Page 1

Retrot Steering Column

Installation Instructions

for 1967 Mustangs

www.ididitinc.com

610 S. Maumee St., Tecumseh, MI 49286

PH: (517) 424-0577 FAX: (517) 424-7293

Revised 1/22/2014

Instruction #: 8000000014

Page 2

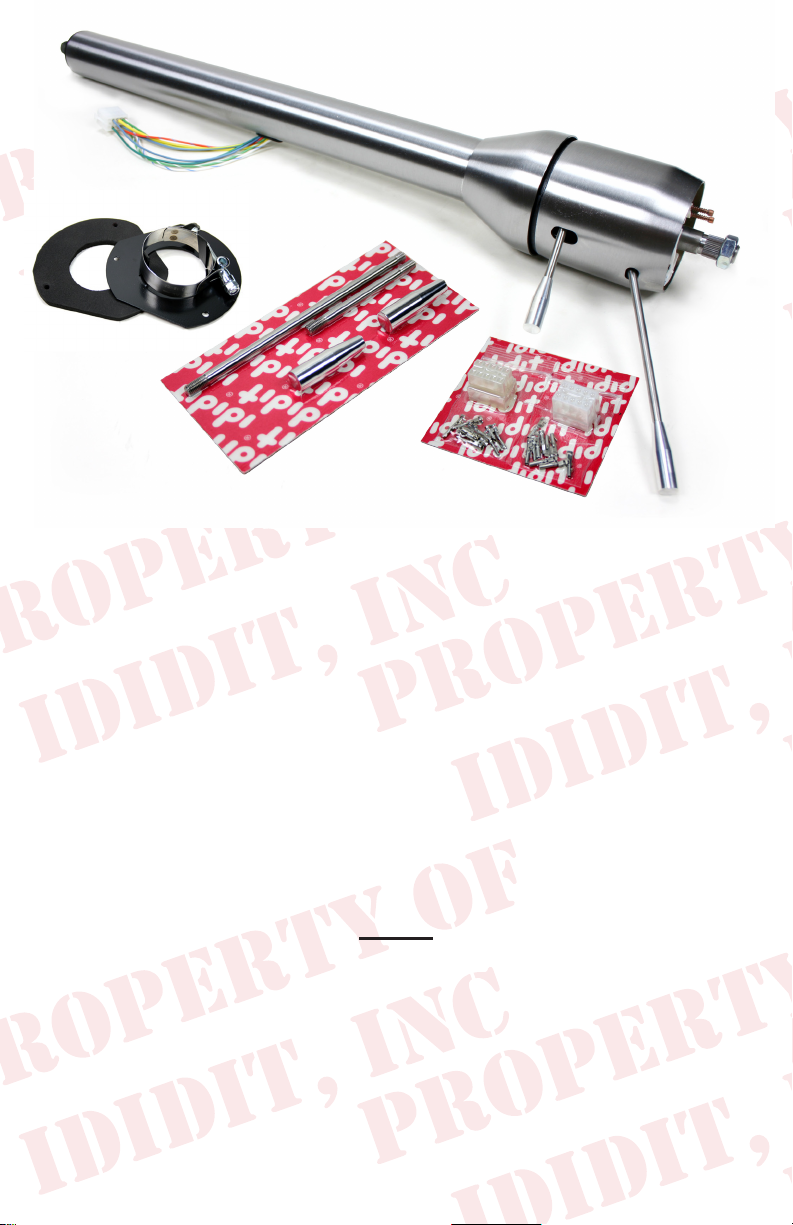

(A)

(B)

(D)

(C)

These are the components that come with the column.

(Paintable Steel Column pictured)

(A) Column

(B) Floor Mount Plate with Clamp & Gasket (Part #: 2400010210)

(C) Male & Female Wiring Plugs with Terminals

(D) Instructions & Dress Up Kit (Dress Up Kit pictured with column)

We will work through this installation using all these parts. For instruction

purposes we will assume the car is all original and has a factory manual

steering gear box and an OEM harness. On the last page there will be a

summary for other applications, such as a rack and pinion or aftermarket gear boxes. There will also be instructions for aftermarket steering

wheels.

INDEX

REMOVAL........................................................................ 2

MODIFYING YOUR SHAFT..............................................3

WIRING INSTALLATION............................................4 & 5

COLUMN INSTALLATION..........................................5 & 6

KNOB & LEVER INSTALLATION......................................6

STEERING WHEEL INSTALLATION................................7

1.

Page 3

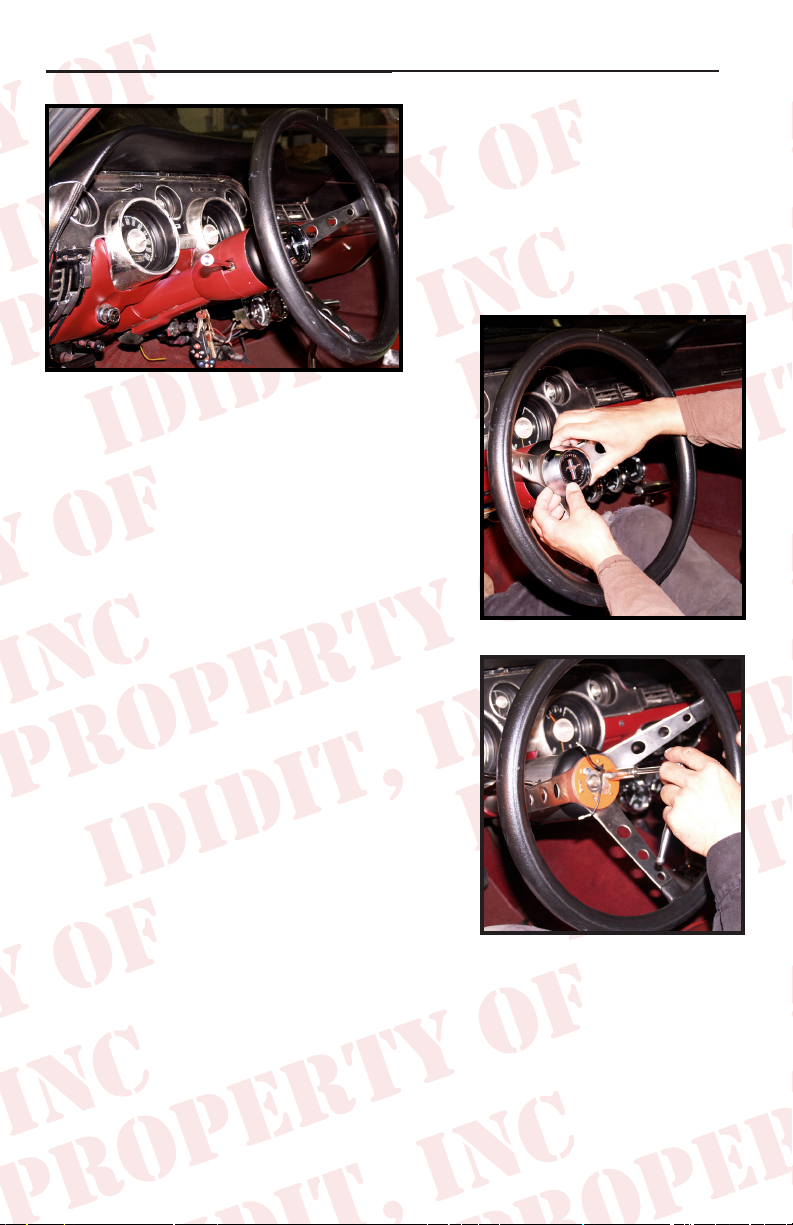

REMOVAL of OEM Column: Disconnect positive battery cable.

To remove the horn button on

your stock steering wheel, push

it in and then rotate counter

clockwise.

Remove the nut and use a wheel

puller to pull the original steering wheel off

the original column.

Now go under the dash and disconnect the

wire plug from the column to the underdash column harness.

Remove the three screws that holds the

gasket to the rewall.

Now you can remove the screws that hold

underdash mount.

You will want to rotate the column left and

right to loosen and then pull the column

back toward the driver to remove it from

the car. There will still be a 3/4” round

shaft sticking into the driver’s side compartment from the gearbox.

(Figure 1)

(Figure 2)

(Figure 2)

2.

Page 4

Measure out 4” from the face of

the nut on the gearbox and cut

shaft.

(Figure 5)

Shaft

4”

The shaft of the gearbox will now

need to be cut into a DD shaft.

Face of Nut

Steering Box

(Figure 5)

This is a round shaft with ats

centered on two sides. An easy way to do this is to make a paper template.

Create your own template by using the measurements from the diagram

below.

Original Shaft

1.000”

New DD Shaft

.395

.945

1.525

2.075

2.356

DD SHAFT

TEMPLATE

Note: Diagram

not to scale

To make 3/4 DD shaft

remove .100” from oppo-

site sides of the shaft

Starting from an 1/8 from the bottom, wrap the paper template around the

shaft and match the horizontal arrows together.

Mark the shaft at the 8 vertical arrow points and draw a line down the length

of the shaft, connecting the marks. This will create the shaded “D” sections

found on the template.

With a grinder or similar tool, grind at the shaded “D” sections to match

the DD shaft. As you work, use the coupler as a guide and test t to ensure

proper tting.

Another option would be to remove the gearbox and take it to your local

machine shop to be modied.

3.

Page 5

Wiring Installation:

The rst few tasks, you can do more easily with the column on a work

bench before you put it in the car!

Wiring

Included in the kit are male and female white plastic connectors and

male & female terminals. The wiring from the switch can be made to t

either this connector OR the original connector. The pins are the same

size as the original.

Using Original Connector: (Easiest!)

Remove the pins from the original

wiring block on the original steering

column and insert the wires on your

new steering column into their proper

location on the original block. *The

color codes should match up. You

will more than likely have to use

a tool to remove the pins from the

plastic connectors. Figure 8 shows two types of tools commonly used.

Using All New Wiring Provided:

Included are male and female blocks along with the necessary terminals

and wiring diagram. You will have to remove the pins from the original

connector off the car side of the harness and insert the pins into the back

side of the new block provided. Insert each terminal completely until

each one snaps into place. You can verify it is secure by lightly tugging

on it. You may need to bend the locking tab back out slightly. Then you

will also install the new block on the column harness. Again, matching

color codes*.

(Figure 8)

*See chart on Page 5

4.

Page 6

Wiring Installation: (Cont.)

Turn Signal Switch**

Orange w/Blue Right rear turn and brake

Green w/Orange Left rear turn and brake

White w/Blue Right front turn signal

Yellow Horn (Power)

Green w/White Left front turn signal

Green Brake feed from brake switch

Blue w/Yellow Horn

Blue Turn signal feed

White w/Red Flasher Feed

*Included with the connector are new terminals for the car side if your originals are not usable or

if you have an aftermarket harness and do not have matching terminals.

**Colors under dash may not match.

Connecting to your Box or Rack:

The ‘67 Mustang will use a 3/4”DDx3/4”36 coupler and depending on

whether you have a Late or Early Mustang will require additional pieces.

The Early ‘67 Mustang (long shaft) will require a 3/4”DDx3/4”36 Coupler.

The Late ‘67 Mustang (short shaft) will require a Coupler (3/4”DDx3/4”36),

Shaft (3/4”DD) and Rag Joint (3/4”36x3/4”DD).

The Early ‘67 Kit Part#: 3000313449 (long shaft steering box)

Kit Includes: 3/4”DDx3/4”36 Coupler, you will also need to modify your

original shaft.

The Late ‘67 Kit Part#: 3006002100 (short shaft steering box)

Kit Includes: 3/4”36x3/4”DD Coupler, 2 5/16” Long DD Shaft,

3/4”DDx3/4”36 Rag Joint.

If you are using a Rack and Pinion set up you will have to design your

own way to hook the column to the rack. We can help with U-Joints and

shafting, but because of headers and different companies making rack

kits we will need more information from you to get the correct installation.

Take the two of the above mentioned kits and install them onto the original steering box per year & kit.

Tip.. Please follow the manufactures instructions on the Coupler & Rag Joint instal-

lation. These instructions vary by manufacturer. But when all is said and done, ididit

recommends that you use Locktite on the threads.

5.

Page 7

Next, slide the oor mount plate, clamp and gasket up the tube of the your

new Mustang column. The nut on the clamp should be on the bottom of

the tube and facing the driver’s side door/fuse box. You can temporarily

hold the mount in place with a piece of masking tape while you install the

column in the car. At this part of the installation an extra set of hands

may be very helpful. With one hand in the middle of the column and one

at the top, slide the column between the pedals and through the hole in

the rewall. Engage the coupler onto the gearbox. Set the column up

into the original dash mount* and loosely install the original bolts into the

original clamp. The tab on the dash mount should be toward the rewall

and engaged into the slot in the bottom side of the tube on the steering

column. Depending on its condition, you may want to replace the rubber

in the dash mount. (We have found that a great substitute is the rubber

from a bicycle inner tube you may have laying around.)

(ididit does have a ‘67 Mustang underdash mount made

for this application if you have misplaced or trashed your

original. That part number is: 2312300010)

Now, if everything is positioned well, you can go back and tighten everything up. Start with the dash mount and tighten original two bolts to 108

– 156 inch lbs*. Next, tighten up the coupler set screw and locking nut to

manufacturer’s specs. Lastly, remove the tape holding the oor mount to

the column. Using the 3 sheet metal screws, secure the oor mount and

gasket to the rewall. Then tighten the oor mount clamp onto the mount

tabs and column to 50 inch lbs*.

*(not foot pounds)

Knobs & Levers:

After removing all items from the package,

assemble the knobs onto the levers. The tilt

lever (shorter of the two levers) goes on the

left side of the column in the hole closest to

the dash. The column has a threaded hole

that this lever threads into. (Figure 9)

The turn signal lever (longer of the two levers)

goes on the left side of the column in the

hole closest to the driver. The column has

a threaded hole that this lever threads into.

(Figure 10)

(Figure 9)

(Figure 10)

6.

Page 8

Steering Wheel:

OEM Wheel - Must be for the same

year application as the column. *Use of

a different year of wheel will result in

damage to the turn signal switch.*

Aim the road wheels so they are pointing straight

ahead. Lower the stock steering wheel onto

the column and center it in its proper position.

Tighten the NEW nut that came with the column

to 45 ft lbs. You may need to adjust the wheel

a bit after driving the vehicle to get the wheel

just where you want it. Re-install the horn and spring by pushing in and

turning clockwise to lock it into place.

Hook the battery back-up and verify that your signals, brake lights, etc

are operating properly. Double check all fasteners including coupler, dash

mount and oor mount to make sure they are all tight.

No part of this guide may be reprinted, reproduced or utilized in any

form without the express written permission of ididit, inc.

2009 ididit, inc.

All Rights Reserved

Printed in the USA

ididit, inc.

610 S. Maumee St., Tecumseh, MI 49286

(517) 424-0577 • (517) 424-7293 fax

www.ididitinc.com

Loading...

Loading...