Page 1

SX9Z-B801-01

SX5L SERIES

®

LONWORKS

Communication T erminals

User’s Manual

Page 2

SAFETY PRECAUTIONS

• Read this user’s manual to make sure of correct operation before starting installation, wiring, operation, maintenance, and

inspection of the SX5L communication terminals.

• All SX5L modules are manufactured under IDEC’s rigorous quality control system, b ut users must add a backup or f ailsafe

provision to the control system using the SX5L in applications where heavy damage or personal injury may be caused in

case the SX5L should fail.

• In this user’s manual, safety precautions are categorized in order of importance to Warning and Caution:

Warning

•Turn off the power to the SX5L before starting installation, removal, wiring, maintenance, and inspection of the SX5L.

Failure to turn power off may cause electrical shocks or fire hazard.

• Special expertise is required to install, wire, program, and operate the SX5L. People without such expertise must not use

the SX5L.

• Emergency stop and interlocking circuits must be configured outside the SX5L. If such a circuit is configured inside the

SX5L, failure of the SX5L may cause disorder of the control system, damage, or accidents.

Caution

• Install the SX5L according to the instructions described in this user’s manual. Improper installation will result in falling,

failure, or malfunction of the SX5L.

• The SX5L is designed for installation in a cabinet. Do not install the SX5L outside a cabinet.

• Install the SX5L in environments described in this user’s manual. If the SX5L is used in places where the SX5L is subjected to high-temperature, high-humidity, condensation, corrosive gases, excessive vibrations, and excessive shocks, then

electrical shocks, fire hazard, or malfunction will result.

• The environment for using the SX5L is “Pollution degree 2.” Use the SX5L in environments of pollution degree 2 (according to IEC 60664-1).

Warning notices are used to emphasize that improper operation may cause

severe personal injury or death.

Caution notices are used where inattention might cause personal injury or

damage to equipment.

• Prevent the SX5L from falling while moving or transporting the SX5L, otherwise damage or malfunction of the SX5L will

result.

• Prevent metal fragments and pieces of wire from dropping inside the SX5L housing. Put a cov er on the SX5L modules dur ing installation and wiring. Ingress of such fragments and chips may cause fire hazard, damage, or malfunction.

• Make sure of safety before starting and stopping the SX5L or when operating the SX5L to force outputs on or off. Incorrect

operation on the SX5L may cause machine damage or accidents.

• Connect a protective ground to the cabinet containing the SX5L using a wire of UL1007 AWG16 (grounding resistance

100 Ω maximum).

• Do not disassemble, repair, or modify the SX5L modules.

• When disposing of the SX5L, do so as an industrial waste.

IMPORTANT INFORMATION

Under no circumstances shall IDEC Corporation be held liable or responsible for indirect or consequential damages resulting

from the use of or the application of IDEC SX5L communication terminals, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit their

application and for choosing an application appropriate for the component, individually or in combination with other equipment.

All diagrams and examples in this manual are for illustrative purposes only. In no way does including these diagrams and examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all programs,

prior to installation, is the responsibility of the end user.

SX5L COMMUNICATION TERMINAL USER’S MANUAL PREFACE-1

Page 3

About This Manual

This user’s manual primarily describes hardware and software specifications of the SX5L communication terminals,

installation and wiring methods, and troubleshooting procedures.

CHAPTER 1: GENERAL INFORMATION

General information about the LONWORKS network system and the features and functions of the SX5L communication

terminals.

CHAPTER 2: HARDWARE SPECIFICATIONS

Hardware specifications of the SX5L communication terminals.

CHAPTER 3: INSTALLATION AND WIRING

Methods and precautions for installing and wiring the SX5L communication terminals.

CHAPTER 4: SOFTWARE SPECIFICATIONS

Software specifications of the SX5L communication terminals. Designing a LONWORKS network requires complete

understanding of the functional blocks available on each SX5L communication terminal. Before starting system configura-

tion, read this chapter to understand available functional blocks.

CHAPTER 5: TROUBLESHOOTING

Procedure to determine the cause of trouble and actions to be taken when any trouble occurs while operating the SX5L

communication terminals.

APPENDIX

Type numbers of the SX5L communication terminals and accessories, and a glossary of major terms related to LON-

WORKS.

INDEX

Alphabetical listing of key words.

LON, LONWORKS, LonMaker, LONMARK, 3120, and Echelon are registered trademarks of Echelon, USA.

PREFACE-2 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 4

TABLE OF CONTENTS

HAPTER 1: GENERAL INFORMATION

C

LONWORKS Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

ONWORKS Device and Functional Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

L

Standard Network Variable Type and Standard Configuration Property Type . . . . 1-2

Address and Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Network Building Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

SX5L Communication Terminal Models and Features . . . . . . . . . . . . . . . . . . . . 1-4

Finger-safe Spring-up Terminal Block Features . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

System Setup Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

HAPTER 2: HARDWARE SPECIFICATIONS

C

Parts Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Hardware Common Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Digital Input Module SX5L-SBN16B1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Digital Output Modules SX5L-SBT16K1 / SX5L-SBT16S1 . . . . . . . . . . . . . . . . . 2-6

Digital I/O Modules SX5L-SBM16K1, -SBM16K2, -SBM16S1, -SBM16S2 . . . . . . 2-8

Analog Input Module SX5L-SBAN041 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Ω Input Modules SX5L-SBPT04X1 / SX5L-SBPT04Y1 . . . . . . . . . . . . . . . 2-14

Pt100

Pulse Input Module SX5L-SBCN081 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Remote-control Relay Control Module SX5L-SBRR081 . . . . . . . . . . . . . . . . . . . 2-18

HAPTER 3: INSTALLATION AND WIRING

C

Mounting on DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Removing from DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Mounting on Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Network Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Terminators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removing the Detachable Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Installing the Detachable Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Insertion Pin Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

SX5L COMMUNICATION TERMINAL USER’S MANUAL i

Page 5

TABLE OF CONTENTS

HAPTER 4: SOFTWARE SPECIFICATIONS

C

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Node Object Functional Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Digital Input Functional Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Digital Output Functional Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Virtual I/O Functional Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Shot Output/Digital Input Functional Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Analog Input Functional Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Pt100Ω Input Functional Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Pulse Count Functional Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Remote-control Relay Control Functional Block . . . . . . . . . . . . . . . . . . . . . . . . 4-17

HAPTER 5: TROUBLESHOOTING

C

PPENDIX

A

Type List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

NDEX

I

ii SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 6

1: GENERAL INFORMATION

Introduction

This chapter describes general information about the LONWORKS network system and provides the features and functions

of the SX5L communication terminals.

LONWORKS Network

LONWORKS refers to the whole multi-purpose network technology de veloped by Echelon Corporation to provide solutions

for building and home automation, industrial, transportation, and public utility control networks. LONWORKS is a fieldlevel open network that enables to build open, multi-vendor control systems of the peer-to-peer distributed control configuration.

Status monitor / scheduled operation control signals

Sensor data / actuator operation control signals

Ethernet

LONWORKS Gateway LONWORKS Gateway LONWORKS Gateway

Air-conditioner

Control Valve

LONWORKS

Network

Digital Data Loader

Thermometer

Non-LONWORKS

SX5L

Device

I/O Module

SX5L

SX5L

SX5L

SX5L

SX5L

SX5L

Control Server / Control Monitor Terminal

Fluorescent Light

Voltage

Current

Power

Alarm

Failure

Control

Illumination Meter

Intrusion Detector

Blind

Example of LONWORKS Network for Building Automation (BA)

In the above control system, LONWORKS devices are connected to the LONWORKS network, such as air-conditioner, control valve, digital data loader, thermometer, fluorescent light, blind, illumination meter, intrusion detector as well as SX5L

communication terminals. These LONWORKS devices contain a microprocessor called Neuron Chip and a LONWORKS

transceiver to communicate with other devices using the LonTalk protocol.

In the centralized control system, the network consists of one host controller, such as a PLC or computer, and multiple terminals, such as sensors and actuators, connected in the 1:N configuration. The host takes care of almost all processing for

intended control operations while terminals work as instructed by the host through the network communication. Therefore,

the host alone contains the control program and network settings.

In contrast to the centralized control system, LONWORKS is a distributed control system with each device containing an

application program. Operation of each device can be programmed by changing configuration parameters. The destination

and contents of communication can be designated for each device using a network management tool.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 1-1

Page 7

1: GENERAL INFORMATION

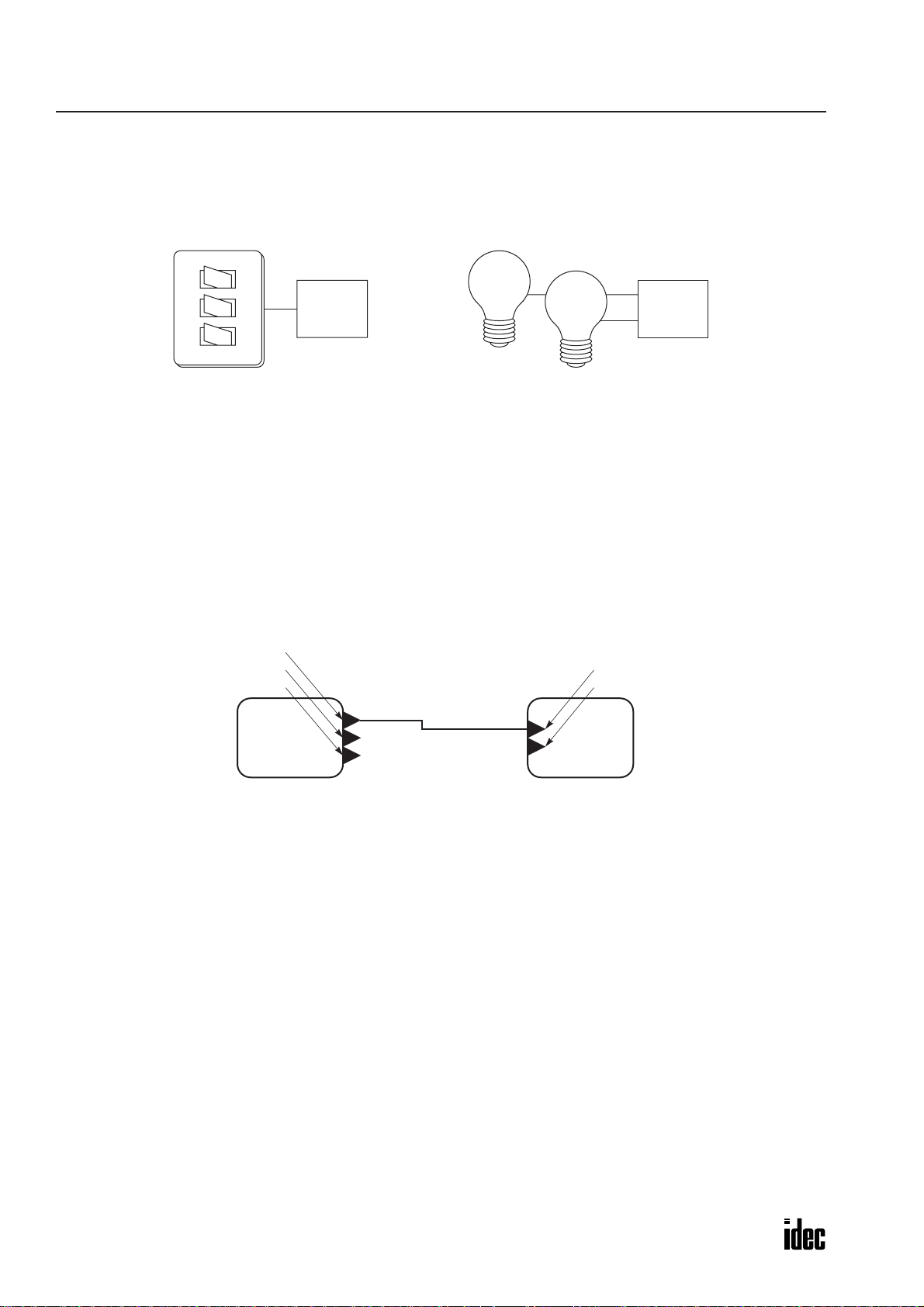

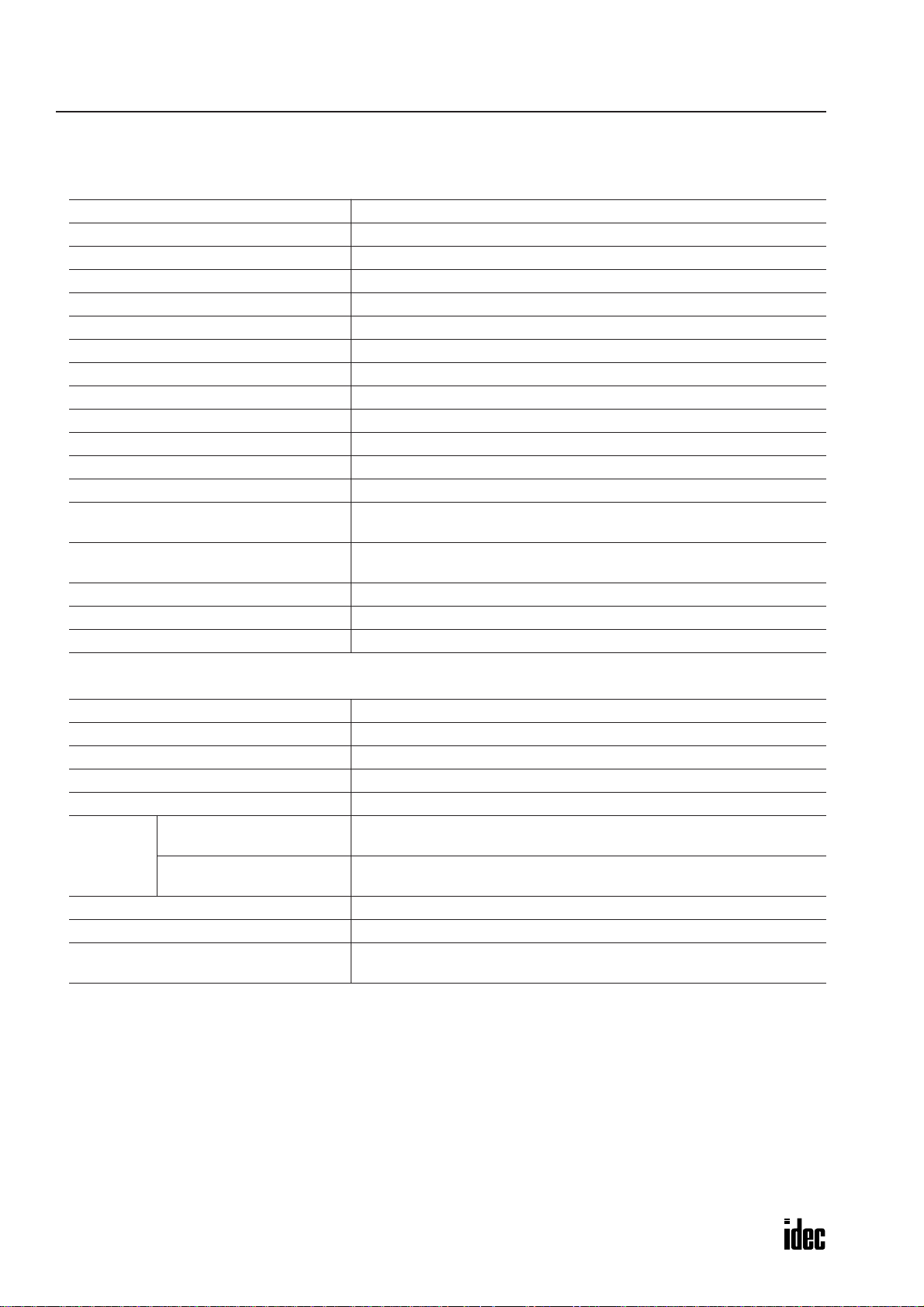

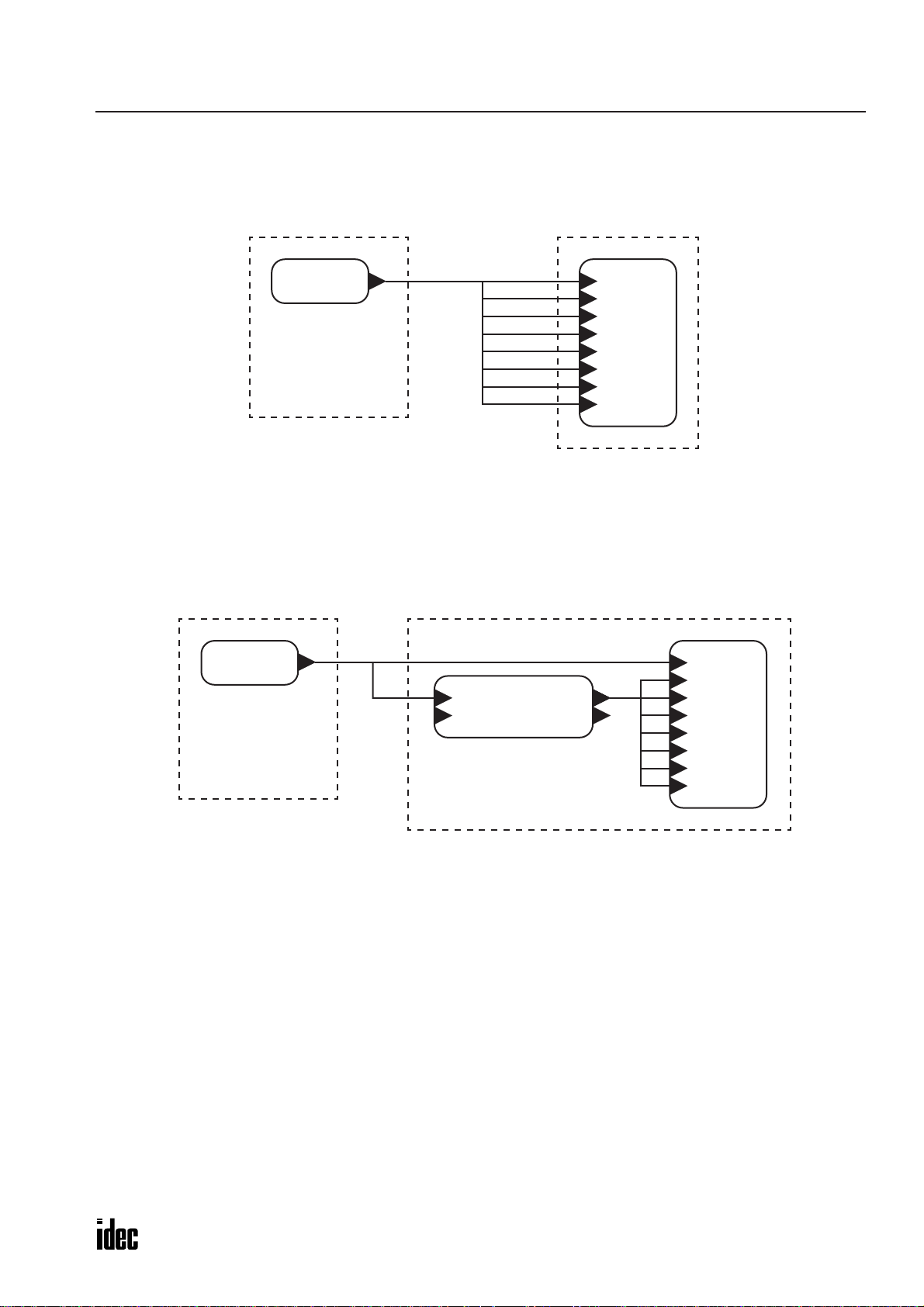

LONWORKS Device and Functional Block

The following figure illustrates examples of LONWORKS devices. Device A consists of switches to send the ON/OFF status

signals of three switches to the network when they are operated. Device B consists of two lamps which go on or off when

receiving ON/OFF signals from the network.

Neuron

Chip

Device A Device B

The intended operation programmed in the L

Example of LONWORKS Devices

ONWORKS device is represented by a functional block. The interf ace with the

Neuron

Chip

network to send the operation results and receive commands is the network variable.

In the next figure, the operation performed by device A is represented by functional block A, which contains three network

variables to send the statuses of three switches. The operation performed by de vice B is represented by functional block B,

which has two network variables to receive commands to turn on and off the lamps. Network variables to send data are

called output network variables, and those to receive data are input network variables.

When network variable D is designated as the destination of network variable A, it is made possible for the device A

switches to turn on or off the device B lamps. This procedure is called binding.

Network Variable A

Network Variable B

Network Variable C

Network Variable D

Network Variable E

Functional Block A

Example of Functional Blocks

Functional Block B

Standard Network Variable Type and Standard Configuration Property Type

As shown in the figure of the example of LONWORKS Network on the preceding page, the LONWORKS network can deal

with various types of data in addition to ON/OFF statuses, such as angle, temperature, illuminance, voltage, and current.

Unlike other field-level networks which transmit data without physical units, LONWORKS can send data with physical

units. The LONMARK Interoperability Association defines Standard Network Variable Types (SNVTs) to facilitate interoperability by providing a well-defined interface for communication between devices made by different manufacturers. The

association also defines Standard Configuration Property Types (SCPTs) to further facilitate interoperability by providing

a well-defined compact mechanism for handling large amounts of configuration information on a device

Address and Table

The LonTalk protocol usually uses a combination of domain ID, subnet ID, and node ID to identify the address of the

receiving device. Each L

store the addresses to send data to (destination addresses). All SX5L communication terminals can store 2 addresses in the

domain table and 15 addresses in the address table, or the maximum quantities allowed for a LONWORKS device.

To identify each network variable contained in a L

selector address. Mutually bound network variables are assigned the same selector address. When the value of a network

variable is sent to multiple network variables, the network variable of the transmitting device sometimes require another

1-2 SX5L COMMUNICATION TERMINAL USER’S MANUAL

ONWORKS device has a domain table to store its address (source address) and an address table to

ONWORKS device, each network variable is assigned an address called

Page 8

1: GENERAL INFORMATION

place, called an alias table, to store the second and subsequent selector addresses. The allowable quantity of selector

address entries for the alias table depends on the type of the device. The maximum quantity is 62 according to the LON-

WORKS specifications. For the quantity of address table entries of the SX5L, see page 4-1.

When using the LonMaker Integration Tool for binding, the tool automatically assigns the selector addresses. Therefore,

users do not have to consider the selector addresses. However, if the device use up the alias table and more binding is

attempted, the tool indicates an error. The network must be designed to keep the selector address quantity within the alias

table entry capacity.

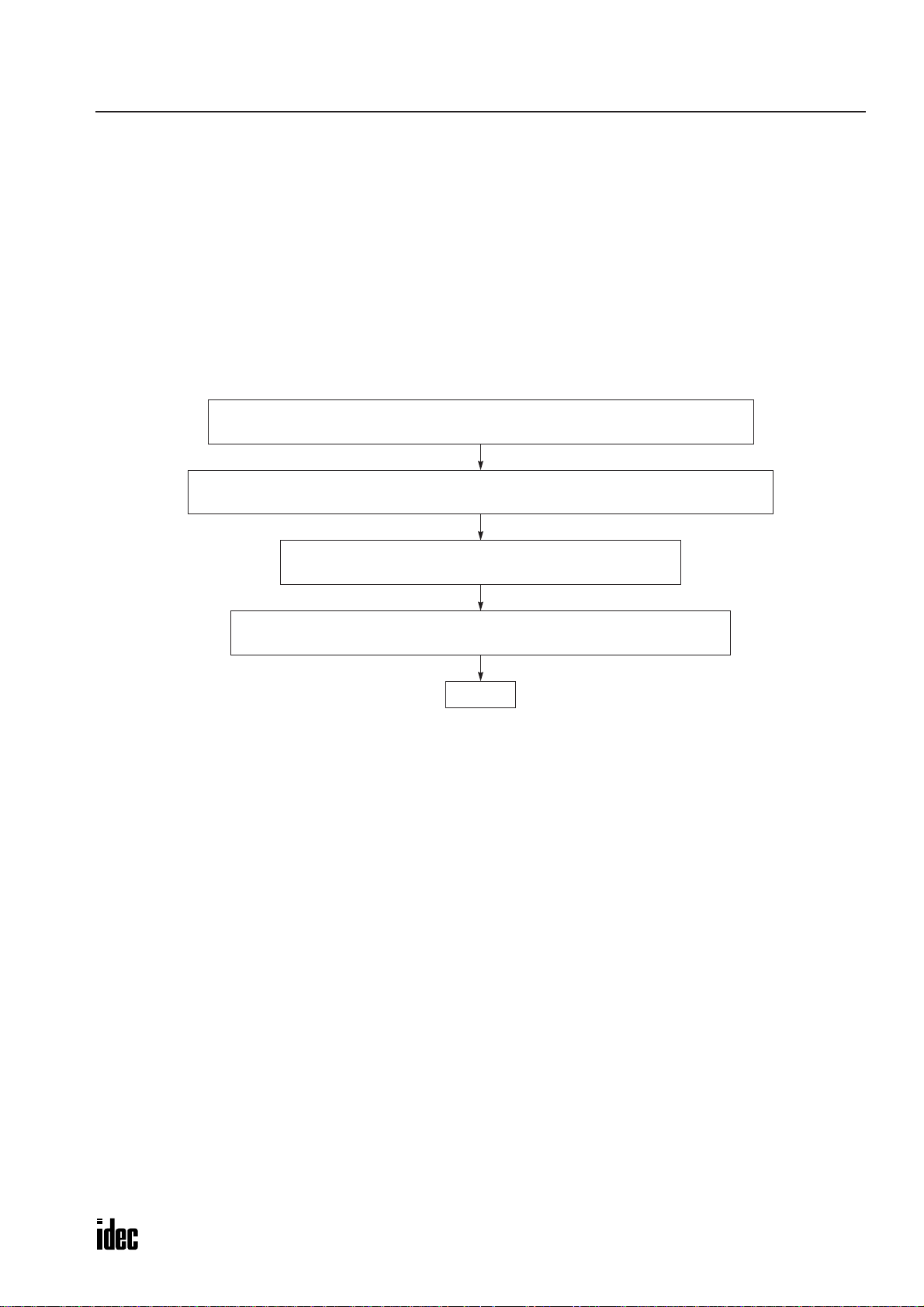

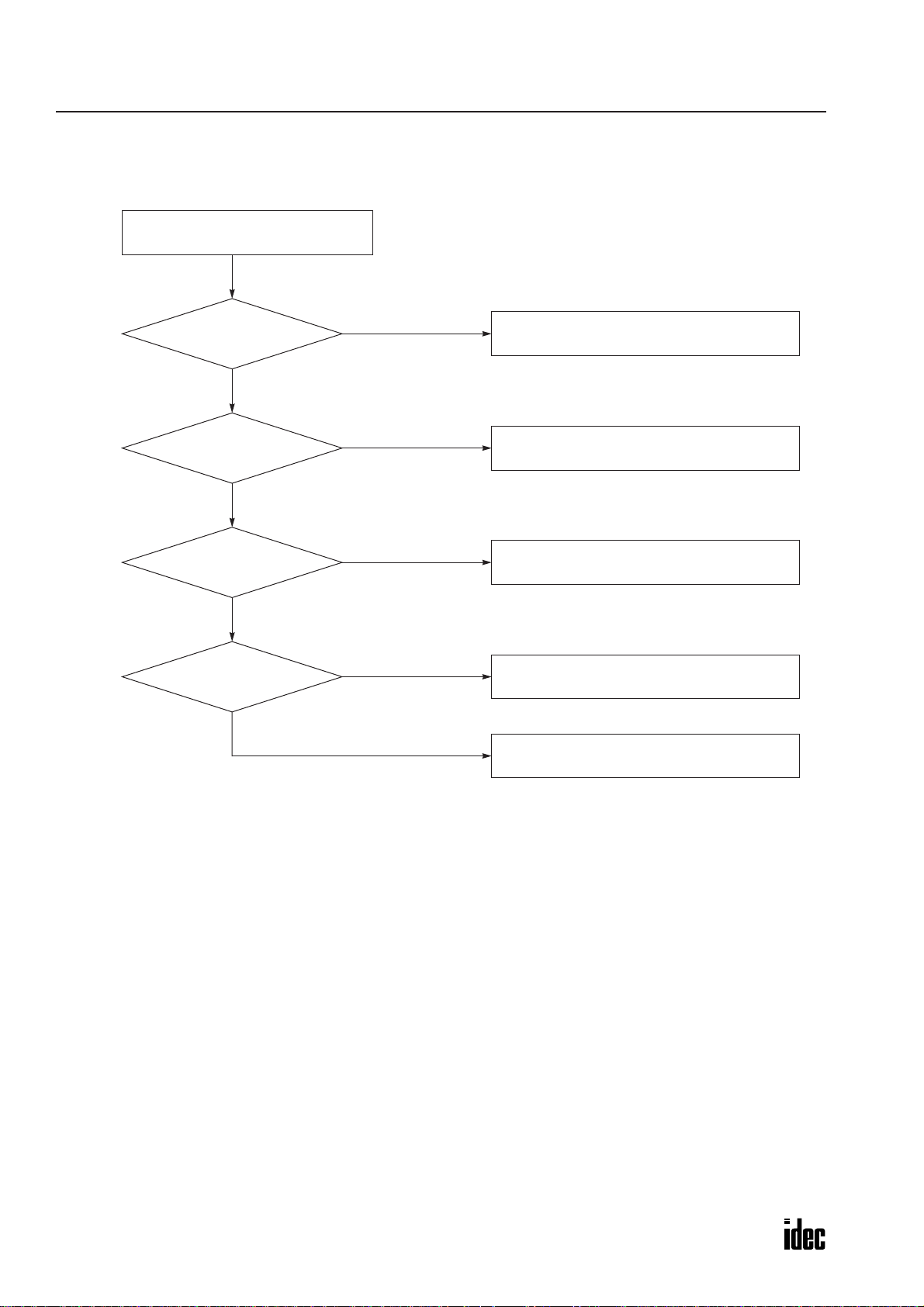

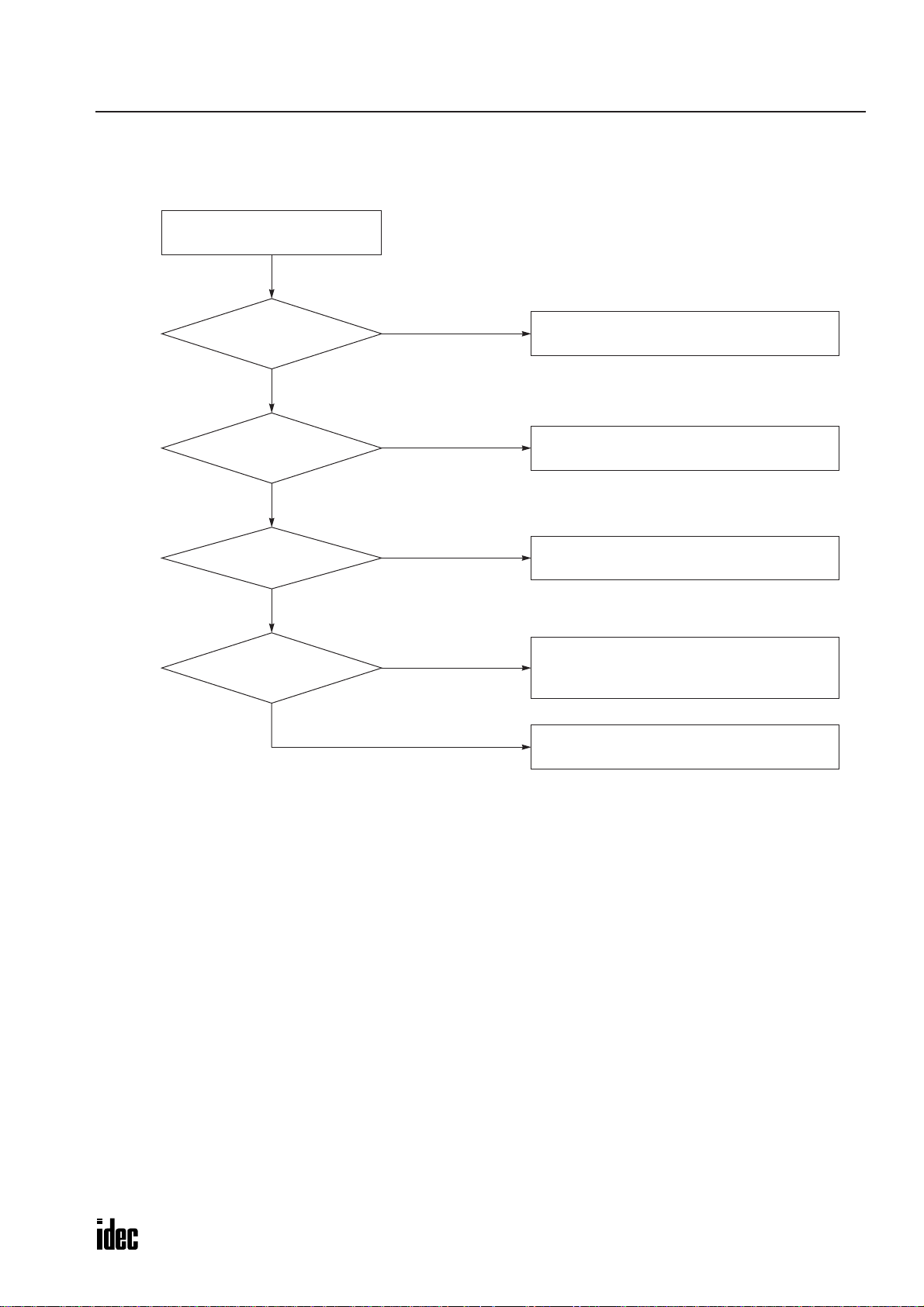

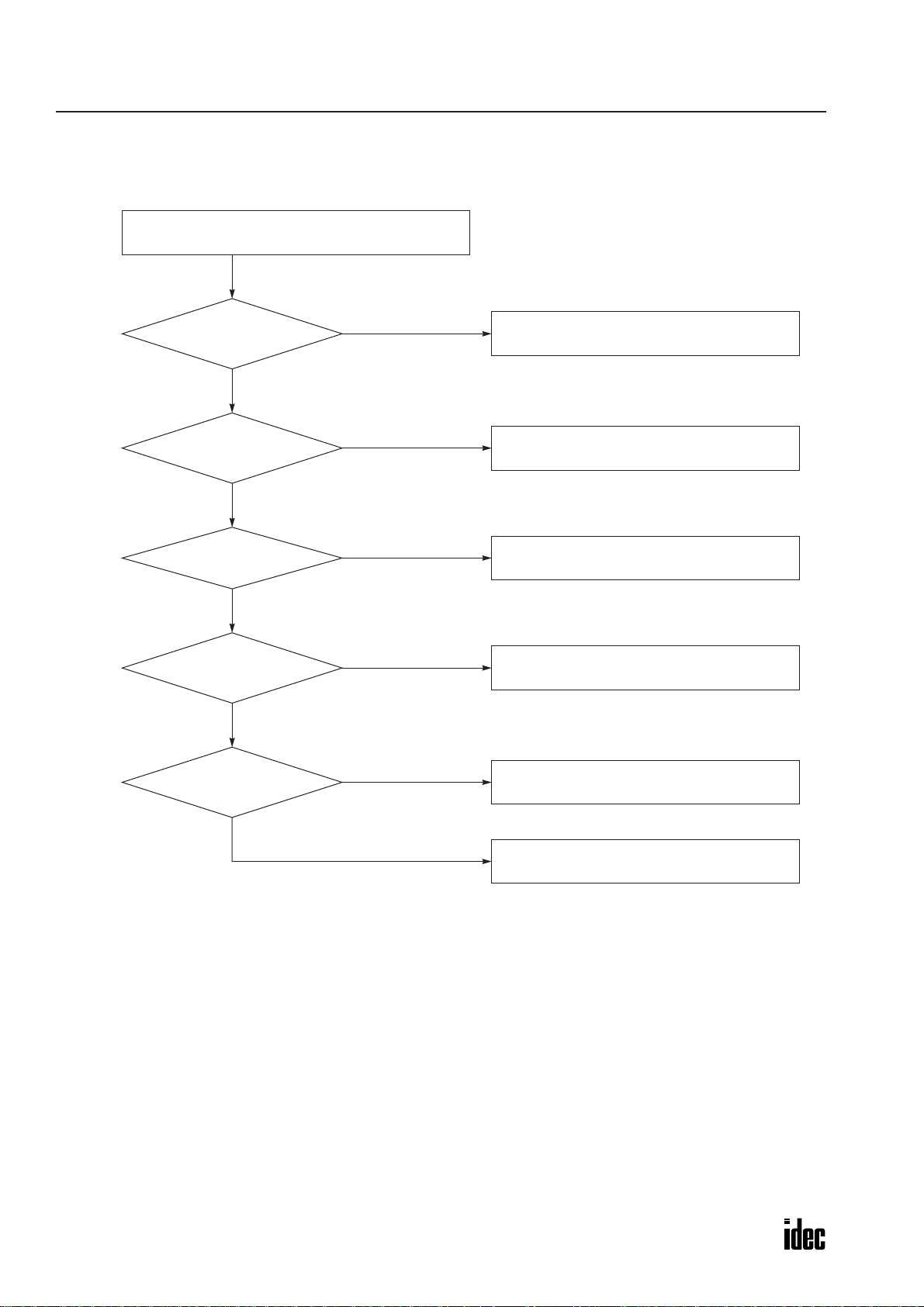

Network Building Procedures

A network management tool is needed to build a LONWORKS network. The most widely used tool is the LonMaker Integration Tool from Echelon. The basic procedures are illustrated below. For detailed procedures, see the user’s manual for

each tool you use.

(1) Understand the functionality of the device.

Confirm the built-in functional blocks and network variables to understand the functionality.

(2) Determine device arrangement (addresses).

A management tool is available which automatically assigns an address when a device is placed.

(3) Place functional blocks and bind network variables.

Connect the transmitter and receiver for each network variable.

(4) Download the programmed network configuration to corresponding devices.

Identify devices by their Neuron ID and write the configuration data to the devices.

End

Network Building Procedures

(1) Understand the functionality of the device.

Before proceeding with building the network, it is necessary to understand the types and quantities of functional blocks

contained in the device you are using, the details of the functionality, and the network variables. F or details about the functional blocks contained in the SX5L, see Chapter 4: Software Specifications.

(2) Determine device arrangement (addresses).

From this step, a network management tool is used. The LONWORKS network identifies the logical location of a device by

its domain ID, subnet ID, and node ID. The LonMaker Integration Tool automatically assigns these three IDs when a

device symbol is placed on the data base. For step (2) and after, the information about the device must be sent to the network management tool. One method is using a XIF file, and another is uploading from the device through the network.

(3) Place functional blocks and bind network variables.

As shown in the figure of functional blocks on the preceding page, bind network variables as many as required for the

entire network. Generally, steps (2) and (3) are performed offline.

(4) Download the programmed network configuration to corresponding devices.

Connect the network management tool to the network, and download the information concerning addresses and binding

specified in steps (2) and (3) to each LONWORKS device through the network. Then use the Neuron ID (hexadecimal 12digit number) contained in the Neuron Chip to identify the download destination device. The SX5L communication terminal is attached with a label indicating the Neuron ID. The Neuron ID can also be sent to the network by pressing the SERVICE REQUEST button on the SX5L.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 1-3

Page 9

1: GENERAL INFORMATION

SX5L Communication Terminal Models and Features

The SX5L is a terminal block type LONWORKS I/O device available in a variety of models designed for multi-vendor

building automation and industrial control networks.

All SX5L communication terminals contain Standard Network Variable Types (SNVTs) defined by the L

Interoperability Association.

Output network variables can be made to be sent only when the input status changes in order to reduce the network traf fic,

and also can be made to be sent at regular intervals (heartbeat) while the input status does not change.

When the network is powered up, each node sends the initial values of the output network variables at different timing.

Digital Input, Output, and I/O Modules

• 16 inputs, 16 outputs, or 8 in/8 out

• Start/stop control module is also available with 8 inputs and 8 outputs.

• Contains virtual I/O functional blocks which can be used for Boolean opera-

tion (AND, OR, NOT) on bit data and for enabling/disabling output network

variables.

• Power voltage 24V DC

Analog Input Module

• 4 analog input channels for 1 to 5V and 4 to 20 mA DC inputs

• Network variable types can be changed to meet the unit of analog input data.

• Power voltage 24V AC/DC

ONMARK

Pt100Ω Input Module

• 4 input channels for room temperature control (0 to +50°C)

• 4 input channels for water temperature control (–20 to +80°C)

• Power voltage 24V AC/DC

Pulse Input Module

• 8 inputs for counting input pulses of minimum pulse width 50 ms

• Maintains counter current values when power is interrupted.

• Counter current values can be changed by input variable.

• Power voltage 24V AC/DC

Remote-control Relay Control Module

• Controls 8 remote control relays for fluorescent lamps.

• Remote-control relays on existing illumination system can also be controlled.

• Power voltage 24V AC

1-4 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 10

Finger-safe Spring-up Terminal Block Features

Time saving

The innovative terminals on the SX5L series use special,

spring-loaded screws. This makes installation as easy as pushing down and turning with a screwdriver. Installation time is

cut in half since the screws do not need to be backed out to

install wiring.

Screw terminals accept bare wire or ring or spade connectors.

Finger-safe

The screws are held captive once installed and are 100% fin-

ger-safe.

1. Insert the wire connector into the slot in the side of the ter-

2. Using a Phillips screwdriver, push down and turn the

The wire is now connected, and the screw terminal is fingersafe.

1: GENERAL INFORMATION

minal block.

screw.

Insertion pin

Detachable

The terminal block can be removed simply by squeezing both

latches on top of the block inward to unlock the block from

the socket. To reattach the terminal block, place the block in

the socket with the latches opened and press the block until it

bottoms in the socket, then the latches snap outward to lock

the terminal block.

Wiring can be done with the terminal block removed, so

installation in narrow areas is quite easy. When replacing the

SX5L modules, simply remove the terminal blocks and reinstall the terminal blocks into the new SX5L module, without

disconnecting wires.

Insertion pins

Insertion pins are positioned on the base of the terminal block

and inside the socket to prevent insertion of invalid terminal

blocks into the socket. The pins are keyed to make sure of

correct matching of terminal block and socket, and to prevent

swapping of upper and lower terminal block.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 1-5

Page 11

1: GENERAL INFORMATION

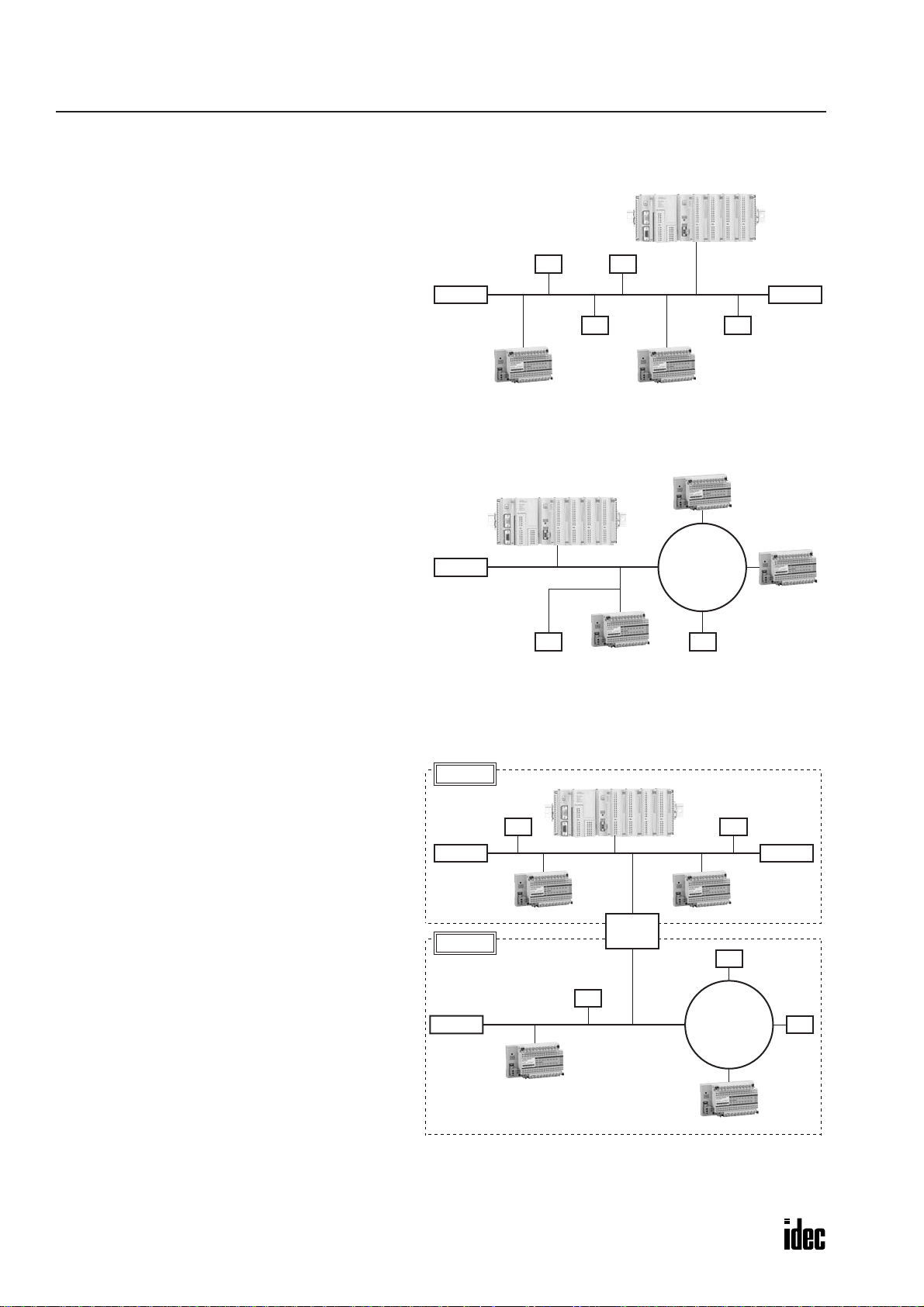

System Setup Examples

Bus Topology

Nodes are connected to one trunk line. The trunk line

can be extended up to 1,400 meters.

Terminators are needed at both ends of the network.

Free Topology

The network can also be connected in star, loop, bus,

and combination of these configurations. The network

can be expanded and modified flexibly.

One terminator is needed at any place on the network.

NodeNode

Ter minator Ter minator

Node Node

Maximum trunk cable length: 1,400 meters

Ter minator

Quantity of Nodes (FTT-10A Transceiver Nodes)

A maximum of 64 nodes can be connected to one

channel. When connecting more than 64 nodes, a

router or repeater is needed.

One router is regarded as one node. Consequently,

when using one router, the maximum number of nodes

connected to one channel will reduce to 63.

NodeNode

Maximum total cable length: 500 meters

Maximum distance between nodes: 400 meters

Channel 1

Node

Ter minator Terminator

Channel 2

Ter minator

Router

Node

Node

Node

Node

1-6 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 12

2: HARDWARE SPECIFICATIONS

Introduction

This chapter describes hardware specifications of the SX5L communication terminals.

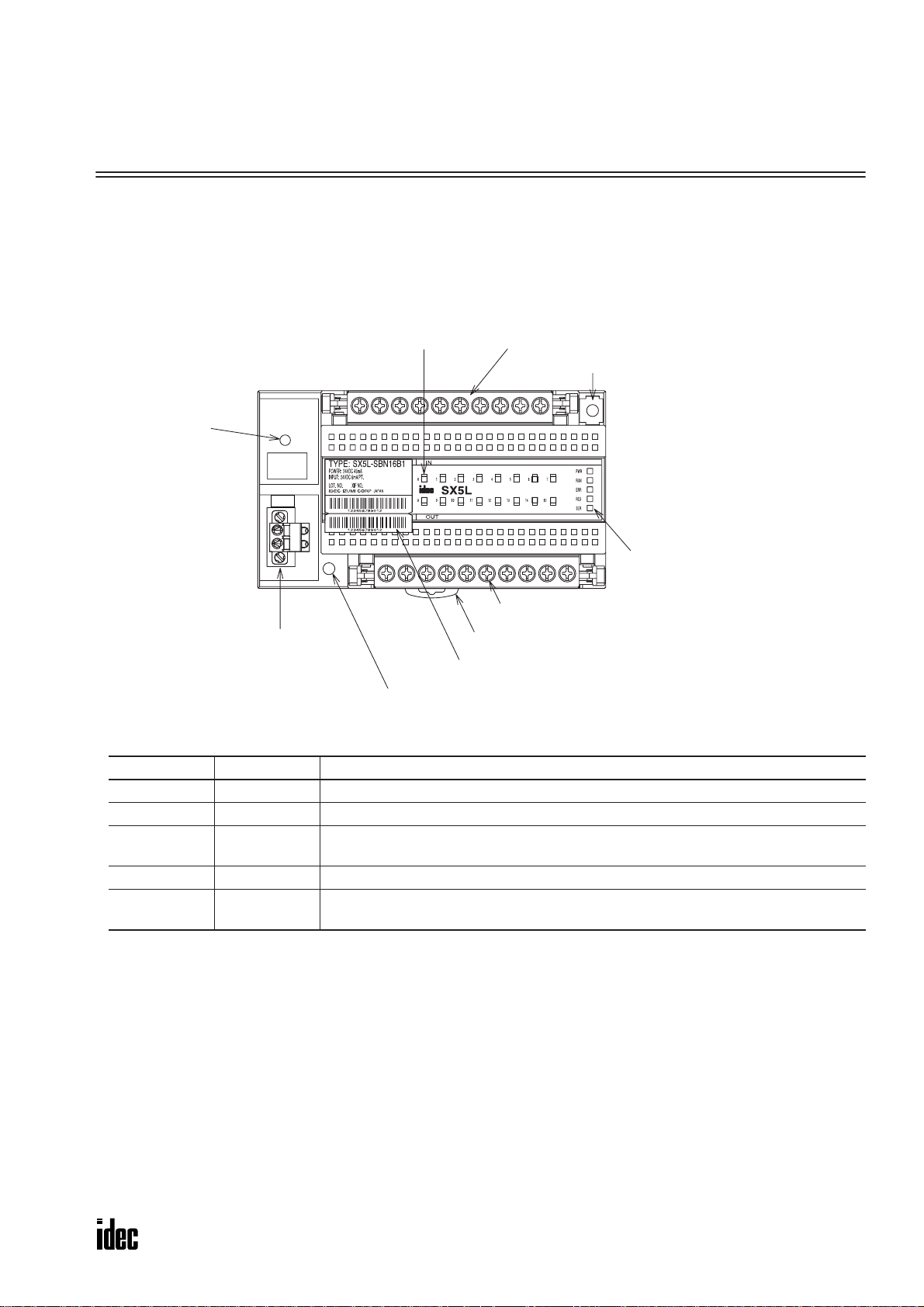

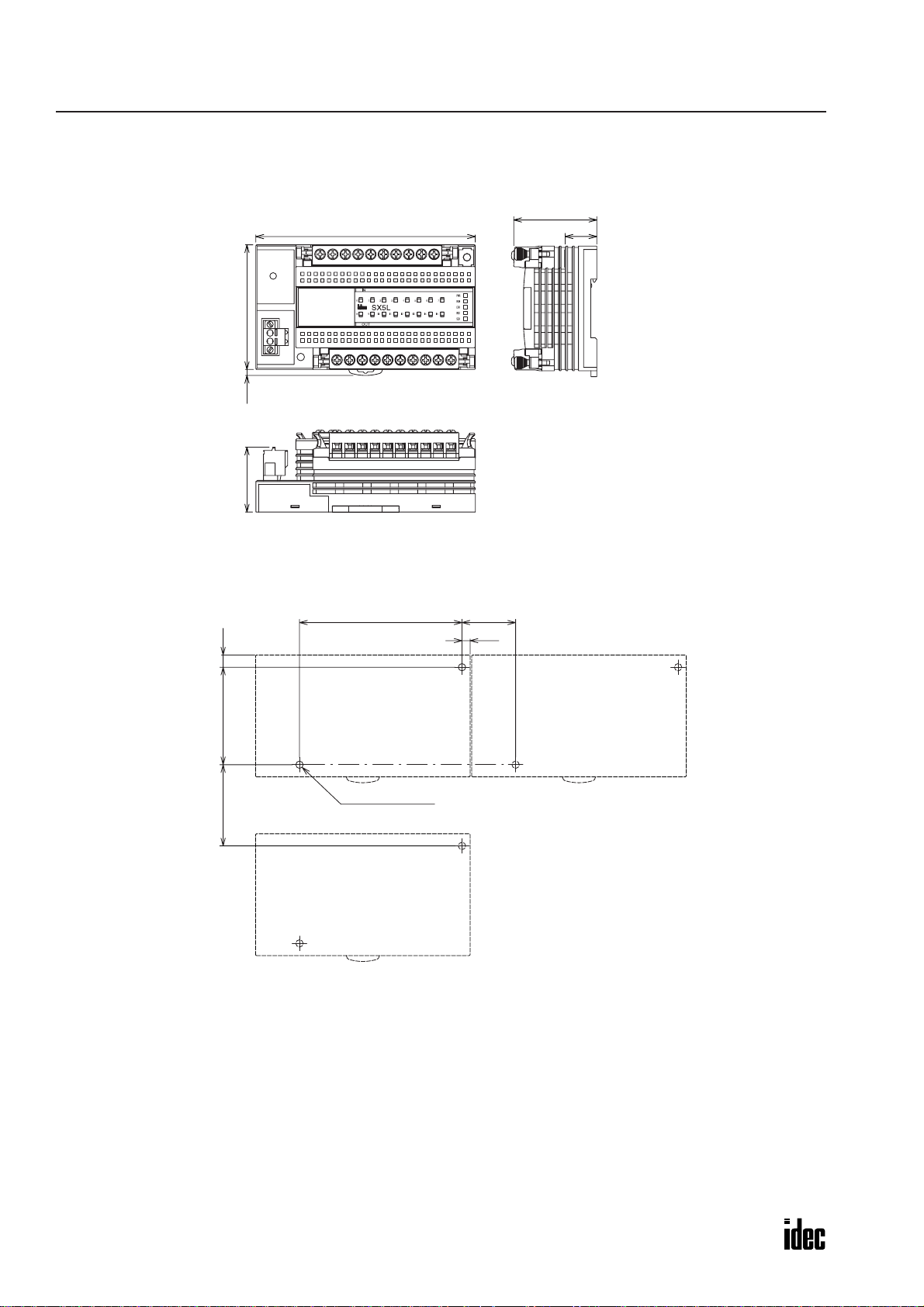

Parts Description

SERVICE

REQUEST

(Pushbutton)

Network Interface Connector

SERVICE

REQUEST

LON

I/O LEDs

Panel Mounting Hole (M4)

Detachable Terminal Block (Upper)

FG Terminal and Panel Mounting Hole (M4)

Communication Status LEDs

Detachable Terminal Block (Lower)

DIN Rail Mounting Clamp

Neuron ID Number and Barcode (Code 39: Narrow bar 0.1 mm)

Communication Status LEDs

Name Color Description

PWR Green Remains on while power is supplied.

RUN Green Goes on when, after powerup, self-diagnosis has completed and application starts.

ERR Red

RES — Reserved (does not go on)

SER Yellow

Goes on when, after application has started, output network variable update failed.

Goes off when output network variable is updated successfully.

Goes on when application program is not configured yet.

Flashes when network information is not configured yet.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 2-1

Page 13

2: HARDWARE SPECIFICATIONS

Dimensions

All SX5L modules has the same external demensions.

132

3.6

39 75

48

19

Mounting Hole Layout

7.560±0.550 min.

100±0.5 33±0.5

5.0

2-M4 or ø4.5 holes

All dimensions in mm.

2-2 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 14

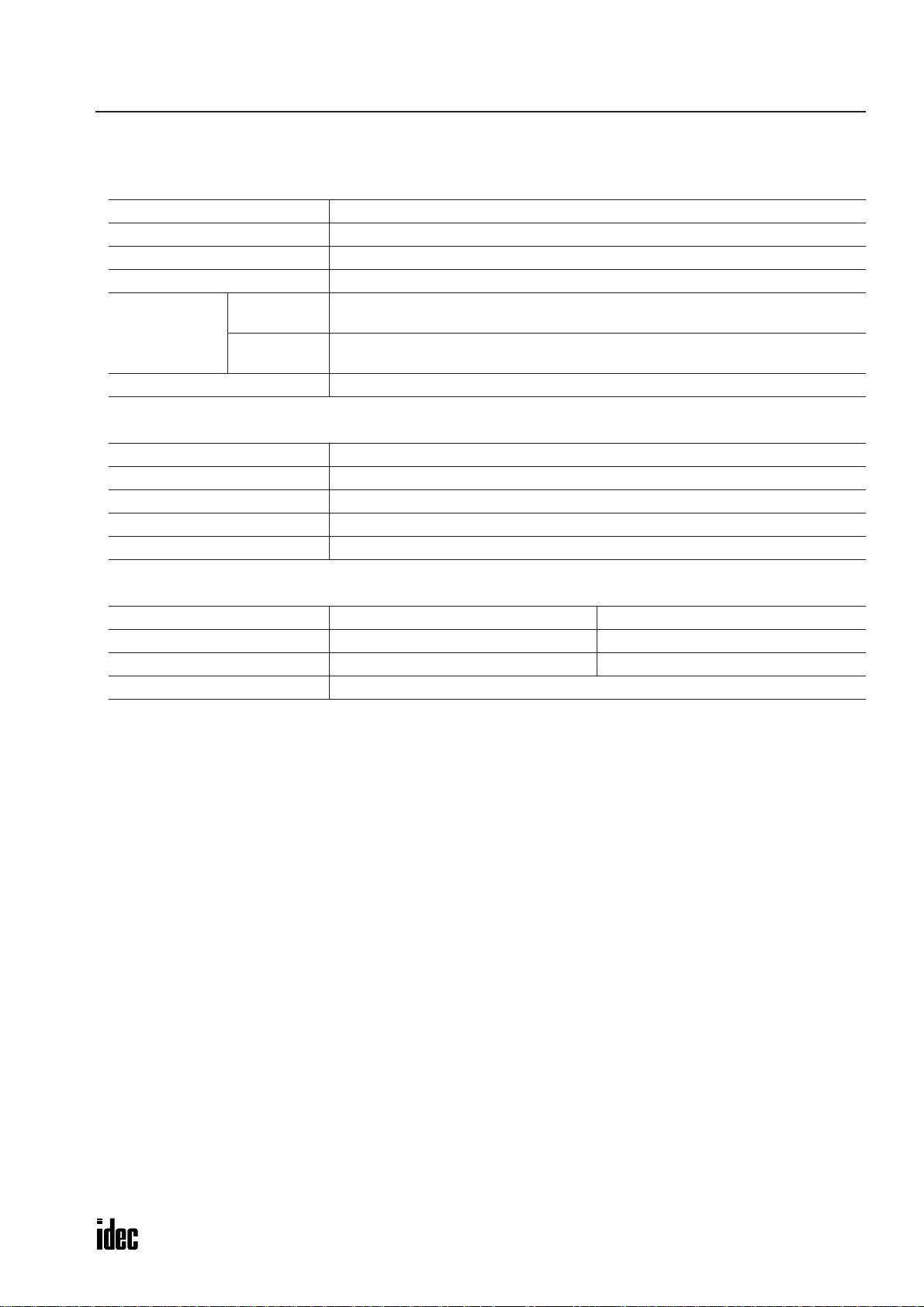

Hardware Common Specifications

Communication Specifications

Communication System LON® system

Transceiver FTT-10A

Connection Topology Bus topology, free topology

Transmission Speed 78 Kbps

Transmission

Distance

Neuron Chip TMPN3120FE5M (Toshiba)

Bus Topology

Free Topology

Detachable Finger-safe Terminal Block

Rated Insulation Voltage 250V

Ter minal Screw M3 (on 7.62-mm centers)

No. of Poles 10 poles

Rated Thermal Current 7A

Insertion/Removal Durability 100 times

1,400m (when using only FTT-10A transceivers)

(Level 4, AWG22 cable)

500m total, 400m between nodes

(Level 4, AWG22 cable)

2: HARDWARE SPECIFICATIONS

Network Interface Connector

Receptacle in Module Housing Connector for Cable

Phoenix Contact Type No. MSTBV2.5/2-GF-5.08 FKC2.5/2-STF-5.08

IDEC Type No. — SX9Z-CN23

Insertion/Removal Durability 100 times

SX5L COMMUNICATION TERMINAL USER’S MANUAL 2-3

Page 15

2: HARDWARE SPECIFICATIONS

Digital Input Module SX5L-SBN16B1

General Specifications

Rated Power Voltage 24V DC

Power Voltage Range 21.6 to 26.4V DC (including 5% ripple)

Power Consumption 1.0W (24V DC)

Power Inrush Current 3A maximum (24V DC)

Allowable Momentary Power Interruption 10 ms minimum (at the rated power voltage)

Dielectric Strength 1,000V AC, 1 minute between power and FG terminals

Insulation Resistance 100 MΩ minimum between power and FG terminals (500V DC megger)

Operating Temperature 0 to 55°C (no freezing)

Operating Humidity 30 to 90% RH (non-condensing)

Storage Temperature –20 to +75°C (no freezing)

Storage Humidity 30 to 90% RH (non-condensing)

Pollution Degree 2 (IEC 60664)

Corrosion Immunity Atmosphere free from corrosive gases

Altitude

Vibration Resistance

Shock Resistance 294 m/s

Mounting 35-mm-wide DIN rail, direct panel mounting (M4 mounting screws)

Weight (approx.) 240g

Operation: 0 to 2,000m

Transport: 0 to 3,000m

10 to 57 Hz amplitude 0.075 mm, 57 to 150 Hz acceleration 9.8 m/s

2 hours per axis on each of three mutually perpendicular axes

2

, 11-ms sinusoidal half-wave pulse

2

Digital Input Specifications

Input Points 16 points

Input Type No-voltage input (DC 2-wire sensor, 3-wire sensor, no-voltage contact)

Rated Input Voltage 24V DC

Input Voltage Range 0 to 26.4V DC

Input Impedance Approx. 4.0 kΩ

Input Current 6 mA/point (24V DC)

No. of Common Circuits 1

Input Common Polarity Plus and minus common compatible

Input Delay Time 250 ms

Input Turn ON Voltage 15V minimum (between input and COM terminals)

Input Turn OFF Voltage 5V maximum (between input and COM terminals)

Input OFF Current 1 mA maximum

Isolation from Power Line Photocoupler isolation

Dielectric Strength

Insulation Resistance

500V AC, 1 minute between input and FG terminals

500V AC, 1 minute between input and power terminals

100 MΩ minimum between input and FG terminals (500V DC megger)

100 MΩ minimum between input and power terminals (500V DC megger)

2-4 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 16

2: HARDWARE SPECIFICATIONS

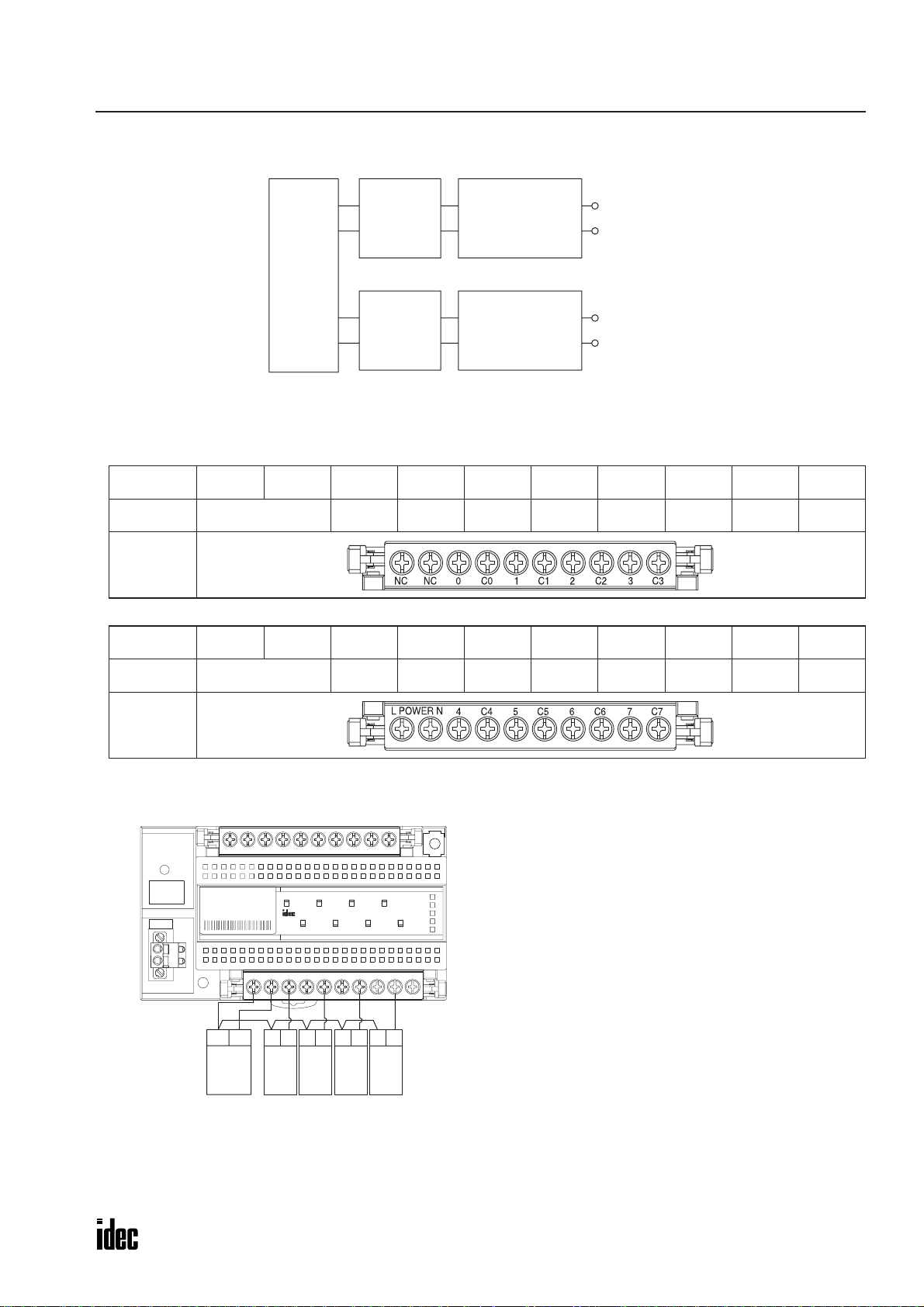

Input Internal Circuit

Input 0

Common

Internal

Circuit

Input 1

Common

Terminal Arrangement

•

Upper Terminal Block (SX9Z-SS10)

Marking COM COM 01234567

Name Input Common Input 0 Input 1 Input 2 Input 3 Input 4 Input 5 Input 6 Input 7

Front View

• Lower Terminal Block (SX9Z-SS2)

Marking

Name

Front View

POWER +POWER

–

Power Voltage

24V DC 0V

Wiring Examples

–

+

SERVICE

REQUEST

LON

NPN

COM COM

TYPE: SX5L-SBN16B1

3-wire

sensor

IN

3210

SX5L

891011 15141312

IN

891011 12 13 14 15

Input 8 Input 9 Input 10 Input 11 Input 12 Input 13 Input 14 Input 15

+–

• Plus Common Wiring• Minus Common Wiring

SX5L

OUT

3-wire

sensor

3210

+

+

–

–

2-wire

sensor

71234560

PWR

7456

RUN

ERR

RES

SER

OUT

–

–

+

+

2-wire

sensor

71234560

PWR

7456

RUN

ERR

RES

SER

SERVICE

REQUEST

LON

+

PNP

–

COM COM

TYPE: SX5L-SBN16B1

891011 15141312

IN

IN

15141312111098

Fuse

+–

24V DC

+

POWER

+–

–

Note: The internal circuit and input circuit can be powered by the same power supply.

Two COM terminals are connected together internally.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 2-5

+

POWER

+–

–

15141312111098

Page 17

2: HARDWARE SPECIFICATIONS

Digital Output Modules SX5L-SBT16K1 / SX5L-SBT16S1

General Specifications

Rated Power Voltage 24V DC

Power Voltage Range 21.6 to 26.4V DC (including 5% ripple)

Power Consumption 1.2W (24V DC)

Power Inrush Current 3A maximum (24V DC)

Allowable Momentary Power Interruption 10 ms minimum (at the rated power voltage)

Dielectric Strength 1,000V AC, 1 minute between power and FG terminals

Insulation Resistance 100 MΩ minimum between power and FG terminals (500V DC megger)

Operating Temperature 0 to 55°C (no freezing)

Operating Humidity 30 to 90% RH (non-condensing)

Storage Temperature –20 to +75°C (no freezing)

Storage Humidity 30 to 90% RH (non-condensing)

Pollution Degree 2 (IEC 60664)

Corrosion Immunity Atmosphere free from corrosive gases

Altitude

Vibration Resistance

Shock Resistance 294 m/s

Mounting 35-mm-wide DIN rail, direct panel mounting (M4 mounting screws)

Weight (approx.) 240g

Operation: 0 to 2,000m

Transport: 0 to 3,000m

10 to 57 Hz amplitude 0.075 mm, 57 to 150 Hz acceleration 9.8 m/s

2 hours per axis on each of three mutually perpendicular axes

2

, 11-ms sinusoidal half-wave pulse

2

Transistor Output Specifications

Type No. SX5L-SBT16K1 SX5L-SBT16S1

Output Points 16 points

Output Type N-MOS open drain (NPN transistor output) P-MOS open drain (PNP transistor output)

Rated Load Voltage 24V DC

Load Voltage Range 21.6 to 26.4V DC

Maximum Load Current

Output Common Polarity Plus common Minus common

Voltage Drop (ON Voltage)

Leakage Current 1 mA maximum

Isolation from Power Line Photocoupler isolation

Dielectric Strength

Insulation Resistance

500 mA per point

6A per common line

0.8V maximum

(voltage between the power – terminal and

output terminals when output is on)

500V AC, 1 minute between output and FG terminals

500V AC, 1 minute between output and power terminals

100 MΩ minimum between output and FG terminals (500V DC megger)

100 MΩ minimum between output and power terminals (500V DC megger)

0.8V maximum

(voltage between the power + terminal and

output terminals when output is on)

2-6 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 18

Output Internal Circuit

2: HARDWARE SPECIFICATIONS

• SX5L-SBT16S1• SX5L-SBT16K1

24V DC

24V DC

Output 0

Output 0

Internal

Circuit

Internal

Circuit

Output 1

Output 1

0V

0V

Terminal Arrangement

•

Upper Terminal Block (SX9Z-SS1)

Marking +–01234567

Name

Load Power

24V DC 0V

Output 0 Output 1 Output 2 Output 3 Output 4 Output 5 Output 6 Output 7

Front View

+

–

• Lower Terminal Block (SX9Z-SS2)

Marking

Name

POWER +POWER

–

Power Voltage

24V DC 0V

891011 12 13 14 15

Output 8 Output 9 Output 10 Output 11 Output 12 Output 13 Output 14 Output 15

Front View

Wiring Examples

SERVICE

REQUEST

LON

TYPE: SX5L-SBT16K1

Fuse

+–

24V DC

+–

+

+–

+

–

891011 15141312

POWER

–

Load

OUT

OUT

SX5L

Load

+–

• SX5L-SBT16S1 (Minus Common Wiring)• SX5L-SBT16K1 (Plus Common Wiring)

–

Load

+

71234560

3210

PWR

7456

RUN

ERR

RES

SER

15141312111098

SERVICE

REQUEST

LON

+–

TYPE: SX5L-SBT16S1

+

POWER

–

+–

Load

OUT

3210

SX5L

891011 15141312

OUT

71234560

PWR

7456

RUN

15141312111098

ERR

RES

SER

Note: The internal circuit and output circuit can be powered by the same power supply.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 2-7

Page 19

2: HARDWARE SPECIFICATIONS

Digital I/O Modules SX5L-SBM16K1, -SBM16K2, -SBM16S1, -SBM16S2

General Specifications

Rated Power Voltage 24V DC

Power Voltage Range 21.6 to 26.4V DC (including 5% ripple)

Power Consumption 1.2W (24V DC)

Power Inrush Current 3A maximum (24V DC)

Allowable Momentary Power Interruption 10 ms minimum (at the rated power voltage)

Dielectric Strength 1,000V AC, 1 minute between power and FG terminals

Insulation Resistance 100 MΩ minimum between power and FG terminals (500V DC megger)

Operating Temperature 0 to 55°C (no freezing)

Operating Humidity 30 to 90% RH (non-condensing)

Storage Temperature –20 to +75°C (no freezing)

Storage Humidity 30 to 90% RH (non-condensing)

Pollution Degree 2 (IEC 60664)

Corrosion Immunity Atmosphere free from corrosive gases

Altitude

Vibration Resistance

Shock Resistance 294 m/s

Mounting 35-mm-wide DIN rail, direct panel mounting (M4 mounting screws)

Weight (approx.) 240g

Operation: 0 to 2,000m

Transport: 0 to 3,000m

10 to 57 Hz amplitude 0.075 mm, 57 to 150 Hz acceleration 9.8 m/s

2 hours per axis on each of three mutually perpendicular axes

2

, 11-ms sinusoidal half-wave pulse

2

Digital Input Specifications

Type No. SX5L-SBM16K1 / SX5L-SBM16K2 SX5L-SBM16S1 / SX5L-SBM16S2

Input Points 8 points

NPN input type

Input Type

Rated Input Voltage 24V DC

Input Voltage Range 0 to 26.4V DC

Input Impedance Approx. 4.0 kΩ

Input Current 6 mA/point (24V DC)

No. of Common Circuits 1

Input Common Polarity Minus common Plus common

Input Delay Time 250 ms

Input Turn ON Voltage 15V minimum (between input and COM terminals)

Input Turn OFF Voltage 5V maximum (between input and COM terminals)

Input OFF Current 1 mA maximum

Isolation from Power Line Photocoupler isolation

Dielectric Strength

Insulation Resistance

No-voltage input (DC 2-wire sensor, NPN

3-wire sensor, no-voltage contact)

500V AC, 1 minute between input and FG terminals

500V AC, 1 minute between input and power terminals

100 MΩ minimum between input and FG terminals (500V DC megger)

100 MΩ minimum between input and power terminals (500V DC megger)

PNP input type

No-voltage input (DC 2-wire sensor, PNP

3-wire sensor, no-voltage contact)

2-8 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 20

2: HARDWARE SPECIFICATIONS

Input Internal Circuit

• SX5L-SBM16S1 / SX5L-SBM16S2• SX5L-SBM16K1 / SX5L-SBM16K2

24V DC

Input 0

Input 0

Input 1

Transistor Output Specifications

Type No. SX5L-SBM16K1 / SX5L-SBM16K2 SX5L-SBM16S1 / SX5L-SBM16S2

Output Points 8 points

Output Type N-MOS open drain (NPN transistor output) P-MOS open drain (PNP transistor output)

Rated Load Voltage 24V DC

Load Voltage Range 21.6 to 26.4V DC

Maximum Load Current

Output Common Polarity Plus common Minus common

Voltage Drop (ON Voltage)

Leakage Current 1 mA maximum

Isolation from Power Line Photocoupler isolation

Dielectric Strength

Insulation Resistance

500 mA per point

4A per common line

0.8V maximum

(voltage between the power – terminal and

output terminals when output is on)

500V AC, 1 minute between output and FG terminals

500V AC, 1 minute between output and power terminals

100 MΩ minimum between output and FG terminals (500V DC megger)

100 MΩ minimum between output and power terminals (500V DC megger)

Internal

Circuit

Input 1

0V

0.8V maximum

(voltage between the power + terminal and

output terminals when output is on)

Internal

Circuit

Output Internal Circuit

Internal

Circuit

• SX5L-SBM16S1 / SX5L-SBM16S2• SX5L-SBM16K1 / SX5L-SBM16K2

24V DC

Output 0

Internal

Output 1

0V

Circuit

SX5L COMMUNICATION TERMINAL USER’S MANUAL 2-9

24V DC

Output 0

Output 1

0V

Page 21

2: HARDWARE SPECIFICATIONS

Terminal Arrangement (SX5L-SBM16K1 / SX5L-SBM16S1)

• Upper Terminal Block (SX9Z-SS1)

Marking +–01234567

Input Common/

Name

Load Power

24V DC

*1

0V

Input 0 Input 1 Input 2 Input 3 Input 4 Input 5 Input 6 Input 7

*2

Front View

+

–

*1: Common terminal for SX5L-SBM16S1 inputs

*2: Common terminal for SX5L-SBM16K1 inputs

• Lower Terminal Block (SX9Z-SS3)

Marking

Name

Front View

POWER +POWER

–

Power Voltage

24V DC 0V

01234567

Output 0 Output 1 Output 2 Output 3 Output 4 Output 5 Output 6 Output 7

+–

Terminal Arrangement (SX5L-SBM16K2 / SX5L-SBM16S2)

• Upper Terminal Block (SX9Z-SS1)

Marking +–01234567

Input Common/

Name

Load Power

24V DC

*1

0V

Status 0 Alarm 0 Status 1 Alarm 1 Status 2 Alarm 2 Status 3 Alarm 3

*2

Front View

*1: Common terminal for SX5L-SBM16S2 inputs

*2: Common terminal for SX5L-SBM16K2 inputs

• Lower Terminal Block (SX9Z-SS3)

Marking

Name

Front View

POWER +POWER

–

Power Voltage

24V DC 0V

01234567

Start 0 Stop 0 Start 1 Stop 1 Star t 2 Stop 2 Star t 3 Stop 3

+–

+

–

2-10 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 22

Wiring Examples

• SX5L-SBM16K1 / SX5L-SBM16K2

(Input: Minus Common Wiring)

(Output: Plus Common Wiring)

2: HARDWARE SPECIFICATIONS

• SX5L-SBM16S1 / SX5L-SBM16S2

(Input: Plus Common Wiring)

(Output: Minus Common Wiring)

SERVICE

REQUEST

LON

Fuse

24V DC

–

+

TYPE: SX5L-SBM16K∗

+–

+–

+

+–

NPN

POWER

IN

OUT

–

Load

–

OUT

+

3-wire

2-wire

sensor

sensor

3210 7456

SX5L

3210 7456

Load

–

+

71234560

PWR

RUN

ERR

RES

SER

76543210

SERVICE

REQUEST

LON

+

–

+–

TYPE: SX5L-SBM16S∗

PNP

+

POWER

+–

IN

SX5L

OUT

–

Load

Note: The internal circuit, input circuit, and output circuit can be powered by the same power supply.

+

+

OUT

–

–

3-wire

2-wire

sensor

sensor

71234560

3210 7456

3210 7456

Load

PWR

RUN

ERR

RES

SER

76543210

SX5L COMMUNICATION TERMINAL USER’S MANUAL 2-11

Page 23

2: HARDWARE SPECIFICATIONS

Analog Input Module SX5L-SBAN041

General Specifications

Rated Power Voltage 24V AC (50/60Hz) / 24V DC compatible

Power Voltage Range 21.6 to 26.4V AC/DC (including 5% ripple)

Power Consumption 3.0 VA (24V AC), 1.8W (24V DC)

Power Inrush Current 15A maximum (24V AC/DC)

Allowable Momentary Power Interruption 10 ms minimum (at the rated power voltage)

Dielectric Strength 1,000V AC, 1 minute between power and FG terminals

Insulation Resistance 100 MΩ minimum between power and FG terminals (500V DC megger)

Operating Temperature 0 to 55°C (no freezing)

Operating Humidity 30 to 90% RH (non-condensing)

Storage Temperature –20 to +75°C (no freezing)

Storage Humidity 30 to 90% RH (non-condensing)

Pollution Degree 2 (IEC 60664)

Corrosion Immunity Atmosphere free from corrosive gases

Altitude

Vibration Resistance

Shock Resistance 294 m/s

Mounting 35-mm-wide DIN rail, direct panel mounting (M4 mounting screws)

Weight (approx.) 250g

Operation: 0 to 2,000m

Transport: 0 to 3,000m

10 to 57 Hz amplitude 0.075 mm, 57 to 150 Hz acceleration 9.8 m/s

2 hours per axis on each of three mutually perpendicular axes

2

, 11-ms sinusoidal half-wave pulse

2

Analog Input Specifications

Input Points 4 points

Input Type

Input Impedance

Digital Resolution 12 bits

A/D Conversion Time 80 ms per point

Sample Duration Time 300 ms per point

Error

Isolation between Input Channels No isolation

Dielectric Strength

Insulation Resistance

Voltage input: 1 to 5V DC

Current input: 4 to 20 mA DC

Voltage input: 1 MΩ

Current input: 250Ω

±0.6% (at 25°C)

±1.0% (over the operating temperature range)

500V AC, 1 minute between input and FG terminals

500V AC, 1 minute between input and power terminals

100 MΩ minimum between input and FG terminals (500V DC megger)

100 MΩ minimum between input and power terminals (500V DC megger)

2-12 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 24

Input Internal Circuit

2: HARDWARE SPECIFICATIONS

Channel 0 Voltage Input

Channel 0 Current Input

Channel 0 Common

Channel 1 Voltage Input

Channel 1 Current Input

Channel 1 Common

A/D

Conversion

Circuit

Photocoupler

Isolation

Power

Supply

Internal

Circuit

Terminal Arrangement

•

Upper Terminal Block (SX9Z-SS12)

Marking NC NC SLD C0 I0 V0 SLD C1 I1 V1

Name No Connection Shield

Common

Channel 0

Current

Input

Voltage

Input

Shield

Common

Channel 1

Current

Input

Front View

• Lower Terminal Block (SX9Z-SS9)

Marking

Name Power Voltage Shield

POWER LPOWER

N

SLD C2 I2 V2 SLD C3 I3 V3

Common

Channel 2

Current

Input

Voltage

Input

Shield

Common

Channel 3

Current

Input

Voltage

Input

Voltage

Input

Front View

Wiring Examples

SERVICE

REQUEST

LON

TYPE: SX5L-SBAN041

Fuse

~

24V AC

+–

24V DC

NC NC

L

+–

POWER

~

+–

N

Analog Current

Output Device

IN

Analog Voltage

Output Device

SX5L

IN

Termination on unused terminals

V1C0 I0 V0 SLD C1 I1SLD

PWR

RUN

ERR

RES

SER

V3I3C3SLDV2I2C2SLD

Note: Connect together the terminals of an unused

channel using an optional jumper BPJ-26B (ring

type) or BPJ-26FB (spade type) or using wires.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 2-13

Page 25

2: HARDWARE SPECIFICATIONS

Pt100Ω Input Modules SX5L-SBPT04X1 / SX5L-SBPT04Y1

General Specifications

Rated Power Voltage 24V AC (50/60Hz) / 24V DC compatible

Power Voltage Range 21.6 to 26.4V AC/DC (including 5% ripple)

Power Consumption 3.0 VA (24V AC), 1.8W (24V DC)

Power Inrush Current 15A maximum (24V AC/DC)

Allowable Momentary Power Interruption 10 ms minimum (at the rated power voltage)

Dielectric Strength 1,000V AC, 1 minute between power and FG terminals

Insulation Resistance 100 MΩ minimum between power and FG terminals (500V DC megger)

Operating Temperature 0 to 55°C (no freezing)

Operating Humidity 30 to 90% RH (non-condensing)

Storage Temperature –20 to +75°C (no freezing)

Storage Humidity 30 to 90% RH (non-condensing)

Pollution Degree 2 (IEC 60664)

Corrosion Immunity Atmosphere free from corrosive gases

Altitude

Vibration Resistance

Shock Resistance 294 m/s

Mounting 35-mm-wide DIN rail, direct panel mounting (M4 mounting screws)

Weight (approx.) 250g

Operation: 0 to 2,000m

Transport: 0 to 3,000m

10 to 57 Hz amplitude 0.075 mm, 57 to 150 Hz acceleration 9.8 m/s

2 hours per axis on each of three mutually perpendicular axes

2

, 11-ms sinusoidal half-wave pulse

2

Pt100Ω Input Specifications

Type No. SX5L-SBPT04X1 SX5L-SBPT04Y1

Input Points 4 points

Input Type 3-wire Pt100Ω resistance thermometer

Temperature Measurement Range 0 to +50°C –20 to +80°C

Digital Resolution 12 bits

Input Detection Current 1.0 mA maximum

A/D Conversion Time 80 ms per point

Sample Duration Time 1 sec

Allowable Conductor Resistance 100Ω maximum (3 wires must have the same resistance)

Burnout Yes (data: +327.67°C)

Error ±0.4% FS

Isolation between Input Channels No isolation

Dielectric Strength

Insulation Resistance

500V AC, 1 minute between input and FG terminals

500V AC, 1 minute between input and power terminals

100 MΩ minimum between input and FG terminals (500V DC megger)

100 MΩ minimum between input and power terminals (500V DC megger)

2-14 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 26

Input Internal Circuit

2: HARDWARE SPECIFICATIONS

A0

B0Channel 0

A1

B1Channel 1

b0

b1

A/D

Conversion

Circuit

Photocoupler

Isolation

Power

Supply

Internal

Circuit

Terminal Arrangement

•

Upper Terminal Block (SX9Z-SS13)

Marking NC NC NC b0 B0 A0 NC b1 B1 A1

Name No Connection Channel 0 Pt100Ω Input

No Con-

nection

Channel 1 Pt100Ω Input

Front View

• Lower Terminal Block (SX9Z-SS14)

Marking

Name Power Voltage

POWER LPOWER

N

NC b2 B2 A2 NC b3 B3 A3

No Connection

Channel 2 Pt100Ω Input

No con-

nection

Channel 3 Pt100Ω Input

Front View

Wiring Examples

SERVICE

REQUEST

LON

Fuse

~

24V AC

+–

24V DC

TYPE: SX5L-SBPT04∗1

NC NC

+–

L

POWER

~

+–

Resistance

Thermometer

IN

Resistance

Thermometer

SX5L

IN

N

Termination on unused terminals

A1b0 B0 A0 NC b1 B1NC

PWR

RUN

ERR

RES

SER

A3B3b3NCA2B2b2NC

Note: Connect together the terminals of an unused

channel using an optional jumper BPJ-26B (ring

type) or BPJ-26FB (spade type) or using wires.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 2-15

Page 27

2: HARDWARE SPECIFICATIONS

Pulse Input Module SX5L-SBCN081

General Specifications

Rated Power Voltage 24V AC (50/60Hz) / 24V DC compatible

Power Voltage Range 21.6 to 26.4V AC/DC (including 5% ripple)

Power Consumption 2.0 VA (24V AC), 1.0W (24V DC)

Power Inrush Current 15A maximum (24V AC/DC)

Allowable Momentary Power Interruption 10 ms minimum (at the rated power voltage)

Dielectric Strength 1,000V AC, 1 minute between power and FG terminals

Insulation Resistance 100 MΩ minimum between power and FG terminals (500V DC megger)

Operating Temperature 0 to 55°C (no freezing)

Operating Humidity 30 to 90% RH (non-condensing)

Storage Temperature –20 to +75°C (no freezing)

Storage Humidity 30 to 90% RH (non-condensing)

Pollution Degree 2 (IEC 60664)

Corrosion Immunity Atmosphere free from corrosive gases

Altitude

Vibration Resistance

Shock Resistance 294 m/s

Mounting 35-mm-wide DIN rail, direct panel mounting (M4 mounting screws)

Weight (approx.) 250g

Operation: 0 to 2,000m

Transport: 0 to 3,000m

10 to 57 Hz amplitude 0.075 mm, 57 to 150 Hz acceleration 9.8 m/s

2 hours per axis on each of three mutually perpendicular axes

2

, 11-ms sinusoidal half-wave pulse

2

Pulse Input Specifications

Input Points 8 points

Rated Input Voltage 24V DC

Input Voltage Range 0 to 26.4V DC

Minimum Pulse Width

Maximum Frequency Response 8 Hz

Input Impedance Approx. 3.4 kΩ

Input Current 7 mA/point (24V DC)

No. of Common Circuits 1 common circuit/point

Input Common Polarity Plus and minus common compatible

Input Turn ON Voltage 15V minimum (between input and COM terminals)

Input Turn OFF Voltage 5V maximum (between input and COM terminals)

Isolation from Power Line Photocoupler isolation

Dielectric Strength

Insulation Resistance

Current Value Backup Times

ON duration: 50 ms

OFF duration: 50 ms

500V AC, 1 minute between input and FG terminals

500V AC, 1 minute between input and power terminals

500V AC, 1 minute between input terminals

100 MΩ minimum between input and FG terminals (500V DC megger)

100 MΩ minimum between input and power terminals (500V DC megger)

100 MΩ minimum between input terminals (500V DC megger)

10,000 times of current value storage into the built-in EEPROM during

power interruption

2-16 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 28

2: HARDWARE SPECIFICATIONS

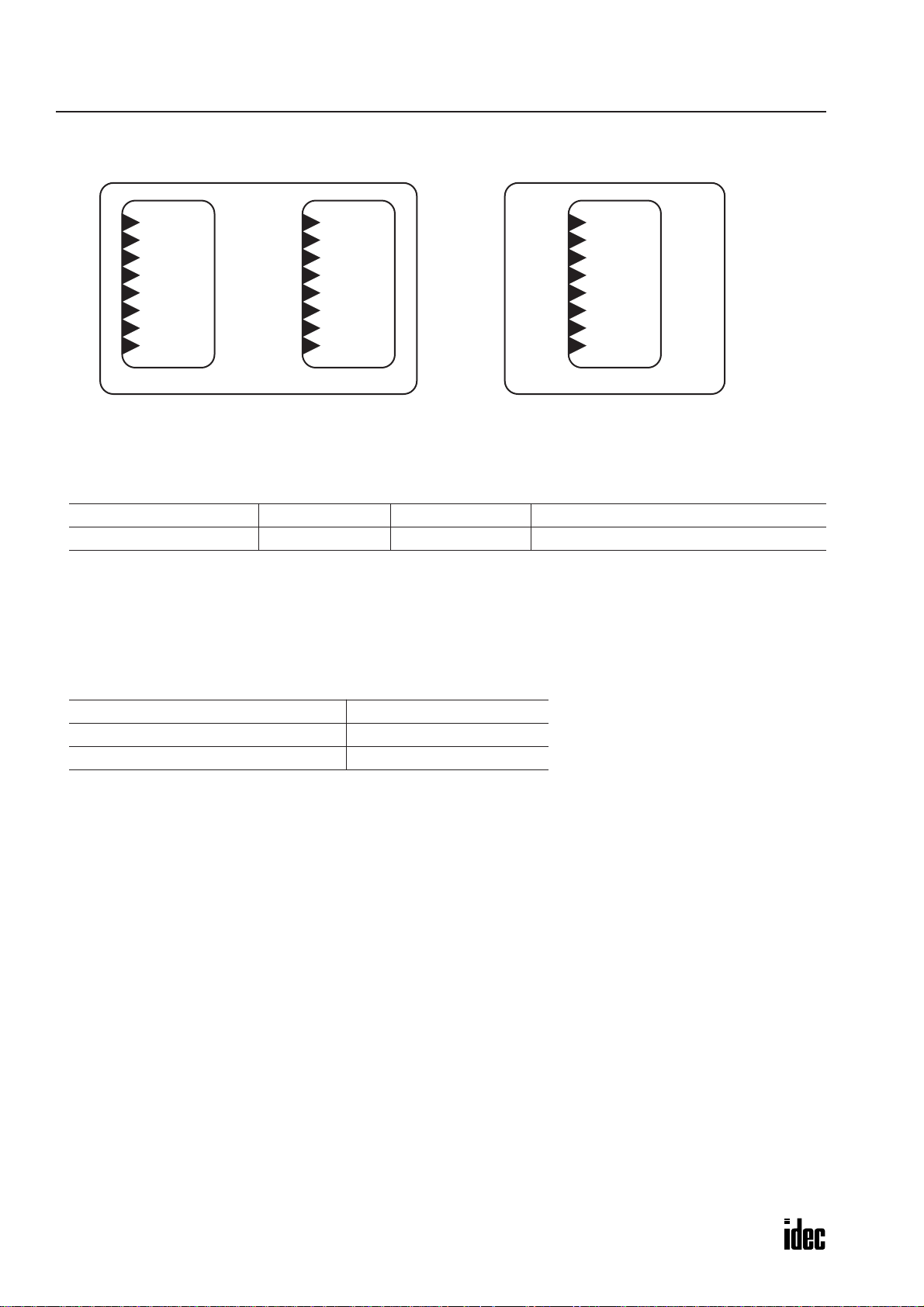

Input Internal Circuit

Input 0

Common 0

Internal

Circuit

Input 1

Common 1

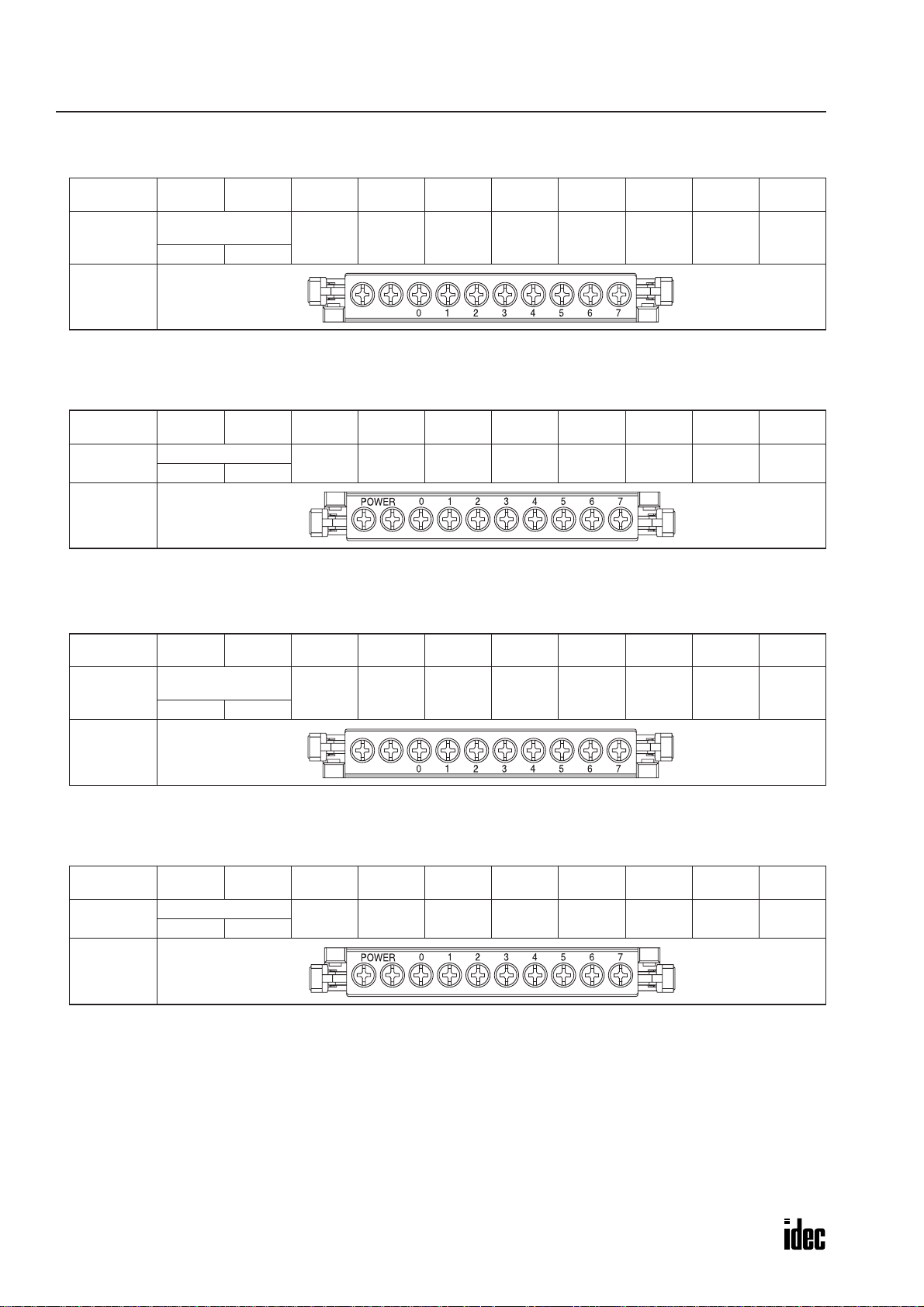

Terminal Arrangement

•

Upper Terminal Block (SX9Z-SS11)

Marking NC NC 0 C01C12C23C3

Name No Connection Input 0

Front View

Common

0

Input 1

Common

1

Input 2

Common

2

Input 3

Common

3

• Lower Terminal Block (SX9Z-SS7)

Marking

Name Power Voltage Input 4

Front View

POWER LPOWER

N

Wiring Examples

NC NC

+–

L

POWER

~

+–

IN

45 76

IN

N

NPN

10

23

SX5L

SERVICE

REQUEST

LON

Fuse

24V AC

24V DC

TYPE: SX5L-SBCN081

~

+–

4C45C56C67C7

Common

4

Input 5

Common

5

Input 6

Common

6

Input 7

Common

7

• Plus Common Wiring• Minus Common Wiring

C3C0 1 C1 2 C2 30

PWR

RUN

ERR

RES

SER

C77C66C55C44

+

–

SERVICE

REQUEST

LON

NC NC

TYPE: SX5L-SBCN081

L

POWER

N

~

+–

+–

IN

10

SX5L

45 76

IN

PNP

C3C0 1 C1 2 C2 30

23

PWR

RUN

ERR

RES

SER

C77C66C55C44

–

+

Note: Besides common wiring, input circuits can also be connected separately.

When using a DC power supply, the internal circuit and pulse input circuit can be powered by the same power supply.

When using an AC power supply for the internal circuit, the same power supply cannot be used for the pulse input circuit.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 2-17

Page 29

2: HARDWARE SPECIFICATIONS

Remote-control Relay Control Module SX5L-SBRR081

General Specifications

Rated Power Voltage 24V AC (50/60Hz) supplied from a remote-control transformer

Power Voltage Range 21.6 to 26.4V AC (including 5% ripple)

Power Consumption 1.8 VA (24V AC) not including power consumption by remote-control relays

Power Inrush Current 15A maximum (24V AC)

Allowable Momentary Power Interruption 10 ms minimum (at the rated power voltage)

Dielectric Strength 1,000V AC, 1 minute between power and FG terminals

Insulation Resistance 100 MΩ minimum between power and FG terminals (500V DC megger)

Operating Temperature 0 to 55°C (no freezing)

Operating Humidity 30 to 90% RH (non-condensing)

Storage Temperature –20 to +75°C (no freezing)

Storage Humidity 30 to 90% RH (non-condensing)

Pollution Degree 2 (IEC 60664)

Corrosion Immunity Atmosphere free from corrosive gases

Altitude

Vibration Resistance

Shock Resistance 294 m/s

Mounting 35-mm-wide DIN rail, direct panel mounting (M4 mounting screws)

Weight (approx.) 250g

Operation: 0 to 2,000m

Transport: 0 to 3,000m

10 to 57 Hz amplitude 0.075 mm, 57 to 150 Hz acceleration 9.8 m/s

2 hours per axis on each of three mutually perpendicular axes

2

, 11-ms sinusoidal half-wave pulse

2

Remote-control Relay Control Specifications

Input Points 8 points

Input Type Feedback input from remote control relays through output signal lines

Output Type Remote-control relay output

Output Pulse ON Width 100 ms

No. of Common Circuits 1 common circuit for 8 points

Applicable

Devices

Isolation from Power Line Photocoupler isolation

Dielectric Strength 500V AC, 1 minute between remote-control relay control and FG terminals

Insulation Resistance

Remote-control Relay

Remote-control Transformer

BR-12D, BR-22D, BR-1 (Mitsubishi Electric)

WR6165 (Matsushita Electric Works)

BRT-10B, BRT-20B, BRT-1 (Mitsubishi Electric)

WR2301 (Matsushita Electric Works)

100 MΩ minimum between remote-control relay control and FG terminals

(500V DC megger)

2-18 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 30

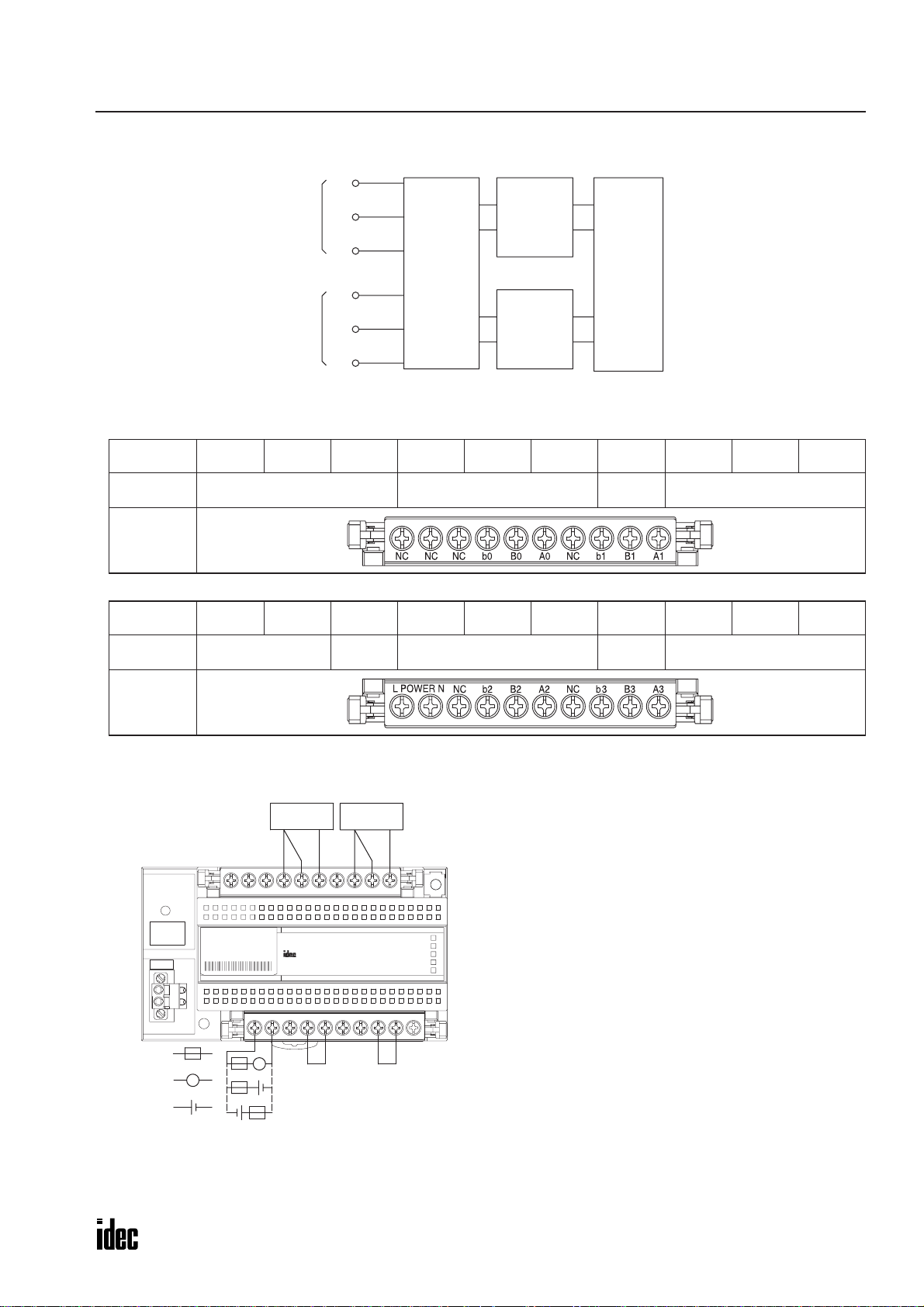

Input Internal Circuit

2: HARDWARE SPECIFICATIONS

Output 0

Common

Output 1

Common

Internal

Circuit

Photocoupler

Photocoupler

Remote-control Relay

Control Circuit

Remote-control Relay

Control Circuit

Terminal Arrangement

•

Upper Terminal Block (SX9Z-SS11)

Marking NC NC 0 C01C12C23C3

Name No Connection Output 0 Common Output 1 Common Output 2 Common Output 3 Common

Front View

• Lower Terminal Block (SX9Z-SS7)

Marking

Name Power Voltage Output 4 Common Output 5 Common Output 6 Common Output 7 Common

POWER LPOWER

N

4C45C56C67C7

Front View

Wiring Examples

SERVICE

REQUEST

LON

TYPE: SX5L-SBRR081

Blue

Remotecontrol

Transformer

NC NC

White

POWER

L

N

Blue

Remotecontrol

Relay

Red Blue

OUT

10

SX5L

45 76

OUT

Red Blue

Remote-

Remote-

control

control

Relay

Relay

C3C0 1 C1 2 C2 30

Red

Remotecontrol

Relay

PWR

RUN

ERR

RES

SER

C77C66C55C44

23

Red Blue

Note: Common terminals C0 through C7 and the POWER N

terminal are connected together internally.

Only one remote-control relay can be connected to

each output circuit.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 2-19

Page 31

2: HARDWARE SPECIFICATIONS

2-20 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 32

Pull out

35-mm-wide DIN Rail

Clamp

3: INSTALLATION AND WIRING

Introduction

This chapter describes the methods and precautions for installing and wiring the SX5L communication terminals.

Before starting installation and wiring, be sure to read “Safety Precautions” in the beginning of this manual and under-

stand precautions described under Warning and Caution.

Mounting on DIN Rail

Warning

Caution

1. Fasten the DIN rail to a panel using screws firmly.

2. Pull out the clamp from the SX5L module, and put

the groove of the module on the DIN rail. Press the

module towards the DIN rail and push in the clamp as

shown on the right.

3. Use BNL6P mounting clips on both sides of the

SX5L module to prevent moving sideways.

• Turn off the power to the SX5L before mounting and removing. Failure to turn power off may

cause electrical shocks or fire hazard.

• Install the SX5L modules according to instructions described in this user’s manual. Improper

installation will result in falling, failure, or malfunction of the SX5L.

• Mount the SX5L modules on a 35-mm-wide DIN rail or a panel surface.

Applicable DIN rail: IDEC’s BAA1000NP or BAP1000NP (1000mm/39.4” long)

Groove

35-mm-wide DIN Rail

Press

Clamp

Removing from DIN Rail

1. Insert a flat screwdriver into the slot in the clamp.

2. Pull out the clamp from the SX5L module.

3. Turn the SX5L module bottom out.

Mounting on Panel

The SX5L modules can also be mounted directly on a panel surface using M4 mounting screws. For the mounting hole

layout, see page 2-2.

SX5L COMMUNICATION TERMINAL USER’S MANUAL 3-1

Page 33

3: INSTALLATION AND WIRING

I/O Wiring

Warning

Caution

• Turn of f the power to the SX5L before wiring the I/O and netw ork cable. Failure to turn po wer off

may cause electrical shocks or fire hazard.

• Prevent metal fragments and pieces of wire from dropping inside the SX5L housing. Put a cover

on the SX5L module during wiring the I/O and network cable. Ingress of such fragments and

chips may cause fire hazard, damage, or malfunction.

• Run the power supply wiring as far away possible from motor lines to prevent malfunction.

• Use wires of an appropriate size to meet the voltage and current requirements. Using inappropri-

ate wires may cause overheat, resulting in possible fire hazard.

• Make sure of correct connection. Incorrect connection may cause overheat, resulting in possible

fire hazard.

• Do not run the I/O wiring in parallel with or in the vicinity of motor lines. Keep the I/O wiring

away from noise sources. Check for loose connection periodically. Loose connection may cause

overheat, resulting in possible fire hazard.

• Keep the power voltage and frequency within the rated values, otherwise the SX5L may be damaged.

• Keep the input signal within the rated values, otherwise the SX5L may be damaged.

Applicable Wires

For power and input wiring, use AWG18 or AWG16 (0.75 to 1.25 mm2) solid or stranded wires. When connecting two

wires together, use wires of the same size.

Terminal Tightening Torque

Tighten the I/O terminals to a toque of 0.6 to 1.0 N·m. Also tighten unused I/O terminals.

Wire Termination

When using crimping terminals for wire termination, be sure to use an insulation tube on

ø3.2 min.

the crimping terminal. One or two crimping terminals can be connected to one screw terminal. Dimensions of an applicable crimping terminal are shown at right.

6.0 max.

When wiring without using crimping terminals, strip the wire as long as the terminal clamp

plate (approx. 6 mm), and insert the wire until the wire insulation touches the end of the ter-

5.2 min.

3.0 max.

minal clamp plate.

Optional Jumper

When using the analog input module or Pt100Ω input module, be sure to interconnect input terminals of each unused

channel using a wire or optional ring or spade type jumper. Otherwise an error may exceeds the rated value.

Grounding

The upper-right mounting hole has a FG terminal. Connect the FG terminal and control box as shown in the figure below.

Use a UL1007 AWG16 wire to connect the FG terminal to the ground (grounding resistance 100Ω at the maximum).

The FG terminal is supplied with an M4 screw and

an embedded nut for ground connection when

mounting on a DIN rail. When mounting the SX5L

directly on a panel, prepare a proper screw for

grounding.

Remove paint from the panel surface for grounding

to make sure of electrical connection.

SERVICE

REQUEST

LON

SERVICE

REQUEST

LON

3-2 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 34

Network Cable Wiring

+

R

C1

C2

Network

+

3: INSTALLATION AND WIRING

Caution

• Do not run the network cable in parallel with or in the vicinity of power, output, or motor lines.

Keep the network cable away from noise sources. Check for loose connection periodically. Loose

connection may cause overheat, resulting in possible fire hazard.

Applicable Cables

Use twisted pair cable with core wires of AWG24 to AWG14 (0.2 to 2.5 mm2) applicable to the LONWORKS network. One

or two wires can be connected to one network interface connector. When connecting two wires together, use wires of the

same size, AWG24 to AWG16 (0.2 to 1.5 mm2). Whether connecting one or two wires, always use ferrules to terminate the

wires for connection to the network interface connector.

Network Interface Connector

The network interface connector features spring-clamp terminals. Push in the

orange pin to open the cable hole using a flat screwdriver, and insert a ferrule

into the cable hole. The LONWORKS network cable can be connected to the

two terminals in either polarity.

For tightening the mounting screws of the network interface connector, use a

flat screwdriver with a straight shank at the tip.

Orange Pin

Recommended Screwdriver: Phoenix Type No. SZS 0,6 x 3,5

(Order No.: 12 05 05 3)

Tightening Torque

Tighten the network interface connector mounting screws to a torque of 0.3 to 0.5 N·m.

Applicable Ferrules

Wire Thickness Phoenix Type (Order No.)

2

AWGCross Section (mm

24 0.25 AI 0,25-8 YE (32 00 85 2) —

20 0.5 AI 0,5-8 WH (32 00 01 4) AI-TWIN 2 x 0,5-8 WH (32 00 93 3)

18 0.75 AI 0,75-8 GY (32 00 51 9) AI-TWIN 2 x 0,75-8 GY (32 00 80 7)

18 1.0 AI 1-8 RD (32 00 03 0) AI-TWIN 2 x 1-8 RD (32 00 81 0)

16 1.5 AI 1,5-8 BK (32 00 04 3) AI-TWIN 2 x 1,5-8 BK (32 00 82 3)

14 2.5 AI 2,5-8 BU (32 00 52 2) —

) For 1-cable connection For 2-cable connection

For 1-cable connection For 2-cable connection

6.0 8.0

7.0 8.0

To crimp the ferrules, use a special crimping tool.

Crimping Tool: Phoenix Type No. CRIMPFOX ZA 3

(Order No.: 12 01 88 2)

AI 1-8 RD AI-TWIN 2 x 1-8 RD

Terminators

LONWORKS networks require terminators. Connect terminators consisting of one resistor and two

capacitors shown at right (note the polarity of capacitors).

The bus topology requires two terminators at both ends of the network, and the free topology can

connect a terminator at any position in the network.

Topology Bus Topology Free Topology

R 105Ω±1%, 1/8W 52.3Ω±1%, 1/8W

C1 and C2 100 µF, ≥50V 100 µF, ≥50V

Connect Position Te rminators at both ends of the network One terminator at any position in the network

Applicable Terminator Echelon 44101 Echelon 44100

SX5L COMMUNICATION TERMINAL USER’S MANUAL 3-3

Page 35

3: INSTALLATION AND WIRING

Removing the Detachable Terminal Block

Warning

• Turn off the power to the SX5L before removing and installing the detachable terminal block.

Failure to turn power off may cause electrical shocks or fire hazard.

To remove the detachable terminal block from the SX5L module, squeeze both latches on top of the terminal block inward

to unlock the terminal block from the socket.

Installing the Detachable Terminal Block

Place the terminal block in the socket with the latches opened and press the terminal block until it bottoms in the socket.

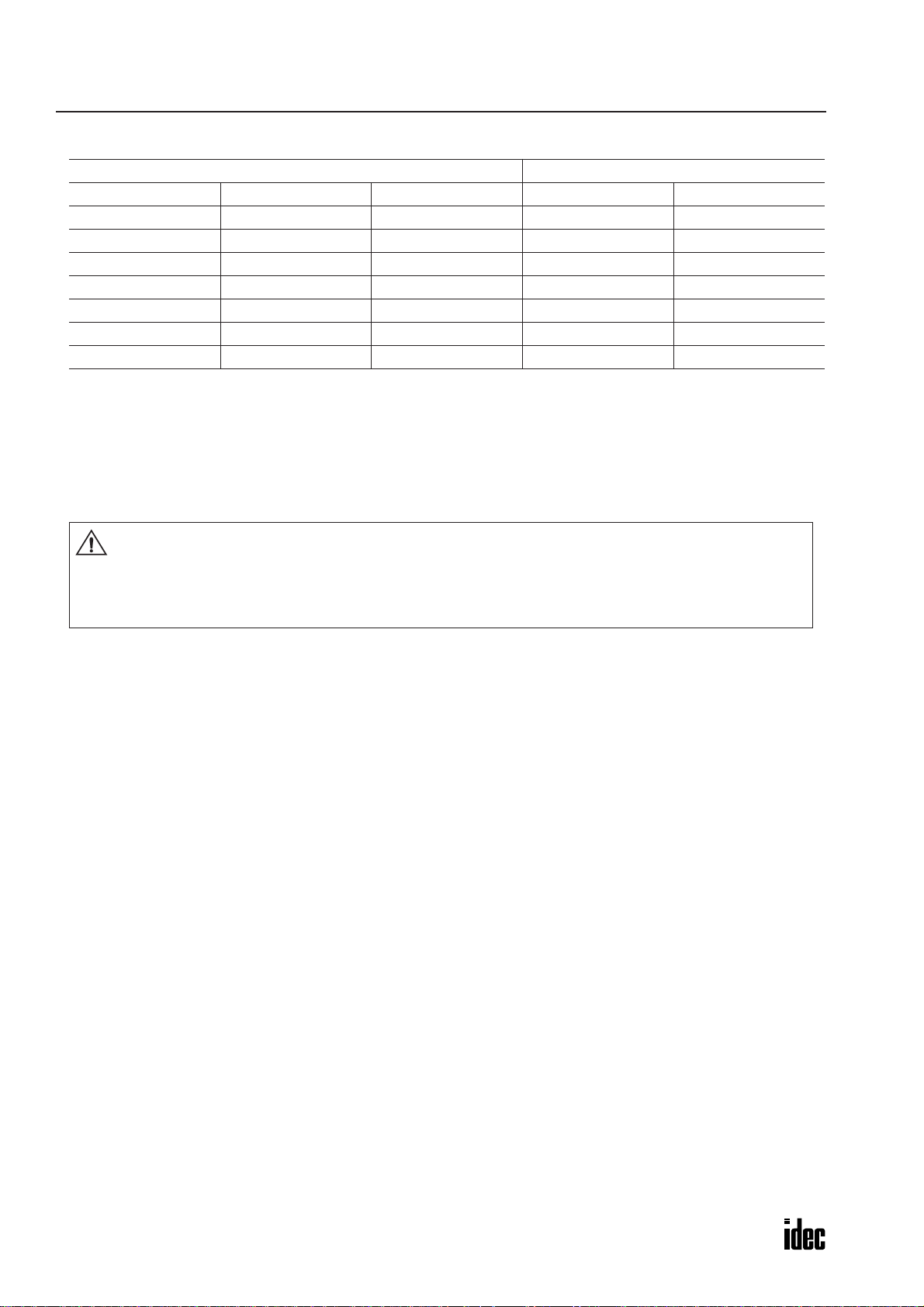

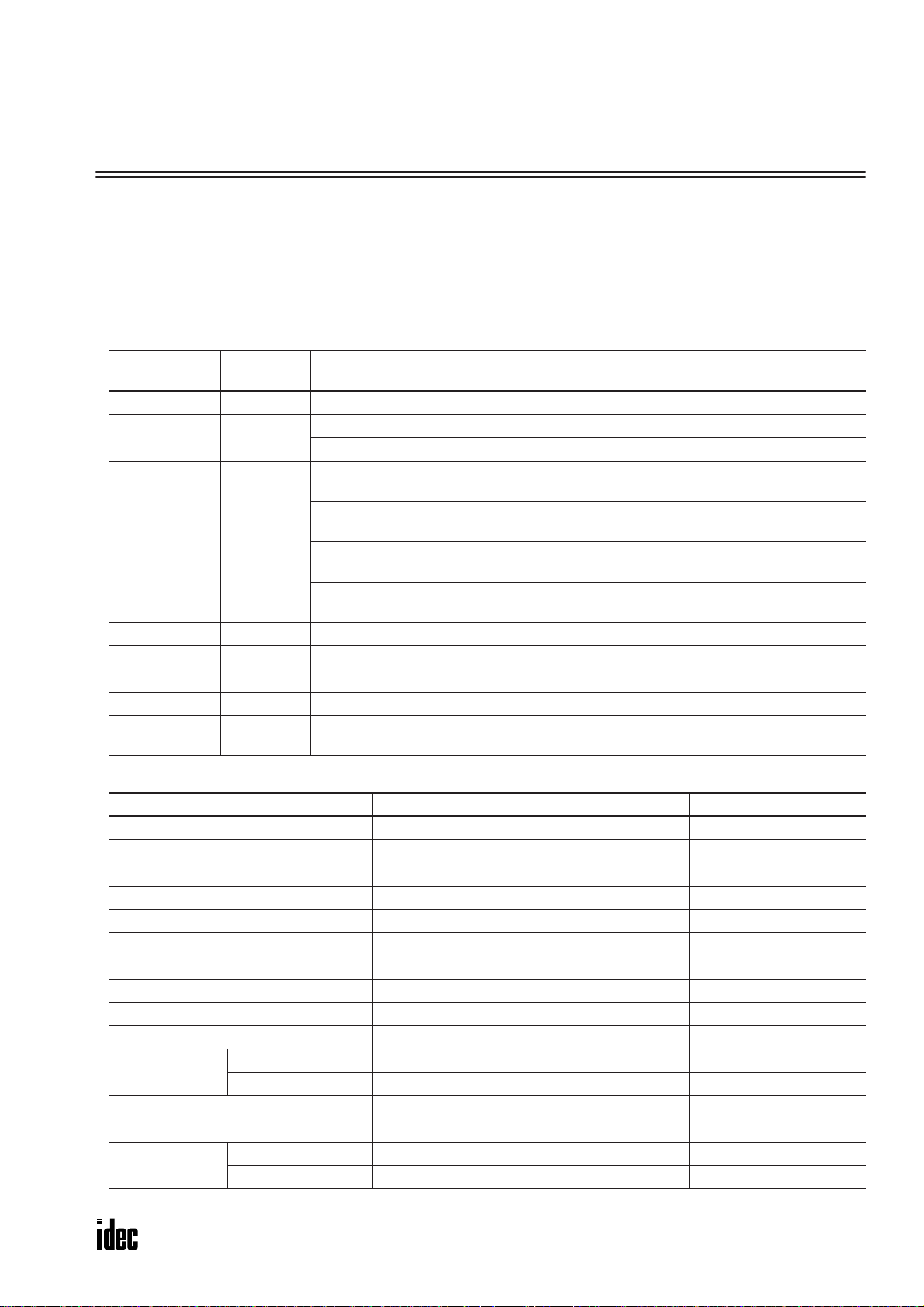

Insertion Pin Positions

Insertion pins are positioned on the base of the terminal block and inside the socket to prevent insertion of invalid terminal

blocks into the socket. The pins are keyed to make sure of correct matching of terminal block and socket, and prevent

swapping of upper and lower terminal blocks.

When the terminal block does not fit into the socket properly, check to see if the pin positions on the terminal block agree

with the pin-slot arrangement in the socket. If the pins and the pin slots are in matching positions, check for any chips and

obstacles in the socket.

When purchasing terminal blocks separately, set the insertion pins as shown below.

ABCD EFGH

HEF GAB CD

Ter minal Block Bottom View

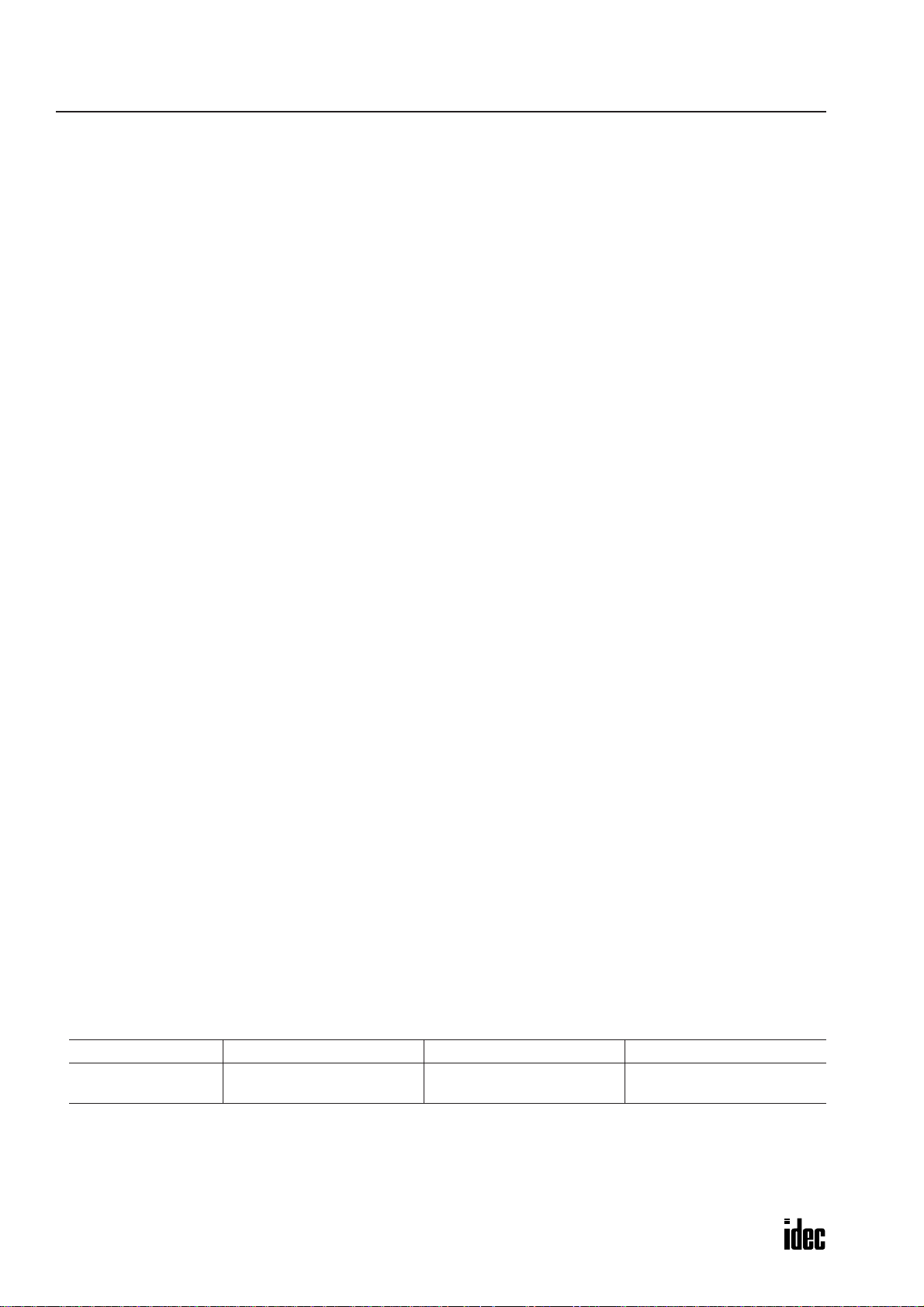

Applicable Terminal Blocks and Insertion Pin Positions

Module Name Type No.

Digital Input SX5L-SBN16B1

Digital Output

Digital I/O

Analog Input SX5L-SBAN041

Pt100Ω Input

Pulse Input SX5L-SBCN081

Remote-control Relay Control SX5L-SBRR081

SX5L-SBT16K1

SX5L-SBT16S1

SX5L-SBM16K1

SX5L-SBM16K2

SX5L-SBM16S1

SX5L-SBM16S2

SX5L-SBPT04X1

SX5L-SBPT04Y1

Ter minal Block

Ter minal Block

Position

Upper SX9Z-SS10 B D F H

Lower SX9Z-SS2 A C F H

Upper SX9Z-SS1 B C E G

Lower SX9Z-SS2 A D F H

Upper SX9Z-SS1 B C F H

Lower SX9Z-SS3 A D E G

Upper SX9Z-SS12 A D E H

Lower SX9Z-SS9 B C F G

Upper SX9Z-SS13 B D E H

Lower SX9Z-SS14 A C F G

Upper SX9Z-SS11 A C E H

Lower SX9Z-SS7 B C E H

Upper SX9Z-SS11 B D F G

Lower SX9Z-SS7 A D F G

Type No.

Insertion Pin

Positions

3-4 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 36

4: SOFTWARE SPECIFICATIONS

Introduction

This chapter describes the software specifications of the SX5L communication terminals. Designing a LONWORKS network requires complete understanding of the functional blocks available on each SX5L communication terminal. Before

starting system configuration, read this chapter to understand available functional blocks.

General

The SX5L communication terminals contain an application program installed before shipment from factory . The functions

of application programs are configured in units of functional blocks. More than one functional block is installed in one

SX5L communication terminal. Available functional blocks are listed in the table below.

To set up a LONWORKS network, every device on the network, including the SX5L modules, must be commissioned individually to assign an address using a network management tool. A Neuron ID is needed to identify each L ONWORKS mod-

ule. While commissioning the SX5L using a network management tool, either enter the 12-digit alphanumeric Neuron ID

printed on the label on the SX5L manually, or press the SERVICE REQUEST button on the SX5L module to send the service pin message.

Available Functional Blocks

Input

Functional Block

Node Object

Digital Input

Digital Output

Virtual I/O

Shot Output/Digital Input

Analog Input

Pt100Ω Input

Pulse Count

Remote-control

Relay Control

Quantity of

Alias Table Entries

Module

SBN16B1

Output

Module

SBT16K1

SBT16S1

I/O

Module

SBM16K1

SBM16S1

I/O

Start/Stop

SBM16K2

SBM16S2

Analog

Input

SBAN041

Pt100Ω

Input

SBPT04X1

SBPT04Y1

Pulse

Input

SBCN081 SBRR081

Remote-

control

xxxxxxxx

xx

xx

xx

x

x

x

x

x

62 62 62 16 8 8 16 16

Page

4-2

4-3

4-4

4-5

4-8

4-10

4-13

4-15

4-17

SX5L COMMUNICATION TERMINAL USER’S MANUAL 4-1

Page 37

4: SOFTWARE SPECIFICATIONS

Node Object Functional Block

nviRequest nvoStatus

Node Status

The Node Object functional block is installed in all SX5L modules. When receiving an input to n viRequest, this functional

block sends out nvoStatus in reply. This functionality makes it possible for the network to confirm that the responding

node is in on-line status.

I/O Name Type Description

Input Network Variable nviRequest SNVT_obj_request For node objects

Output Network Variable nvoStatus SNVT_obj_status For node objects

Delay in sending nvoStatus immediately

nciPwrup SCPTpwrUpDelay

Configuration Property

nciMaxStsSendT SCPTmaxSndT

Initial Status Transmission

This functional block sends output network variable nvoStatus to the network within 3 seconds after powerup. The delay

depends on a random number based on the Neuron ID, and differs on each node.

The sending time can be delayed by changing the nciPwrup value. At system startup, if the SX5L sends nvoStatus before

the addressee device is ready to receive communication, set the nciPwrup to a larger value.

The preset value for nciPwrup can be between 0 and 60 seconds (0.1-sec increments). The sending time is determined by

the sum of the nciPwrup value and a random number.

after powerup

(factory setting: 0 seconds)

nvoStatus heartbeat transmission interval

(factory setting: 3 minutes)

Event-driven Transmission

When receiving nviRequest, this functional block sends output network variable nvoStatus to the network.

Heartbeat Transmission (Periodical Transmission)

After the first transmission of output network variable nvoStatus, this functional block sends nvoStatus repeatedly at intervals designated by nciMaxStsSendT. When the nciMaxStsSendT value is 0, the heartbeat transmission is disabled.

The configuration type of nciMaxStsSendT is SNVT_elapsed_tm (day, hour, minute, second, millisecond). When a value

over 12 hours is set, the interval is designated as 12 hours 00 minutes 00 seconds. The millisecond value has no effect.

Presets

When sending input network variable n viRequest to the SX5L, set all values to 0. The SX5L always sends output network

variable nvoStatus with all values set to 0.

4-2 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 38

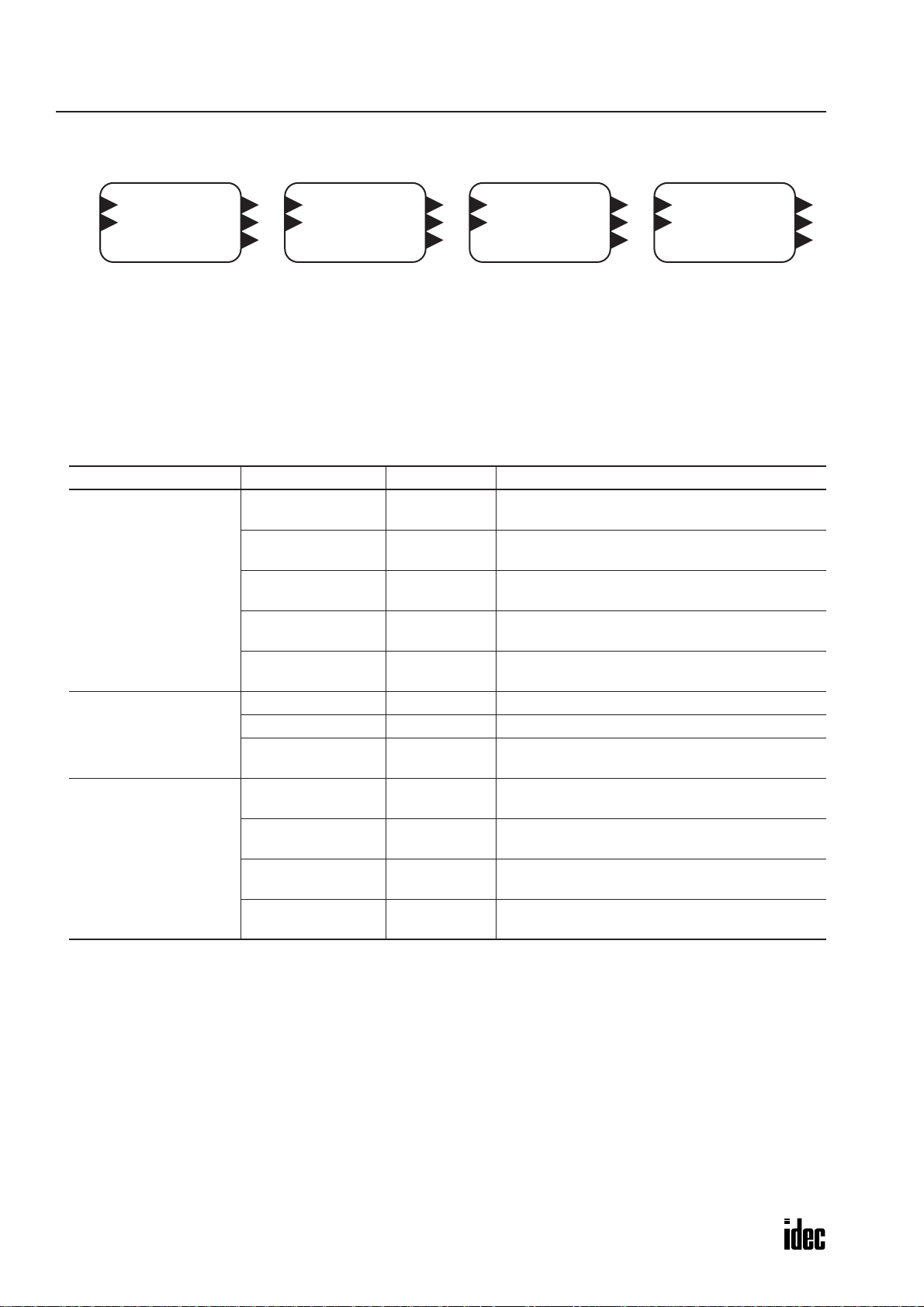

Digital Input Functional Block

4: SOFTWARE SPECIFICATIONS

nvoDI[0]

nvoDI[1]

nvoDI[2]

nvoDI[3]

nvoDI[4]

nvoDI[5]

nvoDI[6]

nvoDI[7]

DI[0]

SX5L-SBN16B1 SX5L-SBM16K1 / SX5L-SBM16S1

nvoDI[8]

nvoDI[9]

nvoDI[10]

nvoDI[11]

nvoDI[12]

nvoDI[13]

nvoDI[14]

nvoDI[15]

DI[1]

nvoDI[0]

nvoDI[1]

nvoDI[2]

nvoDI[3]

nvoDI[4]

nvoDI[5]

nvoDI[6]

nvoDI[7]

DI

Digital input terminals 0 through 15 correspond to output network variables nvoDI[0] through nvoDI[15], respectively.

When the status at any input terminal changes, the Digital Input functional block sends a corresponding output network

variable to the network.

I/O Name Type Description

Output Network Variable nvoDI[0] to [15] SNVT_switch Correspond to inputs 0 through 15

Configuration Property

nciMaxStsSendT1

[0] to [15]

SCPTmaxSndT

nvoDI[0] to [15] heartbeat transmission interval

(factory setting: 3 minutes)

Initial Status Transmission

This functional block sends output network variables nvoDI[0] through nvoDI[15] to the network within 3 seconds after

powerup. The delay depends on a random number based on the Neuron ID, and differs on each node.

The sending time can be delayed by changing the nciPwrup value designated in the Node Object functional block. At system startup, if the SX5L sends output network variables before the addressee device is ready to recei ve communication, set

the nciPwrup to a larger value.

The preset value for nciPwrup can be between 0 and 60 seconds (0.1-sec increments). The sending time is determined by

the sum of the nciPwrup value and a random number.

Event-driven Transmission

When the status at any input terminal changes or when receiving a request (polling) from the network, this functional

block sends a corresponding output network variable to the network.

Heartbeat Transmission (Periodical Transmission)

When the status at any input terminal does not change, this functional block sends the output network variable repeatedly

at intervals designated by nciMaxStsSendT1[0] to [15]. When the nciMaxStsSendT1[0] to [15] value is 0, the heartbeat

transmission is disabled.

The configuration type of nciMaxStsSendT1[0] to [15] is SNVT_elapsed_tm (day, hour, minute, second, millisecond).

When a value over 12 hours is set, the interv al is designated as 12 hours 00 minutes 00 seconds. The millisecond v alue has

no effect.

Input Terminal Status vs. Output Network Variable

Input Terminal Status Output Network Variable

ON (state) = 1, (value) = 100.0%

OFF (state) = 0, (value) = 0.0%

SX5L COMMUNICATION TERMINAL USER’S MANUAL 4-3

Page 39

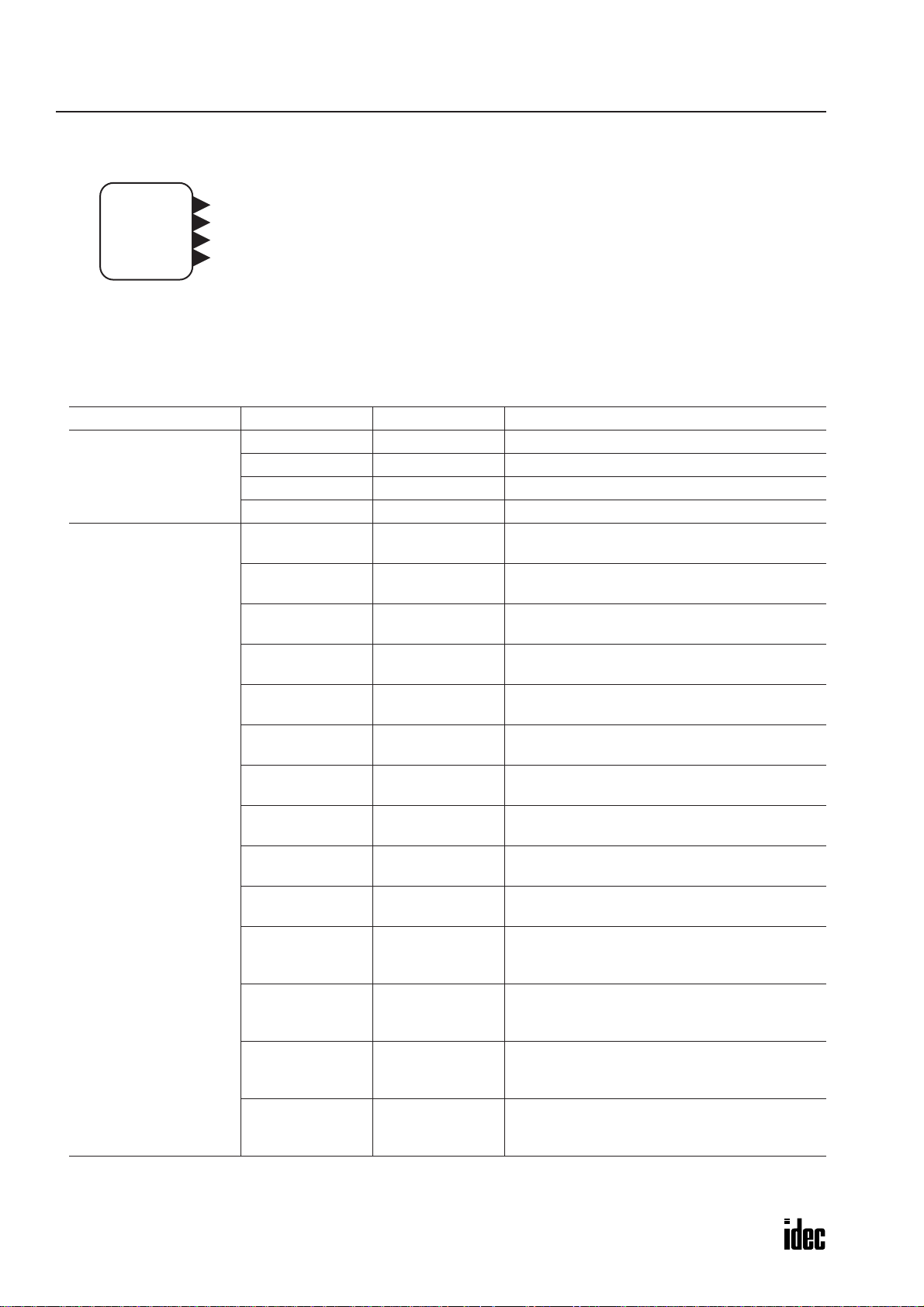

4: SOFTWARE SPECIFICATIONS

Digital Output Functional Block

nviDO[0]

nviDO[1]

nviDO[2]

nviDO[3]

nviDO[4]

nviDO[5]

nviDO[6]

nviDO[7]

DO[0]

SX5L-SBT16K1 / SX5L-SBT16S1 SX5L-SBM16K1 / SX5L-SBM16S1

nviDO[8]

nviDO[9]

nviDO[10]

nviDO[11]

nviDO[12]

nviDO[13]

nviDO[14]

nviDO[15]

DO[1]

nviDO[0]

nviDO[1]

nviDO[2]

nviDO[3]

nviDO[4]

nviDO[5]

nviDO[6]

nviDO[7]

DO[0]

Digital output terminals 0 through 15 correspond to input network variables nviDO[0] through nviDO[15], respectively.

When any of these input network variables receives a new value, the value effects the ON/OFF status of a corresponding

output terminal.

I/O Name Type Description

Input Network Variable nviDO[0] to [15] SNVT_switch Correspond to outputs 0 through 15

Input Network Variable vs. Output Terminal Status

Each time the input network variable is updated, a corresponding output terminal status is updated according to the

received data.

The existing output terminal status is maintained until the input network variable is updated.

When receiving a reset command or when power is cycled, all outputs are initialized to OFF.

Input Network Variable Output Terminal Status

(state) = 1, (value) = no effect ON

(state) = 0, (value) = no effect OFF

4-4 SX5L COMMUNICATION TERMINAL USER’S MANUAL

Page 40

Virtual I/O Functional Block

4: SOFTWARE SPECIFICATIONS

nviSWA[0] nvoSWA[0]

nviSWB[0] nvoSWB[0]

VIO[0]

nviSWA[1] nvoSWA[1]

nviSWB[1] nvoSWB[1]

VIO[1]

nviSWA[2] nvoSWA[2]