Page 1

Preliminary

Thank you for purchasing HG1X Series product from IDEC. HG1X

Series Products are versatile operator interfaces with Windows based

configuration Software.

This manual will help you to

HG1X Products.

All the safety warnings and precautions must be followed to

ensure proper unit performance and personal safety.

Warnings used in this manual:

DANGER

CAUTION

safely

install, configure and operate

Danger Warnings are used to indicate

situations, locations and conditions that

can cause serious injury or death.

Caution Warnings are used to indicate

situations and conditions that can cause

operator injury and/or unit damage

We hope that you find this manual informative. If additional

information or technical assistance is needed please contact:

IDEC Corporation

1175 Elko Drive,

Sunnyvale,

CA 94089, USA

Tel - (800) 262-IDEC

Fax - (800) 635-6246

Website - www.idec.com

Manual Revisions:

If you contact us in reference to this manual, please include the

following revision number

Name: IDEC-HG1X Series Operation Manual

Revision: QMAN\HG1X\1001\Rev0

HG1X Series Products are intended to be operator interfaces,

IMPORTANT

to work with PLCs which actually take control actions. It is

assumed that the user is well acquainted with the PLC

system being used. Never use HG1X units to perform

emergency stop applications. It is advised that separate

switches be used outside the PLC for ANY emergency stops.

Any mechanical or electrical modification to this unit will

void all warranties.

Table of Contents

Preliminary............................................................ i

Contents................................................................ ii

1.0 Introduction........................................................... 1 - 1

1.1 Purpose of this manual................................... 1-1

1.2 Introduction to HG1X....................................... 1-1

1.3 HG1X Series: Specifications........................... 1-2

HG1X-252.............................................. 1-2

HG1X-452.............................................. 1-6

2.0 Hardware............................................................... 2-1

2.1 Mounting......................................................... 2-1

2.2 Power Requirements...................................... 2-2

2.3 Serial Port....................................................... 2-3

2.4 PLC Port......................................................... 2-4

3.0 Getting Started...................................................... 3-1

3.1 Introduction..................................................... 3-1

3.2 Application - Tags, Screens, Keys and Task... 3-1

3.3 PLC Communications..................................... 3-2

4.0 Understanding HG1X Features............................. 4-1

4.1 Screens.......................................................... 4-1

4.2 Keys............................................................... 4-3

4.3 Alarms............................................................ 4-5

4.4 Application Task-List....................................... 4-7

5.0 Configuration Software......................................... 5-1

5.1 Introduction to WindMSG Software................. 5-1

5.2 Installing WindMSG Software.......................... 5-2

5.3 WindMSG Software - Basics........................... 5-3

5.4 Create a new Application................................ 5-3

5.5 Setup Node..................................................... 5-4

5.6 Create Tag Data Base..................................... 5-5

5.7 Create Screens................................................ 5-6

5.8 Define Keys..................................................... 5-7

5.9 Define Alarms.................................................. 5-8

5.10 Application Task List........................................ 5-9

5.11 Download Application...................................... 5-10

6.0 How Do I?............................................................... 6-1

6.1 Frequently asked questions............................. 6-1

Appendix A: Examples to create Applications.... iii

Appendix B: Cable Diagrams.............................. iv

Page 2

Introduction

In this chapter. . . .

1.1 Purpose of this Manual

The intention of this Operation Manual is to provide a guide for Safe

installation, Configuration and operation of HG1X series models.

Purpose of this Manual

Introduction to HG1X

HG1X Series

HG1X-252

HG1X-452

Read this operation manual thoroughly before installing and

operating HG1X products.

This document is based on information available at the time of its

publication. While efforts have been made to be accurate, the

information in this document may not cover all the details or variations in hardware or software. Features described herein may not be

present in all hardwares. IDEC CORPORATION reserves the right to

update information in this publication without prior notice.

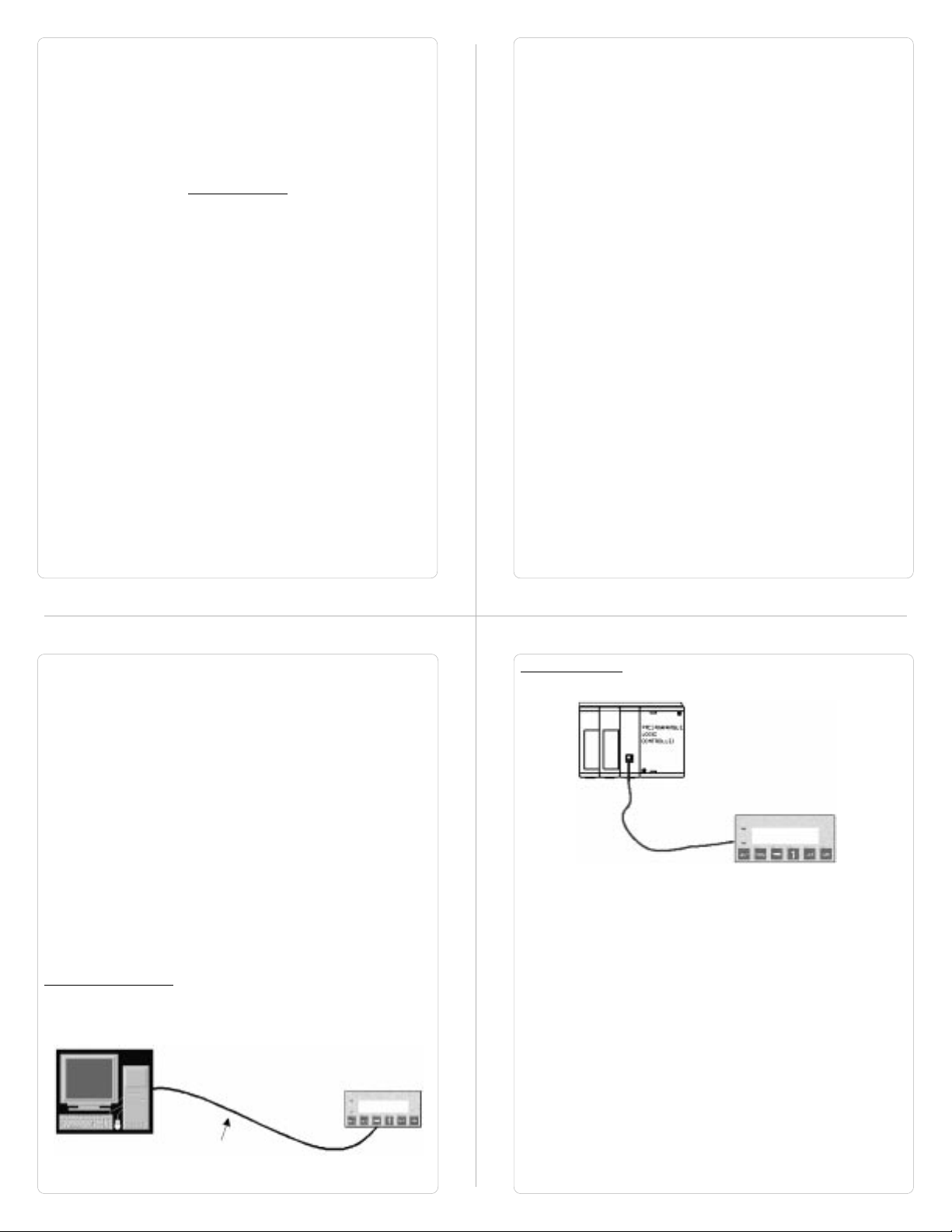

1.2 Introduction to HG1X

HG1X Series operator interfaces provide man-machine interface to

your PLC system. HG1X communicates with your PLC using serial

communication. HG1X models take power from PLC on their PLC

port.

Normal Operation:

Connect HG1X to PLC using the correct PLC-HG1X cable and your

HG1X is running.

Configuration of HG1X:

Each HG1X has to be configured using the WindMSG Software

before connecting it to the PLC.

Programming cable

for HG1X

Page 3

1.3 HG1X Series

Currently models included in the HG1X Series are as follows:

HG1X - 252 and HG1X - 452. HG1X Models take power from the

PLC. Detailed specifications for all the models is given in the

following section.

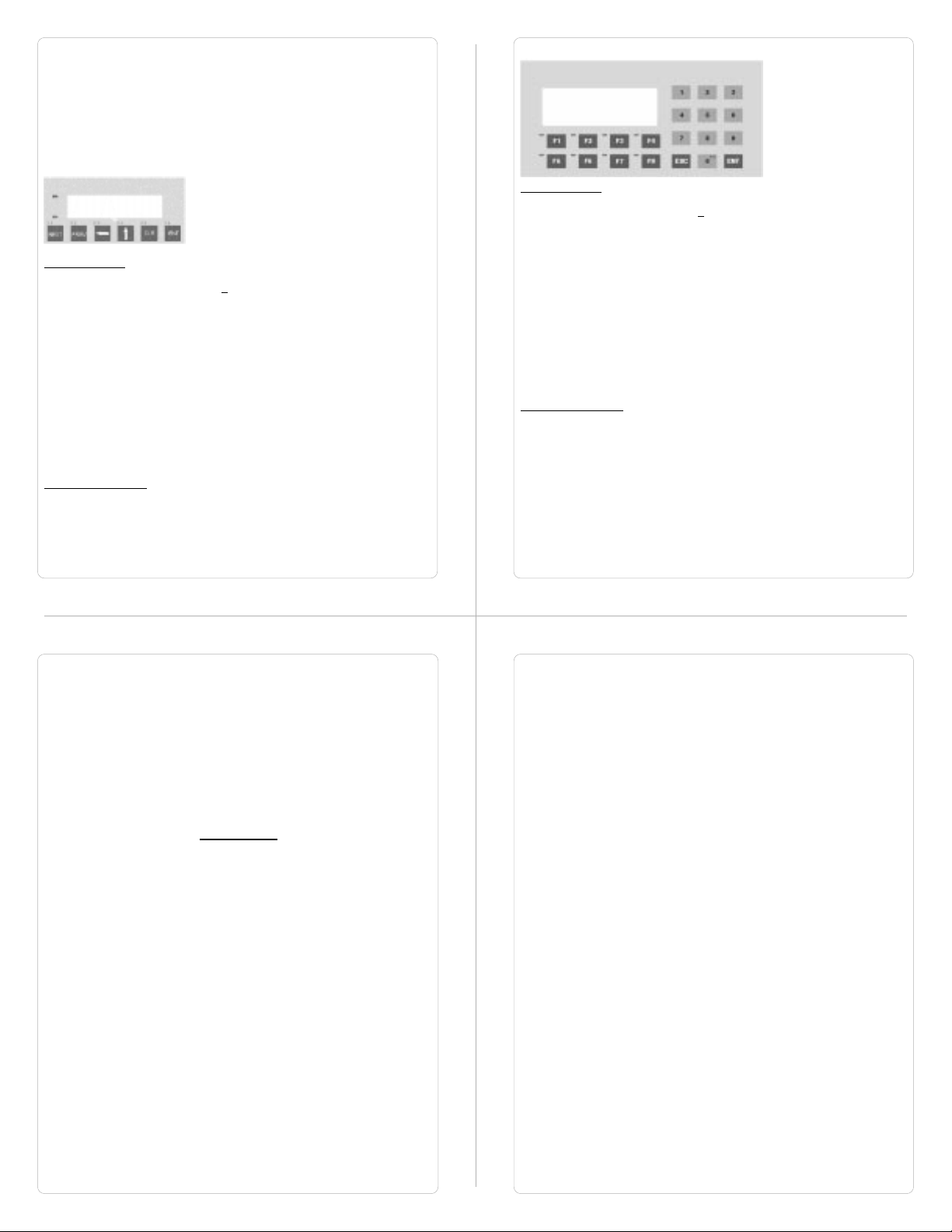

HG1X-252

Specifications:

Power: 5 VDC+ 5%, 130mA typically from PLC port

Display: 2 lines of 16 characters Backlit LCD

Bezel: IP65 rated Keypad

Keys: 6 User definable keys with tactile feedback

LEDs: 2 LEDs

Memory: 24K Application Memory

Communication: Two RS232 ports, one for connecting to

Temperature: 0 to 50 oC

Humidity: 10% to 90% (Non condensing)

Immunity to ESD: Level 3 as per IEC1000-4-2

Immunity to Transients: Level 3 as per IEC1000-4-4

Radiated Susceptibility: Level 3 as per IEC1000-4-3

Emissions: EN55011 CISPR A

System Components:

Note: User should order PLC cables and Software separately.

HG1X-252 unit with LCD display and Membrane keypad

-

- Installation Kit: Gasket, Two Mounting clamps, Two M4

screws, Four hex nuts.

the PLC and one for programming / serial printing.

HG1X-452

Specifications:

Power: 5 VDC+ 5%, 140mA typically from PLC port

Display: 4 lines of 20 characters Backlit LCD

Bezel: IP 65 rated Keypad

LEDs: 8 LEDs

Keys: 20 User definable keys with tactile feedback

Memory: 24K Application Memory

Communication: Two RS232 ports, one for connecting to the PLC

and one for programming / serial printing.

Temperature: 0 to 50 oC

Humidity: 10% to 90% (Non condensing)

Immunity to ESD: Level 3 as per IEC1000-4-2

Immunity to Transients: Level 3 as per IEC1000-4-4

Radiated Susceptibility: Level 3 as per IEC1000-4-3

Emissions: EN55011 CISPR A

System Components:

- HG1X-452 unit with LCD display and Membrane keypad

- Insertable Legends

- Installation Kit: Gasket, Two Mounting clamps, Two M4

screws, Four hex nuts.

Note: User should order PLC cables and Software separately.

Hardware

In This Chapter. . .

Mounting, Panel Cutouts

Power Requirements

Serial Port

PLC Port

Page 4

This chapter is installation guide for HG1X Series.

2.1 Installation Instructions

HG1X should be mounted on a panel. Gasket, mounting screws and

clamps are provided with each HG1X unit for proper mounting.

Environmental Considerations:

Make sure that the unit is installed correctly and that the operating

limits are followed (see Specifications for HG1X). Do not operate

HG1X in areas subject to explosion hazards due to flammable gases,

vapors or dusts. HG1X should not be installed where fast temperature variations are present. Highly humid areas are also to be

avoided. High humidity causes condensation of water in the unit.

Location Considerations

Care should be taken when locating equipments behind the HG1X to

ensure that AC power wiring, PLC output modules, contactors,

starters, relays and any other source of electrical interference are

located away from HG1X. Particular care should be taken to the

position of Variable speed drives and switching power supplies.

Mounting

HG1X should be mounted on a panel. Dimensional sketch and Panel

cutout for each HG1X model is given in section 2.2. Clearance

behind the panel may vary with HG1X Model. Follow the procedure

given below for proper mounting:

1)Make a cutout of the required size. Panel cutout

tolerance is + 0.1mm.

2)Put the gasket behind the bezel. The gasket may be

sealed to the case using an adhesive.

3)Put the HG1X through the panel cutout.

4)Insert the clamps into the case.

5)Pullback the clips until they seat into the retaining

slots.

6)Tighten the clamping screws in an even pattern until

the HG1X is secured into the panel.

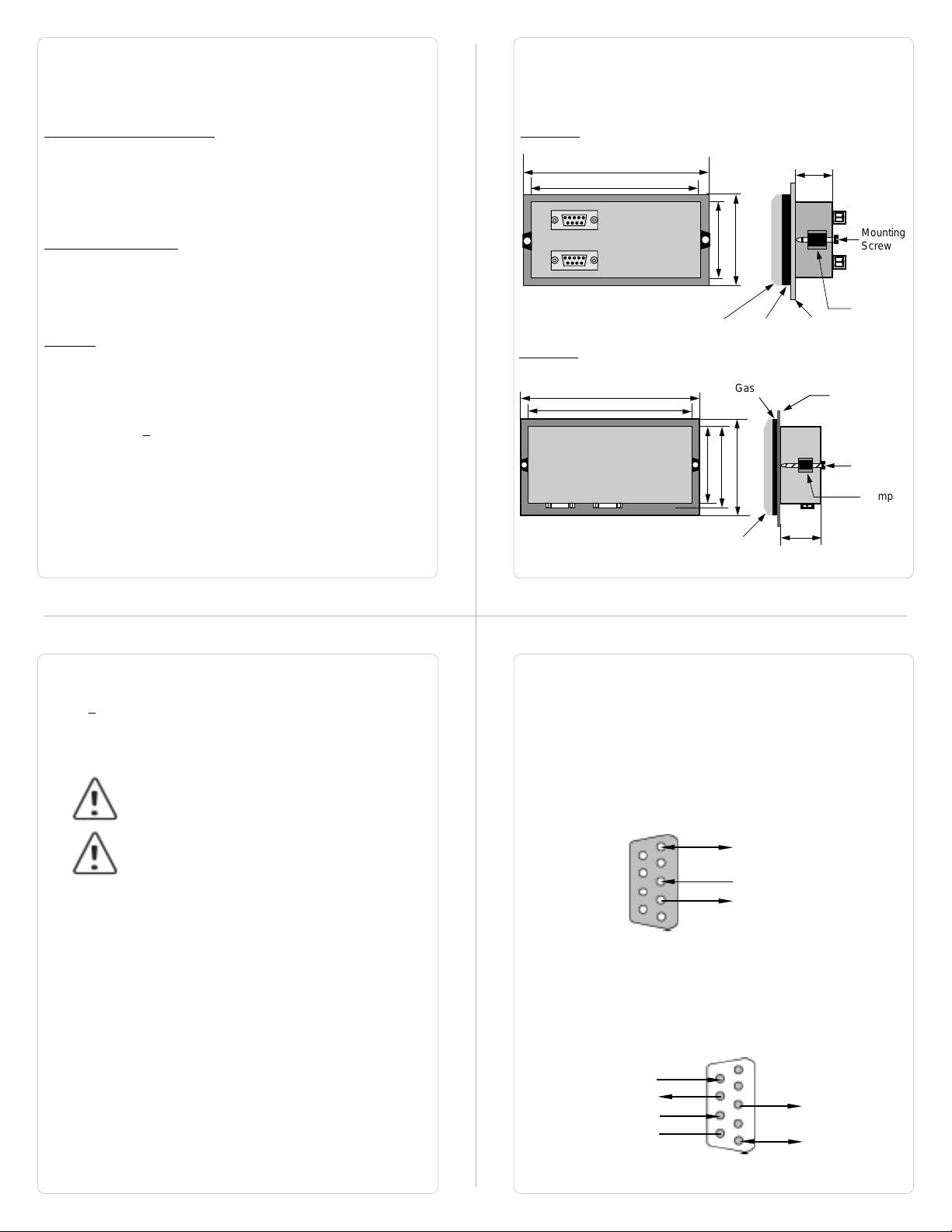

2.2 Dimensional Sketches and Panel Cutouts

This section presents the dimensional sketches and panel cutouts for

all the HG1X models. All dimensions are in mm. Not to Scale.

HG1X-252

Panel cutout: 92.00 x 45.00 (1/8 DIN size)

108.30

91.20

44.18

60.50

Bezel

Gasket

27.10

Mounting

Screw

Clamp

Panel

HG1X-452

Panel cutout: 162.00 x 79.00

75.20

78.50

Bezel

Gasket

101.30

Panel

Mounting

Screw

Clamp

36.8

182.50

160.70

2.3 Power Requirements

HG1X models are DC powered. The specified voltage range is

+5VDC + 5%. Make sure to check PLC power before connecting

cable to HG1X models.

Please follow the instructions given below while making connections

for HG1X models:

If wiring is to be exposed to lightening or surges,

use appropriate surge suppression devices.

Keep AC, high energy and rapidly switching DC

wiring separate from signal wires.

Each HG1X unit has two RS232 ports - a PLC Port and a Serial Port.

Description of each is given in following topics.

2.4 Serial Port

Serial port is used to download the firmware and / or application in to

the HG1X unit. HG1X also has serial printout capabilities. This port

can be attached to a computer/serial printer using the proper cable.

This port is always active. When HG1X is communicating with a PC

for programming, PLC operations are suspended. Pin description of

the Serial Port as seen on the HG1X unit is given below:

9

6

DB9 Female

5

1

Signal Ground

Receive / Data In (RS232C)

Transmit / Data Out (RS232C)

2.5 PLC Port

The cable connecting PLC to HG1X is attached to PLC Port. Different

cables are required for different PLCs / controllers. Cable details for

any particular PLC are given in the Operation Manual for that PLC.

Pin description of PLC Port for HG1X models is as given below:

+5 VDC from PLC

DIR / Open Collector Out

Receive / Data In (RS232C)

Reserved

6

9

1

5

Transmit / Data Out

(RS232C)

Signal Ground

DB9 Male

Page 5

Getting Started

In this chapter....

Introduction

Application - Tags, Screens, Keys and Tasks

PLC communication

3.1 Introduction

HG1X is an Operator Interface for PLCs. It communicates with a PLC

over its serial port to get the information required by the operator.

Information could be the value of a PLC register or the status of a

PLC coil. This information is displayed on the LCD display of HG1X. If

required, HG1X can also change the values of PLC registers / coils.

3.2 Application - Tags, Screens, Keys and Tasks

Microsoft Windows® based configuration software, WindMSG, helps

user to configure HG1X unit. ‘Configuration’ means making the HG1X

unit work as per the system requirements, Eg. HG1X can be

configured to be used with any PLC, display any register data,

perform any action using a key. The complete configuration for a unit

is termed as ‘Application’. Application comprises of Tag Data base,

Screens, Key Definitions, Alarms and Tasks.

Each register in the PLC memory has a unique address and can be

identified by giving a specific name to it. This information is stored as

Tag Data Base in HG1X. Any coil or register to be used in the

application must be first defined in the Tag data base.

LCD display on each unit displays the PLC data on a ‘Screen’.

Screen size varies with HG1X model. PLC data can be arranged on a

screen using different objects.

Operator can control the process by actually changing the value of

PLC registers. This is possible with the help of the keys. Different

tasks can be assigned to keys on the HG1X keypad.

Any register can be constantly monitored if alarms are defined for it.

When alarm condition is reached, the respective alarm is displayed

on the screen.

Page 6

Once the application is defined, firmware for the specific unit and

PLC is downloaded and then application is downloaded into the unit.

HG1X can now communicate with a PLC.

3.3 PLC communication

HG1X can communicate with any PLC without any change in the

hardware. To communicate with a PLC, HG1X needs:

1. Communication Driver for the PLC

2. HG1X - PLC communication cable

1. Communication Driver for the PLC:

Each PLC has a defined protocol for communicating with any

device. Communication Driver is downloaded in to HG1X

alongwith the firmware. Communication driver varies from

PLC to PLC. This driver enables HG1X to talk to a PLC.

2. HG1X - PLC Communication Cable:

Proper HG1X - PLC cable is required for error free

communication with any PLC.

Understanding HG1X Features

In this Chapter...

Screens

Properties of Screen

Screen Objects

Animation Properties

Alpha-Numeric Objects

Keys

Double Key Tasks

Tasks

Alarms

Consecutive

Discrete

Application Task-List

This chapter explains in detail all the features of HG1X. We

recommend that you study this chapter before attempting to configure

and use the HG1X.

4.1 Screens

Operator can view required information on the LCD display of HG1X

unit. This information can be arranged in such a way that the operator

can very easily interpret the information received. This can be done

by using various tools. These tools are the objects. Each screen has

some properties:

Properties of Screen:

1. Password:

Access levels can be achieved by introducing a password for a

screen. Password value can vary between 0 - 9999. Unless user

enters the correct password, the screen will not be displayed. Any

screen can be password protected.

2. Associated Screens:

Associated screen can be specially useful in cases where one or

more objects are common between different screens. The common

part is extracted from all the screens, placed in a new screen and this

new screen is associated with the other screens. Any screen can be

associated to another screen.

Advantages of associated screens:

1. Saves application memory by extracting common part

between different screens and forming a new associate

screen.

2. Saves time of the application programmer.

Please note:

- Only one screen can be associated to any screen.

- No data entry object can be placed in the screen to be

accociated.

Page 7

- No PLC tag embedding in the screen to be associated. To

embed a PLC tag, In Global Task-List the required PLC tag

should be copied to an internal tag. The internal tag should

be embedded in the screen to be associated.

3. Screen Keys or Local Keys:

HG1X keys have two types of definitions: Global and Local.

1. Global Definitions: Definitions remain same for all the

screens. If there is no local definition for a key for the

current screen, global definition for the key will be

executed.

2. Local Definitions: These definitions can vary with

screens. These definitions have priority over Global

definitions.

Please note that for a particular screen, a key can have local and

global definitions, local definition has priority over global and the

global definition task is not performed in this case.

Any task can also be performed by pressing two keys simultaneously.

The definition can be either local or global. The double keys function

can be very useful in HG1X models with less number of keys.

4. Screen Task-List

Tasks are operations performed by HG1X when a certain condition is

reached. Different tasks can be defined for different screens. Screen

Tasks can be assigned for three different conditions:

- Before showing

These tasks are performed before displaying a

particular screen on the display.

- While showing

Tasks are repeatedly performed while the screen is

displayed.

- After Hiding

Tasks are performed after another screen is called and

before displaying a new screen.

Example: Suppose Screen 1 is currently on the display

simultaneously performing ‘while showing’ task. Now PLC Tag calls

for Screen 2. Both the screens have all three types of tasks: Before

showing task, While showing task, After hiding task. Tasks will be

performed in following sequence:

1. After hiding task for screen 1 performed while clearing screen

no. 1.

2. Before showing task for screen 2 performed.

3. Screen 2 displayed.

4. While showing task list performed repeatedly.

5. When another screen is called after hiding task performed

while clearing screen 2.

Types of ScreenTasks:

1. Goto Screen

2. Goto Next Screen

3. Goto Previous Screen

4. Write Value to a Tag

5. Add a Constant Value to Tag

6. Subtract a Constant Value from Tag

7. Add Tag B to Tag A

8. Subtract Tag B from Tag A

9. Turn Bit On

10. Turn Bit Off

11. Copy Tag B to Tag A

12. Swap Tag A and Tag B

13. Print Data

14. Copy Tag to STR*

15. Copy Tag to LED

16. Delay

17. Wait till

* STR: Screen Triggering Register

1. Goto Screen:

Current Screen is replaced by the defined screen. This

command does not work when a PLC register is used as STR.

More information given in Application Task-List Section.

2. Goto Next Screen:

This task is useful when two screens are in succession.

Screen is changed to display the next screen.

If two screens

are not successive, there is a gap between two screens then

‘Screen not defined’ message will be displayed. This

message will stay on the screen till a valid screen is called.

This task does not work when a PLC tag is used as a STR.

3. Goto Previous Screen:

This task is useful when two screens are in succession.

Screen is changed to display the previous screen.

screens are not successive, there is a gap between two

screens then ‘Screen not defined’ message will be displayed.

This message will stay on the screen till a valid screen is

called.

Again this task does not work when a PLC tag is used

as a STR.

4. Write Value to a Tag:

A constant value can be downloaded to a tag using this task,

provided the tag is not a read-only tag.

5. Add a Constant Value to Tag:

A constant can be added to the current value of a tag using

this task.

6. Subtract a Constant Value from Tag:

This task is used to subtract a constant value from the current

value of a tag.

If two

7. Add Tag B to Tag A:*

Tag B can be added to tag A using this task. The result will be

stored in tag A.

8. Subtract Tag B from Tag A:*

Tag B is subtracted from tag A using this task. The result will

be stored in tag A.

9. Turn Bit On:

Any coil or bit can be turned on using this task. The bit/coil

should be a read-write coil.

10. Turn Bit Off:

Any coil or bit can be turned off using this task. The bit/coil

should be a read-write coil.

11. Copy Tag B to Tag A:*

Tag B can be copied to tag A using this task. The value of tag B

will be unchanged. Tag A will be same as tag B.

12. Swap Tag A and Tag B:*

Values of two tags can be swapped using this task. Tag A

value will be copied to tag B and tag B value will be copied to

tag A.

13. Print Data:

All the text data will be printed on the serial port.

Communication settings will be same as defined in ‘Prizm

Settings’ ‘Printer Port Options’ window. Graphical objects will

not be printed.

14. Copy Tag to STR:

A PLC tag can be copied to STR, Screen Triggering Register.

STR is a system register inside Prizm which decides the

screen to be displayed.

Page 8

15. Copy Tag to LED:

LED’s on the keypad of each HG1X can be turned on/off

depending on the value of a tag. The tag should be copied to

LED register and the LEDs will display the tag value.

16. Delay:

Any task can be delayed using this task. Tags will be updated

during this delay.. After the delay is completed the next task will

be performed.

17. Wait till:

This is a conditional delay. Next task will not be performed till

the specified condition is false.

* While defining double Tag operations, make sure both the tags

have same number of bytes. Else the task may lead to erroneous

results.

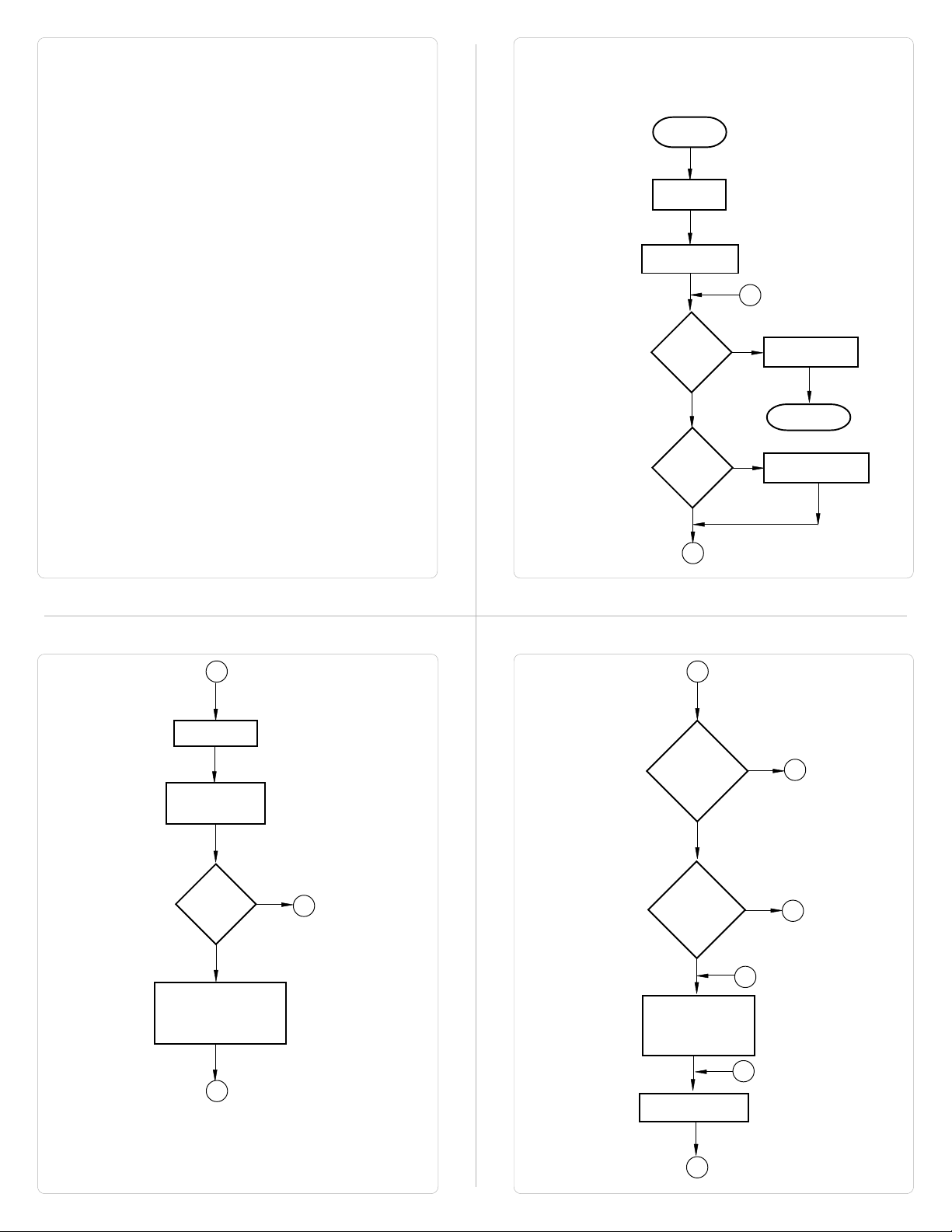

How HG1X works?

All the HG1X models follow a particular sequence for performing the

tasks defined by the user in the application. The sequence is as

shown below:

START

Power-up

Message

Power up Task

A

B

Global Task

Check Screen

Number

IBM

Comm

?

Y

PLC

Comm

Error

?

N

B

E

Password

Protected

Screen

?

Y

N

Complete IBM

Communication

Re-Start

Re-establish PLC

Y

Communication

N

D

Same

Screen

?

Perform After Hiding

Task for Previous

Screen

E

Y

N

C

Valid

Screen

password

?

Y

Perform Before

Showing Task List

for new Screen

Upload Tag Block

H

N

F

D

C

Page 9

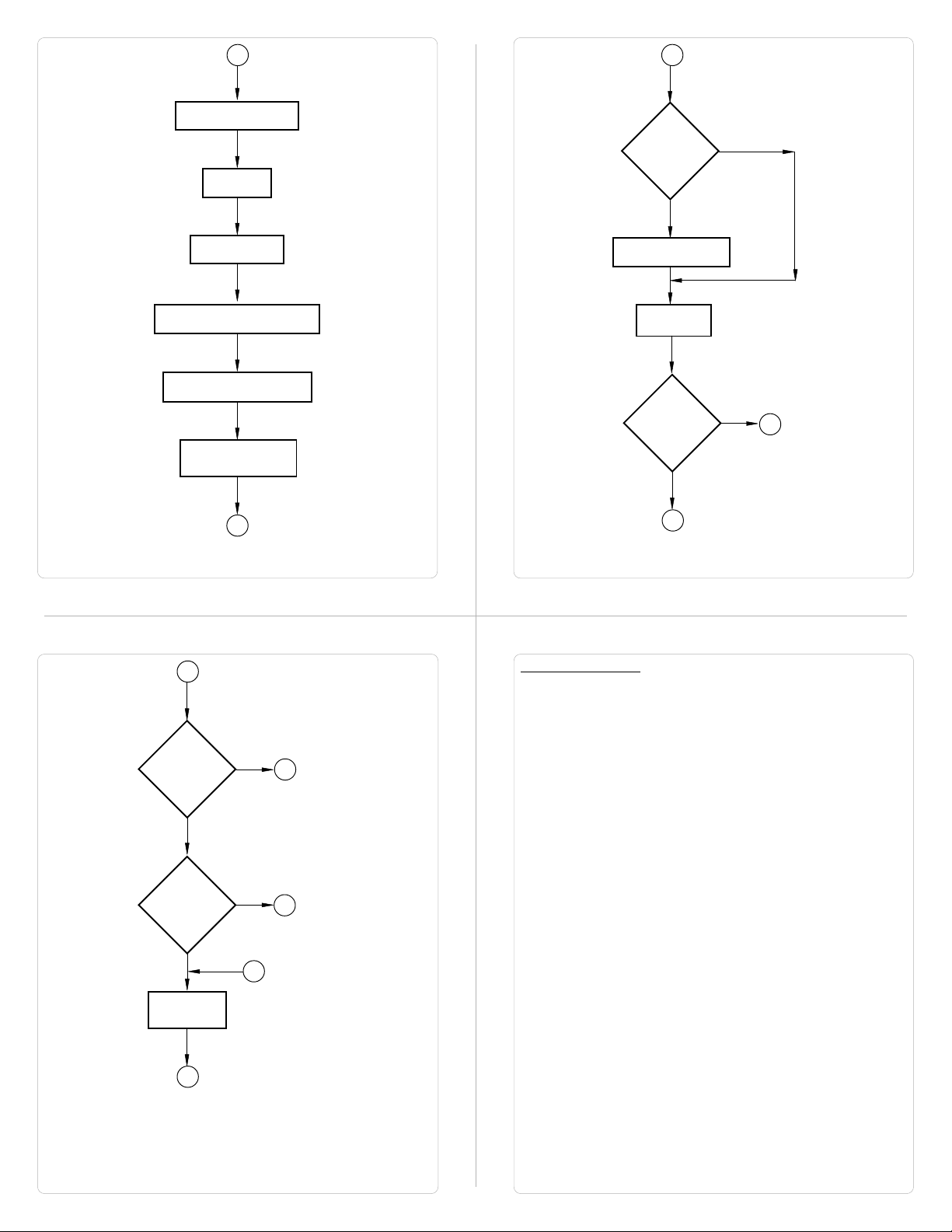

H

Upload Alarm Block

Serv Alarm

I

Same

key

Pressed

?

N

Y

Display Screen

Display Associated Screens

Serv While Showing Task

Check if same key

pressed

I

J

Password

Protected

Key ?

Y

N

G

Key Release task

Load new

keys

N

New

key

Pressed

?

Y

J

Animation Properties:

All the objects (except Register / Coil Data Entry Objects) have

Animation Properties. Animation Property is a conditional property of

an object which changes with the value of the Tag associated with it.

Animation properties are of three types: Show / Hide, Flashing and

Percent filling.

1. Show / Hide Animation: Object is displayed only when the

condition specified by the user is true.

2. Flashing Animation: An object is flashed when the condition

becomes true.

A

Valid Key

Password

?

Y

Serv Key

Press Task

A

Screen Objects have certain properties, referred as ‘Attributes’.

Attributes are useful for suggesting the importance of the particular

N

A

G

text object. Attributes for are:

- Flash

User can assign flashing to any text object*. An object can

flash at three different speeds: Slow, Medium and Fast. By

default no object is assigned flashing attribute. If flashing is

defined, slow flashing is selected by default.

objects (Coil and Register) do not have flash attribute.

* Data Entry

Page 10

Screen Objects can be further divided into:

1. Plain Text

2. Coil Data Entry

3. Register Data Entry

4. Display Coil Data

5. Display Register Data

6. Register Text

7. Error

8. Alarms

9. Bargraph

1. Plain Text:

Plain text object is useful for displaying any message for the

operator. Plain Text Objects do not depend on the PLC. Even

if the PLC is not connected, this object will be displayed.

2. Data Entry Objects:

Any register or coil from the PLC Memory, except Read-only

registers and coils, can be edited using the HG1X keypad.

Coil Data Entry:

Procedure to a edit coil is as follows:

1. Press a key with definition ‘Accept Data Entry‘ to initiate

data entry mode. Data entry mode is indicated by flashing

the complete data entry object.

2. Use keys with definition ‘Increase Digit by 1’ or Numeric

keys ‘0’ and ‘1’ to edit data.

3. Press key with definition ‘Accept Data Entry‘ to accept the

data entered. When a new application is created each

key is assigned a default definition by the software.

Default keys required for coil data entry are as shown in

Table 4.1.

Table 4.1

Model Initiate Edit Keys Accept

Data Entry Data Entry

F6

HG1X-252

HG1X-452 and

ENT

ENT ENT

F4

+/-

0

1

F6

ENT

Register Data Entry:

Procedure to a edit register is as follows:

1. Press key with definition ‘Accept Data Entry‘ to initiate data

entry mode. Data entry mode is indicated by flashing the last

digit of the register. Key with definition ‘Clear Data Entry’

clears the data. Key with definition ‘Cancel Data Entry’

cancels the data entered and exits data entry mode.

2. For models with numeric keypad, press key with definition

‘Sign (+/-) and 0’ to enter negative sign. Sign will be

automatically adjusted for the other models. For models

without numeric keypad, use keys with definition ‘Increase

Digit by 1’ and ‘Shift Value to Left’ else use Numeric keys ‘0’

through ‘9’ to edit register data.

3. Press key with definition ‘Accept Data Entry‘ to accept the

data entered. When a new application is created each key is

assigned a default definition by the software. Default register

data entry keys are as shown in Table 4.2.

Table 4.2

Model Initiate Edit Keys Accept

Data Entry Data Entry

HG1X-252

HG1X-452 through

F6

ENT

ENT

F4 F3

ESC

+/-

0

F5

CLR

9

4. Display Bit Text:

This object displays text depending on the bit status. Bit on and

Bit off text is defined by the user while writing the application.

5. Display Register Value:

This object displays the value of a register.

6. Display Register Text:

This object displays text depending value of a register. Text is

defined by the user while writing the application.

7. Error Field:

This object displays type of error occurred during PLC

communication.

8. Alarms:

This object displays the alarm text when the alarm occurs.

First triggered alarm is on top. Alarm condition for alarm should

be cleared. Each alarm has to be acknowledged. ‘Acknowledge

Alarm’ key acknowledges the alarm. The alarm text is cleared

when the alarm condition is cleared and the alarm is

acknowledged.

9. Bargraph:

Bargraphs are PLC register dependent objects which change

their bar height / width according to the PLC register. Bargraph

F6

ENT

ENT

does not have flash attribute but can be assigned ‘Show-Hide’

and ‘Flash’ animation.

Page 11

4.2 Keys

Keys are needed whenever the operator has to modify some PLC

data, acknowledge an alarm or take a control action. HG1X keypad

has the ability to perform the above mentioned as well as many more

tasks. User can define the task to be performed by each key.

Key Tasks are divided into following types depending upon the type

of key closure:

- Key Press Tasks

These tasks are performed at the instance of key closure.

- Key Pressed Tasks

These tasks are performed while a key is pressed and held

down.

- Key Release Tasks

These tasks are performed when a key is released.

Types of Tasks:

1. Goto Screen

2. Goto Next Screen

3. Goto Previous Screen

4. Write Value to a Tag

5. Add a Constant Value to Tag

6. Subtract a Constant Value from Tag

7. Add Tag B to Tag A

8. Subtract Tag B from Tag A

9. Turn Bit On

10. Turn Bit Off

11. Toggle Bit

12. Copy Tag B to Tag A

13. Swap Tag A and Tag B

14. Print Data

15. Copy Tag to STR

16. Copy Tag to LED

17. Delay

18. Wait till

19. Key Specific Tasks

1. Goto Screen:

Current Screen is replaced by the defined screen. This

command does not work when a PLC register is used as STR.

More information given in Application Task-List Section.

2. Goto Next Screen:

This task is useful when two screens are in succession.

Screen is changed to display the next screen.

If two screens

are not successive, there is a gap between two screens then

‘Screen not defined’ message will be displayed. This

message will stay on the screen till a valid screen is called.

This task does not work when a PLC tag is used as a STR.

3. Goto Previous Screen:

This task is useful when two screens are in succession.

Screen is changed to display the previous screen.

If two

screens are not successive, there is a gap between two

screens then ‘Screen not defined’ message will be displayed.

This message will stay on the screen till a valid screen is

called.

This task does not work when a PLC tag is used as a

STR.

4. Write Value to a Tag:

A constant value can be downloaded to a tag using this task,

provided the tag is not a read-only tag.

5. Add a Constant Value to Tag:

A constant can be added to the current value of a tag using

this task.

6. Subtract a Constant Value from Tag:

This task is used to subtract a constant value from the current

value of a tag.

7. Add Tag B to Tag A:*

Tag B can be added to tag A using this task. The result will be

stored in tag A.

8. Subtract Tag B from Tag A:*

Tag B is subtracted from tag A using this task. The result will

be stored in tag A.

9. Turn Bit On:

Any coil or bit can be turned on using this task. The bit/coil

should be a read-write coil.

10. Turn Bit Off:

Any coil or bit can be turned off using this task. The bit/coil

should be a read-write coil.

11. Toggle Bit:

Any bit can be toggled using this task. The bit / coil will be

toggled each time the key is pressed.

12. Copy Tag B to Tag A:*

Tag B can be copied to tag A using this task. The value of tag

B will be unchanged. Tag A will be same as tag B.

13. Swap Tag B to Tag A:*

Tag A and Tag B values can be swapped using this task.

14. Print Data:

Text data on the particular screen will be printed.

15. Copy Tag to STR:

Any specified task will be copied to STR. This STR decides the

screen to be displayed.

16. Copy Tag to LED:

LEDs of the HG1X can be used to reflect the value of a tag. The

tag should be copied to LED register for such functionality.

17. Delay:

An unconditional delay can be added to the task list. All the tasks

after this task are delayed by the specified time.

18. Wait till:

All the tasks after this task are not performed till the condition

specified by this task does not become true.

19. Keys Specific Tasks:

Apart from the above mentioned tasks each key can be

assigned a task which can be common to all the tags.

Types of key specific tasks:

1. Clear Data Entry

Clears Data after data entry is initiated.

2. Cancel Data Entry

Cancels the data entered and restores previous data.

3. Accept Data Entry

Initiates data entry and accepts data entered.

4. Switch to next Data Entry

Next data entry is selected.

5. Increase Value by 1

Value of a tag is increased by 1.

6. Decrease Value by 1

Value of a tag is decreased by 1.

7. Increase Digit by 1

Value of a single digit of a tag is increased by 1.

8. Decrease Digit by 1

Value of a single digit of a tag is decreased by 1.

9. Shift Value to Left

Value is shifted to left.

10. Move Cursor to Left

Cursor is moved to left to edit next digit.

11. Move Cursor to Right

Cursor is moved to right to edit next digit.

Page 12

12. Sign Key (+/-)

Used for signed data entry.

13. Sign Key (+/-) and 0

Single key used as a sign key as well as numeric key 0. If

this key is pressed immediately after data entry is initiated,

key is taken as sign key else it is taken as ‘0’ key.

14. Numeric Key 0

Enters a ‘0’ after data entry is initiated.

15. Numeric Key 1

Enters a ‘1’ after data entry is initiated.

16. Numeric Key 2

Enters a ‘2’ after data entry is initiated.

17. Numeric Key 3

Enters a ‘3’ after data entry is initiated.

18. Numeric Key 4

Enters a ‘4’ after data entry is initiated.

19. Numeric Key 5

Enters a ‘5’ after data entry is initiated.

20. Numeric Key 6

Enters a ‘6’ after data entry is initiated.

21. Numeric Key 7

Enters a ‘7’ after data entry is initiated.

22. Numeric Key 8

Enters a ‘8’ after data entry is initiated.

23. Numeric Key 9

Enters a ‘9’ after data entry is initiated.

24. Numeric Key A

Enters a ‘A’ after data entry is initiated.

25. Numeric Key B

Enters a ‘B’ after data entry is initiated.

26. Numeric Key C

Enters a ‘C’ after data entry is initiated.

27. Numeric Key D

Enters a ‘D’ after data entry is initiated.

28. Numeric Key E

Enters a ‘E’ after data entry is initiated.

29. Numeric Key F

Enters a ‘F’ after data entry is initiated.

30. Edit Bit On

A coil is turned on after data entry is initiated.

31. Edit Bit Off

A coil is turned off after data entry is initiated.

32. Acknowledge Alarm

Active alarm is acknowledged using this key.

33. Next Alarm

Next alarm from the container is displayed.

34. Previous Alarm

Previous alarm from the container is displayed.

* While defining double Tag operations, make sure both the tags

have same number of bytes. Else the task may lead to erroneous

results.

4.3 Alarms

Any tag can be continuously monitored by defining alarms for each bit

of that tag. To display an alarm on the screen as soon as it is

triggered, alarm object has to be placed on the screen. If the value of

the particular tag becomes nonzero, alarm is displayed in the alarm

object. An alarm is triggered for each bit in a tag. Total 256 alarms

can be defined in HG1X. HG1X stores the alarm information in an

alarm container. Maximum 64 alarms can be stored in the container.

First triggered alarm is on the top of the container. New alarm is

added from the bottom. Operator has to acknowledge each alarm by

using any key with definition ‘Acknowledge Alarm’. When alarm

condition is cleared and the alarm is acknowledged, the alarm is

deleted from the container. Alarm can also be printed on the serial

port. Printing is performed as soon as the alarm is triggered.

Two types of alarms can be defined in HG1X:

1. Consecutive Alarms

2. Discrete Alarms

1. Consecutive Alarms:

Consecutive alarms can be useful when user wants to monitor 16

consecutive tags. All the 16 consecutive tags should be defined in the

tag database. An alarm cab be defined for each bit. HG1X uploads all

16 tags in a single block. When any bit of 16 tags is found to be on

(‘1’) corresponding alarm is triggered. Triggered alarm is displayed in

the alarm object. Each alarm has to be acknowledged. User should

define a key to acknowledge alarms. User can also scroll through the

table of alarms using keys defined as ‘Next Alarm’ and ‘Previous

Alarm’. Acknowledged and inactive alarm is deleted from the

container. New alarm is added from the bottom of the container.

2. Discrete Alarms:

Discrete alarms can be useful when user wants to monitor tags which

are not in a sequence, discrete. An alarm is defined for each bit of

tag. When any bit of any tags is found to be on (‘1’) corresponding

alarm is triggered. Triggered alarm is displayed in the alarm object.

User should define a key to acknowledge alarms. User can also scroll

through the table of alarms using keys defined as ‘Next Alarm’ and

‘Previous Alarm’. Acknowledged and inactive alarm is deleted from

the container. New alarm is added from the bottom of the container.

Page 13

4.4 Application Task-List

Application task-list allows user to define tasks to be performed at

power-on or while application is running i.e. Global Task.

Application task-lists are of two types:

1. Power-on tasks:

Power-on tasks are performed after HG1X unit is powered on.

These tasks are like a boot sequence for HG1X which are

performed only once. Using these tasks user can initialize some

registers, goto a particular screen after power up etc.

Please

note that user MUST define ‘Goto Screen’ Task in Power-On

task list.

2. Global tasks:

Global tasks are performed regularly till the application is in

progress. These tasks are useful when the user wants to

perform some tasks repeatedly. In case the PLC is not connected

then PLC related tasks will not be performed.

The tasks supported are as follows:

1. Goto Screen

2. Goto next screen

3. Goto previous screen

4. Write value to tag

5. Add constant value to tag

6. Subtract constant value from tag

7. Add Tag B to Tag A

8. Subtract Tag B from Tag A

9. Turn bit on

10. Turn bit off

11. Toggle bit

12. Copy Tag B to Tag A

13. Swap Tag A and Tag B

14. Print Data

15. Copy Tag to STR

16. Copy Tag to LED

16. Delay

17. Wait till

1. Goto Screen:

Current Screen is replaced by the defined screen. This

command does not work when a PLC register is used as STR.

More information given in Application Task-List Section.

2. Goto Next Screen:

This task is useful when two screens are in succession.

Screen is changed to display the next screen.

If two screens

are not successive, there is a gap between two screens then

‘Screen not defined’ message will be displayed. This

message will stay on the screen till a valid screen is called.

This task does not work when a PLC tag is used as a STR.

3. Goto Previous Screen:

This task is useful when two screens are in succession.

Screen is changed to display the previous screen.

If two

screens are not successive, there is a gap between two

screens then ‘Screen not defined’ message will be displayed.

This message will stay on the screen till a valid screen is

called.

This task does not work when a PLC tag is used as a

STR.

4. Write Value to a Tag:

A constant value can be downloaded to a tag using this task,

provided the tag is not a read-only tag.

5. Add a Constant Value to Tag:

A constant can be added to the current value of a tag using

this task.

6. Subtract a Constant Value from Tag:

This task is used to subtract a constant value from the current

value of a tag.

7. Add Tag B to Tag A:*

Tag B can be added to tag A using this task. The result will be

stored in tag A.

8. Subtract Tag B from Tag A:*

Tag B is subtracted from tag A using this task. The result will

be stored in tag A.

9. Turn Bit On:

Any coil or bit can be turned on using this task. The bit/coil

should be a read-write coil.

10. Turn Bit Off:

Any coil or bit can be turned off using this task. The bit/coil

should be a read-write coil.

11. Toggle Bit:

Any bit can be toggled using this task. The bit / coil will be

toggled each time the key is pressed.

12. Copy Tag B to Tag A:*

Tag B can be copied to tag A using this task. The value of tag B

will be unchanged. Tag A will be same as tag B.

13. Swap Tag B to Tag A:*

Tag A and Tag B values can be swapped using this task.

14. Print Data:

Text data on the particular screen will be printed.

15. Copy Tag to STR:

Any specified task will be copied to STR. This STR decides the

screen to be displayed.

16. Copy Tag to LED:

LEDs of the HG1X can be used to reflect the value of a tag. The

tag should be copied to LED register for such functionality.

17. Delay:

An unconditional delay can be added to the task list. All the tasks

after this task are delayed by the specified time.

18. Wait till:

All the tasks after this task are not performed till the condition

specified by this task does not become true.

* While defining double Tag operations, make sure both the tags

have same number of bytes. Else the task may lead to erroneous

results.

Page 14

Configuration Software

In this Chapter...

Introduction to HG1X Software

Installing HG1X Software

HG1X Software - Basics

Create a new Application

Setup Node

Create Tag Data Base

Create Screens

Define Keys

Define Alarms

Application Task List

Download Application

5.1 Introduction

WindMSG is Windows based software to configure the HG1X Series

Interfaces by IDEC Corporation. WindMSG's tools and easy

approach can help you create your applications quickly and easily. By

using some of WindMSG's new features, you can be more effective in

what you need. Whether you need a small application to monitor data

or a bigger application for both monitoring and changing data in your

PLC, WindMSG has it all. With WindMSG you can get started quickly

to use your HG1X Interfaces.

Developing your applications for any HG1X Series is easy using

WindMSG. The common functionality found among many Windows

applications can also be found here and will allow you to quickly

adapt to WindMSG. Once you are familiar with the many visual clues

in WindMSG, creating an application will be a breeze. The idea

behind designing WindMSG and the HG1X is to allow you to get

where you want to... FAST!

You can use WindMSG to configure any HG1X model, to work with

ANY of the drivers supported. WindMSG currently supports over 25

PLCs and the following list of HG1X Models:

HG1X Series HG1X-252, HG1X-452

HG1X communicates with a PLC only after downloading correct

driver and application into the unit. HG1X user should follow the

given procedure to configure and use HG1X:

1. Create an application for required PLC.

2. Connect IBM cable.

3. Download Firmware i.e. driver for the PLC. HG1X models

cannot communicate with PLC till the required driver is

downloaded.

4. Download application.

5. Now connect the PLC to the unit using PLC cable.

5.2 Installing WindMSG Software

System requirements for installing WindMSG on your PC:

Windows Version : Microsoft Windows 95 or higher

Processor : PENTIUM or higher

Hard disk Space : 5 MB or more

Serial Mouse : Required

RAM : 16 MB or more

Display resolution : 640 x 480 (VGA) or better

Display colors : 16 colors or more

To install WindMSG software:

1. Open Microsoft Windows. The Start program task button is

located at the bottom left portion of your screen.

2. Place the installation CD into your PC’s CD drive.

3. Select Run, and a pop-up window appears. Type the path and

file name for installing setup (D:\SETUP.EXE).Press OK. Follow

the instructions given in the setup software.

Page 15

5.3 WindMSG Software

HG1X unit has to be configured before its use in any system.

Complete configuration consists of defining:

- HG1X Settings

- PLC node

- Tag Database

- Screens and / or Screens Task-List.

- Keys

- Alarms

- Global and Power-on Task list

The complete configuration is stored as an Application. This

application is downloaded in HG1X.

1. HG1X Settings:

HG1X Settings define following properties of HG1X:

a. Hardware Settings

- Application Memory

Use this if only you have purchased a nonstandard

unit with a different memory option.

b. Keypad options

- Keypad Queue Size

If task for a key is in progress and another key is

pressed, then the second key (latest pressed) is

stored in a Key Queue. User can change the queue

size using this option.

- Queue full options

User has a choice to select what should be done if

the queue is full and another key is pressed. Either

the first or the last key pressed can be ignored.

c. Printer Port Options

HG1X has a Serial Printout Facility. User should connect

Serial Printer cable to the Serial Port of the HG1X.

Communication parameters for serial printing can be changed

using this option.

Please note that this does not affect PC to

unit communication while downloading firmware or

application.

- Baud Rate

Baud Rates available are 300, 600, 1200, 2400,

9600, 19200.

- Number Of Bits

Data bits can either be 7 or 8.

- Parity

Parity options are Odd, Even, None.

- Number of Columns

User can select the column size i.e. length of a line to

be printed. After the specified number of characters,

HG1X sends a terminating character.

- Terminating Character

Options for terminating character are None, CR, LF,

CR+LF.

2. HG1X Network Configuration:

This setting selects the PLC Model, PLC type, Node number in a

system. User can also connect multiple PLCs of the same type

(protocol) to a single HG1X. Each PLC must have unique identification number which is termed as NODE ID.

3. HG1X Tags:

Each register in the PLC memory has a unique address and can be

identified by giving a specific name to it. This information is stored as

Tag Data Base in WindMSG. Any coil or register to be used in the

application must be first defined in the Tag data base.

4. Screens:

Operator views the PLC data on the screen of the HG1X models.

Tasks can be defined for a screen. Also, the action for keys when a

screen is acting can be defined.

5. HG1X Global Key’s Task-List:

All the keys on the HG1X models can have user selectable

definitions. Three types of tasks can be defined for each key: ‘Press’

Task, ‘Pressed’ Task, ‘Released’ Task. Two keys can also be defined

for performing Tasks. Each key single or double can have password.

6. HG1X Alarms:

Alarms can be defined in the Alarms Window. Alarms are defined on

a single bit of any one word tag. All the tags must be defined before

defining the Alarms. Alarms can be set on two types of Tags:

Consecutive and Discrete. In consecutive type, HG1X will fetch 16

words from the PLC beginning with the defined tag. Each bit in each

of these 16 words will be an alarm bit. In discrete type tags need not

be consecutive. Again, in this type each bit of each tag is an alarm

bit.

7. HG1X Application Task-List

Application Task List is of two types: Power-on Task-List and Global

Task-List. Power-On Task-List is performed only once after the unit is

powered on. Global Task-List is performed till the unit and PLC are

communicating.

Run WindMSG.exe. Following splash screen will be displayed.

Main window will be displayed after the splash screen. Main window

consists of two main parts: Menu Bar and the Tool Station.

Menu bar operates in the normal manner.

Click with mouse or use keys in combination

with ALT key just like any other standard Windows based software.

Tool-Station consists of icons. When mouse points to any icon, a

tool-tip is displayed. Click on the icon to select the particular menu.

Page 16

File

Menu

Define

Menu

File

Menu handles the file related functions.

N

ew

- Creates a new application.

O

pen

- Opens a saved application.

Clos

e

- Closes currently open application.

S

ave

- Saves currently open application.

Save as

I

nformation

Exit

- Saves the current application with a different name.

- Application related information can be stored here.

User can enter his comments here.

- Exits WindMSG Software.

This menu actually defines the application. In the main window of

WindMSG software, bottom line of the icons is dedicated for this

menu.

H

G1X Settings

N

etwork Configuration

T

ag DataBase

Screens

Application Keys

Alarms

- Defines alarms in the application.

Application Task-List

- Defines HG1X settings.

change HG1X Settings only if he has

bought a nonstandard unit.

User should

- Defines PLC node, node ID etc.

- Defines tag to be used in the application.

- Defines screens.

- Defines application keys.

- Defines Power-on and Global Task-list.

Communicate

Communicate

Menu

Menu Downloads / uploads application to / from HG1X.

Communication Port

D

ownload

U

pload

- Downloads Application to HG1X.

- Uploads Application from HG1X.

- Sets COM port for communicating with

HG1X.

Utilities

Utilities

informs the user about the memory used for the application.

A

dd or Remove PLCs -

W

indMSG Memory Configuration -

Help

I

ndex -

A

bout WindMSG -

Menu

Menu is basically useful for adding / removing PLCs. It also

Adds / removes PLCs to /

from the Selected PLCs list.

Displays statistics of the

Memory used by the current

application.

Help

Menu

Menu, as the name suggests, offers help for the user.

Lists all the Help topics

Displays the software

version number.

Page 17

5.4 Creating new Application

1. Select

New

Application

from

button.

File

menu or click on the

OR

New

3. Select

or click on the

HG1X Settings

HG1X Settings

from

Define

menu or Press F3 key

button.

OR

2. In the dialog presented, select the HG1X Model and press

5.5 Setup Network / Node

OK

.

4. In HG1X Settings dialog box, select Application memory,

Key Queue Size, Serial printout options. Press OK to

accept the selections made.

5.6 Create Tag Database

1. Select

2. In Network Configuration dialog box, Press

Network Configuration

F4

key or click on the

button. Now select PLC and PLC Model. Assign a Node

Address for the node Press OK to accept the selections

made. If another node has to be added repeat above steps

else press

Close

Network Configuration

from

OR

Define

menu or Press

button.

Add a Node

1. Select

2. In Tags dialog box select the Node, Tag type, Register,

Tag Database..

or click on the

enter Tag name and finally select number of bytes for the

Tag. Press

tags press

Add

Close

from

Define

Tags

button.

to accept the Tag. After adding all the

button.

menu or Press F5 key

OR

Page 18

5.7 Create Screens

1. Select

2. In

Screens..

click on the

Screens

New Screen

Screen Name, Password. Screen Name and Screen

description information is for programmers reference only.

This information is NOT displayed anywhere on the actual

HG1X Screen. Associated Screen option is available only

when some screens have already been defined. Click

to enter the

Screen Editor

from

Define

menu or Press F6 key or

button.

OR

dialog box, enter the Screen number,

.

OK

3. In the

Screen Keys and Screen Task-List . To place an object

click on the respective button in

will take the shape of the object. Click the mouse at the

required location on the screen to place the object. All the

tag dependent objects will allow user to access the Tag

data base from their dialog box. Clicking on the

button or another object button deselects the object

selected. Standard Windows operations like Copy, Cut,

Paste Objects, Redo, Undo are available in

Screens can also be duplicated using the duplicate button.

To exit from the

of

Screen

explained in detail.

Screen Editor

Window. In the following points Screen is

user can define Screen Objects,

Objects

window. Pointer

Screen Editor

, click on the

Selector

Tools

Close

window.

button

4. How to define Text Object:

Click on the

pointer will change. Now place the mouse pointer at

desired location and mark the area of text object while

holding the left mouse button. A block cursor will blink at

the location inside the text outline. Now enter text. Last

character will be overwritten If INSERT Mode (Computer

Keyboard) is disabled, else new character will not be

accepted.

Text

button . The shape of the mouse

5. How to define Coil Data Entry object:

Click on the

change to the tool shape. Now place the mouse pointer at

desired location and click the left mouse button. The data

entry dialog box will appear. This box will allow user to

select between Coil and Register Data entry. If Coil data

entry is selected fields to be completed are Coil Tag and on

/ off text.

Data Entry

button . The mouse pointer will

Page 19

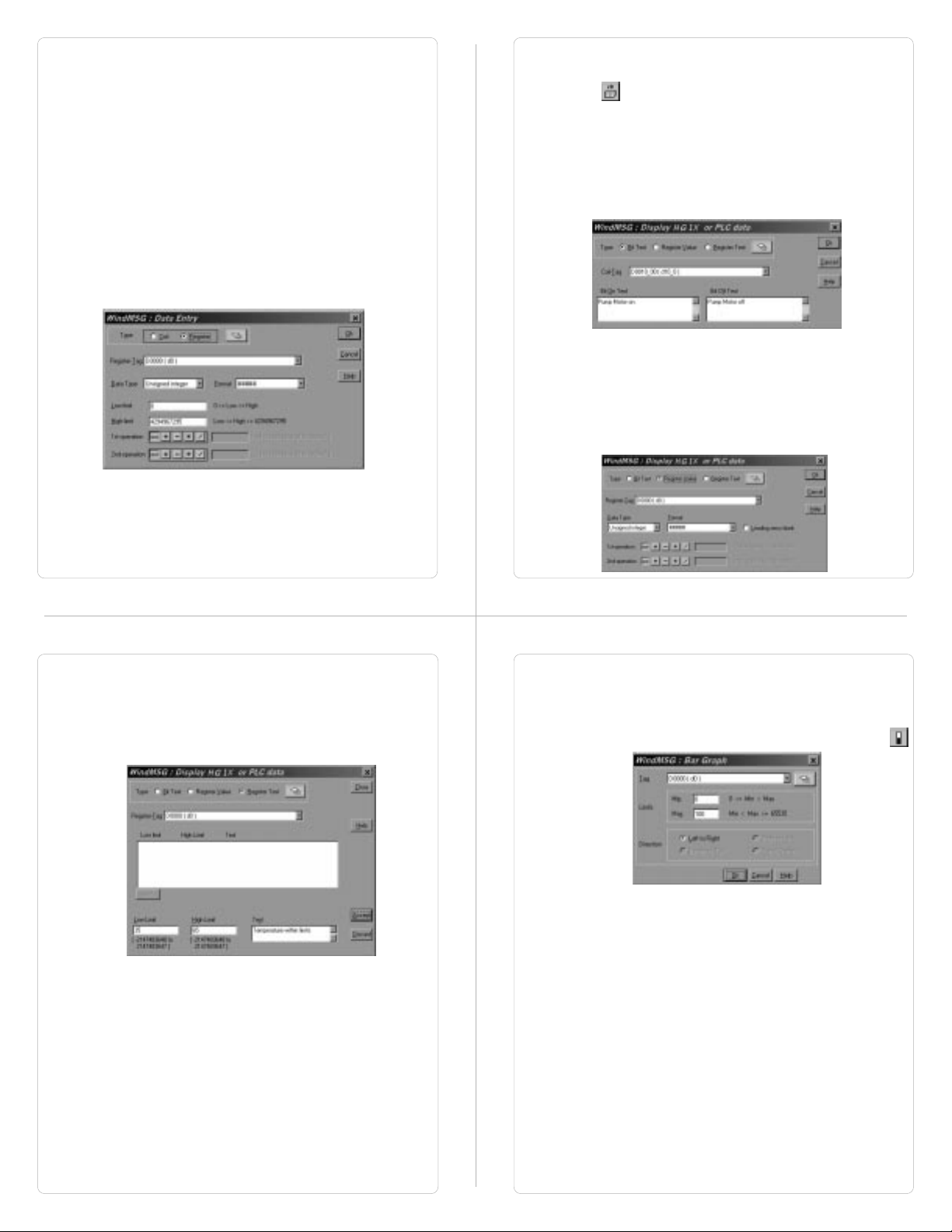

6. How to define Register Data Entry Object:

To edit a register in the PLC, select

the Data entry dialog box. Register Data Entry dialog box

allows user to select the tag, Data type, data format, low

limit, high limit, Math -1st and 2nd operation. In tag

selection window, there is the list of Tags available data

can be written. You can select the one you want from the

list. The list will NOT display any read only registers which

can not be modified. Data entered can be limited by

assigning Low and High limit for the data entry. Data can

be entered in various types viz., Unsigned Integer, Signed

Integer, Hexadecimal, BCD, Binary (1 word), Float. Data

format can also be selected by the user. Low and High

limits restrict the data that can be entered in the register.

Two mathematical calculations can be performed on the

data be entered.

Register Data Entry

in

7. How to define Display HG1X / PLC Data object:

This object can be used to view HG1X / PLC data. To place

an embedding object click on ‘Display HG1X / PLC

Data’ Tool. In the dialog box user can select either Bit Text

or Register Value or Register Text. Bit Text displays text

depending on the state of coil or bit. Register Value

displays the actual value of the register. Register Text

displays text depending on the value of a register. To add

Bit Text object, select Bit Text in the Display HG1X or

PLC Data dialog box. In the window, user can enter text to

be displayed depending on the state of the Coil.

To display a register value, select Register Value type in

Display HG1X or PLC Data window. The window will now

change to display Register options. Select the register to be

displayed. Select the Data type and Format to display the

register. Leading Zero Blank option decides whether zeros

preceding the value will be displayed or not. If this option

is enabled then register value will be displayed without

Leading Zeros.

Register Text Object is value dependent text object. User

can define different text strings for different limits of register

values. When the limit is crossed the text changes. First

select the register from the Tags list. Now enter low limit,

high limit and text for that range. Click Accept button to

accept the entered data. Now click Add to enter new limits

and corresponding text.

10. How to define Bargraph object:

Bargraph is a graphical representation of the value of any

register. Bargraph is available in all the HG1X models. User

can also view the bargraph of a particular range of register

value. To place a bargraph click on the Bargraph button

.

Bargraph can be drawn for a specific range of the register

value. The maximm range is 0 to 65535.

Page 20

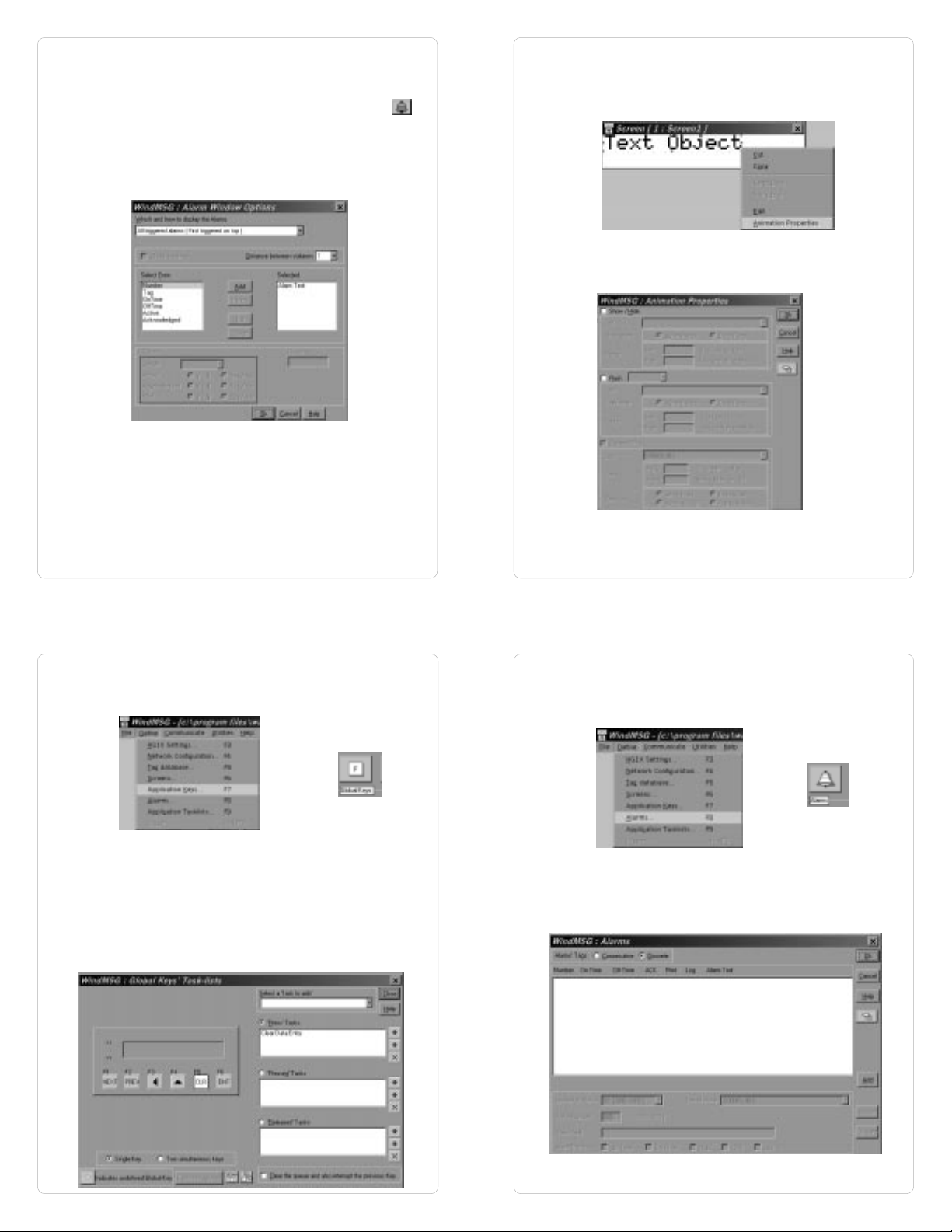

11. How to define Alarm object:

Alarm object displays alarm immediately after any alarm is

triggered. Alarm text is defined in the

To place an Alarm object, click on the

Alarms object can be edited by double clicking on the

object placed on the screen.

enable user to select the fields to be displayed in an

Alarms

be varied.

object. Sequence and length of each field can also

Alarms

dialog box.

Alarms

button .

Alarms Dialog box

will

14. To assign

the object with the mouse. Place the mouse on the

selected object and click with the right mouse button. From

the menu box presented select

option.

Flash

or

Scroll Animation

to any object, select

Animation Properties

5.8 Define Keys

1. To define Global Keys click on

Define

menu or press F7 or click on Global Keys Button.

Application Keys

from

15. In the

5.9 Define Alarms

1. Click on

Animation Properties

appropriate animation. Only Basic Graphical objects can

have Percent filling animation.

Alarms

Alarms Button to define Alarms.

from

dialog box select the

Define

menu or press F8 or click on

2. In

tasks to keys protect keys by assigning password. All the

keys on the HG1X keypad are redefinable. Most of HG1X

models have default definitions to keys.

Entry objects may not function properly if the required tasks

are not assigned to keys.

two keys. The task will be performed only when the two

keys are pressed simultaneously. Click on

close

Global Keys’ Task-Lists

Tasks can also be assigned to

Global Keys’ Task-Lists

OR

dialog box, user can assign

Please note Data

Close

dialog box.

button to

2. In

For

define alarms. Select group of alarms. Enter alarm number

and alarm text. Click relevant options for the particular

alarm. Click

Alarms

dialog box click either

Consecutive

Accept

OR

Consecutive

type select the first tag. Click

to accept the alarm.

or

Discrete

Add

.

to

Page 21

5.10 Application Task-List

1. Click on

F9 or click Application Task-List Button to define

Application Task-List.

Application Task-List

from

OR

Define

menu or press

5.11 Save Application

1. To save the application, click on

press F2.

Save

OR

from

File

menu or

2. In

2. Select the appropriate COM port and click OK to set the

Application Task-List

power-on tasks. Power-on task-List is like a boot sequence

for HG1X. User must direct HG1X to display a particular

screen in Power-on Task-List. Global task-list depends on

the system requirements. User can either use keys to

switch between screens or use a PLC tag to trigger

different screens.

COM port.

user can define global and

2. Default location to save application is ..\WindMSG\Result\

5.12 Download Application to HG1X

1. Click on

directory. Extension should be *.PZM.

to set the COM port.

Communication Port

from

Communicate

menu

3. Click on

4.

5. After Application Download is successfully completed, click

download application into the HG1X unit.

In Download

on

Download..

Close

to exit Download dialog box.

from

dialog box click on

Communicate

OR

Application

menu to

. Click OK.

Page 22

How Do I?

In this Chapter...

6.1 Frequently asked questions

This chapter answers the questions user normally asks.

1. How can I read PLC data?

To read any PLC data, the required tag should be defined in

the Tag Database. In a screen the tag should be embedded

in the required format.

2. Can I edit PLC data? How?

Any PLC register / coil can be edited except for ‘Read only’

registers / coils. Generally System registers and Input coils

are ‘Read only’. ‘Read only’ registers / coils vary from PLC to

PLC. Please refer to PLC manual for details. To edit any PLC

data define the tag in Tag Database. Place a ‘Data Entry’

object in a screen. Make sure to define the required keys.

Register and Coil data entry key definitions are given in

Table 4.1 and Table 4.2.

3. Can I keep a record of the Process data?

HG1X models can send screen data (Alphanumeric data

only) on its serial port. This output can be given to a serial

printer and a record of events can be achieved. A screen with

‘Print Data’ task can print all the alphanumeric objects.

4. Can I change screens using PLC logic?

Any PLC tag can be copied to STR, a system register internal

to HG1X, and HG1X will display the corresponding screen.

User must define the task ‘Copy tag to STR’ in Global

Application Task-List. Make sure to define screens to all the

possible values of the tag to avoid ‘Screen not defined’

message. Please note that the ‘Goto screen’, ‘Goto next

screen’ and ‘Goto previous screen’ tasks will not work in this

case. To change the screen the value of the PLC ta should

be changed.

Frequently asked questions

5. Can I perform any task continuously?

To perform any task continuously define the task in Global

Application Task-List. This task will be performed till the unit

is powered.

6. How can I ‘Hold’ any Bit on or off using a key?

To hold a bit on using a key, define ‘Turn bit on’ task in ‘Key

press task-list’ and ‘Turn bit off’ task in ‘Release key task-list’

for the same key.

7. How do I keep any screen or any key locked?

Any screen or a key can be kept secret using the ‘Password’

feature of HG1X. Password protected screen will not be

displayed till the user enters the correct password. Similarly

task for password protected key will not be performed till user

enters the correct password.

8. Can I assign scaling factor for any tag?

Value of any tag can be converted in to the required format

by performing ‘Math Operations’ on it. This DOES not change

the value of the actual tag. ‘Math Operations’ can be

performed in ‘Display HG1X / PLC Data’ objects. Data to be

written to a tag can also be manipulated by assigning ‘Math

Operations’ in ‘Data Entry’ object.

9. Can I limit the data to be entered in a tag?

Data entered in any register tag can have high and low limits.

This keeps a check on the register limits.

Refer to ‘Configuration software’ section for detailed information on

how to define an application.

Page 23

Appendix A

WindMSG Tutorials

Example to create Application for HG1X

Tutorial 1: Create an Application for HG1X

Model

We will create an application for HG1X-252 unit with internal tags

only. Follow the following steps:

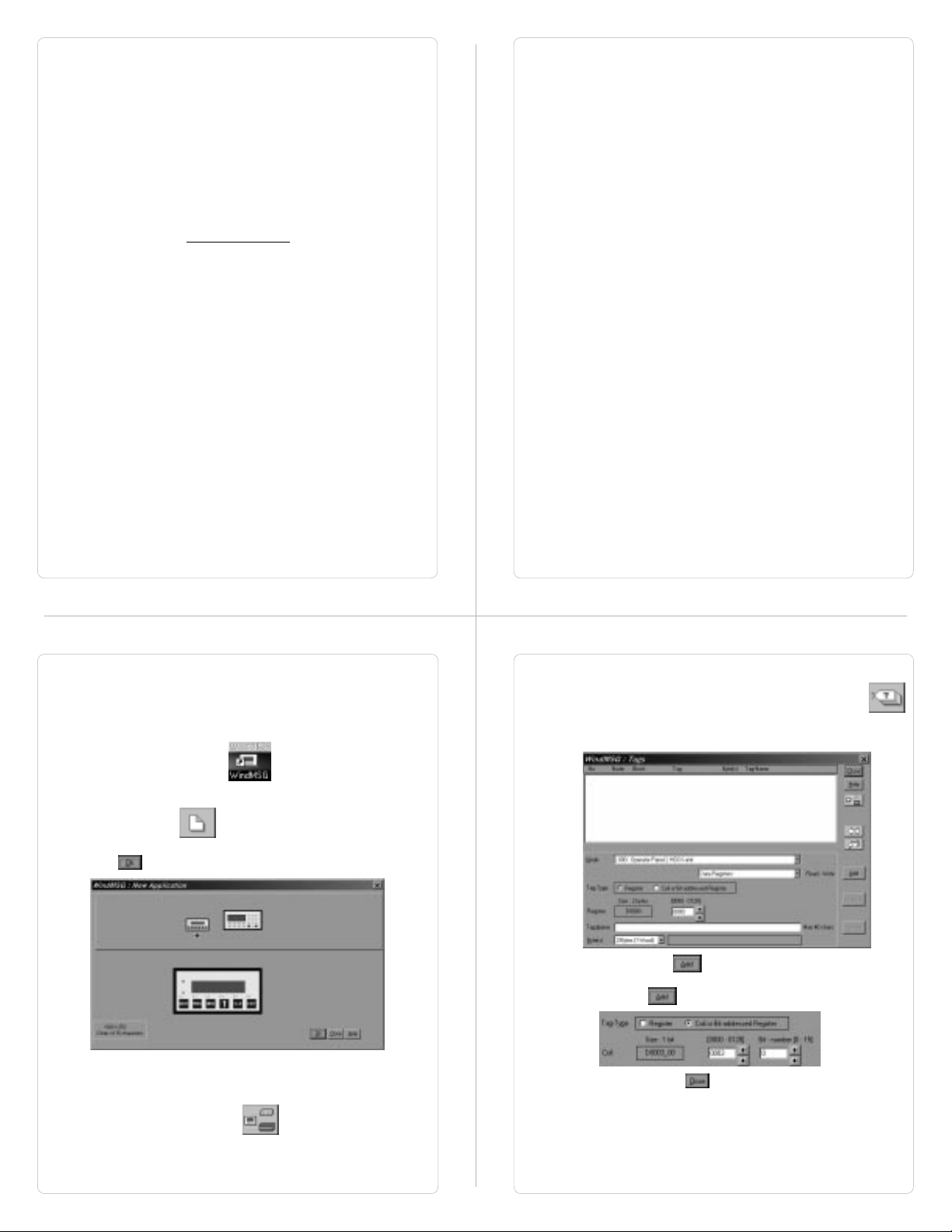

1. Run WINDMSG.EXE.

2. After the main window is displayed, click on the New

Application icon

3. From the New application dialog box, select required unit and

click to accept the selection made.

4. As said earlier, this application is being developed with

internal tags only, hence we will not be adding any PLC in the

network. If user wants to add PLC in the network, click on the

Network Configuration icon

5. Now we have to define tags required for the application. It is a

good practice to define the tags before developing the

application. To define Tags click on Tag Database icon.

Following dialog box will be displayed. Select required

register type and register address, enter your name for the

tag.

Click on Add button to accept the tag defined. To define

a coil, change the selection Tag-type. Enter coil number, tag

name and click to accept the tag entry.

Click on Close button to close the Tag Database

window.

Page 24

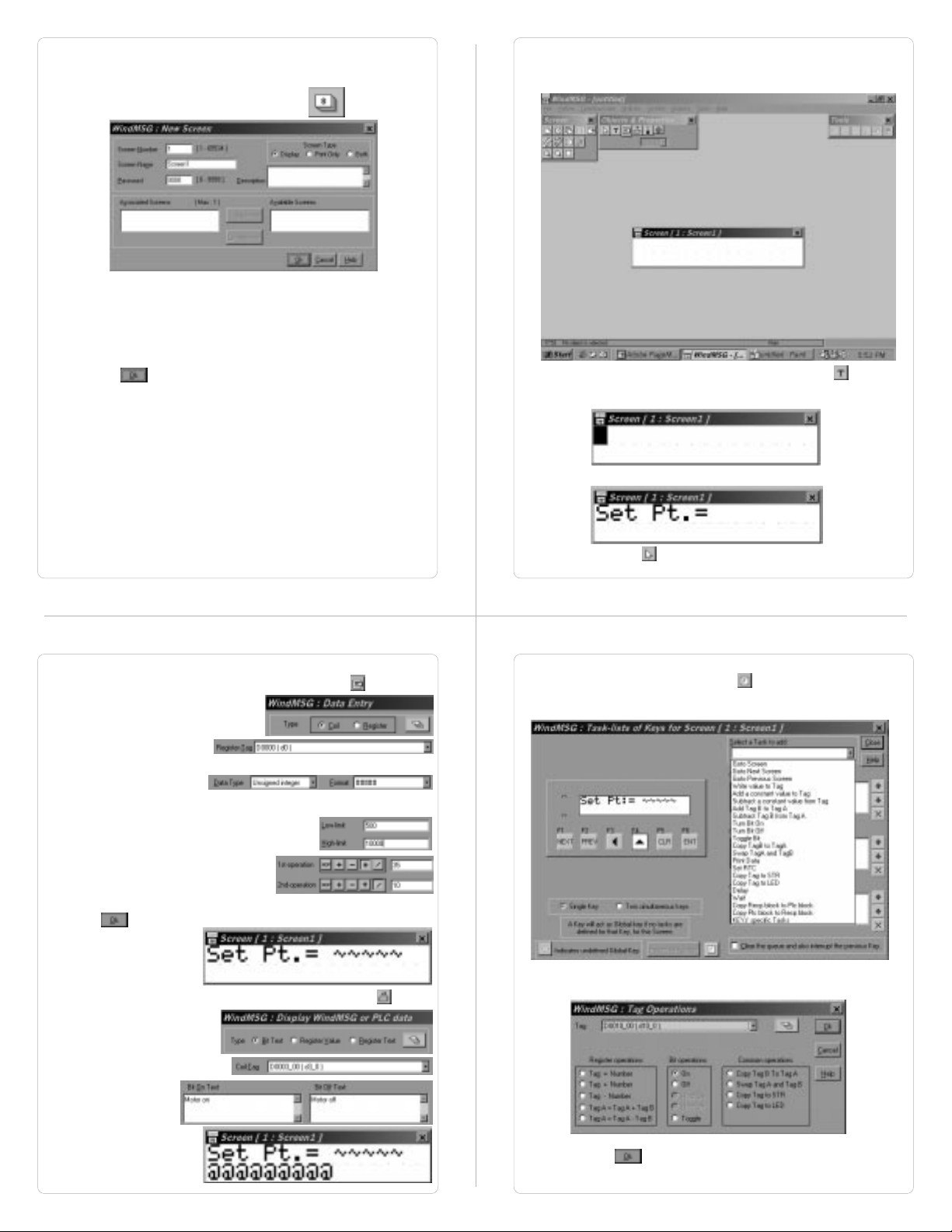

6. Now we will define Screens. Screens form the most important

part of any application as it displays the information required

by the operator. HG1X has various objects to make a screen

operator-friendly. Click on Screens icon to define

screens.

In the dialog box, enter the screen number, name and

password. Also select screen type.

Display: Screen will be displayed and will perform all tasks.

Print Only: Screen will only be printed after it is triggered.

Both: Screen will be displayed and printed after it is triggered.

Click to create a new screen.

Following Screens window will now appear on the monitor.

This window defines all Screen objects, Screen task-list and

Screen keys.

Now we have to place plain text objec, click on text icon . Place

the object at required place on the screen and click. A blinking blob

will appear.

Enter Text.

Now we have to place a register data entry with math and limits. To

place the object on the screen, click on data entry icon .

Select Type ‘Register’.

Select tag from the tag list.

Select data type and format.

We select ‘Unsigned Integer’

and 5 digit format.

Select low and high limit for data entry.

To multiply the tag by 3.5 we should

define 1st operation as ‘x35’ and

2nd operation as ‘/10’.

Now click to accept the data entry.

Data entry object will now

be placed at required

position.

To place ‘Display HG1X / PLC data’ object click on the icon .

Click on selector icon to complete text object.

To hold the coil on till a key is pressed screen keys should be

defined. Click on ‘keys for screen’ icon .

In the Screen keys dialog box select the key to be defined.

Select Turn bit on task as ‘press task’ for the key.

Select ‘Bit Text’ type.

Select coi from tag list.

Enter Bit on text and

Bit off text.

Object will be placed at

required location.

Select coil. Click to accept the task.

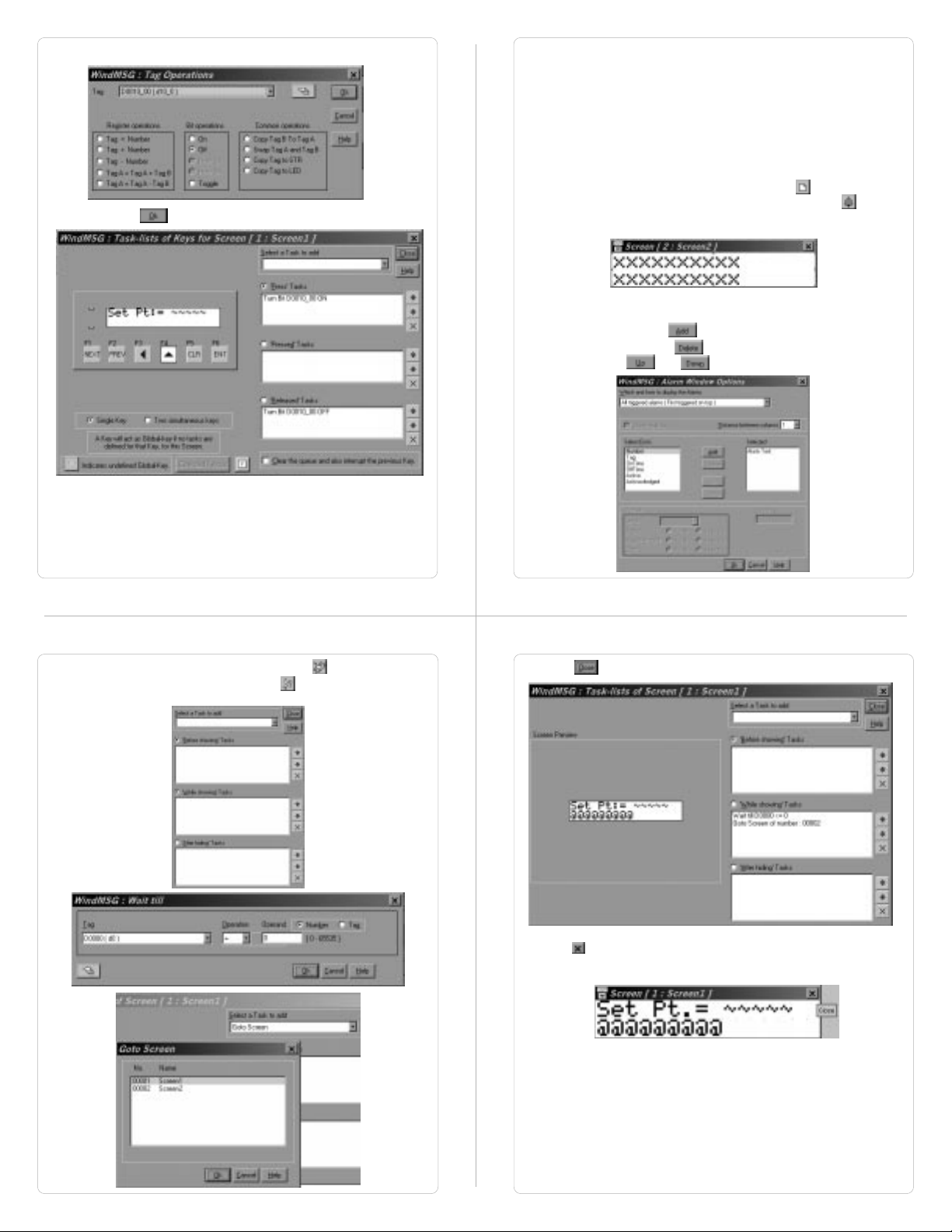

Page 25

Select Turn bit off task as ‘relesed task’ for the same key.

Select coil. Click to accept the task.

We want to display an alarm when bit 0 of tag D5 turns on. An alarm

object has to be placed on the screen so as to display alarm

condition. But as the space on the screen is limited we will create a

new screen, screen 2, with alarm object on it. This screen will be

triggered when the bit turns on. So in the While showing task list for

the screen no 1, a define ‘wait till’ task followed by ‘goto screen’ task.

So the screen 1 will be displayed till the alarm bit is off. Immediately

after the bit turns on the screen will change and display screen 2.

To create a new screen click on New screen icon . Enter essential

screen information. In screen 2, click on alarm object icon . Click

on the screen. Alarm object will be placed on the screen. Double click

the object to edit.

An alarm dialog box will be displayed. This window will enable user to

select text to be displayed whrn alarm is displayed. Select item from

‘Select From’ list and click . If any item is to be removed select

from ‘selected’ list and click . Sequence of selected items can be

adjusted using the and buttons.

Now go to screen no 1 using ‘select screen’ icon . To define while

showing task list, click on screen task icon . Select ‘While showing

Task’. Add ‘wait till’ and ‘goto screen’ tasks.

Now click to add the tasks to screen task list.

Now click to close screen dialog box.

Page 26

Now click alarm icon to define alarms. Alarm dialog box will

Click to define application Task-list for the application. Here we

be displayed.

Click to add alarms. We want to define only one alarm for tag

D5, so we will select ‘discrete’ Alarms tags. Select Group of alarms,

Tag of group, Alarm Number,

Alarm Text, Alarm Options.

Click to accept

alarms defined.

will define the power-up screen and Global Task-list if any. Select

task from the task-list.

Click to download application.

Select COM port.

Select Application.

Click to download application to HG1X - 252 unit.

Appendix B

Cable Diagrams

Page 27

IDEC Micro3 to HG1X Cable: Pin Configuration

IDEC Part # HG9Z-SCI25A

IDEC Micro Smart to HG1X Cable: Pin Configuration

IDEC Part # HG9Z-SCI25B

Micro3 PLC End

8 Pin Minidin

1

A

2

B

7

GND

8

VCC

HG9Z-SCI25A

HG9Z-SCI25A

HG1X End

DB9 Female

8

RXD

3

TXD

5

GND

5

SHIELD

6

VCC

7

DE

Micro Smart PLC End

8 Pin Minidin

TXD

RXD

GND

SHIELD

VCC

3

4

6,7

8

8

RXD

3

TXD

5

GND

SHIELD

6

VCC

HG1X End

DB9 Female

Programming Cable for HG1X: Pin Configuration

IDEC Part # HG9Z-125A

PC End

DB9 Female

TXD

RXD

GND

2

3

5

2

3

5

HG1X End

DB9 Male

RXD

TXD

GND

Koyo DL 205 to HG1X Cable: Pin Configuration

HG1X End

DB9 Female

TXD

RXD

GND

VCC

3

8

5

6

DL 205 End

6 x 6 Modular

Connector

3

RXD

4

TXD

1

GND

2

VCC

Loading...

Loading...