FUNCTION

-

CANCEL

ENTER

+

INSTRUCTION MANUAL

Handy Controller Exclusive for SE4D Series

SE9Z-HC

B-1430(0)

MJE-SE9ZHC No.0027-96V

1

(MEMO)

2

Thank you for purchasing IDEC’s Handy Controller SE9Z-HC exclusive for SE4D series.

Please read both the instruction manual of this manual and SE4D series carefully and thoroughly for

the correct and optimum use of this device.

Kindly keep this manual in a convenient place for quick reference.

This manual has been written for the following personnel who have undergone suitable training and

have knowledge of light curtains, as well as, safety systems and standards (ANSI, etc.).

● who are responsible for the introduction of this device

● who design a system using this device

● who install and connect this device

● who manage and operate a plant using this device

1) All the contents of this instruction manual are the copyright of the publishers, and may not be

reproduced (even extracts) in any form by any electronic or mechanical means (including

photocopying, recording, or information storage and retrieval) without permission in writing

from the publisher.

2) The contents of this instruction manual may be changed without prior notice for further

improvement of the device.

3) A part of / all of this instruction manual or the software may not be copied without permission

from the publisher.

4) Though we have carefully drawn up the contents of this instruction manual, if there are any

aspects that are not clear, or any error that you may notice, please contact our local IDEC

ofce or the nearest distributor.

5) We shall not be responsible for any consequences of use regardless of the descriptions

above.

NOTICE

3

Contents

CHAPTER 1 INTRODUCTION ..............................................................................4

1-1 Attention Marks ..................................................................................................... 4

1-2 Safety Precautions ................................................................................................4

CHAPTER 2 GENERAL OUTLINE .......................................................................6

2-1 Features ................................................................................................................6

2-2 Part Descriptions ..................................................................................................6

2-3 Connecting / Setting Procedures .......................................................................... 7

CHAPTER 3 FUNCTIONS ....................................................................................8

3-1 Functional Descriptions ........................................................................................8

3-1-1 Fixed Blanking Function.....................................................................................8

3-1-2 Floating Blanking Function.................................................................................9

3-1-3 Auxiliary Output Switching Function...................................................................10

3-1-4 Emission Intensity Control Function...................................................................11

3-1-5 Copy Function ....................................................................................................11

3-1-6 Muting Setting Changing Function .....................................................................11

3-1-7 Interlock Setting Changing Function ..................................................................12

3-1-8 External Device Monitor Setting Changing Function .........................................12

3-1-9 Protective Function ............................................................................................13

3-1-10 Initialization Function .......................................................................................13

3-1-11 Setting Contents Monitoring Function ..............................................................13

3-1-12 Override Setting Changing Function ................................................................13

3-2 Function Setting (Operation Procedure) ............................................................... 14

3-2-1 Fixed Blanking Function.....................................................................................17

3-2-2 Floating Blanking Function.................................................................................18

3-2-3 Auxiliary Output Switching Function...................................................................19

3-2-4 Emission Intensity Control Function...................................................................20

3-2-5 Copy Function ....................................................................................................21

3-2-6 Muting Setting Changing Function .....................................................................22

3-2-7 Interlock Setting Changing Function ..................................................................24

3-2-8 External Device Monitor Setting Changing Function .........................................25

3-2-9 Protective Function ............................................................................................26

3-2-10 Initialization Function .......................................................................................27

3-2-11 Setting Contents Monitoring Function ..............................................................28

3-2-12 Override Setting Changing Function ................................................................29

CHAPTER 4 TROUBLESHOOTING .....................................................................30

CHAPTER 5 SPECIFICATIONS / DIMENSIONS ..................................................31

5-1 Specications ........................................................................................................31

5-2 Dimensions ........................................................................................................... 31

4

CHAPTER 1 INTRODUCTION

1-1 Attention Marks

This instruction manual employs the following attention marks , depending on the

degree of the danger to call operator’s attention to each particular action. Read the following

explanation of these marks thoroughly and observe these notices without fail.

Besides, the attention mark is prepared for the helpful information, detail instruction related to each

part, and reference item or page.

If you ignore the advice with this mark, death or serious injury could result.

If you ignore the advice with this mark, injury or material damage could result.

Remarks

The supplementary content is described with this mark.

REFERENCE

The related content is described with this mark.

1-2 Safety Precautions

■ Use this device as per its specifications. Do not modify this device since its functions and

capabilities may not be maintained and it may malfunction.

■ This device has been developed / produced for industrial use only.

■ Before using this device, check whether the device performs properly with the functions and

capabilities as per the design specications.

■ In case of disposal, dispose this device as industrial waste.

♦ User in charge

● The user in charge has responsible to indicate the person to take the training required for the

safety system, using method, installation, operation, and maintenance.

● This device is used and managed by the specialist, never use this device by other operator.

♦ Specialist

● A person who is appropriately educated, has widespread knowledge and experience, and

can solve various problems which may arise during work.

♦ Operator

● The operator should read this instruction manual thoroughly, understand its contents, and perform

operations following the procedures described in this manual, for the correct operation of this device.

● In case this device does not perform properly, the operator should report this to the person in

charge and stop the machine operation immediately. The machine must not be operated until

correct performance of this device has been conrmed.

5

♦ Fixed blanking function, oating blanking function

● With the xed blanking function, this device prevents the person or object from entering into

the dangerous parts of the machine through the invalid sensing area. However, even though

this device can prevent the interference of the person or object into the invalid sensing area

with the xed blanking function, there might exist the more space between the SE4D series

and already-existence object. Therefore, set the protecting structure so as not to exist any

space in the dangerous sensing area. Detecting human body in the sensing area could result

in death or serious injury.

● With the floating blanking function, this device changes the size of the minimum sensing

object of the S E 4D series that is pre-set the function. When setting or changing the

function, calculate and measure the safety distance again, and check that the device has the

wider space than the safety distance between the dangerous parts of the machine and the

sensing area of the SE 4D serie s.

If the sufcient distance is not maintained, the machine will

not stop before its dangerous parts are reached, which can result in death or serious injury.

● Set and change the function of the device following the relative laws, regulation, and

standard without fail.

♦ Muting setting changing function

● The muting setting changing function temporarily invalidates safety function of the connected

devices. Conrm all of the applied laws and standards, and install or operate this device and

peripheral devices correctly. Failure to do so, the operator may suffer a serious injury.

♦ Environment

● Do not use a mobile phone or a radio phone near this device.

● Do not use this device in the following environments.

1) Areas with high humidity where condensation is likely to occur

2) Areas exposed to corrosive or explosive gases

3) Areas exposed to vibration or shock of levels higher than that specied

4) Areas exposed to contact with water

5) Areas exposed to too much steam or dust

♦ Wiring

● Be sure to carry out the wiring in the power supply OFF condition.

● All electrical wiring should conform to the regional electrical regulations and laws. The wiring

should be done by engineer(s) having the special electrical knowledge.

● Do not run the wires together with high-voltage lines or power lines or put them in the same

raceway. This can cause malfunction due to induction.

♦ Maintenance

● Clean this device with a clean cloth. Do not use any volatile chemicals.

♦ Other

● Never reassemble or remodel this device.

INTRODUCTION

6

CHAPTER 2 GENERAL OUTLINE

This chapter gives the system construction, part description, etc. of this device.

2-1 Features

Thi s dev ice is t h e han dy c ontr oller for setti ng e ach funct ion of the ligh t curt ain SE4D

se ries.

Beside s , th i s d e vice performs th e ch e cking and copying th e se t ting contents of th e

fu nction, and prot ection o f writin g.

<Functions>

● Fixed blanking function

● Floating blanking function

● Auxiliary output switching function

● Emission intensity control function

● Copy function

● Muting setting changing function

● Interlock setting changing function

● External device monitor setting changing function

● Protective function

● Initialization function

● Setting contents monitoring function

● Override setting changing function

2-2 Part Descriptions

FUNCTION

-

CANCEL

ENTER

+

Male connector

Cable (0.5m)

FUNCTION indicator × 9

(Green)

FUNCTION switch

Digital display (Red)

+ switch

ENTER switchCANCEL switch

- switch

Female connector

7

Connecting / Setting Procedures

2-3 Connecting / Setting Procedures

This section describes the connecting / setting procedures for both this device and SE4D series.

1. Set the SE4D series, and check that the

SE4D series works properly. For mounting

method o f SE 4 D se r i e s , re fer t o th e

Instruction Manual.

2. Tur n OFF the powe r and conn ect this

device to the SE4D series. Use the handy

controller connection cable (SE9Z-WNC1)

for the connection. The handy controller

connection cable (SE9Z-WNC1) can be

connec ted by c onn ecti ng the include d

SE9Z-CCJ02-HC1 to the device’s female

connector.

3. Turn ON the power, and set the function with this device.

After the power of this device is ON, approx. 30 sec. will be taken for data transmission with SE4D

series. While data transmission, “

” lights up in revolving.

The control output (OSSD 1 / 2) of SE4D series is set to “OFF” while this device has been

connected.

REFERENCE Refer to “3-1 Functional Descriptions” for the details of the functions, and refer to “3-2

Function Setting (Operation Procedure)” for the setting procedures of the functions

respectively.

4. Turn OFF the power, then remove this device.

5. Check that the SE4D series works as set at the procedure 3.

Then, inspect the SE4D series.

REFERENCE Refer to “Chapter 4 Maintenance” of the SE4D series instruction manual for the details of

the inspection of the SE4D series.

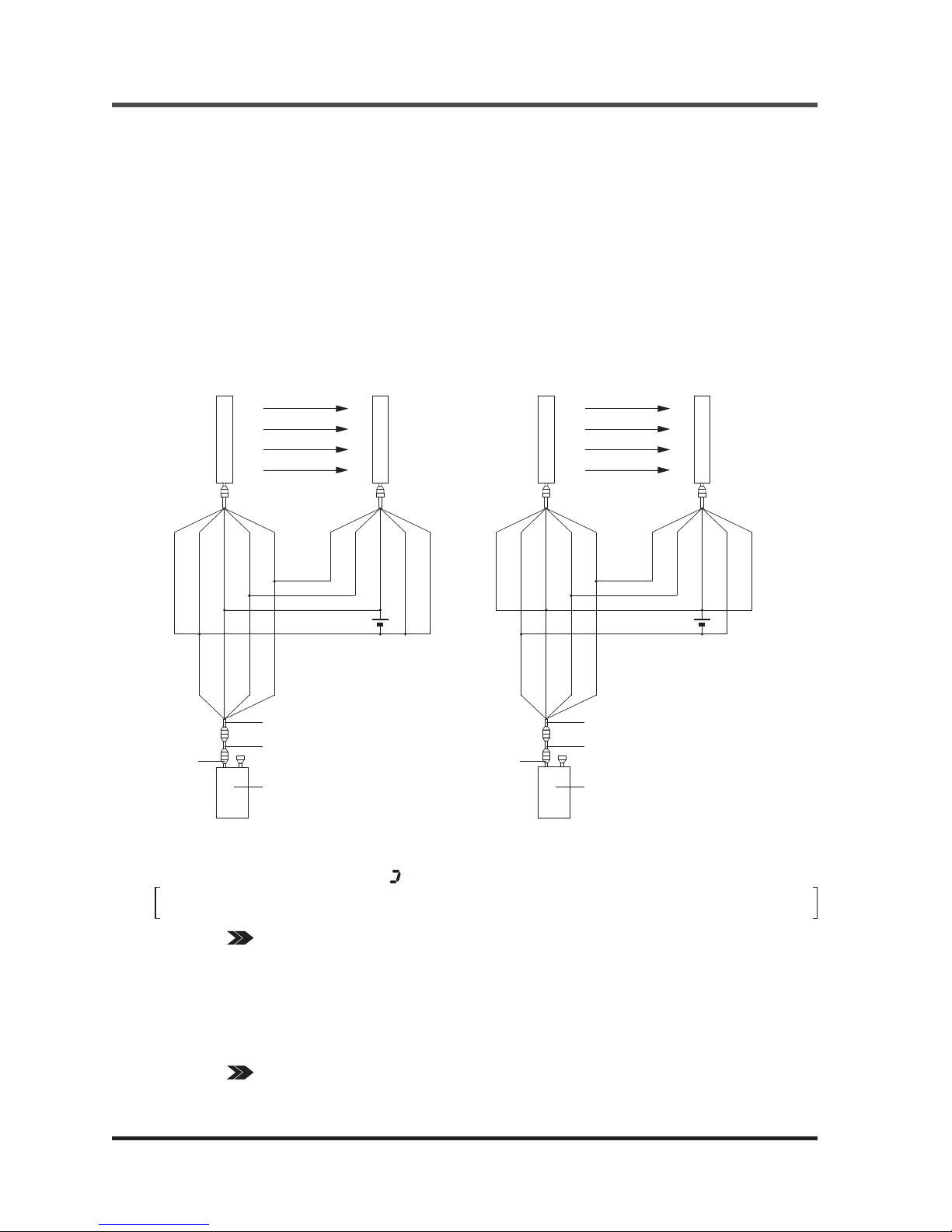

<For PNP output> <For NPN output>

24V±10%

+

-

Emitter

Receiver

(Shield)

(Blue)

(Brown)

(Orange)

(Orange

/ Black)

(Blue)

(Brown)

(Orange)

(Orange

/ Black)

(Shield)

(Blue)

(Brown)

(Orange)

(Orange / Black)

24V±10%

+

-

Emitter

Receiver

(Shield)

(Blue)

(Brown)

(Orange)

(Orange

/ Black)

(Blue)

(Brown)

(Orange)

(Orange

/ Black)

(Shield)

(Blue)

(Brown)

(Orange)

(Orange / Black)

Handy controller connection

cable (SE9Z-WNC1)

This device

SE9Z-CCJ02-HC1

Female

connector

Handy controller connection

cable (SE9Z-WNC1)

This device

SE9Z-CCJ02-HC1

Female

connector

8

CHAPTER 3 FUNCTIONS

If conguration of the system is changed (replace the SE4D series etc.), set the function

again.

3-1-1 Fixed Blanking Function

This is a function that the control output (OSSD 1 / 2) of SE4D series is not turned OFF, even if the

specied beam channel(s) is blocked OFF.

This is useful when an obstacle always blocks OFF the specic beam channel(s).

There are “Clear,” “Auto” and “Manual” for the setting method.

● Clear setting : The xed blanking function is to be invalid (factory setting).

● Auto setting : The currently blocked OFF beam channels are set as “effective beam channels”

in the xed blanking function. Be sure to set this function in the state where the

emitter emits light. Furthermore, this function cannot be set in the state where all

beam channels receive lights / are blocked.

● Manual setting : Each beam channel can be set to “effective / ineffective” in the fixed blanking

function respectively.

3-1 Functional Descriptions

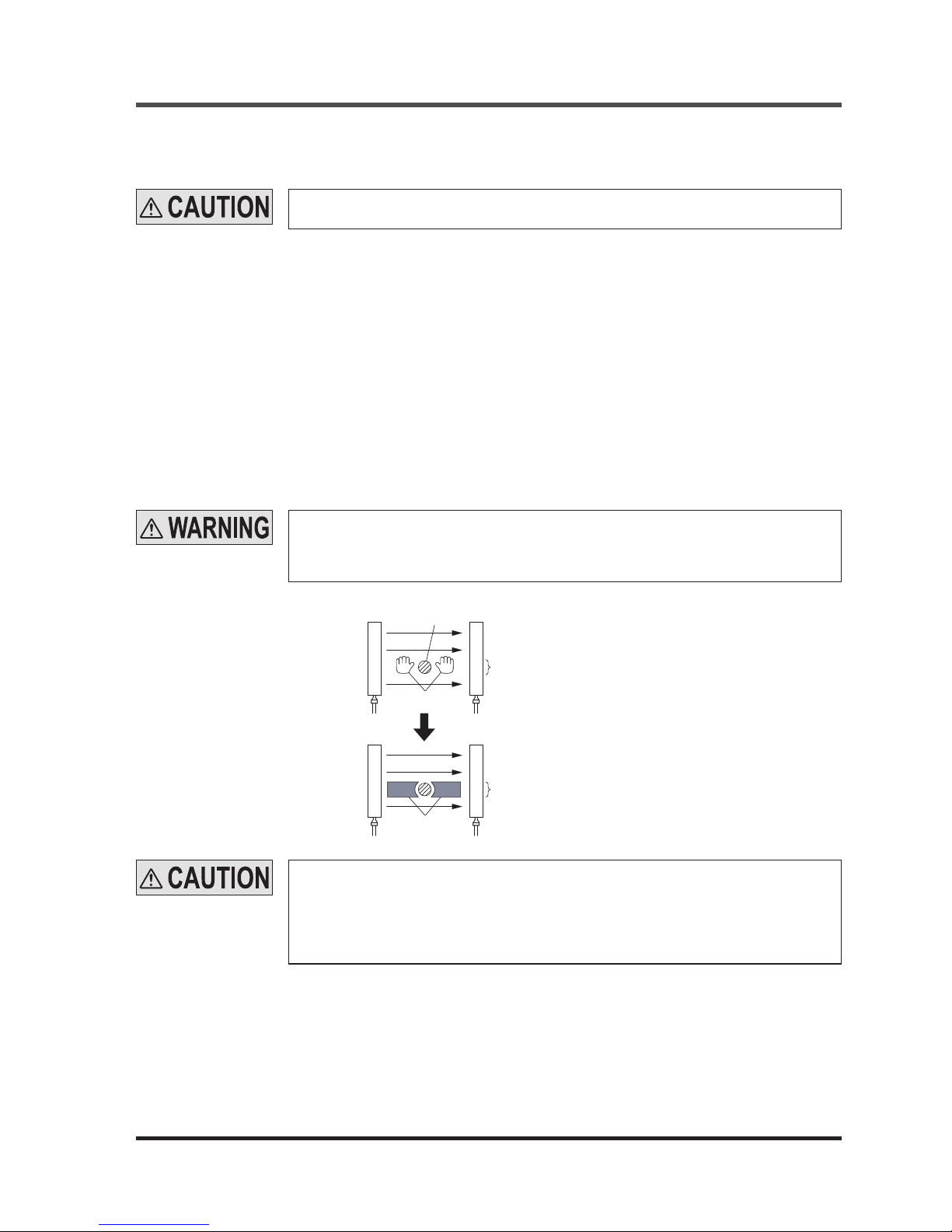

When the xed blanking function is used, the control output (OSSD 1 / 2) of SE4D series

is not turned OFF even if the particular beam channels are blocked.

By using a protection structure etc., make the dangerous parts of the machine inaccessible

to personnel through the sensing area of the particular beam channels.

<Before measures>

<After measures>

Obstacle

Dangerous area

Protection structure

Beam channels the xed blanking

function has been set to ON

Beam channels the xed blanking

function has been set to ON

Emitter

Receiver

Emitter

Receiver

When the effective beam channel(s) in the xed blanking function receive(s) the beam(s)

from the emitter, the control output (OSSD 1 / 2) of the SE4D series is xed to “OFF.” In

this case, check the mounting condition and turn the power ON again.

(Even if the power is turned ON again, the xed blanking function still stays effective.)

When the xed blanking function is used, the received light intensity indicator of SE4D

series is turned OFF regardless of the received light intensity.

9

Functional Descriptions

3-1-2 Floating Blanking Function

This function is set in each SE4D series.

If the number of the blocked beam channels is less than the set number of the beam channels, the

control output (OSSD 1 / 2) of SE4D series is not turned “OFF.”

This function is useful when an obstacle moves within the sensing area.

The factory setting of this function is “ineffective.”

The following items can be set.

Set number of beam channels

● Selectable among 0 (the oating blanking function is ineffective), 1, 2 or 3.

Ineffective setting of both end beam channel

● “Effective / ineffective” of the oating blanking function for the both end beam channels can be

selected.

• SET (Effective) : The floating blanking function becomes ineffective for the both end beam

channels. In case either end of the beam channel is blocked, the control

output (OSSD 1 / 2) of SE4D series is turned “OFF” regardless of the set

number of the beam channels.

• CLR (Ineffective) : The floating blanking function becomes effective for all beam channels

including both end beam channels.

Non-serial beam channel setting

• SET (Effective) : Even if the beam channels are blocked discontinuously in the set beam

channels, the control output (OSSD 1 / 2) of SE4D series is turned “ON.”

(Discontinuous mode)

• CLR (Ineffective) : When the beam channels are blocked discontinuously even in the set beam

channels, the control output (OSSD 1 / 2) of SE4D series is turned “OFF.”

(Continuous mode)

[For use in Europe (EU) (as EN 999)] (Also applicable to ISO 13855)

(For intrusion direction perpendicular to the sensing area)

<In case that the minimum sensing object is ø40mm or less>

● Equation S = K × T + C

S : Safety distance (mm)

Minimum required distance between the sensing area surface and the dangerous parts of

the machine.

K : Intrusion velocity of operator’s body or object (mm/sec.)

Taken as 2,000 (mm/sec.) for calculation

T : Response time of total equipment (sec.)

T = T

m

+ T

SE4D

Tm: Maximum halting time of machine (sec.)

T

SE4D

: Response time of SE4D series (sec.)

C : Additional distance calculated from the size of the minimum sensing object of the SE4D

series (mm)

However, the value of C cannot be under 0.

C = 8 × (d - 14)

d: Diameter of the minimum sensing object (mm)

● When using the floating blanking function, the size of the minimum sensing object

becomes larger, and the safety distance is longer as well. For the calculation of the

safety distance, refer to the instruction manual enclosed with SE4D series.

● Before designing the system, refer to the relevant laws and standards of the region

where SE4D series is to be used and then install SE4D series.

● The minimum sensing object differs depending on the set number of the beam channels.

10

Functional Descriptions

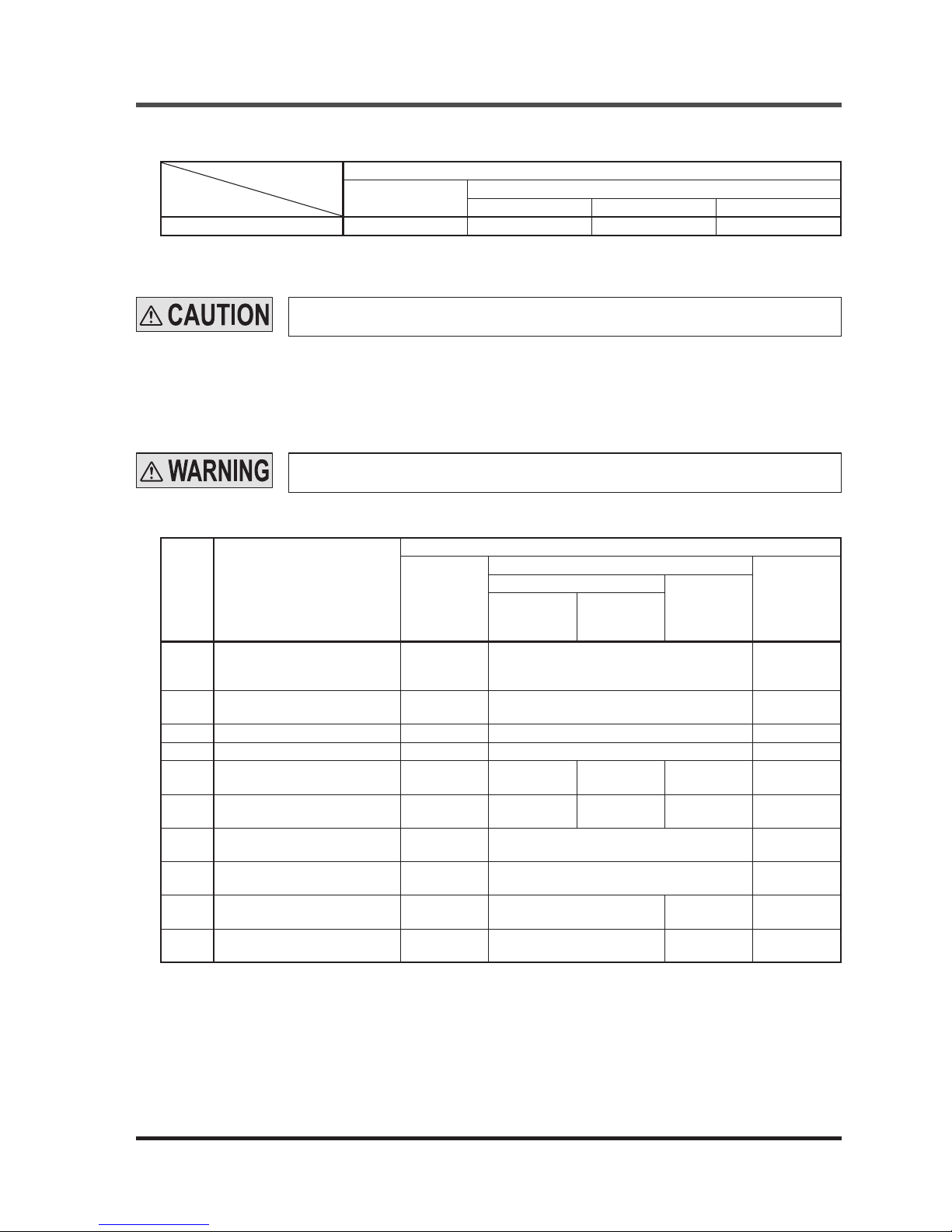

<Minimum sensing object>

Floating blanking function

Ineffective

Effective

1 beam channel 2 beam channels 3 beam channels

SE4D-H□ ø25mm ø45mm ø65mm ø85mm

3-1-3 Auxiliary Output Switching Function

This function changes the operation state of the auxiliary output. It is useful when desired to make an

indicator to operate or inform the operation state of the SE4D series to PLC.

The following settings are selectable.

Setting

mode

Auxiliary output setting

Operation of the auxiliary output corresponding to SE4D series state

Emission

halt

State of sensing area when emitting

Lockout

Unshielded

Shielded

Unstable

light-receiving

condition

Others

0

Negative logic of the control

output (OSSD 1 / 2)

(factory setting)

ON

OFF when OSSD is ON

ON when OSSD is OFF

ON

1

Positive logic of the control

output (OSSD 1 / 2)

OFF

ON when OSSD is ON

OFF when OSSD is OFF

OFF

2 ON when emitting OFF ON OFF

3 OFF when emitting ON OFF ON

4

OFF under unstable light

receiving condition (Note 1)

(Note 3) OFF ON (Note 3) (Note 3)

5

ON under unstable light

receiving condition (Note 1)

(Note 3) ON OFF (Note 3) (Note 3)

6 ON during muting OFF

ON during muting

Others: OFF

OFF

7 OFF during muting ON

OFF during muting

Others: ON

ON

8

ON in light receiving condition

(Note 2)

OFF ON OFF OFF

9

OFF in light receiving condition

(Note 2)

ON OFF ON ON

Notes: 1) When the xed blanking function, the oating blanking function or the muting function is used, the setting of ON / OFF

under unstable light-receiving condition does not work.

2) By the setting of ON / OFF in light receiving condition, light-receiving / light interrupted condition is output regardless of

the xed blanking function, the oating blanking function or the muting function.

<e.g.>

When the fixed blanking function is used, if an obstacle exists in the set area and other area is in light receiving

condition, the control output (OSSD 1 / 2) is in ON sate, however, the auxiliary output becomes OFF since the SE4D

series has been detecting the obstacle.

3) The state of the auxiliary output remains the same even if the SE4D series state changes.

If the oating blanking function is used, the incident light intensity indicator is turned OFF

when an obstacle exists in the sensing range regardless of the incident light intensity.

Do not use the auxiliary output for the purpose of stopping the machine in which the SE4D

series is installed. Failure to do so could result in death or serious injury.

Loading...

Loading...