Page 1

VersaClock® 6 - 5P49V69xx Family Programmer

Board

USER GUIDE

Introduction

The VersaClock6 - 5P49V69xx family programmer board is made to ease the programming of blank 5P49V69xx parts. With the

on-board USB interface, IDT Timing Commander™ GUI can be used to communicate with the VersaClock5 family of devices in

the socket for configuration and programming. The family of VersaClock 6 devices includes the following part numbers:

5P49V6901, 5P49V6913, 5P49V6914.

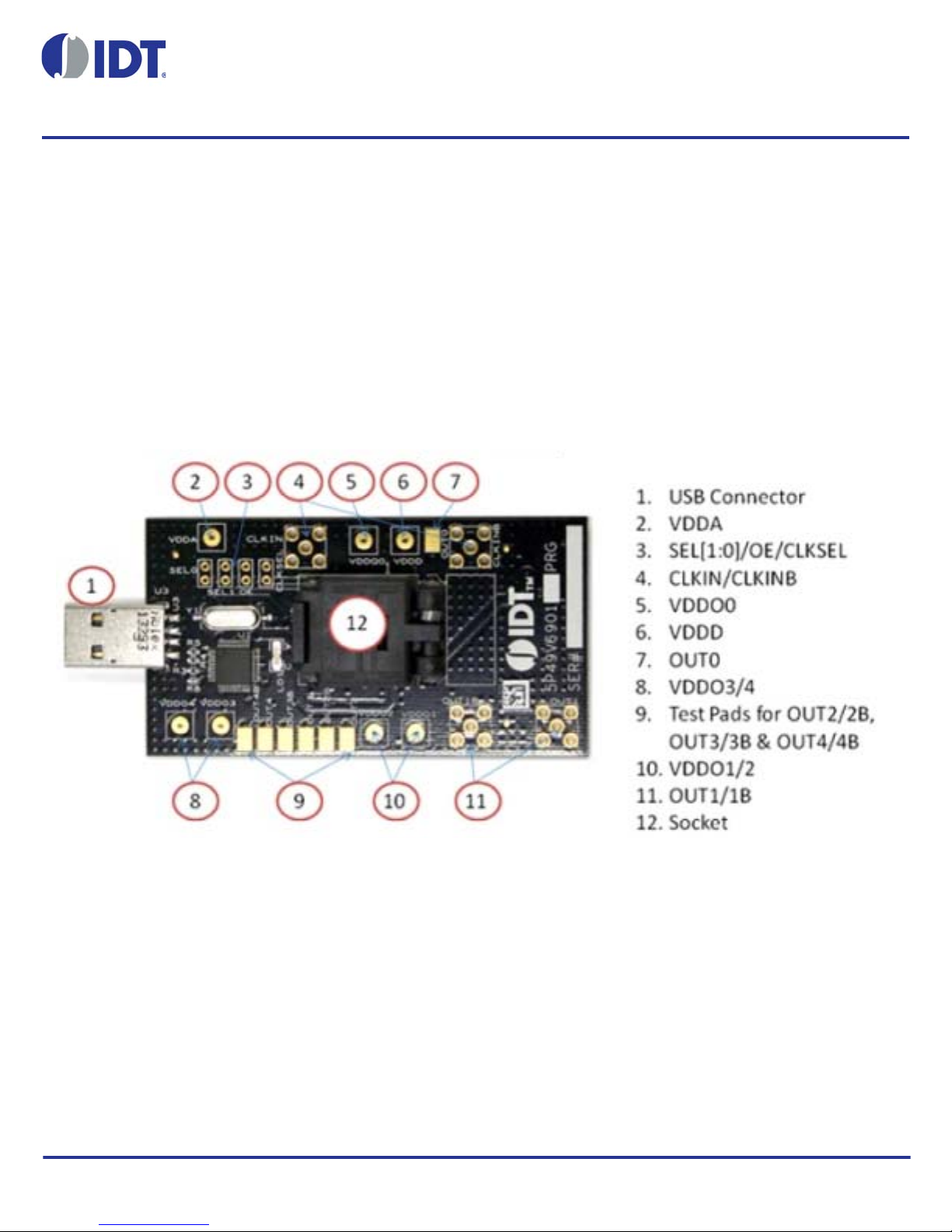

Board Overview

As shown the in the following diagram, all necessary components and connections are available to test the functionality of the

configuration after the device is programmed. By installing R14 on the back of the board with a 100K resistor, the device will

be powering up in hardware select mode, in which SEL1 and SEL0 pins can be used to switch among 4 configurations that the

device supports.

Figure 1. Programmer Board Overview (socket closed)

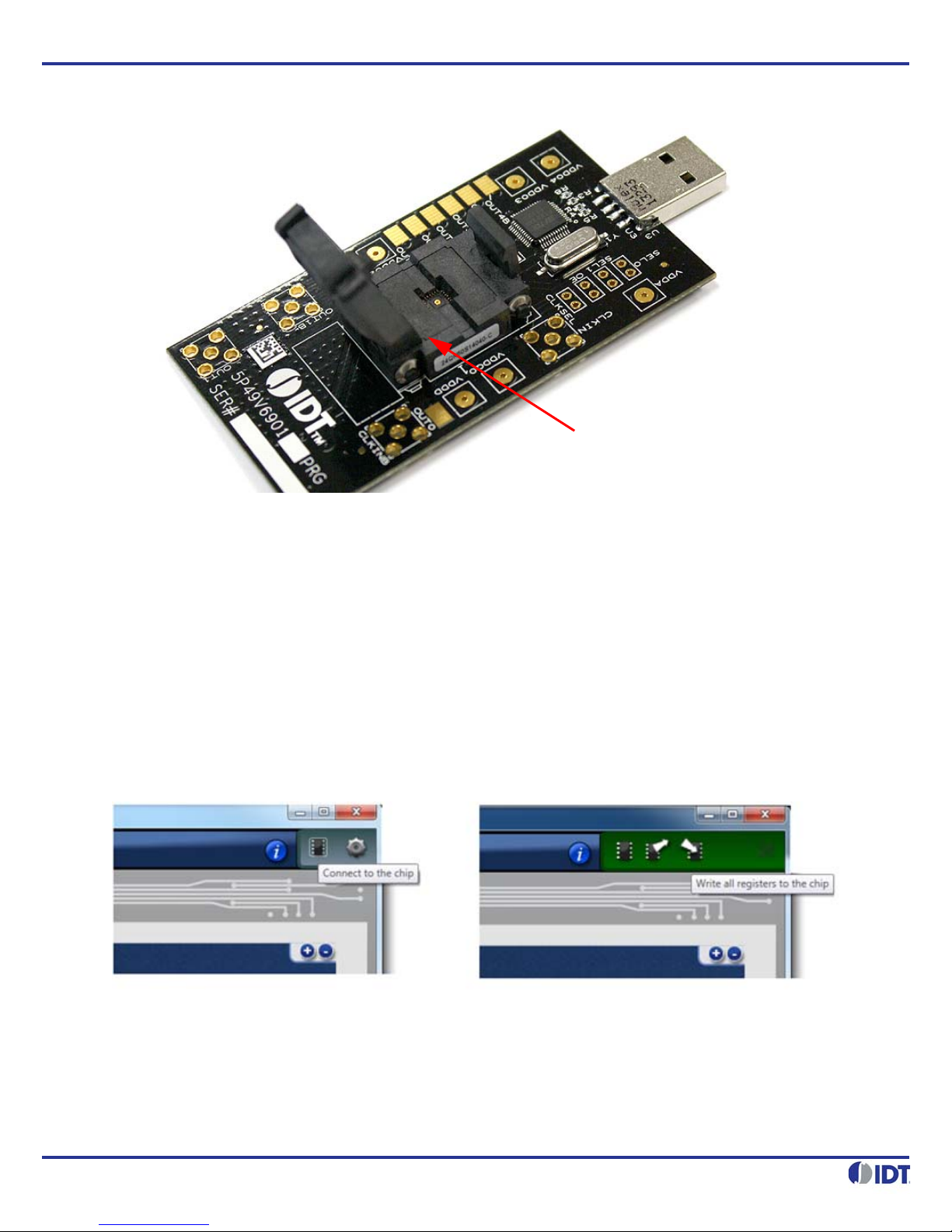

Placing a Blank Chip in the Socket

When socket is open, identify the position of Pin 1 as shown in Figure 2. Align the dot of the blank device with the round dent

engraved on the corner of the socket as pointed. After placing the blank device, secure the socket cover.

REVISION 12/03/15 1 ©2015 Integrated Device Technology, Inc.

Page 2

Figure 2. Programmer Board Overview (socket open)

Pin 1

VERSACLOCK® 6 - 5P49V69xx Family Programmer Board

Programming Steps

1. Place a blank part in the socket–Refer to Figure 2 above. With socket opened, identify pin 1 position and place a blank part

accordingly. Close the socket and secure the socket lid.

2. Plug the board into USB port –USB port provides power to the board as well as a communication channel between GUI and

the device.

3. Start Timing Commander GUI–Launch the Timing Commander GUI software. Load the proper personality file.

4. Start a new settings file or open a pre-optimized configuration file.

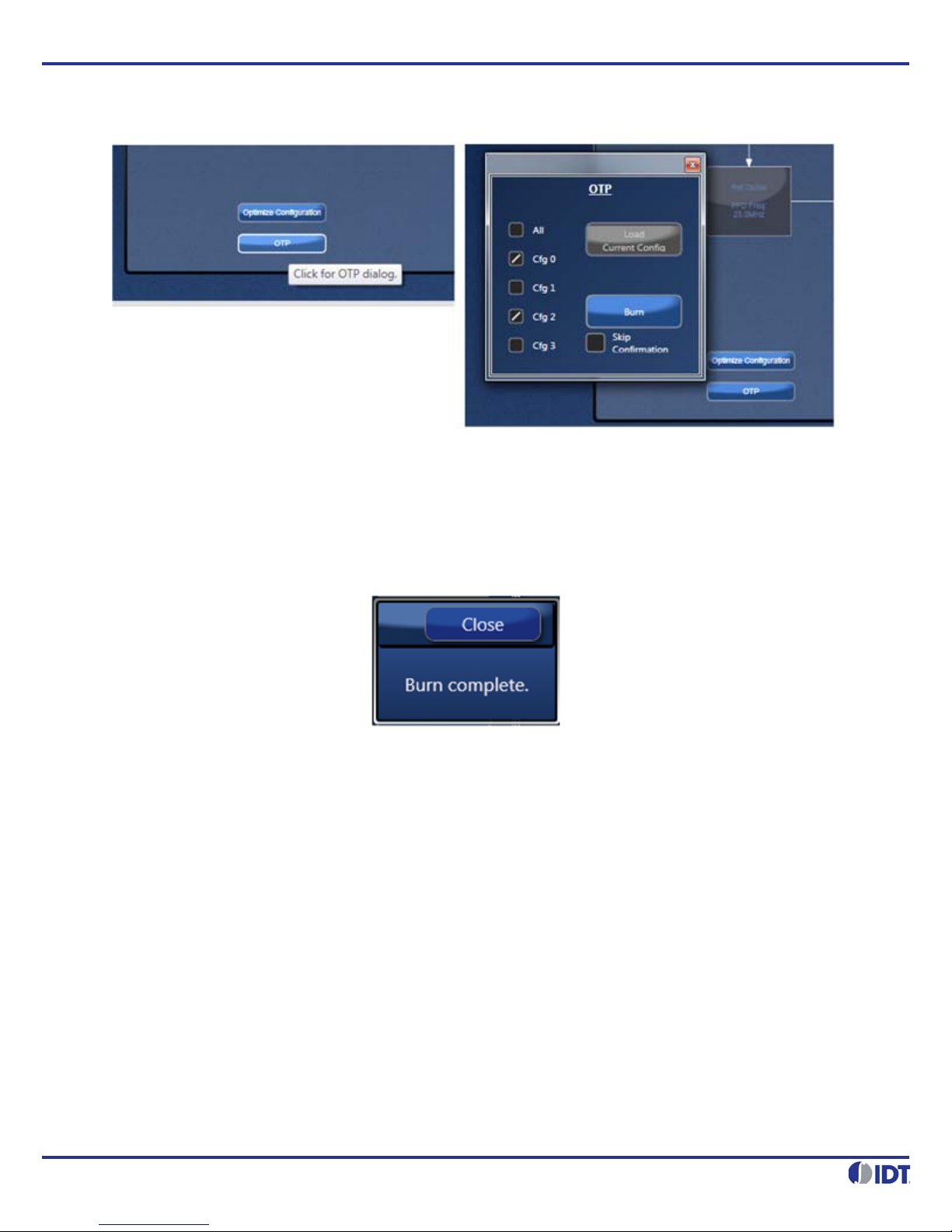

5. Connect to the board–Click on the chip symbol on the top-right corner of the GUI window, as shown in Figure 3 below (left).

A rectangular area in green will display (right).

Figure 3. Connecting to the chip: Left: click on the chip symbol to make the connection; Right: A green area

appears if I

2

C communication is established.

6. Execute “Write All” command–Double check the setting file that is open in GUI window and make sure everything is correct.

Then click on “Write-All” symbol in the green area (See Figure 3 above, right). This is a step that must be executed before OTP

programming of the device.

7. Click on OTP button in the GUI–On lower left portion of GUI window, there is a button called OTP (Figure 4: left). Click this

button to open OTP Programming dialogue window (Figure 4: right).

REVISION 12/03/15 2

Page 3

VERSACLOCK® 6 - 5P49V69xx Family Programmer Board

Figure 4. OTP Dialogue Window

In OTP dialogue window, there is a box in front of each configuration. Check the box for the configuration(s) that you want to

program. One or more configurations can be selected at the same time. If All is checked, all 4 configuration will be programmed.

After intended configuration(s) is selected, then programming the device is only one click away – click on the blue “Burn” button

will launch the programming. If one or more of the target configurations have already been burned, there will be a warning.

Once done, a completion message will pop out which indicates a successful programming:

Figure 5. Message for Successful Programming

Important: Burning irreversibly converts ones to zeroes; it is possible to go back and burn an unburned bit or bits to zero; zeroes

cannot be restored to ones. This allows revision of a burn under limited circumstances.

Loading from OTP

For loading one or more configurations from a burned part into the VC6 GUI (“load OTP”) follow these steps: Before reading back

cycle the power on the part and set the input crystal and/or clock frequencies in the GUI to those in the original configuration(s).

This must be done manually because there is no way to store this information on the part itself. If there is more than one

configuration, this step must be repeated for each one.

Connect to the part. The “OTP” button becomes enabled. The “Active” and “Configuration” indicator lights will be displayed (see

Figure 6 below), and be illuminated or dark as appropriate. The green “Active” light means that the “OTP Burned” bit (R0[7]) has

been burned. The red “Configuration” lights are illuminated as appropriate: if on, that configuration in the OTP has been burned.

Click the “OTP” button. In the OTP dialog, check the boxes of the configurations to be loaded. If you check a box corresponding

to an unburned configuration, there will be a warning (see Figure 7 below).If there are four configurations, there is an “All”

checkbox for convenience (see Figure 8 below). Click “Load”.

REVISION 12/03/15 3

Page 4

Figure 6. Indicator Lights

Figure 7. Unburned Configuration Warning

VERSACLOCK® 6 - 5P49V69xx Family Programmer Board

Figure 8. OTP “All” Checkbox

REVISION 12/03/15 4

Page 5

VERSACLOCK® 6 - 5P49V69xx Family Programmer Board

In-System VersaClock 6 OTP Non-Volatile Programming via I2C

The procedure below enables the user to calibrate the device to a proper VCO band that will guarantee functionality over the full

temperature range of the device. That band will then be programmed into the OTP. Certain conditions are required to properly

program the device.

1. Conditions: Ambient temperature 25°C, 3. 3V. For any other conditions, contact IDT.

2. Procedure:

a.Power-up the device

b.Write all relevant bits to the device to program PLL, FOD and output types

c. Provide a reference clock to the IC corresponding to the configuration.

d.Specific bits need to be set:

• Set VCO Monitoring in address x1D, bit[1] to “0”

• Set “AFC Enable” bit in address x16, bit[3] to “0”

• Set Test mode bit in register 0x11 (bit[5]) to “0”

e.Perform VCO Calibration:

• Toggle bit[7] in 0x1C by writing the bit to 0 then 1 and then back to 0. Final state of the bit should be 0.

• Wait 100 ms

• Read band in I2C register 0x99 bit[7:3]

(read only register located in the factory programmable section of the RAM)

• The value read from register 0x99 has to be different from 0 or 23. If this is not the case then repeat th e Calibration step.

• Write the content of the I2C register 0x99 bit[7:3] to the bits bit[4:0] into register 0x11.

f. Programming the OTP

Before programming the OTP, change T est mo de bit in register 0x1 1 (bit[5 ]) to “1” to force the chip to run the b and number written

previously in bits[4:0].

Now program the OTP by following the steps on page 5 of the VersaClock 6 Family Register Descriptions and Programming

Guide.

REVISION 12/03/15 5

Page 6

VERSACLOCK® 6 - 5P49V69xx Family Programmer Board

VersaClock 6 Volatile Programming via I2C

The procedure below enables the user to calibrate the device to a proper VCO band that will guarantee functionality over the full

temperature range of the device. Certain conditions are required to properly calibrate the VCO.

1. Conditions: Ambient temperature 25°C, 3. 3V. For any other conditions, contact IDT.

2. Procedure:

a.Power-up the device

b.Write all relevant bits to the device to program PLL, FOD and output types

c. Provide a reference clock to the IC corresponding to the configuration

writteninpointb.

d.Specific bits need to be set:

• Set VCO Monitoring in address x1D, bit[1] to “0”

• Set Test mode bit in regis ter 0x11 (bit[5]) to “0”

e.Perform VCO Calibration:

f. Toggle bit[7] in 0x1C by writing the bit to 0 then 1 and then back to 0. Final state of the bit should be 0.

• Wait 100 ms

REVISION 12/03/15 6

Page 7

VERSACLOCK® 6 - 5P49V69xx Family Programmer Board

Programmed Device Testing

As indicated in the Board Overview section, the programmed device can be verified with this same board. To verify, complete the

following:

• Install R14 (100K) and then power up to latch the board in hardware selection mode

• Pull-up or pull-down SEL1 and SEL0 pins to proper levels to match the specific configuration for verification

• Supply VDDA, VDDD and VDDO0~4

• Supply a reference signal via CLKIN/CLKINB (needed to populate C20 and C22) or a Crystal (X1) needs to placed, if not

populated in the 3.2x2.5mm package.

• In order to probe the output(s) of interest the following components need to be placed:

1) R15 and C15 need to be populated to measure OUT0.

2) R17, R18 and J2 to measure OUT1.

3) R20, R21 and J3 to measure OUT1B. R19 s required only when measuring OUT1B and OUT1 in LVDS mode.

4) R26, R27 to measure OUT 2.

5) R30, R31 to measure OUT2B. R29 is only required when measuring OUT2B and OUT2 in LVDS mode.

6) R34, R35 to measure OUT 3.

7) R37, R39 to measure OUT3B. R36 is only required when measuring OUT3 and OUT3B in LVDS mode.

8) R41, R42 to measure OUT4.

9) R44, R45 to measure OUT4B. R43 is only required when measuring OUT4B and OUT4 in LVDS mode.

The recommended values depends on which driver output has been selected – LVDS, LVPECL, HCSL or LVCMOS:

• LVCMOS requires 33 resistor termination in series.

• LVDS requires 0 resistor in series and 100 in parallel between the 2 differential outputs.

• LVPECL requires 0 resistor in series and 180 to ground for each differential signal.

• HCSL requires 33 resistor in series and 50 to ground for each differential signal.

Please refer to the board schematics on the following pages of this document.

REVISION 12/03/15 7

Page 8

VERSACLOCK® 6 - 5P49V69xx Family Programmer Board

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

3mm

L

L

2.0 oz

Copper

L = 5mm is more

than enough

PCB Copper Decal

Recommandations for LM317LD

SO-8

XTOUT

3V3_USB

3V3_USB

XTIN

VCC2232

3V3_USB

VCC2232

USB_5V

VCC2232_3V

USB_5V

SEL1_SDA

SEL0_SCL

USB_PWR

Title

Size Document Number Rev

Date: Sheet

of

<Doc> <RevCod

e

<Title>

B

12Monday, January 27, 2014

Title

Size Document Number Rev

Date: Sheet

of

<Doc> <RevCod

e

<Title>

B

12Monday, January 27, 2014

Title

Size Document Number Rev

Date: Sheet

of

<Doc> <RevCod

e

<Title>

B

12Monday, January 27, 2014

C7

33pf

C6

0.047uF

L1

600 ohm 500mA

R2

470

C45

0.1uF

R59 402_1%

R7 0

C5

0.1uF

R4

27

C2 0.1uF

U3

USB_A

VBUS

1

D+

3

GND

4

D-

2

R5 1.5K

U1

ft2232_chip

EESK1EEDATA

2

VCC

3

RESET#

4

RSTOUT#

5

3V3OUT

6

USBDP7USBDM

8

GND

9

SI/WUA

10

GPIOH311GPIOH212GPIOH1

13

VCCIOA

14

GPIOH0

15

GPIOL316GPIOL2

17

GND

18

GPIOL119GPIOL0

20

TMS/CS

21

TDO/DI22TDI/DO

23

TCK/SK

24

GND

25

SI/WUB

26

UNUSED1127UNUSED10

28

UNUSED929UNUSED8

30

VCCIOB

31

UNUSED732UNUSED6

33

GND

34

UNUSED535UNUSED436UNUSED337UNUSED238UNUSED139UNUSED0

40

PWREN#

41

VCC

42

XTIN

43

XTOUT

44

AGND

45

AVCC

46

TEST

47

EECS

48

R9

10K

R3

27

C3 0.1uF

R10

10K

C46

10uF

C1 10nF

R1

680

R6 0

C8

33pf

C4

10uF

LD1

Green

Y1

6MHz

12

U5

LM317LBD

VIN1VOUT_22VOUT_33Adjust

4

NC_8

8

VOUT_77VOUT_6

6

NC_5

5

R58

243_1%

R8 10K

REVISION 12/03/15 8

Page 9

VERSACLOCK® 6 - 5P49V69xx Family Programmer Board

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

SD/OE

VDDD

VDDQ0

VDDO1

VDDO3

VDDO4

CLKSEL

VDDA

VDDO2

SEL1/SDA

SEL0/SCL

VDDD

VDDD

VDDD

VDDD

VDDD

VDDD

VDDD

VDDD

VDDD

SEL1_SDA

SEL0_SCL

USB_PWR

USB_PWR

USB_PWR

USB_PWR

USB_PWR

USB_PWRUSB_PWR

Title

Size Document Number Rev

Date: Sheet

of

<Doc> <RevCode>

<Title>

C

22Friday, January 24, 2014

Title

Size Document Number Rev

Date: Sheet of

<Doc> <RevCode>

<Title>

C

22Friday, January 24, 2014

Title

Size Document Number Rev

Date: Sheet of

<Doc> <RevCode>

<Title>

C

22Friday, January 24, 2014

TP2

R38

10(np)

R18

180(np), 49.9(np)

R24

1k(np)

R23

49.9(np)

R41

0(np), 33(np)

R50

0 (np)

C33

10u(np)

C23

2p(np)

R17

0(np), 33(np)

R12

0

C28

10u(np)

R30

0(np), 33(np)

C30

2p(np)

C16

10u(np)

C13

10u(np)

R39

180(np), 49.9(np)

TP6

OUT2

R28

1k(np)

R43

100(np)

C34

0.1u(np)

R27

180(np), 49.9(np)

U2

IDT5P49V5901

CLKIN1CLKINB2XOUT3XIN/REF4VDDA5CLKSEL

6

SD/OE

7

SEL1/SDA

8

SEL0/SCL

9

VDDO4

10

OUT4

11

OUT4B

12

OUT3B

13

OUT3

14

VDDO3

15

OUT2B

16

OUT2

17

VDDO2

18

OUT1B

19

OUT1

20

VDDO1

21

VDDD

22

VDDO0

23

OUT0_SELB_I2C

24

e_PAD

25

R32

49.9(np)

JP2

OE

R16

0

J4

TP12

OUT4B

R29

100(np)

TP4

OUT0_SELB_I2C

C17

0.1u(np)

R25

100(np)

C29

0.1u(np)

R37

0(np), 33(np)

X1

25MHz(np)

1 3

2

4

R49

4.7k

C24

10p(np)

C18

2p(np)

C26

2p(np)

JP3

SEL1

C9

10u(np)

R26

0(np), 33(np)

C31

2p(np)

J5

C11

0.1u(np)

R13

0

R45

180(np), 49.9(np)

TP8

OUT3

TP3

R33

1k(np)

R35

180(np), 49.9(np)

C35

10u(np)

C20

0.1u(np)

TP5

JP4

SEL0

R51

0

C25

10p(np)

TP7

OUT2B

R21

180(np), 49.9(np)

J3

C19

2p(np)

R44

0(np), 33(np)

TP1

C10

0.1u(np)

R47

0 (np)

C21

2p(np)

R22

1k(np)

R34

0(np), 33(np)

R15

20(np)

TP11

OUT4

C32

0.1u(np)

C27

2p(np)

TP9

R36

100(np)

C12

10u(np)

J2

R20

0(np), 33(np)

R46

4.7k

TP14

C22

0.1u(np)

R48

0

R42

180(np), 49.9(np)

C15

5p(np)

R14

100k(np)

TP13

C14

0.1u(np)

TP10

OUT3B

R31

180(np), 49.9(np)

R40

0

R19

100(np)

R11

0

JP1

CLKSEL

REVISION 12/03/15 9

Page 10

VERSACLOCK® 6 - 5P49V69xx Family Programmer Board

Corporate Headquarters

6024 Silver Creek Valley Road

San Jose, CA 95138 USA

Sales

1-800-345-7015 or

408-284-8200

Support

www.idt.com/go/support

Fax: 408-284-2775

www.IDT.com

DISCLAIMER Integrated Device Technology, Inc. (IDT) and its subsidiaries reserve the right to modify the products and/or specifications described herein at any time and at IDT’s sole discretion. All information in this document,

including descriptions of product features and performance, is subject to change without notice. Performance specifications and the operating parameters of the described products are determined in the independent state and are not

guaranteed to perform the same way when installed in customer products. The information contained herein is provided without representation or warranty of any kind, whether express or implied, including, but not limited to, the

suitability of IDT’s products for any particular purpose, an implied warranty of merchantability, or non-infringement of the intellectual property rights of others. This document is presented only as a guide and does not convey any

license under intellectual property rights of IDT or any third parties.

IDT’s products are not intended for use in applications involving extreme environmental conditions or in life support systems or similar devices where the failure or malfunction of an IDT product can be reasonably expected to significantly affect the health or safety of users. Anyone using an IDT product in such a manner does so at their own risk, absent an express, written agreement by IDT.

Integrated Device Technology, IDT and the IDT logo are registered trademarks of IDT. Product specification subject to change without notice. Other trademarks and service marks used herein, including protected names, logos and

designs, are the property of IDT or their respective third party owners.

Copyright 2015. All rights reserved.

Loading...

Loading...