Page 1

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc. 1 December 18, 2017

P9242-R-EVK MM Evaluation Board (Transmitter)

Transmitter Coil

P9221-R-EVK MM

Evaluation Board

(Receiver)

Description

The IDT P9221-R-EVK Mass-Market (MM) Evaluation Board demonstrates the features and performance of the P9221-R 15W

Wireless Power Receiver (Rx). The P9221-R-EVK offers the flexibility to program parameters, such as the output voltage, overcurrent limit threshold, and external temperature sensing function.

It also allows tuning the Foreign Object Detection (FOD) feature by

varying values in the resistor divider connected to the VOSET/

Q-Fact pin.

The P9221-R-EVK MM Evaluation Board is designed to function as

the receiver in a wireless power transfer system using IDT’s P9242R-EVK MM Evaluation Board as the power transmitter. The P9242R-EVK is ordered separately. The P9221-R-EVK can also be used

with the user’s WPC-1.2 compliant transmitter.

The high-efficiency, turnkey reference design is supported by

comprehensive online, digital resources to significantly expedite

design-in effort and enable rapid prototyping. The printed circuit

board (PCB) has four layers. The total active area is optimized to

28mm x 15mm.

Kit Contents

P9221-R-EVK Mass-Market Evaluation Board

Features

P9221-R-EVK MM Evaluation Board supports WPC-1.2

Up to 15W output power

Selectable output voltage: 12V or 9V

Adjustable over-current limit

External FOD tuning

Power transfer LED indicator

Alignment guide information using the PCB coils

4-layer PCB

Total active area: 420mm

2

Fully assembled with test points and coil fixture

P9221-R-EVK MM Evaluation Board

Wireless Power Transfer System using the P9221-R-EVK and P9242-R-EVK

Page 2

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc. 2 December 18, 2017

Important Notes

Disclaimer

Integrated Device Technology, Inc. and its affiliated companies (herein referred to as “IDT”) shall not be liable for any damages arising out of defects resulting from

(i) delivered hardware or software

(ii) non-observance of instructions contained in this manual and in any other documentation provided to user, or

(iii) misuse, abuse, use under abnormal conditions, or alteration by anyone other than IDT.

TO THE EXTENT PERMITTED BY LAW, IDT HEREBY EXPRESSLY DISCLAIMS AND USER EXPRESSLY WAIVES ANY AND ALL WARRANTIES, WHETHER

EXPRESS, IMPLIED, OR STATUTORY, INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A

PARTICULAR PURPOSE, STATUTORY WARRANTY OF NON-INFRINGEMENT, AND ANY OTHER WARRANTY THAT MAY ARISE BY REASON OF USAGE

OF TRADE, CUSTOM, OR COURSE OF DEALING.

Restrictions in Use

IDT’s P9221-R-EVK Mass Market Evaluation Board is designed for evaluation purposes only. It must not be used for module production or production test setups.

Contents

1. Setup ............................................................................................................................................................................................................4

1.1 Required or Recommended User Equipment ......................................................................................................................................4

1.2 Kit Hardware Connections ...................................................................................................................................................................4

2. Usage Guide .................................................................................................................................................................................................5

2.1 Overview of the P9221-R-EVK ............................................................................................................................................................5

2.2 Setting the Output Voltage and Reference Q-factor Value – VOSET/Q-Fact Pin ...............................................................................6

2.3 Alignment Aid – ALIGNX and ALIGNY ................................................................................................................................................7

2.4 Adjustment of Over-Current Limit ........................................................................................................................................................8

2.5 External Temperature Sensing and End of Charge – TS/EOC ...........................................................................................................9

2.6 Receiver Coil .....................................................................................................................................................................................10

3. P9221-R-EVK MM Evaluation Board Schematics ......................................................................................................................................11

4. Bill of Materials (BOM) ................................................................................................................................................................................12

5. Board Layout ..............................................................................................................................................................................................14

6. Ordering Information ...................................................................................................................................................................................17

7. Revision History ..........................................................................................................................................................................................17

Page 3

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc. 3 December 18, 2017

List of Figures

Figure 1. Evaluation Kit Setup using the P9242-R-EVK MM Evaluation Board as the Transmitter ....................................................................4

Figure 2. P9221-R-EVK MM Evaluation Board V2.2 Features ...........................................................................................................................5

Figure 3. R33 and R34 Locations .......................................................................................................................................................................6

Figure 4. Recommended Structure of the X-Y Alignment Coil ............................................................................................................................7

Figure 5. R38 and R22 Location .........................................................................................................................................................................8

Figure 6. Over-Current Limit vs. ILIM Pin Voltage ..............................................................................................................................................9

Figure 7. Optional External Temperature Sensing by Connecting an RTS Thermistor ....................................................................................10

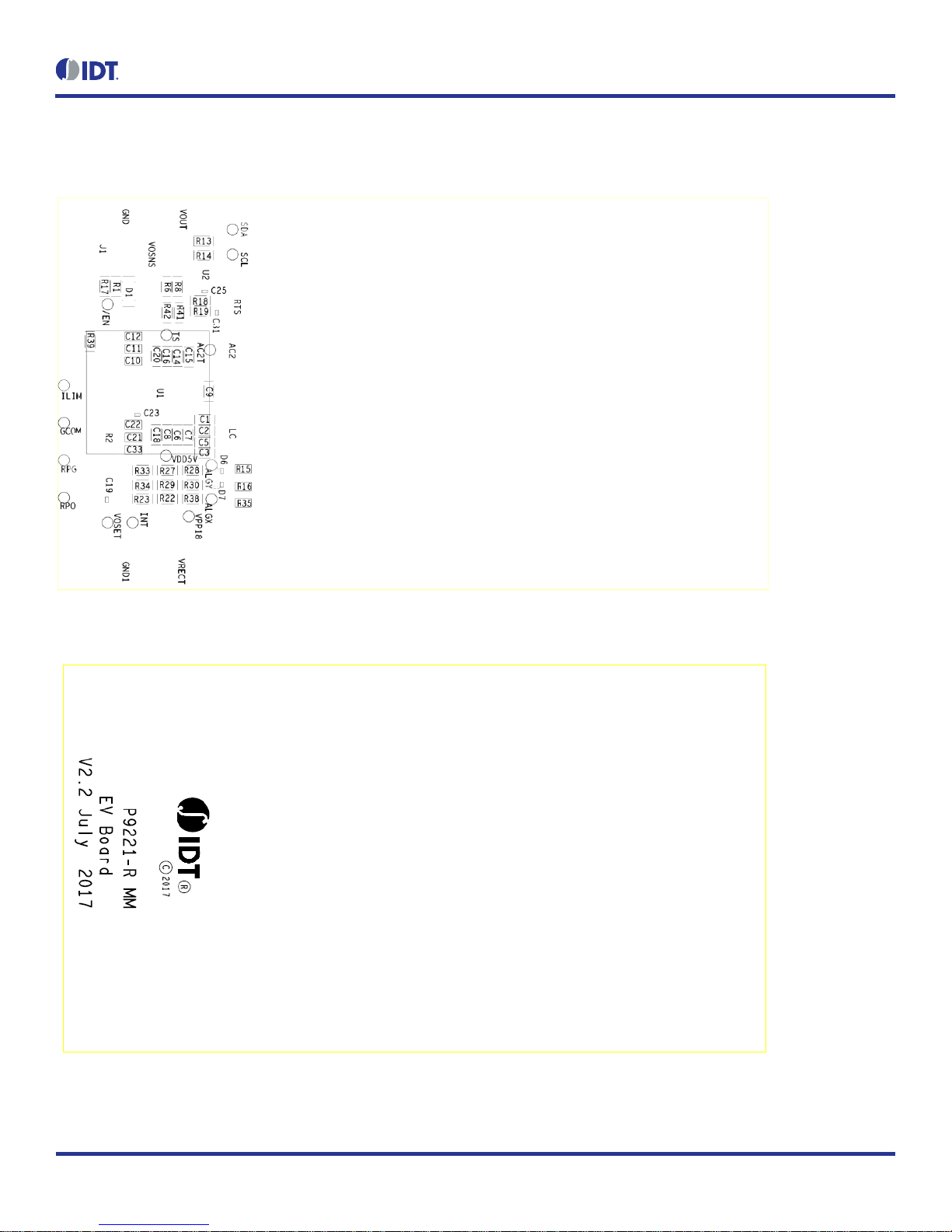

Figure 8. Silkscreen – Top of Board .................................................................................................................................................................14

Figure 9. Silkscreen – Bottom of Board ............................................................................................................................................................14

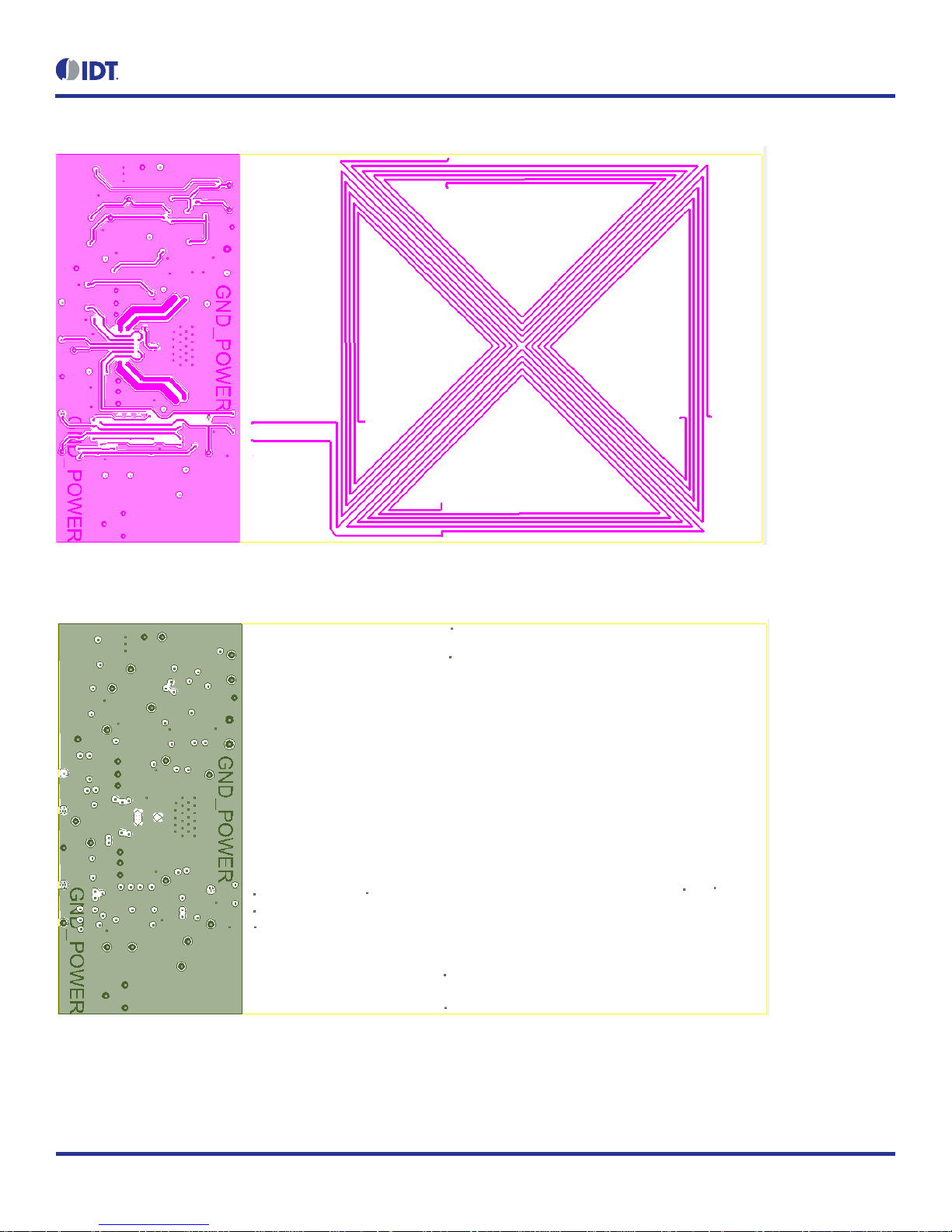

Figure 10. Top Copper Layer ..............................................................................................................................................................................15

Figure 11. L2 Copper Layer ................................................................................................................................................................................15

Figure 12. L3 Copper Layer ................................................................................................................................................................................16

Figure 13. Bottom Copper Layer ........................................................................................................................................................................16

List of Tables

Table 1. Setting the Output Voltage and Reference Q-factor Value ..................................................................................................................6

Table 2. Setting the Over-Current Limit .............................................................................................................................................................8

Table 3. Recommend Coil Manufacturers .......................................................................................................................................................10

Table 4. P9221-R-EVK MM Evaluation Board BOM V2.2 ...............................................................................................................................12

Page 4

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc. 4 December 18, 2017

1. Setup

1.1 Required or Recommended User Equipment

The following additional lab equipment is required for using the kit:

P9242-R-EVK MM Evaluation Board or any WPC-1.2 compliant transmitter

Power supply or 12V/2A AC adaptor

1.2 Kit Hardware Connections

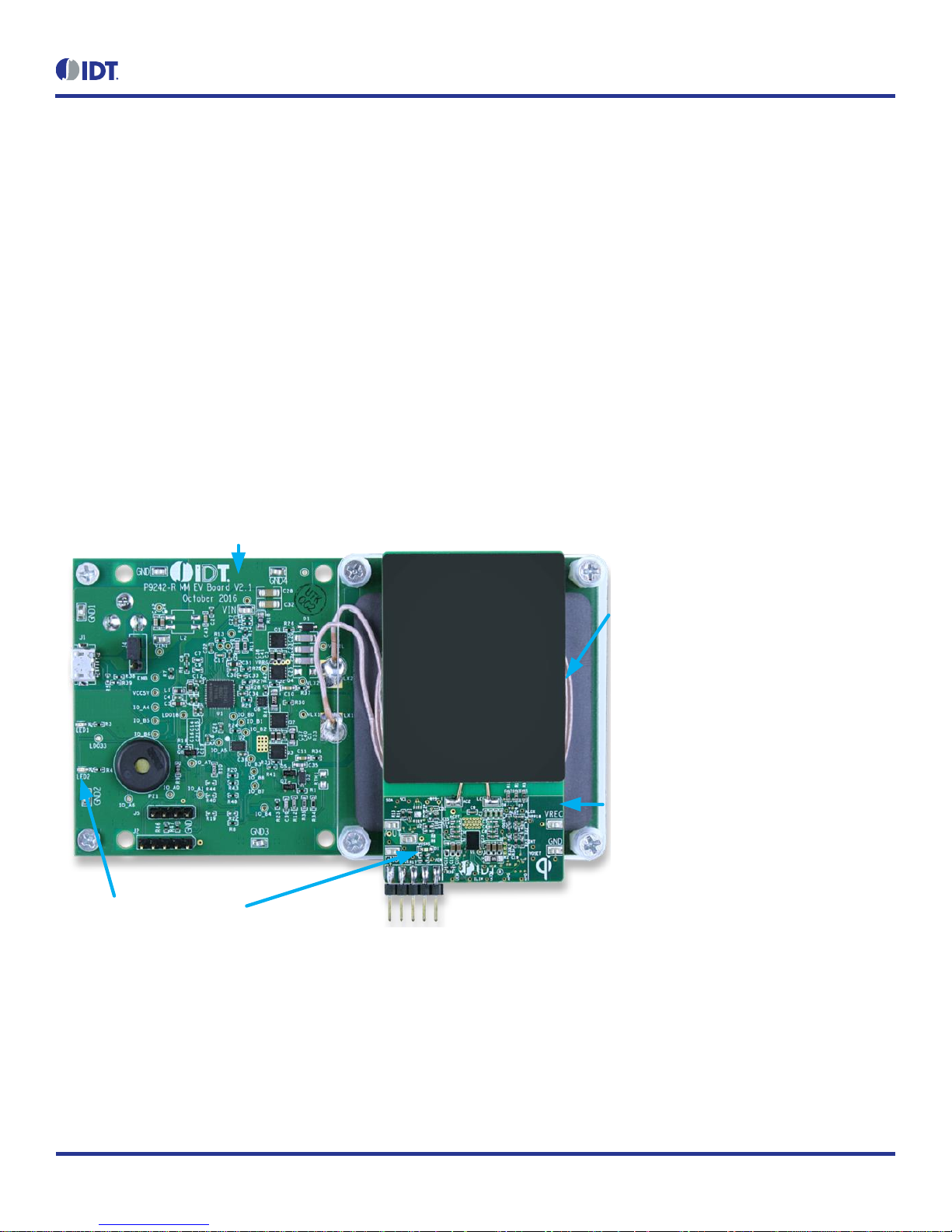

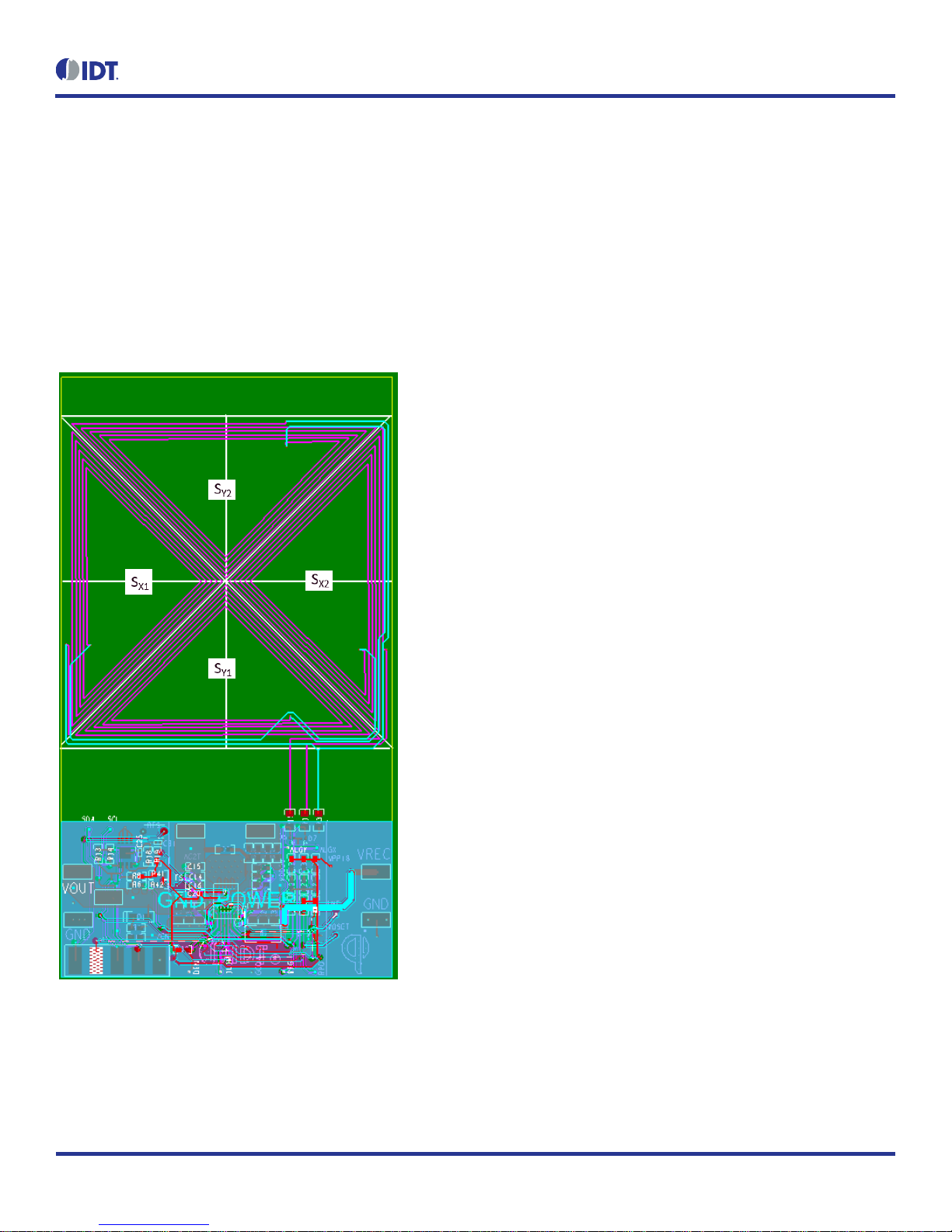

Follow these procedures to set up the kit as shown in Figure 1:

1. Set up the P9242-R-EVK Evaluation Board (or user transmitter) according to the board’s user manual.

2. Place the P9221-R-EVK on the transmitter (TX) pad with the components facing up as shown in Figure 1.

3. Verify that the green LEDs on both boards are illuminated indicating that coupling has been established.

4. Connect wires to the VOUT and GND test points to measure the output voltage and apply a load.

Figure 1. Evaluation Kit Setup using the P9242-R-EVK MM Evaluation Board as the Transmitter

P9242-R-EVK

Transmitter Coil

P9221-R-EVK

Green LEDs illuminate when

connection has been established.

Page 5

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc. 5 December 18, 2017

2. Usage Guide

2.1 Overview of the P9221-R-EVK

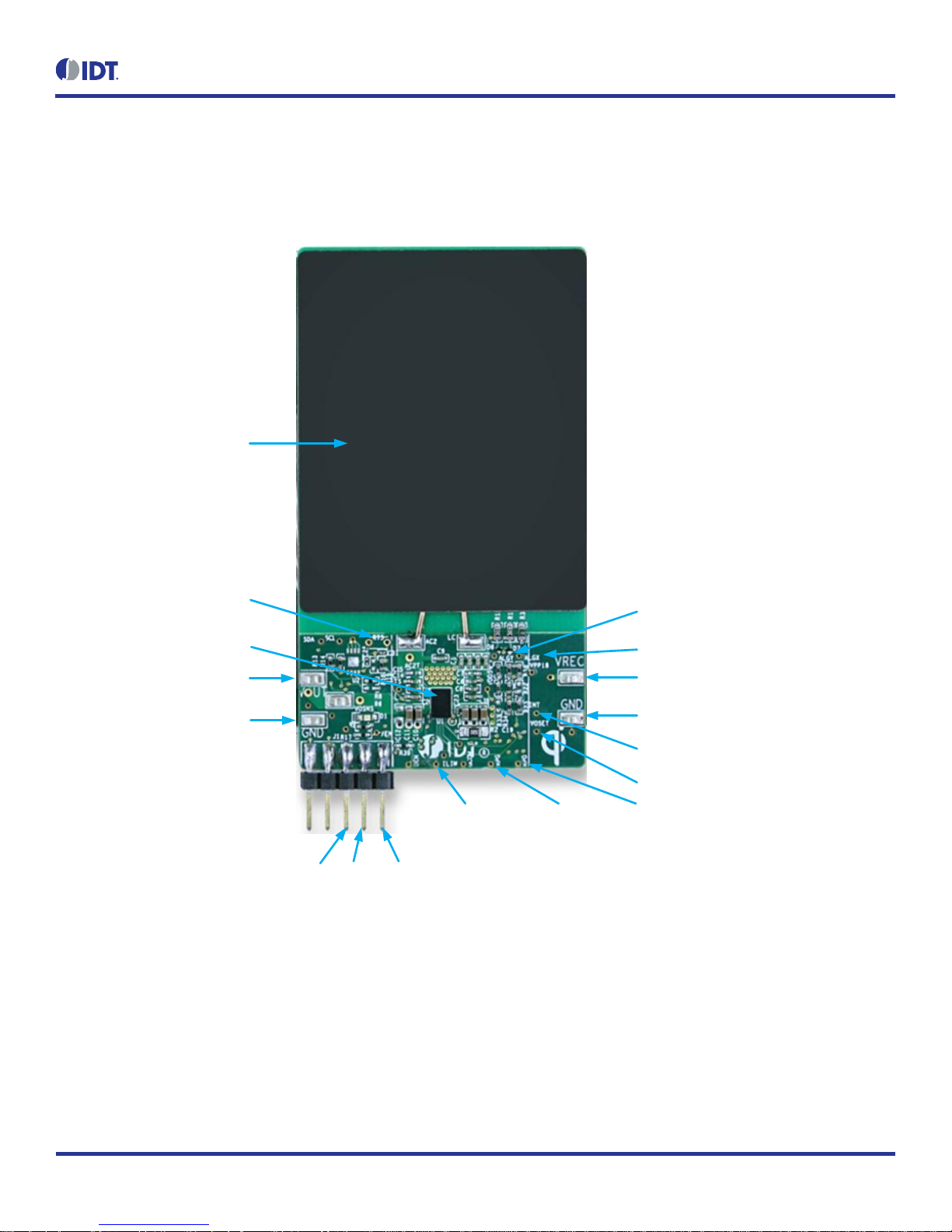

Figure 2. P9221-R-EVK MM Evaluation Board V2.2 Features

FOD Offset

Adjustment

(RPO)

External Temperature

Sensing Resistor

Output Voltage Adjustment (VOSET)

FOD Gain

Adjustment

(RPG)

Over-Current

Limit Adjustment

(ILIM)

Y- Alignment Guide Voltage (ALGY)

X- Alignment Guide Voltage (ALGX)

SCL SDA GND

GND

VRECT

GND

VOUT

Receiver Coil

IDT P9221-R IC

Interrupt Flag

Page 6

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc. 6 December 18, 2017

2.2 Setting the Output Voltage and Reference Q-factor Value – VOSET/Q-Fact Pin

The output voltage on the P9221-R is programmed by connecting the center tap of the divider network comprising external resistors R34 and

R33 to the VOSET/Q-Fact pin as shown in the schematic in section 3. The output voltage can be set to 9V or 12V. The recommended settings

for R33 and R34 are given in Table 1.

The default output voltage is set to 12V on the P9221-R-EVK MM Evaluation Board (R34 = 10kΩ; R33 = open). For applications where the

transmitter is capable of delivering only 5W, the P9221-R will automatically switch to 5V output to ensure 5W power delivery. The 5W option

can be disabled by changing R33 as described in Table 1. In this case, if the receiver is placed on a 5W transmitter, the receiver output pin will

be high impedance.

The VOSET/Q-Fact pin also allows setting the Q-factor value by adjusting R34 and R33 as shown in Table 1. The default value is set to 103

on the P9221-R-EVK MM Evaluation Board. For development purposes, the Q-factor should be set to 20 to avoid prematurely triggering the

Q-factor.

Table 1. Setting the Output Voltage and Reference Q-factor Value

Note: The default values on the P9221-R-EVK are indicated with blue shading.

Q Factor

Value Setting

VOUT Setting (R34/R33 Values)

9V without 5V

9V with 5V

12V without 5V

12V with 5V

R34

R33

R34

R33

R34

R33

R34

R33

103

10kΩ

4.87kΩ

Open

10kΩ

10kΩ

21kΩ

10kΩ

Open

80

10kΩ

4.32kΩ

10kΩ

0.31kΩ

10kΩ

22.6kΩ

10kΩ

324kΩ

60

10kΩ

3.65kΩ

10kΩ

0.681kΩ

10kΩ

27.4kΩ

10kΩ

147kΩ

40

10kΩ

3.09kΩ

10kΩ

1.1kΩ

10kΩ

32.4kΩ

10kΩ

90.9kΩ

20

10kΩ

2.55kΩ

10kΩ

1.54kΩ

10kΩ

39.2kΩ

10kΩ

64.9kΩ

Figure 3. R33 and R34 Locations

R34

R33

Page 7

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc. 7 December 18, 2017

2.3 Alignment Aid – ALIGNX and ALIGNY

The signal magnitude on the P9221-R’s ALIGNX and ALIGNY pins provides directional alignment information by measuring the phase between

the input power AC signal and the horizontal (ALIGNX) and vertical (ALIGNY) alignment signals. After the signal is measured by the analog-todigital converter, the alignment information is represented by two 8-bit signed numbers, which can be read via the I2C interface from the Align_X

and Align_Y registers (see the P9221-R Datasheet).

The difference in the electromotive force (EMF) voltage of the two coils can be represented by the amount of magnetic flux, which depends on

the misalignment position of the receiver coil relative to the transmitter coil. With the combination of two symmetrical coils on the vertical (Y)

axis and horizontal (X) axis, it is possible to sense alignment in two dimensions as shown in Figure 4. The trace length and width were designed

with 452.12mm and 0.254mm respectively for each segment coil on the P9221-R-EVK MM Evaluation Board, which was assembled with the

AMOTECH ASC-504060E00-S00 coil as shown in Figure 4.

Figure 4. Recommended Structure of the X-Y Alignment Coil

Page 8

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc. 8 December 18, 2017

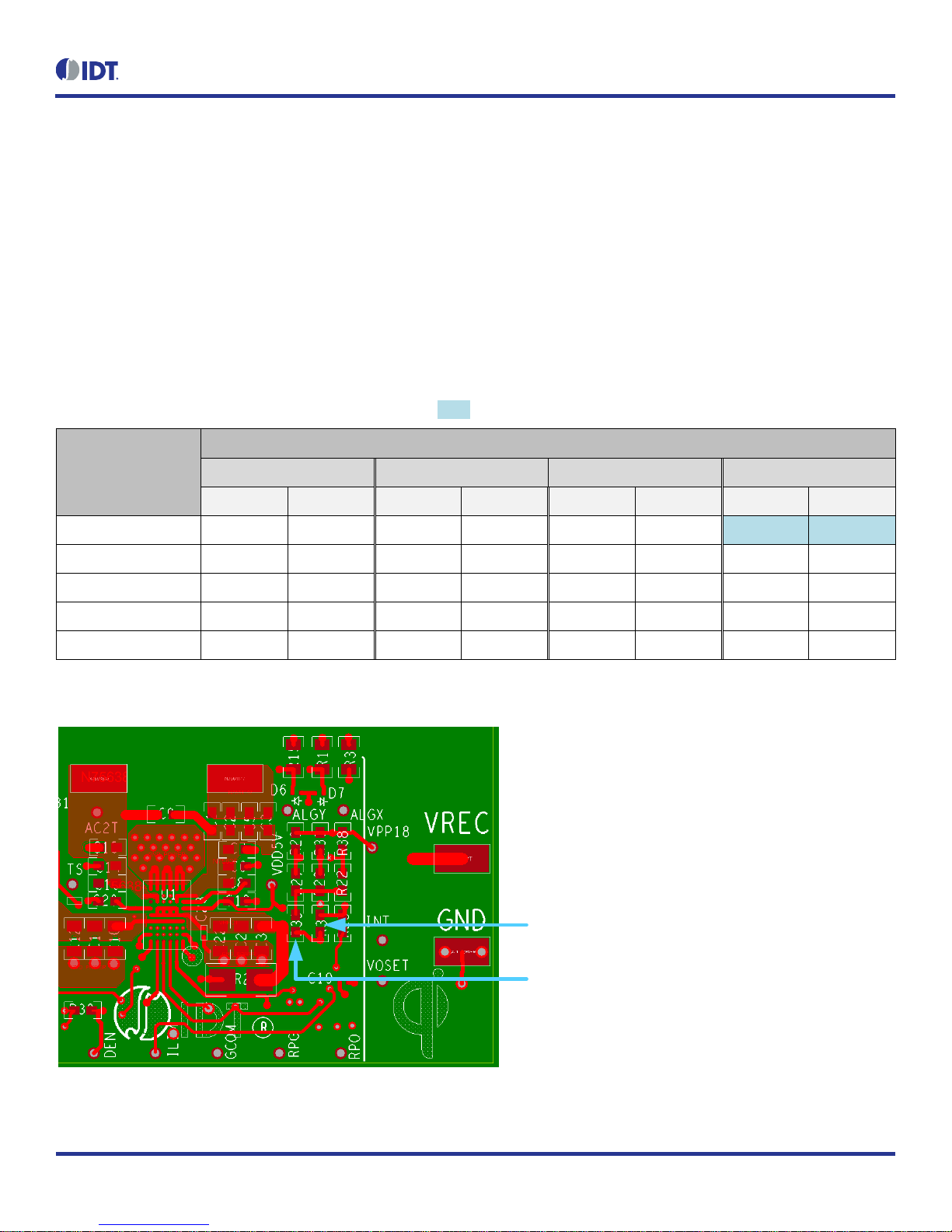

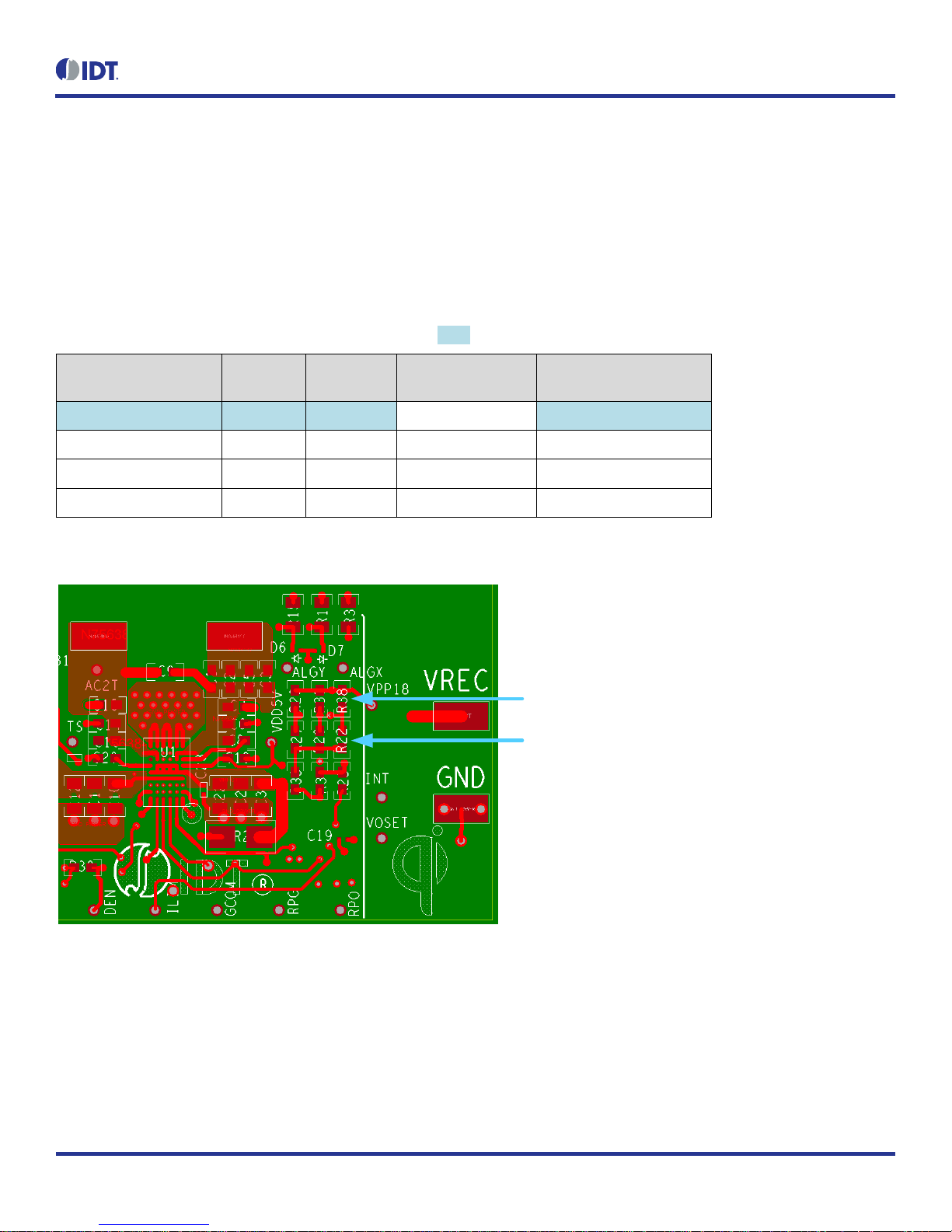

2.4 Adjustment of Over-Current Limit

The P9221-R has a programmable current limit function for protecting the device in the event of an over-current or short-circuit fault condition.

If the output current exceeds the programed threshold, the P9221-R will limit the load current by reducing the output voltage. The recommended

current limit setting is 120% of the maximum output current. The default value for the over-current limit is set to 1.6A. The ILIM pin allows

changing the over-current limit value without modification of the firmware by selecting the values of R38 and R22 as shown in Table 2. R38 and

R22 form a divider network from the 1.8V supply to ground with the center tap connected to the ILIM pin as shown in the schematic in section 3.

The voltage at the ILIM pin sets the over-current limit. See Figure 6 for the relationship between the current limit and the voltage on the ILIM

pin.

Table 2. Setting the Over-Current Limit

Note: The default values on the P9221-R-EVK are indicated with blue shading.

Voltage on ILIM Pin [V]

R38 [kΩ]

R22 [kΩ]

Maximum Output

Current [A]

Over-Current Limit [A]

Pull-up

10

Open

1.25

1.6

0.60

10

5.1

0.80 1 0.45

10

3.3

0.64

0.8

0.25

10

1.6

0.40

0.5

Figure 5. R38 and R22 Location

R38

R22

Page 9

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc. 9 December 18, 2017

Figure 6. Over-Current Limit vs. ILIM Pin Voltage

2.5 External Temperature Sensing and End of Charge – TS/EOC

The P9221-R has a temperature sense input pin, TS, which can be used to monitor a remote temperature, such as a thermistor reading for a

coil or a battery charger. The built-in comparator’s reference voltage is 0.6V and 0.1V in the P9221-R, and it is used for monitoring the voltage

level on the TS/EOC pin as described by Equation 1.

V

TS

=

V

VDD18

∗

NTC

R19 + NTC

Equation 1

Where NTC is the thermistor`s resistance and R19 is the pull-up resistor connected to the 1.8V supply voltage on the P9221-R-EVK MM

Evaluation Board. The over–temperature shutdown is triggered when the TS pin voltage is between 0.6V and 0.1V. The RTS is not populated

on the P9221-R MM Evaluation Board.

When the TS/EOC pin is less than 0.1V, the End-of-Charge (EOC) function is activated, and the P9221-R will send the End-Power-Transfer

(EPT) packet to the transmitter terminating the power delivery.

0

200

400

600

800

1000

1200

1400

1600

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

ILIM [mA]

V

ILIM

[V]

Page 10

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc.

10

December 18, 2017

Figure 7. Optional External Temperature Sensing by Connecting an RTS Thermistor

RTS

2.6 Receiver Coil

The ASC-504060E00-S00 coil is used in the kit. The following alternative coils are recommended for the P9221-R receiver for 15W applications

for optimum performance. The recommended vendor coils have been tested and verified as shown in Table 3.

Table 3. Recommend Coil Manufacturers

Output Power

Vendor

Part Number

Inductance at 100kHz

ACR at 20°C

Series Resonant Capacitance

15W

AMOTECH

ASC-504060E00-S00

8.2µH

220mΩ

400nF

15W

TDK

WR424245-13K2-G

11.2µH

170mΩ

300nF

15W

SUNLORD

SWA50R40H06C02B

8.4µH

150mΩ

400nF

15W

WURTH

760308102207

8.0µH

80mΩ

400nF

Page 11

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc.

11

December 18, 2017

3. P9221-R-EVK MM Evaluation Board Schematics

D1

LED

C12

NP

C10

10uF

INT

INT

SDA

C9

3.3nF

R18

NP

VDD5V

D6

5.1V

R8 0

RSV1

C25

NP

ALGX

R33

NP

R39

10k

C19

0.1uF

C21

10uF

C16

15nF

U1

P9221-R

COMM1

A1

COMM2

A6

RSV4

B1

RSV5

B6

EN

B5

ALIGNX

A2

SCL

A3

VOSET/Q-Fact

A4

RPPG

A5

SDA

B3

ALIGNY

B2

ILIM

B4

RPPO

C4

DEN

C5

OUT

D1

INT

C3

SINK

C2

OUT1D2OUT2

D3

OUT3D4OUT4

D5

OUT5

D6

VRECTE1VRECT1

E2

VRECT2E5VRECT3

E6

VRECT4F2VRECT5

F3

VRECT6F4VRECT7

F5

AC1G2AC1_1

H1

AC1_2

H2

AC2G5AC2_1

H5

AC2_2

H6

BST1

G1

BST2

G6

PGND

C1

PGND1

C6

PGND2

J1

PGND3

J2

PGND4

J3

PGND5

J4

PGND6

J5

PGND7

J6

VDD5V

F1

VDD18

F6

RSV3

G3

RSV2

H3

RSV1

G4

TS/EOC

H4

C20

1uF

/EN

R19

10K

I2CRAI L

VOUT

VOSET

P9221-R MM EV Board V2.2

C31

0.1uF

C8

15nF

VRECT

R35 0

J1

I2C

1

2

3

4

5

L1

SCL

R28

NP

R17 10k

VPP18

R42

NP

VDD5V

R22

NP

R2

36

R14

5.1k

C3

100nF/50V

RPO

C11

10uF

RSV1

R13

5.1k

TS

VOUT

C23

0.1uF

GND1

R16 10K

VRECT

R29

10K

C7

NP

VOSNS

ILIM R34

10k

R23

10k

C22

10uF

VDD5V

R38

10K

RX Power Coil

AlignX coil

C18

1uF

C6

47nF

VPP18

Vrect

R1

5.1k

ALGY

TS

C2

100nF/50V

D7

5.1V

U2

NP

A0

1

A1

2

A2

3

VSS

4

SDA

5

SCL

6

WP

7

VCC

8

E_PAD

9

VPP18

RTS

NP

VPP18

C1

100nF/50V

AlignY coil

WP

C5

100nF/50V

R41

NP

LC

SDA

INT

R27

10K

VOUT

C33

10uF

DEN

R30

NP

AC2T

TS

C15

NP GND

SCL

R6 NP

R15 10K

GCOM

AC2

RPG

C14

47nF

Page 12

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc.

12

December 18, 2017

4. Bill of Materials (BOM)

Table 4. P9221-R-EVK MM Evaluation Board BOM V2.2

Item

Reference

Quantity

Value

Description

Part number

PCB Footprint

1

AC2T, VDD5V,

VPP18, VOSET, TS,

SDA, SCL, RPO,

RPG, INT, ILIM,

GCOM, DEN, ALGY,

ALGX, /EN

16

PTH_TP

Test Pad

10MIL_35PAD

2

AC2, LC

2

NP

TEST POINT

test_pt_sm_135x70

3

C1, C2, C3, C5

4

100nF

CAP CER 0.1µF 50V X5R 0402

GRM155R61H104KE19D

0402

4

C6, C14

2

47nF

CAP CER 0.047µF 50V X7R 0402

C1005X7R1H473K050BB

0402

5

C7, C15

2

NP

CAP CER 0.047µF 50V X7R 0402

C1005X7R1H473K050BB

0402

6

C8, C16

2

15nF

CAP CER 0.015µF 50V X7R 0402

GRM155R71H153KA12J

0402

7

C9 1 3.3nF

CAP CER 3300PF 50V X7R 0402

CL05B332KB5NNNC

0402

8

C10, C11, C21, C22,

C33

5

10µF

CAP CER 10µF 25V X5R 0603

CL10A106MA8NRNC

0603

9

C12 1 NP

CAP CER 10µF 25V X5R 0603

CL10A106MA8NRNC

0603

10

C18,C20

2

1µF

CAP CER 1µF 10V X5R 0402

GRM155R61A105KE15D

0402

11

C19,C31

2

0.1µF

CAP CER 0.1µF 10V X5R 0201

C0603X5R1A104K030BC

0201

12

C23 1 0.1µF

CAP CER 0.1µF 25V X5R 0201

CL03A104KA3NNNC

0201

13

C25 1 NP

CAP CER 0.1µF 10V X5R 0201

C0603X5R1A104K030BC

0201

14

D1 1 LED

LED GREEN CLEAR 0603 SMD

150 060 GS7 500 0

0603_diode

15

D6,D7 2 5.1V

DIODE ZENER 5.1V 100MW 0201

CZRZ5V1B-HF

0201

16

GND1, VRECT,

VOUT, VOSNS,

GND

5

Test

Point

TEST POINT PC MINIATURE SMT

5015

test_pt_sm_135x70

17

J1 1 I2C

HEADER_1X5_0P1PITCH60P42D

68002-205HLF

header_1x5_0p1Pit

ch60p42d

18

L1 1 8.2µH

Wireless power receiver coil

ASC-504060E00-S00

sm_135x70

19

RTS 1 NP

NTC2

20

R1, R13, R14

3

5.1kΩ

RES SMD 5.1K OHM 5% 1/16W

0402

MCR01MRTJ512

0402

21

R2 1 36Ω

RES SMD 36 OHM 5% 1/2W 0805

ERJ-P06J360V

0805

22

R6 1 NP

RES SMD 0.0OHM JUMPER

ERJ-2GE0R00X

0402

23

R8 1 0Ω

RES SMD 0.0OHM JUMPER 1/10W

0402

ERJ-2GE0R00X

0402

24

R15, R16

2

10KΩ

RES SMD 10K OHM 1% 1/10W

0603

RC0603FR-0710KL

0603

Page 13

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc.

13

December 18, 2017

Item

Reference

Quantity

Value

Description

Part number

PCB Footprint

25

R17, R19, R23, R27,

R29, R34, R38, R39

8

10kΩ

RES SMD 10K OHM 5% 1/16W

0402

CRCW040210K0JNEDIF

0402

26

R18, R22, R28, R30,

R33, R41, R42

7

NP

RES SMD 10K OHM 5% 1/16W

0402

CRCW040210K0JNEDIF

0402

27

R35 1 0Ω

RES SMD 0.0OHM 1/10W 0603

MCR03EZPJ000

0603

28

U1 1 P9221-R

MP Wireless power receiver

P9221-R

csp52_2p64x3p94_

0p4mm

29

U2 1 NP

IC EEPROM 128KBIT 400KHZ

8TDFN

24AA128T-I/MNY

TDFN08

Page 14

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc.

14

December 18, 2017

5. Board Layout

Figure 8. Silkscreen – Top of Board

Figure 9. Silkscreen – Bottom of Board

Page 15

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc.

15

December 18, 2017

Figure 10. Top Copper Layer

Figure 11. L2 Copper Layer

Page 16

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc.

16

December 18, 2017

Figure 12. L3 Copper Layer

Figure 13. Bottom Copper Layer

Page 17

P9221-R-EVK Evaluation Board User Manual

© 2017 Integrated Device Technology, Inc.

17

December 18, 2017

6. Ordering Information

Orderable Part Number

Description

P9221-R-EVK

P9221-R-EVK MM Evaluation Board

7. Revision History

Revision Date

Description of Change

December 18, 2017

Updates for V2.2 of the P9221-R-EVK.

Minor edits.

December 19, 2016

Initial release of document.

Corporate Headquarters

6024 Silver Creek Valley Road

San Jose, CA 95138

www.IDT.com

Sales

1-800-345-7015 or 408-284-8200

Fax: 408-284-2775

www.IDT.com/go/sales

Tech Support

www.IDT.com/go/support

DISCLAIMER Integrated Device Technology, Inc. (IDT) and its affiliated companies (herein referred to as “IDT”) reserve the right to modify the products and/or specifications described herein at any time,

without notice, at IDT's sole discretion. Performance specifications and operating parameters of the described products are d etermined in an independent state and are not guaranteed to perform the same

way when installed in customer products. The information contained herein is provided without representation or warranty of a ny kind, whether express or implied, including, but not limited to, the suitability

of IDT's products for any particular purpose, an implied warranty of merchantability, or non -infringement of the intellectual property rights of others. This document is presented only as a guide and does not

convey any license under intellectual property r ights of IDT or any third parties.

IDT's products are not intended for use in applications involving extreme environmental conditions or in life support systems or similar devices where the failure or malfunction of an IDT product can be

reasonably expected to significantly affect the health or safety of users. Anyone using an IDT product in such a manner does so at their own risk, absent an express, written agreement by IDT.

Integrated Device Technology, IDT and the IDT logo are trademarks or registered trademarks of IDT and its subsidiaries in the United States and other countries. Other trademarks used herein are the

property of IDT or their respective third party owners. For datasheet type definitions and a glossary of common terms, visit www.idt.com/go/glossary. All contents of this document are copyright of Integrated

Device Technology, Inc. All rights reserved.

Loading...

Loading...