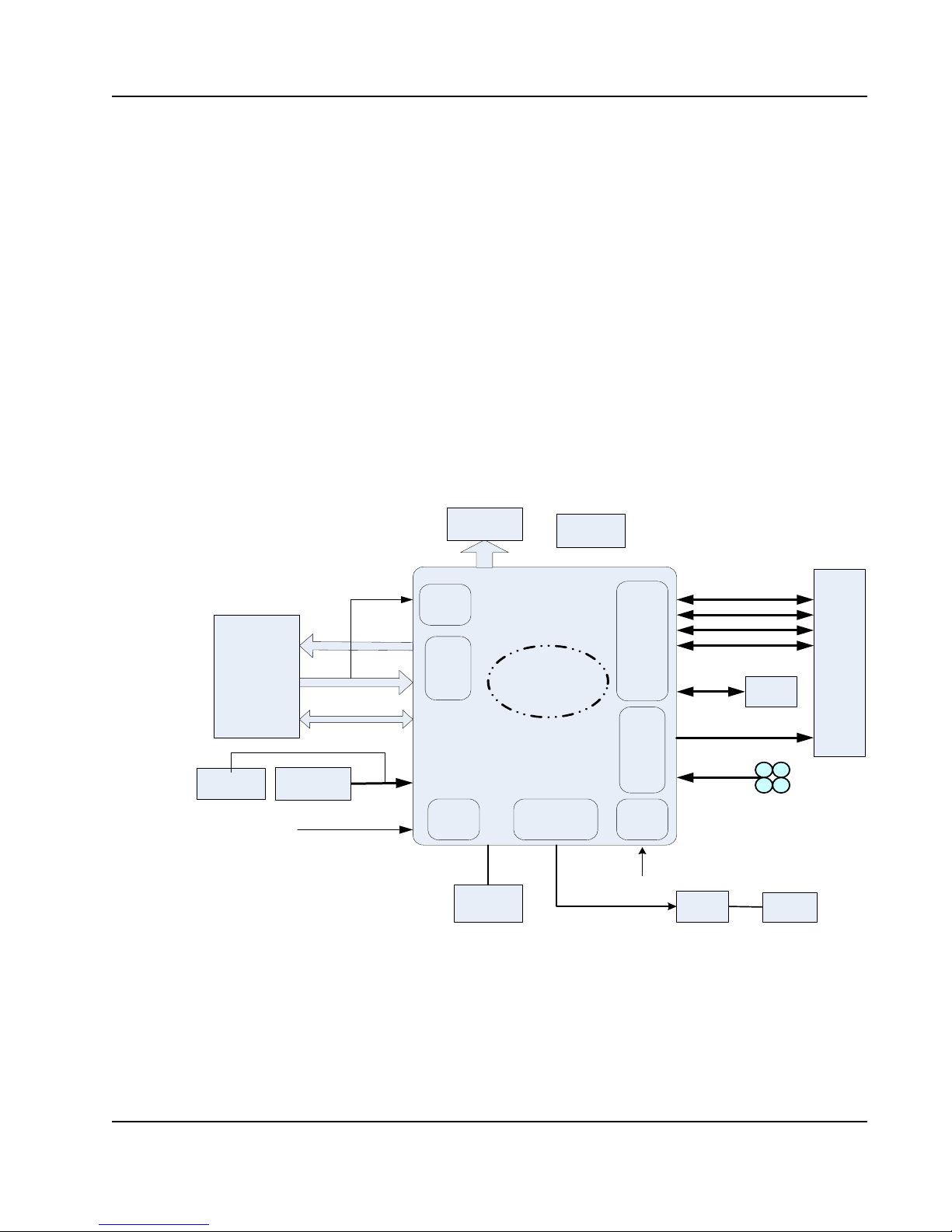

1.3.1 sRIO Switching and PrPMC Module

Tsi620 sRIO switch provides the high-speed interconnection of AMC backplane, on-board vertical

AMC slot, Stratix3 FPGA, TI DSP, and the processor module (see Figure 3).

1.3.1.1 sRIO Switch

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

• Tsi620 sRIO switch with an endpoint to PCI interface

• 4x sRIO link to AMC backplane with speed at 1.25 Gbaud. 2.5 Gbaud, and 3.125 Gbaud

• AMC finger connector with MMC support

• 4x sRIO link to on-board AMC slot connector with speed at 1.25 Gbaud, 2.5 Gbaud, and

3.125 Gbaud

• Conforms to AMC.1 and AMC.4 specification by PCIMG

• AMC.4 fabric port assignment support: Type4 (4x) only

• Two 1x sRIO links between TCI6488 and Tsi620

• XGMII interface to FPGA with 4x RapidIO protocol

Intergrated Device Technology

www.idt.com

Page 13

Figure 3: sRIO Switch and PrPMC Interface

SP0

SP2

4x SRIO

4x SRIO

SP4

SP5

1x SRIO

1x SRIO

SP6

4x FMAC

XGMI I R x 37pin

XGMI I Tx 37pin

SREP

PCI 32b 66M

AMC Finger

Connector

AMC Vertical

Connector

TCI6488

DSP

Stratix3

FPGA

Pr PMC 32 b

Connector

I2C

EEPROM

I2C_Master

PCI_CLK

PCI_Arbiter

TSI620 SRIO Switch

USB to

JTAG

JTAG

USB

S_CLK

156.25MHz

REF_CLK

CRSTn BRSTn

Reset

Controller

GPIO[0:15]

PCI_Reset

Pull-up/down

Resistors

PWRUP

CONFIG

GPIO[16:23]

1.2V3.3V 1.5V

INT(a,b,c,d)

MMC

156.25MHz

RX_CLK

JTAG

PHY

1x SGMII

RJ45

13

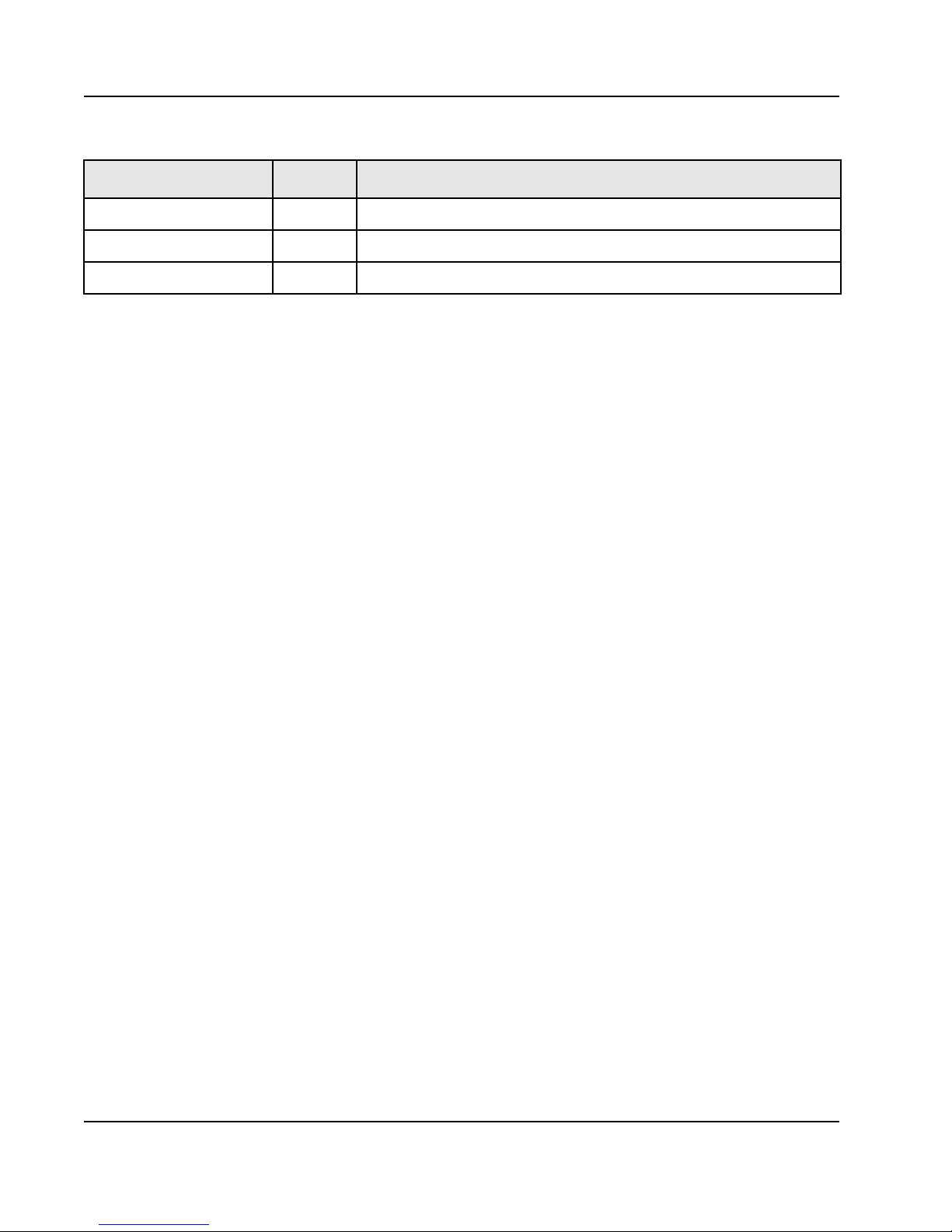

Table 1: sRIO Switch Power-Up Configuration Setting

Pin Name Setting Description

SP_HOST 0/1 0 = Not host

1 = Host (PrPMC is supposed to be the host) (S4 bit[1])

SP_MAST_EN 1 EndPoint can issue RapidIO Request packets

SP0_MODE_SEL 0 0 = 4x Connect to AMC vertical connector

SP2_MODE_SEL 0 0 = 4x Connect to AMC finger connector

SP4_MODE_SEL 1 1 = SP4 1x and SP5 1x connect to dual DSP 1x sRIO

SP6_MODE_SEL 1 1 = SP6 4x mode for FPGA I/F

SP_IO_SPEED[1:0] (10),01,00 10 = 3.125 Gb (Default)

SP_CLK_SEL[1:0] 01 01 = 156.25 MHz

SP(n)_PWRDN n=2,4,5,6 0 0 = Port 2, 4, 5, 6 are powered up (assuming SP(0) is always powered up)

Intergrated Device Technology

www.idt.com

01 = 2.5 Gb

00 = 1.25 Gb (S4 bit[4:3])

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 14

14

Table 1: sRIO Switch Power-Up Configuration Setting (Continued)

Pin Name Setting Description

SP(n)_PWRDN n=1,3 1 1 = Port 1 and 3 are powered down

SP_TX_SWAP 1 1 = Ports [0, 2, 4] Tx lane order is D, C, B, A

SP_RX_SWAP 1 1 = Ports [0, 2, 4] Rx lane order is D, C, B, A

1.3.1.2 Processor PMC (PrPMC) Interface

The PrPMC module is a high-performance, processor-based intelligent controller that can perform the

following functions:

• On-board system management

• Board software configuration

• Board booting control

• System interrupt handling

• Interface bridging between the module and the external networking system

• System operation status report and maintenance

• Baseband data processing assistance in real time

The PrPMC interface has the following features:

• Compliant to the following specifications:

— PCI Local Bus Specification (Revision 2.3)

— PCI Bus Power Management Specification (Revision 1.1)

— IEEE1386.1

— ANSI/VITA 32-2003

• PCI interface:

— 32-bit bus

— 33MHz/66MHz

— 3.3V signal only

— Tsi620 internal PCI arbiter

— Tsi620 PCI clock generator performs PCI clocking

— PCI interrupt handler: PrPMC module

— Tsi620 drives reset to PrPMC (PrPMC may issue system reset from PMC_RESETOUT#)

• PrPMC: system host for sRIO switching and monarch for PCI bus

• Physical position: PrPMC module located on AMC extension segment out of chassis

• Physical connector: 3x 64-pin CMC connectors (Jn1, Jn2, Jn3)

• Maximum power consumption: 24W

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 15

Table 2: PCI Interface Power-Up Configuration Setting

Pin Name Setting Description

PCI_RSTDIR 1 1 = PCI_RSTn is an output

PCI_M66EN 1/0 1 = 66MHz (PrPMC card could force it to 0 to 33 MHz operation using

S3 bit [1])

PCI_PLL_BYPASS 0 0 = PCI PLL is enabled

PCI_ARBEN 1 1 = PCI internal arbiter is used

PCI_HOLD_BOOT 0 0 = Release PCI software reset immediately after a Tsi620 reset is

completed

SPARE[1:0] 00 00 = Tsi620 (pull-up/down required for BOM selection)

Table 3: PrPMC Interrupt Routing

Interrupt Line Source Description

15

INTA Tsi620 Tsi620 interrupt output to PrPMC

INTB FPGA FPGA real-time events

INTC System Controller System administration coordination

INTD DSP DSP real-time events

1.3.1.3 XGMII FPGA Interface

• Tx/Rx clocking: synchronous 156.25, 125, or 62.5 MHz

• Tx_CLK: source to FPGA for RIO-XGMII interface clocking

• Signaling: HSTL-1.5V DDR

• Transmit: Tx_CLK, Tx_D[31:0], Tx_CTL[3:0], Tx_PHY_DISABLE

• Receive: Rx_CLK, Rx_D[31:0], Rx_CTL[3:0], Rx_ERROR

• The FPGA provides both on-chip parallel and serial termination for the XGMII interface.

Note: This feature is not supported on revision 1 of the prototype board.

1.3.1.4 JTAG, GPIO, and I2C

• Tsi620 supports I2C master mode or optional slave mode with jumper setting

• External socket I2C device with 8 DIP package (AT24C64B)

• Supports I2C configuration loading

• Uses FT2233D, USB to UART/FIFO controller, as USB to JTAG port converter

• Supports Tsi620 register access through JTAG port (mini-USB connector)

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 16

16

• Mini USB connector on front panel with USB2.0 compatible

• Tsi620 GPIO[0:15] connection to DSP and FPGA

• Standard JTAG header for Tsi620 on-die scope support

Table 4: I2C Power-Up Configuration Setting

Pin Name Setting Description

I2C_MA (PU) 0 1 = Multi-byte peripheral addressing

I2C_SA[6:0] (PU) 0000000 I2C port slave address

I2C_SLAVE (PU) 0 0 = Disable the I2C slave mode

I2C_SEL (PU) 0 only 0 = Asserted, I2C_SA[1,0] are used as the lower 2 bits of EEPROM

I2C_DISABLE (PD) 0/1 0 = Enable I2C register loading

1 = Disable I2C register loading (DIP Switch, S4 bit [2])

Table 5: Tsi620 GPIO Signal Assignment

GPIO Signal Connect To Description

GPIO[0:15] FPGA Intercommunicating between Tsi620 and FPGA

GPIO[16:23] DIP Switch and LED GPIO[16:19] connected to DIP Switch S2[1:4]

GPIO[20:23] connected to LED D3, D5, D6, and D4, respectively

GPIO[24:31] LED, Test point Intercommunicating between Tsi620 and the system controller (AFS600)

1.3.1.5 AMC Interfaces

• AMC finger connector supports sRIO AMC backplane

• AMC finger connector supports MMC including I2C

• AMC finger connector supports port 0 GigE (1000Base-BX) interface to RJ45 through the

VSC8221 PHY (AMC.2)

• AMC finger connector does not support JTAG

• 3.3V management power; maximum 100 mA from figure connector

• AMC vertical slot connector does not support JTAG, I2C, and MMC functions

• AMC vertical slot shared with 12V power and local 3.3V

• Total power consumption including PrPMC and AMC slot should not be more than 60W

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 17

1.3.2 FPGA Block

30.72MHz_REF

Stratix3 FPGA

780FBGA

EP C S64 AS-CF GHeader

RIO

XGMI I

OBSAI

Frame_Sync

XGMI I R x 38pi n

XGMI I Tx 38pin

Tsi620

GPIO[0:15]

156. 25M

DDR

PLL

x1

RX_CLK

PLL

x10

PLL

x8/10

GigE_ REF(p,n)

SFP

SMT_IN

FSYNC_OUT

FSYNC_IN

156. 25MHz

Mictor

Switching

Fabric

LED

Display

OBSAI

SERDES

O

B

S

A

I

7

6

8

M

b

/

C

P

R

I

6

1

4

.

4

M

b

DSP

JTAG

EMAC

10/100M

PHY

MII

RJ45

100B aseT

The Altera Stratix3 FPGA can function as either a baseband data processing engine or as an accelerator

to assist DSP baseband data processing (see Figure 4). The FPGA block includes a 780-pin FPGA,

FPGA configuration, RIO XGMII interface, and an antenna interface.

1.3.2.1 FPGA Device

• Altera Stratix3 EP3SL150 in 780-pin BGA

• Package: 29 x 29 mm, 780-pin FBGA with 1 mm pitch

• Speed grade: -3

• Core voltage: 1.1V

• Clock tree performance: 450 MHz for -4 grade

• Maximum IO pins: 480

• Maximum allowed power consumption: 10W

Figure 4: FPGA Block Diagram

17

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 18

18

1.3.2.2 RIO XGMII Interface

• Up to 12-Gb bandwidth of data transfer between FPGA and sRIO switch

• Reference clock: RX_CLK from Tsi620

• Frequency: 62.5, 125, or 156.25 MHz (Note: Revision 1 of the Tsi620 evaluation board does not

support 156.25 MHz.

• Tx_CLK: sync with Rx-CLK and must be PLL locked before driving out

• Signaling: HSTL-1.5V Class-II

• Termination: FPGA on-die parallel 50-ohm termination for the receiver and on-die 25 ohm serial

termination for the transmitter

• Protocol: RapidIO for logical and transport layers

• Rx: 38 signals

• Tx: 38 signals

1.3.2.3 RF Antenna Interface

• Compliant specifications: CPRI specification v2.1, OBSAI v2.0, OBSAI RP3 v4.0

• Supports 1x link to SFP connector with OBSAI-768 Mb or CPRI-614.4 Mb

• Supports 4x link to DSP with OBSAI-768 Mb or CPRI-614.4 Mb

• Clocking Source: FPGA local PLL with reference clock at 30.72 MHz and LVDS/LVPECL logic

1.3.2.4 OBSAI System Clock an Synchronization

• Compliant specifications: OBSAI RP1 standard

• Source mode: AMC backplane or SMA connectors

• System clock input: 30.72 MHz with LVDS/LVPECL logic standard

• Frame synchronization burst input: 3.84 MHz with LVTTL logic

• FPGA outputs the system synchronization signals to the DSP Frame Sync Module (FSM)

1.3.2.5 EMAC 100BaseT Port

• 10Mb/100Mb BaseT with MII interface

• External PHY to RJ45 connector

1.3.2.6 FPGA Testing Support

• 2-digit LED display

• One Mictor connector

• One 2-bit DIP switch

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 19

1.3.2.7 FPGA Configuration

• Configuration mode: Active serial and JTAG

• Serial configuration device: EPCS64, 3.3V, 67 Mb, 16-pin SOIC

• Dedicated header support USB blaster programming cable

• Dedicated JTAG port for FPGA JTAG configuration and debugging

• Voltage: 3.3V

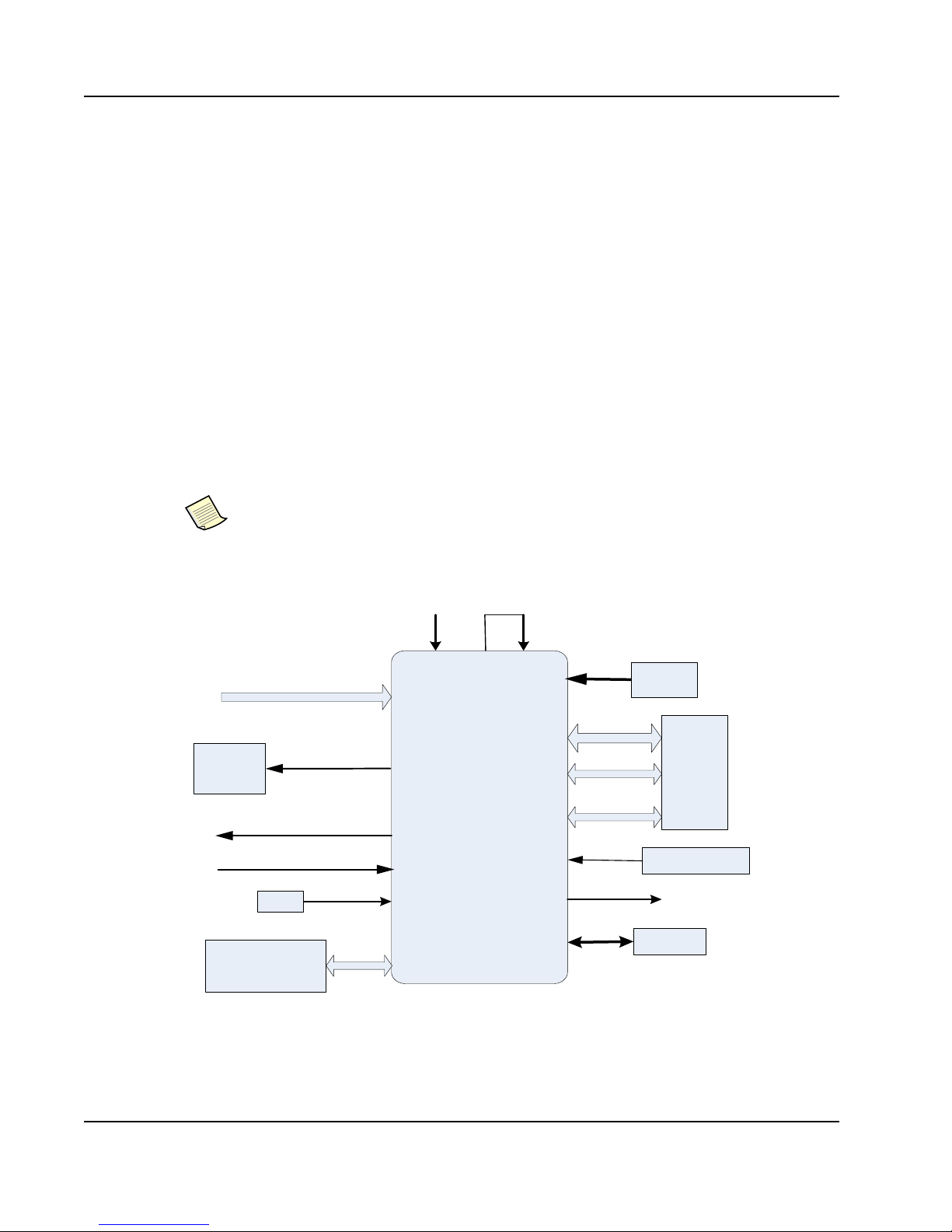

1.3.3 DSP Block

The DSP block includes TI TCI6488 DSP, DDR2 memory, antenna interface, sRIO links, serial flash,

GigE link, and JTAG emulation port (see Figure 5). The TI TCI6488 is the major baseband processing

engine on the Tsi620 evaluation board.

1.3.3.1 TCI6488 DSP

• DSP core: Triple C64X+

• Core frequency: 983 MHz (61.44Mx16)

• Core PLL multiplier: 4 ~ 16

19

• Core reference clock: 61.44 MHz

• Cache: L1-64 KB, L2-3 MB

• Boot mode: I2C, EMAC, sRIO

• 16-bit GPIO assignment:

— 4 bits to FPGA

— 4 bits to Tsi620 through AFS600

— 1 bit to PrPMC for interrupt

— 1 bit to AFS600 for status report

— 6 bits for DSP local configuration

• Package: 561-pin, 23 x 23 mm BGA with 0.8 mm pitch

• Voltage supply: core-1.1V SerDes-1.1V, IO-1.8V

• Power consumption: max 8W

• Thermal dissipation management: Passive heat-sink, core voltage auto-scaling

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 20

20

DDR2

SDRAM

64Mx16b

DQ[0:31]

DQS( p,n)

ADD/

CTRL

DDR2 Controller

CK/ CK#

DDR

PLL

DDRREFCLK(p,n)

61.4 4MHz

307.2MHz

SRIO

SERDES

PLL

RIOS GMIIR EFCLK(p,n)

LVPECL/

156.25 MHz

1x SRIO

1x SRIO

Tsi620

SRIO

SWITCH

EMAC

SGMII

GIGE SGM II

SGMII

PHY

AIF

PLL

STSCLK(p,n)

61.44M Hz

OBS AI /CPRI I/F

FSYNC

FBURST(p,n)

O

B

S

A

I

7

6

8

M

b

/

C

P

R

I

6

1

4

.

4

M

b

SFP

BcB SP

SPI-Master

Serial

FLASH

8MB

FPGA

SPI Bus

3.3V-1.8V

LevelShifter

1.8V

PORZz

XWRSTz

MDI

I2C

EEPROM

60pin Port

Emulation

JTAG

TCI6488 DSP

RJ45

w/ Mag

GIGE SGM II

1x Link

4x Link

1x Link

AMC

GPIO x 16

FPGA

AFS600

x4

x6

x6

Conf igurati on

Figure 5: DSP Block Diagram

1.3.3.2 DDR2 SDRAM Memory

• DDR2 memory device: 2x MT47H64MHR-3, 64Mx16b-677M

• Interface speed: 307.2 MHz or 614.4M DDR

• Memory size: 256 MB

• DDR PLL provide the clocking to DDR2 SDRAM

• Interface data width: 32 bit

• Reference clock: 61.44 MHz

• I/O Standard: SSTL-1.8V

1.3.3.3 Antenna Interface

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

• Antenna I/F link: 1x to SFP connector with up to 3 Gbps

• Antenna I/F link: 1x to AMC backplane Port 17 with up to 3 Gbps

• FPGA link: 4x to FPGA with up to 768 Mbps per lane

• CPRI compatible: 614.4 Mbps, 1.2288 Gbps, 2.4576 Gbps link rates

• OBSAI compatible: 768 Mbps, 1.536 Gbps, 3.072 Gbps link rates

Intergrated Device Technology

www.idt.com

Page 21

• Reference clock: 61.4 MHz LVDS/LVPECL

• Frame synchronization: receive the system clock and synchronization burst from FPGA

1.3.3.4 sRIO Links and GigE Port

• Two x1 sRIO links to Tsi620

• sRIO link rates: 1.25 Gbps, 2.5 Gbps, and 3.125 Gbps

• One GigE link with SGMII interface

• Reference clock: LVPECL 156.25 MHz

• MII interface to GigE switch and GigE PHY through 3.3V to 1.8V level shifter

• One RJ45 connector with integrated magnetic

• 10/100/1000BaseT capable

• VSC8221 GigE-PHY SGMII interface

• MII port controller by DSP

1.3.3.5 Serial FLASH

21

• McBSP0 is configured to SPI bus master to support serial flash memory

• Serial flash can store the boot loader or software image

• Serial flash: SF25L064, 64 Mb, 50 MHz SPI, 3.3V device

• 3.3V to 1.8V level shifter is required between DSP and Serial flash

1.3.3.6 EEPROM and Emulation Interface

• 1.8V I2C EEPROM, AT24C64B-10TU-18

• Support emulation interface with 60-pin emulation connector

1.3.3.7 DSP Interrupt Assignment

• Three non-mask interrupts with active high are routed to FPGA for user-defined usage.

• Interrupts between DSP and FPGA through DSP_GPIO[12:15] with active low

• Interrupts between DSP and Tsi620 by DSP_GPIO[6] through the AFS600 as the level shift.

Note: Care must be taken that the interrupt signals must be always driven after the reset once their

direction and function has been defined.

• The DSP is responsible for managing two GiGe PHYs and two GiGe PHY MI interface interrupts

(MINT# is connected to DSP_GPIO[7] pin).

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 22

22

3.3V_MP

1.5V

AFS600

Flash-FPGA

Analog

Bank

REFCLK

IPMB

Power Monitoring

Reset

Control

25MHz

SYN C_CLK

3.3V_Prog

1.5V_Reg

JTAG

R/C

2.5V

Bank

3.3V

Bank

1. 8 V

Bank

Pushbutton

DSP

SMT_CLK

MMC

GPIO

GPIO

FRAME-

SYNC

Tsi620

3.3V

Bank

LVDS

LVDS

UART

3.3V

Bank

USB

I/F

McBSP

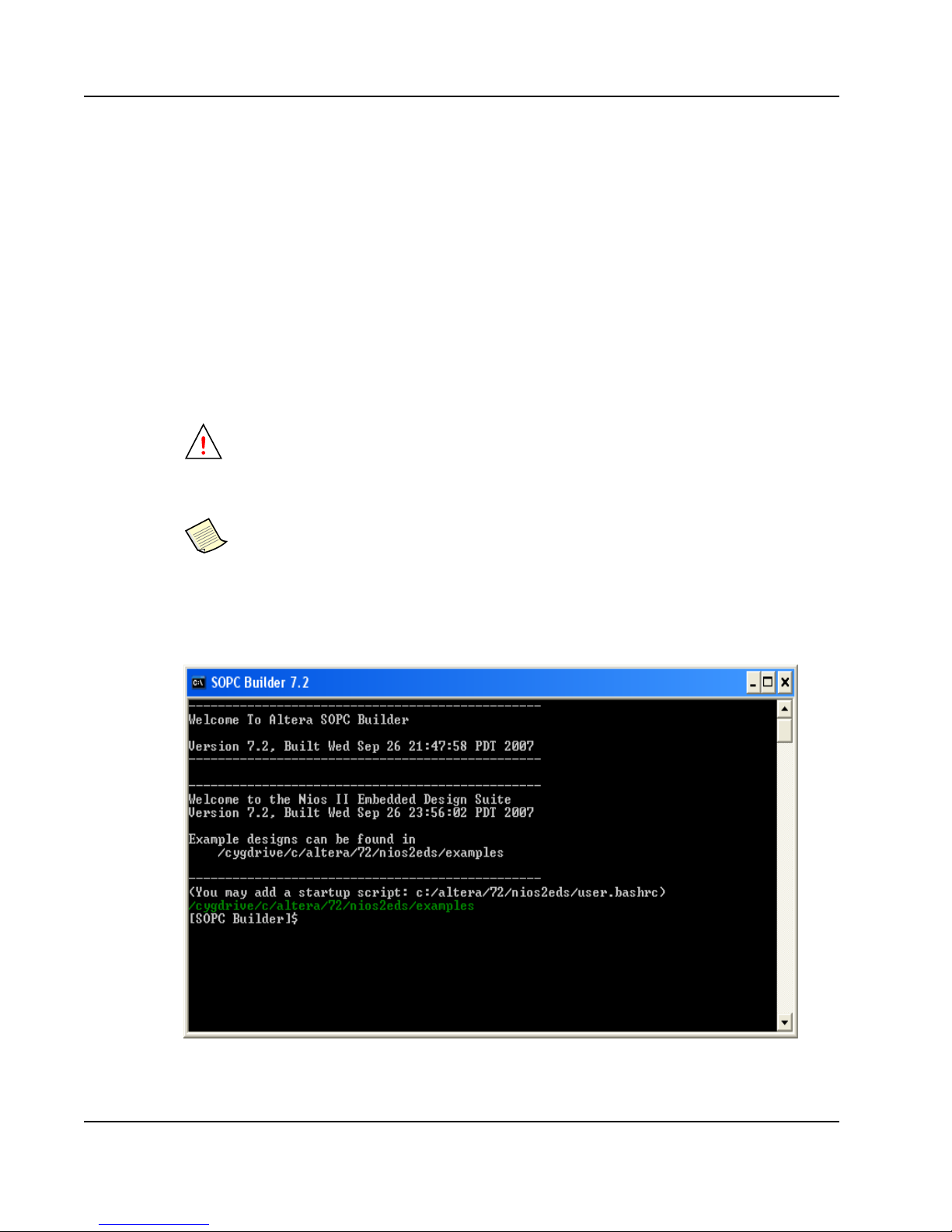

1.3.4 System Management Controller

The system management controller is implemented with an Actel FPGA AFS600-256, which is a flash

memory based mixed signal FPGA (see Figure 6). This FPGA has an embedded processor and is

mainly powered by 3.3V_MP from an AMC finger connector since the system controller must be

functioning whenever 3.3V_MP is available.

1.3.4.1 System Controller Functionality

• Board reset control

• Board power sequencing control and power monitoring

• Real-time clock

• AMC MMC (Memory management control)

• Multi-voltage level conversion

• UART port to USB interface

• Board status report

For more information on the function of the system controller, see the source files for the

Tsi620 Evaluation Board System Controller (35D7000_PL007).

Figure 6: System Management Controller

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 23

1.3.4.2 AFS600-FBGA256 Implementation

• Bank 0: 1.8V LVCOMS1V8

• Bank 1: 3.3V LVTTL, LVCOMS, LVPECL

• Bank 2: 2.5V LVCOMS2V5

• Bank 4: 3.3V LVTTL, LVCOMS, LVPECL

• Analog Bank: 0 ~ 12V power monitoring

• Power: 3.3V_MP only with max. 100mA

1.3.4.3 Reset Control

The Actel Flash FPGA is used on the evaluation board to implement the module management

controller of the AMC interface. The Actel FPGA also functions as the central reset controller to

handle the reset control glue logic.

Reset Control Requirement

Table 6: Major Components Reset Signal List

23

Devices Reset Signal Logic Function

Tsi620 CHIP_RSTn 3.3VLVTTL Tsi620 chip reset

Tsi620 BLOCK_RSTn 3.3VLVTTL Tsi620 block reset

TI-DSP PORz 1.8VLVCOMS DSP power-on reset. Held low >1 ms after power and clk

TI-DSP XWRSTz 1.8VLVCOMS DSP warm reset. No affect on PLL and emulation

FPGA HRSTn 3.3VLVTTL FPGA power-on reset and trigger device reset

FPGA SRSTn 3.3VLVTTL FPGA soft reset and no affect to PLL

V8221 HRESETn 3.3VLVTTL GigE PHY reset

Reset Control Logic

• System management controller: Actel AFS256-FG256, Flash-based mixed signal FPGA

• Supports multi-volt device control

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 24

24

PrPMC

DSP

Tsi620

AFS600

System

Controller

Chip_RSTn

PORn

Push

Button

Power

Monitor

XWRSTn

FPGA

HW_RSTn

SW_RSTn

GigE

PHY

RSTn

PCI_RSTn

Block_RSTn

Interrupts

RSTOUTn

CLK_RSTn

Status

Figure 7: Reset Control Illustration

1.3.4.4 MMC Implementation

The MMC’s design is based on Actel’s MMC reference design, which has been customized with an

extended analog block for additional on-board voltage, current, and temperature monitoring functions.

The Actel MMC reference design is a custom 8051-based microcontroller implemented in an Actel

AFS600-FG256 Fusion mixed-signal FPGA, and is supported by IPMI firmware from uBlade. The

MMC design supports the basic requirements defined by the PICMIG AMC.0 and Intel IPMI v2.0

specifications. For additional information about the MMC design, contact the Actel or IDT Technical

Support team.

1.3.5 Clocking Management

This section specifies the clocking generation and distribution implementation.

1.3.5.1 Clocking Source Requirement

General requirements for all clocking sources:

• Stability: +/-100 ppm

• Duty cycle: 40/60%

• Trise/Tfall: 50 ps–1300 ps for 20% to 80% swing

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 25

Table 7 summarizes the clocking sources requirements for all major components on the Tsi620

evaluation board.

Table 7: Clocking Sources List

Clock Name Function/Domain Logic Standard Frequency Input Jitter

25

SCLK(p,n) Tsi620 system

reference

SP6_RXCLK Tsi620 XGMAI RXCLK HSTL-1.5V 62.5 MHz, 125 MHz,

PCI_CLK Tsi620 PCICLK input PCI-3.3V 66.7 MHz/33.3 MHz +/-100 ps

RIO_XGMII_RxCLK FPGA XGMII RxCLK

input from Tsi620

GigE_REFCLK FPGA GigE EMAC

reference

AIF_REFCLK FPGA OBSAI/OPRI

reference

SYSCLK{p,n} DSP core and AIF

reference

DDRREFCLK(p,n) DSP DDR2 reference LVDS/PECL(AC) 61.44 MHz 75 ps (pk2pk)

RIOSGMIICLK(p,n) DSP sRIO and SGMII

reference

LVDS/PECL(AC) 156.25 MHz

175 ps (pk2pk)

156.25 MHz

HSTL-1.5V 62.5 MHz, 125 MHz,

156.25 MHz

LVDS/PECL(AC) 156.25 MHz

LVDS/PECL(AC) 30.72 MHz

LVDS/PECL(AC) 61.44 MHz 2 ps RMS

LVDS/PECL(AC) 156.25 MHz 4 ps RMS

56 ps (pk2pk)

GigE PHY_REFCLK GigE PHY Crystal 25 MHz

AFS600_REFCLK AFS600 reference

clock

Internal RC 100 MHz +/-1%

1.3.5.2 Clocking Architecture Implementation

There are two clock synthesizers on board that provide the reference clocking required for the FPGA,

DSP, and sRIO switch. The first synthesizer has a 25-MHz crystal source: it outputs 156.25 MHz with

LVPECL logic to serve sRIO system reference clock, FPGA EMAC and SGMII reference, and DSP

sRIO and SGMII reference. The second clock synthesizer has a 30.72-MHz oscillator source: it

supplies 30.72 MHz and 61.44 MHz CML clocking references for the DSP, DDR2, FPGA antenna

interface, DSP core PLL, and DSP antenna interface (see Figure 8).

In order to simplify the clocking architecture, both the DSP core frequency and the on-board DDR2

memory operation frequency, run at slightly lower than their maximum specification. Both DSP and

DDR2 memory use the same clocking source at 61.44 MHz, DSP core frequency is 983 MHz, and

DDR2 memory operates at 614.4 M double data rate.

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 26

26

Tsi620

25MHz

Crystal

ICS843004

CLK Synthesizer

LVPECL/156.25M

SCLK TxCLK

PCLKOUT PCLKIN

PCI3V3/

66.7M

FPGA

RxCLK

PrPMC

HSTL-1.5

62.5/125/

156.25M

HSTL-1.5

XGMII

PLL x1

Sync to RxCLKin

LVPECL/156.25M

AIF

PLL

sRIO

PLL

SGMII

PLL

LVPECL/

156.25M

AFS600

CDCL6010

CLK Synthesizer

OBSA

PLL

CML/61.44MHz

DDR2

PLL x10

DDR2

SSTL-1.8

307.2M

30.72MHz

LVDS

Core

PLL

DSP

I2C

614.4Mb/

768Mb

OBSAI/CPRI

4to1

MUX

30.72MHz

OSC

FPGA

AFS600

CML/61.44MHz

CML/61.44MHz

CML/61.44MHz

CML/30.72MHz

30.72MHz

SERDES

PLL

SMT

AMC

25MHz

OSC

GigE

PHY

GigE

PHY

MII

PHY

LVPECL/156.25M

The Tsi620 FMAC and FPGA RIO-XGMII interface function in the synchronous mode. The TX_CLK

from the Tsi620 is sourcing from its SYSCLK(p,n), while the FPGA must use RX_CLK as its

RIO-XGMII operation reference clock. The TX_CLK driven from the FPGA must therefore be

synchronized with TX_CLK driven by the Tsi620. In addition, TX_CLK of the FPGA cannot be

applied to the Tsi620 until the FPGA PLL is locked.

Figure 8: Clocking Generation and Distribution

The FPGA XGMII PLL is synchronized to received RX_CLK from the Tsi620.

CDC6010 must be managed through its serial interface, while the DSP is responsible for CDC6010

configuration through its I2C bus.

1.3.6 Power Management

1.3.6.1 Power Supply and Consumption Analysis

The board power distribution design must comply with AMC.1 power management requirements. The

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

AMC card has only single +12V supply available from either AMC finger connector or DC barrel plug:

• AMC max power consumption: <60W including all add-in cards

• AMC finger connector: 12V@5A for MicroTCA chassis operation

• DC barrel plug: 12V@5A for stand-alone operation

The clock synthesizer

Intergrated Device Technology

www.idt.com

Page 27

Table 8 summarizes the major components’ supply requirements and max potential current demand.

Table 8: Major Components Power Supply Requirement (Power Budget)

27

Device 1.1V 1.2V 1.5V 1.8V 2.5V 3.3V 3.3VSB 5V 12V Notes

Tsi620 3A 0.5A 0.5A <4.7W, sequencing

TCI6488 7A+1A 1A <9W, sequencing req.

EP3SL150 8A 0.5A 0.5A 0.5A 0.5A Assume <10W (TBV)

DDR2 x6 0.7A 350mA x2

VCS8221x2 0.5Ax2 <0.8w inner reg@1.2v

S25FL064 IG

PrPMC 4.5A 3A 0.5A Tall<25W, -12V@0.5A

AT24C512 IG

AMC SLOT 3A ½(60W)=30W

AFS600 80mA 0.1A 3.3V_MP@100mA

CDCL6010 0.5A

AMC FGR -6A 8V~14Vin, 60W

Ex Power -5A From DC barrel plug

a

LED 0.5A

Total 8A+8A 3A 1A 3A 0.5A 7A 1A 3A

a. IG = Ignore, FGR = Finger connector.

1.3.6.2 Power Distribution Implementation

• The LTM4601, LTC DC/DC switching micro module generates +5V, +3.3V, 1.1V_DSP, and

1.1V_FPGA (see Figure 9)

• 4x LTM4601 work in synchronous mode and are controlled by a 4 phase PLL driver

• TCI6488 power management supports the core voltage scaling for power consumption

auto-control

• TCI6488 SerDes 1.1V supply comes from FPGA_CORE_1.1v

• Both LTM4601and TI switching modules support auto-tracking, which is used for silicon power

sequencing control

• The LTM4604, 4A, (15 mm x 9 mm x 2.3 mm) DC/DC switching regulator generates +1.2V,

+1.5V, +1.8V, and +2.5v from either 5V rail or 3.3V rail.

• -12V is implemented on-board for PrPMC only with max I <= 350mA

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 28

28

1.3.6.3 Power Monitoring and Sequencing Control

• The Actel AFS600 is the on-board power monitor and power-on sequencing controller, and should

be working whenever 12V and 3.3V_MP are available. A 2.5V reference and a couple of

comparators are used to assist the sequencing control.

• Tsi620 sequencing: 1.5V1.2V3.3V

• TI-DSP sequencing: 1.8V 500uS CVdd and 1.1V

• FPGA sequencing: VCCio VCCcore

• Proposed sequencing: 12V 5V 1.5V 1.2V 3.3V 2.5V 1.8V 1.1V_core +

1.1V_dsp

• 3.3V_MP (100mA) is for AFS600. 3.3VSB is only working in stand-alone mode

The power-up sequencing has four stages:

1. After 3.3V_MP available, the AFS600 system controller is functioning and waiting for +12V from

the AMC backplane once the Hot Swap handler is closed.

2. When +12V is powered up and SW2 is turned on, the AFS600 signals to start +5V, 1.5V, and 1.2V.

3. After 1.2V is powered up, the third power chain, +3.3V, 2.5V, and 1.8V, start to ramp up.

4. When 1.8V power-good is detected, the sequencing control logic turns on the 1.1V_DSP and

1.1V_FPGA rails.

1.3.6.4 Power Consumption Assumption

The real power consumption of PrPMC and FPGA are critical to the power management. An active

cooling fan is required for the FPGA, and passive cooling heat sinks are needed for the DSP and

Tsi620.

• Assuming the power consumption of PrPMC module is <15W

• Assuming the power consumption of FPGA is <5W

• Assuming the power consumption of DSP + DDR2 are <10W

• Assuming the power consumption of MISC is <10W

• Assuming the power consumption of Tsi620 is <5W

So, the maximum power consumption allowed for the AMC vertical slot is <15W.

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 29

Figure 9: Power Distribution and Management

AMC12Vin

Plug-DC12Vin

@5A

@5A

DC/DC SW

LTM 4601

5V@ 8A

DC/DC SW

LTM 4601

3.3V@12A

DC/DC SW

LTM 4601

1.1V_DSP@10A

DC/DC SW

LTM 4601

1.1V@ 10A

DC/DC SW

LTM 4604

DC/DC SW

LTM 4604

DC/DC SW

LTM 4604

1.8V@4A

1.2V@ 4A

1.5V@ 2A

DC/DC SW

LTM 4604

2.5V@ 1A

5V@3A

3.3V@7A

DSP_IO,

AMC-Slot, PrPMC

FPGA

Tsi620_CORE

PrPMC, TSI620_IO

MISC_Devices

FPGA_IO, Tsi620_IO

DDR2 Memory

DSP_SERDES

FPGA_CORE

Scale

3.3VSB@1.0A

System

Management

+5V@3.5A

AFS600

Reset

Filters

1.1V@1.0A

DSP_CORE

Regulat or

senser

PLL Sy nc

PrPMC

FPGA_IO

-12V@0. 5A

Regulat or

PrPMC

Power

Monitoring

Sequencing

Control

Sequencing

29

1.3.7 JTAG Port and I2C Bus

1.3.7.1 JTAG Interface Implementation

• The Altera FPGA and Actel FPGA are in the same 3.3V JTAG chain (they share the single 10-pin

JTAG header)

• Tsi620’s internal registers can be accessed by either USB or JTAG header

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 30

30

System I2C Bus 3.3V

Tsi620

I2C

SFP2

EEPROM

SFP1

EEPROM

DSP

I2C

1.8V I2C Bus

CDCL

6010

• The FDTI-2232D is self-powered by 3.3V_USB from the mini-USB connector. It provides bridges

the USB interface and JTAG port for the Tsi620, and also provides a USB to UART interface for

the AFS600.

• JTAG connectors for the following:

— TI 6488 DSP (60-pin emulator)

— Tsi620 JTAG

— Actel FPGA and Stratix3 JTAG chain access

1.3.7.2 Local I2C Bus

There are two segments of the local I2C bus (see Figure 10):

• 3.3V I2C bus: The Tsi620 is I2C master. This bus includes the Tsi620 I2C EEPROM and two SFP

optical transceivers.

• 1.8V I2C bus: The DSP is I2C master. This bus includes the DSP, I2C EEPROM, and CDCL6010.

Figure 10: Local I2C Bus Connection

1.4 PCB Characteristics

1.4.1 PCB Form Factor

• Board form factor: AMC single width module

• Module dimension: 73.5 mm x 350 mm (Out-chassis section length 169 mm)

• Module height: Full height, components side 1 is <13.7 mm; components side 2 is <2.5 mm

• Thickness: 1.6 mm+/-10 %

• No mechanical front panel (face-plate) implemented

• Additional stand off or mounting holes are available for both chassis and standalone operation

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 31

1.5 Configuration Options

ON: represent “0” or logic “Low”

OFF: represent “1” or logic “High”

This section describes the configuration options for the Tsi620 evaluation board.

1.5.1 DIP Switches

Switches S1 to S5 combine four small slide switches identified with numbers 1 to 4 (see example in

Figure 5). For information on the individual DIP switches, see Tables 9 to 13.

31

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 32

32

1.5.1.1 S1 – DSP Boot-mode Setting

Table 9: S1[1:2:3:4] BSP Boot-mode Setting

Switch S1[1:2:3:4] BOOTMODE[0:3] DSP Boot-mode Note

ON-ON-ON-ON 0-0-0-0 No Boot

OFF-ON-ON-ON 1-0-0-0 I2C Master Boot A Not supported

ON-OFF-ON-ON 0-1-0-0 I2C Master Boot B I2C address at 0x51

OFF-OFF-ON-ON 1-1-0-0 I2C Slave Boot

ON-ON-OFF-ON 0-0-1-0 EMAC Master Boot

OFF-ON-OFF-ON 1-0-1-0 EMAC Slave Boot

ON-OFF-OFF-ON 0-1-1-0 EMAC Forced-Mode Boot

ON-OFF-ON-OFF 0-1-0-1 sRIO Boot – 1.25 G CFG2 - 1.25 G (Default)

OFF-OFF-ON-OFF 1-1-0-1 sRIO Boot – 3.125 G CFG3 – 3.125 G

All others Reserved

1.5.1.2 S2 – Tsi620 GPIO Setting

Table 10: S2[1:2:3:4] Setting

Switch S2 Signal Assignment Default ON/OFF Setting

Bit 1 Tsi620_GPIO16 OFF ON = 0 or logic low

OFF = 1 or logic high

Bit 2 Tsi620_GPIO17 OFF ON = 0 or logic low

OFF: 1 or logic high

Bit 3 Tsi620_GPIO18 OFF ON = 0 or logic low

OFF = 1 or logic high

Bit 4 Tsi620_GPIO19 OFF ON = 0 or logic low

OFF = 1 or logic high

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 33

1.5.1.3 S3 – MISC Setting

Table 11: S3[1:2:3:4] Setting

Switch S3 Signal Assignment Default ON/OFF Setting

Bit 1 PCI_M66EN 1 = OFF ON = Force PCI bus clock at 33 MHz

OFF = Set PCI bus clock at 66 MHz

Bit 2 Tsi620_BCE 1 = OFF ON = Set Tsi620_BCE to “0” for on-die-scope operation

OFF = Normal operation

Bit 3 FPGA_SET_3V3 1 = OFF ON = 0 or logic low to FPGA

OFF = 1 or logic High to FPGA

Bit 4 AFS_SET_3V3 1 = OFF Reserved

1.5.1.4 S4 – Tsi620 Option Setting

Table 12: S4[1:2:3:4] Setting

33

Switch S4 Signal Assignment Default ON/OFF Setting

Bit 1 TSI620_SP_HOST 1 = OFF ON = Force PCI bus clock at 33 MHz

OFF = Set PCI bus clock at 66 MHz

Bit 2 TSI620_I2C_DISABLE 1 = OFF ON = Set Tsi620_BCE to 0 for on-die-scope operation

OFF = Normal operation

Bit4_Bit3 TSI620_SP_IO_

SPEED[1:0]

1_0

OFF_ON

0_0 = 1.25 Gbps sRIO link

0_1 = 2.5 Gbps sRIO link

1_0 = 3.125 Gbps sRIO link

1_1 = Reserved

1.5.1.5 S5 – DSP Clocking Setting

Table 13: S5[1:2:3:4] Setting

Switch S5 Signal Assignment Default ON/OFF Setting

Bit 1 CORECLKSEL 1 = OFF ON = Force PCI bus clock at 33 MHz

OFF = Set PCI bus clock at 66 MHz

Bit 2 FPGA_SET_1V8 1 = OFF ON = 0 or logic low to FPGA

OFF = 1 or logic high to FPGA

Bit4_Bit3 30M72_SEL[0:1] 0_0

Intergrated Device Technology

www.idt.com

ON_ON

0_0: On-board 30.72 MHz oscillator

0_1: 30.72 MHz from AFS600

1_0: 30.72 MHz from FPGA

1_1: External 30.72 MHz clock from SMA J13

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 34

34

1.5.2 Jumpers

The Tsi620 evaluation board has only one jumper, J6, which is reserved for the future use. This jumper

should be left open for the normal operation.

1.5.3 Push Button and Toggle Switch

Reference Designator Switch Type Signal Assignment Function Description

SW1 Push button SOFT_RESETN When the button is pushed, the following

occurs:

• Negative asserted at Tsi620 pin, BLK_RSTN

• Negative asserted at DSP pin, XWRSTN;

and FPGA pin, FPGA_SRSTN

• Negative asserted at GigE PHY VSC8621

pin, SRESETN

SW2 Toggle Switch POWER_ON/OFF

HotSwap_

OPEN/CLOSE

SW3 Push button SYSTEM_RESETN When the button is pushed, the following

In non AMC-Chassis mode, after +12V applied,

SW2 functions as the power sequencing

ON/OFF switch.

In AMC-Chassis mode, SW2 functions as Hot

Swap switch

When switch handler position points to RJ45

side, it represents as “Power OFF” or “Hot

Swap Switch Open”.

When switch handler position points to push

button side, it represents as “Power ON” or

“Hot Swap Switch Close”.

occurs:

• Negative asserted FPGA pin, NCONFIG, for

FPGA re-configuration

• Negative asserted FPGA pin, FPGA_HRSTN

• Negative asserted Tsi620 pin, CHIP_RSTN

and TRSTN

• Negative asserted USB_RSTN

• Negative asserted DSP pin, PORSTN

• Negative asserted GigE PHY pin, HRSTN

• Positive asserted U7, 156.25M PLL buffer,

pin MR

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 35

Figure 11: Location of Switches and Connections

Tsi620 EVB Placement Top View

S1

S2

S3

S4

J14-FPGA SFP

J15-DSP SFP

U35

Mini-USB

U26

FPGA-RJ45

U34

GigE-RJ45

SW2

ON/OFF

J4: Mictor

U29

+12Vin

J2: DSP

Emulator Port

J10

Tsi620 JTAG

P1: AMC Slot

J5

FPGA Active

Serial

Programming

U21

U22

2-Chars

LED Display

SW1:

Soft-Reset

SW3:

System-Reset

J13: SMA

ExCLK 32.72MHz

DSP-GigE

AMC-GigE

J7/J8 & J11/J12

SMA to FPGA

S5

JN2

JN1

JN3

Tsi620 EVB Placement Bottom View

PrPMC

Connector

J9

FPGA JTAG

35

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 36

36

1.6 Board Connectors

This section discusses the external connectors on the Tsi620 evaluation board.

The pin definition for each board connector is not included in this document. For information

on pin assignments, see the Tsi620 evaluation board schematics (60D7000_SC003).

1.6.1 JTAG and FPGA Programming Connectors

Reference

Connector Name

DSP Emulator J2 A dedicated 60-pin header for TI DSP emulator connection

FPGA Programmer J5 A dedicated 10-pin header for Altera FPGA active serial flash programming

Designator

Function Description

FPGA JTAG J9 A 10-pin header of the JTAG chain of both Actel FPGA and Altera FPGA. The header

supports both Actel and Altera FPGA programming download cables.

Tsi620 JTAG J10 A dedicated 16-pin header for the Tsi620 JTAG port; this header is pin-matched to a

Wiggler JTAG cable.

USB Port U35 A mini-USB port to access the Tsi620 JTAG port or AFS600 UART port through an

FTDI FT2232D converter.

a. The header supports both Actel FPGA and Altera FPGA JTAG access only when both FPGAs are powered up. IDT does not

recommend re-programming the Actel FPGA without consulting the IDT Technical Support team.

b. Both J10 and U35 can be used to access the Tsi620’s internal registers through its JTAG port; however, they work exclusively.

c. FT2232D has independent USB-to-JTAG and USB-to-UART channels.

b

c

a

1.6.2 Communication Interface Connectors

Reference

Connector Name

FPGA RJ45 U26 A dedicated RJ45 port for Altera FPGA 10/100BaseT Ethernet interface

GigE RJ45 U34 Dual RJ45 Jack for GigE interface

Designator

Function Description

Upper RJ45 port: AMC-SGMII GigE port

Lower RJ45 port: DSP-SGMII GigE port

FPGA SFP J14 A dedicated FPGA SFP connector of antenna RF SerDes interface for OBSAI at

DSP SFP J15 A dedicated DSP SFP connector of antenna RF SerDes interface for OBSAI at

a. IDT recommends Avago optical transceiver: AFBR-57J5APZ, tri-speed OBSAI/CPRI optical transceiver.

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

768 Mbps or CPRI at 614.4 Mbps

3072 Mbps or CPRI at 2457.6 Mbps.

a

a

Intergrated Device Technology

www.idt.com

Page 37

1.6.3 SMA Connectors

Reference

Connector Name

Designator

37

Function Description

Differential SMA pair J7 & J8 Connected to FPGA pin, AE2 & AF1

Differential SMA pair J11 & J12 Connected to FPGA pin, AC2 & AC1

MICTOR J13 30.72 MHz external clock source

a. LVDS or 2.5V

b. 3.3VTTL

a

a

b

1.6.4 MISC Connectors

Reference

Connector Name

+12V Supply U29 A dedicated +12V DC barrel input connector

AMC Slot P1 AMC card slot with the components side facing SMA

MICTOR J4 A 32-pin Mictor connector attached to the FPGA

PrPMC J17, J18,

a. IDT recommends minimal 5A supply capability.

Designator

J16

Function Description

a

Standard PrPMC card connector

1.7 LEDs and Display

The following figure shows the location of the board’s LEDs and displays.

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 38

38

J14-FPGA SFP

J15-DSP SFP

D21

U21

U22

2-Chars

LED Display

D22

D20

D16

D17

D3

D5

D6

D7

D15

D14

D13

D12

D19

D18

D11

D10

D9

D8

Figure 12: Location of LEDs and Displays (Top View)

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 39

1.7.1 Power Good Indicators

Reference

Designator

D21 Red Indicates +12V and 3.3VSB are good

D22 Orange Indicates 5V is good

D20 Orange Indicates 3.3V is good

D16 Green Indicates 1.1V_DSP is good

Color Description

39

D17 Green Indicates 1.1V_FPGA is good

a. Not supported by the Tsi620 evaluation board.

1.7.2 AMC MMC LEDs

Reference

Designator

D15 Yellow Pharos Flash: Normal operation

D14 Green MMC LED2

D13 Red MMC LED1

D12 Blue MMC LED0

Color Description

1.7.3 LED Display

Two 7-segment LED displays, U21 and U22, are directly controlled by the FPGA. The LED display

can be used as an FPGA operation status indication.

a

Solid Yellow: Either HRSTn or SRSTn is asserted

1.7.4 Tri-color LEDs

D18 and D19 are tri-color LED devices, which are attached to the Actel FPGA AFS600. By default,

D18 and D19 demonstrate rotated color display in the second interval. They can be used as a board

status indicator by the system controller, which is implemented with the AFS600 FPGA.

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 40

40

1.7.5 SFP Optical Transceiver LEDs

Reference

Designator

D8 Green J14 SFP optical transceiver transmitter is good

D9 Orange J14 SFP optical transceiver receiver is good

D10 Green J15 SFP optical transceiver transmitter is good

D11 Orange J15 SFP optical transceiver receiver is good

1.7.6 GPIO LEDs

Reference

Designator

D3 Yellow Tsi620 GPIO20:

D5 Yellow Tsi620 GPIO21:

D6 Yellow Tsi620 GPIO22

Color Description

Color Description

0 = ON

1 = OFF

0 = ON

1 = OFF

0 = ON

1 = OFF

D4 Yellow Tsi620 GPIO23

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

0 = ON

1 = OFF

Intergrated Device Technology

www.idt.com

Page 41

2. Board Software

This chapter describes how to use the software that is on the Tsi620 evaluation board. The following

topics are discussed:

• “PMC Software” on page 41

• “FPGA Software” on page 45

• “DSP Software” on page 51

• “PMC/DSP/FPGA Software Execution” on page 53

2.1 PMC Software

The Tsi620 evaluation board (EVB) features a PCI Mezzanine Card (PMC) connector on the underside

of the board for connecting a third-party board to the PCI port of the Tsi620. The standard evaluation

kit ships with the Embedded Planet EP8343 PMC connected to this port. The software running on the

PMC is based on the Linux kernel, the GNU software utilities, and custom applications provided by

IDT. The PMC software demonstrates the use of Tsi620 generated RapidIO transactions to access both

the FPGA and the DSP from the PMC.

41

The PMC software consists of four main components:

• Linux kernel and GNU utilities

• Tsi620 driver (tsi620.ko)

• RapidIO device access driver (rio-dev.ko)

• User space applications

The Linux kernel is based on version 2.6.26 available from www.kernel.org. A few modifications have

been done to the kernel to provide for better support of the EP8343 board and enhanced RapidIO

capabilities. The modified source of the Linux kernel is licensed under the GNU Public Licence (GPL),

and is available on the companion CD for the Tsi620 evaluation board. The GNU utilities consist of a

number of programs for Unix-like operating systems. The utilities included are from the Embedded

Linux Development Kit (ELDK) collection available from www.denx.de.

The Tsi620 driver (tsi620.ko) is a low-level hardware driver for the Linux operating system that allows

the Tsi620 device to be accessed as a RapidIO device. This driver translates RapidIO requests from the

Linux kernel into PCI accesses that perform the requested operations from the Tsi620. While the source

code for this driver is available on the companion CD for the Tsi620 evaluation board, the driver is not

licensed under the GPL and should not be compiled into the kernel. As a result, only the compiled

binary kernel module (tsi620.ko) should be distributed to customers (for licensing information, please

contact IDT by sending an email to sRIO@idt.com).

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 42

42

The RapidIO device access driver (rio-dev.ko) is another kernel module that allows for user space

applications to communicate with RapidIO devices. This driver allows special device files (in the /dev

directory of the system) to be created and used to access RapidIO devices as if they were simply a file.

The driver works with any RapidIO host that implements a specific set of kernel interfaces; however,

the only known driver that implements these interfaces is the Tsi620 driver. For example, the RapidIO

port built into the Freescale 8548 could potentially be accessed through this driver, however the

Freescale driver would have to be modified to support the device access routines. Because the driver

depends on the RapidIO system being enumerated, this driver must be loaded after the RapidIO

hardware driver. As the Tsi620 driver may only be loaded from a binary module after boot, the device

access driver should also be compiled as a binary module and loaded after the Tsi620 driver. This

driver may be released under the GPL, and the source code is included with the Linux kernel code on

the companion CD for Tsi620 evaluation board.

The user space applications demonstrate access of RapidIO devices using the device access driver

described above. The applications communicate with the DSP (or FPGA) to demonstrate correct

operation of the Tsi620 driver. There are two included applications:

• memdump – This accesses the memory of an endpoint and displays its memory contents

• askdsp – This communicates with a program executing on a DSP to perform a calculation

Although both applications are relatively simple, they demonstrate that the RapidIO devices are

accessible and useful from user space. This means that much more complex applications may be built

using RapidIO resources to extend and enhance the system’s capabilities. The user space applications

are provided in pre-compiled binary form on the EP8343 ramdisk image, or in both pre-compiled and

source code form on the EP8343 NFS image (both which can be found on the companion CD for the

Tsi620 evaluation board).

2.1.1 Running the Software Using Ramdisk

1. Ensure the serial cable is connected to the PMC’s RS-232 port using an RJ-45 cable and an RJ-45

to DB9 adapter.

2. Start the terminal program of your choice.

IDT has had success using the TeraTerm software although other terminal emulation programs can

be used (for information about the TeraTerm software, see hp.vector.co.jp/authors/VA002416/

teraterm.html). The terminal program should be configured to communicate 115200 bps with 8

data bits, 1 stop bit, and no parity bits.

3. Power up the Tsi620 evaluation board by connecting the power adapter, and setting the toggle

switch to the “on” position.

The U-Boot boot loader software should start and a prompt should appear on the terminal program.

4. Enter the command run rd.

This command boots the Linux kernel stored in flash. The Linux kernel uses a ramdisk stored in

flash as the file system.

5. Log in to the system as “root”; no password is required.

From the shell prompt you are presented with, enter the command cd /root to get to the root

user's home directory.

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 43

6. Load the binary kernel drivers by executing insmod ./tsi620.ko followed by

insmod ./rio-dev.ko.

7. Enter the command ls to see a list of directory contents. There are two programs:

• askdsp

• memdump

8. Enter the command ./memdump to see the contents of a portion of the DSP L2 cache. Additional

areas of DSP memory space can be viewed by specifying the memory address. For more

information, run ./memdump -h and a list of options are displayed. For information about the

DSP memory map, see the Texas Instruments 6487 User Manual.

9. If the DSP software is currently running on the DSP (see “Running the DSP Software”) then you

can enter the command ./askdsp 100.

This places a value of 100 in the DSP’s memory, and asks the DSP to calculate the square root of

the number. Other values can be substituted for 100.

2.1.2 Running the Software Using NFS Server

To facilitate testing and development, the PMC can also be run using a kernel and filesystem not stored

on internal Flash memory. A filesystem usable for this type of execution is provided on the CD;

however, directions for configuring an NFS server is beyond the scope of this document. To execute a

kernel downloaded from a remote TFTP server, and to boot it using a remote NFS file system,

complete the following:

43

1. Complete steps 1 to 3 in “Running the Software Using Ramdisk” to enter the U-Boot console.

2. Set the PMC’s IP address to a static value using the setenv ipaddr command (for example,

setenv ipaddr 192.168.1.6).

3. Set the address of the TFTP server to be used by using the setenv serverip command (for

example, setenv serverip 192.168.1.50).

4. Set the filename environment variable to the name of the kernel located on the TFTP server (for

example, setenv filename cuImage.mpc834x).

5. Set the nfsargs variable in U-Boot with the setenv nfsargs command (enter the

printenv command to see an example). When completing this command, ensure the

riohdid=1 argument is present in the argument.

6. Use the run nfs command to download the kernel and run it.

7. You may now complete execution by performing steps 5 to 9 in “Running the Software Using

Ramdisk”.

Intergrated Device Technology

www.idt.com

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Page 44

44

2.1.3 Installing the PMC Software

The PMC software is pre-installed on the Flash memory of the PMC. Re-installation is only required if

you need to modify the software (see “Modifying the PMC Software”).

Installing the software onto the Flash memory of the PMC requires it to be transferred to the card using

a TFTP server. Note that kernels must be in “cuImage” or “compatibility uImage” file format, and that

ramdisks must be in U-Boot image file format. The default images included on the CD are of this

format.

To install the PMC software, complete the following steps:

1. Follow step 1 to 3 in “Running the Software Using Ramdisk” to enter the U-boot console.

2. Set the PMC’s IP address to a static value using the setenv ipaddr command (example: setenv

ipaddr 192.168.1.6).

3. Set the address of the server to be used by using the setenv serverip command (example:

setenv serverip 192.168.1.50).

4. If installing a new Linux kernel, set the name of the kernel file on the TFTP server by using the

setenv kernel command (for example, setenv kernel cuImage.mpc834x). Transfer

the kernel and save it to flash using run install_kernel.

5. If installing a new ramdisk, set the name of the image file on the TFTP server by using the

setenv ramdisk command (for example, setenv ramdisk ramdisk.img). Transfer the

file and save it to flash using run install_ramdisk.

6. Run saveenv to save changed environment variables to flash (this is required to update file

sizes).

2.1.4 Modifying the PMC Software

To modify the PMC software, different steps must be followed depending on which aspect of the PMC

software you wish to modify.

2.1.4.1 Modifying the Linux Kernel

To modify the Linux kernel, unpack the source code from the CD into a directory of your choice. The

kernel may be compiled with ELDK 4.1 software available from DENX (www.denx.de) with the

“ARCH” and “CROSS_COMPILE” environment variables set to “powerpc” and “ppc_82xx-”

respectively. Note that the included Linux kernel source has been modified by IDT to support

additional RapidIO functionality, and to include the rio-dev driver. These modifications can be

distributed to customers or applied to your own custom software under the terms of the GPL. A sample

kernel configuration file which will build the kernel with these features enabled is included in

config.rio in the source directory. This file can be copied to “.config” to build a kernel with identical

functionality to the included precompiled kernel.

Example:

[/root] export ARCH=powerpc

[/root] export CROSS_COMPILE=ppc_82xx[/root] tar -xjf linux-2.6.26-rio

[/root] cd linux-2.6.26-rio

Tsi620 Evaluation Board User Manual

60D7000_MA001_03

Intergrated Device Technology

www.idt.com

Page 45

[/root/linux-2.6.26-rio] cp config.rio .config

[/root/linux-2.6.26-rio] make

2.1.4.2 Modifying the Tsi620 Driver

The Tsi620 low-level driver is not included in the Linux kernel source code because it is not licensed

under the GPL. To compile the binary kernel module, first compile the kernel as described above.

Uncompress the Tsi620 driver into a location of your choice and — from the Linux kernel source

directory — run “make SUBDIRS=<location> modules” with the same environment settings.

Example: