ididit Retrofit Steering Column 1973 Chrysler B-Body User Manual

Retrot Steering Column

Installation Instructions

for 1973 Chrysler B-Body

For Part #’s: 1620870010, 1620870020, 1620870051, 1620879910,

1620879920, 1620879951

www.ididitinc.com

610 S. Maumee St., Tecumseh, MI 49286

PH: (517) 424-0577 FAX: (517) 424-7293

Instruction # 8000000008 REV 01/13

(A)

Images or examples in this booklet may vary from your specic installation.

(B)

(C)

These are the components that come with the column.

(Paintable Steel column pictured above)

(A) Column

(B) Wiring Plugs

(C) Floor Mount

(D) Instructions & Dress Up Kit (Dress Up Kit installed on this column)

We will work through this installation using all the above parts. For

instruction purposes we will assume the vehicle is all original and

uses the OEM harness.

(D)

INDEX

REMOVAL.................................................................... 1 & 2

INSTALLATION OF COLUMN.............................................4

ELECTRICAL INSTRUCTIONS........................................6-7

INSTALLATION OF KNOBS & LEVERS..............................5

WHEEL INSTALLATION......................................................7

No part of this guide may be reprinted, reproduced or utilized in any form without the

express written permission of ididit, inc.

2011 ididit, inc. All Rights Reserved Printed in the USA

Images or examples in this booklet may vary from your specic installation.

REMOVAL of OEM Column: Disconnect positive battery cable.

Before you start your installation, verify that your turn signals, brake

lights, horn & 4-way ashers are working properly. If they all function

now, then they should function properly again once the installation is

complete.

Verify that your steering wheel and driving wheels are straight.

Disconnect the positive terminal on the battery.

While inspecting the components of the kit, take a moment and notice

the output shaft of the new ididit column. We have been the leading

manufacturer of steering columns for a reason. This column can be

used for a Power gearbox, Manual gearbox or a Rack and Pinion

steering system. Note that the lower shaft is a telescoping shaft. If you

grab it and pull, the shaft has enough travel to accommodate all the

different lengths needed. Since these vehicles were also known to

have a lot of ex in the frames, this telescoping feature also increases

the life of the joints in the steering system.

Column Removal

Disconnect the rag joint from your gearbox.

Remove the bolts and nuts that hold the rag joint

together on the box side (1/2 inch wrench). This

allows more room to drive out the roll pin that

goes through the joint end that is attached to the

box. When driving this pin out it is recommended

that you use a 5/16 punch as this will remove the

pin without destroying it. (Figure 1)

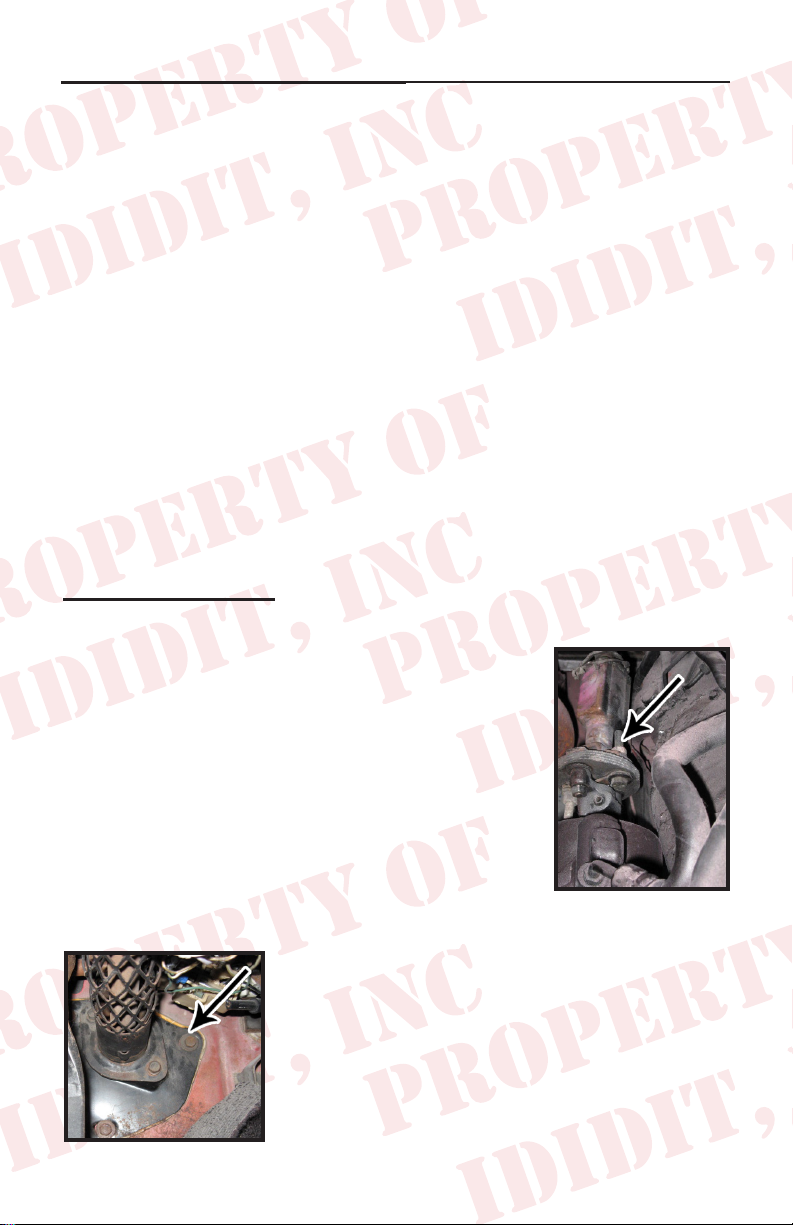

Remove the two bolts that lock the rewall

mount to the column ( ½ inch socket with

extension). Remove the three bolts that hold

the rewall mount to the rewall. Next pry (if

necessary) and loosen the large part of the

mount from the rewall. (Figure 2)

(Figure 2)

1

(Figure 1)

Carefully disconnect both wire plugs from

the column to the dash harness. Take extra

caution, these plugs may be delicate to work

with. (Figure 3)

A helper is great for the next steps.

(Figure 3)

Loosen and remove the three nuts that

hold the column mount under the dash.

Use a 7/16 deep dish socket with a 3 inch

extension to remove the nuts. (Figure 4)

When removing the last nut the weight

of the column will be released. Have

your helper hold the column up while

the last nut is being removed. Now

pull the column out through the inside

(Figure 4)

of the vehicle while the other guides the

column through the pedal area. Guiding will ensure the original

column clears any obstructions that may be in the way (ie. wires,

pedals, etc.).

New Column Preparation

The original under dash mount with the plastic

release blocks will be used on the new column.

If your release blocks are damaged or broken

they need to be replaced either through a

dealer or an online store.

Install the under dash bracket onto the new

column using the provided bolts (5/16-18

with built in lock washers) torque to 22 ft. lbs.

(Figure 5)

Wrap the lower column tube with masking tape

and cover the bottom 4 inches to prevent any

scratches to your new column. (Figure 6)

2

(Figure 5)

(Figure 6)

Loading...

Loading...