Page 1

®

Tsi382™ (BGA)

Evaluation Board User Manual

60E2010_MA001_03

September 28, 2009

6024 Silver Creek Valley Road, San Jose, California 95138

Telephone: (800) 345-7015 • (408) 284-8200 • FAX: (408) 284-2775

©2009 Integrated Device Technology, Inc.

Printed in U.S.A.

Page 2

Integrated Device Technology, Inc. reserves the right to make changes to its products or specifications at any time, without notice, in order to improve design or performance

and to supply the best possible product. IDT does not assume any responsibility for use of any circuitry described other than the circuitry embodied in an IDT product. The

Company makes no representations that circuitry described herein is free from patent infringement or other rights of third parties which may result from its use. No license is

granted by implication or otherwise under any patent, patent rights or other rights, of Integrated Device Technology, Inc.

GENERAL DISCLAIMER

Code examples provided by IDT are for illustrative purposes only and should not be relied upon for developing applications. Any use of the code examples below is completely

at your own risk. IDT MAKES NO REPRESENT ATIONS OR WARRANTIES OF ANY KIND CONCERNING THE NONINFRINGEMENT, QUALITY, SAFETY OR SUITABILITY

OF THE CODE, EITHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT. FURTHER, IDT MAKES NO REPRESENT ATIONS OR WARRANTIES AS TO THE TRUTH, ACCURACY OR COMPLETENESS

OF ANY STATEMENTS, INFORMATION OR MATERIALS CONCERNING CODE EXAMPLES CONTAINED IN ANY IDT PUBLICATION OR PUBLIC DISCLOSURE OR

THAT IS CONTAINED ON ANY IDT INTERNET SITE. IN NO EVENT WILL IDT BE LIABLE FOR ANY DIRECT, CONSEQUENTIAL, I NCIDENTAL, INDIRECT, PUNITIVE OR

SPECIAL DAMAGES, HOWEVER THEY MAY ARIS E, AND EVEN IF IDT HAS BEEN PREVIOUSLY ADVISED ABOUT THE POSSIBILITY OF SUCH DAMAGES. The code

examples also may be subject to United States export control laws and may be subject to the export or import laws of other countries and it is your responsibility to comply with

any applicable laws or regulations.

Integrated Device Technology's products are not authorized for use as critical components in life support devices or systems unless a specific written agreement pertaining to

such intended use is executed between the manufacturer and an officer of IDT.

1. Life support devices or systems are devices or systems which (a) are intended for surgical implant into the body or (b) support or sustain life and whose failure to perform,

when properly used in accordance with instructions for use provided in the labeling, can be reasonably expected to result in a significant injury to the user.

2. A critical component is any components of a life support device or system whose failure to perform can be reasonably expected to cause the failure of the life support device

or system, or to affect its safety or effectiveness.

IDT, the IDT logo, and Integrated Device Technology are trademarks or registered trademarks of Integrated Device Technology, Inc.

CODE DISCLAIMER

LIFE SUPPORT POLICY

Page 3

Contents

About this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Related Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1. Board Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 PCI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.2 IDSEL Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.3 Interrupt Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.4 Pull-up Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 PCIe Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.1 Power Regulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4.3 Power Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.4 System Power Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4.5 PCI Vaux (PCI Auxiliary) Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5 Clock Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5.1 PCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.5.2 System Clock Distribution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.6 Other Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.6.1 JTAG Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.6.2 EEPROM Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.6.3 GPIO Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.7 Hardware Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.8 Logic Analyzer Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3

2. Configurable Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1.1 DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1.2 Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2 Shunt Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.2.1 J6 Shunt Jumper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.2.2 J21 Shunt Jumper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.3 Debug Headers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.3.1 J22 Tsi382 JTAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.3.2 J23 Logic Analyzer PADs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.4 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 4

Contents4

2.4.1 J1, J2, J36, J37 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.4.2 J3 ATX Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.4.3 P1 x1 PCIe Finger Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.5 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 5

About this Document

This document describes how to test the key features of the Tsi382 using the Tsi382 evaluation board.

It can be used in conjunction with the Tsi382 Evaluation Board Schematics.

Related Information

• Tsi382 User Manual

• Tsi382 Evaluation Board Schematics

• PCI Express Base Specification (Revision 1.1)

• PCI Express CEM Specification (Revision 1.1)

• PCI Express-to-PCI/PCI-X Bridge Specification (Revision 1.0)

Terms

5

Term Definition

PCIe PCI Express

SerDes Serial/De-serializer

Revision History

60E2010_MA001_03, Formal, September 2009

This document was rebranded as IDT. It does not include any technical changes.

60E2010_MA001_02, Formal, January 2008

There were no technical changes made to this version.

60E2010_MA001_01, Formal, January 2008

This is the first version of the Tsi382 Evaluation Board User Manual.

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 6

About this Document6

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 7

1. Board Design

Topics discussed include the following:

• “Overview” on page 7

• “PCI Interface” on page 9

• “PCIe Interface” on page 10

• “Power Management” on page 10

• “Clock Management” on page 14

• “Other Interfaces” on page 15

• “Hardware Reset” on page 16

• “Logic Analyzer Connectivity” on page 17

7

1.1 Overview

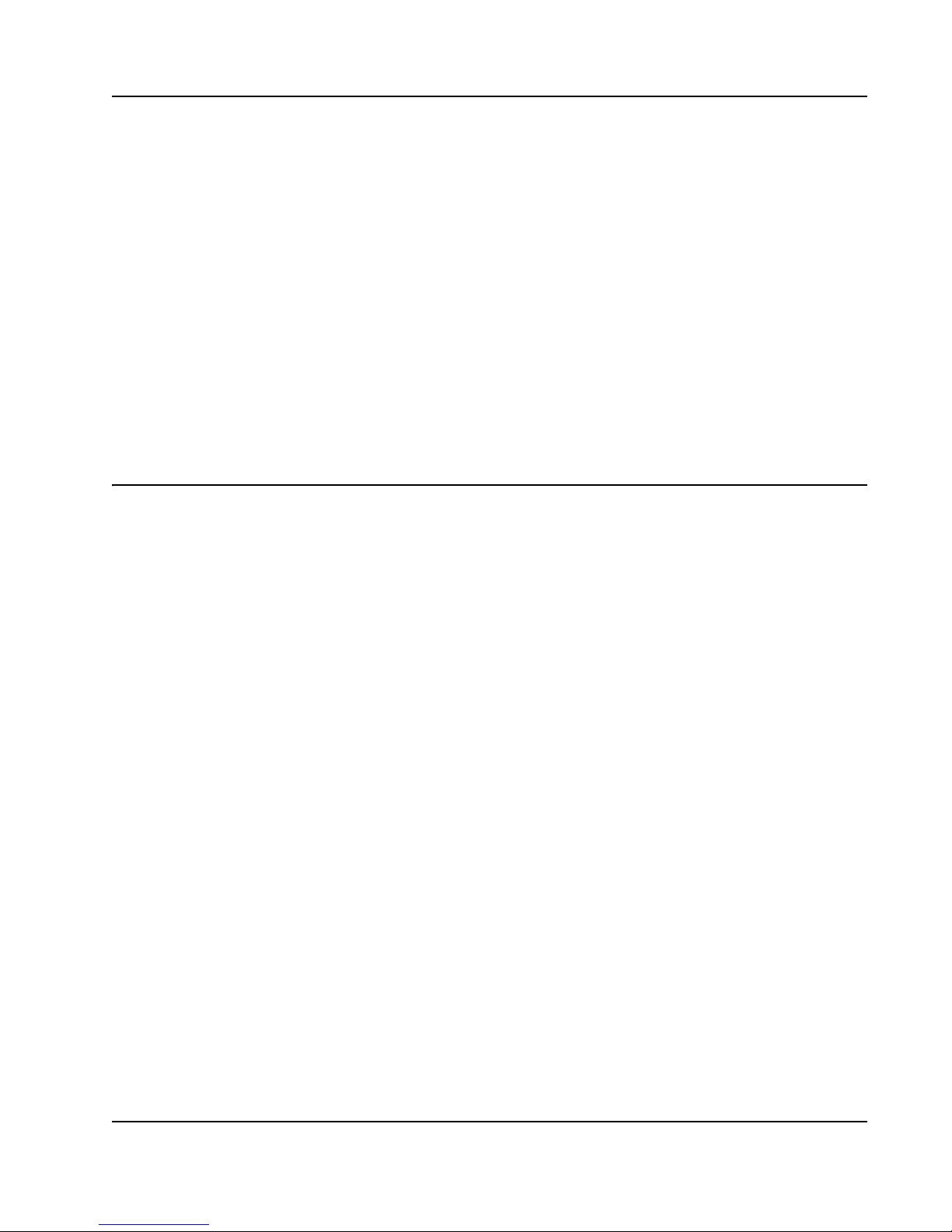

The key features of the Tsi382 evaluation board include the following (see also Figure 1):

• Single x1 lane, 2.5 Gbps PCIe 1.1 compatible riser card (extended height form factor)

• Four PCI slots

• 32-bit PCI bus, 25–66 MHz operation

• PCI power support through system or external supply

• PCIe compliance/debugging test points

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 8

Figure 1: Evaluation Board Block Diagram

EEPROM

Tsi382

3.3V PCI 32-b it Connector

Slot 0

PCI

Power

Management

PCI Expres s Card Edge X1

PCIe

LA Probe

JTAG

Header

ATX Connectors

EEPROM

1x SerDes SMA

Points

SerDes Path

Resistor Select

Clock

Management

3.3V PCI 32-bit Connector

Slot 1

3.3V PCI 32-bit Connector

Slot 2

3.3V PCI 32-bit Connector

Slot 3

GPIO

GPIO

1. Board Design > Overview8

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 9

1. Board Design > PCI Interface 9

1.2 PCI Interface

1.2.1 Overview

The PCI Interface is implemented on the board with four slots, in which one is an R/A mounted

connector on the top of the board. All PCI connectors are compliant with the PCI 3.0 specification.

Appropriate clearance is provided such that up to four PCI cards can be inserted for testing while the

board is in an open-chassis standard ATX case.

The PCI Interface supports four slots operating at 25, 33, 50, or 66 MHz.

1.2.2 IDSEL Signals

IDSEL signals are connected in the following order:

• Slot 0 – R/A connector top slot: 150 ohms to AD16 (Device 0)

• Slot 1 – 150 ohms to AD17 (Device 1)

• Slot 2 – 150 ohms to AD19 (Device 3)

• Slot 3 – 150 ohms AD18 (Device 2)

1.2.3 Interrupt Signals

The PCI interrupt signals are connected to the slots as shown in the following table.

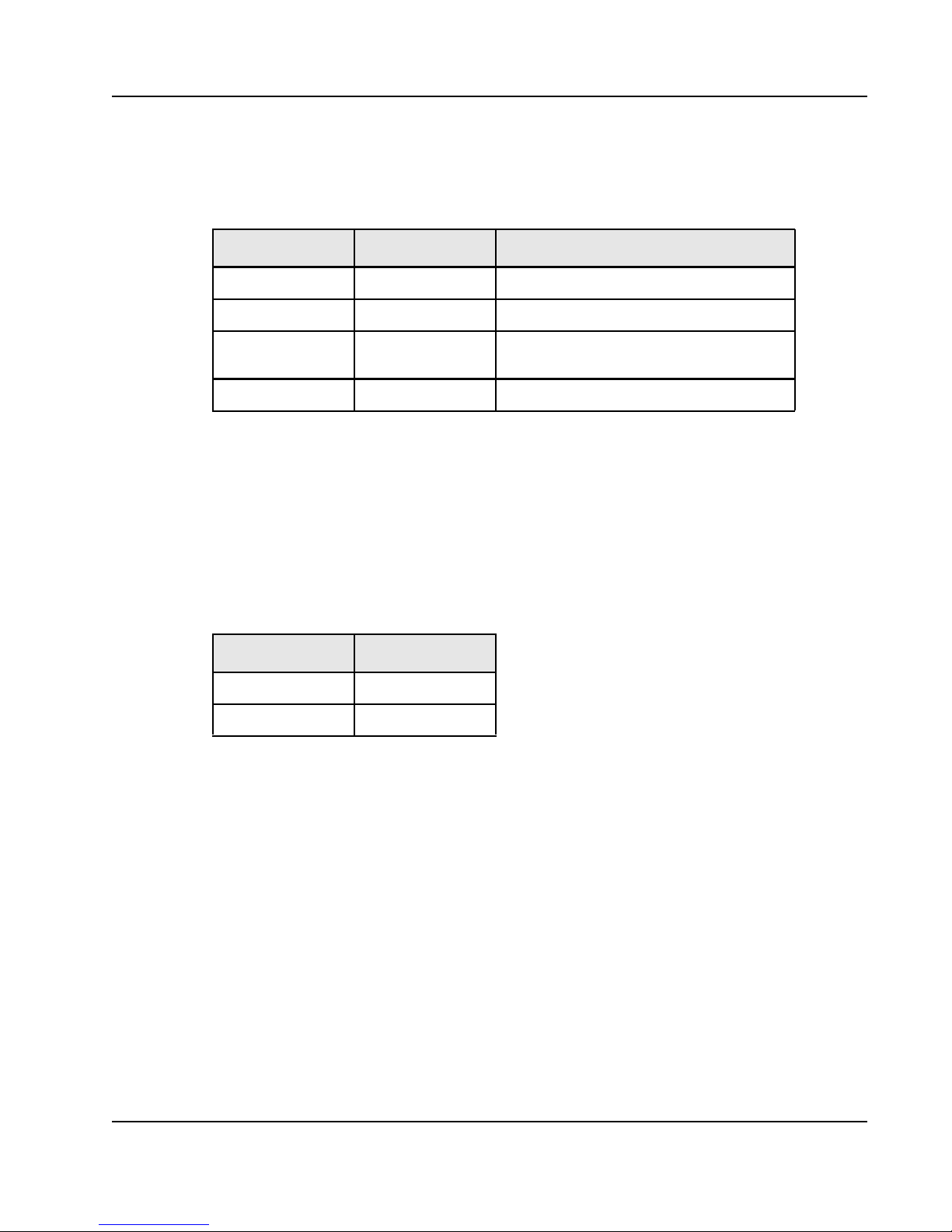

Table 1: PCI Interrupt Routing

Tsi382 Slot 0 Slot 1 Slot 3 Slot 4

AABDC

BBCAD

CCDBA

DDACB

1.2.4 Pull-up Signals

The following pull-ups are added to the PCI bus, in which a value of 8.2Kohm is used.

Table 2: PCI Pull-up Signals

Signal Description

PCI_REQ#[0:3] Bus request

PCI_GNT#[0:3] Bus grant

PCI_FRAME# Control signal

PCI_IRDY#, PCI_TRDY# Control signal

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 10

Table 2: PCI Pull-up Signals (Continued)

Signal Description

PCI_STOP# Control signal

PCI_SERR# System error

PCI_PERR# Parity error

PCI_DEVSEL# Device select line

PCI_INT#[A:D] Interrupt line

PCI_PME# PCI Power Management Event occurred

1.3 PCIe Interface

The Tsi382 evaluation board implements a single lane PCIe Interface. It is designed to connect to a

PCIe system with a standard x1 finger connector. The system must provide the REFCLK and PERSTN

signals. The PCIe Interface has the following design elements:

1. Board Design > PCIe Interface10

• Supports hot insertion and removal

• Mid-bus logic analyzer pads for PCIe RXD/TXD signal probing

• AC coupling on the TXD lanes

• JTAG TDI - TDO loopback for chain continuity

The PCIE_REXT signal must be tied to ground through a 190-ohm resistor.

1.4 Power Management

1.4.1 Power Regulation

The evaluation board’s power regulation is implemented as follows:

• Digital 3.3V power supply available from DC/DC regulator or ATX supply

• Digital 1.2V switching regulator

• PCIe supplies filtered using EMI ferrite networks

To support PCI cards, the following additional power resources are included:

• 12V to 5V DC/DC converter

• 12V to 3.3V DC/DC converter

• External power connectors – ATX 20-pin connector for supplying all power from an ATX power

supply

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 11

1. Board Design > Power Management 11

1.4.2 Power Requirements

The power requirements and implementation for the Tsi382 is as follows.

Table 3: Tsi382 Power Requirements

Supply Name Symbol Supplied Source

Device Core 1.2V_384 DC/DC switching regulator w/Enable pin

PCIe 1.2V Core 1.2V_A_384 Passive Filter

PCI 3.3V supply 3.3V_384 Power switch w optional Ferrite filter to reduce

EMI/noise from PCI environment

PCIe 3.3V supply 3.3V_A_384 Passive Filter

The target power draw of the Tsi382 is a maximum of 1W, all supplies combined. The supplies to the

Tsi382 are controlled during ramp up using enable pins on regulators and switches.

1.4.2.1 PCIe

The PCIe CEM Specification 1.1 defines power limits on PCIe slots according to the number of lanes

available on a card. Power rules regarding x1 PCIe slots are a maximum of 25W slot. Current limits are

included in Table 4.

Table 4: PCIe Connector Current Limits

Rail Current

3.3V 3A

12V 2.1A

The usage of the 12V supply provides access to the full 25W available from the system to the board.

The PCIe pinout design includes more 1 2V power pi ns as it allows more power -per -pin capability. The

evaluation board regulates all power from the 12V system rail; however, 3.3V from the system remains

unused.

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 12

1.4.2.2 PCI

The PCISIG defines the power rules regarding PCI cards as a maximum of 25 Watts per card (All

power rails combined power draw). The individual current limits on voltage rails are included in

Table 5.

Table 5: PCI Connector Current Limits

It is not possible to provide the full power required to the PCI bus without violating the specification

while drawing power from only a x1 PCIe system. Up to 23W not including regulator efficiency losses

can be made available. The evaluation board provides the power requirements in one of two ways

depending on the application:

1. Board Design > Power Management12

Rail Current

3.3V 7.6A

5V 5A

-12V 100mA

12V 500mA

• PCIe system power

• ATX System connector

The following conditions summarize the power available for a single PCI card without external supply.

An efficiency of 85% is taken into account for switching regulators. These limits can be exceeded in

cases where the system can provide more than the suggested limit, which is usually only implemented

in hot swap systems.

Table 6: PCI Connector Current Limit with No External Supply

Rail Supplying Topology Current (Maximum)

3.3V 12V to 3.3V regulator 6A

12V 12V directly 500mA

-12V N/A N/A

5V 12V to 5V regulator 4A

For additional slots, or in cases where the system cannot supply enough power, a separate ATX power

connector is used to power the card. The evaluation board senses the presence of this supply, and

disables the slave PCIe slot power. For the case of a separate external ATX supply, all four slots are

provided with the required power.

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 13

1. Board Design > Power Management 13

3v3/5v DC/DC

Regulator

(TPS5124)

PCIe

System

12v

ATX

20-pin

-12v

12v

5v

3.3v

Unused

GND

1.2v DC/DC

12V

3.3V

1.2V

Power

Sequencer

3.3v/5v Disable

1.2V PCIE_VDD

3.3V PCIE AVDD

-12V

3.3V I/O

PCI

Bus

Connectors

Current

Sense

Current

Sense

Current

Sense

Current

Sense

Tsi382

Electronic/Mech

Breaker w/

Current Limit

1.4.3 Power Sequencing

On power-up, the board’s power sequence is as follows:

1. 1.2V powered on

2. PCI I/O slot power and pull-ups, and Tsi382 3.3V

12V/-12V/5V PCI are not sequence controlled.

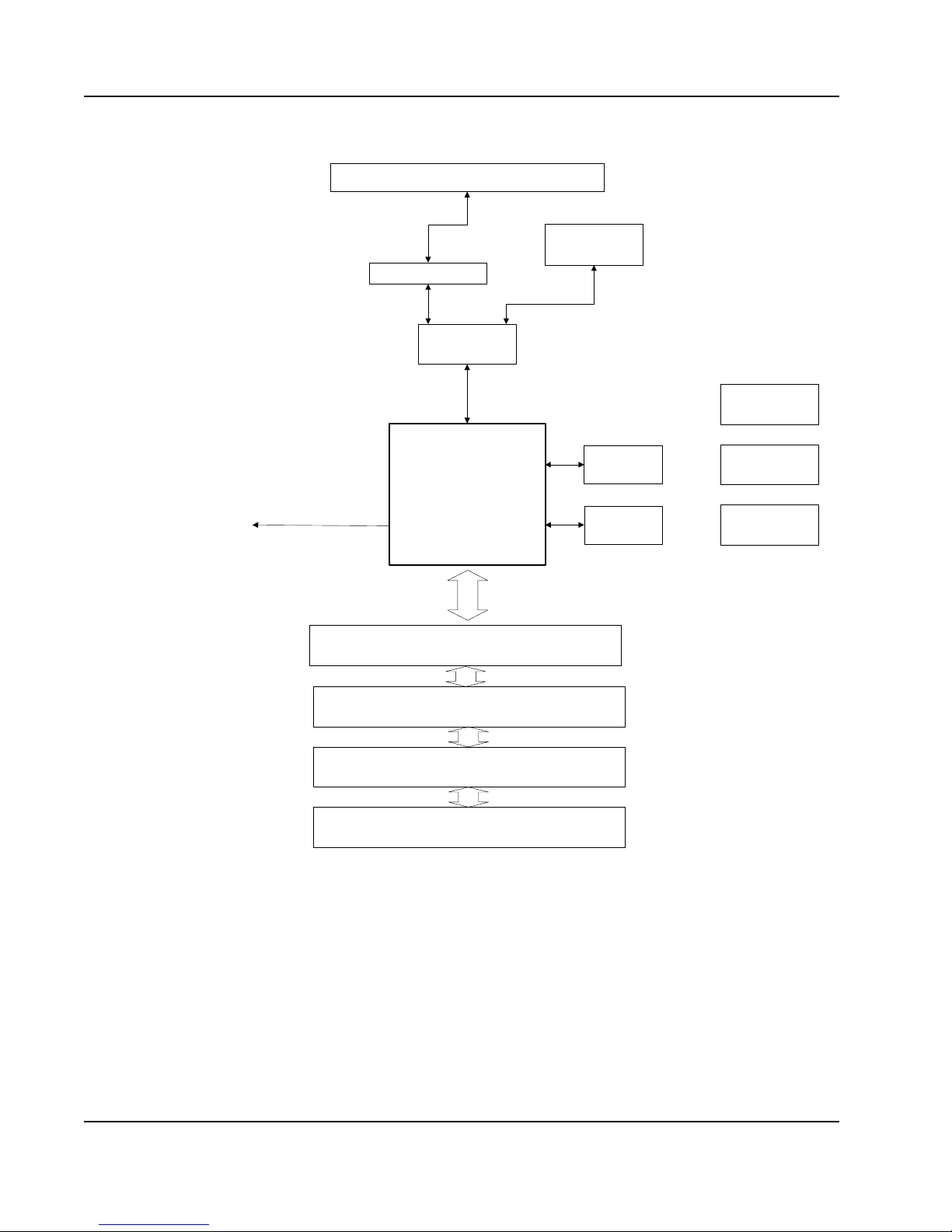

1.4.4 System Power Design

Figure 2 illustrates the power distribution for the riser card. The following list is a functional summary

of the power design:

1. Sequencing control over the following rails:

•3.3V PCI

• 3.3V Tsi382 I/O/PCIe A

• 1.2V Ts i382 Core/PCIe V

2. ATX 20-pin connector override, which disables all power draw from the PCIe system.

Figure 2: System Power Distribution

VDD

DD

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 14

1.4.5 PCI Vaux (PCI Auxiliary) Support

PCI connectors are provided with a 3.3V supply to the vaux pins only during operation. There is no

support for this power supply in standby mode.

1.5 Clock Management

The Tsi382 requires up to two input clocks to operate:

• 25–66 MHz clock for PCI

• 100-MHz reference clock for PCIe

The PCI and PCIe input clocks are briefly discussed .

The Tsi382 supports five PCI clock outputs, PCI_CLKO[0:4]. The Tsi382 evaluation board

demonstrates only PCI_CLKO[0:1].

1.5.1 PCI

The evaluation board supports master and slave clocking for PCI.

1. Board Design > Clock Management14

• Master – When in master mode, the Tsi382 generates the required PCI clock for all slots.

• Slave – When in slave mode, an on-board selectable 25–66 MHz clock generator is used.

On-board resistor muxes are used to multiplex either Tsi382’s PCI clock or the external clock

generator.

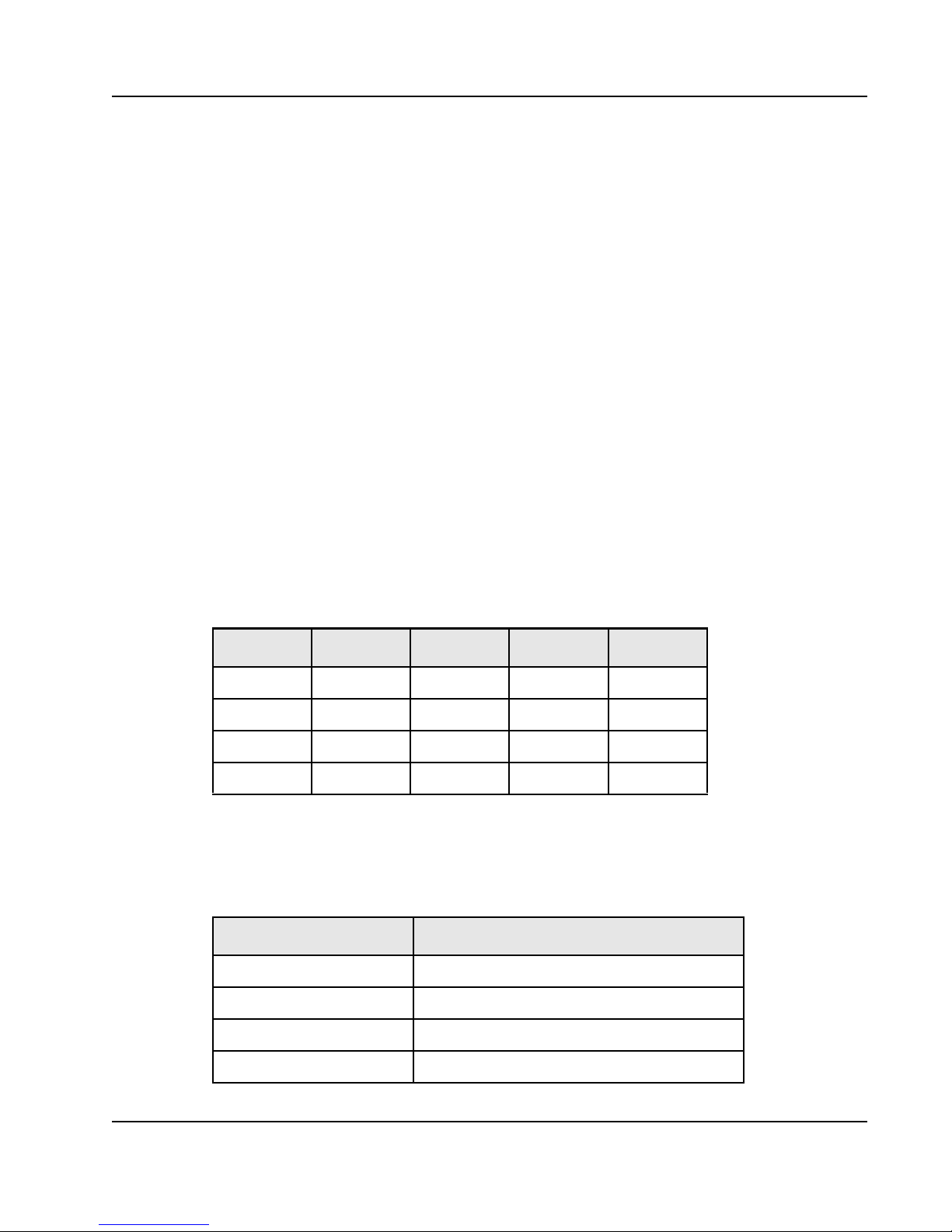

1.5.1.1 PCIe

For PCIe clocking, a 100-MHz differential HCSL clock source is required. The clock source is

available in two forms:

• Edge connector clock source – This clock source synchronizes the system SerDes with the Tsi382.

• On-board 100-MHz reference – This clock source can separate the clock domains between the

The two PCIe clock sources are multiplexed with an analog multiplexer to select between the system

clock or on-board clock (see Figure 3).

bridge and the root complex.

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 15

1. Board Design > Other Interfaces 15

Tip

ICS87604I

PCIe System

PCIe_REFCLK

PCI Bus

Connectors

Tsi382

PCI_CLK

CLKOUT[0:1]

PCI_INT_CLK[0]

PCI_EXT_CLK[0]

PCI Clock

Buffer

CY2305

PCI_FBK_CLK

PCI_CLK[0:3]

PLD

ICS557-01

Diff.

SMA

Input

Passive

Mux

(0r0 RES)

ANALOG

MUX

PCIe_SYS_CLK

PCIe_GEN_CLK

PCIe_BERT_CLK

PCIe_REF_CLK

(AC coupled)

Config

PCI_EXT_CLK[1]

Resistor Mux

for CPLD

PCI_INT_CLK[1]

1.5.2 System Clock Distribution

The following figure shows the distribution of the system clock on the Tsi382 evaluation board.

Figure 3: System Clock Distribution

1.6 Other Interfaces

1.6.1 JTAG Interface

1.6.2 EEPROM Interface

Integrated Device Technology

www.idt.com

To support debug and testing of device, JTAG access to the Tsi382 is available using a standard JTAG

header for Wiggler connection.

For more information about accessing the Tsi382 using JTAG, see the JTAG Register Access

Software Application Note.

A single EEPROM device socket is available for programming the Tsi382’s registers during startup.

The socket is in an 8-pin DIP format.

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 16

1.6.3 GPIO Interface

PCIe Edge Connector X1

Reset

Controller

SYS_PCIe_PERSTn

PUSHBUTTON

PCIe_PERSTn

The GPIO Interface is comprised of the following:

• On-board LEDs on GPIO lines

• Available 100mil Header to send/receive external 3.3V level signals

The following list outlines the connections to GPIO :

• External I/O header:

— J7.1: NC

— J7.2: GPIO0

— J7.3: GPIO1

— J7.4: GPIO2

— J7.5: GPIO3

— J7.6: Connected to ground

• LEDs:

— D11: GPIO0, active led when driven low

1. Board Design > Hardware Reset16

— D1: GPIO1, active led when driven low

— D13: GPIO2, active led when driven low

— D12: GPIO3, active led when driven low

1.7 Hardware Reset

The following figure shows the reset options of the Tsi382 evaluation board.

Figure 4: Board Reset

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 17

1. Board Design > Logic Analyzer Connectivity 17

Tip

Three levels of reset are available:

• Cold reset – This reset is applied during power up. System (card edge) PCIe_PERSTn is muxed

with the board’s reset controller.

• Warm reset – This reset is activated by a push-button reset on the board.

• Hot reset – This reset is activated by the in-band message sent by the root complex. No supporting

hardware is necessary.

For more information on cold, warm, and hot reset levels, see the “Resets, Clocking, and

Initialization Options” chapter in the Tsi382 User Manual.

1.8 Logic Analyzer Connectivity

The serial buses have Midbus pads (TMS818 probe) for visibility of SerDes lines using a

pre-processor. Each probing pad provides access to the RX and TX segments of a x1 link.

T o access the PCI bus, a Nexus PCI interposer card can be used with Tektronix mictor cables. The card

can be plugged into any PCI edge slot, or in-line with the device under test.

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 18

1. Board Design > Logic Analyzer Connectivity18

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 19

2. Configurable Options

ON

OFF

Topics discussed include the following:

• “Switches” on page 19

• “Shunt Jumpers” on page 24

• “Debug Headers” on page 26

• “Connectors” on page 29

• “LEDs” on page 31

2.1 Switches

2.1.1 DIP Switches

Switches S1 to S6 combine four, small slide switches identified with numbers 1 to 4 (see Figure 6 for

individual switch definition).

19

Figure 5: DIP Switch Package/Individual Switch Position

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 20

Figure 6: Switch Locations

SW2

S3

S4

SW1

S5

S6

S1

2. Configurable Options > Switches20

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 21

2. Configurable Options > Switches 21

Switch S1 is used to manually set PCI bus modes.

Table 7: S1 Settings

Switch

Number

1 M66EN ON ON = Connects M66EN to all cards

2 M66EN OFF ON = Forces M66EN to GND

Description

Default

State

On/Off Setting

OFF = Forces M66EN high if S1.2 OFF

OFF = Disables forcing M66EN to GND

Switches S3 and S4 are used to set the PCI bus external clock frequency. By default the PCI bus clock

source is the T si382. The external clock can only be connected to the PCI bus by replacing resistors on

the board. When an external clock source is used, an on-board PLL is used to set the proper bus clock

frequency. Table 8 contains the clock frequency settings for S3.

Table 8: S3 Settings

Switch

Number

1 DIV_SEL0 OFF [FBDIV_SEL1, FBDIV_SEL0, DIV_SEL1, DIV_SEL0]

2DIV_SEL1OFF

3FBDIV_

4FBDIV_

Description

SEL0

SEL1

Default

State

OFF

OFF

On/Off Setting

ON = 1

OFF = 0

0,0,0,0 = x 4

0,0,0,1 = x 3

0,0,1,0 = x 2

0,0,1,1 = x 1

0,1,0,0 = x 5.33

0,1,0,1 = x 4

0,1,1,0 = x 2.667

0,1,1,1 = x 1.33

1,0,0,0 = x 6.667

1,0,0,1 = x 5

1,0,1,0 = x 3.33

1,0,1,1 = x 1.67

1,1,0,0 = x 8

1,1,0,1 = x 6

1,1,1,0 = x 4

1,1,1,1 = x 2

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 22

Switch S4 controls the external clock PLL.

Table 9: S4 Settings

2. Configurable Options > Switches22

Switch

Number

1 PLL Reset ON ON = PLL in reset. PLL clock outputs are low.

2 XT AL select OFF ON = Clock source for PLL is reference clock from connector

3 PLL select OFF ON = PLL is bypassed.

4 No function - -

Description

Default

State

On/Off Setting

OFF = PLL is active and clock outputs are enabled.

J10

OFF = Clock source for PLL is a 25-MHz oscillator.

OFF = PLL is enabled. External clock source is multiplied as

per S3 setting

Switch S5 controls the PCIe clock multiplexer and the on-board PCIe reference clock PLL.

Table 10: S5 Settings

Switch

Number

1 No Function - -

Description

Default

State

On/Off Setting

2PCIe

on-board

PLL enable

3 PCIe clock

multiplexer

enable

4 PCIe clock

source select

ON ON = On-board PCIe reference clock PLL is disabled.

OFF = On-board PCIe reference clock PLL is enabled.

OFF ON = On-board PCIe clock multiplexer is disabled.

OFF = On-board PCIe clock multiplexer is enabled.

OFF ON = On-board PCIe reference clock is used.

OFF = System PCIe reference clock is used.

Switch S6 configures Tsi382’s power-up options.

Table 11: S6 Settings

Switch

Number

1 No function - 2 Internal

Description

arbiter option

Default

State

ON ON = Internal arbiter is enabled

OFF = Internal arbiter is disabled

On/Off Setting

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 23

2. Configurable Options > Switches 23

Table 11: S6 Settings (Continued)

Switch

Number

3 No function - 4 PCI PLL

2.1.2 Push Button

SW1 is used to turn the ATX power supply ON. This switch is used only when the Tsi382 evaluation

board is powered up with a stand-alone ATX power supply.

SW2 is used to reset the evaluation board. When pushing the reset button, the board is reset the same

way a PCIe system reset would reset the board.

Description

bypass

Default

State

ON ON = PLL is enabled

OFF = PLL is bypassed

On/Off Setting

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 24

2.2 Shunt Jumpers

J21

J6

Shunt jumpers control special features on the evaluation board (see Figure 7). These jumpers are

explained in the following sub-sections.

Figure 7: Shunt Jumper Locations

2. Configurable Options > Shunt Jumpers24

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 25

2. Configurable Options > Shunt Jump ers 25

2.2.1 J6 Shunt Jumper

J6 is used to bypass the On/Off push button to enable the ATX power supply.

Table 12: J6 Shunt Jumper Setting

Jumper

Setting

Installed Removed Forces AT X power supply ON.

Removed Normal operation, ATX power supply is turned On/OFF from push button.

Default

State

2.2.2 J21 Shunt Jumper

J21 is used to force the Tsi382 into a special debug mode. The Default State for this jumper is ON.

Function

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 26

2.3 Debug Headers

J23

J22

J23

Debug headers are used to connect to signals on the evaluation board (see Figure 8). This section

provides header pinouts.

Figure 8: Debug Header Locations

2. Configurable Options > Debug Headers26

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 27

2. Configurable Options > Debug Headers 27

1

7

5

9

3

2

4

6

8

10

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

2.3.1 J22 Tsi382 JTAG

Table 13: J22 Pin Assignment

Pin

Number

1TDO

2NC

3TDI

43.3V

5NC

63.3V

7TCK

8NC

9TMS

Signal Assignment Pin Location

10 NC

11 NC

12 GND

13 NC

14 NC

15 NC

16 GND

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 28

2.3.2 J23 Logic Analyzer PADs

1

7

5

9

3

2

4

6

8

10

1

2

3

45678910

11

12

131415

1617181920

212223

24

Table 14: J23 Pin Assignment

Pin

Number

1 PCIE_RXD_EDG_P0

2GND

3 PCIE_RXD_EDG_N0

4 PCIE_TXD_EDG_P0

5GND

6 PCIE_TXD_EDG_N0

7N/C

8GND

9N/C

Signal Assignment Pin Location

2. Configurable Options > Debug Headers28

10 N/C

11 GND

12 N/C

13 N/C

14 GND

15 N/C

16 N/C

17 GND

18 N/C

19 N/C

20 GND

21 N/C

22 N/C

23 GND

24 N/C

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 29

2. Configurable Options > Connectors 29

P1

J2 (Slot 0) J1 (Slot 2) J37 (Slot 3)

J3

J36 (Slot 1)

2.4 Connectors

Figure 9: Board Connector Locations

Figure 10:

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 30

2.4.1 J1, J2, J36, J37 Connectors

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

These connectors are used to connect a plug-in card to the Tsi382’ s PCI Interface. The connectors’ pin

assignments are as per the PCI standard for 32-bit connectors.

2.4.2 J3 ATX Power Connector

A standard ATX power supply can be used to power up the board when used stand alone (not plugged

into a PCIe system).

Table 15: J3 Pin Assignment

Pin

Number

13.3V

23.3V

3GND

45V

Signal Assignment J3 Pin Location

2. Configurable Options > Connectors30

5GND

65V

7GND

8N.C.

95VSB

10 12V

11 3.3V

12 -12V

13 GND

14 GND

15 GND

16 GND

17 GND

18 N.C.

19 5V

20 5V

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 31

2. Configurable Options > LEDs 31

2.4.3 P1 x1 PCIe Finger Connector

The pin assignment for the finger connector is as per the PCIe standard. Note that the JTAG signals

TDI and TDO are connected together on the board.

2.5 LEDs

LEDs D2–D8 indicate voltage supplies that are present on the evaluation board. Depending on whether

your board is powered from the PCIe slot or the ATX power connector, the LEDs will indicate the

source of power for the board.

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 32

Figure 11: LED Locations

D2-D8

D18

2. Configurable Options > LEDs32

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 33

2. Configurable Options > LEDs 33

Table 16: D2–D8 LEDs

LED Name Description

D2 -12V This indicates -12V is applied to the evaluation board through the

ATX connector.

D3 3.3V_384 This indicates 3.3V is applied to the Tsi382.

D4 5V This indicates 5V is applied to the evaluation board.

D5 5VSB This indicates 5V is applied to the evaluation board through the

ATXconnector.

D6 3.3V This indicates 3.3V is applied to the evaluation board.

D7 12V This indicates 12V is applied to the evaluation board.

D8 3.3VPCI This indicates 3.3V (power applied to PCI slots) is applied to the

evaluation board.

Table 17: D18 LED

Default

LED Description

D18 PCI 66 MHz OFF OFF = The Tsi382 PCI Interface is operating at 66 MHz.

State

On/Off Setting

ON = The Tsi382 PCI Interface is operating at 33 MHz.

Integrated Device Technology

www.idt.com

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Page 34

2. Configurable Options > LEDs34

Tsi382 (BGA) Evaluation Board User Manual

60E2010_MA001_03

Integrated Device Technology

www.idt.com

Page 35

CORPORATE HEADQUARTERS

6024 Silver Creek Valley Road

San Jose, CA 95138

DISCLAIMER Integrated Device Techno l ogy, Inc. (IDT) and its subsidiaries reserve the right to mo di fy th e p ro du cts an d/or specifications described herein at any time an d a t ID T’s sol e di scr etion . A ll i nf or m ation i n th is do cum en t, incl u ding de scri p ti on s of

product features and performance, is subject to change without notice. Performance specifications and the operating parameters of the described products are determined in the in de pe nde nt sta te and are not guaranteed to perform the same way when

installed in customer products. The in format ion co ntaine d her ein is prov ided wit hout re prese ntat ion or warrant y of any kin d, wh ether expr ess or implied , includ ing, but not limi ted to, the suitab ility of IDT’s products for any particu lar purp ose, an impli ed

warranty of merchantability, or non-infringement of the intellectual property rights of others. This document is presented only as a guide and does not convey any license under intellectual property rights of ID T or any third parties.

IDT’s products are not intended for use in life support systems or similar devices where the failure or malfunction of an IDT product can be reasonably expected to significantly affect the health or safety of users. Anyone using an IDT product in such a

manner does so at their own risk, absent an express, written agreement by IDT.

Integrated Device Technology, IDT and the IDT logo are registered trademarks of IDT. Other trademarks and service marks used herein, including protected names, logos and designs, are the property of IDT or their respective third party owners.

Copyright 2009. All rights reserved.

2009 Integrated Device Technology, Inc *Notice: The information in this document is subject to change without notice

for SALES:

800-345-7015 or 408-284-8200

fax: 408-284-2775

www.idt.com

for Tech Support:

email: ssdhelp@idt.com

phone: 408-284-8208

Document: 60E2010_MA001_03

September 28, 2009

Loading...

Loading...