Page 1

i-B2 S/NA User’s Guide

Version 1.0

IDENTEC SOLUTIONS AG

Millennium Park 2

A-6890 Lustenau

Austria

Tel: +43 (0) 5577 87387 - 0

Fax: +43 (0) 5577 87387 - 15

info@identecsolutions.at

www.identecsolutions.com

Page 2

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page ii/12

Proprietary Notice

This document contains confidential information proprietary to IDENTEC SOLUTIONS and may not be used or

disclosed to other parties in whole or in part without prior written authorization from IDENTEC SOLUTIONS.

Disclaimer and Limitation of Liability

IDENTEC SOLUTIONS AG and its affiliates, subsidiaries, officers, directors, employees and agents provide the

information contained in this Manual on an “as-is” basis and do not make any express or implied warranties or

representations with respect to such information including, without limitation, warranties as to non-infringement,

reliability, fitness for a particular purpose, usefulness, completeness, accuracy or currentness. IDENTEC

SOLUTIONS AG shall not in any circumstances be liable to any person for any special, incidental, indirect or

consequential damages, including without limitation, damages resulting from use of or reliance on information

presented herein, or loss of profits or revenues or costs of replacement goods, even if informed in advance of

the possibility of such damages.

Trademarks

“IDENTEC SOLUTIONS”, “Intelligent Long Range”, “ILR” and the stylized “i” are registered trademarks and

“i-Q”, “i-D”, “i-CARD”, “i-PORT”, “i-LINKS”, “Solutions. It’s in our name.”, “Smarten up your assets.” are

trademarks of IDENTEC SOLUTIONS, Inc. and/or IDENTEC SOLUTIONS AG.

Copyright Notice

Copyright © 2006 IDENTEC SOLUTIONS. All rights reserved.

No part of this document may be reproduced or transmitted in any form by any means, photographic, electronic,

mechanical or otherwise, or used in any information storage and retrieval system, without the prior written

permission of IDENTEC SOLUTIONS.

Page 3

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page iii/12

Radio Frequency Compliance Statement

IDENTEC SOLUTIONS AG. is the responsible party for the compliance of the following devices:

MODEL: i-B2 S i-CARD CF i-D TAGS i-Qxx TAGS

FCC ID: OO4-ILR-IB2NA OO4-ILR-ICARDCF OO4-ILR-ID2 OO4-ILR-IQ8T or

OO4-ILR-IQR

CANADA: Pending Pending 3538A 12112 35381021756A or

35381021825

EUROPE: CE CE CE 0678(!) CE 0682(!)

The user(s) of these products are cautioned to only use accessories and peripherals approved, in advance, by

IDENTEC SOLUTIONS. The use of accessories and peripherals, other than those approved by IDENTEC

SOLUTIONS, or unauthorized changes to approved products, may void the compliance of these products and

may result in the loss of the user(s) authority to operate the equipment.

Operation is subject to the following conditions: (1) these devices may not cause harmful interference, and (2)

these devices must accept any interference, including interference that may cause undesired operation of the

device.

FCC Compliance (i-B2 S/NA)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communication. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his/her own expense.

Warning: Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Industry Canada Compliance (i-B2 S/NA)

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

To reduce potential radio interference to other users, the antenna type and its gain should be so chosen that the

equivalent isotropically radiated power (EIRP) is not more than that required for successful communication.

The installer of this radio equipment must ensure that the antenna is located or pointed such that it does not

emit RF field in excess of Health Canada limits for the general population; consult Safety Code 6, obtainable

from Health Canada.

Page 4

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page iv/12

European Notification according R&TTE Directive (i-B2 S/EU)

This equipment complies to Art. 6.4 of R&TTE Directive (1999/5/EC) and can be used in the following European

countries:

Austria, Belgium, Denmark, Finland, France, Germany, Greece, Iceland, Italy, Ireland, Luxembourg, Netherlands

, Norway, Portugal, Switzerland, Sweden, Spain, United Kingdom, Czech Republic, Cyprus, Estonia, Hungary,

Lithuania, Latvia, Malta, Poland, Slovenia.

Page 5

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page v/12

Table of Contents

1.0 Overview __________________________________________6

2.0 Functionality________________________________________6

2.1 Telegram content __________________________________________ 6

2.2 Programming _____________________________________________ 6

Appendix A: Technical Specifications ____________________________7

Appendix B: Battery lifetime__________________________________8

Appendix C: Tag mounting___________________________________9

C.1 Rivets ______________________________________________9

C.2 Screws ____________________________________________10

C.3 Taping (on metal surfaces) ___________________________11

C.4 Mounting with Suction Cups ___________________________12

Page 6

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page 6/12

1.0 Overview

This guide explains how to install and operate the beacon tag i-B2 S.

2.0 Functionality

The i-B2 S/NA is a high performance maintenance free beacon tag to be used with IDENTEC SOLUTIONS’

Intelligent Long Range (ILR®) beacon readers. Its’ robust and slim housing allows easy mounting on most of the

assets to be tracked.

Beacon tags of IDENTEC SOLUTIONS’ i-B series transmit a unique ID together with user definable data in

regular intervals (ping rate). Combined with fixed readers read ranges of typically 100 m can easily be reached.

With mobile readers based on i-CARD R2 (PC card Type 2) or i-CARD CF B (CF Type 2) reading distances up to

30 m are realistic.

2.1 Telegram content

The tag transmits telegrams via the air interface to the reader. After decoding the following information is

supplied to the host:

- Unique Tag ID (UID)

Length 32 bits, LSB first. Can not be set or altered by the user.

- User data

Length 9 bytes. Is reported by the reader in exactly the same format as programmed on the tag. Can be

written to the tag via a proximity 13.56 MHz link using IDENTEC SOLUTIONS’ i-B2 programmer.

- Flag byte

Length 8 bits. Meaning of the single bits depend on implemented tag functionality, in the standard

version these 8 bits are user definable.

- Age Counter

Length 2 x 8 bits. These 2 bytes are 2 cut outs from the tag internal tag age counter which is

incremented by 1 with each transmission.

The low byte is incremented by 1 and can therefore be used to detect missing telegram reception. The

high byte counts millions of telegrams and indicate battery usage. Comparing the actual value to a

predefined maximum remaining lifetime can be calculated.

2.2 Programming

With IDENTEC SOLUTIONS’ i-B2 programmer following data can be written to the i-B2 S tag:

- User Data (9 bytes)

- Flag byte (8 bis)

- Ping rate in steps of 0.5 seconds

In addition the tag can be switched between active and inactive state if needed, i.e. if permanent transmission is

not allowed.

Page 7

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page 7/12

Appendix A: Technical Specifications

Performance

Read range to i-PORT R2 Up to 100 m (300 ft) (free air)

Read range to i-CARD R2 Up to 100 m (300 ft) (free air)

Operating frequency 868 MHz (EC) or 915 MHz (NA)

Operation Transmits in regular intervals a pre-programmed data string

Repetition rate (ping rate) 0.5 – 60 seconds in 0.5 second steps

Transmit power <1 mW

Certification CE (EN 300 220-1, -3; ETSI EN 301 489-1, -3),

FCC part 15 (US), Industry Canada pending

Electrical

Power source Lithium battery (not replaceable)

Expected battery life See table

Data

Programmability One time

Programming and activation Wireless by proximity device over a distance of maximum 5 cm

Reprogrammable Yes

Deactivation Yes

Lockable Yes

Memory capacity 4 bytes ID + 9 bytes user data

Environmental

Operating temperature -30°C to +70°C (-22ºF to +158ºF) *1

-50°C to +85°C (-58°F to +185°F) *1

Shock 50 G, 3 times DIN IEC 68-2-27

Multiple drops to concrete from 1 m (3 ft)

Vibration 3 G, 20 sine wave cycles, 5 Hz to 150 Hz,

DIN IEC 68-2-6

5 G, noise 5 Hz to 1000 Hz, 30 minutes

DIN IEC 68-2-64

Physical

Dimensions 131 mm x 28 mm x 21 mm (5.2 in. x 1.1 in. x 0.85 in.)

Case Material Plastic (Luran® S)

Mass 50 grams (1.75 ounces)

Enclosure rating IP 65 — Protected against dust and low-pressure jets of water

Colour dark blue

*1: Depending on battery type

Page 8

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page 8/12

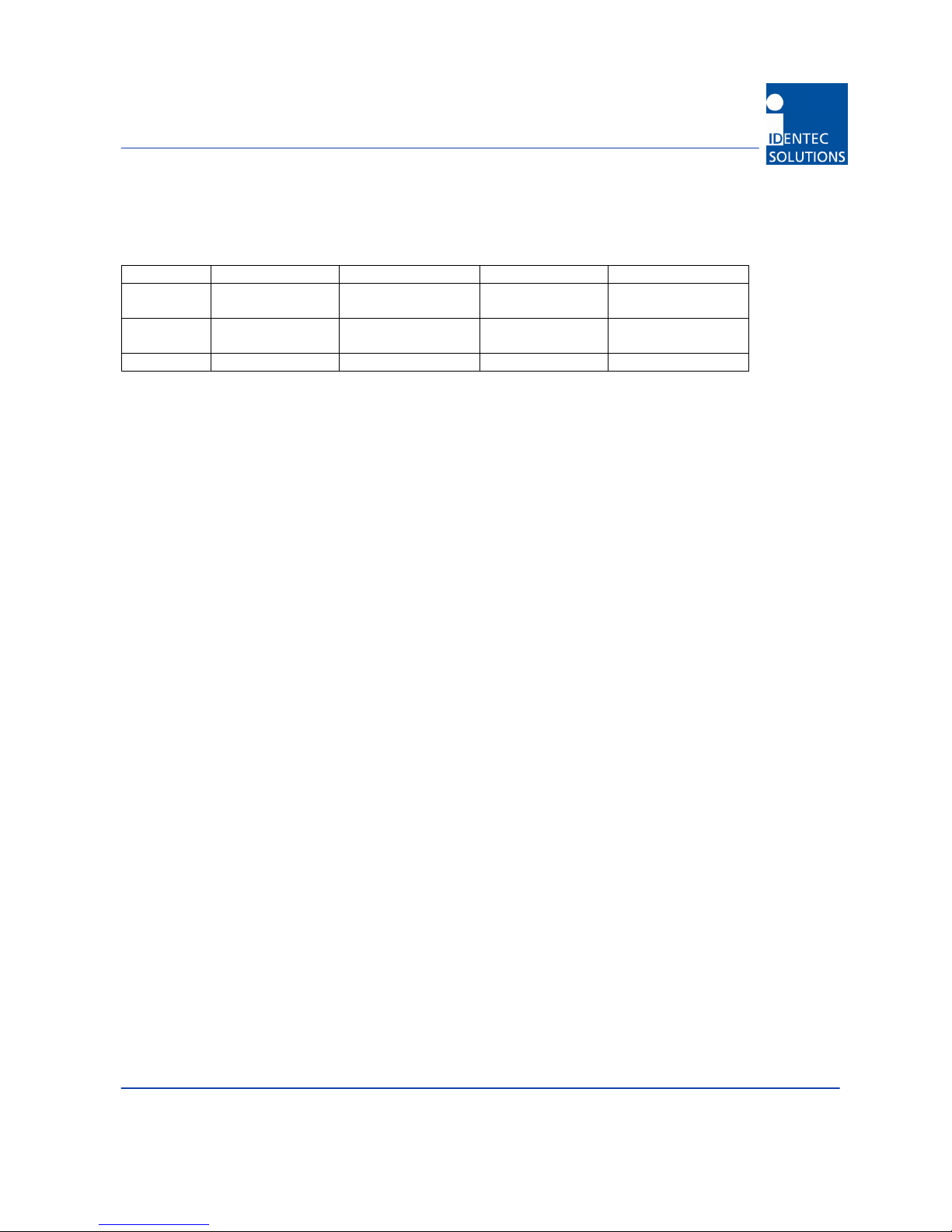

Appendix B: Battery lifetime

Life time of the whole tag depends on battery lifetime and therefore primarily on ping rate and battery capacity.

The i-B2 S can be equipped with either a 560 mAh or a 2,100 mAh battery. Following table shows these

influences:

Battery 560 mAh Battery 2,100 mAh

Ping rate (sec) Lifetime (years) Max. Age Counter Lifetime (years) Max. Age Counter

0.5 1.25 74 4.90 147

1.0 2.43 73 9.56 144

2.0 4.65 69 >10 137

5.0 10.00 61 >10 120

10.0 >10 51 >10 100

Page 9

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page 9/12

Appendix C: Tag mounting

C.1 Rivets

Important Information:

(1) A temperature of at least +10°C (+50°F) must be maintained during riveting to prevent the casing from

cracking.

(2) Always position the blind-rivet gun straight down on the rivet site and all the way to the rivet socket.

(3) On occasion, a tag casing has been damaged through improper handling of the blind-rivet gun (slanted

positioning of the gun to access the rivet socket). If there is a chance this might occur, it is better to use

a blind rivet with a large head1 or insert an M5 washer. This has the effect of distributing the pressure

over a larger surface area during riveting. The use of the washer has the added effect of positioning the

rivet slightly higher in the depression, so that one can better access the rivet socket with the rivet gun.

(4) Metal surfaces in direct proximity to the tag can reduce the tag’s range of function. Tags should therefore

not be mounted in metal recesses or corners.

(5) After mounting, the tag’s function should be tested, i.e. with a handheld.

1

Refer to UN9924

Blind Rivets 5 x ...

Page 10

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page 10/12

C.2 Screws

Important Information:

(1) Only screws with cylindrical heads are suitable for mounting the tag. We do not advise using counter-

sunk screws. If for some reason this should be necessary, then only together with a suitable countersunk cushioning disc2.

(2) Secure the screws so they cannot work themselves loose i.e. by using self-locking nuts or spring washers

or Nordlock washers3.

(3) If the tag is mounted out-of-doors or in a damp environment, all mounting parts need to be made of

stainless steel or other non-rusting material.

(4) A temperature of at least +10°C (+50°F) must be maintained during mounting to prevent the casing

from cracking.

(5) Depending on the type and strength category of the M5 screw used, the maximum tightening torque

must be between 2 and 10 Nm. If the torque is any greater, the screw may overtighten, or the casing

might break.

(6) Metal surfaces in direct proximity to the tag can reduce the tag’s range of function. Tags should therefore

not be mounted in metal recesses or corners.

(7) After mounting, the tag’s function should be tested, i.e. with a handheld.

2

refer to UN 1277

3

refer to UN 7014

i.e. cylinder head or lenticular head screws M5 x

i.e. M5 hexagonal locknut with M5 washer

OR M5 hexagonal nut, but together with spring

washer or M5 Nordlock washer

Page 11

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page 11/12

C.3 Taping (on metal surfaces)

The following double-sided tapes from 3M are currently being used/recommended:

• On level, flat surface: 3M acrylic foam tape #5952 F (Temperature: 120°C [248°F], short-term at 150°C

[300°F])

• On uneven, slightly curved surface: 3M acrylic foam tape #4959 F (Temperature 150°C [300°F], short-term

at 204°C [368°F])

Dimensions

• On the roll: 50m (164 feet)

• Width: 19mm (3/4 inch)

• Thickness: 1.1mm (0.043 inches) for #5952 or 3.0mm (1/8 inch) for#4959

• Length: max. 130mm (5 1/8 inches) – cut to length

Procedure

• Preparation of surfaces:

-

Plastic casing: preliminary cleaning, 3M Primer 26 GZH, 2 minutes waiting period

-

Metal surface: preliminary cleaning, 3M Primer 86 A, 15 minutes waiting period

• First attach tape to tag bottom and press on with the roll

• Then attach the tag to the prepared metal surface

Important Information:

(1) Before using the tape, cleaning agents and primers as listed, need to check if these are compatible with

the customer’s operating conditions. The customer’s approval must be obtained.

(2) Metal surfaces in direct proximity to the tag can reduce the tag’s range of function. Tags should therefore

not be mounted in metal recesses or corners.

(3) After mounting, the tag’s function should be tested, i.e. with a handheld.

Double-sided

Tape

Page 12

i-B2 S – User’s Guide

Version 1.0 03.08.2006 Page 12/12

C.4 Mounting with Suction Cups

*) Supplier: i.e. Vakuplastic Kunststoff GmbH & Co. KG, Berlin Vendor part number: 1.1.3510

Suction cup 35mm [1

3/8 inch] with threaded bolts M4 x 10

Glass plate (c

lean, free of fatty substances

)

M4 washe

r

M4 screw nut

M4 screw nut

10 mm [0.4

inch] bushing with M4 inside th

read

Loading...

Loading...