Page 1

Terminal Blocks

Instructions

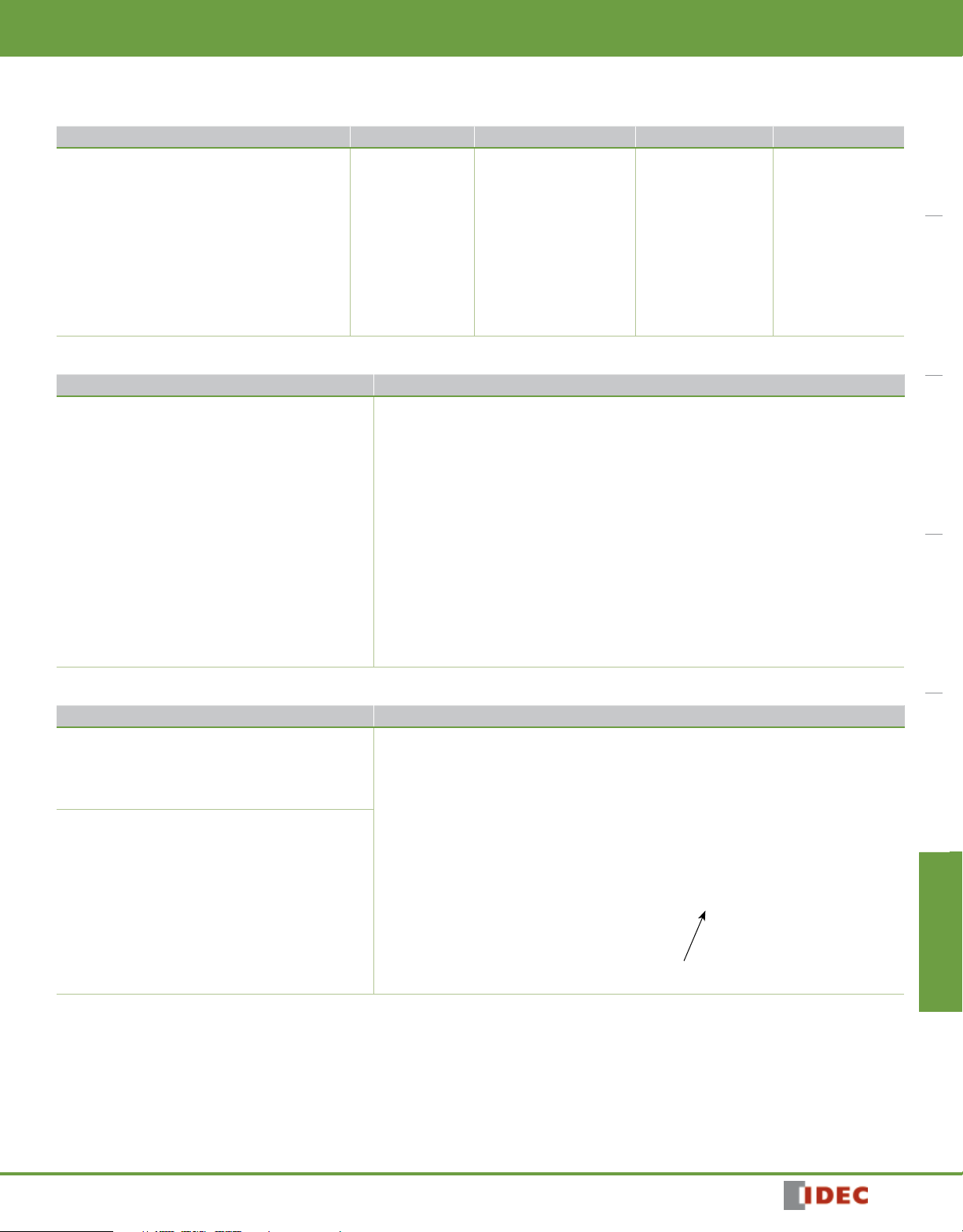

Wiring Touch-Down Terminal Blocks: BNH Series

Instructions Step 1 Step 2 Step 3 Step 4

Step 1. Insert the wire (or crimping terminal) into the

terminal block with the terminal screws in the open

position. (Use of crimping terminals is optional.)

Step 2. Push the terminal screw down to hold the wire in

place.

Step 3. Hold the terminal screw down, and tighten with a

screwdriver.

Step 4. To remove the wire, loosen the terminal screw and

pull up until wire is released.

Installation and Removal of Terminal Blocks

Instructions Appearance

Step 1. Slide the terminal blocks onto the DIN rail from one end.

Step 2. Use BNL5 or BNL6 end clips to secure the terminal block

row and to prevent side-to-side movement. BNH10W,

BNH15MW, BNH15LW, and BNH30W can be installed

from the middle of a DIN rail.

Step 3. To install, place the terminal block on top of the DIN rail

and push down until both edges of the terminal block

snap onto the DIN rail.

Step 4. To remove the terminal block, use the BND2 removal tool

as shown on the right.

Instructions

Switches & Pilot Lights Signaling Lights Relays & Sockets Timers Contactors Terminal Blocks Circuit Breakers

Removal Tool

BND2

Mounting Double-Deck Terminal Blocks

Instructions Appearance

DIN Rail Mount:

Step 1. First install the end plate. Then mount the terminal blocks

onto the DIN rail.

Step 2. To prevent side-to-side movement on the DIN rail, use the

BNL-8 mounting clip at both ends of the rail.

Panel Mount:

Step 1. Assemble a row of terminal blocks with end plates on

exposed end(s).

Step 2. Use BNDL2 mounting clips at both ends of a row.

Step 3. With the two holes of the mounting clip aligned with

the terminal block holes, insert a connecting rod through

each hole.

Step 4. Secure the ends of the connecting rods with the connect-

ing nuts, as shown below.

Connecting

Nut (hex)

Mounting Clip

End Plate

Terminal Block

Connecting Rod

Connecting

Nut (round)

Mounting Clip

800-262-IDEC (4332) • USA & Canada

915

Page 2

BN150W BNE150W

Instructions

Calculating DIN Rail Lengths

Instructions Appearance

Terminal Blocks

Terminal Blocks

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

Step 1. Add widths of all terminal blocks

(reference pages 864 through

869).

Step 2. Add the endplate thickness (usu-

ally only one).

Step 3. Add the DIN rail stop widths

(usually two are used).

Step 4. Round to the nearest 2” (50mm)

increment to allow for DIN rail

hole spacing.

Step 5. Add 1” (25mm) to ensure 0.5”

(12.5mm) of clearance at each

end of the DIN rail.

DIN Rail Stop Dimensions

Part No. Width

BNL-5 .374” (9mm)

BNL-6 .374” (9mm)

BNL-8 .571” (14.5mm)

BN30W (BNH30W

BN15LWT (BNH15LWT

BN15LW (BNH15LW

BN15MWT (BNH15MWT

BN15MW (BNH15MW

BN10W (BNH10W

12.5

BN40W (BNH40W

)

)

)

)

)

8.5

6.7

6

87

BN50W (BNH50W

)

)

9.6

10.5

)

BN75W

BN100W

17

201315.5121412

BNT20

BNF10S

BNE20

92 (2P

)

)

)

)

BN300BW2 (BN300NW2

BN200BW2 (BN200NW2

23

26

1523526

3

78 (2P

115 (3P

152 (4P

(Mounting Centers)

L

2

(

Rail Length

L

1

)

)

)

)

)

136 (3P

180 (4P

524033131513

BN400BW2 (BN400NW2

119 (2P

176 (3P

233 (4P

)

)

)

)

Torque Specifications and Applicable Connector Sizes

Screw Size M3 M3.5 M4 M5 M6 M8 M10 M12 Diagram

Torque

Dimension A

Dimension B

Dimension C

Dimension D

(N-m) 0.6 to 1.0 1.0 to 1.3 1.4 to 2.0 2.6 to 3.7 3.9 to 5.4 10 to 13.5 21 to 28 38 to 49

(kgf-cm) 6.1 to 10.2 10.2 to 13.3 14.3 to 20.4 26.5 to 37.7 39.8 to 55.1 102 to 138 214 to 286 388 to 500

0.257”

(6.6mm)

0.129”

(3.3mm)

0.195”

(5mm)

Ø 0.125”

(3.2mm)

0.332”

(8.5mm)

0.156”

(4mm)

0.195”

(5mm)

Ø 0.140”

(3.6mm)

0.371”

(9.5mm)

0.176”

(4.5mm)

0.234”

(6mm)

Ø 0.164”

(4.2mm)

0.499”

(12.8mm)

0.176”

(4.5mm)

0.254”

(6.5mm)

Ø 0.203”

(5.2mm)

0.655”

(16.8mm)

0.234”

(6mm)

0.332”

(8.5mm)

Ø 0.242”

(6.2mm)

0.890”

(22.8mm)

0.312”

(8mm)

0.429”

(11mm)

Ø 0.332”

(8.5mm)

1.279”

(32.8mm)

0.429”

(11mm)

0.624”

(16mm)

Ø 0.410”

(10.5mm)

1.981”

(50.8mm)

0.546”

(14mm)

1.014”

(26mm)

Ø 0.488”

(12.5mm)

Rated Current

Applicable Wire Rated at 60˚C Applicable Wire Rated at 60˚C

22 AWG (0.3mm2) 3A 6 (14mm2) 50A

20 AWG (0.5mm2) 5A 4 (22mm2) 75A

18 AWG (0.75mm2) 7A 0 (38mm2) 100A

16 AWG (1.25mm2) 10A 00 (60mm2) 150A

14 AWG (2mm2) 15A 0000 (100mm2) 200A

2

12 (3.5mm

) 20A 300mcm (150mm2) 300A

10 (5.5mm2) 30A 400mcm (200mm2) 350A

UL/CSA ratings are specified. The current carrying capacity depends on the rating of the wire used, as shown.

916

916

www.IDEC.com

www.IDEC.com

Loading...

Loading...