Page 1

VISIBILITY DELIVERED.

i-Q350 RCM

SensorSMART™

Installation and Operation Manual

Page 2

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 2 OF 28

Proprietary Notice

This document contains confidential information proprietary to IDENTEC SOLUTIONS and may not be used or

disclosed to other parties in whole or in part without the prior written authorization from IDENTEC

SOLUTIONS.

Disclaimer and Limitation of Liability

IDENTEC SOLUTIONS AG and its affiliates, subsidiaries, officers, directors, emp loye es and agents do not make

any express or implied warranties or representations with respect to such information including, without

limitation, warrantie s as to non-infringement, reliability, suitabilit y for a particular purp ose and accuracy.

IDENTEC SOLUTIONS shall not under any circumstances be liable to any person for any special, incidental,

indirect or conseq uential damages, inc luding without limitation, damages resulting from use of or reliance on

information prese nted herein, or loss o f p r ofits or revenues or costs of replacement goods, even if informed in

advance of the possibility of such damages.

Customer shall be solely responsible for proper selection, application, and use of Products, as well as the

incorporation/inte gration of Products into other equipment or systems. Customer shall indemnify and hold

IDENTEC SOLUTIONS harmless from and aga inst any and all dama ge s, liabilities, claims, or expens es

(including reasonable attorneys' fees) arising out of or relating to (i) improper se lection , app lication,

installation, use or in c orporation/integration of Products; or (ii) infringement of any patent, trademark,

copyright or other third party interest arising out of IDENTEC SOLUTIONS' compliance with any of Customer's

designs, specifications, or instructions

Trademarks

“IDENTEC SOLUTIONS”, “Intelligent Long Range”, “ILR” and the stylized “i” are registered trademarks and “iCARD”, “i-PORT”, “i-LINKS”, “Visibility Delivered.” are trademarks of IDENTEC SOLUTIONS, Inc. and/or

IDENTEC SOLUTIONS AG.

Copyright Notice

Copyright © 2014 IDENTEC SOLUTIONS. All rights reserved.

No part of this document may be reproduced or transmitted in any form by any means, photographic,

electronic, mechanical or otherwise, or used in any information storage and retrieval system, without the prior

written permission of IDENTEC SOLUTIONS.

Issue 1.3 / December 2014 (EGD)

Subject to alteration without prior notice.

Printed in Austria

Page 3

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 3 OF 28

Radio Frequency Compliance Statement

IDENTEC SOLUTIONS is the responsible party for the com pliance of the following devices:

MODEL:

i-Q350 RCM

Region/Country

Organization

Marking

EUROPE:

EC

CE

USA:

FCC

OO4-ILR-IQ350WAM

OO4-ILR-IQ350WAM2

Canada:

Industry Canada

3538A-IQ350WAM

3538A-IQ350WAM2

The user(s) of these products are cautioned to only use accessories and peripherals approved, in advance, by

IDENTEC SOLUTIONS. The use of accesso ries and periph era ls, other th an th ose app rov ed by IDE N TE C

SOLUTIONS, or unauthorized changes to approved products, may void the compliance of these products and may

result in the loss of the user(s) authority to operate the equipment.

European Notification according R&TTE Directive

This equipment complies to Art. 6.4 of R&TTE Directive (2006/95/EU, 2004/108/EC, 1999/5/EC). It is tested for

compliance with the following standards: EN 300 220-1, ETSI EN 300 220-2, ETSI EN 301 489-1, ETSI EN 301

489-3, EN 60950-1:2006 + A11:2009 + A1:2010 + A12:2011

USA Notification

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, an d

(2) this device must accept any interference received, including interfe ren ce th at m a y cau se undesired

operation.

Canada Certification

This device complies with Industry Canada’s license exempt RSS’s. Operation is subject to the following two

conditions:

(1) This device may not cause harmful interference, an d

(2) this device must accept any interference received, including inte rfere nc e tha t m ay cau se u nd es ired

operation.

Le présent appareil est conforme aux CNR d‘Industrie Canada applicables aux appareils radio exempts de

licence. L‘exploitatio n est autorisée aux deux conditions suiv a ntes:

(1) l‘appareil ne doit pa s produire de brouillag e, et

(2) l‘utilisateur de l‘appareil doit accepter tout brouillage radioélectrique subi, même s i le brouillage es t

susceptible d‘en compromettre le fonctionnement.

Page 4

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 4 OF 28

This product contains components that are sensitive to electrostatic discharges. Please observe the special

instructions for the ir protection. Incorrect handling can dam age the unit and cause the invalidation o f t he

warranty.

Minimum safety precautions against electrostatic discharge:

• Establish earth contact before you touch the unit. For example, touch the earthing screw on the unit.

Even better: Use an antistatic ribbon and earth yourself permanently for the time you handle the unit.

• Avoid unnecessary contact with the unit connectors and assemblies inside the unit.

• Only open the unit if the operational settings (as described in the manual) expressly require this.

• Use antistatic tools for the setting of the unit. (Warning: Do not touch life-threatening voltag es with

these tools).

• Do not store unit and components without protective packaging.

• Only remove unit and components from the packaging immediately prior to installation.

These notes are not sufficient to guarantee complete protection from electrostatic discharges!

We recommend the use of suitable protective equipment.

Page 5

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 5 OF 28

Contents

1.! SAFETY INSTRUCTIONS .............................................................................................. 6!

1.1.! PREPARATIONS .............................................................................................................. 7!

1.2.! SCOPE OF THIS DOCUMENT .............................................................................................. 7!

1.3.! RESPONSIBILITY ............................................................................................................ 8!

1.4.! UPDATES ..................................................................................................................... 8!

1.5.! SCOPE OF DELIVERY—VISUAL INSPECTION ........................................................................... 8!

1.6.! ASSOCIATED DOCUMENTS ................................................................................................ 8!

2.! INTRODUCTION .......................................................................................................... 9!

2.1.! FUNDAMENTALS ............................................................................................................. 9!

2.2.! COMPONENT OVERVIEW .................................................................................................. 9!

3.! INTRODUCTION ........................................................................................................ 10!

3.1.! FUNDAMENTALS ........................................................................................................... 10!

3.2.! SYSTEM COMPONENTS—SENSORS .................................................................................... 10!

3.3.! SYSTEM COMPONENTS—READERS .................................................................................... 12!

3.4.! SYSTEM COMPONENTS—ANTENNAS .................................................................................. 12!

4.! TAG MOUNTING SOLUTIONS ..................................................................................... 16!

4.1.! CABLE STRAPS ............................................................................................................ 16!

4.2.! SCREWS .................................................................................................................... 16!

4.3.! MAG NET (OPTIONAL) .................................................................................................... 18!

5.! CONNECTING TO THE REEFER CONTROLLER ............................................................ 19!

6.! ACCESSORIES ............................................................................................................ 21!

6.1.! EXTENSION CABLE ....................................................................................................... 21!

6.2.! ADAPTORS ................................................................................................................. 22!

6.3.! CONNECTING TO THE TAG .............................................................................................. 23!

7.! TROUBLESHOOTING .................................................................................................. 25!

7.1.! GEN ERAL ................................................................................................................... 25!

7.2.! STATUS DISPLAY (LEDS) ............................................................................................... 25!

8.! MAINTENANCE .......................................................................................................... 26!

8.1.! GEN ERAL ................................................................................................................... 26!

8.2.! REGULAR CLEANING OF THE SURFACE ............................................................................... 26!

8.3.! PRECAUTIONARY MAINTENANCE ....................................................................................... 26!

8.4.! RETURNS ................................................................................................................... 26!

9.! TECHNICAL DATA ...................................................................................................... 27!

Page 6

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 6 OF 28

1. SAFETY INSTRUCTIONS

The system described in this manual is for exclusive operation of trained employees. Only qualified personnel

that have knowledge of the potential dangers involved sh ou ld perfo rm th e insta llation, settings, maintenance

and repair of the units used.

Operational Safety

The correct and safe use of these systems assumes that operating and service personnel follow the safety

measures described in the manual alongside the generally acceptable safety procedures.

If there is a possibility that safe operations cannot be guaranteed, the system m us t be sw itche d o ff, secure d

against accidental use and the service unit responsible immediately informed.

Safety Documents

The i-Q350 tag was designed, tested and supplied in perfect condition according to document IEC348 Safety

Requirements for Electronic Units of Class 1.

Condensate / Change of Temperature

To avoid condensation in the system, the unit must be allowed to slowly adjust itself to warmer temperatures

after removal from cold and cool environments.

Do not open the housing

There is absolutely no need to open the systems housing during set up. Configuration is done with built in

interface wirelessly .

Earthing

Before establishing any connections the housing of the system must be earthed.

Battery Inside

All system tags contain a battery; therefore the following warning should be heeded:

WARNING - Fire, explosion and burn hazard risk of explosion if battery is replaced by a n

incorrect type. Do not recharge, short circuit, crush, disassemble, heat above

100 °C (212 °F)

Do not incinerate, or expose contents to water

Fuses

Only experts who are aware of the dangers involved may replace the fuses. It must be ensured that only

fuses of the required current rating and the correct type are use d for re place m en t. The use o f repaired fuses

and/or short-circuiting the fuse holders is prohibited.

Page 7

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 7 OF 28

Spare Parts

We recommend that only personnel, original products, spare and replacement parts authorized by IDENTEC

SOLUTIONS be used for installation, service and repair. IDENTEC SOLUTIONS does not accept any

responsibility for materials used, work carried out or possible consequences from una uth orized third party

vendors.

Electrostatic Discharge

Semi-conductors of the type MOS or CMOS as well as two-pin types and precision resistance are sensitive to

ESD. All components, printed circuit boards and auxiliary systems should therefore always be classed as

sensitive to electrostatic discharge.

Before opening the cover the unit should be placed onto an ESD-protected surface. As with all work on

modern electronic modules, the use of ESD clamps and ESD mats during work on the unit is recommended.

• Sufficiently protect all printed circuit boards that were removed from the unit from damage.

• Observe all normal precautions for the use of tools.

• Use ESD-protected packaging material.

Never use measuring units with low impedance for measuring or testing systems with semi-conductor

components. Never use high voltage testing units or dielectric test units to test systems with semi-conductor

components.

If it is necessary to check the isolating properties of the field wiring, the assemblies (electronic units and

sensors) should be disconnected.

Earth the test units.

IDENTEC SOLUTIONS does not accept th e retu rn of pro du cts w h ere the reg ulation s con ce rning the ES D

precautions and protective packaging materials were not followed.

ESD – Electrostatic Discharge

EMC – Electromagnetic Compatibility

SELV – Safety Extra Low Voltage – Protective measure against dangerous body currents, formerly: protective first voltage range

1.1. Preparations

This installation manual must be read carefully prior to starting the installation. The described installation

works assume that installation materials like cable, antenna and data sensor holder, etc. are available.

1.2. Scope of This Document

This document is the hardware description of the i-Q350TLX R. This document is intended only for me c h an ic a l

and electrical installation of these central units.

Page 8

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 8 OF 28

1.3. Responsibility

IDENTEC SOLUTIONS reserves the right to ma ke chan ge s an d up da tes to th e co nte nt con taine d he rein. It is

the user’s responsibility to contact the service department for a ny pos sible ch an ge s or u pd ates to op era ting

and maintenance procedures.

1.4. Updates

Updates will be provided upon request. The information in this document may be subjected to changes

without prior notice.

1.5. Scope of Delivery—Visual Inspection

Check whether delivery is complete and for any damages. If the delivery is not complete or damaged

immediately inform the carrier. The dis patch and service or ganization of IDENT EC SOLUTIONS should also be

informed to facilitat e the repair or excha nge of the system.

1.6. Associated Documents

Software description and Programmer’s Guide

• SDK Online Help

• i-SHARE Manual

• Specific sensor manuals

Page 9

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 9 OF 28

2. INTRODUCTION

2.1. Fundamentals

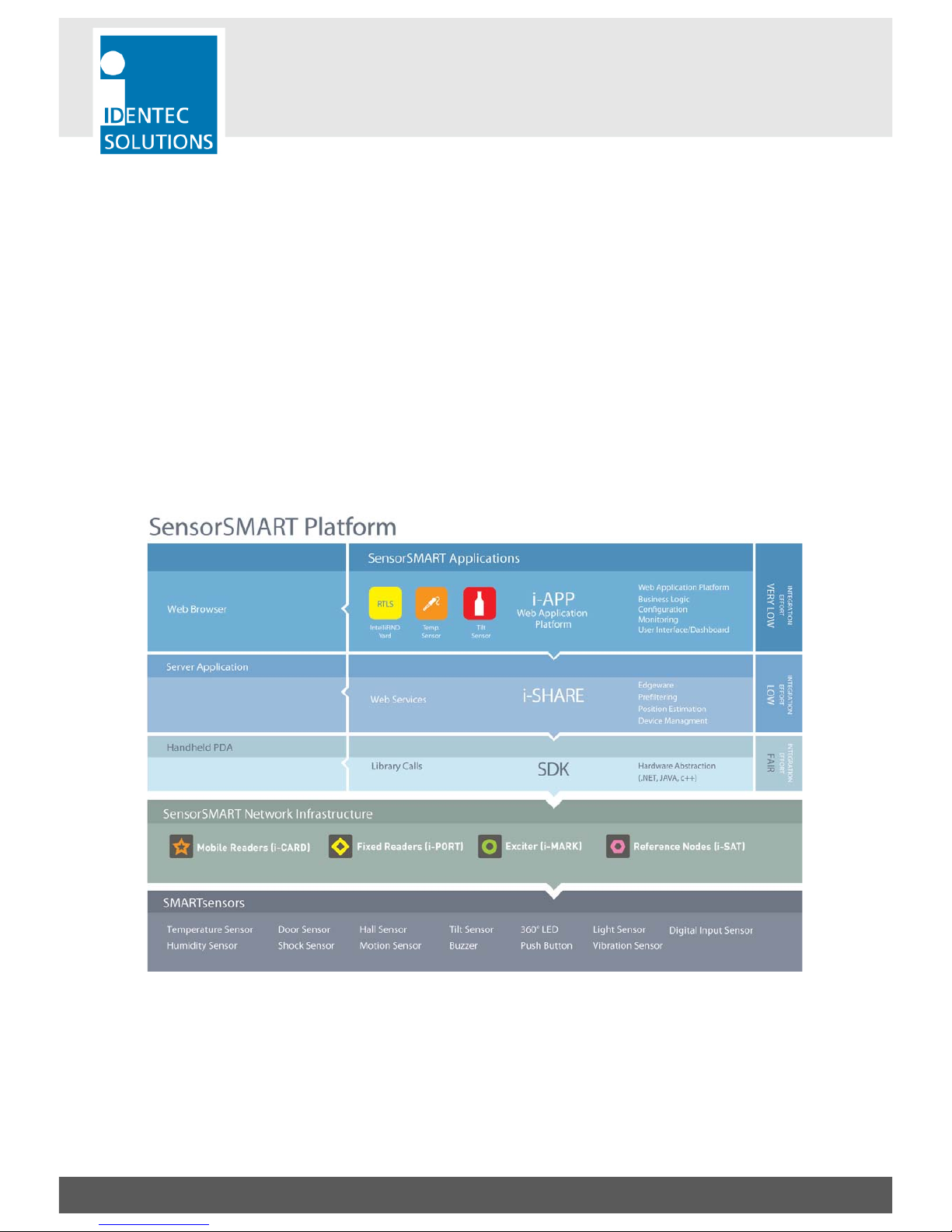

The IDENTEC SOLUTIONS’ SensorSMART Platform is the latest development in asset management,

localization and pro cess optimization. Developed to deliver t he last mile in industria l communication, the

SensorSMART Platform fulfills a niche not previously addressed by available networks.

The SensorSMART Platform takes the complexity out of managing assets, personnel safety monitoring and/or

the tracking of valuable cargo and the need for multiple techn o logies. T he un ique combination of active RFID,

RTLS and WSN in one platform eliminates the necessity for complex deployments of multiple technologies, or

the need to compromise with one techno logy ’s spe cific function alities. The pinn acle o f the Sen so rSM A R T

Platform is that it captures the best of RFID, WSN, and RTLS while also avoiding the less desirable features of

each technology. Third party application development is also simplified for added flexibility.

2.2. Component Overview

Page 10

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 10 OF 28

3. INTRODUCTION

3.1. Fundamentals

Designed to automate the data collection and business processes associated with refrigerated container

management in complex marine and intermodal terminal environments, the Reefer Container Monitoring

System (RCMS) from IDENTEC SOLUTIONS represents the next generation in ‘plug and play’ wireless reefer

monitoring and control.

RCMS increases visibility and helps optimize operational performance with a proven, off the shelf solution for

proactive reefer box management:

• View and manage temperatures and other critical condition parameters with two-way monitoring and

control software

• Avoid undetected reefer failures and respond rapidly to events with real-time alarms

• Eliminate the need for power-line modems with low infrastr u cture wireless hardware

• Reduce capital outlay with managed service options

The innovation at the heart of the system is the iQ350 RCM sensor which talks directly with the reefer unit’s

microprocessor controller via the standard external serial port for immediate, live monitoring operations.

The RCM System, in conjunction with the i-Q350 RCM, provides the perfect combination to monitor the status

of all reefer containers within your terminal.

3.2. System Components—Sensors

i-Q350 RCM 3.2.1.

The i-Q350 series of tags is IDENTEC SOLUTIONS’ newest generation of

Intelligent Long Range® (ILR®) active RFID tag s.

ILR provides highly accurate, real-time data collection without human

intervention in wireless applications suc h as:

• identification

• tracking and tracing

• localization and

• Measurements monitoring.

Using advanced UHF radio frequency technology, i-Q350 WAM tags

transmit and receive data at distances of up to 30 meters (100 feet) from a

handheld device or up to 500 meters (1,640 feet) from a fixed interrogator.

The i-Q350 RCM tag includes a serial interface which communicates to containe r refrige ration u nits. Th e ta g

auto detects the type of the controller and monitors the status information.

Also, LEDs support visual signalization during search, locate and alarms. The i-Q350 Reefer tag operates in

the 850 – 928 MHz UHF band.

Page 11

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 11 OF 28

Polarization of Sensors 3.2.2.

Vertically Polarized

Horizontally Polarized

Polarization is dependent on orientation and is rotation symmetrical.

Page 12

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 12 OF 28

3.3. System Components—Readers

i-PORT M350-2 3.3.1.

The i-PORT M350-2 is a reader for the i-Q350 and i-B350 series of

IDENTEC SOLUTIONS’s Response a n d Broadcast Sensors . Built into a

compact housing, the i-PORT M350-2 reads and writes data to the sensors

at distances of up to 500 meters (1640 feet) on two antennas. Connection

to the host system is established via a RS422 interface, resu lting in the

capability to connect up to 8 readers in a Daisy Chain using commercially

available CAT 5 cables and connectors.

A simple master/slave protocol enables data exchange. Not only does the

protocol contain the data received from the sensor but it can also provide

information about t he time of data rece ption, field strength a nd information

about the number of times the sensor has been received by the reader.

3.4. System Components—Antennas

IDENTEC SOLUTIONS’ antennas are distinguishe d by their compact design. A variety of antennas can be used,

depending on application. The antennas are differentiated by characteristics such as polarization, apex angle,

and gain. Optimal fit to the reading zone is ac hieved by the right c hoice of antenna (characteristics) and

receive sensitivity. As the antennas are passive system elements, no tun ing is requ ired, wh ich facilitates

installation and maintenance.

Elliptical Polarized Antennas 3.4.1.

Because of the wide apex angle (120º), a large read zone is achieved,

which is desirable when a large quantity of sensors need to be read at one

time, or when sensors moving at great speed s ne ed to b e interro ga ted .

Since the polarization is elliptical, orientation of the sensor relative to the

antenna is not important; if the sensor is in front of the antenna the sensor

may be polarized horizontally or vertically along the line of sight of the

antenna. Due to its small size and weight, this antenna is very easy to

integrate.

Page 13

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 13 OF 28

Orientation Diagrams: Elliptical polarized antenna

Elevation Azimuth

For this antenna, the maximum transmit power setting is:

• A-9185: -8 dBm

Linear Polarized Antennas 3.4.2.

Because of the smaller apex angle (60º), this antenna is more suited to

selective data collection and restriction of read zones.

Depending on the direction of mounting, the antenna’s field is either

vertically or horizontally polarized, requiring the sensor to have the same

orientation.

Because of the greater gain, longer read ranges can be achieved with this

antenna compared to the elliptical polarized type above.

Page 14

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 14 OF 28

Orientation Diagrams: Linear polarized antenna

Elevation Azimuth

Vertical Polarization Horizontal Polarization

For this antenna, the maximum transmit power setting is:

• W-900R: -12 dBm

Antenna Orientation

Page 15

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 15 OF 28

1-Wave Rod Antenna 3.4.3.

Overall Dimensions: 425 × 90 mm Mounting proposal

Antenna diagram

Vertical

For this antenna, the maximum transmit power setting is:

• Rod antenna: 6 dBm

Page 16

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 16 OF 28

4. TAG MOUNTING SOLUTIONS

The Tag can be mounted either with cable straps using the 2 slits at each end, by using screws or a magnet

as described in the following 3 subchapters.

4.1. Cable Straps

4.2. Screws

Page 17

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 17 OF 28

Important Information

1. Only screws with cylindrical heads are suitable for mounting the tag. We do not advise using countersunk screws. If for some reason this should be necessary, then use only with a suitable counter-sunk

cushioning disc (refer to UN 1277).

2. The attached bushing is recommended to protect the plastic around the mounting hole from being

damaged when tightening the rivet.

3. Secure the screws with self-locking nuts, spring washers o r Nord-lock washers ( r efer to UN 7014). Should

mounting be completed with self-tapping screws, loosening may occur over time.

4. If the tag is mounted outdoors or in a damp environment, all mou nting parts nee d to b e m ad e of

stainless steel or other non-rusting material.

5. A temperature of at least +10 °C (+50 °F) must be maintained during mounting to prevent the casing

from cracking.

6. Recommended maximum torque

M4/ #8 (with bushing): 2 Nm

M5/#10 (w/o bushing): 3 Nm

M6/#14 (w/o bushing): 3 Nm

If the torque is any greater, the screw may over tighten, or the casing m ight bre ak.

7. Metal surfaces in direct proximity to the tag may reduce the tag’s range of function. Tags should not be

mounted in metal recesses or corners.

8. After mounting, the tag’s function should be tested with appropriate devices and software.

Page 18

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 18 OF 28

4.3. Magnet (optional)

The tag can be easily removed by grabbing it on the part of its body with the cable outlet. Slightly pull it off

the wall and the magnetic holding force is removed at once.

DO NOT pull the cable.

Page 19

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 19 OF 28

5. CONNECTING TO THE REEFER CONTROLLER

Safety Instructions

A screened cable must be used for the data cable.

Important Note

The total cable runs between tag and the monitored device must not exceed a total of 15 m. This is due to

limitations of the RS232 (EIA-232) standard.

Connecting the i-Q350 RCM to the controller

3 of the 5 connector pins are coded with a small edge to align correctly the plug and connector. The 2

connector pins which are not coded are longer to simplify identification. The data rate of the external device is

automatically detected.

Follow the process hereafter to connect the tag to the reefer controller.

Step 1

Align the male connector of the i-Q350

RCM tag to the female connector on

the reefer connector.

In order to align correctly the

connectors, use the indent and edges

highlighted on the pictures on the left.

Step 2

Connect the male connector to the

female connector.

Do not apply too much pressure since

the bayonet locking mechanism might

not be properly aligned.

Page 20

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 20 OF 28

Step 3

Align the bayonet locking mechanism

by rotating the outer ring on the male

connector.

Step 4

Press both connector together and lock

the bayonet mechanism to insure

proper electrical connection and

weatherproofness.

Page 21

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 21 OF 28

6. ACCESSORIES

In order to accomodate different installations and to operate with mo st of the re efer co nta iner's plug 's

variation, we are providing several accessories.

6.1. Extension Cable

We are providing a 2 meters (6 ft) extension cable to accomodate installation where the i-Q350 RCM is

installed on racks.

The extension cable can be used between the i-Q350 RCM and an adaptor.

Up to 5 extension cables can be connected together to reach greater distances.

Extension Cable

Page 22

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 22 OF 28

6.2. Adaptors

Multiple adaptors are available in order to connect the i-Q350 RCM to different type of reefer controllers.

Each adaptor is 50 centimeters (19 inches) long and use the standard 5 pin Deustch female connector to

connect to the tag. Adaptors can be use in combination with extension cable.

Hereafter are the list of adaptors available for the RCMS solution.

RCM Adaptor 3

Adaptor with a 5-pin Cannon connector used by some Carrier or Thermoking reefer controllers

p/n: 450363

RCM Adaptor 4

Adaptor with a 3-pin Deutsch connector used by some Daikin reefer controllers.

p/n: 450464

Page 23

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 23 OF 28

6.3. Connecting to the tag

Follow the process hereafter to connect the extension cable or adaptors to the i-Q350 RCM.

Step 1

Align the male connector of the i-Q350

RCM tag to the female connector of

the adaptor or extension cable.

In order to align correctly the

connectors, use the indent and edges

highlighted on the pictures on the left.

Step 2

Connect the male connector to the

female connector.

Do not apply too much pressure since

the bayonet locking mechanism might

not be properly aligned.

Step 3

Align the bayonet locking mechanism

by rotating the outer ring on the male

connector.

Page 24

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 24 OF 28

Step 4

Press both connector together and lock

the bayonet mechanism to insure

proper electrical connection and

weatherproofness.

Page 25

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 25 OF 28

7. TROUBLESHOOTING

7.1. General

This chapter covers how faults can be recognized and rectified. There are potentially four main problem

sources:

• The user control system, including task requirements, communication cables, peripheral units with

possible object recognition switches.

• The SensorSMART platform including peripheral units and their cables, also potential object recognition

switches.

• The environment including large objects between antenna and sensor, electrical disturbance sources,

intervention by pe r sons, etc.

• The quality of the technical design, including alignment between antenna, data, ratio of task

requirements/available communication time etc. T he information about system performance is contained

in the relevant datasheets.

When planning the total system, not overlook the problem sources and “Fault finding procedures on system

level” should be inc luded in the host sys t em. How this could look in detail depends on the relevant system

concept and very likely varies from one system to another.

7.2. Status Display (LEDs)

BAT

Green

Red

PWR

Green

Red

RFR

Green

Orange

Red

tag’s battery is OK

tag’s battery is low and needs to be replaced

the external device is powered up

the external device is switched off

the external device is working properly

no communication with the external device

not connected to the external device or no successful

communication with the external device

Page 26

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 26 OF 28

8. MAINTENANCE

8.1. General

When installed correctly the ILR System will operate virtually maintenance free for many years. However, in

the event maintenance is required only trained and auth o rized p erso nn el are permitted to perform the

updates, changes and maintenance necessary.

8.2. Regular Cleaning of The Surface

Remove dust with a brush or compressed air. If there are fatty or oily substances use a soft cloth moistened

with a mild rinsing agent.

Warning

Do not clean the tag in a dishwasher. Do not sandblast the tag. Do not use high pressure water jet or steam

cleaner. Do not use cleaning products containing chemical additives.

8.3. Precautionary Maintenance

A regular check of the system is recommended. Unstable connections could lead to damage and malfunctions

of the system and should therefore be repaired as soon as possible.

A Brief Checklist

• Are all housings intact?

• Are all cables intact?

• Are all connectors intact?

• Are all connectors securely fastened?

• Are all screws still tight?

• Is there a malfunction at a specific unit?

8.4. Returns

Parts or main components returned for repair or exchange must be handled with great care. PC cards must be

returned in the appropriate ESD-protecting packaging material. A ll r eturns should include an error description

and a short application overview and be sent to the local distributor or to:

IDENTEC SOLUTIONS AG

Service Department

Millenium Park 2

6890 Lustenau

AUSTRIA

Page 27

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 27 OF 28

9. TECHNICAL DATA

Communication Broadcast 350

Operation Mode

Transmits Sensor ID and user data in pre-defined interval

Read Range

up to 500m*

Compatibility

i-PORT M350, i-CARD CF 350 and i-PORT 4-350

Operating Frequency

868 MHz (EU) or 920 MHz (NA)

Transmit Power

<1mW

Communication Response 350

Operation Mode

Bi-directional communication (reading log, blink LED, write/read

data)

Read Range

up to 250m*

Compatibility

i-PORT M350 and i-CARD CF 350

Operating Frequency

868 MHz (EU) or 920 MHz (NA)

Transmit Power

<1mW

Data

Data Retention

> 10 years without power

Write Cycles

100,000 writes

Memory Size

10,000 Bytes user definable

Identification Code

48 bit fixed ID

Configuration

Device

i-PORT M350 or i-CARD CF350

Ping Rate

Configurable from 0.5 to 300 seconds insteps of 0.5 seconds

Number of Bursts

Configurable from 0 to 15

Broadcast User Data

Up to 50 Bytes

Interface

serial interface

RS232 Deutsch connector

supported Reefer units

Thermo King

MP4000 (monitoring only)

Daikin

Decos IIIc

Decos IIId

Starcool

RCCU5

SCC6

Carrier

Microlink 3

Microlink 2i

Microlink 2

Electrical

Power Source

Lithium Battery (replaceable)

Battery Monitoring

Yes

Page 28

i-Q350 RCM

USER MANUAL

VISIBILITY DELIVERED. PAGE 28 OF 28

Environmental Conditions

Operating Temperature

–20 °C to +70 °C (–4 °F to +158 °F)

Humidity

10% to 95% relative humidity @ 30°C

Shock

Multiple drops to concrete from 1m (3ft), 3 times DIN IEC 68-227

Vibrations

3G, 20 sine wave cycles, 5 to 150 Hz, DIN IEC 68-2-6

5G, noise 5 to 1.000 Hz, 30 minutes, DIN IEC 68-2-64

Standard/Certification

Europe

CE (EN 300 220-1, -3; EN 301 489-1,-3; EN 60950)

North America

FCC Part 15 (US); Industry Canada

Mechanical Data

Dimensions

171 x 56 x 26 mm (6.7 x 2.2 x 1.0 inches)

Enclosure Material

Plastics

Enclosure Rating

IP 65

Weight

50 grams (1.75 ounces)

Loading...

Loading...