Page 1

WB2F 2D Code Scanner

User’s Manual

B-1952(0)

Page 2

Introduction

Attention

z

IDEC Corporation holds all rights related to this manual. Unauthorized duplication, reproduction, sales, transfers, or leasing without the express consent of IDEC is prohibited.

z

Information contained in this manual may be changed or updated without notice.

z

Every eort has been made to ensure the accuracy of the information contained in this manual. However, if you do note

any errors or inconsistencies please contact the dealer from which you purchased the product or an IDEC sales representative.

Applicable standards

This product is in compliance with the following standards:

z

IEC/EN 61000-6-1 (2007)

z

IEC 62471 (2006)

z

IEC 61000-6-3 (2006)

z

EN 61000-6-3 (2007)

z

EN 55032 (2012) Class A

z

EN 55024 (2010)

z

UL 60950-1, 2nd Edition, 2011-12-19

z

FCC Part 15 Subpart B Class A (Verication)

z

CSA C22.2 No.60950-1

z

ICES-003 Class A (self-declared)

z

VCCI Class A (compliance conrmed)

FCC Regulations

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in whitch case the user will be required to correct the interference at his own expense.

Canadian Department of Communications Compliance Statement

• CAN ICES-3(A) / NMB-3(A)

For further details on any of the above standards, please contact your sales agent directly.

i

Page 3

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

Introduction

Version Information

The following is the latest version information for the WB2F 2D Code Scanner. Prior to use, conrm the main application

version of the rmware currently installed on the WB2F.

To conrm the rmware version currently installed on the WB2F, refer to "No. 46 Main Application Version Information" of

[5.6 List of Control Commands] located on page 5-20.

Fixes and Improvements

Initial Release A-001.000.00

Main application version

WB2F-100S1B

ii

Page 4

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

Introduction

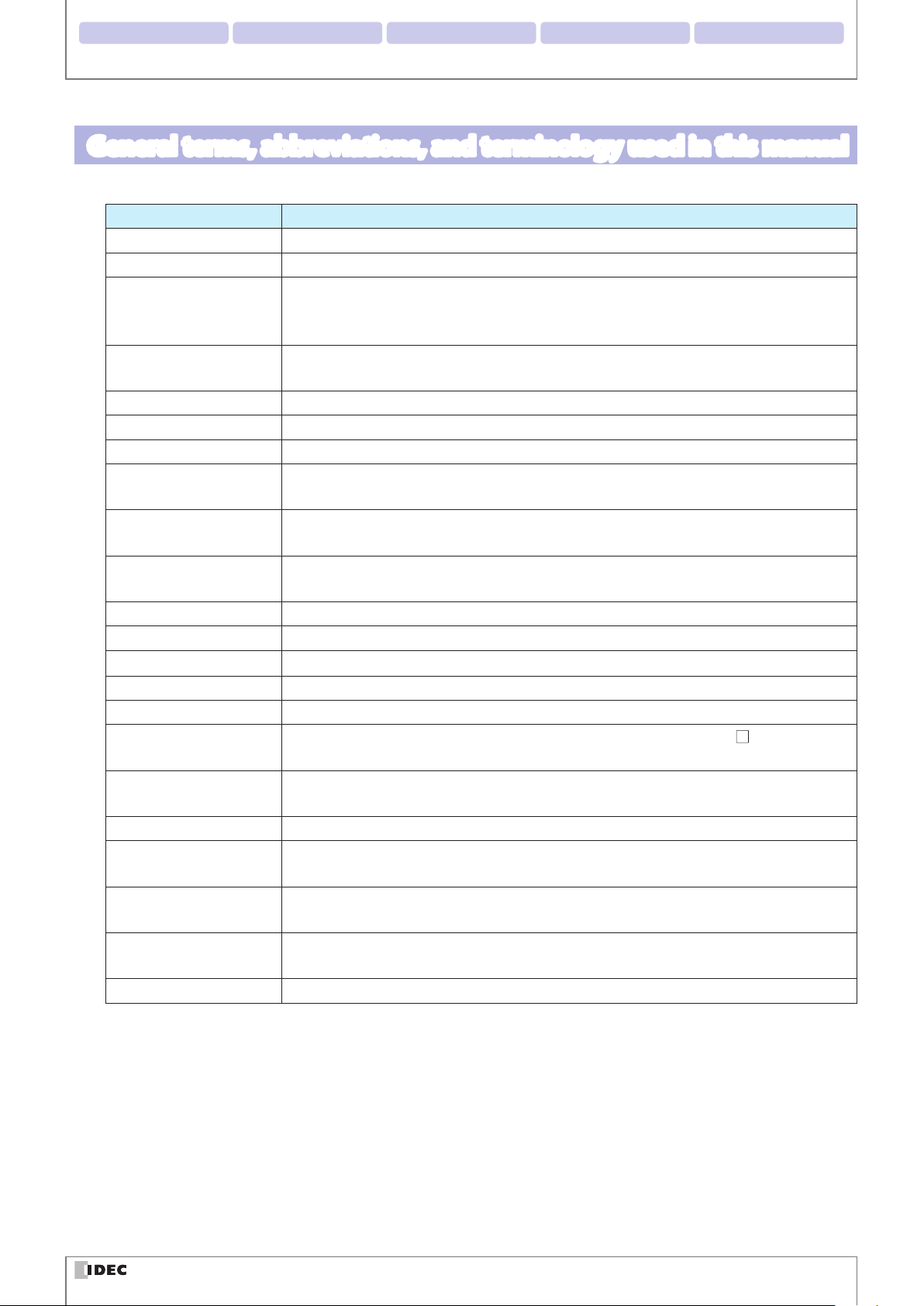

General terms, abbreviations, and terminology used in this manual

The general terms, abbreviations, and terminology used in this manual are as follows.

Item Denition

WB2F An abbreviation for the WB2F-100S1B.

Communication interface RS-232 Serial Communication Interface

Refers to the Communication Unit WB9Z-CU100 available for purchase separately. The

Communication Unit

Preventing Double Read

Time

Number of characters The sum of 1 byte codes either transmitted or received via the RS-232 interface.

AIM ID An abbreviation for AIM Symbology Identier

AI An abbreviation for Application Identier (standardized by GS1)

Pitch

Skew

Tilt

Reading Timeout A parameter that species the maximum time the WB2F will spend on reading a symbol.

Decode Timeout A parameter that species the maximum time the WB2F will spend on a decode processing.

Receive Buer A storage area that temporarily stores received data.

Send buer A storage area that temporarily stores transmission data.

Quiet Zone Blank region that surrounds the symbol

Control characters

Prex

Sux Character data that is added to the end of output data and communication commands.

Output

Input

DPM

IDEC website www.idec.com

WB9Z-CU100 is a protocol converter that allows the WB2F to connect to RS-232/RS-422/

Ethernet enabled devices.

A parameter that species a time interval between reads to prevent the WB2F from reading

the same code twice.

Rotation of the symbol around the y-axis. Refer to F [5. 2. 3 Angle Characteristics] on

page 5-5.

Rotation of the symbol around the x-axis. Refer toF [5. 2. 3 Angle Characteristics] on page

5-5.

Rotation of the symbol around the z-axis. Refer toF [5. 2. 3 Angle Characteristics] on page

5-5.

ASCII codes 00H - 1FH and 7FH. In this manual, they are expressed using

to F [5. 9 ASCII Code Table] on page 5-22.

Character data that is added to the beginning of output data and communication commands.

Depending on the context, refers to the following: External Output, Communication Output, Status LED

Depending on the context, refers to the following: READ/ENTER button, SELECT button, External Input, Communication Input

An abbreviation for Direct Part Marking. A process used to directly mark parts made out of

materials such as metal and resin with product information such as 2D codes.

. For details, refer

iii

Page 5

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

WarningWarning

CautionCaution

Graphic Symbol Glossary

This manual uses the following graphic symbols to simplify explanations:

Notes

Graphic Symbol Description

Failure to operate the product in accordance with the information provided may result in severe personal injury or death.

Failure to operate the product in accordance with the information provided may result in personal

injury or damage to equipment.

Notes information that should be carefully noted. Failure to operate the product in accordance with

the information provided may aect the appearance and performance of the main unit as well as any

peripheral devices.

Denotes additional information that may prove useful for using a given function.

Introduction

Status LED/Position Display LED

Graphic Symbol Description

(*)

(*)

(*)

* In case of Status LED, color will change based on status (green/orange/red). In case of Position LED, a number denoting

position (1/2/3/4) will be shown. In addition, the color of the graphic symbol will be drawn in accordance with the color

of the LED.

Indicates that the LED is turned OFF

Indicates that the LED is turned ON

Indicates that the LED is Flashing

iv

Page 6

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

WarningWarning

CautionCaution

WarningWarning

Introduction

SAFETY PRECAUTATIONS

z

Before installing and wiring this product, operating it, or performing maintenance and inspection, read this manual

carefully and use the product correctly.

z

The degree of possible danger that may occur if the product is mishandled is classied and denoted by "Warning"

and "Caution" symbols. The meaning of each is as follows.

Failure to operate the product in accordance with the information provided may result in severe

personal injury or death.

Failure to operate the product in accordance with the information provided may result in personal injury or damage to equipment.

Safety precautions

z

This product was not designed for use in applications that require a high safety and reliability

standard such as in medical equipment, equipment related to nuclear power, transportation

equipment and devices related to rail, aviation and automotive products. Please do not use

this product for these and/or similar applications.

z

When using this product in applications that may impact human life, such as in the management of chemicals, only do so after taking the utmost care to include all redundancies, failsafes and safety features into the design so as to ensure that human life is not impacted even

if data is mistaken.

z

Do not modify, disassemble, or attempt to repair this product. Doing so may result in electrical shock, damage, re, malfunctions and other other serious accidents.

z

When using this product in situations where it is not built into other equipment, do not use

an integrated power supply. Otherwise there is a risk of re or electric shock.

z

Do not look directly at the scan window or direct the scanner towards other people's eyes

while the LED light is on. There is a risk of causing damage to the eyes.

z

This product has been designed for use in general electronic equipment only. It is not authorized for use in applications that require a high safety/reliability standard where malfunction

or failure of the product may result in severe personal injury or death.

z

Always turn the power supply o before performing any wiring, or mintenance work. Failure

to do so may result in electric shock or malfunction.

v

Page 7

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

CautionCaution

CautionCaution

Introduction

z

Do not connect the product to a power supply outside the rated power supply voltage range

or to an AC power supply. Otherwise there is a risk of explosion or burnout.

z

Mistakenly wiring the product may cause the internal circuit to be damaged. Wire the input

and output circuits by referring to the connection examples in F P. 2-5 "2. 3. 1 Wiring the RS232 type". This product is not equipped with a protection circuit for a reversed power supply

connection, so there is a risk of damage when the power supply connection is reversed. Use

extreme caution when connecting the power supply.

z

Avoid parallel wiring of the product's wires in the same conduit or duct with high voltage

lines or power lines (inverter power lines in particular) as this may cause malfunction or damage due to the eect of induction noise.

z

If the wires are long and when there is a risk of being aected by power sources or solenoids,

independently wire the product as a general rule.

z

Avoid installing or using the product in the following locations as there is a risk of malfunction or damage.

- Near induction equipment or heat sources

- Locations with many vibrations or shocks

- Dusty and dirty locations

- In an atmosphere with hazardous gases such as suldizing gas

- Locations in direct contact with water, oils, or chemicals

- Outdoors

z

This product is not an explosion-proof product. Conrm that explosion-proof capabilities are

not required when installing the product.

Precautions for Use

z

Use the product in the environment listed in the catalog and manual. If this product is used

in locations with high temperatures, high humidity, condensation, corrosive gas, or excessive

vibration/shock, there is a risk of electric shock, re, and malfunction.

z

The usage environment pollution degree for this product is "pollution degree 2". Use the

product in a pollution degree 2 environment.

(Based on the IEC 60664-1 standard)

z

The power reset time is under 5s. Perform operations 5s after turning the power on.

z

When the load and the unit are connected to dierent power supplies, always turn on the unit's power

supply rst.

z

Install the product so that the scan window is not directly exposed to sunlight or uorescent light.

z

The non-volatile memory equipped on the WB2F can be overwritten 100,000 times.

vi

Page 8

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

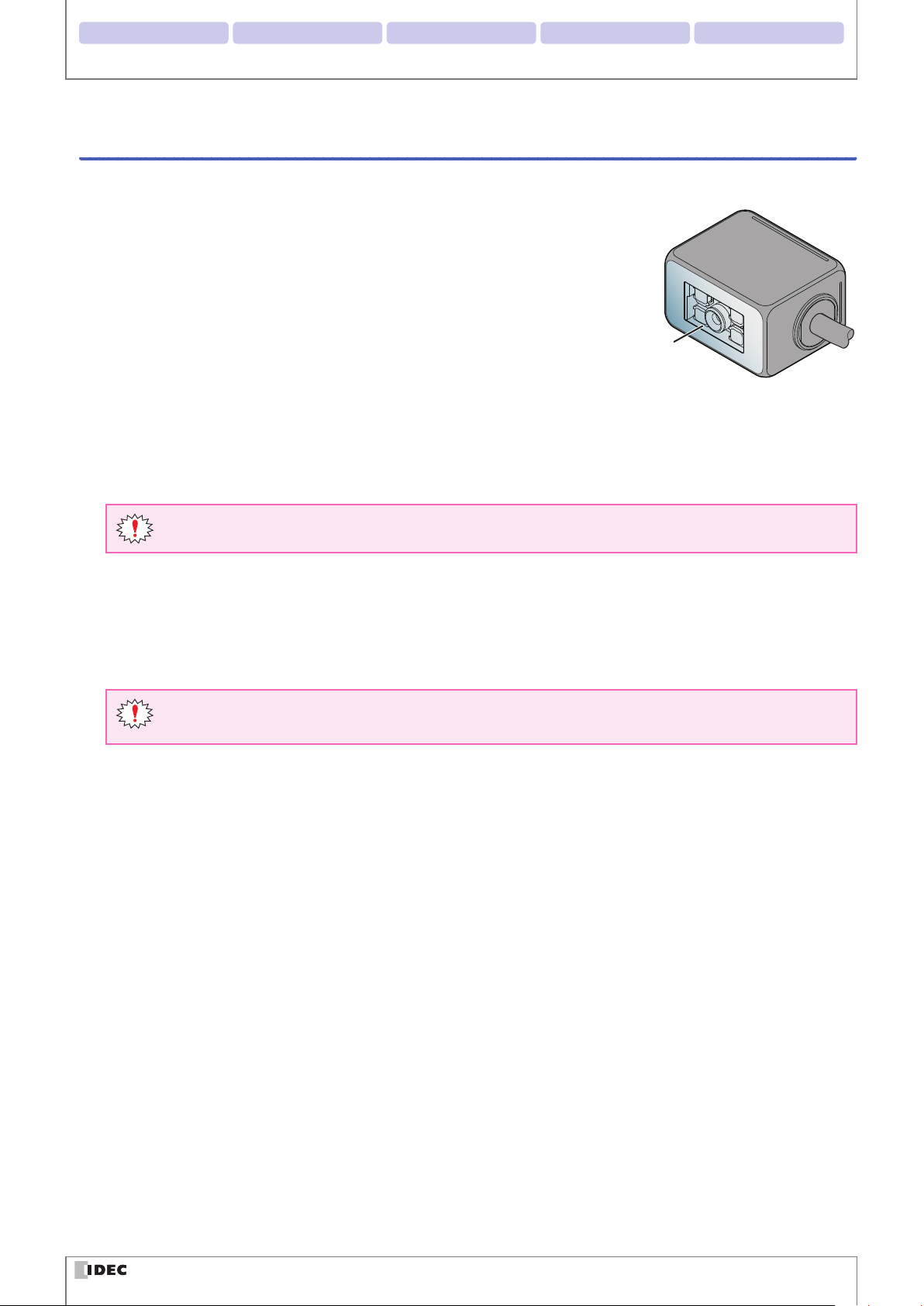

Introduction

Cleaning

zCleaning the Scan Window

Keep the scan window free of dust, dirt, moisture and scratches as it will negatively

aect scanning performance.

Inspect the scan window periodically and remove any dirt or dust that may have

accumulated.

Scan Window

Cleaning methods

z

To clean the scan window, blow the dust/dirt away with an airbrush, and then gently wipe it o with a cotton swab or a

similarly soft object.

z

If moisture has collected on the scan window, wipe with a soft cloth.

z

Always turn the WB2F power o before cleaning the product.

Do not use organic solvents such as alcohol, thinner or benzene as they may aect the optics of the WB2F.

zCleaning the unit

z

Wipe any dust or dirt o of the WB2F with a soft, dry cloth.

z

If the product is excessively dirty, wipe the surface with a soft cloth that has been soaked in a dilute neutral detergent

solution and thoroughly wrung out. Dry with a soft dry cloth.

Do not use organic solvents such as alcohol, thinner, or benzine as this may alter the housing or strip the

paint.

vii

Page 9

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

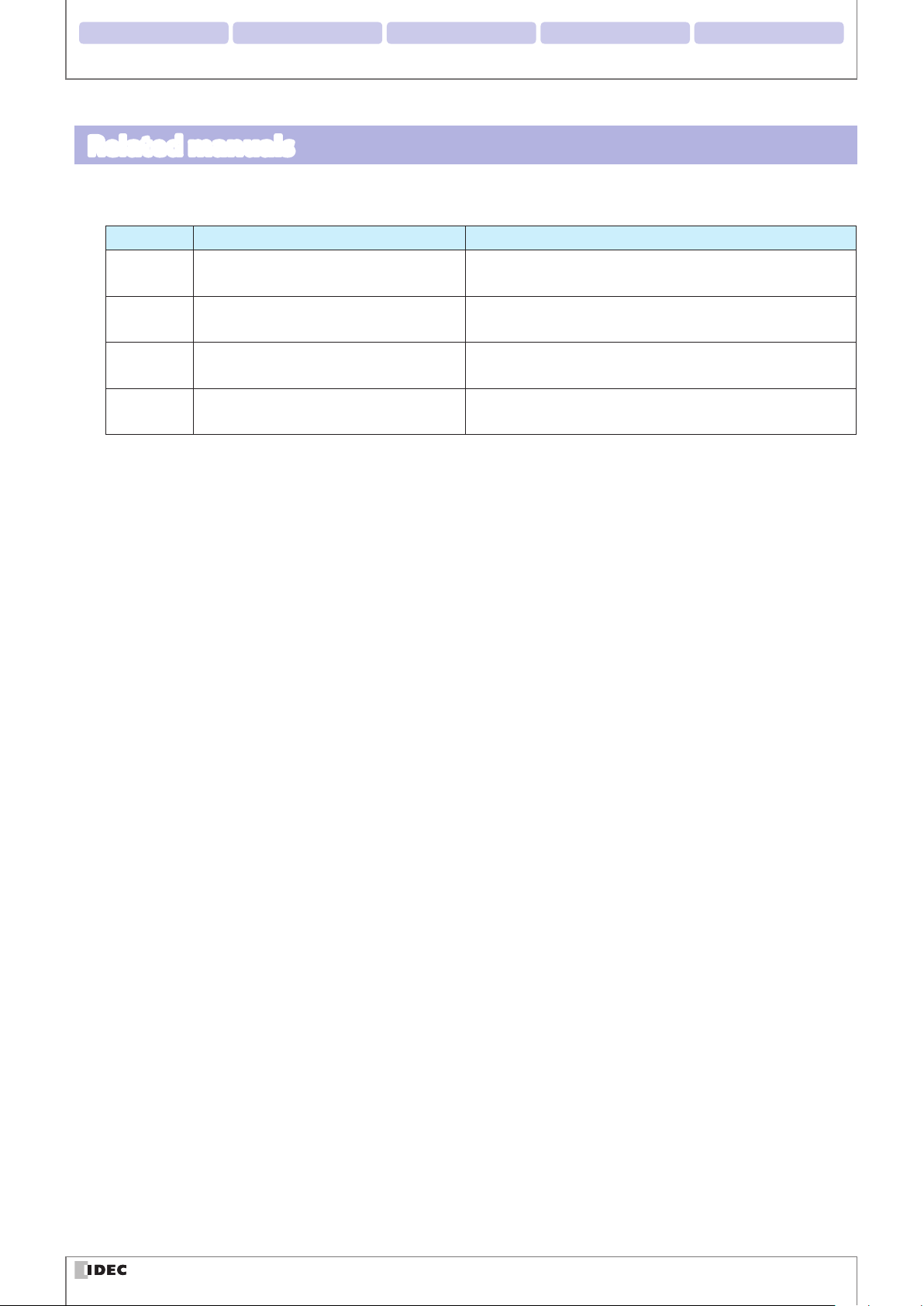

Related manuals

Manuals related to the WB2F are as follows. Refer to them together with this manual.

All related manuals are available for download from our website.

Type Manual name Details

B-1952

B-1945

B-1946

B-1963

WB2F 2D Code Scanner

User’s Manual (this manual)

Instruction Sheet:

WB2F 2D Code Scanner

Instruction Sheet:

WB9Z-CU100 Communication Unit

WB9Z-CU100 Communication Unit

User’s Manual

Gives an overview of the functions and capabilities of the

WB2F, and instructions on its use.

Included with the product.

Included with the product.

Gives an overview of the functions and capabilities of the

communication unit as well as instructions on its use.

Introduction

viii

Page 10

Contents

Introduction i

Attention .............................................................................................................................................................. i

Applicable standards ....................................................................................................................................... i

Version Information ........................................................................................................................................ii

General terms, abbreviations, and terminology used in this manual ..........................................iii

Graphic Symbol Glossary .............................................................................................................................iv

Notes ..................................................................................................................................................................................... iv

Status LED/Position Display LED ................................................................................................................................. iv

SAFETY PRECAUTATIONS ..............................................................................................................................v

Safety precautions .............................................................................................................................................................v

Precautions for Use .......................................................................................................................................................... vi

Cleaning .............................................................................................................................................................................. vii

Related manuals ........................................................................................................................................... viii

Contents ix

Overview 1-1

1

1. 1 Checking the packaged product and the product conguration ...............................1-1

1. 2 Part names and functions ..........................................................................................................1-2

1. 3 System conguration ..................................................................................................................1-3

1. 4 Accessories and Peripheral Devices .......................................................................................1-5

Installation & wiring 2-1

2

2. 1 Installation precautions ..............................................................................................................2-1

2. 2 Mounting methods ......................................................................................................................2-3

2. 2. 1 WB2F mounting methods ..................................................................................................................... 2-3

2. 2. 2 Setup symbol position ............................................................................................................................ 2-4

2. 3 Wiring ................................................................................................................................................2-5

2. 3. 1 Wiring Instructions: Connecting the WB2F to the Communication Unit ............................. 2-5

2. 3. 2 Wiring Instructions: Setting up the WB2F without the Communication Unit .................. 2-12

2. 3. 3 Connecting the USB Cable ..................................................................................................................2-15

ix

Page 11

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

Operational Check 3-1

3

3. 1 Performing an Operational Check using a PC ....................................................................3-1

3. 1. 1 Necessary operating environment of the PC ................................................................................ 3-1

3. 1. 2 Installing the Device Driver ................................................................................................................... 3-1

3. 1. 3 Connecting to a PC .................................................................................................................................. 3-2

3. 2 Conrming a Successful Read ..................................................................................................3-3

3. 3 Symbol Read Data Conrmation .............................................................................................3-4

Function 4-1

4

4. 1 Overview ..........................................................................................................................................4-1

Contents

4. 1. 1 Operation mode ........................................................................................................................................ 4-1

4. 1. 2 Operation mode switching operation and status.........................................................................4-3

4. 2 Slave Mode ......................................................................................................................................4-4

4. 2. 1 Switching operation to slave mode ................................................................................................... 4-4

4. 2. 2 Symbol reading ......................................................................................................................................... 4-5

4. 2. 3 Output data additional information ................................................................................................4-15

4. 2. 4 Output data editing ...............................................................................................................................4-20

4. 2. 5 Verication ................................................................................................................................................ 4-22

4. 2. 6 Command alias ........................................................................................................................................4-26

4. 2. 7 Communication command .................................................................................................................4-28

4. 2. 8 Parameter Changeover .........................................................................................................................4-31

4. 2. 9 Image Capture .........................................................................................................................................4-34

4. 2. 10 Image Filter ...............................................................................................................................................4-37

4. 2. 11 I/O ................................................................................................................................................................. 4-40

4. 3 Setup support mode ................................................................................................................. 4-41

4. 3. 1 Switching operation to setup support mode ...............................................................................4-41

4. 3. 2 Reading Success Rate Measurement ...............................................................................................4-44

4. 3. 3 Decoding Processing Time Measurement .....................................................................................4-45

4. 3. 4 Symbol Position Measurement ..........................................................................................................4-46

4. 3. 5 Autotuning ................................................................................................................................................4-48

4. 4 Maintenance mode ................................................................................................................... 4-50

4. 4. 1 Switching operation to maintenance mode ................................................................................. 4-50

4. 4. 2 Maintenance support ............................................................................................................................4-52

4. 4. 3 Firmware updating .................................................................................................................................4-52

4. 5 Master Mode ................................................................................................................................ 4-53

4. 5. 1 Switching to Master Mode ..................................................................................................................4-53

4. 5. 2 Connecting to a PLC ..............................................................................................................................4-53

x

Page 12

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

4. 6 Conguration Item Table ......................................................................................................... 4-54

4. 7 Communication Unit ................................................................................................................ 4-93

4. 7. 1 Overview .................................................................................................................................................... 4-93

4. 7. 2 Names and functions of its parts ......................................................................................................4-94

Appendix 5-1

5

5. 1 Product specications .................................................................................................................5-1

5. 2 Field of view/characteristics ......................................................................................................5-3

5. 2. 1 Reading Range........................................................................................................................................... 5-3

5. 2. 2 Field of View ................................................................................................................................................ 5-4

5. 2. 3 Angle Characteristics ............................................................................................................................... 5-5

Contents

5. 3 Dimensional outline drawings .................................................................................................5-7

5. 4 Troubleshooting ............................................................................................................................5-9

5. 5 Timing Chart ................................................................................................................................ 5-10

5. 5. 1 Scan Operation Timing Chart ............................................................................................................. 5-10

5. 5. 2 External Output Timing Chart ............................................................................................................ 5-11

5. 6 List of Control Commands ...................................................................................................... 5-13

5. 7 Control Commands (Details) ..................................................................................................5-17

5. 8 Check digit calculation method ............................................................................................ 5-21

5. 9 ASCII Code Table ......................................................................................................................... 5-22

5. 10 AIM symbology ID table .......................................................................................................... 5-24

5. 11 GS1-128 Application Identier .............................................................................................. 5-26

5. 12 Initialization Barcode ................................................................................................................ 5-27

5. 13 Sample labels...............................................................................................................................5-28

5. 14 Installing the USB driver .......................................................................................................... 5-31

5. 15 Setting check digit ..................................................................................................................... 5-32

Index A-1

Revision history A-3

xi

Page 13

1

This chapter describes the product conguration of the WB2F, the names and functions of its parts, and the basic system

conguration during operation.

Overview

1. 1

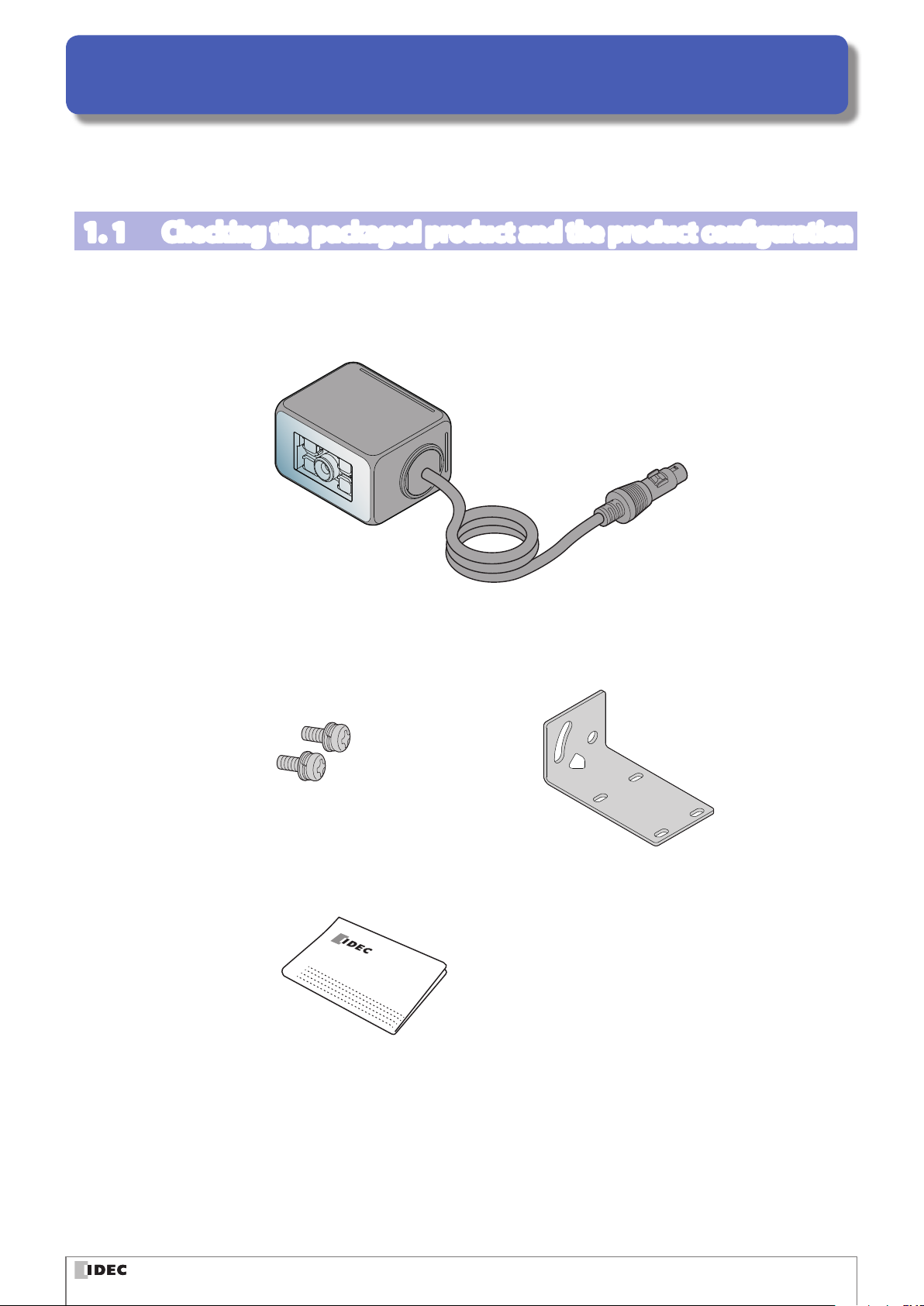

The WB2F is packaged with the following items:

Before using the WB2F, check that the unit and accessories are present and that they have suered no damage.

Checking the packaged product and the product conguration

Unit: 1

Mounting screws (M3): 2

the WB2F is shipped with the

mounting screws attached

Mounting Bracket: 1

Instruction Manual: 1

INSTRUCTION SHEET

WB2F 2D Code Scanner

1-1

Page 14

2. Installation & wiring 3. Operational Check 4. Support tool 5. AppendixOverview

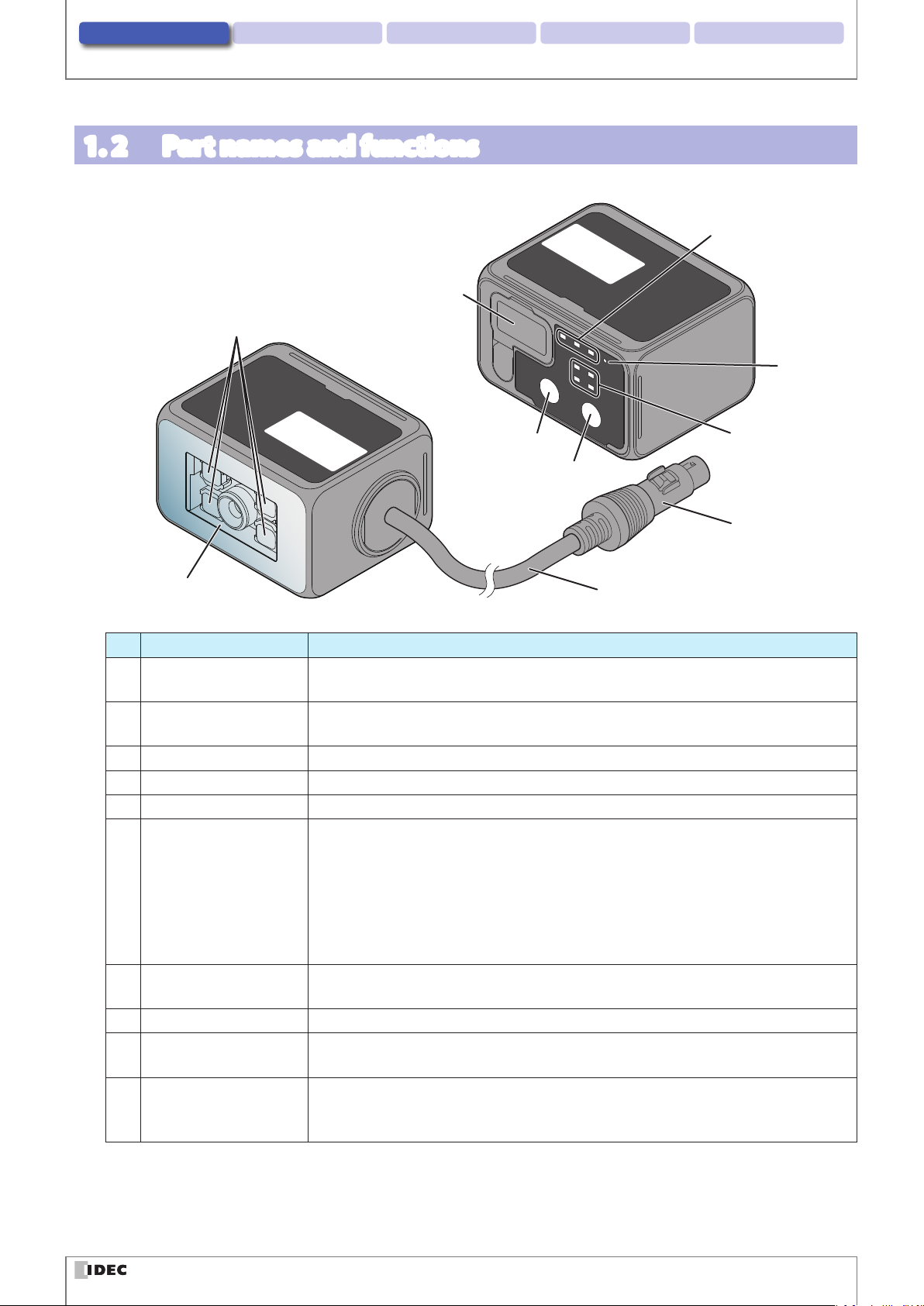

1. 2 Part names and functions

This section describes the names and functions of WB2F parts.

(10)Maintenance Port (USB)

(2)Emitter LED

Scanner

Operational

Surface

(3)SELECT button

(4)READ/ENTER button

Part names and functions

(6)Status LED

(5)Power-ON

Indicator LED

(7)Position LED

Scanner

Reading

Surface

(1)Scan Window

No. Description Function

(1) Scan Window

(2) Emitter LED

(3) SELECT button Used to select various functions

(4) READ/ENTER button Used to conrm various functions that have been selected

(5) Power-ON Indicator LED Green LED will light up when the WB2F's power is on

(6) Status LED

(7) Position LED

(8) Connecting cable Cable length: 2 m

(9) Connector

(10) Maintenance Port (USB)

The window protects the optical components of the WB2F from dust, debris and moisture.

Lights up during scan operation (based on settings, this is not the only time it will light

up) Lighting modes, the number of LEDs that light up etc. can be altered via settings.

The Status LED indicates the operating status of the unit.

(Green): Turns on when reading has succeeded and the read image is matched on com-

parison.

(Orange) : Turns on during a reading operation.

(Red): Turns on when reading fails and the read image is not matched on comparison.

This operation may dier due to the settings.

The status of the Status LEDs also changes due to the unit's operating status.

Displays the Position of the symbol. (1) - (4): The position of the symbol placed in the

WB2Fs FOV will light up on the LED display.

DIN Connector (manufactured by Hosiden, TCP9386, Male) used to provide power to the

WB2F, or connect to the communication unit.

Port that utilizes the USB interface to perform various maintenance operations (USB 2.0,

Mini-B). If connecting to a host device, use its accessory or any commercially available

USB cable.

(8)Connecting cable

(9)Connector

1-2

Page 15

2. Installation & wiring 3. Operational Check 4. Support tool 5. AppendixOverview

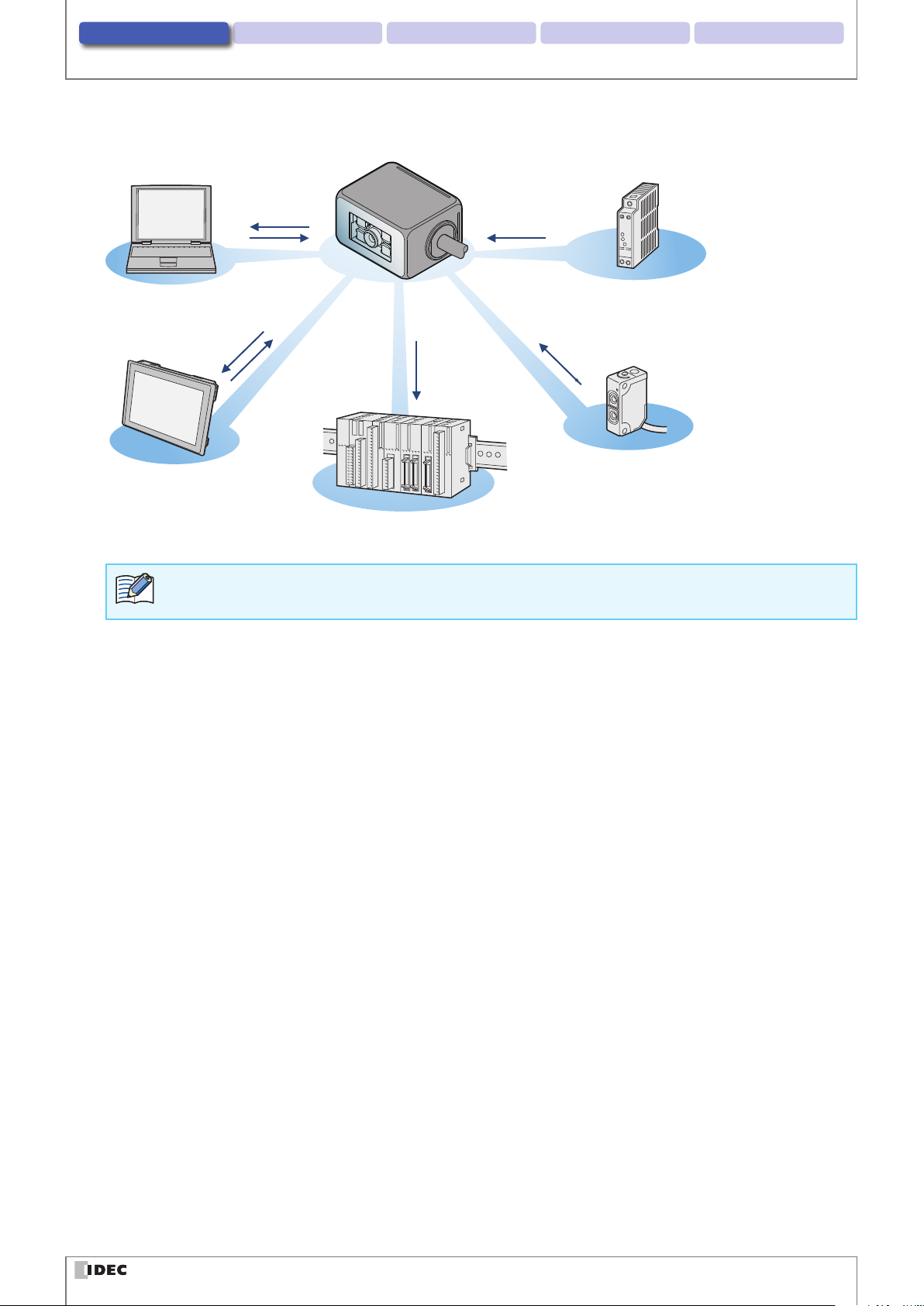

1. 3 System conguration

The typical system conguration when operating the WB2F is as follows.

With the Communication Unit

USB

(for Maintenance

Purposes)

WB2F

PC

5V DC power supply

RS-232

I/Os

(DIN Connector)

System conguration

24V DC

Power Supply

Communication Unit

RS-232

RS-422

Ethernet

External Output

Host device

PLC, External Light Source

24V DC Power Supply

External Input

Sensor

The device driver must be installed prior to connecting the WB2F to a PC via USB. Refer to F [5. 14 Installing

the USB driver] on page 5-31 for installation instructions.

1-3

Page 16

2. Installation & wiring 3. Operational Check 4. Support tool 5. AppendixOverview

Without the Communication Unit

USB

(for Maintenance

Purposes)

System conguration

5V DC Power Supply

PC

WB2F

RS-232

External Output

Host device

PLC, External Light Source

5V DC Power Supply

External Input

Sensor

The device driver must be installed prior to connecting the WB2F to a PC via USB. Refer to F [5. 14 Installing

the USB driver] on page 5-31 for installation instructions.

1-4

Page 17

2. Installation & wiring 3. Operational Check 4. Support tool 5. AppendixOverview

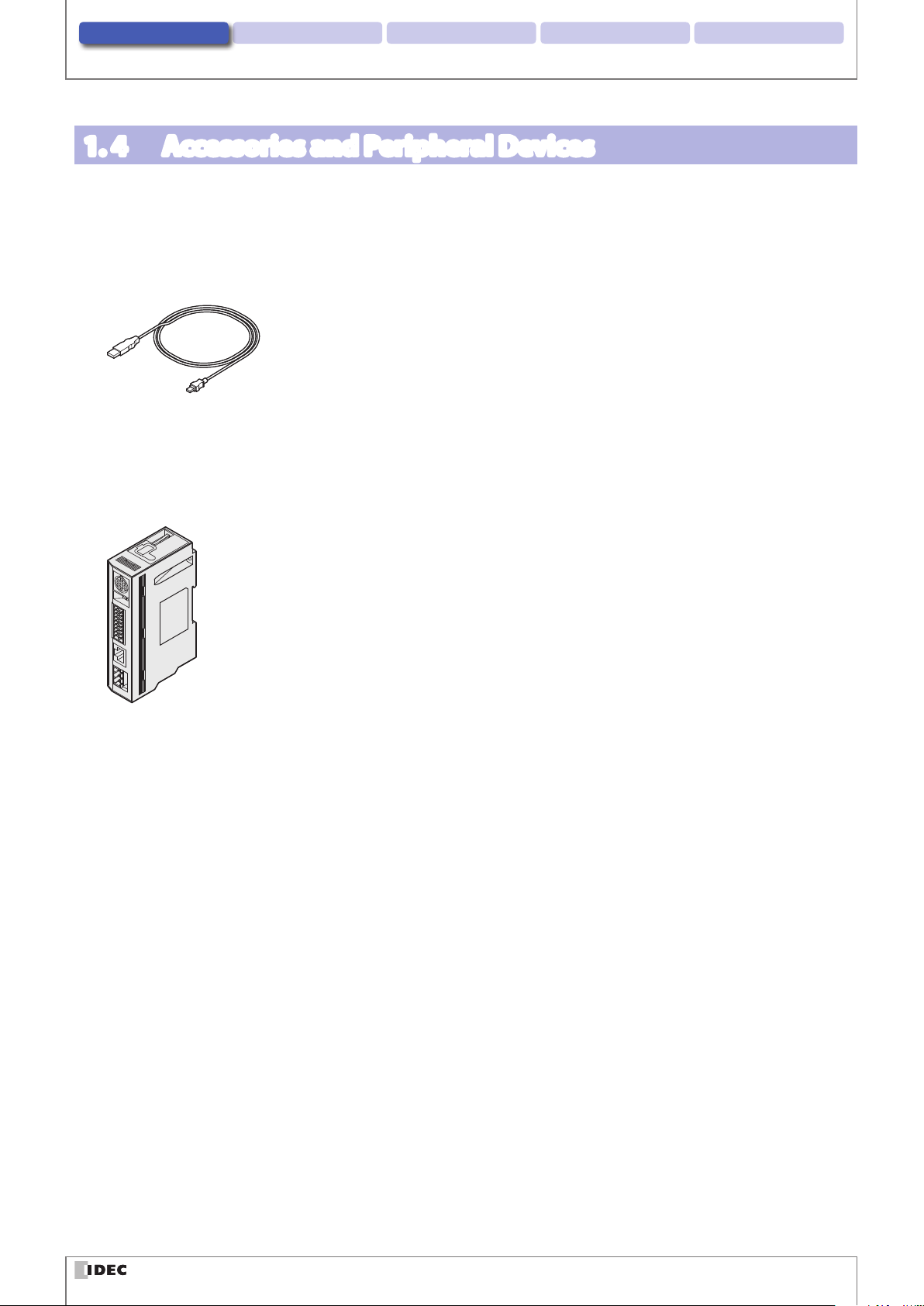

1. 4 Accessories and Peripheral Devices

The WB2F's accessories and peripheral devices are as follows:

zAccessories

USB Maintenance Cable

HG9Z-XCM42

zPeripheral Devices

WB2F compatible communication unit

WB9Z-CU100

Accessories and Peripheral Devices

1-5

Page 18

2

This chapter describes WB2F installation locations, mounting methods, and wiring the WB2F to peripheral devices.

Installation & wiring

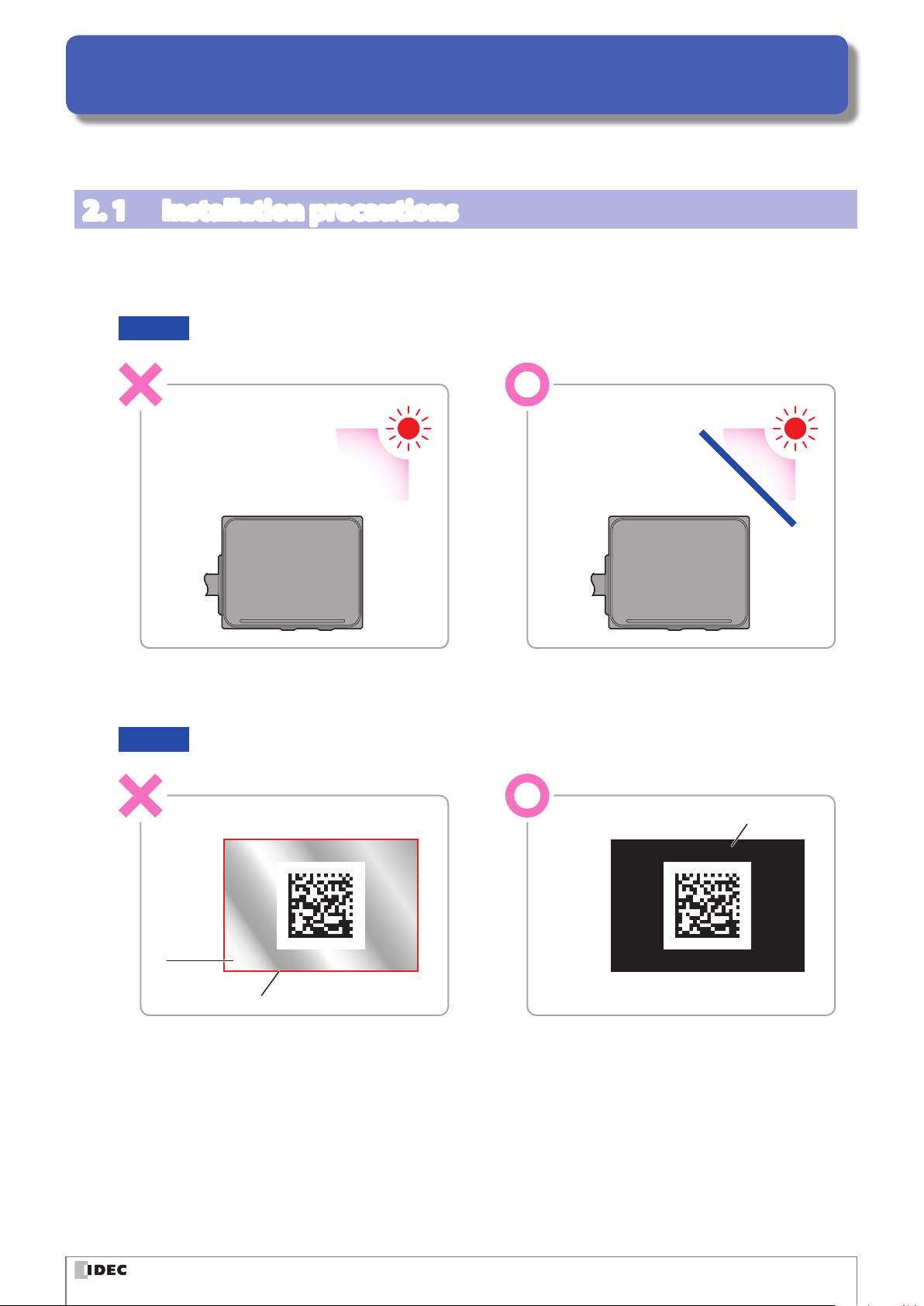

2. 1 Installation precautions

z

Install the unit so that ambient light such as sunlight, uorescent light, and photoelectric switches does not enter the

scan window.

Otherwise the unit may not be able to read symbols or it may erroneously read them.

Example Take measures to block ambient light or to change the position of photoelectric switches.

Block

the light

z

Do not install a reective body (metal or mirror) along the light receiving axis.

Otherwise the unit may not be able to read symbols or it may erroneously read them.

Example Tape over any mirrored/reective surfaces with black tape to prevent the reection of light.

Black tape

Mirror

Field of view

2-1

Page 19

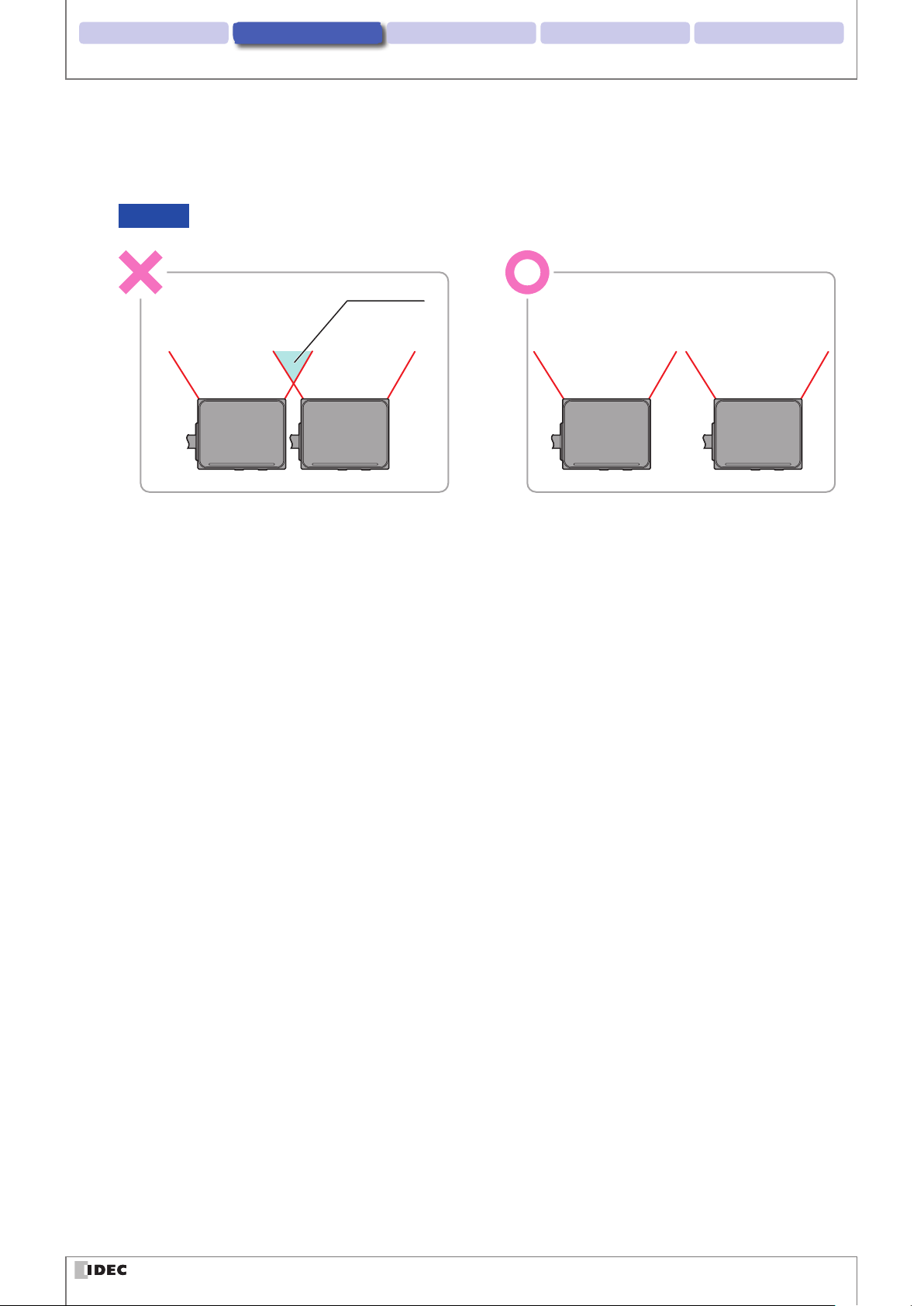

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

Installation precautions

z

When installing WB2F units in a series, install them so the emitted LED light does not overlap (so they do not interfere

with each other).

Otherwise the unit may not be able to read symbols or it may erroneously read them.

Example Install the WB2F units by increasing the spacing between them.

Interference

2-2

Page 20

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

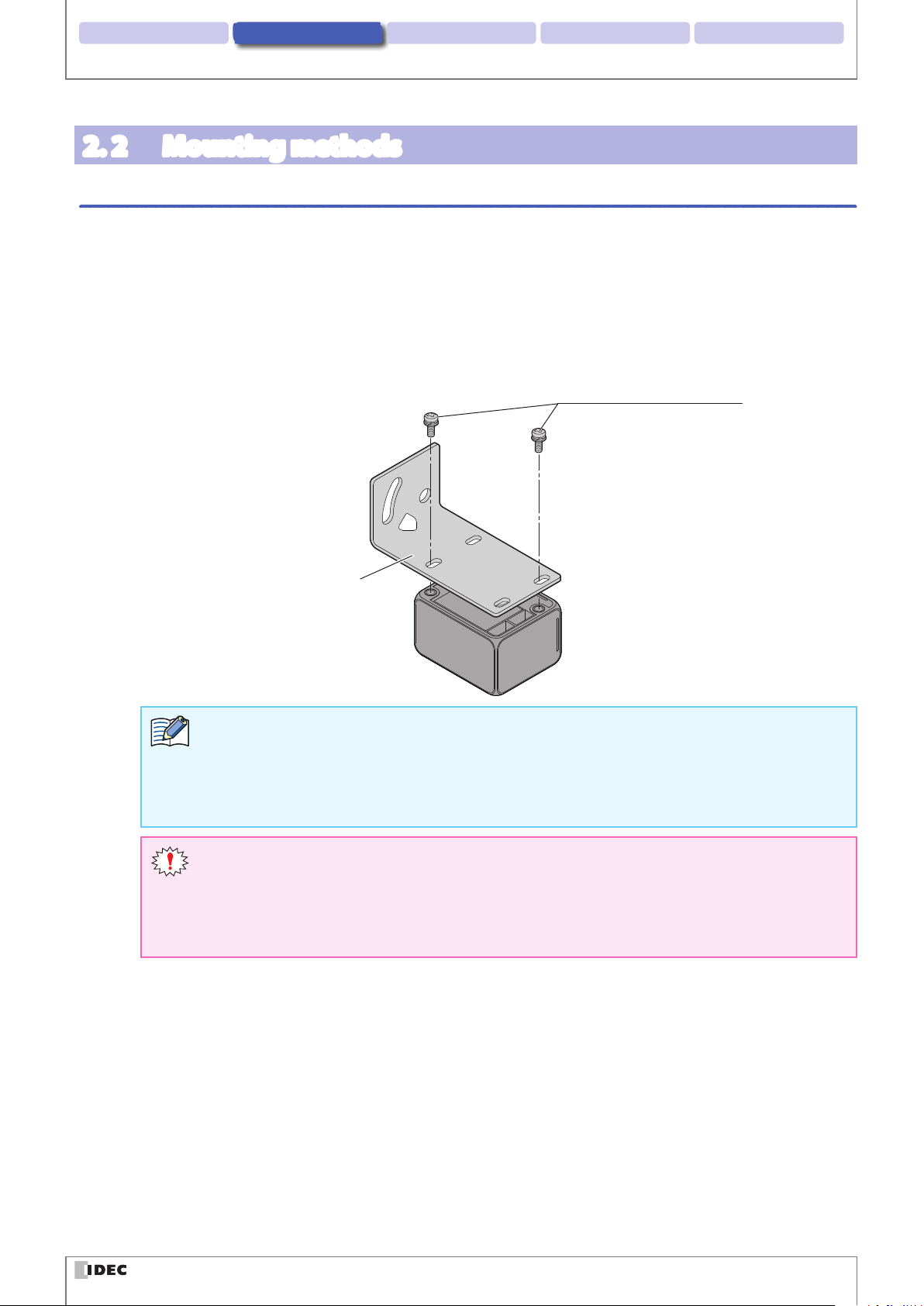

2. 2 Mounting methods

2. 2. 1 WB2F mounting methods

Double check the dimensions of the mounting hole and drill a hole in the mounting board

1

For the dimensions of the mounting hole, refer to F [5. 3 Dimensional outline drawings] on page 5-7.

Mounting methods

If you use the brackets provided, use the two mounting screws (also provided) to secure the bracket to

2

WB2F before you secure the bracket to the mounting board.

If you do not use the brackets provided, use the two mounting screws to secure the WB2F to the mounting

board.

The tightening torque for the product mounting screws is 0.4 to 0.5 N·m.

Mounting Screws (Included)

M3 SEMS x 6 (2 screws)

Mounting Bracket

(Included)

z

Instead, use two M3 screws with an eective thread length of 3 to 5 mm and secure the WB2F to the

plate.

z

If you use a bracket other than the one that was included, make sure that the dimensions of the

mounting holes is at most Φ3.4mm

z

When using the WB2F, remove the protective lm on the scan window.

the

z

If you attach to a plate that is thicker than 2.3 mm, do not use the included mounting screws.

z

If, during installation, the WB2F is exposed to excessive force (e.g. the mounting screws are

tightned excessively, the product is hit with a hammar, the base of the cable is exposed to excessive stress (pulled strongly, bent etc.)), it could undermine the IP65 protective structure of the

WB2F.

2-3

Page 21

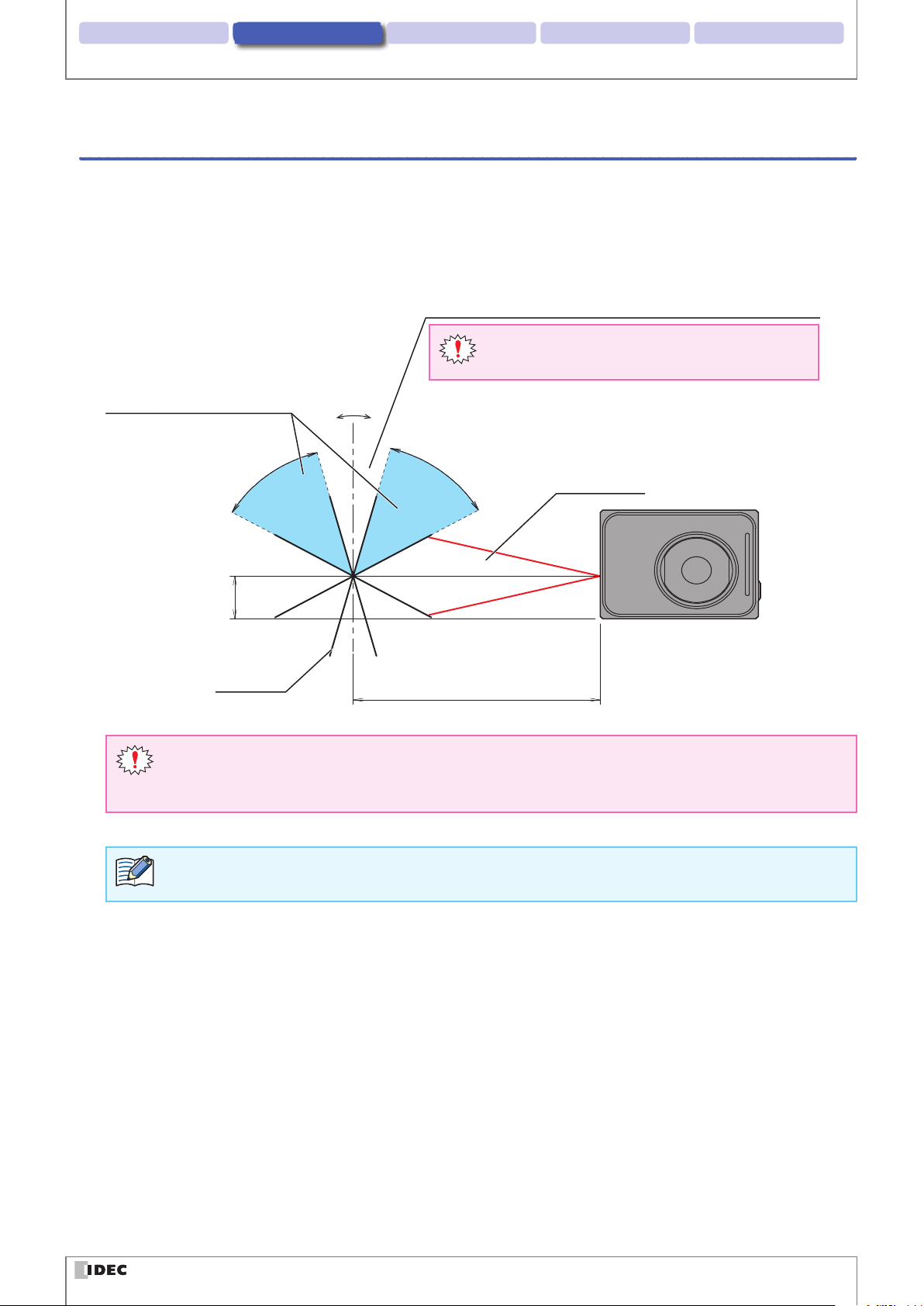

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

Mirror reflection area (dead zone)

Setup symbol position range

Mounting methods

2. 2. 2 Setup symbol position

Install the unit so that symbol skew θ is in the range of +15° ≤ θ ≤ +60° and -60° ≤ θ ≤ -15°.

For the reading range, refer to F [5. 2. 1 Reading Range] on page 5-3. For other angular characteristics, refer to F

[5. 2. 3 Angle Characteristics] on page 5-5. For detailed dimensions, refer to F [5. 3 Dimensional outline drawings] on

page 5-7.

e.g. Changing Emitter LED pattern to 4

Do not read symbols in the skew range -15° < θ <

+15°.

θ

+

+15 to +60°

-

-

15 to -60°

Field of view

z

z

To adjust the WB2F's position while conrming the symbol's read success rate, follow the steps described in

F

9.4mm

Symbol

Skew in a range of -15° < θ < +15° is in the mirror reection area (dead zone), so reading performance

100mm

may drastically decrease in ways such as the unit not being able to read or misreading symbols

The mirror reection area (dead zone) will dier based on the emitter LED's lighting pattern.

[4. 3 Setup support mode] on page 4-41.

2-4

Page 22

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

Wiring

2. 3 Wiring

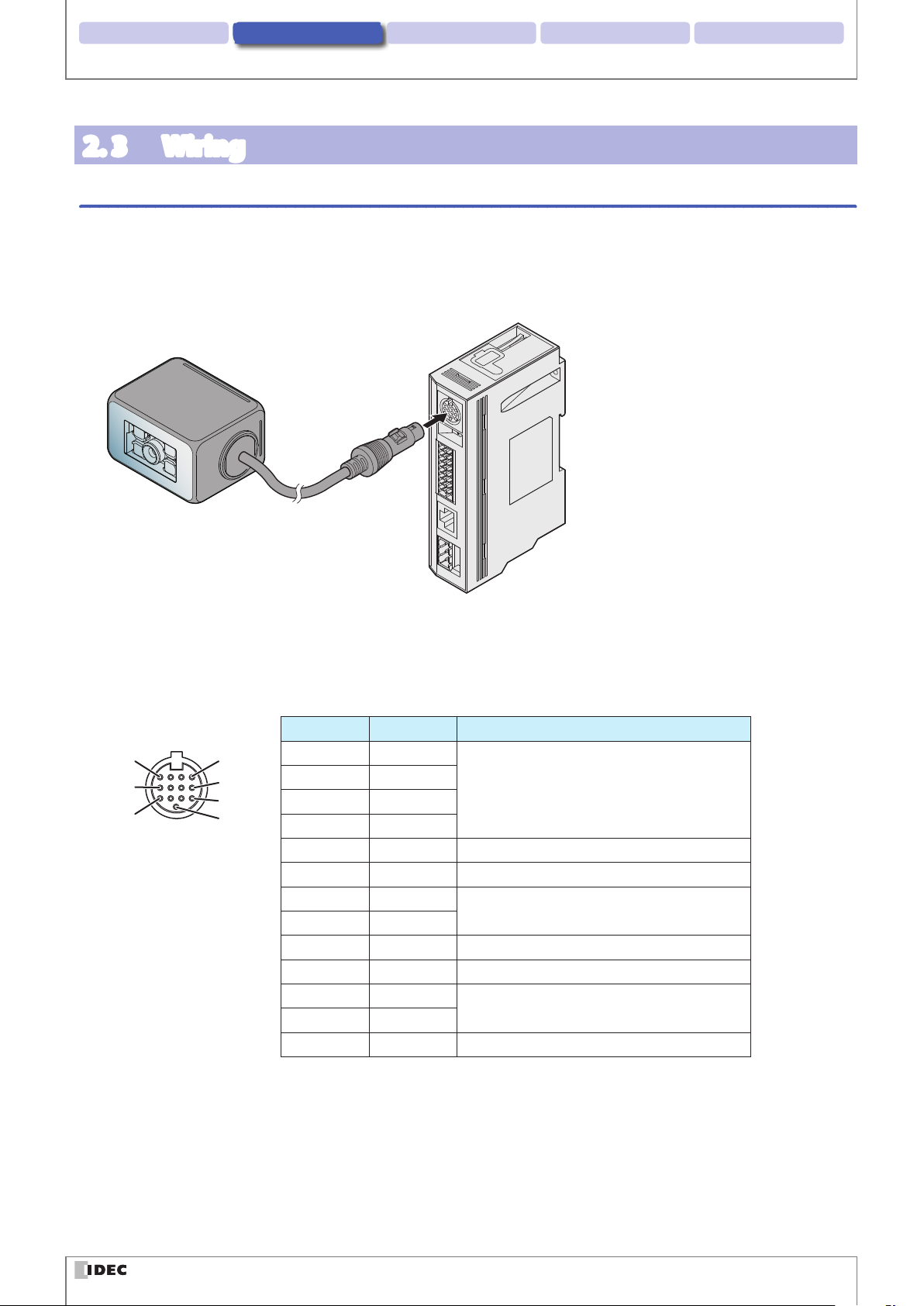

2. 3. 1 Wiring Instructions: Connecting the WB2F to the Communication Unit

For an overview of the communication unit refer to F [4. 7 Communication Unit] on page 4-93. For dimensions of the

communication unit refer to F [5. 3 Dimensional outline drawings] on page 5-7.

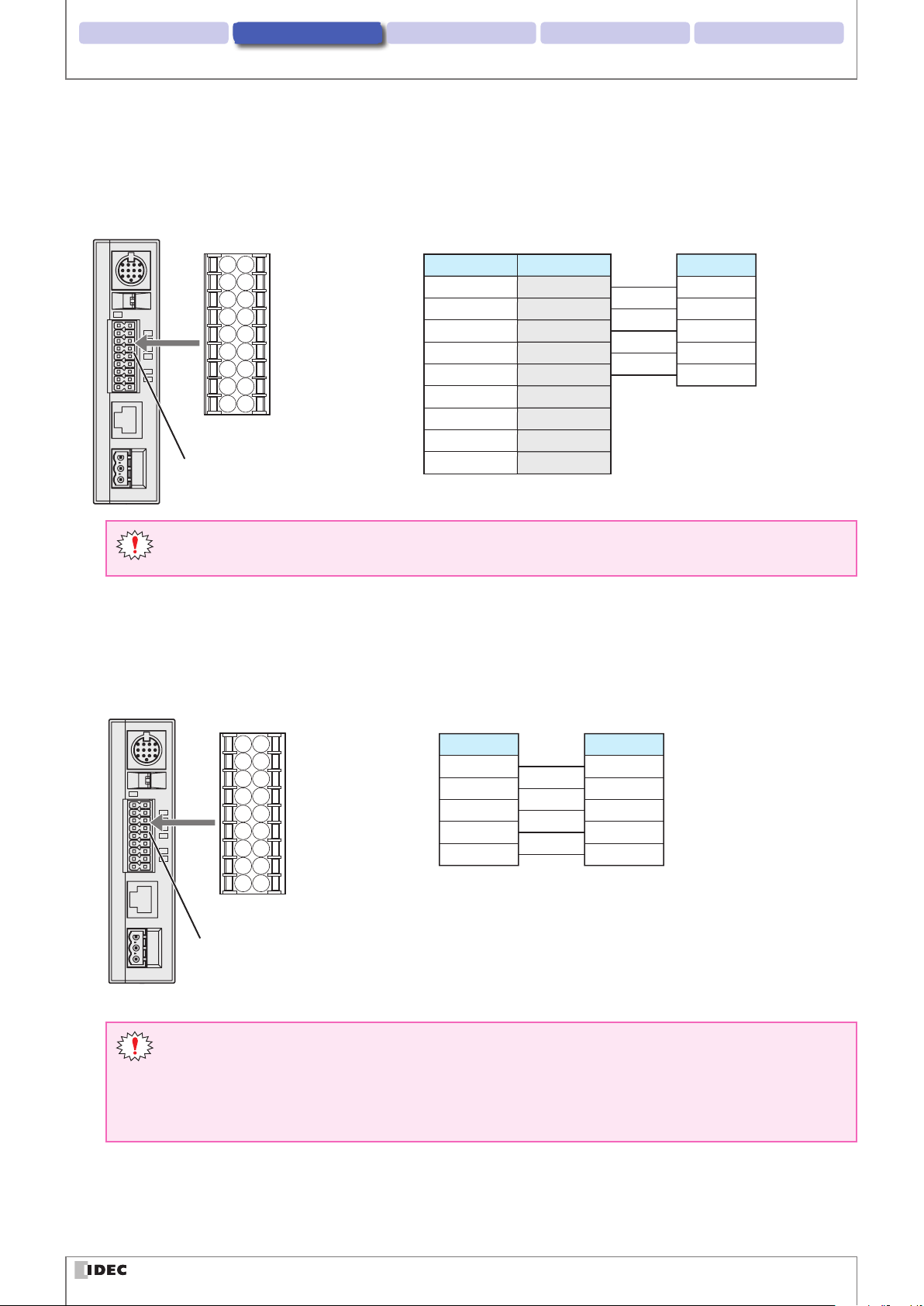

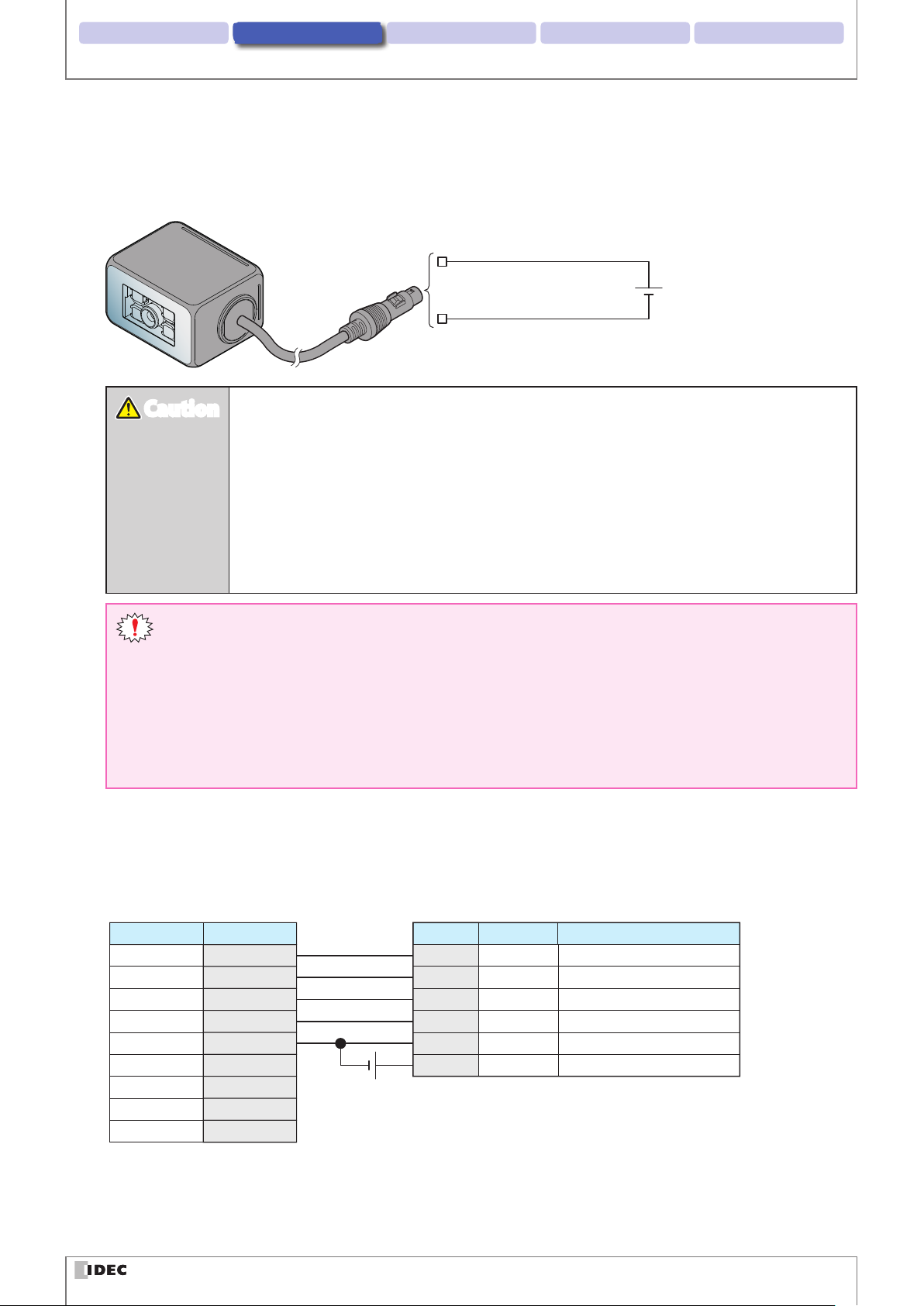

zConnecting to the WB2F

The WB2F and the Communication Unit's connection diagram is the following:

Communication Unit

WB2F

DIN Connector

zConnector Pin Assignment

Communication Unit's connector pin assignment is as follows:

Scanner Port

DIN Connector Pin Number Description Function

1 Out_0

2 Out_1

3 Out_2

4 Out_3

5 5VDC WB2F Power Supply (+V)

6 S_RD WB2F Received Data (RS-232)

7 In_0

8 In_1

9 0V WB2F Power Supply (-V, SG Shared)

10 S_SD WB2F Transmission Data (RS-232)

11 S_RS

12 S_CS

13 0V WB2F Power Supply (-V, SG Shared)

Output from the WB2F

(NPN Open Collector)

Input to the WB2F

RS-232 Control Signal

12

4

8

1

5

9

13

2-5

Page 23

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

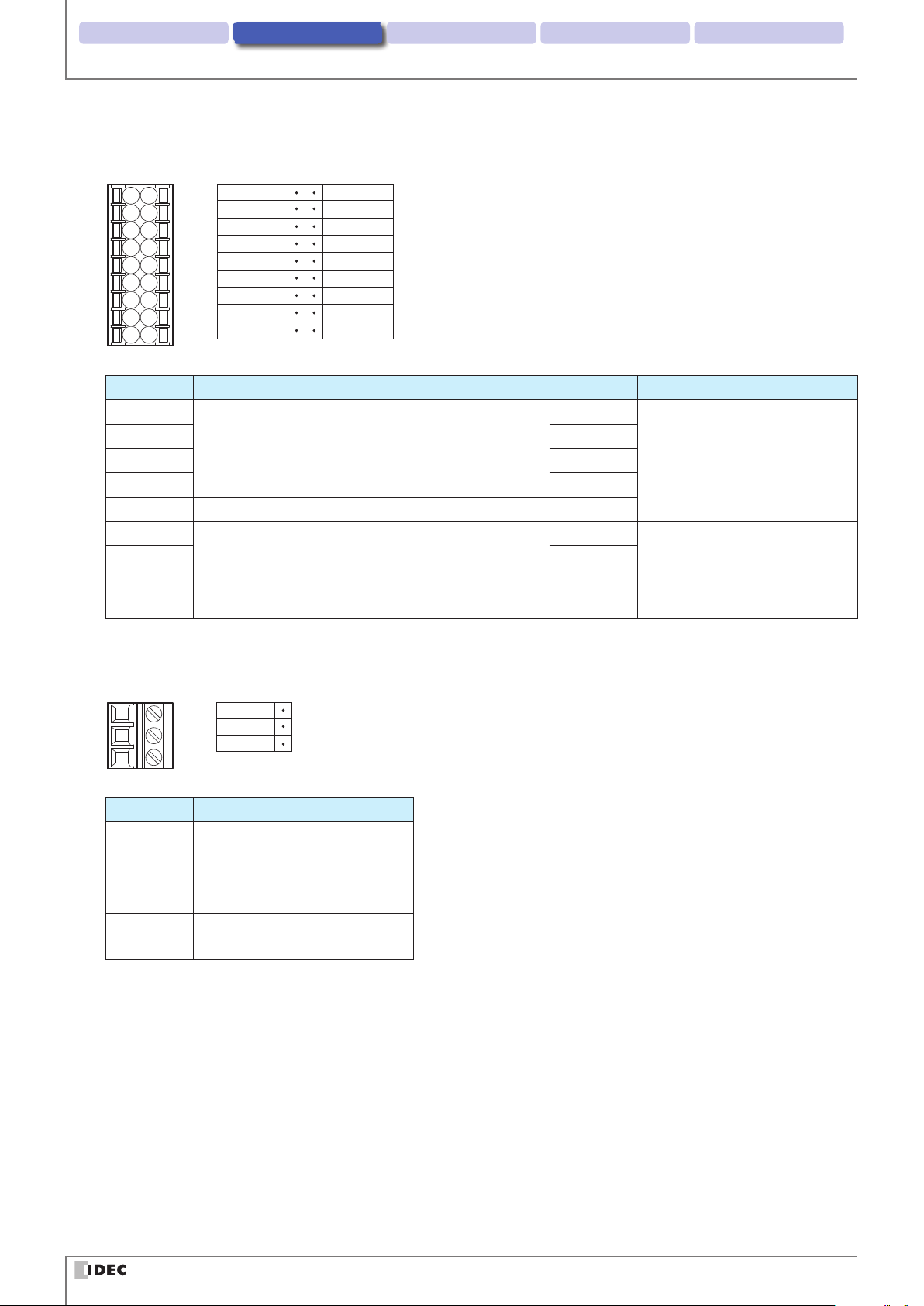

Input/Output/RS-232/RS-422 port

Connector for Input/Output/RS-232/RS-422 port

SDA

SDB

RDA

RDB

SG

RD

SD

CS

RS

Description Function Description Function

SDA

SDB OUT_0

RDA OUT_1

RS-422 Connection with a Host Device

RDB OUT_2

SG RS232/RS422 Connection with Host Device OUT_3

RD

CS IN_1

RS-232 Connection with a Host Device

RS NC Unused

OUT_COM

OUT_0

OUT_1

OUT_2

OUT_3

IN_COM

IN_0

IN_1

NC

OUT_COM

Output from the WB2F

IN_COM

Input to the WB2FSD IN_0

Wiring

External Power Port

Connector for an External Power Port

DC24V

0V

FE

Description Function

DC24V Power Supply (+V) for Communi-

cation Unit

0V Power Supply (-V) for Communi-

cation Unit

FE Functional Ground for Communi-

cation Unit

2-6

Page 24

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

CautionCaution

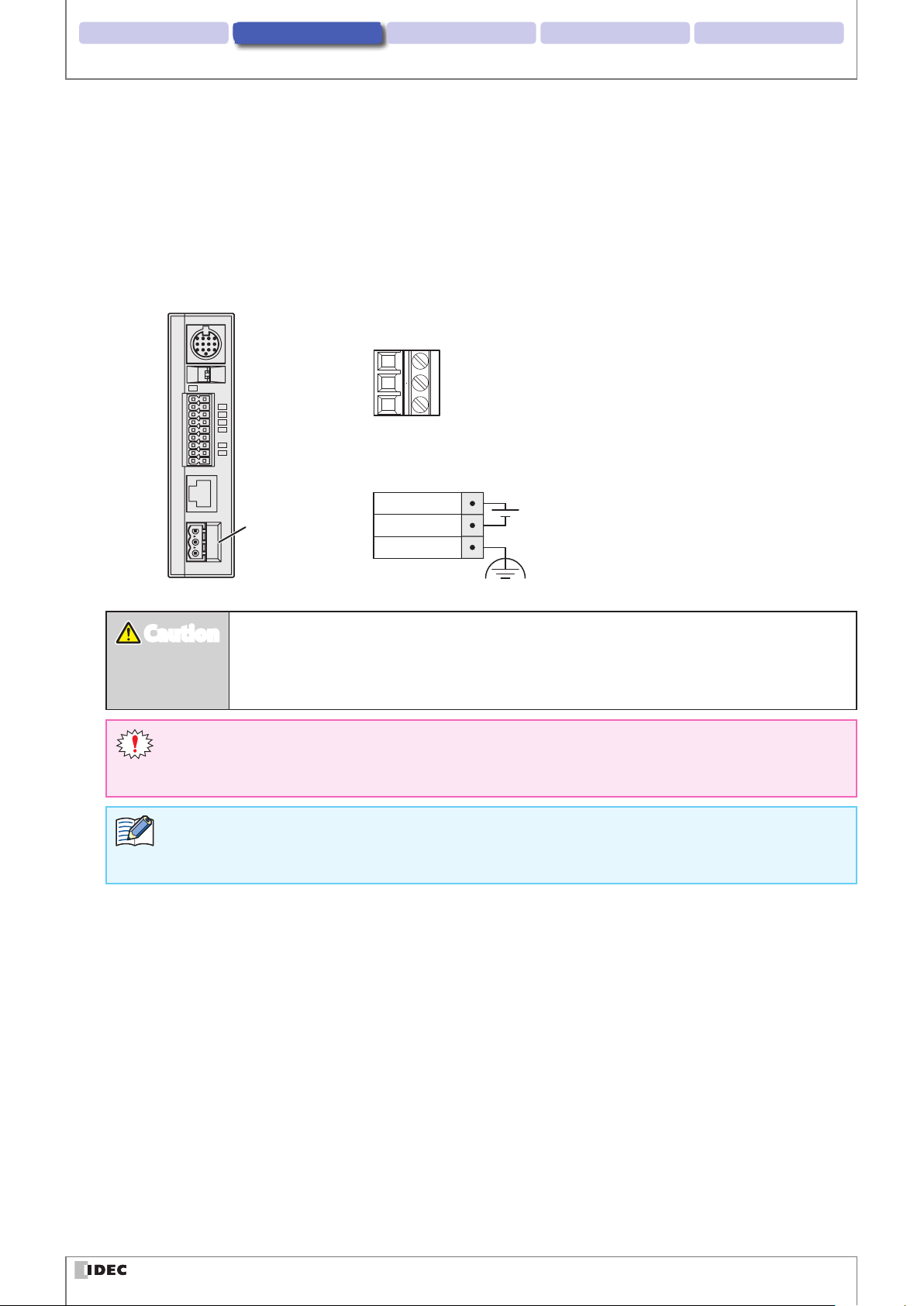

zConnecting the Power Supply

There are two methods for connecting the power supply

z

Using an external power supply

z

Using PoE (Power over Ethernet)

Using an Exernal Power Supply

Connect the 24V DC power supply adaptor to the communication unit's external power supply port.

Connector for the External Power Port

Pin assignment for the External Power Supply Port

Wiring

24V DC

External

Power Port

z

Do not reverse the power supply connections under any circumstances. Doing so may result

0V

FE

24V DC

in damage.

z

Use the product within the rated power supply voltage range. Otherwise there is a risk of explosion or burnout.

z

Always turn o the WB2F's power supply before wiring the product.

z

Do not simultaneously use an external power supply and PoE.

z

Use an AWG12 to 24 Cable for wiring.

z

If using as a UL certied product, the external power source must be at most 24V DC, 8A, 100VA Limited

Power Source or Class 2 Power Source.

z

A normal type fuse rated 2.5A, 60V DC is built into the product.

2-7

Page 25

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

Wiring

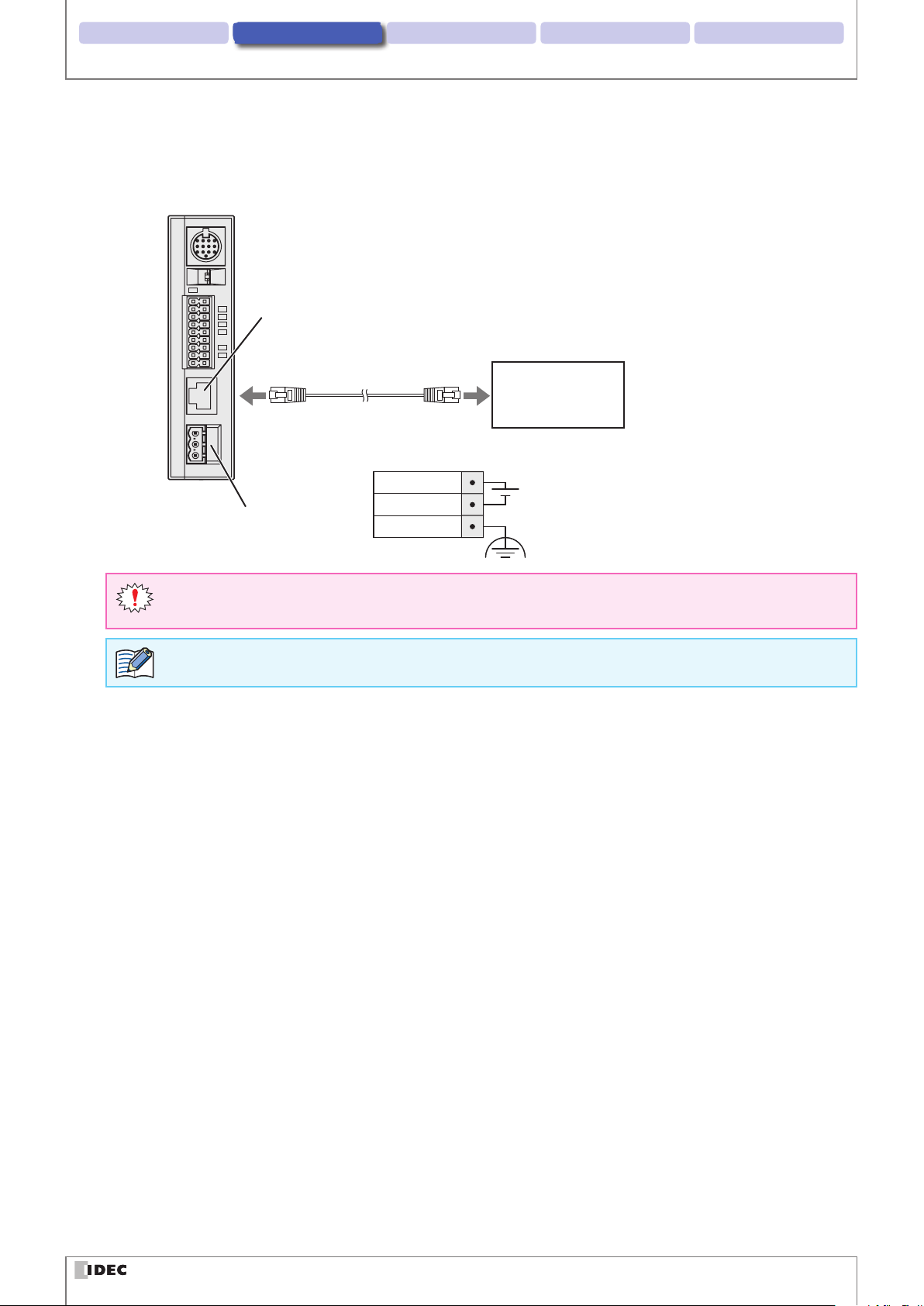

Using PoE

Connect the PoE to the Communication Unit's Ethernet Port. Even if using PoE, ground the FE terminal of the external

power supply's port connector.

Ethernet Port

Ethernet

PoE

(Alternative A/B)

Pin assignment for the External Power Supply Port Connector

24V DC

External

Power Port

z

Turn the communication unit's power to OFF prior to performing any wiring work.

z

Do not simultaneously use an external power supply and PoE.

0V

FE

24V DC

PoE is treated as Class 0.

2-8

Page 26

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

Wiring

zRS-232 wiring

If connecting the WB2F to a host device such as programmable display or a computer using RS-232, do so according to

the following wire instructions:

Connector for Input/Output/

RS-232/RS-422 port

Host device

Pin NumberDescription

2RXD

3TXD

7RTS

8CTS

5GND

Connector for Input/Output/

RS-232/RS-422 port

Description

SD

RD

CS

RS

SG

1DCD

4DTR

6DSR

Input/Output/RS-232/RS-422 port

9RI

D-sub 9-pin connector

z

Ethernet/RS-232/RS-422 cannot simultaneously use more than two types of communication.

z

Use an AWG16 to 24 Cable for wiring.

zRS-422 wiring

If connecting the WB2F to a host device such as programmable display or a computer using RS-422, do so according to

the following wire instructions:

Connector for Input/Output/

RS-232/RS-422 port

Host device

Description

RDA(RD+)

RDB(RD-)

SDA(SD+)

SDB(SD-)

SG

Connector for Input/Output/

RS-232/RS-422 port

Description

SDA(SD+)

SDB(SD-)

RDA(RD+)

RDB(RD-)

SG

Input/Output/RS-232/RS-422 port

z

Ethernet/RS-232/RS-422 cannot simultaneously use more than two types of communication.

z

Do not use a cable that is longer than 500m.

z

If using a cable that is longer than 30m, use a shielded cable and connect the shield to the FE terminal.

Wire the shield with sucient consideration of the environment.

z

Use an AWG16 to 24 Cable for wiring.

2-9

Page 27

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

Wiring

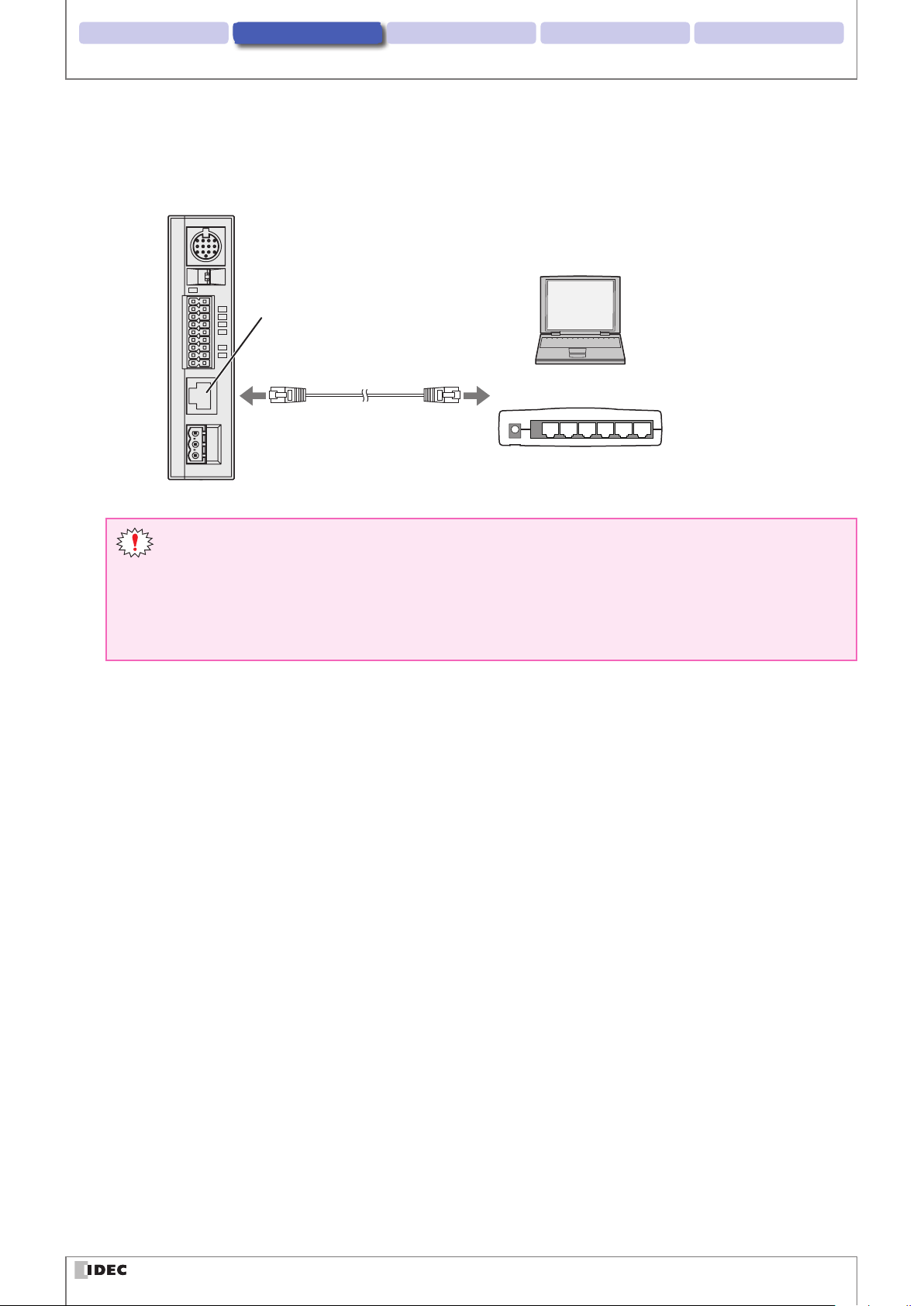

zWiring for Ethernet Communication

If connecting the WB2F to a host device such as programmable display or a computer using an ethernet connection, do

so according to the following wire instructions:

Ethernet Port

Ethernet

Host device

Ethernet Hub

z

Ethernet/RS-232/RS-422 cannot use more than two types of communication at once.

z

Connect the PoE to the Communication Unit's Ethernet Port. Even if using PoE, ground the FE terminal of

the external power supply's port connector.

z

Use a cable rated over category 5.

z

Do not use a cable that is longer than 100m.

z

If using a cable that is longer than 30m use a shielded cable.

2-10

Page 28

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

CautionCaution

CautionCaution

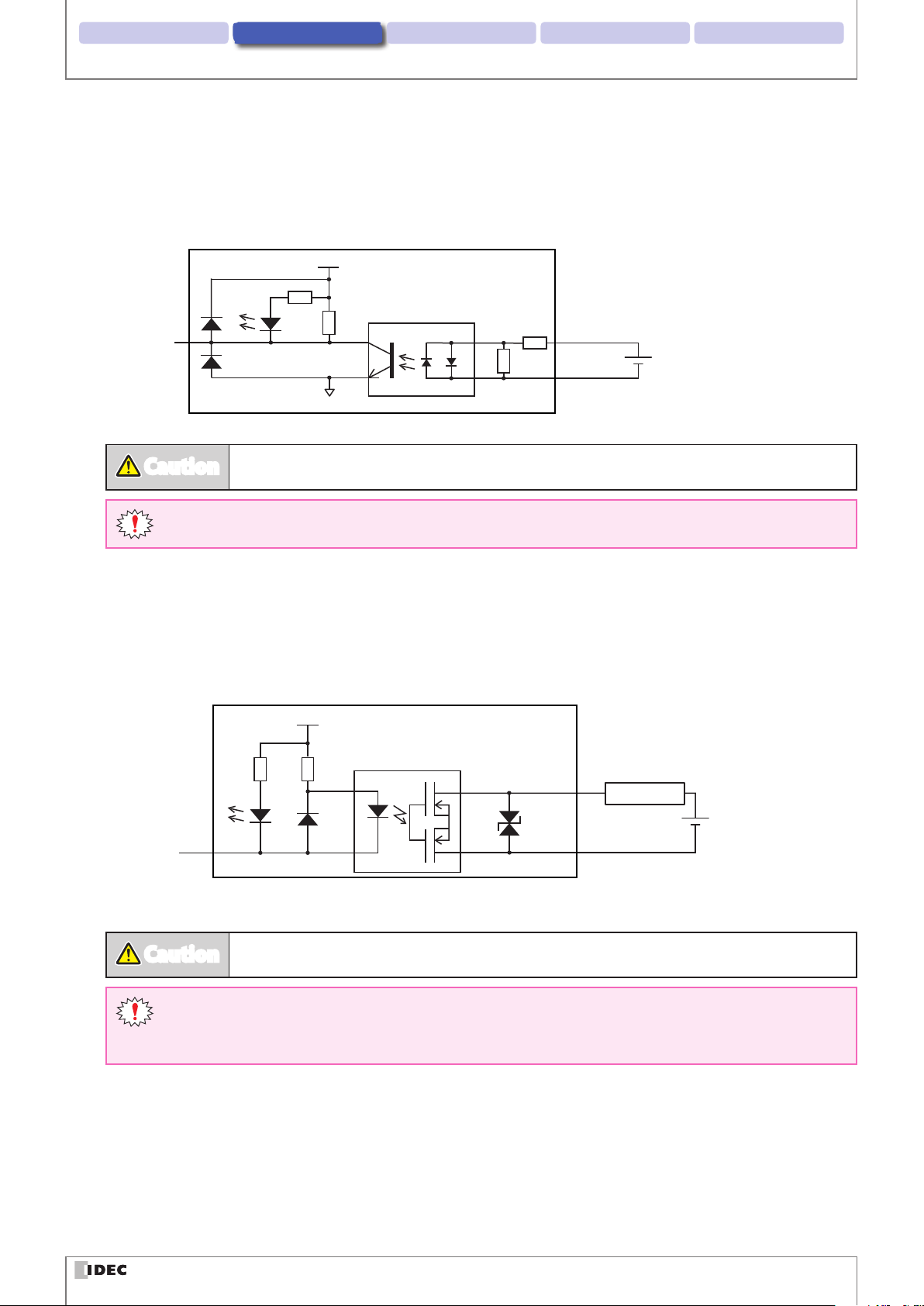

zWiring for External Input

External Input is a trigger input used to turn Read Request ON/OFF.

External Input will operate given the following voltage input (VIL:0-5V, VIH: 15-28.8V).

Refer to the following example prior to wiring the WB2F.

Communication Unit

VCC

R

Input to

the WB2F

R

R

0V

Miswiring may cause damage to internal circuitry.

IN_0,1

R

IN_COM

Wiring

24V DC

(28.8V DC max.)

Use an AWG16 to 24 Cable for wiring.

zWiring for External Output

External Output is used to determine read success/read failure during read operations.

Refer to the following example prior to wiring the WB2F.

Communication Unit

VCC

R R

Output

from WB2F

(NPN Open Collector)

Miswiring may cause damage to internal circuitry.

OUT_0-3

OUT_COM

Load

24V DC

(30V DC max.)

z

If the Load and the WB2F are connected to separate power supplies, make sure that you turn the WB2F's

power on rst.

z

Use an AWG16 to 24 Cable for wiring.

2-11

Page 29

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

Wiring

2. 3. 2 Wiring Instructions: Setting up the WB2F without the Communication Unit

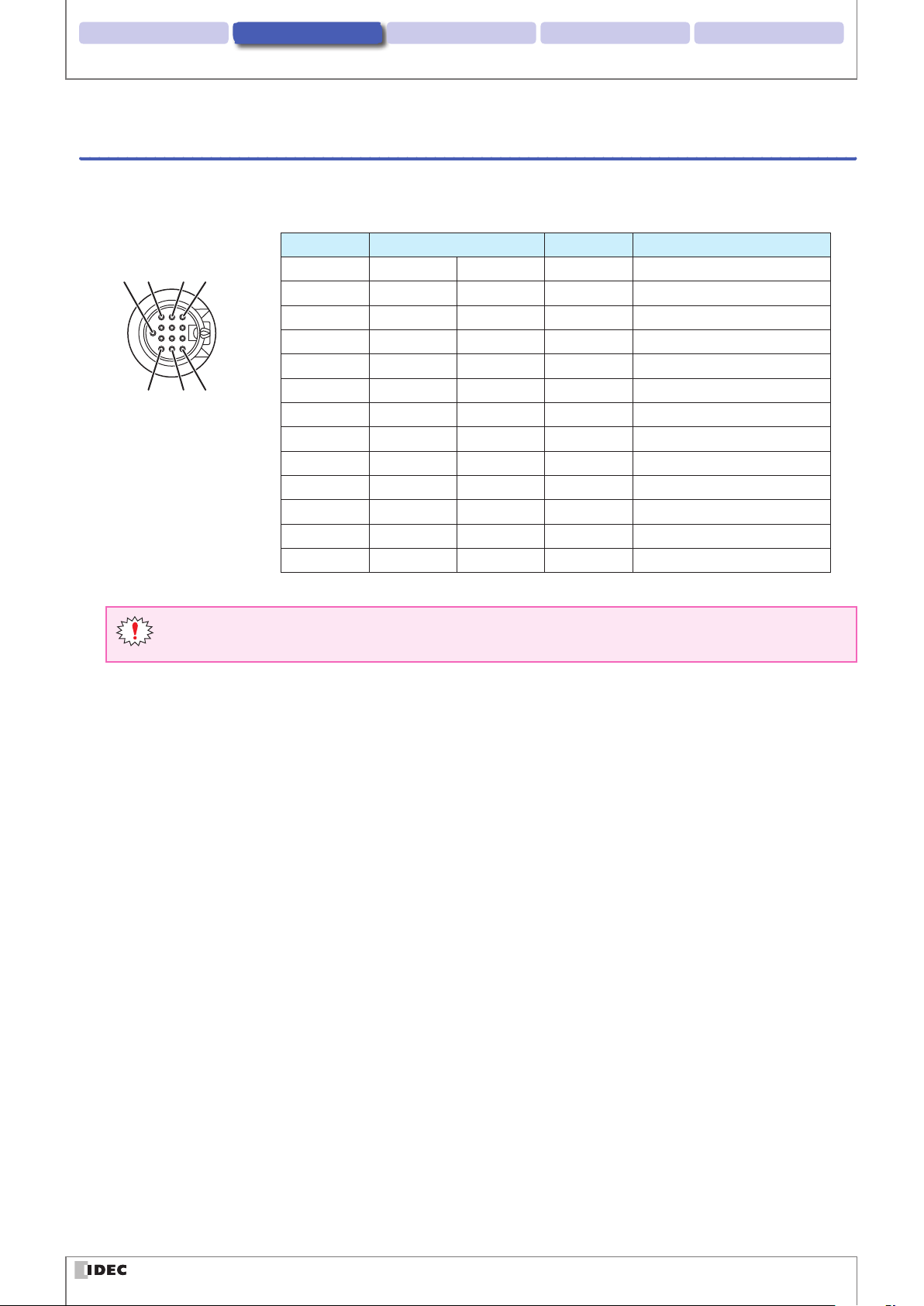

zConnector Pin Assignment

The WB2F's connector pin assignment is as follows.

DIN Connector Pin Number Wire color Discription Function

13

9

15

4812

1 Gray Red Dot OUT0 External Output 0

2 Gray Black Dot OUT1 External Output 1

3 White Red Dot OUT2 External Output 2

4 White Black Dot OUT3 External Output 3

5 Orange Red Dot2 +5V Power Supply +

6 Pink Black Dot TXD RS-232 Transmission Data

7 Orange Red Dot IN0 External Input 0

8 Orange Black Dot IN1 External Input 1

9 Orange Black Dot2 0V Power Supply (- SG Shared)

10 Pink Red Dot RXD RS-232 Received Data

11 Yellow Red Dot CTS RS-232 Control Signal

12 Yellow Black Dot RTS RS-232 Control Signal

13 – – NC No connection

Either the DIN Connector Shell or the Cable Shield is not connected to the main body

Make the determination to connect to FE or SG depending on the level of surrounding noise

2-12

Page 30

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

5V DC±0.25V

WB2F

CautionCaution

Wiring

zWiring the power supply

Connect pin number 5 (+ 5V) to the 5V DC power supply + side and pin number 9 (0 V) to the - side. Read the following

notes carefully and refer to the wiring example below before attempting to wire the power supply.

Pin Number5: Power Supply +

DIN Connector

Pin Number9: Power Supply -

z

Do not reverse the power supply connections under any circumstances. Doing so may result

in damage.

z

Use the product within the rated power supply voltage range. Otherwise there is a risk of explosion or burnout.

z

When using this product in situations where it is not built into other equipment, do not use

an integrated power supply. Otherwise there is a risk of re or electric shock.

z

Avoid parallel wiring of the product's wires in the same conduit or duct with high voltage

lines or power lines (inverter power lines in particular) as this may cause malfunction or damage due to the eect of induction noise.

z

The power reset time is under 5s. Perform operations 5s after turning the power on.

z

Always turn o the WB2F's power supply before wiring the product.

z

If the wires are long and when there is a risk of being affected by power sources or solenoids, independently wire the product as a general rule.

z

If you elongate the cable via a DIN connector, be careful of short circuit between adjacent terminals

and consider the subsequent voltage drop of the power supply and use a cable thicker diameter than

AWG28. If the entire cable exceeds a length of 2.8m, there is a possibility that the it will adversely eect

noise immunity. Do so only after thoroughly conrming that the WB2F's performance is not impacted.

zRS-232 wiring

When connecting the unit to a host device such as an operator interface or a computer via RS-232, wire it referring to the

following example.

WB2FHost device

Pin NumberDescription

D-sub 9-pin connector

2RXD

3TXD

7RTS

8CTS

5GND

1DCD

4DTR

5V DC

6DSR

9RI

Pin Number6Description

TXD

10 RXD

11 CTS

12 RTS

9 0V

5 +5V

Function

RS-232 Transmission Data

RS-232 Receive Data

RS-232 Control Signal

RS-232 Control Signal

Power Supply (- SG Shared)

Power Supply +

2-13

Page 31

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

Main circuit

CautionCaution

(26.4V DC max.)

WB2F

Main circuit

CautionCaution

zWiring for External Input

External Input is a trigger input used to turn Read Request ON/OFF.

The external trigger input operates as a non-voltage input or a voltage input (VIL: 1.0 V, VIH: 4.0 V-VCC).

Refer to the following example prior to wiring the WB2F.

WB2F

VCC

Wiring

R

R

Mistakenly wiring the product may cause the internal circuit to be damaged.

Pin Number 7: IN0

Pin Number 8: IN1

zWiring for External Output

External Output is used to determine read success/read failure during read operations.

Refer to the following example prior to wiring the WB2F.

Pin Number1-4: OUT0-3

0V

Load

Non-voltage contact

24V DC

Mistakenly wiring the product may cause the internal circuit to be damaged.

When the load and the unit are connected to dierent power supplies, always turn on the unit's power

supply rst.

2-14

Page 32

Installation & wiring 3. Operational Check 4. Function 5. Appendix1. Overview

2. 3. 3 Connecting the USB Cable

zUSB connector pin assignment

USB connector is Mini-B (Female) type.

Pin Number Signal name Function

1 VBUS bus power

2 D- Data-

3 D+ Data+

4 NC No connection

5 GND Ground

The WB2F cannot be powered via the USB connector.

USB Connector (Mini-B)

5

1

Wiring

zConnecting the USB connector

When connecting the unit to a host device, rmly insert the USB connector straight into the USB port on the host device

in the correct orientation.

Host device USB port

USB-A Connector

To connect the WB2F, open the Maintenance Port Hatch and insert the USB Mini-B connector.

Maintenance Port

(USB Port)

USB Mini-B Connector

2-15

Page 33

3

This section will describe how to check the WB2F's operations.

Operational Check

3. 1 Performing an Operational Check using a PC

3. 1. 1 Necessary operating environment of the PC

Check to ensure that the PC fullls the following conditions.

Item Details

OS Windows 7 / 8 / 8.1 /10

Communication Port USB2.0 or later

3. 1. 2 Installing the Device Driver

Prior to connecting the WB2F to a PC you must rst install the USB device driver.

In order to install, refer to F [5. 14 Installing the USB driver] on page 5-31.

3-1

Page 34

2. Installation & wiring Operational Check 4. Function 5. Appendix1. Overview

CautionCaution

Performing an Operational Check using a PC

3. 1. 3 Connecting to a PC

zIf you use a communication unit

If you use the WB2F with the communication unit, refer to F [2. 3. 1 Wiring Instructions: Connecting the WB2F to the

Communication Unit] on page 2-5 for wiring instructions.

After completing wiring, turn power ON

WB2F Communication Unit

Pigtail Cable

DIN Connector

USB Mini-B Connector

DC Power Supply

24V DC

USB-A Connector

USB Cable

PC

zIf you do not use a communication unit

If you use the WB2F without the Communication Unit refer to F [2. 3. 2 Wiring Instructions: Setting up the WB2F with-

out the Communication Unit] on page 2-12.

After completing wiring, turn power ON

WB2F

DC Power Supply

Pigtail Cable

5V DC

USB Mini-B Connector

USB-A Connector

USB Cable

PC

z

Note, the DC power supply voltage requirements varies depending on whether you use a

communication unit or not. Using a voltage level other than what is specified within this

manual may result in damage and/or malfunction.

z

Do not reverse the Power Supply connection. Doing so may result in damage.

3-2

Page 35

2. Installation & wiring Operational Check 4. Function 5. Appendix1. Overview

3. 2 Conrming a Successful Read

You can use the WB2F to conrm that a symbol was successfully read.

Operate based on the procedure below.

Place the symbol within the Reading Range

1

2D Code

Barcode

Push the READ/ENTER button while the power is ON

2

Emitter LED continuously lights up as reading begins

Conrming a Successful Read

Power-ON Indicator LED

Due to the WB2F's settings, there are symbols that cannot be read. If you read a symbol double check the

settings to ensure that the symbol is enabled.

You can conrm the Status of a read simply by looking at the Status LED lights

3

During Reading Operation Read Success Time Read Failure

Status LED

(O) (G)(R)

During

Reading Operation

The Status LED (Orange) will continuously be ON during Reading Operations but

will turn OFF once Reading Operations

are terminated

The Status LED settings can be changed. The settings here describe the default settings.

After a successful read the green status

LED will turn ON (300ms)

Status LED

(O) (G)(R)

Read Success

Status LED

(O) (G)(R)

Read Failure

After a read failure, or a reading timeout,

the red status LED will turn ON (300ms)

3-3

Page 36

2. Installation & wiring Operational Check 4. Function 5. Appendix1. Overview

3. 3 Symbol Read Data Conrmation

Conrm the data read by the WB2F by using a PC.

Operate based on the procedure below.

Install a generic terminal software onto the PC

1

WB2F's reading management will be done via the generic terminal software

Start up the generic terminal sfotware, select the port the WB2F is connected to and begin communications

2

The Connector Port can be viewed from [Device Manager]

Because you are connecting via USB, there is no need to separately set communication speed.

Place the symbol within the reading range

3

Transmit the following command from a PC to the WB2F

4

Emitter LED continuously lights up as reading begins

Symbol Read Data Conrmation

Request

Read Start ^ get CR

The prex and sux of Control Commands varies based on settings. The explanation in this manual assumes that factory default settings have been maintained.

Read Data can be conrmed via PC from the data the WB2F transmits

5

Read results can be determined by checking the Read data.

Read Result

Read Success — Such as 123456789 CR

Read Failure or

Read Time Out

The prex and sux of the read data varies based on settings. The explanation in this manual assumes

that factory default settings have been maintained.

Prex Mnemonic Sux

Global Prex Barcode Data Global Sux

— ? CR

Control command (Transmitted Data PC)

Read Data (Data received from PC)

LF

LF

LF

3-4

Page 37

4

This chapter describes the functions of the WB2F.

Function

4. 1 Overview

4. 1. 1 Operation mode

The functions that the WB2F can execute dier by the operation mode.

There are four operation modes: slave mode, setup support mode, maintenance mode, master mode.

Slave mode

This mode is used during normal operation. Slave mode has the following functions.

Function Details Reference page

Symbol reading This function reads a symbol and outputs the reading results.

Output data additional information

Output data editing

Verication

Command alias

Communication command

Parameter Changeover

Image Capture

Image Filter

I/O Function

This function adds various types of data when outputting the

symbol reading results data.

This function outputs the symbol reading results data after editing it according to the specied method.

This function matches the symbol reading results data with

the master data, judges whether or not it is matched, and outputs that.

This function executes the control commands "start symbol

reading" and "stop symbol reading" with other strings.

This function transmits and receives data with the connected

host device via the WB2F communication interface.

This function automatically switches from Read Algorithm to

Imaging parameters

This function stores code images within the WB2F during the

decoding process

This function digitally correct captured images to improve

reading performance.

This function utilizes external input and output terminals in

order to determine the WB2F's operation and condition status.

F

F

F

F

F

F

F

F

F

F

Page 4-5

Page 4-15

Page 4-20

Page 4-22

Page 4-26

Page 4-28

Page 4-31

Page 4-34

Page 4-37

Page 4-40

4-1

Page 38

2. Installation & wiring Function3 Operational Check 5. Appendix1. Overview

Overview

Setup support mode

This mode is used to check the installation position and reading status of the WB2F. Setup support mode has the following function.

Function Details Reference page

Read Success Rate Measurement

Decode Processing Time Measurement

Symbol Position Measurement

This function outputs and displays Read Success Rate for a given symbol.

This function outputs and displays the minimum, maximum

and average symbol decoding time.

This function outputs and displays a symbol's position information (coordinates)

F

F

F

Page 4-44

Page 4-45

Page 4-46

This function automatically adjusts settings to optimal param-

Auto-tuning

eters for a given symbol and saves the settings in a parameter

F

Page 4-48

table.

Maintenance mode

This mode is used to maintain the WB2F after installation and to perform actions when problems occur. Maintenance

mode has the following functions.

Function Details Reference page

Maintenance support

Firmware updating This function updates the WB2F rmware.

Master mode

This function forcibly operates the unit with the factory default

settings.

F

F

Page 4-52

Page 4-52

This mode is used to connect to a PLC with using its communication protocol.Master mode has the following functions.

Function Details Reference page

PLC connection

This function directly write reading results into the data memory of a PLC (programmable logic controller).

F Page 4-53

4-2

Page 39

2. Installation & wiring Function3 Operational Check 5. Appendix1. Overview

Normal usage

4. 1. 2 Operation mode switching operation and status

The operation mode is switched using the READ/ENTER button or communication commands.

For the communication commands, refer to F [4. 2. 7 Communication command] on page 4-28.

Unit power supply

Off

Unit power

supply On

Overview

Master mode

Slave mode

For details on the operation modes, refer to the following.

z

Slave mode ................................................................ F Page 4-4

z

Setup support mode ............................................. F Page 4-41

z

Maintenance mode ................................................ F Page 4-50

z

Master Mode ............................................................. F Page 4-53

Maintenance

mode

Setup support

mode

Be aware that if you change the operation mode without executing the control command "Save setting

values" after changing the set value, the set value will return to the state before change.

4-3

Page 40

2. Installation & wiring Function3 Operational Check 5. Appendix1. Overview

4. 2 Slave Mode

This operation mode is used during normal operation. Use the unit in this mode after installation.

Slave mode has the following functions.

z

Symbol reading .......................................................F Page 4-5

z

Output data additional information ................F Page 4-15

z

Output data editing ...............................................F Page 4-20

z

Verication ................................................................F Page 4-22

z

Command alias ........................................................F Page 4-26

z

Communication command .................................F Page 4-28

z

Paramter Changeover ...........................................F Page 4-31

z

Image Capture.. .......................................................F Page 4-34

z

Image Filter ...............................................................F Page 4-37

z

I/O .................................................................................F Page 4-40

Slave Mode

4. 2. 1 Switching operation to slave mode

There are two methods to switch to slave mode.

Use the methods according to the situation.

The status LEDs (red/orange/green) will turn o when switching to slave mode.

Method 1 Turn on the power to the unit. (Do not push the READ/ENTER button)

Turn on power supply

Method 2 Input the "switch to slave mode" control command.

Status LED

(O) (G)(R)

OFF

Status LED

Host device

Control command

Switch to slave mode

4-4

(O)(R)

OFF

(G)

Page 41

2. Installation & wiring Function3 Operational Check 5. Appendix1. Overview

4. 2. 2 Symbol reading

The symbol reading reads symbols and outputs the reading result.

Refer to F [4. 6 Conguration Item Table] on page 4-54 for details on code reading functions and their vari-

ous settings.

zSymbol Reading Method

There are three methods to start reading (reading request ON).

Method 1 Push the READ/ENTER button.

Slave Mode

Status LED

(O) (G)(R)

Method 2 Input Control Command [Start Reading].

Control command

Host device

Start Reading

Method 3 Turn External Input ON.

Turn External

Pin Number 7: IN0

Input ON

Non-voltage contact

Status LED

(O) (G)(R)

Status LED

(O) (G)(R)

z

Do not use multiple methods to turn the reading request ON/OFF.

z

Prior to setting External Input to trigger the reading request ON, set External Input function to [Start Reading]. For details refer to F [4. 2. 11 I/O] on page 4-40.

z

Reading Results can be set to reect Status LED, External Output and the Communication Interface.

z

The Status LED (Orange) will turn ON during Reading Operations. To customize Interlock Control, Lighting

Patterns, and Light On Times, refer to F [4. 6 Conguration Item Table] on page 4-54.

4-5

Page 42

2. Installation & wiring Function3 Operational Check 5. Appendix1. Overview

Slave Mode

zSymbol Reading

There are three types of Symbol Reading.

z

Single Read...... ..........................................................F Page 4-6

-Edge Activation. ....................................................F Page 4-7

-Level Activation ....................................................F Page 4-8

z

Multi-read Sequential Output ............................F Page 4-9

z

Multi-read Batch Output ......................................F Page 4-10

Single Read

For a single read: Once the Reading Request is turned on, the symbol reading operation commences. Once either Reading

Success is attained or Reading Time Out elapses, the Reading result is output. 1 read is executed per 1 Reading Request.

There are two types of single read operations.

z

Edge Activiation ......................................................F Page 4-7

z

Level Activation .......................................................F Page 4-8

4-6

Page 43

2. Installation & wiring Function3 Operational Check 5. Appendix1. Overview

Slave Mode

Edge Activation

After detecting that Reading Request has been activated (OFF → ON), symbol reading will commence.

If the Reading Time Out time has been set to anything other than innite, Edge activation will occur. For details refer to

[4. 6 Conguration Item Table] on page 4-54.

F

If Reading Request was turned on by External Input, conditions for activating Stop Reading is one of the following:

z

Reading Success

z

Reading Timeout Elapsed

To control the READ/ENTER button or Reading Request using control commands, refer to F [Start Reading and Stop

Reading conditions for each Reading Request] on page 4-11.

The following timing chart is an example of an operation with the External Input.

Reading Request

Emitter LED

Reading Processing

Data Output

External Output

(OK/NG)

External Output

(Busy)

ON

OFF

ON

OFF

ON

OFF

ON

OFF

[Reading Failure][Reading Success]

Lighting ON Time

Reading Timeout Reading Timeout

Reading

Execute

[1]

OK

Reading

Execute

[1]

NG

Reading

Result

[1]

OK

Reading

Execute

[2]

NG

The filter time is enabled only

if external input is used for read

oeprations

The filter time is enabled only

if external input is used for read

oeprations

Reading

Execute

[3]

NG

Reading

Result

NG

z

Operation of the External Input and the External Output will vary depending on settings parameters.

z

If Reading Linked Control parameter is enabled, the Status LED (orange) will turn ON when symbol reading

starts. Turns o when either the illumination time elapses or symbol reading stops.

z

If Reading Linked Control parameter is enabled, the Status LED (Green/Red) will turn ON when symbol reading

stops. Turns o when either the illumination time elapses or symbol reading starts.

z

If Reading Linked Control parameter is enabled, the WB2F will determine Reading Success/Reading Failure or

Verication Match/Verication Un-match when symbol reading stops and perform output control based on the

parameters that are set.

4-7

Page 44

2. Installation & wiring Function3 Operational Check 5. Appendix1. Overview

Slave Mode

Level Activation

If Reading Request is turned ON, symbol reading commences and as long as Reading Request remains ON, symbol reading will continue.

If Read Time Out time is set to innite, Level activate will occur. For details refer to F [4. 6 Conguration Item Table] on

page 4-54.

If Reading Request was turned ON by External Input, conditions for activating Stop Reading is one of the following:

z

Reading Success

z

External Input OFF (Reading Request OFF)

To control reading requests using the control command, refer to F [Start Reading and Stop Reading conditions for

each Reading Request] on page 4-11.

The following timing chart is an example of an operation with External Input.

Reading Request

LED Lighting

Reading Processing

Data Output

External Output

(OK/NG)

External Output

(Busy)

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Illumination time

Reading

Execute

[1]

OK

Reading

Result

[1]

OK

[Reading Failure][Reading Success]

Reading

Execute

[1]

NG

Reading

Execute

[2]

NG

Stop Reading

Reading

Execute

[3]

NG

Reading

Result

NG

z

Operation of the External Input and the External Output will vary depending on settings parameters.

z

If Reading Linked Control parameter is enabled, the Status LED (orange) will turn ON when symbol reading is

ON. Turns oFF when either the illumination time elapses or symbol reading stops.

z

If Reading Linked Control parameter is enabled, Status LED (Green/Red) will turn ON when symbol reading

stops. Turns oFF when either the illumination time elapses or symbol reading starts.

z

If Reading Linked Control parameter is enabled, the WB2F will determine Reading Success/Reading Failure or

Verication Match/Verication Un-match when symbol reading stops and perform output control based on the

parameters that are set.

4-8

Page 45

2. Installation & wiring Function3 Operational Check 5. Appendix1. Overview

Reading Processing

Slave Mode

Multi-Read Sequential Output

If Reading Request is turned ON, symbol reading commences and will continue for as long as Reading Request remains

ON. The WB2F will output the Reading Result for each symbol that is read.

Once Reading Request is turned OFF, symbol reading will stop.

if Reading Timeout is set to innite, Level Activate will occur. For all other cases, Edge Activate will occur.

For more details refer to F [4. 6 Conguration Item Table] "Symbol Reading" on Page 4-58.

If Reading Request was turned ON by external input and level activation, conditions for activating Stop Reading is as follows:

z

External Input OFF

To control Reading Request using control commands, refer to F [Start Reading and Stop Reading conditions for each

Reading Request] on page 4-11.

The following timing chart is an example of an operation with both the External Input and Level Activation

[Reading Failure][Reading Success]

Reading Request

Emitter LED

ON

OFF

ON

OFF

Lighting ON Time

Preventing Double

Read Time

Preventing Double

Read Time

Stop Reading Stop Reading

Data Output

External Output

(OK/NG)

External Output

(Busy)

z

Preventing Double Read Time setting range is 100ms to 25,500ms

z

Even if the Preventing Double Read Time has passed, symbol reading will not begin until communication

response has been established.

z

To prevent reading the same symbol twice, the WB2F will not acknowledge symbols with the same symbology and data as the prior symbol during the Preventing Double Read Time. However, this does not apply to

symbols that have either dierent symbology or data.

z

If you turn Reading Request OFF before the WB2F is able to read a single symbol, it will be treated as a Reading Failure.

z

Operation of the External Output will change based on how its settings are congured.

z

If Reading Linked Control parameter is enabled, the Status LED (orange) will turn ON when symbol reading is

ON. Turns OFF when either the Illumination Time elapses or symbol reading stops.

z

If Reading Linked Control parameter is enabled, the Status LED (Green/Red) will turn ON when symbol reading stops. It will turn OFF when the Illumination time elapses, or symbol reading starts.

z

If Reading Linked Control parameter is enabled, the WB2F will determine Reading Success/Reading Failure or

Verication Match/Verication Un-match when symbol reading stops and perform output control based on

the parameters that are set.

ON

OFF

ON

OFF

Reading

Execute

[1]

OK

Reading

Execute

[2]

NG

Reading

Result

[1]

OK

Reading

Execute

[3]

OK

Reading

Execute

[N]

NG

Reading

Result

[2]

OK

Reading

Execute

[1]

NG

Reading

Execute

[2]

NG

Reading

Execute

[3]

NG

Reading

Result

NG

4-9

Page 46

2. Installation & wiring Function3 Operational Check 5. Appendix1. Overview

Slave Mode

Multi-Read Batch Output

If Reading Request is turned ON, symbol reading commences and will continue for as long as the Reading Request remains

ON. Once the Reading Request is turned OFF, symbol reading will cease and the Reading Results will be output in batch.

The maximum number of symbol data that can be ouput at once is 32. Symbol data for the Symbol Reading past that will

be discarded.

If the Reading Timeout is set to innite, Level Activate will occur. For all other cases, Edge Activate will occur.

For more details, refer to F [4. 6 Conguration Item Table] on page 4-54.

If the Reading Request was turned ON by the external input and level activation, conditions for activating the Stop Reading is as follows:

z

External Input OFF

To control the Reading Request using control commands, refer to F [Start Reading and Stop Reading conditions for

each Reading Request] on page 4-11.

The following timing chart is an example of an operation with both the External Input and Level Activation

[Reading Failure][Reading Success]

Reading Request

Emitter LED

ON

OFF

ON

OFF

Lighting ON Time

Preventing Double

Read Time

Preventing Double

Read Time

Stop Reading Stop Reading

Reading Processing

Data Output

External Output

(OK/NG)

External Output

(Busy)

Reading

Execute

ON

OFF

ON

OFF

z

The sum of the characters of Reading Results [1] to [N] must be under 10,000 characters.

[1]

OK

Reading

Execute

[2]

OK

Reading

Execute

[N-1]

OK

Reading

Execute

[N]

NG

Reading

Result

[1]

OK

Reading

Result

[N-1]

Reading

Execute

[1]

NG

Reading

Execute

[2]

NG

Reading

Execute

[3]

NG

Reading

Result

NG

If the total number of characters exceeds 10,000, the accuracy of the output results is not guaranteed.

z

Preventing Double Read Time setting range is 100ms to 25,500ms

z

To prevent reading the same symbol twice, the WB2F will not acknowledge symbols with the same symbology and data as the prior symbol during the Preventing Double Read Time. However, this does not apply to

symbols that have either dierent symbology or data.

z

The External Output, the Status LED (Green/Red) will show only the WB2F's last Reading Result.

z

Operations of the External Output and the Status LED will change based on how settings are congured

z

If Reading Linked Control parameter is enabled, the Status LED (orange) will turn ON when symbol reading

starts. Turns oFF when either the Illumination Time elapses or symbol reading stops.

z

If Reading Linked Control parameter is enabled, the Status LED (Green/Red) will turn ON when symbol reading stops. It will turn OFF when the Illumination Time elapses, or symbol reading starts.

z

If Reading Linked Control parameter is enabled, the WB2F will determine Reading Success/Reading Failure or

Verication Match/Verication Un-match when symbol reading stops and perform output control based on

the parameters that are set.

4-10

Page 47

2. Installation & wiring Function3 Operational Check 5. Appendix1. Overview

Slave Mode

zStart Reading and Stop Reading conditions for each Reading Request

Symbol Reading and Reading Request Operation

Symbol Reading Reading Timeout Reading Request Start Reading Conditions Stop Reading Conditions

z

READ/ENTER button Push the READ/ENTER button

100ms to 25,500ms

External Input External Input OFF → ON

(Edge Activation)

Control command Start Reading Command Input

Single Read

READ/ENTER button *1

External Input ON

Innite

(level activate)

External Input

(Continues to read only while

Trigger is ON)

Control command Read Start Command Input

READ/ENTER button *1

100ms to 25,500ms

External Input External Output OFF → ON

(Edge Activation)

Multi-Read

Sequential

Output

Innite

(level activate)

Control command Start Reading Command Input

READ/ENTER button *1

External Input ON

External Input

(Continues to read only while

Trigger is ON)

Control command Start Reading Command Input

READ/ENTER button *1

100ms to 25,500ms

External Input External Output OFF → ON

(Edge Activation)

Control command Start Reading Command Input

Multi-Read

Batch Output

Innite

(level activate)

READ/ENTER button *1

External Input ON

External Input

(Continues to read only while

Trigger is ON)

Control command Start Reading Command Input Input Stop Reading Command

*1 Symbol Reading executed via the READ/ENTER button forcibly executes xed operation of single read edge activation

(Reading Timeout: 5s)

Reading Success

z

Reading Timeout (5s) Elapsed