Page 1

Operating Instructions

ø30 XN Series Emergency Stop Switches

Emergency Stop Switches

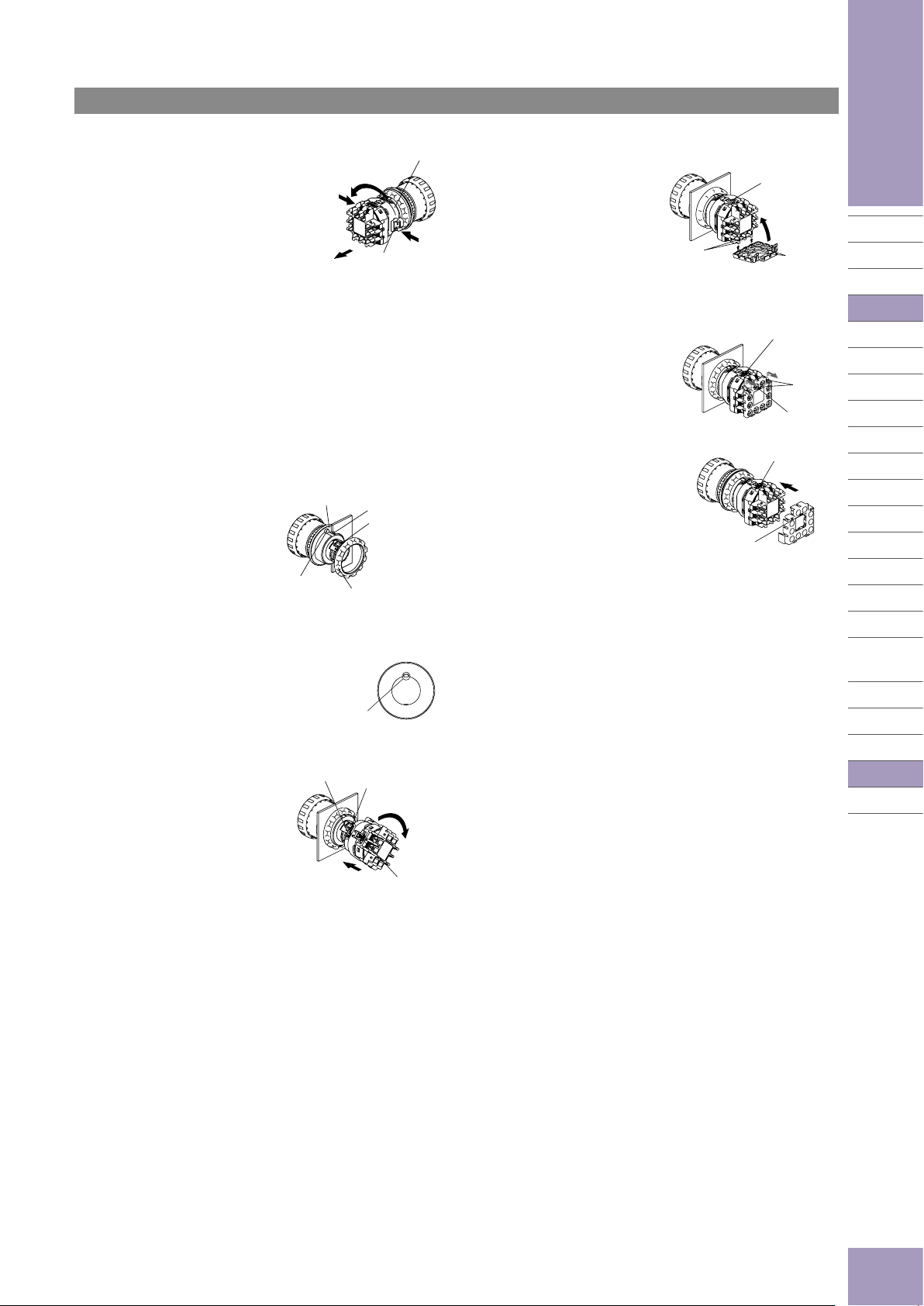

Removing the Contact Block

First unlock the operator button.

Grab the yellow bayonet ring ➀ and

Turn counterclockwise

pull back the bayonet ring until the

latch pin clicks ➁, then turn the contact block counter clockwise and pull

out ➂.

Notes for removing the contact block

1. Do not attempt to remove the contact block while the oper ator is

latched, otherwise the switch may be damaged.

2. When the contact block is removed, the monitor contact (NO contact)

is closed.

3. While removing the contact block, do not use excessive force, otherwise the switch may be damaged.

4. An LED lamp is built into the contact block for illuminated pushbuttons. When removing the contact block, pull the contact block

straight to prevent damage to the LED lamp. If excessive force is

used, the LED lamp may be damaged and fail to light.

Grab

Pull

Bayonet Ring (yellow)

Grab

Latch

Panel Mounting

Remove the locking ring from

the operator and check that the rub-

Rubber Gasket

ber gasket is in place. Insert the

operator from panel front into the

panel hole. Face the side without

thread on the operator with TOP

marking upward, and tighten the

lock ing ring using ring wrench

Anti-rotation

Projection

XN9Z-T1 or TWST-T1 to a torque of

2.5 N·m maximum.

When using a nameplate

When using a nameplate HNAV-,

break the projection from the nameplate using pliers.

Locking Ring

Projection

Operator without

thread

TOP Marking

Installing the Contact Block

First unlock the operator button.

Align the small ▼ marking on the

edge of the operator with the small ▲

marking on the yellow bayonet ring.

Hold the contact block, not the bayonet ring. Press the contact block onto

the operator and turn the contact

block clockwise until the bayo net ring

clicks.

Notes for installing the contact block

1. Do not attempt to install the contact block when the opera tor is

latched, otherwise the switch may be damaged.

2. Make sure that the bayonet ring is in the locked position.

Marking

W

Push

V Marking

Turn clockwise

TOP Marking

Installing & Removing Terminal Covers

XW9Z-VL2M

To install the terminal cover, align

the TOP marking on the terminal

cover with the TOP marking on

the contact block. Place the two

projec tions on the bottom side of

the contact block into the slots

in the terminal cover. Press the

terminal cover toward the contact

block.

To remove the terminal cover,

pull out the two latches on the top

side of the terminal cover. Do not

exert excessive force to the latches,

otherwise the latches may break.

IP20 Fingersafe Terminal Cover

Projections

➀ Place the projections

on the contact block.

TOP Markings

➁ Press the

TOP Marking

(Pull)

TOP Marking

terminal cover

Slots

Projections

XW9Z-VL2MF

To install the IP20 fingersafe terminal

cover, align the TOP marking on the

cover with the TOP marking on the

contact block, and press the cover

toward the contact block.

Notes:

1. Once installed, the XW9Z-VL2MF cannot

be removed.

2. With the XW9Z-VL2MF installed, crimping terminals cannot be used. Use solid

wires.

3. The XW9Z-VL2MF cannot be installed after wiring.

4. Make sure that the XW9Z-VL2MF is securely installed. IP20 cannot be

achieved when installed loosely, and electric shocks may occur.

TOP Marking

(Press)

TOP Marking

Notes for Operation

When using the XN emergency stop switches in safety-related part

of a control system, observe safety standards and regulations of the

relevant country or region. Also be sure to perform a risk assessment

before operation.

Wiring

Tighten the M3 terminal screws to a torque of 0.6 to 1.0 N·m.

Contact Bounce

When the button is reset by pulling or turning, the NC main contacts

will bounce. When pressing the button, the NO monitor contacts will

bounce.

When designing a control circuit, take the contact bounce time into

consideration (reference value: 20 ms).

LED Illuminated Switches

An LED lamp is built into the contact block and cannot be replaced.

Handling

Do not expose the switch to excessive shocks and vibra tions, for

example by operating the switch with tools. Other wise the switch may

be deformed or damaged, causing malfunction or operation failure.

APEM

Switches &

Pilot Lights

Control Boxes

Emergency

Stop Switches

Enabling

Switches

Safety Products

Explosion Proof

Terminal Blocks

Relays & Sockets

Circuit

Protectors

Power Supplies

LED Illumination

Controllers

Operator

Interfaces

Sensors

AUTO-ID

X6

XA

XW

XN

SEMI

D-046

Loading...

Loading...