Page 1

SE9Z-B1865

SE2L Series

Safety Laser Scanner

User’s Manual

Page 2

Table of contents

1. Introduction ................................................................................................................................................. 6

1.1 About this manual ................................................................................................................................. 6

1.2 Applic

1.3 Abbr

1.4 Special m

1.5 Applic

1.6 Registe

2. Safety pr

2.1 Gener

2.2 Operatin

2.3 Installat

2.4 W

2.5 Configur

2.6 Inspection and mainte

3. P

roduct overview....................................................................................................................................... 13

3.1 Featur

3.2 Compone

3.3 Operation principle

3.4 Scanning

able products............................................................................................................................... 6

eviations......................................................................................................................................... 6

arkings and symbols ............................................................................................................. 6

able directives and standards ....................................................................................................7

red trademarks.......................................................................................................................... 8

ecautions .......................................................................................................................................9

al precautions .............................................................................................................................. 9

g environment....................................................................................................................... 10

ion of SE2L............................................................................................................................. 10

iring................................................................................................................................................... 10

ation....................................................................................................................................... 11

nance ............................................................................................................... 11

es of SE2L-H05LP / SE2L-H05LPC.......................................................................................13

nts of SE2L-H05LP / SE2L-H05LPC ................................................................................14

............................................................................................................................. 16

area....................................................................................................................................... 17

3.4.1 P

3.4.2 W

3.5 Ar

3.6 Incr

3.6.1 Puls

3.6.2 Re

3.6.3

3.6.4 Ar

3.7 OSSD

3.7.1 Se

3.7.2 Lock

3.7.3 Inter

3.8 Exte

3.9 Muting function

3.9.1 Muting

3.9.2 Muting

3.9.3 Muting

rotection zone............................................................................................................................... 17

arning zone .................................................................................................................................20

ea switching...................................................................................................................................... 21

emental encoder............................................................................................................................ 24

e per cm travel generated by incremental encoders............................................................25

commend increment encoder specification............................................................................. 26

Tolerances allowed for encoder ....................................................................................................26

ea switching by encoder input .................................................................................................. 27

.................................................................................................................................................... 28

lf-diagnostic function of OSSD ................................................................................................. 29

out state.................................................................................................................................. 29

lock function .......................................................................................................................... 29

rnal device monitoring (EDM) function ....................................................................................32

................................................................................................................................... 33

start condition................................................................................................................... 33

stop condition ...................................................................................................................34

override function.............................................................................................................. 35

3.10 Refe

3.10.

rence monitoring function......................................................................................................... 36

1 Area protection............................................................................................................................. 36

SE2L User’s Manual (SE9Z-B1865)

1

Page 3

3.10.2 Access protection.......................................................................................................................... 37

3.11 Area sequence function...................................................................................................................... 39

3.12 Respons

3.13 Other

3.13.1 W

3.13.2 W

3.13.

3 Muting output 1 (MUT_OUT 1)................................................................................................. 40

3.13.

4 Muting output 2 (MUT_OUT 2)................................................................................................. 40

3.13.

5 Reset Request 1 (RES _ REQ1) .................................................................................................. 41

3.13.

6 Reset Request 2 (RES _ REQ2) .................................................................................................. 41

3.14 Inform

3.14.

1 LED............................................................................................................................................... 42

3.14.

2 7-Segment display ........................................................................................................................ 42

3.15 Ethernet

3.15.

1 Ethernet Setting ........................................................................................................................... 43

3.16 Function

3.17 Maste

4.

Application examples of SE2L.................................................................................................................. 46

4.1

Access protection (Horizontal application Stationary Protection zone 1) ...................................... 46

e time ....................................................................................................................................39

outputs..................................................................................................................................... 40

arning output 1 (WARNING 1)............................................................................................... 40

arning output 2 (WARNING 2)............................................................................................... 40

ation indicator........................................................................................................................ 41

communication .................................................................................................................. 43

to configure SE2L by SD card .......................................................................................... 44

r-Slave Function ...................................................................................................................... 44

4.2

Access protection (Stationary Horizontal application with Dual Protection zone)........................ 49

4.3

Access protection (Vertical application- whole body detection) ......................................................49

4.4

Access protection (Vertical application Stationary).......................................................................... 51

4.5

Area protection (Horizontal application Mobile) Fixed area .......................................................... 53

4.6

Area protection (Mobile, Horizontal, Single Protection, Variable Area)........................................ 56

4.7

Area protection (Mobile, Horizontal, Single Protection, Encoder Input)....................................... 57

4.8

Area protection (Mobile, Horizontal, 2 Units Interconnected, Variable......................................... 57

4.9

Area protection (Mobile, Horizontal, 4 Units Interconnected, Variable Area) ..............................58

4.10

Area protection (Mobile, Horizontal, Autonomous Navigation) ................................................... 59

5. Installation

5.1 Light interfer

5.2 Mutual interfer

5.3 High

5.4 Lim

6. W

iring......................................................................................................................................................... 65

6.1 Pr

6.2 Power

................................................................................................................................................. 60

ence ................................................................................................................................ 60

ence............................................................................................................................. 61

reflective background ................................................................................................................ 63

ited detection capability zone ......................................................................................................64

ecautions........................................................................................................................................... 65

supply........................................................................................................................................ 65

6.3 W

ire color and function ......................................................................................................................65

6.4 W

iring example.................................................................................................................................... 67

6.5 Input/ Output cir

cuit........................................................................................................................... 72

SE2L User’s Manual (SE9Z-B1865)

2

Page 4

6.5.1 OSSD/ Warning Output circuit .................................................................................................... 72

6.5.2 Other output circuits..................................................................................................................... 72

6.5.3 Input cir

7.

Function configuration of SE2L............................................................................................................... 74

7.1

About SLS Project Designer application........................................................................................... 74

7.2 System

7.3 Installat

7.3.1 Uninstallation SLS P

7.4 Device dr

7.4.1 Installin

7.4.2 Installin

7.4.3 Installin

7.5 S

tarting the SLS Project Designer .....................................................................................................83

7.5.1 S

tartup Main window.................................................................................................................... 84

7.5.2 Cr

7.5.3 Open c

7.5.4 Connect

7.6 Compone

7.7 Menu bar

cuit.................................................................................................................................... 73

requirements........................................................................................................................... 74

ion of SLS Project Designer.................................................................................................. 75

roject Designer............................................................................................75

iver installation.................................................................................................................... 76

g the driver in Windows 8............................................................................................... 76

g the driver in Windows 7............................................................................................... 78

g the driver in Windows XP............................................................................................ 83

eate new configuration.............................................................................................................. 84

onfiguration file .................................................................................................................85

to SE2L ............................................................................................................................ 86

nts of SLS Project Designer................................................................................................ 87

.............................................................................................................................................. 87

7.7.1 F

7.7.2 Edit

7.7.3 M

7.7.4 Connect

7.7.5 Option

7.7.6 Language

7.7.7 He

7.8 T

7.9 Subpanel

7.9.1 Configuration t

7.9.2 M

7.9.3 Report tab..................................................................................................................................... 101

7.10 S

7.1

7.12 P

7.12.

7.12.

ile................................................................................................................................................... 88

.................................................................................................................................................. 88

ode ...............................................................................................................................................89

ion...................................................................................................................................... 89

............................................................................................................................................. 90

........................................................................................................................................ 90

lp................................................................................................................................................. 90

ool bar................................................................................................................................................. 91

............................................................................................................................................... 92

ab ..........................................................................................................................92

onitor tab ..................................................................................................................................101

tatus bar ......................................................................................................................................... 104

1 Connecting SE2L with PC .............................................................................................................. 104

assword .......................................................................................................................................... 105

1 Changing the password ............................................................................................................. 105

2 Reclaim the forgotten password............................................................................................... 106

7.13 Configu

7.14 Function

7.15 Ar

ea configuration........................................................................................................................... 108

ration mode ........................................................................................................................ 106

configuration.................................................................................................................... 107

SE2L User’s Manual (SE9Z-B1865)

3

Page 5

7.15.1 Area configuration by drawing tools........................................................................................ 109

7.15.2 Area configuration by teaching function ................................................................................. 111

7.15.

3 Muting configuration ................................................................................................................ 112

7.15.

4 Reference region configuration ................................................................................................ 113

7.16 T

ransmit configurations to SE2L................................................................................................... 114

7.17 Save project file

7.18 Read

7.19 Open project file

7.20 Rec

7.21 Replay t

7.22 Save s

7.23 SE2L

8. Inspection

8.1 Pr

8.2 Operation inspection

8.3 Daily

8.4 Per

8.5 Cleanin

8.6 Replac

8.6.1 Method

8.6.2 Adjustment

9. T

roubleshooting ....................................................................................................................................... 133

configuration from SE2L ...................................................................................................... 117

ording the SE2L data................................................................................................................ 118

he log data .......................................................................................................................... 119

ettings to SD card.................................................................................................................. 121

configuration through SD card............................................................................................ 122

and maintenance ................................................................................................................... 123

e-operation inspection................................................................................................................... 123

inspection.................................................................................................................................. 125

iodical inspection .........................................................................................................................127

g the optical window............................................................................................................. 129

ing the optical window........................................................................................................... 129

............................................................................................................................... 115

.............................................................................................................................. 117

......................................................................................................................... 124

of replacing the optical window.................................................................................... 130

of the optical window .............................................................................................. 131

10.

Specification........................................................................................................................................... 137

10.

1 SE2L-H05LP / SE2L-H05LPC ....................................................................................................... 137

1

1. Package contents.................................................................................................................................... 139

12.

Options ...................................................................................................................................................140

12.

1 Base mounting bracket (Type number: SE9Z-HS2-BK01).......................................................... 140

12.

2 Rear mounting bracket (Type number: SE9Z-HS2-BK02) .........................................................140

12.

3 Simple base mounting bracket (Type number: SE9Z-HS2-BK03) .............................................140

12.

4 Simple rear mounting bracket (Type number: SE9Z-HS2-BK04).............................................. 140

12.

5

Simple rear mounting bracket (Long Type) (Type number: SE9Z-HS2-BK04)

12.6 Micro USB cable (Type number: SE9Z-HS2-XCM11) ................................................................140

12.

7 Ethernet cable (Type number: SE9Z-HS2-XCD13) .....................................................................140

12.

8 Extension cable (Type number: SE9Z-HS2-XCE***).................................................................. 141

12.

9 Connector Cable (Type number: SE9Z-HS2-C***) ..................................................................... 141

12.

10 Optical window for replacement (Type number: SE9Z-HS2-WD01) ....................................... 141

12.1

1 Cover Bracket (Type number: SE9Z-HS2-CM01) ..................................................................... 141

13.

External dimension................................................................................................................................ 142

13.

1 SE2L-H05LP.................................................................................................................................... 142

.................................... 140

SE2L User’s Manual (SE9Z-B1865)

4

Page 6

13.2 SE2L-H05LPC................................................................................................................................. 143

13.3 Base mounting bracket ...................................................................................................................144

13.

4 Rear mounting bracket ................................................................................................................... 145

13.

5 Simple base mounting bracket ....................................................................................................... 146

13.

6 Simple rear mounting bracket........................................................................................................147

13.

7 Simple rear mounting bracket (Long type)................................................................................... 148

13.

8 Cover Protection Bracket ............................................................................................................... 149

14.

EU Declaration of conformity .............................................................................................................. 150

15.

Revision history ..................................................................................................................................... 151

16.

Representative contacts.........................................................................................................................152

SE2L User’s Manual (SE9Z-B1865)

5

Page 7

1. Introduction

This user’s manual is designed with the purpose of providing guidelines and instructions for the machine

user or system designer while operating, installing, wiring and servicing the SE2L-H05LP or the

SE2L-H05LPC.

1.1 About this manual

SE2L’s features, installation and handling method are described in this document.

Read this document carefully before installation, wiring, operation, inspection and maintenance.

User should have a copy of this document at an easy-to-access place for quick reference.

Information provided in this document is subject to change without prior notice. For the latest

information visit the company’s website http://www.idec.com

Actual product may differ from the illustrations and figures in this document as they are used for

explanatory purpose only.

1.2 Applicable products

This document is for the following sensor model.

SE2L-H05LP

SE2L-H05LPC

1.3 Abbreviations

The list below shows abbreviations used in this document.

Table 1-1 Abbreviations

Abbreviation Meaning

AGV Automated guided vehicle

AOPDDR Active optoelectronic protective device responsive to diffuse reflection

AWG

EDM External device monitoring

EMC Electromagnetic compatibility

MSCE Machine secondary control element

OSSD Output signal switching device

SELV Safety extra low voltage

American wire gage

1.4 Special markings and symbols

Markings and symbols are used in this document to alert the user about safety-related issues. Follow the

instructions of these special markings and symbols to ensure safety during the operation.

SE2L User’s Manual (SE9Z-B1865)

6

Page 8

Table 1-2 Special markings and symbols

Mark Meaning

Procedures that could lead to dangerous situation, critical injury or death if not

carried out properly

Procedures that could lead to dangerous situation, serious injury or physical

damage if not carried out properly

1.5 Applicable directives and standards

SE2L is certified by TÜV SÜD Product Service GmbH, and UL / c-UL, FDA (CDRH) as a safety

sensor defined in EU Machinery Directive (2006/42/EC).

Table 1-3 Applicable directives and standards

Certified authority Directives/Standard Details

TÜV SÜD

UL / c-UL

EU directives

EN standards

IEC standards

ISO standards

UL standards

IEC standards

ISO standards

CSA standards

Machinery Directive : Directive 2006/42/EC

EMC Directive : Directive 2014/30/EU

IEC61496-1 :2012

EN 61496-1 :2013

IEC 61496-3 :2008 Type 3

IEC 61508 Part1-7 :2010 SIL 2

EN 62061 :2005 / A1 :2013 SIL 2

EN ISO13849-1 :2015

IEC60825-1 :2007

UL 508 :2010

ANSI / UL 1998 :2013

IEC 61496-1 :2012

IEC 61496-3 :2008

IEC 61508 Part 1-3 :2010

ISO 13849-1 :2006

CSA C22.2 No.14 :2013

Safety of laser products

Type 3

Category 3, PL d

Class 1

Type 3

Type 3

SIL 2

Category 3, PL d

FDA (CDRH)

21 CFR Part 1040.10

and 1040.11

SE2L User’s Manual (SE9Z-B1865)

7

Safety of laser products

Class 1

Page 9

1.6 Registered trademarks

MicrosoftⓇ, WindowsⓇ are the registered trademarks of Microsoft Corporation USA.

Pentium

Other products mentioned in the document are trademarks or registered trademarks of their respective

companies.

Ⓡ

is the registered trademark of Intel Corporation.

SE2L User’s Manual (SE9Z-B1865)

8

Page 10

2. Safety precautions

Read the following guidelines for correct use of the SE2L. Proper handling and

usage will ensure the SE2L to operate accordingly.

2.1 General precautions

SE2L is designed to protect human begins or systems by monitoring the hazardous area. It is not

designed for the protection from high speed objects or the electromagnetic radiation.

Perform pre-operation tests in order to verify the performance of SE2L.

Do not modify or disassemble SE2L. Such modifications will affect the detection capability leading to

injuries or death.

Do not modify or disassemble SE2L to maintain its housing rating. Such modifications will void the

warranty.

The person-in-charge should be qualified to operate SE2L. The person must be trained, on safety

requirements with necessary cautions for handling the device.

The person-in-charge should train the user with correct installation, operation, inspection and

maintenance procedures.

The person-in-charge is responsible to ensure the proper working environment for SE2L.

The person-in-charge is responsible for the compliance with the local safety requirements, standards,

rules and regulations, laws of respective nations, states or districts when SE2L is used in a safety-related

system.

SE2L has been manufactured and shipped under the strict quality control. If you find any defect in the

product contact the nearest distributor or sales representative.

IDEC cannot be held responsible for the damages or failure due to misuse of the product.

User should prepare test pieces for detection capability verification. The test piece should emulate the

smallest object that is intended to be detected during the operation.

Maximum level of homogeneous pollution for SE2L to operate normally is under 30%. SE2L will

report error if the pollution exceeds the stated limit. Always keep the optical window in clean condition

to avoid the error.

Before resetting the interlock of SE2L, user must ensure the surrounding is safe especially the protected

area.

Apply sufficient measures to ensure safety of the protected area when decommissioning SE2L.

Protective materials such as guards or light curtain should be used to prevent the passage to the

hazardous area.

SE2L including its accessories are subject to change without prior notice for the improvement.

SE2L should be disposed as industrial waste or in accordance with the local disposal directives.

SE2L User’s Manual (SE9Z-B1865)

9

Page 11

Do not drop the product. Otherwise, the product may be damaged, lead to failure and the performance

will be degraded. Injury may also be caused.

2.2 Operating environment

Make sure that SE2L’s operating environment is within the stated specification (temperature, humidity,

vibration, ambient light, etc.)

Do not use or mount SE2L near devices that could generate strong electromagnetic waves as it could

affect the operation of SE2L.

Do not use or mount SE2L in dusty, smoky, or misty environments, or where corrosive substances are

present. Operating under such environments may decrease the detection capacity of SE2L.

This product is for indoor use only.

2.3 Installation of SE2L

Install SE2L on a firm surface or structure to avoid displacement. Also, do not step on or hung on SE2L

after installation.

SE2L should be firmly mounted using the screws (recommended torque for screws is 3N・m). Shock

and vibration should not loosen the mounting. Detection may fail if actual protection zone differs from

the intended zone due to displacement of SE2L.

Safety distance should be determined before installing SE2L. User must verify the function of SE2L

after installation by placing a test piece at all the positions of protection zone (refer to chapter 4 for the

details on the safety distance calculation for various applications).

When installing the SE2L, protective materials such as guards or light curtain should be used to prevent

any passage into the hazardous area.

Reset switch used for interlock, muting and override function should be mounted at a location away

from the protection zone.

Mutual interference can occur when identical SE2Ls are mounted at the same detection plane. Refer to

chapter 5 for countermeasures to avoid mutual interference.

SE2L should be mounted at the location which has sufficient space for maintenance.

Do not add any protective materials such as, glass and transparent cover, in front of the optical window.

This could lead to loss of detection capability of the SE2L.

Minimum detectable width varies with the distance. Refer to chapter 10 for details.

2.4 Wiring

Switch off all the power supplies during wiring.

When a converter is used for supplying the power, make sure it fulfills the following requirements.

A rated output voltage within the range of 24V DC ±10% (SELV circuit, Category II).

Reinforced insulation or double insulation for the primary and secondary circuit.

Holding time of the output should be above 20ms.

The power supply complies with the requirements of electromagnetic compatibility

SE2L User’s Manual (SE9Z-B1865)

10

Page 12

regulations (EMC) of the respective country, state and district.

All the input/output signal cables should be installed away from machines power lines and high-

voltage cables.

Use the OSSD signal of SE2L to control safety-related machines or control system. Do not use warning

signals to control safety related machine as these are non safety signals.

Both the OSSD1 and OSSD2 outputs should be connected to the safety-related machines or control

system. If OSSD3 and OSSD4 are used they must be connected in the same manner.

Use shield cable for the connection between OSSD signals and safety-related machines or systems.

2.5 Configuration

Configuration of safety functions are password protected. Only authorized users with password are

allowed to configure SE2L.

SE2L does not operate without initial configuration.

Pre-operation tests should be performed to verify the configurations before operating the SE2L.

Increasing the response time of OSSD will increase the stability of SE2L. However, this will reduce the

detection capability towards moving objects. User must perform risk assessment before using this

function.

Changes made during the configuration must be recorded and saved. Use the report function in the SLS

Project Designer for this purpose. (

page 101)

2.6 Inspection and maintenance

User must perform inspection and maintenance by referring to the checklists provided in this document

(

Chapter 8)

・ Pre-operation inspection

・ Operation inspection

・ Daily inspection

・ Periodic inspection

The checklists in this document are provided as basic guidelines while performing the test and

maintenance. User must perform additional inspection and maintenance tasks deemed necessary for the

respective application.

Stop the machine and system if faults are detected during these tests.

Clean the optical window when it gets contaminated. If the optical window is damaged it should be

replaced by a new one.

For the repair of SE2L, contact the nearest distributor or sales representative.

User should not repair or disassemble SE2L.

SE2L User’s Manual (SE9Z-B1865)

11

Page 13

Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

Safety Standard Class 1 Laser of SE2L-H05LP / SE2L-H05LPC: It is

guaranteed as safety class laser. Additional measures are not necessary to

maintain the laser safety.

Figure 2-1 Example of product labels

SE2L User’s Manual (SE9Z-B1865)

12

Page 14

3. Product overview

SE2L emits pulsed laser beam which is reflected on a rotating mirror within the configured protection

zone. When the emitted laser beams are reflected back from an object its distance is measured. This chapter

describes the features and properties of SE2L.

3.1 Features of SE2L-H05LP / SE2L-H05LPC

Protection range: Maximum 5m ( page 137)

Warning range : Maximum 20m (

Detection angle : 270°(

Minimum response time of 60ms (Configurable) (

32 set of areas (Configurable)

2 modes of scanning area setting (

Dual Protection Mode (Configurable)(

Scanning area switch through incremental encoder input (Configurable)(

Interlock function (Configurable) (

EDM function (Configurable) (

Muting /Override function (Configurable)(

Reference monitor function (Configurable) (

Area sequence function (Configurable) (

LED indicator for SE2Ls status (

7-segment display (

Ethernet communication (

A maximum of 4 sensors for master/slave operation (

Configuration with SD card

page 15)

*1

page 42)

page 43)

*2

( page 44)

page 137)

( page 17)

page 17)

page 19)

page 29)

page 32)

page 41)

page 40)

page 33)

page 36)

page 39)

page 44)

page 27)

Easy configuration with SE2L configuration application software installed in PC (

*1: Depending on the used functions, maximum area varies from 2 to 32 sets of area.

*2: “SD card” in this manual indicates Micro SD/SDHC card.

SE2L User’s Manual (SE9Z-B1865)

13

page 83)

Page 15

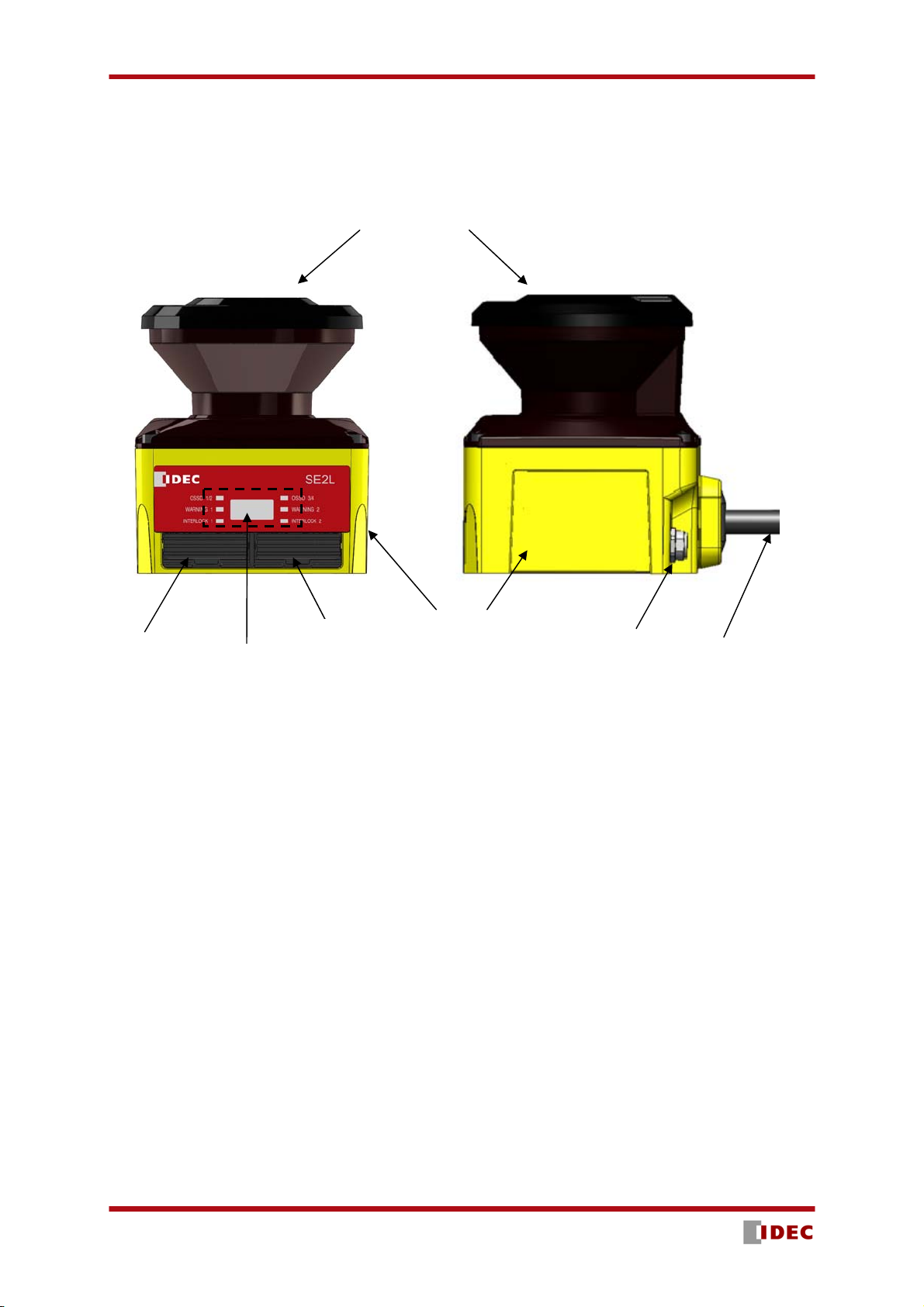

3.2 Components of SE2L-H05LP

Optical window

/ SE2L-H05LPC

SD card slot

Micro USB Connector

7-segment display

Figure 3-1 SE2L-H05LP / SE2L-H05LPC components

Housing

Ethernet Connector

Cable

SE2L User’s Manual (SE9Z-B1865)

14

Page 16

Figure 3-2 Scanning range and detection zone origin (Top view)

Figure 3-3 Detection plane of SE2L-H05LP / SE2L-H05LPC (Side view)

SE2L User’s Manual (SE9Z-B1865)

15

Page 17

3.3 Operation principle

Warning zone 2

Warning zone 1

Protection zone

Figure 3-4 Scanning range

Figure 3-4 shows the scanning range of SE2L. Protection zone and warning zones are configured using

the SLS Project Designer application software. Any object or human beings entering the protection zone will

lead the OSSD signal to change from ON-state to OFF-state. Similarly, an object detected in the warning

zones will lead the warning signals to change to OFF-state.

Distance to the object is measured using the Time of Flight (TOF) principle. Pulsed laser beams are

radiated into the scanning range of 270º by the rotating motor. These pulsed laser beams are reflected back

by objects inside the scanning range. The duration of reflected beams are used for distance calculation as

shown below:

Where, L=Distance of the object

C=Speed of the light

T=Time difference

SE2L User’s Manual (SE9Z-B1865)

16

Page 18

The operating principle of TOF is schematically shown in Figure 3-5. The angular resolution of SE2L is

0.125°.

Figure 3-5 TOF operation principle

3.4 Scanning area

Scanning area of SE2L consists of protection zone and warning zones. Maximum 32 sets of area can be

configured. Further, two combinations for protection and warning zones can be selected for the operation.

Combination 1: Protection zone, Warning zone 1 and Warning zone 2

Combination 2: 2 Protection zones (Dual Protection)

In dual protection mode, two protection areas can be configured but it is not possible to configure the

warning zones Protection and warning zones can be configured by using SLS Project Designer. Refer to

Chapter 7 for configuration details.

3.4.1 Protection zone

Protection zone is safety-critical and directly connected to the OSSD signal. When an obstacle is

detected in the protection zone, SE2L will switch the OSSD to OFF-state (which should trigger a switch to

stop a machine or AGV). For mobile applications, the OSSD signal can be used as the emergency stop signal.

Figure 3-6 and 3-7 show the examples of protection zone configured using manual mode and teaching mode

respectively. User can configure these zones accordingly to ensure hazardous area is completely protected.

SE2L User’s Manual (SE9Z-B1865)

17

Page 19

Figure 3-6 Protection zone configured using manual mode

Figure 3-7 Protection zone configured using teaching mode

User should verify the configuration before actual operation.

The configured zone should be of minimum safety distance or more.

Figure 3-7 Protection zone configured using teaching mode

Minimum possible detectable width changes according to the distance.

Additional distance must be taken into account while configuring the protection

zone.

User should verify the detection capability using an actual object.

SE2L User’s Manual (SE9Z-B1865)

18

Page 20

In dual protection mode, two protection zones can be configured independently. SE2L will monitor these

zones simultaneously. OSSD1 and OSSD2 are dedicated to protection zone1 and OSSD3 and OSSD4 are

dedicated to protection zone2.

Figure 3-8 shows an example of the dual protection zone configuration. Warning zones cannot be

configured in dual protection mode.

Figure 3-8 Example of Dual protection zone configuration

SE2L User’s Manual (SE9Z-B1865)

19

Page 21

3.4.2 Warning zone

Warning zones are non-safety zones and are connected to Warning1 and Warning2 outputs. When the

obstacle is detected in the warning zones, SE2L will switch the respective warning signal from ON-state to

OFF-state.

Warning signals can be used as an alert signal to avoid human beings or objects from approaching near

the protection zone. For mobile applications, warning signals can be used for reducing the speed of

automatic guided vehicle (AGV) to avoid collision. Figure 3-9 shows an example of warning zone

configuration.

Warning zone 2

Warning zone 1

Protection zone

Figure 3-9 Warning zones

Warning zones are non-safety zones.

Warning signals should not be used for controlling any machine or vehicle for the

safety-related purposes.

Warning signals are non safety-signal.

Warning signals and OSSD signal is not inter-related.

SE2L User’s Manual (SE9Z-B1865)

20

Page 22

3.5 Area switching

A maximum of 32 sets of area can be configured in SE2L. However the maximum configurable area

number differs depending on the selected function such as, muting and dual protection. Table 3-1 shows the

maximum configurable area number according to the used mode.

External input signals are provided in SE2L for switching the area. Each signal has a pair of normal and

inverted signal. For example, it is necessary to provide both input signal IN_A and inverse IN_A signal to

switch the area. Error will occur if IN_A and inverse IN_A signals do not complement each other. Table 3-2

below shows the combination of input signal to switch the area. Area in use will be displayed in the 7

segment LED of SE2L.

It is also possible to configure area input delay. Configure the necessary delay required for the system to

provide stable input signals to SE2L. The default value is 30ms.

There are maximum 5 input pairs (a pair is combination of normal and inverted signal) in SE2L therefore,

it can operate with maximum 32 sets of area. Further, it is also possible to switch the area through the speed

monitoring of increment encoder signal connected to SE2L (

Table 3-1 Input combination for area switching

Mode Protection Max internal input Max Area Max encoder area

Standard

EDM

MUTING / EDM

Encoder *1

*1: Muting function and dual protection mode cannot be used if encoder input mode is selected.

*2: Among the 4 input patterns, at least one pattern must be used for encoder input. Other 3 remaining

patterns can be selected to be used as static input or not in use. A pattern with encoder input mode can

have maximum 32 sets of area (for detail, refer to section 3.6.4).

1 5 32

2 5 32

1 4 16

2 4 16

1 2 4

2 1 2

1 2 3

page 24).

-

-

-

-

-

-

32*2

SE2L User’s Manual (SE9Z-B1865)

21

Page 23

Table 3-2 Input combination for area switching

a) In the case of 5 Input

Area IN_A IN_B IN_C IN_D IN_E

Area 1 ON ON ON ON ON OFF OFF OFF OFF OFF

Area 2

Area 3

Area 4

Area5 ON ON OFF ON ON OFF OFF ON OFF OFF

Area6 OFF ON OFF ON ON ON OFF ON OFF OFF

Area7 ON OFF OFF ON ON OFF ON ON OFF OFF

Area8 OFF OFF OFF ON ON ON ON ON OFF OFF

Area9 ON ON ON OFF ON OFF OFF OFF ON OFF

Area10 OFF ON ON OFF ON ON OFF OFF ON OFF

Area11 ON OFF ON OFF ON OFF ON OFF ON OFF

Area12 OFF OFF ON OFF ON ON ON OFF ON OFF

Area13 ON ON OFF OFF ON OFF OFF ON ON OFF

Area14 OFF ON OFF OFF ON ON OFF ON ON OFF

Area15 ON OFF OFF OFF ON OFF ON ON ON OFF

OFF ON ON ON ON ON OFF OFF OFF OFF

ON

OFF OFF ON ON ON ON ON OFF OFF OFF

OFF ON ON ON OFF ON OFF OFF OFF

IN_

IN_

IN_ IN_

IN_

Area16 OFF OFF OFF OFF ON ON ON ON ON OFF

Area17 ON ON ON ON OFF OFF OFF OFF OFF ON

Area18 OFF ON ON ON OFF ON OFF OFF OFF ON

Area19 ON OFF ON ON OFF OFF ON OFF OFF ON

Area20 OFF OFF ON ON OFF ON ON OFF OFF ON

Area21 ON ON OFF ON OFF OFF OFF ON OFF ON

Area22 OFF ON OFF ON OFF ON OFF ON OFF ON

Area23 ON OFF OFF ON OFF OFF ON ON OFF ON

Area24 OFF OFF OFF ON OFF ON ON ON OFF ON

Area25 ON ON ON OFF OFF OFF OFF OFF ON ON

Area26 OFF ON ON OFF OFF ON OFF OFF ON ON

Area27 ON OFF ON OFF OFF OFF ON OFF ON ON

Area28 OFF OFF ON OFF OFF ON ON OFF ON ON

Area29 ON ON OFF OFF OFF OFF OFF ON ON ON

Area30 OFF ON OFF OFF OFF ON OFF ON ON ON

Area31 ON OFF OFF OFF OFF OFF ON ON ON ON

Area32 OFF OFF OFF OFF OFF ON ON ON ON ON

SE2L User’s Manual (SE9Z-B1865)

22

Page 24

b) In the case of 4 Input number

Area IN_A IN_B IN_C IN_D

Area 1 ON ON ON ON OFF OFF OFF OFF

Area 2

Area 3

Area 4

Area5 ON ON OFF ON OFF OFF ON OFF

Area6 OFF ON OFF ON ON OFF ON OFF

Area7 ON OFF OFF ON OFF ON ON OFF

Area8 OFF OFF OFF ON ON ON ON OFF

Area9 ON ON ON OFF OFF OFF OFF ON

Area10 OFF ON ON OFF ON OFF OFF ON

Area11 ON OFF ON OFF OFF ON OFF ON

Area12 OFF OFF ON OFF ON ON OFF ON

Area13 ON ON OFF OFF OFF OFF ON ON

Area14 OFF ON OFF OFF ON OFF ON ON

Area15 ON OFF OFF OFF OFF ON ON ON

OFF ON ON ON ON OFF OFF OFF

ON

OFF OFF ON ON ON ON OFF OFF

OFF ON ON OFF ON OFF OFF

IN_

IN_

IN_ IN_

Area16 OFF OFF OFF OFF ON ON ON ON

c) In the case of 3 Input number

Area IN_A IN_B IN_C

Area 1 ON ON ON OFF OFF OFF

Area 2

Area 3

Area 4

Area5 ON ON OFF OFF OFF ON

Area6 OFF ON OFF ON OFF ON

Area7 ON OFF OFF OFF ON ON

Area8 OFF OFF OFF ON ON ON

OFF ON ON ON OFF OFF

ON

OFF OFF ON ON ON OFF

OFF ON OFF ON OFF

IN_

IN_

IN_

d) In the case of 2 Input number

Area IN_A IN_B

Area 1 ON ON OFF OFF

Area 2

Area 3

OFF ON ON OFF

ON

OFF OFF ON

IN_

IN_

e) In the case of 1 Input number

Area

Area 1 ON OFF

Area 2 OFF ON

Area 4

OFF OFF ON ON

IN_A

IN_

SE2L User’s Manual (SE9Z-B1865)

23

Page 25

3.6 Incremental encoder

In SE2L there are 2 pairs of encoder input terminals for connecting 2 units of dual channel incremental

encoder signals. Area will be switched depending on the encoder speed. Direction of travel is detected by

encoder's phase A and phase B signals having the phase difference of 90°. Speed and rotating direction of

both encoders are constantly monitored to detect abnormal travel and stop the AGV.

Incremental encoder output signals should be connected to the respective input terminals of SE2L. There

are two patterns of signals generated by the combination of Phase A and Phase B of encoders depending on

the direction of travel (Figure 3-10). In the first pattern, Phase B is 90 degrees ahead of Phase A wherein, at

the rising edge of Phase A, state of Phase B is “H”. This pattern is considered as positive direction (forward

motion). In the second pattern, Phase B lags behind Phase A by 90 degrees and the state of Phase B at the

rising edge of Phase A is “L”. This is considered as negative direction (backward motion).

Figure 3-10 Input signal through Incremental encoder

SE2L User’s Manual (SE9Z-B1865)

24

Page 26

3.6.1 Pulse per cm travel generated by incremental encoders

When AGV travels, increment encoder generates pulses due to the transmission ratio between AVG tires

and increment encoder frictional wheel. Pulse count per cm depends on AGV's speed.

Figure 3-11 Calculation of pulse count for per centimeter travel

AGV tire diameter : 40 cm

Frictional wheel diameter mounted in increment encoder: 5 cm

Increment encoder pulse number per revolution : 1000 pulse

AGV tire circumference = Diameter × Circumference ratio = 40 cm × 3.14 = 125.6 cm

AGV tire's one rotation is equivalent to 8 rotation of frictional wheel. This equals to the 8,000 pulse of

increment encoder.

From above, increment encoder pulse count per cm is obtained as

8,000/125.6 = 63.7

While setting encoder parameters (Encoder Pulse1 and Encoder Pulse2) in SLS Project Designer, set the

encoder pulse count after rounding the calculated value to nearest whole number (64 in this case).

In the explanation above, the transfer method of the rotation was based on the frictional wheel. Same

method can be applied for other cases to estimate the pulse count generated for one rotation of the wheel.

SE2L User’s Manual (SE9Z-B1865)

25

Page 27

f

User should verify the proper area switching through encoder inputs.

Always use 2 units of increment encoder. It is not possible to detect the failure o

increment encoder or abnormal travel of the vehicle with single unit.

Use separate sets of cable to connect outputs from incremental encoder 1 and 2 to the

respective encoder input terminals of SE2L.

Separate the power supply cables and power source of each incremental encoder.

Output pairs of encoder connection should match the input pair of SE2L.

Do not wire other power lines parallel to encoder and SE2L or wire in the same duct.

There is a possibility of noise disturbance.

3.6.2 Recommend increment encoder specification

・ Phase setting 90° dual channel rotary encoder

・ Power supply: 24V DC

・ Output : Complementary output

・ Protective class : IP 54 or more

・ Output cable : Twist pair/ shield cable

・ Maximum pulse frequency : 100 kHz

・ Minimum pulse frequency : 50 pulse / cm

3.6.3 Tolerances allowed for encoder

When AGV travels in a forward direction, speed input through the two increment encoder will be same as

the original pulse frequency. However, there are cases when two speed input values may differ, such as while

cornering and due to AGV tire exhaustion. The difference between two input speeds should not exceed the

error tolerance for more than a fixed period of time. Set the error tolerance in the range of 0 to 45%.

Of the two speeds, the larger value will be considered for vehicles speed calculation. When permitted error

tolerance exceeds the fixed period OSSD will go to OFF state. Tolerance period differs according to the

vehicle speed as shown in table 3-3.

Table 3-3 Relation between AVG speed and tolerance

AGV speed v (cm/s) Tolerance

-9≦ v ≦+9

-30<v<-9 or 9<v<30 60s

v≦-30 or +30≦v

v<-9 or +9<v

(Two encoders with different rotating direction)

Infinity

20s

0.3s

SE2L User’s Manual (SE9Z-B1865)

26

Page 28

3.6.4 Area switching by encoder input

When encoder setting is enabled, four patterns can be selected from two available external inputs. For

each pattern, select either to use as static input or the encoder input or not in use. It is necessary to select at

least one pattern for encoder input.

For encoder input pattern maximum 32 sets of area switching can be performed for the range of speed.

Encoder setting is enabled by the SLS Project Designer, as shown in Figure 3-12. For using the SLS Project

Designer refer to chapter 7.

Set the error tolerance and encoder pulse count for per cm travel.

The minimum and maximum speed is automatically calculated from the pulse count and maximum pulse

frequency (100 kHz). Next, select the input patterns to use as static input or for the encoder input or not used.

Figure 3-12 shows an example of encoder input setting. In this example, pattern 1 and pattern 2 are used as

static input, pattern 3 is used as encoder input and pattern 4 is not used.

Figure 3-12 Example of pattern switching through encoder input

Next, divide the speed into number of ranges and specify the area number for each range. An example is

shown below (maximum 32 sets of area can be set). Same area cannot be specified for different speed within

a pattern. However it is possible to select same area for a different pattern.

Figure 3-13(a) shows the example of encoder input setting.

In this example, speed is divided into 4 ranges and each speed range is assigned Area 3 to Area 6.

Figure 3-13 (a) Example of encoder input setting

SE2L User’s Manual (SE9Z-B1865)

27

Page 29

When the pattern is set for static input, area number and encoder speed monitoring are configured. Speed

r

d

monitoring monitors the speed of the encoder and if it exceeds the limit OSSD will be switched to OFF state.

Figure 3-13(b) shows the example of static input setting. In this example, Area1 is assigned to the input

pattern and speed monitoring is enabled with the monitoring speed range -20 to 500cm/sec.

Figure 3-13 (b) Example of static input setting

3.7 OSSD

OSSD is safety-related signal. When humans or objects are detected in the protection zone, the OSSD

signal will switch to OFF state from ON-state. OSSD signal has the self- diagnostic function which tests the

signal periodically by switching it to OFF state for a brief period. Signal is continuously switched to

OFF-state when an error is detected during the diagnostic.

Output states of OSSD1 and OSSD2 signal are identical. Both signals should be connected to the safety

related machines or control system to fulfill the required safety level. If OSSD3 and OSSD4 are used they

must be connected in the same manner.

OSSD is a safety related signal and should be connected directly to the relay o

device that switches the machine or vehicle under control.

Both the OSSD1 and OSSD2 outputs should be connected to the safety related

machines or control system. If OSSD3 and OSSD4 are used they must be connecte

similarly.

Sufficient time for the machine or vehicle must be allocated to stop when configuring

the response time of OSSD.

User must verify the configuration before actual operation.

When OSSD is at ON state, the signal is 24V and the signal is 0V during OFF state.

SE2L User’s Manual (SE9Z-B1865)

28

Page 30

3.7.1 Self-diagnostic function of OSSD

Self-diagnostic is a function to detect the malfunction in the output circuit by switching OFF the OSSD 1

to OSSD 4 for an interval of 300μs. Therefore, safety-relay or power converter used must not response to

this diagnostic function. Figure 3-14 below shows the timing chart of the self diagnostic function of the

OSSD during dual protection mode.

Figure 3-14 Timing chart of the OSSD’s self-diagnostic function

In single protection mode, self-diagnostic function is done for OSSD 1 and OSSD 2 only.

3.7.2 Lockout state

When an error is detected by the self-diagnostic function and SE2L cannot operate normally it will

switch to lockout state. During the lockout state, OSSD1/2, OSSD3/4, WARNING1, WARNING2 will

switch to OFF-state. After removing the error, SE2L can be reset by restoring the power to release from the

lockout state.

3.7.3 Interlock function

Interlock is a function to prevent automatic restart of the OSSD signal switching from OFF-state to

ON-state. Automatic restart, manual restart and manual start interlock functions are configurable using the

SLS Project Designer.

SE2L User’s Manual (SE9Z-B1865)

29

Page 31

3.7.3.1 Automatic restart

SE2L will restart automatically when interlock function is disabled or only the start interlock function is

enabled. When obstacle from the protection zone is removed, OSSD signals switch from OFF-state to

ON-state automatically. OSSD response times for ON and OFF states are configurable (See section 3.12).

However, if SE2L is in the lockout state due to error, OSSDs will remain in OFF-state even if the interlock

function is disabled.

Figure 3-15 Timing chart of automatic restart

In automatic restart configuration OSSD will automatically switch to ON state after

the object is removed. Confirm the safety while removing the object.

Configured response time should be sufficient for the machine or AGV to stop safely.

SE2L User’s Manual (SE9Z-B1865)

30

Page 32

3.7.3.2 Manual restart (Interlock enabled)

SE2L operates in manual restart mode when interlock function is set to manual mode. The OSSD signal

switches from ON-state to OFF-state, if SE2L detects any obstacle within the protection zone or detects any

system error. In this mode, even if the detected obstacles or system error is removed, OSSD signals will

remain in OFF-state. An external reset input signal is required to release the interlock which allows the SE2L

to switch to normal operation.

SE2L will resume normal operation only after confirming the reset signal (RESET). The duration of the

reset signal should be more than 500ms. Figure 3-16 shows the timing chart of the manual restart. After reset

signal is confirmed, the OSSD signal will switch to ON-state after the lapse of the configured delay time. If

OSSD's OFF-state is due to an internal fault, it will remain in OFF-state even when reset signal is provided.

Reset delay is configurable in the range of 1s to 6s.

Figure 3-16 Timing chart of manual restart

User should verify that the detected obstacle is safely removed before resetting the

SE2L.

If restart interlock function is used to restart the machine, the reset switch should be

mounted away from the protection zone.

Falling to comply with the above could lead to critical injury or death.

Even after the object is removed from the protection zone, if the OSSD still

remains in OFF-state, check the error code and suggested solution (Refer to

Chapter 9).

Duration of reset input should not exceed 30s; otherwise it will be detected as

hardware malfunction.

SE2L User’s Manual (SE9Z-B1865)

31

Page 33

3.7.3.3 Manual start (Interlock enabled)

Start interlock is a function which keeps the OSSD in OFF-state during the start-up until an external

reset input is applied. Start interlock setting has only manual mode. The RES_REQ signal switches to

ON-state after the SE2L completes initial routines and ready to accept the RESET input. When RESET input

is applied, OSSD will switch to ON state if no object is detected in the protection zone. The duration of the

reset input should be more than 500ms. Figure 3-17 shows the sequence of start interlock. Delay can be

configured in the range of 1s to 6s.

Figure 3-17 Manual start sequence

3.8 External device monitoring (EDM) function

EDM is a function that monitors the state of the input signal from the controlled machine or automated

guided vehicle (AGV). EDM is configured using the SLS Project Designer. When EDM function is enabled,

any fault detected in EDM signal will switch the OSSD signal to OFF-state. Logic of EDM signal should be

always inverse of the OSSD signal. EDM input signal ON/OFF delay is configurable to match the user’s

system. Figure 3-18 and 3-19 below shows the EDM circuit and EDM timing chart respectively.

Figure 3-18 EDM circuit

SE2L User’s Manual (SE9Z-B1865)

32

Page 34

Figure 3-19 EDM timing chart

In dual protection mode, EDM2 circuit and timing chart for OSSD3 and OSSD4 are same as above.

3.9 Muting function

Muting function temporarily suspends the safety function in the configured zone of SE2L when the

specified conditions are fulfilled. In the muting state OSSD remains in the ON-state even when an object is

detected in the configured muting zone. Two independent hard wired input signals are provided to start and

end the muting function. Muting zone is configured using the SLS Project Designer (Refer to section 7.9.1).

When muting inputs fulfill the muting start conditions, SE2L will suspend the safety function within 60ms

and resume the safety function if they fulfill the muting stop conditions.

3.9.1 Muting start condition

Muting function will start when the following conditions are fulfilled:

a) There are no objects in the protection zone and the OSSD is in ON-state.

b) The two independent hard wired muting input signals are switched to ON state in the predefined

sequence within the pre-set time interval. However, the switching interval between two input signals

should not be 0 (Refer to figure 3-20).

The following configurations are necessary for the muting function. User can configure these by using the

SLS Project Designer.

Muting inputs sequence

▶ Muting 1 Muting 2

▶ Muting 2 Muting 1

Time interval between two inputs (T1)

▶ 1second

▶ 3seconds

▶ 5seconds

▶ 10seconds

When using muting function in dual protection mode, Muting 3 and Muting 4 are configured in the similar

way.

SE2L User’s Manual (SE9Z-B1865)

33

Page 35

3.9.2 Muting stop condition

Muting function will stop when any one of the condition below is fulfilled:

a) One of the muting inputs switches to OFF-state.

b) When the predefined (preset) maximum muting time T2 exceeds (1 minute and above) (Figure 3-20).

c) Objects are detected in the protection zone which is not covered by the muting zone.

d) Error is detected by the self-diagnostics function.

e) During muting state when the area is switched to other area.

Figure 3-20 shows the muting sequence.

Maximum muting period (T2)

Maximum muting period can be selected from one of these values

▶ 1 minute

▶ 6 minutes

▶ 12 minutes

▶ Unlimited

When using the muting function in dual protection mode, Muting 3 and Muting 4 are configured in the

similar way. Same applies for muting input sequence, time interval between inputs and maximum muting

period.

Figure 3-20 Muting sequence

SE2L User’s Manual (SE9Z-B1865)

34

Page 36

3.9.3 Muting override function

Muting override is a function to recover SE2L when the OSSD is switched to OFF state due to muting

related errors by temporarily suspending the safety function. Override function is active when the override

input (OVERRIDE 1/2) and the reset input (RESET 1/2) are switched in a sequence. Figure 3-21 shows the

override sequence.

Override start conditions

▶ At least one of the muting inputs is in ON-state.

▶ Object is present in the protection zone.

▶ Time interval between override input and reset input is within 0.03s to 1s (T3).

Override stop conditions

▶ Both muting inputs are in OFF-state.

▶ Override input or reset input is in OFF-state.

▶ When predefined maximum override time T4 exceeds.

▶ Error is detected by self-diagnostic function of the SE2L.

▶ During override state when area is switched to the other area.

Maximum override period (T4)

Maximum override period can be selected from one of these values

▶ 1 minute

▶ 6 minutes

▶ 12 minutes

Figure 3-21 Override Sequence

SE2L User’s Manual (SE9Z-B1865)

35

Page 37

When using muting override in dual protection mode, Muting 3, Muting 4, Override input 2 and Reset

input 2 are configured in the similar way.

When muting function is enabled, user must ensure the safety of the protection zone.

Before using the muting function, user must perform risk assessment.

A qualified person should configure the appropriate muting period according to the

requirement of the application. It is the user’s responsibility to properly perform the risk

assessment when configuring muting period to unlimited.

Failing to comply with the above could lead to critical injury or death.

3.10 Reference monitoring function

Reference monitoring is a function to monitor the displacement of the SE2L or the structure used as

reference boundary.

3.10.1 Area protection

An example of reference monitor function used for area protection is shown in figure 3-22. If reference

segments are configured on moveable objects (example: door) the OSSD will switch to OFF-state when the

door position is changed.

SE2L

Figure 3-22 Top view of the area protection using reference monitor function

SE2L User’s Manual (SE9Z-B1865)

36

Page 38

3.10.2 Access protection

An example of reference monitor function used for access protection is shown in figure 3-23(a), (b).

Reference segments should be configured on each surface for displacement detection. Reference segments

should be configured such that displacement can be easily detected. The OSSD will switch to OFF-state

when access penetration is detected, and also if the distance between SE2L and the reference structure

changes. This function is compulsory for vertical applications.

SE2L

Figure 3-23 (a) Front view of the access detection using reference monitor function

SE2L User’s Manual (SE9Z-B1865)

37

Page 39

SE2L

Figure 3-23 (b) Front view of the access detection using reference monitor function

SE2L

Figure 3-23 (c) Incorrect configuration of reference segment

SE2L User’s Manual (SE9Z-B1865)

38

Page 40

3.11 Area sequence function

Area sequence is a function to monitor sequences of area switching. When this function is activated,

OSSD signal will switch to OFF-state if the switching pattern is other than the configured sequence. This

function prevents the machine to operate with random protection zone.

From each area, switching selection to maximum 31 other areas is possible when configuring the area

sequence. And, it is necessary to specify 1 or more areas to avoid error.

<Area switching sequence>

When area sequence is disabled, SE2L can switch from an area to any other areas (Figure 3-24 (a) whereas

it can only switch to specified areas if area sequence is enabled. (Figure 3-24 (b)).

Area sequence function is recommended for control systems where switching area sequences can be

configured.

Figure 3-24 (a) Operation without area sequence Figure 3-24 (b) Operation with area sequence

3.12 Response time

Response times of OSSD signal (Figure 3-25), OFF response time (Default 60ms) and ON response

time (Default 270ms) are configurable individually for each area using the SLS Project Designer. Response

time of the Warning 1 and Warning 2 will be same as the OSSD response time. Table 3-4 shows the possible

configurable values. In the dual protection mode, it is possible to set a separate response time for each

protection area.

When longer response time is configured, the stability of SE2L can be increased. However, longer

response time requires longer safety distance. (Refer to chapter 4). User must perform risk assessment before

configuring the response time. Addition of maximum 1 cycle (30ms) has to be taken into account for the area

switching.

Figure 3-25 Response time

SE2L User’s Manual (SE9Z-B1865)

39

Page 41

Table 3-4 Response time of SE2L

OFF

60 90 120 150 180 210 240 270

(ON -> OFF)

300 330 360 390 420 450 480 510

Response time (ms)

ON

270

(OFF -> ON)

300 330 360 390 420 450 480 510

Response time (ms)

* Default value

* Minimum configurable response time in Master/Slave mode is 120ms for OFF and 300ms for ON.

3.13 Other outputs

SE2L consist of 6 non-safety outputs, WARNING1, WARNING2, MUT_OUT1, MUT_OUT2 and

RES_REQ1 and RES_REQ2. WARNING1/OSSD3, WARNING2/OSSD4, RES_REQ1/ MUT_OUT1 and

RES_REQ2/ MUT_OUT2

selected using SLS Project Designer, outputs are configured automatically.

are configurable outputs that share the same terminal. When the functions are

3.13.1 Warning output 1 (WARNING 1)

This signal will switch to OFF-state when an obstacle is detected in the configured warning zone 1.

3.13.2 Warning output 2 (WARNING 2)

This signal will switch to OFF-state when an obstacle is detected in the configured warning zone 2.

3.13.3 Muting output 1 (MUT_OUT 1)

MUT_OUT1 indicates the muting/override status of the protection zone 1. When the muting function is

activated, MUT_OUT1 will switch to ON-state. At the same time, number 37 is displayed on the 7-segment

LED. This signal should be used to indicate that protection zone 1 is in muting state or override state.

3.13.4 Muting output 2 (MUT_OUT 2)

MUT_OUT2 indicates the muting/override status of the protection zone 2. When the muting function is

activated, MUT_OUT2 will switch to ON-state. At the same time, number 38 is displayed on the 7-segment

LED. This signal should be used to indicate that protection zone 2 is in muting state or override state.

When both protection zone 1 and protection zone 2 are in muting or override state, number 39 is displayed

on the 7-segment LED.

SE2L User’s Manual (SE9Z-B1865)

40

Page 42

3.13.5 Reset Request 1 (RES _ REQ1)

This signal will switch to ON-state when the protection zone 1 of the SE2L is ready to receive reset signal.

3.13.6 Reset Request 2 (RES _ REQ2)

This signal will switch to ON-state when the protection zone 2 of the SE2L is ready to receive reset signal.

3.14 Information indicator

LEDs and 7-segment display indicate the SE2L status. These indicators are located in front of SE2L.

Figure 3-26 shows the information indicators of the SE2L.

OSSD 1/2 indicator

Warning 1 indicator

Interlock 1 indicator

7-Segment display

Figure 3-26 Indicator lamp

OSSD 3/4 indicator

Warning 2 indicator

Interlock 2 indicator

SE2L User’s Manual (SE9Z-B1865)

41

Page 43

3.14.1 LED

Descriptions of the LED and are shown in below Table 3-5.

Table 3-5 Description of Indicator lamp

LED Color Description

OSSD 1/2 Green/Red

OSSD 3/4 Green/Red

WARNING 1 Orange

WARNING 2 Orange

Interlock 1 Orange

Interlock 2 Orange

Green LED when OSSD 1/2 signal is in ON state,

Red LED when OSSD 1/2 signal OFF state

Green LED when OSSD 3/4 signal is in ON state,

Red LED when OSSD 3/4 signal OFF state

Green LED when OSSD 3/4 signal is not in use

LED ON when Warning 1 signal is in OFF state

LED OFF when Warning 1 signal is not in use

LED ON when Warning 2 signal is in OFF state

LED OFF when Warning 2 signal is not in use

LED ON when OSSD 1/ 2 is in interlock state

LED ON when OSSD 3/ 4 is in interlock state

3.14.2 7-Segment display

Table 3-6 shows the 7 segment display.

Table 3-6 Explain the display of 7 segment

Display number Details

00 Sensor is initializing

01 – 32 Selected Area 1 to 32

33 Setting mode

34

35 Interlock state (Protection zone 2)

36 Interlock state (Both protection zone 1and 2)

37

38 Muting or Override state (Protection zone 2)

39 Muting or Override state (Both protection zone 1 and 2)

F2 SD card is detected with correct configuration file

F3 Configuring the sensor from the SD card information

F4 Configuring from the SD card is successful. Remove the SD

F5 SD card process is complete. Sensor is going to restart.

Fb Reset of IP address is complete. Sensor is going to restart.

Note: Display numbers other than the above are error state. For details refer to table 9-2 for details ( page 134).

Interlock state (Protection zone 1)

Muting or Override state (Protection zone 1)

card to complete the process.

SE2L User’s Manual (SE9Z-B1865)

42

Page 44

3.15 Ethernet communication

Measurement data of SE2L can be obtained from the Ethernet communication. Water proof Ethernet

connector is located at the back of SE2L. To connect sensor with PC, use an Optional Ethernet cable

(SE9Z-HS2-XCD13).

For the communication specification of SE2L, contact the nearest distributor or sales representative.

3.15.1 Ethernet Setting

● Default setting

Factory default value is shown below.

IP address : 192.168.0.10

Subnet mask : 255.255.255.0

Default gateway : 192.168.0.254

Port number : 10940

● Changing the IP address

IP address can be changed by using SLS Project Designer. Refer to section 7.13 and 7.9.1 for details.

● IP address initialization

Ethernet settings can be set to factory default by using IP initialization switch.

<Initialization steps>

a) Prepare a thin strong pin for IP initialization process. IP initialization switch is located exactly below the

SD card Slot (Refer to figure 3-27)

b) When SE2L is operating in normal state, press and hold the IP initialization switch for more than 3

seconds. After initialization process is complete 7-segment display status changes to “Fb”.

c) Sensor restarts with 7-segment display showing the status “00”.

IP Initialization switch SD Card Insert Slot

Figure 3-27 IP initialization switch

SE2L User’s Manual (SE9Z-B1865)

43

Page 45

3.16 Function to configure SE2L by SD card

Configuration generated by SLS Project Designer can be saved in the SD card. It is possible to transfer

the setting directly from the SD Card to SE2L without connecting to a PC. “SD card” in this manual

indicates Micro SD/SDHC card. Recommended specification of Micro SD/SDHC card is given below.

Create a project file with set the serial number and password of the SE2L and save it on the SD card

using SLS Project Designer. When the SD card is inserted to the specified SE2L, settings are automatically

transferred. It is possible to register multiple serial number and password in the SD card to simultaneously

configure multiple devices. Setting will not be transferred to the unspecified SE2L or if the password

verification fails.

Specification of Micro SD/SDHC card

Capacity: 16GB or less

3.17 Master-Slave Function

Maximum 4 units of SE2L can be interconnected using RS-485 for Master/slave operation. One unit will

function as a master unit communicating with up to 3 units that function as slaves via safety communication

channel. Use the SLS Project Designer to configure the devices. SE2L will report error if the number of