Page 1

Safety Laser Scanner

SE2L

Page 2

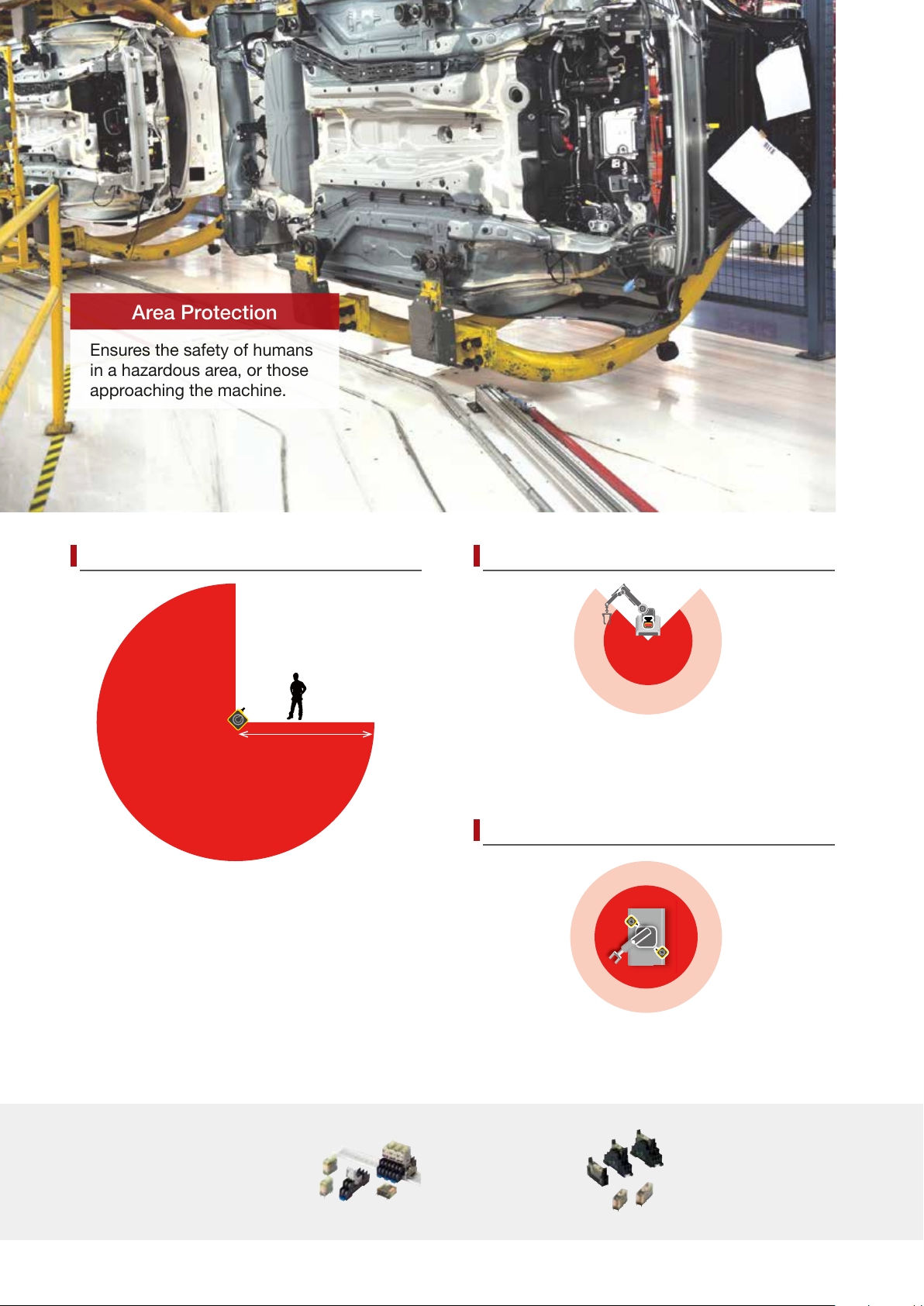

Distance 5m, sensing angle 270º

Area Protection

Ensures the safety of humans

in a hazardous area, or those

approaching the machine.

1

7 steps or more

Ensures productivity and safety

Stop

∗

Low speed

5m

One SE2L protects a wide area (270º and 5m) and

can be used in a variety of applications such as large

sized systems or long conveyor lines.

*

1: average stride length (70 cm) of a 170 cm person

IDEC’s safety products

for safe and productive

production lines

The SE2L is a safety sensor that can detect approach.

Stop area can be made smaller by detecting approach

at the additional protection zone to start slowdown.

(Conventional conguration of one protection zone +

two warning zones is possible)

Master slave function, rst in its industry

A maximum of four SE2Ls can be interconnected using

RS-485 for master/slave operation.

RF2 force-guided relay

(2-pole)

Can be used as interface

relays to send input

signals to a controller, or to

amplify current for driving a

contactor.

RF1V force-guided relay

(4-pole/6-pole)

Can interrupt a small load

directly.

2

Page 3

Dual protection function Ensures safety at positional change

r

!

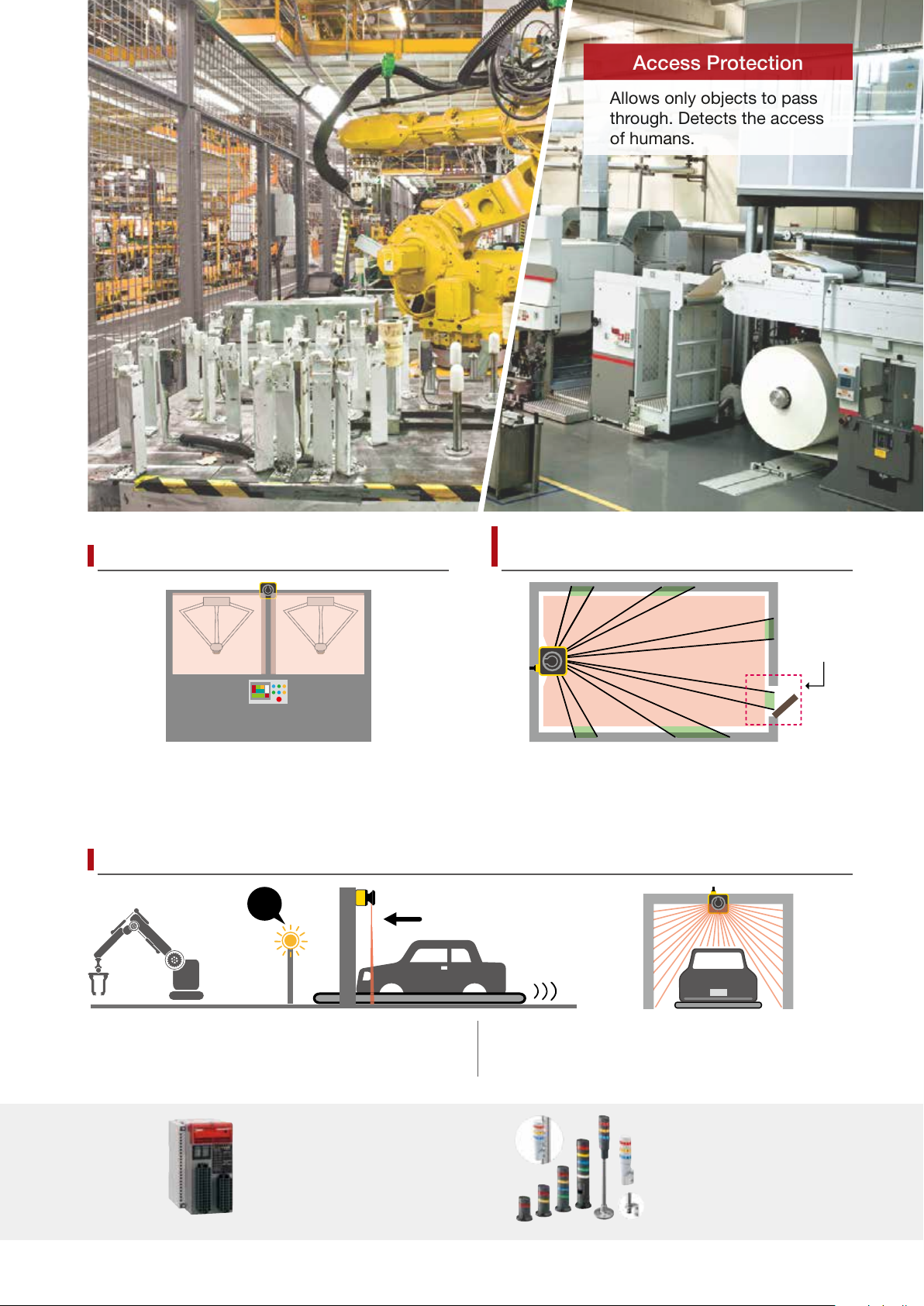

Access Protection

Allows only objects to pass

through. Detects the access

of humans.

Doo

An SE2L can monitor two separate hazardous areas to

stop machines when detecting the access of humans. No

reective sensor is necessary, thus eliminating the need

of optical axis alignment. Can replace two light curtains.

Reference monitoring function ensures safety by

detecting the positional change of SE2L or reference

boundary, such as a door’s opening/closing status.

Ensures safety at entrance of works. Override function enables restart from unintended stop.

By disabling some areas of protection zone, muting

function allows objects to enter the hazardous area

without stopping the machine.

FS1A Safety Controller LD6A LED SignaLight Towers

A variety of safety products can be

connected to the controller equipped

with various control logics.

With override function, when stopped by errors

at muting status, the work can be moved easily.

Used to indicate the status of

processes. Visible even at a distance.

3

Page 4

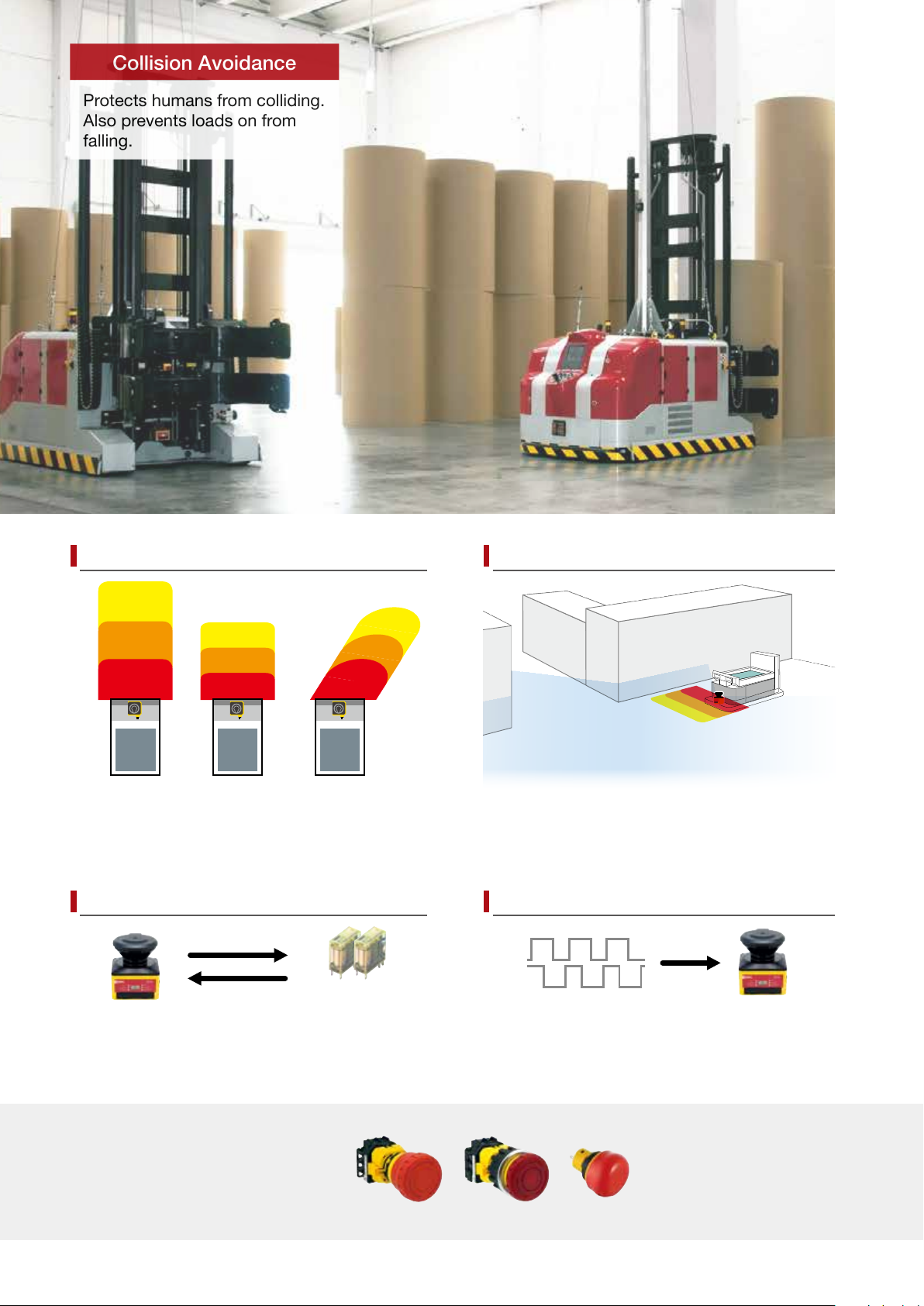

Collision Avoidance

A maximum of 32 area patterns

Protects humans from colliding.

Also prevents loads on from

falling.

Utilize distance measurement data

A maximum of 32 area patterns can be congured/

switched according to the mobile application such

as AGV, ensuring the optimum protection in various

applications.

Monitors external output equipment

EDM function monitors the status of external

devices, enabling monitoring of welded contacts and

such.

IDEC’s safety products

for safe and productive

production lines

4

During safety protection, the SE2L can send out

distance measurement data through the Ethernet

port, in order to obtain the data of the obstacles.

Encoder inputs

Force-guided relay

Pulse signals from an incremental encoder can be sent

to the SE2L directly without a controller, enabling to

switch areas easily depending on the speed.

Emergency Stop Switches

XW/XN/X6

A variety of models to choose from.

Page 5

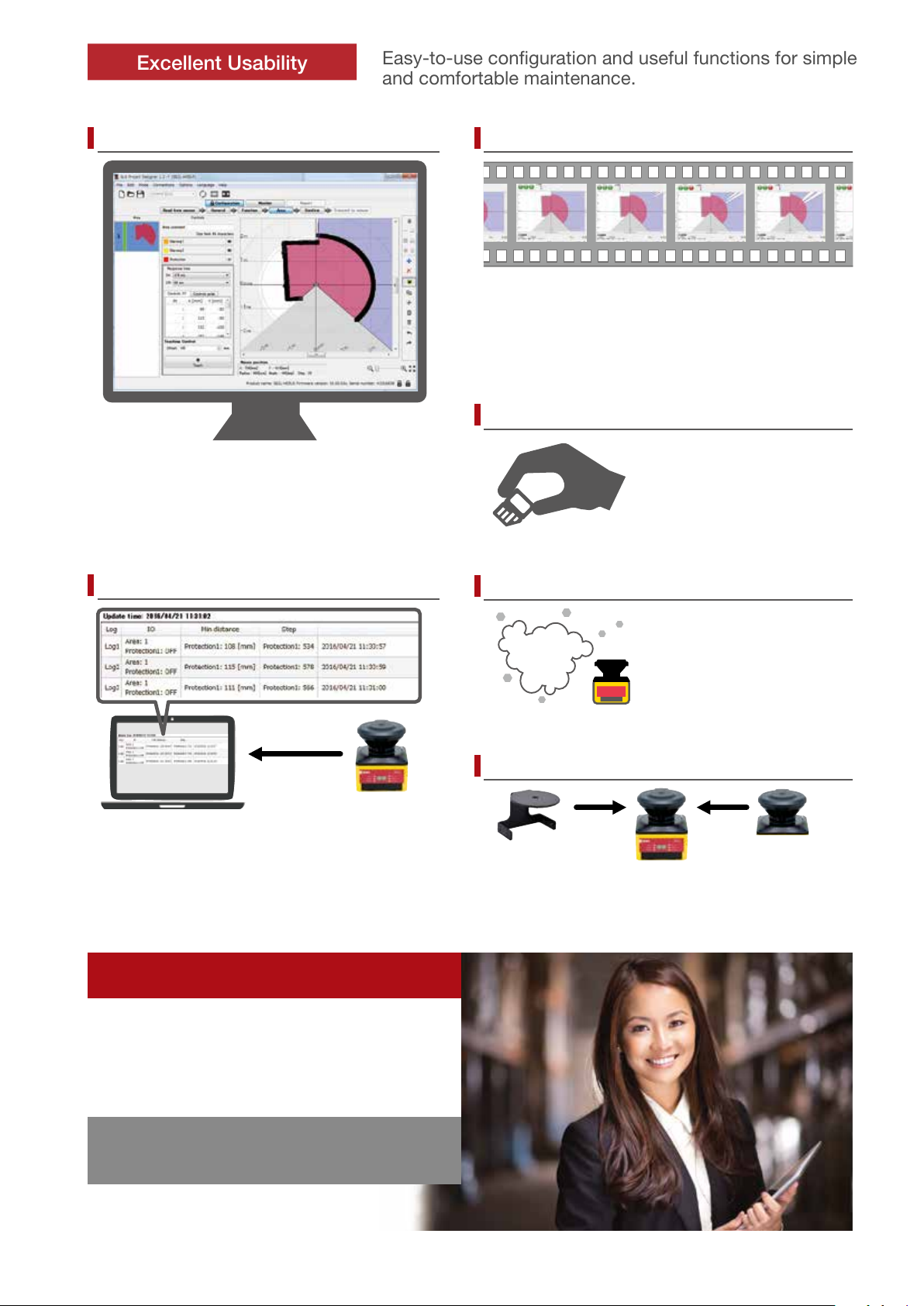

Supports area conguration

Excellent Usability

Easy-to-use conguration and useful functions for simple

and comfortable maintenance.

Check detection status with video

Teaching function enables automatic area

conguration by referring to obstacles such as walls

and columns. Area can be congured easily even

with complicated background.

Detection log report reduces maintenance

No human in the

protection zone

Area data and distance measurement data can be

recorded while monitoring on PC. Video of detection

status can be replayed with the le.

Human approaching

the protection zone

Human inside the

protection zone

Reduce maintenance and start-up time

Area data and function settings

created on PC can be transferred

to the SE2L using not only by

USB cable but also micro SD

card.

Stable operation even in dusty environment

Checks dust in air with signals

and reduces unintended

detection. Safety function is not

impaired.

Operational status is displayed on the SE2L. It can

also be displayed on PC to monitor errors and data

log for easy trouble shooting.

IDEC Safety Solution

− Safety system

− Safety consulting

− Risk assessment

− Safety seminars

IDEC—Committed to creating the optimum safety

environment—both for humans and systems.

Optical window can be replaced on-site

Cover Bracket Optical Window

Optical window can be replaced by the user, reducing

downtime and cost. A cover bracket to protect the SE2L

for damage by collision is also available.

5

Page 6

SE2L Safety Laser Scanner

SE2L Safety Laser Scanner

Model

Name & Shape Cable Length Part No. Remarks

Cable Model

3m

Connector Model

0.3m

SE2L-H05LP

SE2L-H05LPC

Production

monitored

Safety

tested

Functional

Safety

Package Quantity: 1

•Attachment: SLS Project Designer CD

(includes: User's Manual, SLS_Optical Window Adjuster)

•Applicable OS:

Windows XP, 32 bit (SP3 or higher)

Windows 7, 32/64 bit (SP1 or higher)

Windows 8, 32/64 bit

Windows 8.1, 32/64 bit

Windows 10 32/64 bit

Accessories (optional)

Part No. Cable Length Part No. Remarks

Connector Cable

Micro USB Cable

Ethernet Cable

Extension Cable

Base Mounting Bracket

Rear Mounting Bracket

Simple Base Mounting Bracket

Rear Mounting Bracket

Cover Bracket

Optical Window

2m SE9Z-HS2-C002

5m SE9Z-HS2-C005

10m SE9Z-HS2-C010

20m SE9Z-HS2-C020

1m SE9Z-HS2-XCM11

3m SE9Z-HS2-XCD13

10m SE9Z-HS2-XCE010

20m SE9Z-HS2-XCE020

SE9Z-HS2-BK01

SE9Z-HS2-BK02

SE9Z-HS2-BK03

SE9Z-HS2-BK04L

SE9Z-HS2-CM01

SE9Z-HS2-WD01

Package Quantity: 1

•Degree of protection: IP65

•Used with connector model SE2L-H05LPC only.

•Used to connect the SE2L and PC.

•Degree of protection: IP65

•Waterproof L AN cable

•Used to extend the cable length of the SE2L.

•Used to change the vertical angle alignment of the SE2L.

•Adjustable by 15 degrees total (7.5 degrees each direction)

•Material: iron

•Attachment: Four bolts (M5×12)

•Used to change the vertical/horizontal angle adjustment of the SE2L.

•Adjustable by 15 degrees total (7.5 degrees each direction)

•Material: iron

•Attachment: Four bolts (M5×12)

•Attachment: Four bolts (M5×10)

•Attachment: Four bolts (M5×10)

•Used to protect the optical window in combination with base

mounting bracket or rear mounting bracket.

•Material: iron

•Attachment: Four bolts (M5×12)

•Material: polycarbonate

•Attachment: Four bolts (M3×8)

Safety Products

Safety Controller

Name & Shape Part No. Remarks

FS1A-C11S •24 logics

FS1A-C21S •11 logi c s

Force-guided Relay

Name & Shape Part No. Remarks

2-pole

RF2S-*

RF2V-*

4-pole

RF1V-*

6-pole

RF1V-*

*

See product catalogs or IDEC's website for detailed part no.

6

•Force guided contact

mechanism (EN50205

Type A TÜV approved).

LED SignaLight Tower

Name & Shape Part No. Remarks

•Degree of protection:

LD6A-*

IP65

Emergency Stop Switches

Name & Shape Part No. Remarks

ø30mm

ø22mm

ø16mm

XN1E-*

XW1E-*

AB6E-*

•Degree of protection:

IP65

Page 7

SE2L Safety Laser Scanner

Performance Specifications

Part No. SE2L-H05LP/SE2L-H05LPC

Protection Zone 5.0m maximum

Warning Zone (Note 1) 20m maximum (non-safety)

Additional Safety Distance (Note 2) +100 mm

Sensing Characteristics Black reflector sheet (1.8%) to retro-reflector sheet

Sensing

Characteristics

Light Source

Type Type 3 (IEC 61946-1, IEC 61496-3)

Functional Safety SIL 2 (Type B, HFT=1) (IEC 61508)

PFHd

Master Slave Connection 4 maximum

Enclosure

Power Voltage

Power

Consumption

Output

Input

Interface

Environmental

Resistance

Note 1: When the reflectance of object is 90% or above.

Note 2: Additional distance of 200 mm is needed when the SE2L operates under high reflective background.

Note 3: Total current supply of OSSD output and warning output should be below 1.0A.

Note 4: The angle between the sensing plane and the light source should be more than 5 degrees.

Sensing Angle 270°

Minimum Sensing Width

Scan Cycle 30 ms (rotating speed 2,000 rpm)

Scan Area 32 patterns maximum

Response Time

Element Pulse laser diode

Wavelength 905nm

Laser Class Laser class 1 (IEC 60825-1)

Dimensions 80W × 80D × 95H (mm) (cable not included)

Weight (approx.) Cable model: 0.8 kg (incl. cable)/Connector model 0.5 kg

Degree of Protection IP65 (IEC 60529)

Material Body: aluminum diecast / Optical window: polycarbonate

Cable Cable model: 3 m/Connector model 0.3 m

Without Output Load 6W

Maximum (without output load) 50W

OSSD1/2 (safety)

OSSD3 (safety)

OSSD4 (safety)

WARNING1 (non-safety)

WARNING2 (non-safety)

RES_REQ1, RES_REQ2,

MUT_OUT1, MUT_OUT2

Area Switching

(5 inputs × 2 channels)

EDM1/EDM2/MUTING1/MUTING2/

MUTING3/MUTING4/OVERRIDE1/

OVERRIDE2/RESET1/RESET2/

ENC1_A/ENC1_B/ENC2_A/ENC2_B

PC USB2.0 (USB micro type-B connector)

Master Slave RS-485 (cable)

Distance Measurement Data Output Ethernet 100BASE-TX (water proof connector)

Operating Temperature −10 to +50˚C (no freezing)

Storage Temperature −25 to +70˚C (no freezing)

Operating Humidity 95% RH (no condensation)

Storage Humidity 95% RH (no condensation)

Surrounding Light Intensity (Note 4) 1500 lx maximum

Vibration Resistance

Shock Resistance Acceleration: 98 m/s

Outdoor Operation Not permitted

Altitude Below 2,000m

ø30 mm (maximum distance: 1.8m)

ø50 mm (maximum distance: 3.0m)

ø70 mm/ø150 mm (maximum distance: 5.0m)

ON→OFF: 60 to 510 ms

OFF→ON: 270 to 510 ms

-8

(T1=20 years): when master slave function is disabled

7.8×10

1.6×10-7 (T1=20 years): when master slave function is enabled

24V DC ±10%: power from converter

24V DC −30%/+20%: power from battery

Output type (high side SW)

Output current (maximum: 500 mA) (Note 3)

Leakage current (maximum: 1 mA)

Cable (AWG 26)

Allowable load (L/R=25 ms, C=1μF)

Output type (high side SW)

Output current (maximum: 250 mA) (Note 3)

Leakage current (maximum: 1 mA)

Cable (AWG 28)

Allowable load (L/R=25 ms, C=1μF)

Output type (PNP transistor output)

Output current (maximum: 200 mA)

Leakage current (maximum: 1 mA)

Cable (AWG 28)

Input Resistance: 4.7kΩ

Cable: AWG 28

Frequency: 10 to 55 Hz Sweep: 1 octave/minute

Amplitude: 0.35 mm ±0.05 mm

2

(10G) Pulse duration: 16 ms

7

Page 8

SE2L Safety Laser Scanner

82

124

120

133.5

Dimensions

Safety Laser Scanner

SE2L-H05LP

Scan angle 270°

9

Connection cable

(30)

Ethernet cable (sold separately)

Cover Bracket

SE9Z-HS2-CM01

All dimensions in mm.

90.7

30

95

67.4

80

4-M5 Depth 8

Cable Model

4-M5 Depth 8

Connector Model

54.5

(Sensing Plane)

68

68

Base Mounting Bracket

SE9Z-HS2-BK01

4-ø5.3 SE2L

Mounting Holes

28

3-ø5.3

ø

85

40

33

29.5

17

21

96.2

70

9

4-M5

18

•Used to protect the optical window in combination

25

15

50

80

66

32

(10)

(30)

28

with base mounting bracket or rear mounting bracket.

66

32

28

Cannot be used with simple base mounting bracket or

rear mounting bracket.

Rear Mounting Bracket

SE9Z-HS2-BK02

4-ø5.3

SE2L Mounting Holes

28

130

66

110

(18)

60

68

110

10

48.2 25

45

70

60

25

Simple Base Mounting Bracket

SE9Z-HS2-BK03 (Note 1)

110

92

37

68

15 15

11

Note 1:

•Usewasherswhenfasteningscrews.

•UsetwoM6screwswheninstallingonanaluminumframe.

(1) Position A: M5 screws

4-M5

screws

68

(2) Position B, C, or D: M6 screws

2-M6

screws

±0.1

110

±0.1

110

4-ø5.3

Cover Bracket

Mounting Holes

7.5° 7.5°

36

A

B

C

D

66

68

134

150

Rear Mounting Bracket

SE9Z-HS2-BK04L (Note 1)

(1) Position A: M5 screws

49.5

(2) Position B: M6 screws

2-M6

screws

88

106

32.4

R53

45

50

(93.2)

7.5° 7.5°

32.4

(101.2)

±0.1

48.2 25

45

20

±0.1

106

4-M5 screws

106

4-ø6

91.5

25

61.2

A

B

4-ø5.3

Cover Bracket

Mounting Holes

7.5° 7.5°

8

Page 9

Wiring Examples

a) When using 32 scanning areas (e.g. AGV)

E-STOP

+24VDC

0VDC

OSSD1

OSSD2

OSSD3

OSSD4

IN_A

IN_A

IN_B

IN_B

IN_C

IN_C

IN_D

IN_D

IN_E

IN_E

FG

X0

X1

X2

Controller

FS1A-C11S

X3

Logic 105

X4

X5

Safety

SE2L Safety Laser Scanner

c) When switching 32 scanning areas using an encoder

+24VDC

0VDC

OSSD1

Y0

Y1

OSSD2

EDM1

WARNING1

WARNING2

IN_A

IN_A

IN_B

IN_B

ENC1_A

ENC1_B

ENC2_A

ENC2_B

RES_REQ1

RESET1

FG

RF2

K1

LED

Pilot Light

RF2

K2

SignaLight

w/alarm

COM

IN1

PLC

IN2

Rotary

Encoder 1

Rotary

Encoder 2

LD6A

OUT

IDEC safety products

Safety Controller: FS1A

E-STOP: X series

b) When using muting/override/EDM

+24VDC

0VDC

OSSD1

OSSD2

EDM1

WARNING1

WARNING2

MUT_OUT1

IN_A

IN_A

IN_B

IN_B

MUTING1

MUTING2

OVERRIDE1

RESET1

FG

RF2

K1

RF2

K1

LD6A

SignaLight

w/alarm

OUT

COM

IN1

PLC

IN2

Muting Sensor 1

Muting Sensor 2

IDEC safety products

SignaLight w/alarm: LD6A

PLC: FC6A

LED pilot light: AP22

Force-guided relay: RF2

Muting Lamp

(PNP)

(PNP)

IDEC safety products

SignaLight w/alarm: LD6A

PLC: FC6A

Muting sensor: SA1E

Muting sensor lamp: HW1P-5

Force-guided relay: RF2

9

Page 10

SE2L Safety Laser Scanner

d) When using the master slave function to guard

an AGV or robot

E-STOP

+24VDC

0VDC

OSSD1

OSSD2

WARNING1

WARNING2

IN_A

IN_A

IN_B

IN_B

IN_C

IN_C

IN_D

IN_D

IN_E

IN_E

RES_REQ1

RESET1

RS-485+

RS-485–

+24VDC

0VDC

RS-485+

RS-485–

FG

+24VDC

0VDC

RS-485+

RS-485–

FG

+24VDC

0VDC

RS-485+

RS-485–

FG

FG

LED

Pilot Light

T4

X4

T5

X5

FS1A-C11S

X0

X1

COM

IN1

IN2

IDEC safety products

SignaLight w/alarm: LD6A

PLC: FC6A

LED pilot light: AP22

Safety Controller: FS1A

E-STOP: X series

Safety

Controller

Logic 11C

PLC

OUT

Y0

Y1

LD6A

SignaLight

w/alarm

e) When using the master slave function to guard

multiple hazards and perform partial stops

E-STOP

+24VDC

0VDC

OSSD1

OSSD2

WARNING1

WARNING2

IN_A

IN_A

IN_B

IN_B

IN_C

IN_C

IN_D

IN_D

IN_E

IN_E

RES_REQ1

RESET1

RS-485+

RS-485–

FG

+24VDC

0VDC

OSSD1

OSSD2

WARNING1

WANING2

RES_REQ1

RESET1

RS-485+

RS-485–

FG

+24VDC

0VDC

OSSD1

OSSD2

WARNING1

WANING2

RES_REQ1

RESET1

RS-485+

RS-485–

FG

+24VDC

0VDC

OSSD1

OSSD2

WARNING1

WANING2

RES_REQ1

RESET1

RS-485+

RS-485–

FG

LED

Pilot Light

Pilot Light

Pilot Light

LED

LED

LED

Pilot Light

IDEC safety products

SignaLight w/alarm: LD6A

PLC: FC6A

LED pilot light: AP22

Safety Controller: FS1A

E-STOP: X series

X0

X1

X2

Safety

X3

Controller

X4

FS1A-C11S

X5

Logic 105

X6

X7

X10

X11

COM

IN1

IN2

IN3

IN4

PLC

IN5

IN6

IN7

IN8

OUT1

OUT2

OUT3

OUT4

Y0

Y1

Y2

Y3

LD6A

SignaLight

w/alarm

LD6A

SignaLight

w/alarm

LD6A

SignaLight

w/alarm

LD6A

SignaLight

w/alarm

Input/Output Circuit

OSSD/WARNING Output Circuit Other Output Circuit

OSSD/WARNING outputs are N

channel MOSFET outputs.

+24V

OSSD1

OSSD2

Control

Circuit

OSSD3 / WARNING1

OSSD4 / WARNING2

10

RES_REQ1, RES_REQ2, MUT_OUT1,

MUT_OUT2 outputs are PNP outputs.

+24V

Control

Circuit

RES_REQ1 / MUT_OUT1

RES_REQ2 / MUT_OUT2

Input Circuit

Available for are input, EDM1, EDM2,

RESET1, RESET2, MUTING1, MUTING2,

MUTING3, MUTING4, OVERRIDE1, and

OVERRIDE2.

Input

Control

Circuit

0V

Page 11

SE2L Safety Laser Scanner

Operating Principle

With the SE2L, the distance is measured by the Time

of Flight (TOF) principle. The SE2L sends out very short

pulses of infrared light. The mirror rotated by the motor

sends the infrared light within the scanning range of 270º,

and is reected back from an object within the range.

Laser

Photodiode

Time difference

Emitted pulse laser

Object

Received pulse laser

Distance to object (L)

The distance can be calculated as follows:

1

=

−

L

× c × T

L = Distance to the object

2

c = Speed of light

T = Time difference

Scanning Area

A scanning area of the SE2L consists of:

•Aprotection+twozones

•Aprotectionzone

•Twoprotectionzones

Up to 32 sets of scanning areas can be congured.

A software SLS Project Designer supplied with the SE2L

is used to congure the protection and warning zones,

providing excellent user interface. Automatic zone

conguration by referring the boundary is also possible.

See SE2L User's Manual “7. Function Conguration of

SE2L” for details. The latest version of the software can be

downloaded from IDEC website.

Area Switching

The SE2L can store up to 32 area patterns. The number

of maximum congurable areas depends on selected

functions such as scan area mode and muting.

Maximum number of patterns

Mode Protection

Standard

EDN

MUTING/EDM

Encoder (Note 1) 1 2 3 32 (Note 2)

Note 1: Dual protection and muting function modes cannot be

used when encoder input mode is selected.

Note 2: Among the four input patterns, at least one pattern must

be used for encoder input. Other three remaining patterns

can be selected to be used as a static input or not in use.

A pattern with encoder input mode has up to 32 sets of

area.

1 5 32 −

2 5 32 −

1 4 16 −

2 4 16 −

1 2 4 −

2 1 2 −

Max.

Internal

Input

Max.

Area

Input combination for area switching

(ex. 5 inputs)

Area

IN_A IN_B IN_C IN_D IN_E IN_A IN_B IN_C IN_D IN_E

1 ON ON ON ON ON OFF OFF OFF OFF OFF

2 OFF ON ON ON ON ON OFF OFF OFF OFF

3 ON OFF ON ON ON OFF ON OFF OFF OFF

4 OFF OFF ON ON ON ON ON OFF OFF OFF

5 ON ON OFF ON ON OFF OFF ON OFF OFF

6 OFF ON OFF ON ON ON OFF ON OFF OFF

7 ON OFF OFF ON ON OFF ON ON OFF OFF

8 OFF OFF OFF ON ON ON ON ON OFF OFF

9 ON ON ON OFF ON OFF OFF OFF ON OFF

10 OFF ON ON OFF ON ON OFF OFF ON OFF

Max.

Encoder

Area

Protection zone: The area obtained by risk assessment

and calculation of safety distance

Warning zone: The area to send alarms which can be

set according to the application

Area preview

Area comment

Response time (ON/OFF)

Area selection

Point coordinate

Area display

Mouse position

Zoom-in, zoom-out tool

Drawing tools bar

•See User's Manual for more combinations (max. 32 areas)

11

Page 12

SE2L Safety Laser Scanner

Response Time

The OFF response time (default: 60ms) for the OSSD signal

and ON response time (default: 270ms) can be congured

by using the SLS Project Designer. The response time for

WARNING 1, 2 is the same as the response time for OSSD.

In dual protection mode, different response time can be

set for protection zone 1 and 2 each. The stability of the

SE2L can be increased by setting a long response time,

but a long safety distance is required (see User's Manual

4. Application Examples of SE2L). Before setting the

response time, the user must perform a risk assessment

thoroughly. The congurable response time is shown in the

table below. Be sure to add the time taken to switch areas

(30 ms).

Time Chart

Object

Object

Detection

OSSD

SE2L Response Time

OFF

(ON→OFF)

present

Object

absent

ON

OFF

OFF Response Time ON Response Time

Response Time (ms)

60 90 120 150 180 210 240 270

300 330 360 390 420 450 480 510

Warning zones 1 and 2 are set around the protection

zone to send alarms to prevent humans or objects from

entering the hazardous area and stopping the machine. By

detecting humans or objects in the protection zone, the

OSSD signal switches from ON to OFF. Also, when humans

or objects are detected in the warning zone, WARNING

signal switches from ON to OFF.

Upper view (stationary)

b

Protection

zone

a

Hazardous

area

•Maintain the distance “a” shorter than the minimum

detection width. To prevent unwanted detection, maintain

the distance "b" 100mm.

s

Zs

Zs

S

a

S

b

Side view (stationary)

Response Time (ms)

ON

(OFF→ON)

•

− − − − − − − 270

300 330 360 390 420 450 480 510

Default value

•Minimum congurable response time in Master/Slave mode

OFF: 120ms, ON: 300ms

Safety Distance

Access protection

In this application, the SE2L is horizontally installed to

protect the hazardous area. The protection zone is set

around the hazardous area to prevent humans or objects

from entering the hazardous area. Warning zones 1 and 2

are congured to surround the protection zone.

Protection zone 1 application

(horizontal, stationary installation)

Hazardous

area

a

H

Calculation

S = (K × (Tm + Ts) + C + Z

S = Safety distance (mm)

K = Human approach speed 1,600 (mm/s)

T

= Maximum stop speed of machine or system (s)

m

T

Response time of SE2L (s)

s =

C = 1200 − 0.4 × H ≥ 850

H = height from the oor to the sensing plane (mm)

1000 ≥ H ≥ 15 × (d − 50)

d = Minimum sensing width of object (mm)

Z

= Additional safety distance of SE2L (mm)

s

•See User's Manual for access protection and area protection (access detection, collision avoidance for mobiles)

s

12

Warning

Zone 1

Warning

Zone 2

Protection

Zone

Page 13

SE2L Safety Laser Scanner

Installation

Light Interference

SE2L is a sensor that transmits pulsed laser for obstacle

detection. Interfering light sources may lead to false

detection. Before using the SE2L, examine the surrounding

environment. If the SE2L must be used under the

environment shown below, install the SE2L so that the light

source is located more than ±5 degrees from the sensing

plane to prevent light interference.

a) Incandescent light

b) Florescent light

c) Strobe light

d) Flashing beacon

e) Sunlight

f) Infrared light source

Light source

Sensing

plane

Light source

5 degrees

5 degrees

Detection

origin point

Mutual Interference

When using several safety laser scanners or scanning

range nders of the same model, pulse laser signals from

other sensors may be falsely detected. To prevent mutual

interference, see the installation methods shown below.

See User's Manual for more details.

1) Changing the installation height

Install the SE2Ls at different heights to keep at least 5

degree distance between the detection planes.

Face to face installation

Detection plane

5° or more

5° or more

Detection plane

Parallel installation

Detection plane

5° or more

5° or more

Detection plane

2) Changing the installation angle

Adjust the angle of SE2Ls to keep at least 5 degree

distance between the detection planes.

Face to face installation

Detection plane

5° or more

Detection plane

Parallel installation

Detection plane

5° or more

Detection plane

3) Using shields

Install a shield between the SE2Ls to prevent prevent

the laser beams from entering the other SE2L.

Face to face installation

Detection plane Detection plane

Sheild

Parallel installation

Detection plane Detection plane

Sheild

13

Page 14

SE2L Safety Laser Scanner

Highly Reflective Background

Highly reective backgrounds may cause false detection

causing the SE2L to detect a longer distance than the

actual distance. If an operating environment with a highly

reective background cannot be avoided, an additional

distance of 200 mm, in addition to the 100mm additional

safety distance, is needed when conguring protection or

warning zones.

Protection Zone

or

Warning Zone

m

m

0

0

* Additional

distance (100 + 200 mm)

1

0

0

2

* Additional distance: the distance required to operate the SE2L

under high reective background

m

m

Highly reective

background

Limited Detection Capability Area

The limited detection capability area is the area between

the optical window and the beginning of the detection

zone. The area from the origin point of the SE2L to 90 mm

from the origin point is the limited detection capability area.

In this area, a low reective object is difcult to detect.

90mm

Protection Zone

Limited detection

capability zone

Wiring

The table below shows the functions of each wire. Use of a

shielded wire is recommended.

Wire Color and Functions

Color Signal Function Description AWG Pin No.

Brown +24V DC

Blue 0V DC Power: 0V DC 22 2

Red OSSD 1

Yellow OSSD 2 Protection zone output 2 26 4

Red/

Black

Yellow/

Black

OSSD 3

WARNING1

OSSD 4

WARNING2

Purple IN_A

Gray

IN_B

MUTING3

IN_C

White

OVERRIDE1

ENC1_A

IN_D

Pink

MUTING1

ENC1_B

Green

Purple/

Black

Gray/

Black

White/

Black

Pink/

Black

Green/

Black

Yellow/

Green

Yellow/

Blue

Orange

Orange/

Black

White/

Blue

White/

Red

IN_E

EDM1

IN_A Area switching input A invert 28 12

IN_B

MUTING4

IN_C

OVERRIDER2

ENC2_A

IN_D

MUTING2

ENC2_B

IN_E

EDM2

RESET1 Reset input 1 28 17

RESET2 Reset input 2 28 18

RES_REQ1

MUT_OUT1

RES_REQ2

MUT_OUT2

RS-485+

Commu-

RS-485−

Shield FG

Power: 24V DC 22 1

Power

Protection zone output 1 26 3

Output

Protection zone output 3

Output

Warning zone output 1

Protection zone output 4

Output

Warning zone output 2

Area switching input A 28 7

Area switching input B

Muting input 3

Area switching input C

Override input 1

Encoder input 1_A

Area switching input D

Muting input 1

Encoder input 1_B

Area switching input E

External device monitoring 1

Input

Area switching input B invert

Muting input 4

Area switching input C invert

Override input 2

Encoder input 2_A

Area switching input D invert

Muting input 2

Encoder input 2_B

Area switching input E invert

External device monitoring 2

RES_REQ1: request output 1

MUT_OUT1: muting state

output 1

Output

RES_REQ2: request output 2

MUT_OUT2: muting state

output 2

Communication protocol

RS-485 (twisted pair)

Communication protocol

nication

RS-485 (twisted pair)

−

Frame ground − Case

28 5

28 6

28 8

28 9

28 10

28 11

28 13

28 14

28 15

28 16

28 19

28 20

28 21

28 22

14

14

1

2

22

15

3

16

4

17

5

1918

6

87

SE2L-H05LPC

Pin No.

1

14

13

12

21

11

20

10

9

13

12

21

11

20

10

9

2

15

22

3

16

4

17

5

1819

6

78

SE9Z-HSC-C

Socket No.

Page 15

SE2L Safety Laser Scanner

OSSD

In SE2Ls, the OSSD signal has a self-diagnosis function

that tests the signal periodically to detect malfunction. The

OSSD signal will turn OFF when a error is detected due to

the self-diagnosis function. The self-diagnosis function of

the OSSD detects abnormality by switching off OSSD 1 to

OSSD 4 at intervals of 300 µs maximum. Be sure to use a

force-guided relay, converter, or controller that does not

respond to this self-diagnosis function.

Safety Precautions

Safety Precautions

For correct use of the SE2L, take note of the following

precautions.

x SE2L is a AOPDDR (Active Optoelectronic Protective

Device responsive to Diffuse Reection) that detects

diffused emitted light within the protection zone.

x Perform tests before operation to check the function and

performance of the SE2L.

x SE2L is designed to protect human beings or systems by

monitoring the hazardous area. It is not designed for the

protection from high speed objects or electromagnetic

radiation.

x To maintain the degree of protection and to prevent injury

or death, do not modify or disassemble the SE2L.

x IDEC does not warrant any problems that were caused by

modication or disassembly of the SE2L.

x The operator must be a person qualied to operate

the SE2L. The operator must be trained and be able to

operate the SE2L correctly.

x The administrator must provide continuous training to the

operator for correct use of the SE2L.

x The administrator must understand the user's manual

and be responsible for ensuring appropriate operating

conditions for SE2L.

x SE2L has been manufactured and shipped under strict

quality control. If you nd any defect in the product,

contact distributor or sales representative.

x IDEC does not take responsibility for damage caused

by improper use of the product by customers or third

parties. IDEC cannot take responsibilities for any loss

from the misuse except for the responsibilities governed

by law.

x To examine the object detecting performance, use a test

piece the size equivalent to the minimum detectable

object.

x Error occurs when detection capability is below 30% due

to homogenous dirt on the optical window. The operator

must keep the windows clean.

x When the interlock function is active, make sure that the

surrounding environment, especially within the protection

zone, is safe before resetting the interlock.

x While SE2L is removed, a protective measure must

be taken to ensure safety within the protection zone.

To prevent entry into the danger zone, use protective

materials such as a safety guard or light curtain.

x SE2L and its accessories are subject to change for

improvement without prior notice.

x Dispose the SE2L as industrial waste or in accordance

with the local regulations.

Time chart

30ms 30ms 30ms 30ms

OSSD1

OSSD2

OSSD3

OSSD4

300μs

Operating Environment

x Make sure that the operating environment is within the

range of the specications (temperature, humidity, light

interference) described in User’s Manual, otherwise

malfunction or degradation of detection performance may

result.

x Do not use the SE2L near a machine that may generate

strong radio waves. It may interfere with the operation of

the SE2L.

x Do not use or install the SE2L where dust, smoke, or

corrosive chemical substances exist. Using the SE2L

under these environments may lead to degradation of

detection performance.

x The SE2L is for indoor use only.

Installation

x Install the SE2L on a stable surface or structure to

prevent displacement of the sensor.

x Install the SE2L securely so that screws do not loosen

due to shock or vibration. (Recommended tightening

torque 3 N∙m). Displacement may degrade protection

performance.

x Determine the safety distance before installing the SE2L.

After installing the SE2L, use a test piece for all protection

zones to check the sensing functions.

x After installing the SE2L, use protective materials such as

safety guards and light curtains to prevent entry into the

protective zone.

x The following switches must be installed far from the

protection zone, so that the operator can operate the

switches while overseeing the entire protection zone.

* Switch to reset the interlock function

* Switch to start muting function

* Switch to start override function

x If several SE2Ls are installed on the same sensing plane,

mutual interference may occur.

x Provide enough space for installation and maintenance of

the SE2L.

x Do not cover the front of the optical window with glass or

transparent cover, otherwise detection characteristics of

the SE2L may be impaired.

x Minimum sensing width differs according to the distance.

15

Page 16

SE2L Safety Laser Scanner

Safety Precautions

Safety Precautions

Wiring

x Be sure to turn off all power before wiring.

x When using converter power, make sure to use power

that satises the following requirements.

1) The rated output voltage is within 24V DC±10% (SELV

circuit, overvoltage category II)

2) The circuit between primary circuit and secondary

circuit is reinforced insulation or double insulation.

3) The output holding time is 20 ms.

4) The power supply must comply with electrical safety

and electromagnetic compatibility (EMC) regulations

requirements of each country, state, and district.

x All input/output cables must be located away from power

cables and high voltage cables.

x To control safety-related machine or system, use OSSD

output. Because warning zone output (warning signal) is

a non-safety signal, do not use for safety purposes.

x Both the OSSD1 and OSSD2 outputs should be

connected to safety-related machines or control system.

When OSSD3 and OSSD4 are used, connect the outputs

in the same manner.

x Use shielded cable for the connection between OSSD

signals and safety-related machines or systems.

Installation

x A password is used for conguring the safety function.

Only an administrator or operator should be able to set

safety functions.

x SE2L will not operate without initial conguration.

x Perform test operation and check the conguration

before using the SE2L.

x The stability of the SE2L increases by delaying the

response time of the OSSD signal but the sensing

performance decreases for moving objects. Before using

this function, be sure to carry out risk assessment.

x The operator must record the changes made in the

conguration. SLS Congurator report function is

available. For details, see the User's Manual.

Testing and Maintenance

x The operator should perform the following tests or

maintenance based on the checklist described in the

User's Manual.

1) Pre-operation inspection

2) Operation inspection

3) Daily inspection

4) Periodic inspection

The checklist in the User's Manual is a basic guideline

for performing tests and maintenance. The operator

should perform additional tests and maintenance if

necessary.

x Stop the machine if failure occurs during tests.

x Clean the optical window if any dirt is found, and ask for

repair if damaged. Refer to the User's Manual for details.

16

Loading...

Loading...