RTE

Key features:

• 20 time ranges and 10 timing functions

• Time delays up to 600 hours

• Space-saving package

• High repeat accuracy of ± 0.2%

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

• ON and timing OUT LED indicators

• Standard 8- or 11-pin and 11-blade termination

• 2 form C delayed output contacts

• 10A Contact Rating

Timers

Timers

RTE

RTE Series — Analog Timers

Cert. No. E9950913332316 (EMC, RTE)

Cert. No. BL960813332355 (LVD, RTE)

UL Listed

File No. E66043

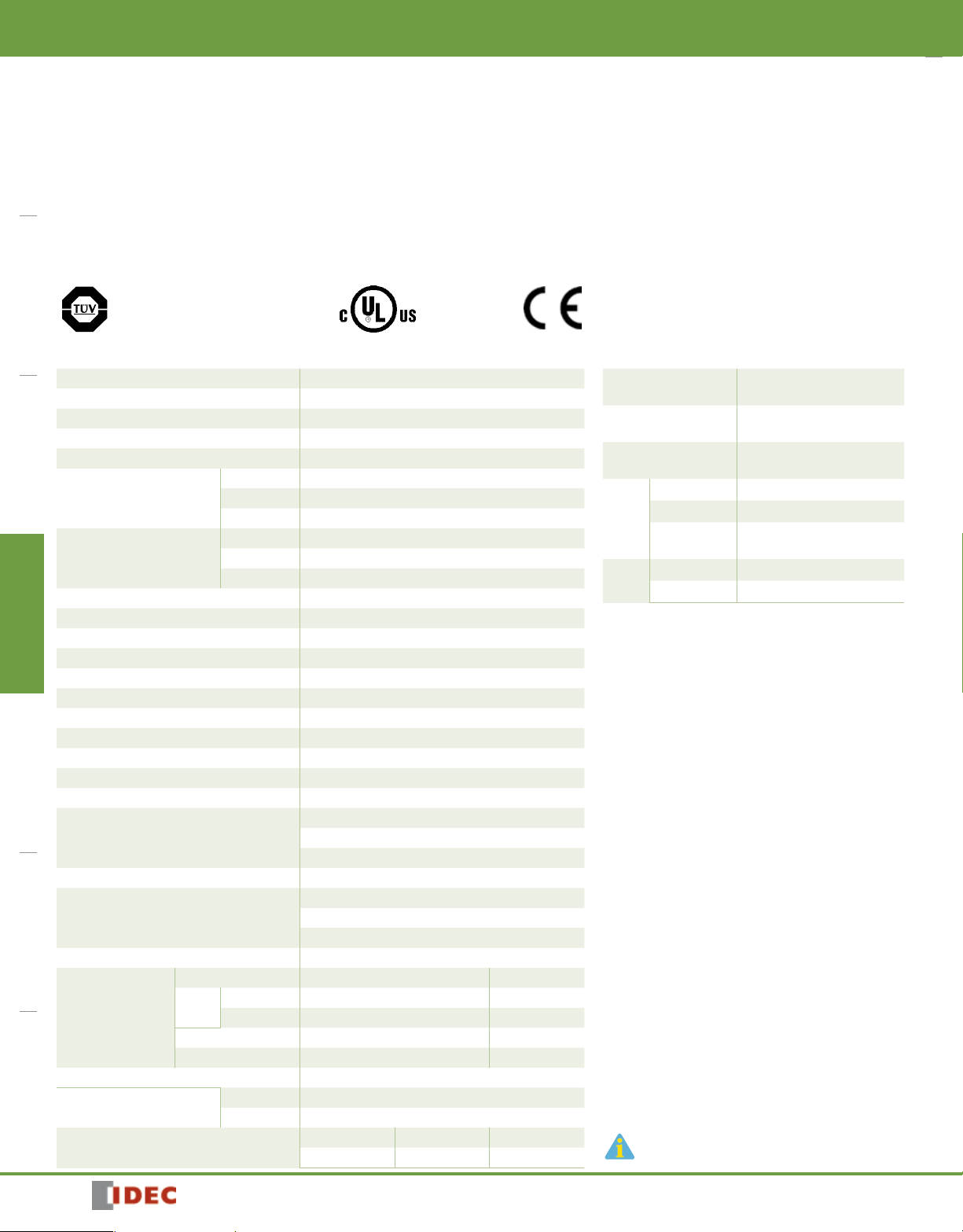

General Specifications Contact Ratings

Operation System Solid state CMOS Circuit

Operation Type Multi-Mode

Time Range 0.1sec to 600 hours

Pollution Degree 2 (IE60664-1)

Over voltage category III (IE60664-1)

AF20 100-240V AC(50/60Hz)

Rated Operational Voltage

Voltage Tolerance

Input off Voltage Rated Voltage x10% minimum

Ambient Operating Temperature -20 to +65ºC (without freezing)

Ambient Storage and Transport Temperature -30 to +75ºC (without freezing)

Relative Humidity 35 to 85%RH (without condensation)

Atmospheric Pressure 80kPa to 110kPa (Operating), 70kPa to 110kPa (Transport)

Reset Time 100msec maximum

Repeat Error ±0.2%, ±20msec*

Voltage Error ±0.2%, ±20msec*

Temperature Error ±0.5%, ±20msec*

Setting Error ±10% maximum

Insulation Resistance 100MΩ minimum (500V DC)

Dielectric Strength

Vibration Resistance 10 to 55Hz amplitude 0.5mm

Shock Resistance

Degree of Protection IP40 (enclosure) (IEC60529)

Power Consumption

(Approx.)

Mounting Position Free

Dimensions

Weight (Approx.)

AD24 24V AC(50/60Hz)/24V DC

D12 12V DC

AF20 85-264V AC(50/60Hz)

AD24 20.4-26.4V AC(50/60Hz)/21.6-26.4V DC

D12 10.8-13.2V DC

Between power and output terminals: 2000V AC, 1 minute

Between contacts of different poles: 2000V AC, 1 minute

Between contacts of the same pole:1000V AC, 1 minute

2

hours in each of 3 axes

Operating extremes: 98m/sec2 (10G)

Damage limits: 490m/sec2 (50G)

3 times in each of 3 axes

TYPE RTE-P1, -B1 RTE-P2, -B2

120V AC/60Hz 6.5VA 6.6VA

AF20

240V AC/60Hz 11.6VA 11.6VA

24V AC 60Hz/DC 3.4VA/1.7W 3.5VA/1.7W

D12 1.6W 1.6W

RTE-P1, P2 40Hx 36W x 77.9D mm

RTE-B1, B2 40Hx 36W x 74.9D mm

RTE-P1 RTE-P2 RTE-B1, -B2

87g 89g 85g

Contact Configuration

Allowable Voltage /

Allowable Current

Maximum Permissible

Operating Frequency

Resistive 10A 240V AC, 30V DC

Rated

Inductive 7A 240V AC, 30V DC

Load

Horse Power

Rating

Electrical 500,000 op. minimum (Resistive)

Life

Mechanical 50,000,000 op. minimum

*For the value of the error against a preset

time, whichever the largest, applies.

2 Form C, DPDT

(Delay output)

240V AC, 30V DC / 10A

1800 cycles per hour

1/6 HP 120V AC, 1/3 HP 240V AC

836

www.IDEC.com

Timers

RTE

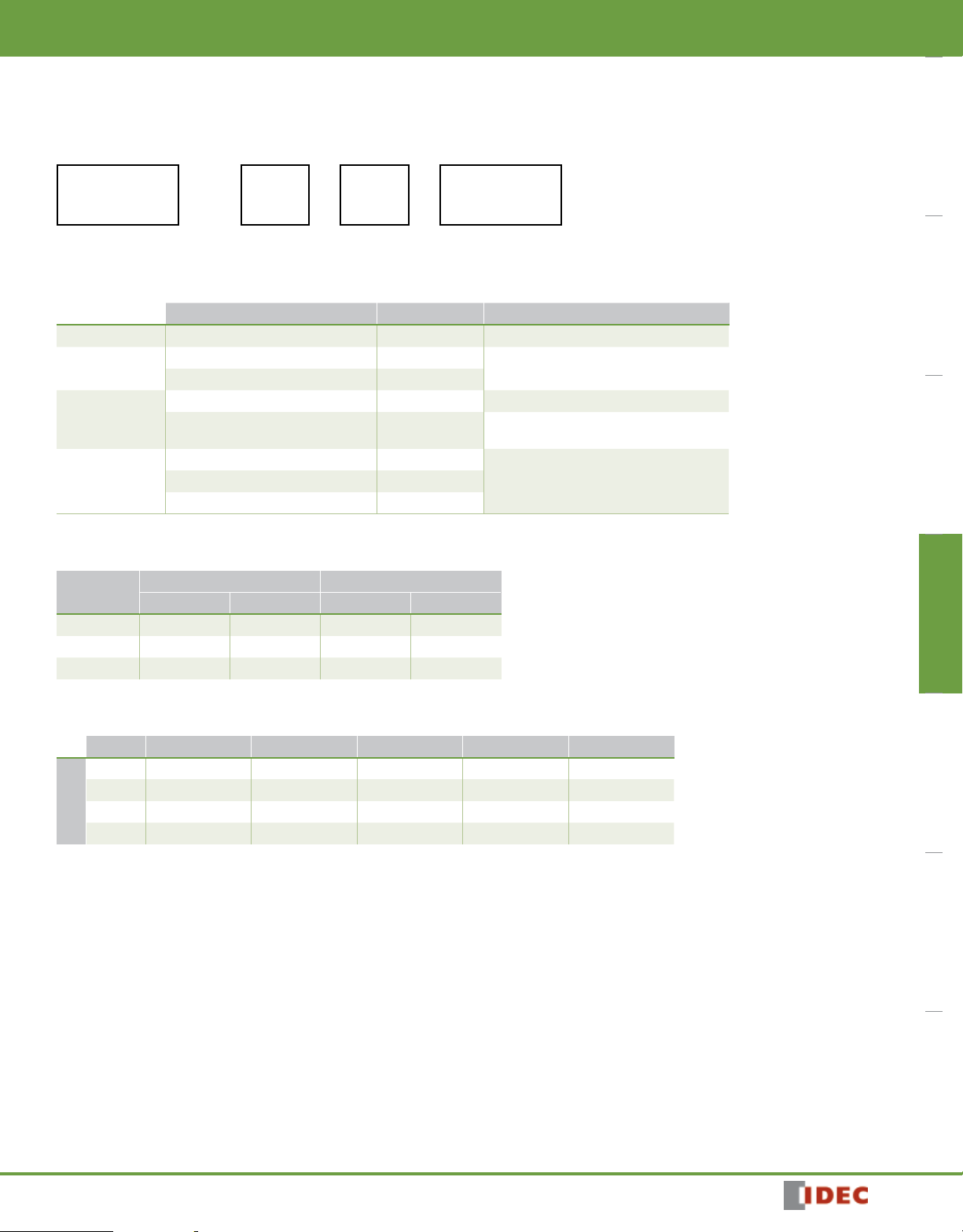

Part Numbering Guide

RTE series part numbers are composed of 4 part number codes. When ordering a RTE series part, select one code from each category.

Example: RTE-P1AF20

RTE — P 1 AF20

j Series k Terminal

Style

Part Numbers: RTE Series

Description Part Number Code Remarks

j Series

k Terminal Style

l Function Group

m Input Voltage

RTE series RTE For internal circuits, see next page.

Pin P

Blade B

ON-delay, interval, cycle OFF, cycle ON 1 Each function group has different timing functions.

ON-delay, cycle OFF, cycle ON, signal ON/

OFF delay, OFF-delay, one-shot

100 to 240V AC(50/60Hz) AF20

24V AC(50/60Hz)/24V DC AD24

12V DC D12

l Function

Group

m Input Voltage

Select one only.

2 See page 832.

Switches & Pilot Lights Signaling Lights Relays & Sockets Timers Contactors Terminal Blocks Circuit Breakers

Part Numbers

Voltage

12V DC RTE-P1D12 RTE-B1D12 RTE-P2D12 RTE-B2D12

24V AC/DC RTE-P1AD24 RTE-B1AD24 RTE-P2AD24 RTE-B2AD24

100-240V AC RTE-P1AF20 RTE-B1AF20 RTE-P2AF20 RTE-B2AF20

Power Triggered Start Input Triggered

8-Pin Blade 11-Pin Blade

Time Range Determined by Time Range Selector and Dial Selector

Dial 0 - 1 0 - 3 0 - 10 0 - 30 0 - 60

Second 0.1 sec - 1 sec 0.1 sec - 3 sec 0.2 sec - 10 sec 0.6 sec - 30 sec 1.2 sec - 60 sec

Minute 1.2 sec - 1 min 3.6 sec - 3 min 12 sec - 10 min 36 sec - 30 min 1.2 min - 60 min

Hour 1.2 min - 1 hr 3.6 min - 3 hr 12 min - 10 hr 36 min - 30 hr 1.2 hr - 60 hr

Range

10 Hours 12 min - 10 hr 36 min - 30 hr 2 hr - 100 hr 6 hr - 300 hr 12 hr - 600 hr

800-262-IDEC (4332) • USA & Canada

837

RTE

RTE-P2

11

10

9

1

2

3

4

5

6

7

8

start

RTE-B2

2

3

A

B

9

1

(~/-)(~/+)

4

5

6

7

8

2

3

A

B

9

1

(~/-)(~/+)

4

5

6

7

8

RTE-B1

start

external

control

signal

external

control

signal

RTE-B2

2

3

A

B

9

1

(~/-)(~/+)

4

5

6

7

8

start

external

control

signal

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

RTE-P1

4

3

2

1

Timers

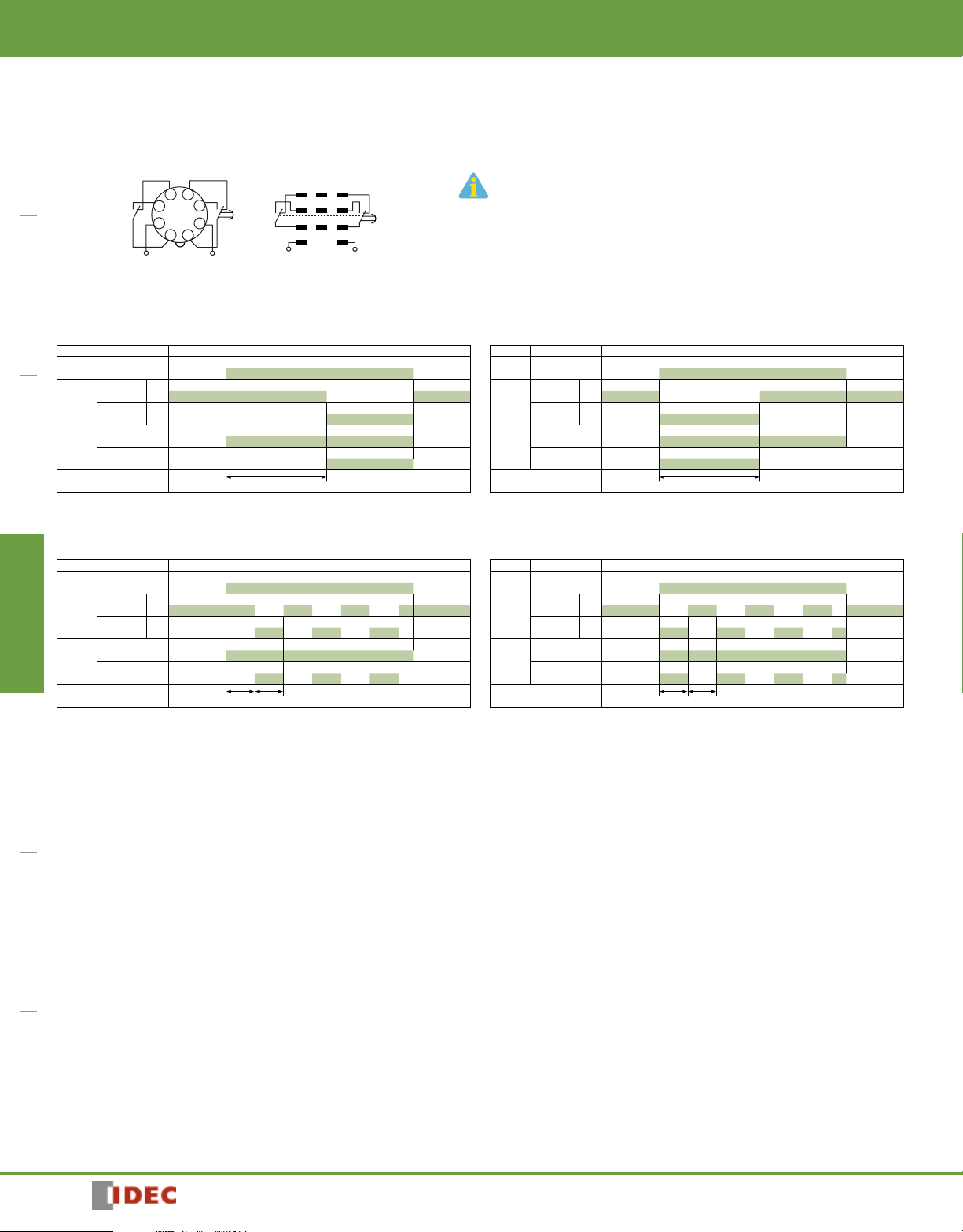

Timing Diagrams

RTE-P1, -B1

RTE-B1

1

3

5

6

7

8

(~/-)(~/+)

2

5

4

6

7

8

9

A

B

(~/-)(~/+)

1. RTE-B1: Do not apply voltage to terminals #2, #5 & #8.

2. IDEC sockets are as follows: RTE-P1: SR2P-06* pin type socket,

RTE-B1: SR3B-05* blade type socket, (*-may be followed by suffix

letter A,B,C or U).

A: ON-Delay 1 (power start)

Set timer for desired delay, apply power to coil. Contacts transfer after preset time has elapsed, and

remain in transferred position until timer is reset. Reset occurs with removal of power.

Item Terminal Number Operation

(1) 2 - 7

Power

(2) A - B

Delayed

Contact

Indicator

Set Time

(1) 1 - 4, 5 - 8

(2) 1 - 7, 3 - 9

(1) 1 - 3, 6 - 8

(2) 4 - 7, 6 - 9

PWR

OUT

(NC)

(NO)

T

C: Cycle 1 (power start, OFF first)

Set timer for desired delay, apply power to coil. First transfer of contacts occurs after preset delay has

elapsed, after the next elapse of preset delay contacts return to original position. The timer now cycles

between on and off as long as power is applied (duty ratio 1:1).

Item Terminal Number Operation

(1) 2 - 7

Power

(2) A - B

Delayed

Contact

Indicator

Set Time

(1) 1 - 4, 5 - 8

(2) 1 - 7, 3 - 9

(1) 1 - 3, 6 - 8

(2) 4 - 7, 6 - 9

PWR

OUT

(NC)

(NO)

T T

B: Interval (power start)

Set timer for desired delay, apply power to coil. Contacts transfer immediately, and return to original

position after preset time has elapsed. Reset occurs with removal of power.

Item Terminal Number Operation

(1) 2 - 7

Power

(2) A - B

Delayed

Contact

Indicator

Set Time

(1) 1 - 4, 5 - 8

(2) 1 - 7, 3 - 9

(1) 1 - 3, 6 - 8

(2) 4 - 7, 6 - 9

PWR

OUT

(NC)

(NO)

T

C: Cycle 3 (power start, ON first)

Functions in same manner as Mode C, with the exception that first transfer of contacts occurs as soon

as power is applies. The ratio is 1:1. Time On = Time Off

Item Terminal Number Operation

(1) 2 - 7

Power

(2) A - B

Delayed

Contact

Indicator

Set Time

(1) 1 - 4, 5 - 8

(2) 1 - 7, 3 - 9

(1) 1 - 3, 6 - 8

(2) 4 - 7, 6 - 9

PWR

OUT

(NC)

(NO)

T T

838

www.IDEC.com

Timers

RTE-B2

2

3

A

B

9

1

(~/-)(~/+)

4

5

6

7

8

2

3

A

B

9

1

(~/-)(~/+)

4

5

6

7

8

RTE-B1

start

external

control

signal

(~/-)(~/+)

RTE

Timing Diagrams con’t

RTE-P2

external

start

control

signal

6

5

7

4

8

9

3

2

10

11

1

A: ON-Delay 2 (signal start)

When a preset time has elapsed after the start input turned on while power is on, the NO output

contact goes on.

Item Terminal Number Operation

(A) 2 - 10

Power

(B) A - B

(A) 5 - 6

Start

(B) 2 - 5

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

Delayed

Contact

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

PWR

Indicator

OUT

Set Time

C: Cycle 4 (signal start, ON first)

When the start input turns on while power is on, the NO contact goes on. The output oscillates at a

preset cycle (duty ratio 1:1).

Item Terminal Number Operation

(A) 2 - 10

Power

(B) A - B

(A) 5 - 6

Start

(B) 2 - 5

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

Delayed

Contact

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

PWR

Indicator

OUT

Set Time

E: Signal OFF-Delay

When power is turned on while the start input is on, the NO output contact goes on. When a preset

time has elapsed after the start input turned off, the NO output contact goes off.

Item Terminal Number Operation

(A) 2 - 10

Power

(B) A - B

(A) 5 - 6

Start

(B) 2 - 5

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

Delayed

Contact

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

PWR

Indicator

OUT

Set Time

(NC)

(NO)

(NC)

(NO)

T T T T T T T T Ta

(NC)

(NO)

T Ta T Ta

external

control

signal

T

RTE-B2

start

1

2

5

4

7

8

A

3

6

9

B

RTE-P2, -B2

1. RTE-P2: Do not apply voltage to terminals #5, #6 & #7.

2. RTE-B2: Do not apply voltage to terminals #2, #5 & #8.

3. IDEC sockets are as follows: RTE-P2: SR3P-05* pin type socket,

RTE-B2: SR3B-05* blade type socket, (*-may be followed by suffix

letter A,B,C or U).

B: Cycle 2 (signal start, OFF first)

When the start input turns on while power is on, the output oscillates at a preset cycle (duty ratio 1:1),

starting while the NO contact off.

Item Terminal Number Operation

(A) 2 - 10

Power

(B) A - B

(A) 5 - 6

Start

(B) 2 - 5

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

Delayed

Contact

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

PWR

Indicator

OUT

Set Time

D: Signal ON/OFF-Delay

When the start input turns on while power is on, the NO output contact goes on. When a preset time

has elapsed while the start input remains on, the output contact goes off. When the start input turns

off, the NO contact goes on again. When a preset time has elapsed after the start input turned off, the

NO contact goes off.

Item Terminal Number Operation

(A) 2 - 10

Power

(B) A - B

(A) 5 - 6

Start

(B) 2 - 5

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

Delayed

Contact

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

PWR

Indicator

OUT

Set Time

F: One-Shot (signal start)

When the start input turns on while power is on, the NO output contact goes on. When a preset time

has elapsed, the NO output contact goes off.

Item Terminal Number Operation

(A) 2 - 10

Power

(B) A - B

(A) 5 - 6

Start

(B) 2 - 5

(A) 1 - 4, 8 - 11

(B) 1 - 7, 3 - 9

Delayed

Contact

(A) 1 - 3, 9 - 11

(B) 4 - 7, 6 - 9

PWR

Indicator

OUT

Set Time

(NC)

(NO)

T T T T T T T T T Ta

(NC)

(NO)

T T Ta T T Ta

(NC)

(NO)

Switches & Pilot Lights Signaling Lights Relays & Sockets Timers Contactors Terminal Blocks Circuit Breakers

800-262-IDEC (4332) • USA & Canada

839

RTE

Mounting A

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

Timers

Temperature Derating Curves

10A

7A

Mounting A

Allowable

Current

Derating Curve

Ambient Temperature

65

º

C

50ºC

Instructions

Mounting B

7A

5A

Mounting B

Allowable

Current

Derating Curve

Ambient Temperature

50ºC

65

º

C

Installation of Hold-Down Springs

DIN Rail Mount Socket

Socket SR2P-06

Insert the springs into the outer

slots with the projections

facing inside.

Hold-down Spring (sold separately)

SFA-202 (use two springs)

Socket SR2P-05

Insert the springs

into the slots.

Hold-down Spring (sold separately)

SFA-203 (use two springs)

Safety Precautions

Special expertise is required to use Electronic Timers.

• All Electronic Timers are manufactured under IDEC’s rigorous quality control

system, but users must add a backup or fail safe provision to the control

system when using the Electronic Timer in applications where heavy damage

or personal injury may occur should the Electronic Timer fail.

• Install the Electronic Timer according to instructions described in this catalog.

• Make sure that the operating conditions are as described in the specifica-

tions. If you are uncertain about the specifications, contact IDEC in advance.

• In these directions, safety precautions are categorized in order of importance

under Warning and Caution.

Warnings

Warning notices are used to emphasize that improper operation may cause

severe personal injury or death.

• Turn power off to the Electronic timer before starting installation, removal,

wiring, maintenance, and inspection on the Electronic Timer.

• Failure to turn power off may cause electrical shocks or fire hazard.

Switch Settings

j

jOperator Mode Selector

kScale Selector

lTime Range Selector

1. Turn the selectors securely using a flat screwdriver 4mm wide (maximum).

Note that incorrect setting may cause malfunction. Do not turn the selectors beyond their limits.

2. Since changing the setting during timer operation

may cause malfunction, turn power off before

changing.

• Do not use the Electronic Timer for an emergency stop circuit or inter-

locking circuit. If the Electronic Timer should fail, a machine malfunction,

breakdown, or accident may occur.

l

k

Caution

Caution notices are used where inattention might cause personal injury or damage to equipment.

• The Electronic Timer is designed for installation in equipment. Do not install

the Electronic Timer outside equipment.

• Install the Electronic Timer in environments described in the specifications. If

the Electronic Timer is used in places where it will be subjected to high-temperature, high-humidity, condensation, corrosive gases, excessive vibrations,

or excessive shocks, then electrical shocks, fire hazard, or malfunction could

result.

• Use an IEC60127-approved fuse and circuit breaker on the power and output

line outside the Electronic Timer.

• Do not disassemble, repair, or modify the Electronic Timer.

• When disposing of the Electronic Timer, do so as industrial waste.

840

www.IDEC.com

Timers

RTE

DIN Rail Mounting Accessories

DIN Rail/Surface Mount Sockets and Hold-Down Springs

DIN Rail Mount Socket Applicable Hold-Down Springs

Style Appearance Use with Timers Part Number Appearance Part Number

11-Pin Screw Terminal

(dual tier)

11-Pin FingerSafe Socket

8-Pin Screw Terminal

Accessories

RTE-P2 SR3P-05

RTE-P2 SR3P-05C

RTE-P1

Switches & Pilot Lights Signaling Lights Relays & Sockets Timers Contactors Terminal Blocks Circuit Breakers

SFA-203

SR2P-06

SFA-2028-Pin Fingersafe Socket SR2P-05C

11-Blade Screw Terminal

DIN Mounting Rail

Length 1000mm

RTE-B1

RTE-B2

— BNDN1000

SR3B-05

Panel Mounting Accessories

Flush Panel Mount Adapter and Sockets that use an Adapter

Accessory Description Appearance Use with Part No.

Panel Mount Adapter

Sockets for use with

Panel Mount Adapter

Adaptor for flush panel

mounting RTE timers

8-pin screw terminal

11-pin screw terminal RTE-P2 SR6P-M11G

(Shown: SR6P-M08G Wiring Socket Adapter)

8-pin solder terminal

All RTE timers RTB-G01

RTE-P1 SR6P-M08G

RTE-P1 SR6P-S08

11-pin solder terminal

800-262-IDEC (4332) • USA & Canada

RTE-P2 SR6P-S11

841

RTE

40.0

13.0

48

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

36.0

Timers

Dimensions

77.9

13.7

RTE-P1 (8 pin) Terminal Style

RTE-P2 (11 pin)Terminal Style

RTE Timer, 8-Pin and 11-Pin with SR6P-S08 or SR6P-S11

Panel Thickness 0.8 to 5mm

RTE-B1/RTE-B2 (11 blade) Terminal Style

Panel Mount Adapter

Panel Thickness 0.8 to 5mm

48

80.5

11 61.2

RTE Timer, 8-Pin with SR6P-M08G

44.6

RTE Timer, 11-Pin with SR6P-M11G

11-M3.5 Teminal Screws

45

34

98 maximum

8-M3.5 Terminal Screw

44.6

3456

30.4

2187

7

9.8 x 3

45

16.7

11

2

176

5

4 389

Back Wiring Socket

3.5 max.

6.9 max.

10

7.3

1.7

42.5

3.5 max. 5.6 min.

6.9 max.

5.8 min.

ø3.6 min.

ø3.6 min.

842

30.5 7

92

8.5 x 4

www.IDEC.com

General Instructions

Timers

General Instructions for All Timer Series

Load Current

With inductive, capacitive, and incandescent lamp loads, inrush current more

than 10 times the rated current may cause welded contacts and other undesired

effects. The inrush current and steady-state current must be taken into consider-

Switches & Pilot LightsSignaling LightsRelays & SocketsTimersContactorsTerminal BlocksCircuit Breakers

ation when specifying a timer.

Contact Protection

Switching an inductive load generates a counter-electromotive force (back EMF)

in the coil. The back EMF will cause arcing, which may shorten the contact life

and cause imperfect contact. Application of a protection circuit is recommended

to safeguard the contacts.

Temperature and Humidity

Use the timer within the operating temperature and operating humidity ranges

and prevent freezing or condensation. After the timer has been stored below

its operating temperature, leave the timer at room temperature for a sufficient

period of time to allow it to return to operating temperatures before use.

Environment

Avoid contact between the timer and sulfurous or ammonia gases, organic solvents (alcohol, benzine, thinner, etc.), strong alkaline substances, or strong acids.

Do not use the timer in an environment where such substances are prevalent. Do

not allow water to run or splash on the timer.

Vibration and Shock

Excessive vibration or shocks can cause the output contacts to bounce, the

timer should be used only within the operating extremes for vibration and shock

resistance. In applications with significant vibration or shock, use of hold down

springs or clips is recommended to secure a timer to its socket.

Time Setting

The time range is calibrated at its maximum time scale; so it is desirable to use

the timer at a setting as close to its maximum time scale as possible. For a more

accurate time delay, adjust the control knob by measuring the operating time

with a watch before application.

Input Contacts

Use mechanical contact switch or relay to supply power to the timer. When

driving the timer with a solid-state output device (such as a two-wire proximity

switch, photoelectric switch, or solid-state relay), malfunction may be caused by

leakage current from the solid-state device. Since AC types comprise a capacitive load, the SSR dielectric strength should be two or more times the power

voltage when switching the timer power using an SSR.

Generally, it is desirable to use mechanical contacts whenever possible to apply

power to a timer or its signal inputs. When using solid state devices, be cautious

of inrushes and back-EMF that may exceed the ratings on such devices. Some

timers are specially designed so that signal inputs switch at a lower voltage

than is used to power the timer (models designated as “B” type).

Timing accuracies are calculated from the following formulas:

Repeat Error

Voltage Error

Tv: Average of measured values at voltage V

Tr: Average of measured values at the rated voltage

Temperature Error

Tt: Average of measured values at °C

T20: Average of measured values at 20°C

Setting Error

= ± 1 x Maximum Measured Value – Minimum Measured Value x 100%

2 Maximum Scale Value

= ± Tv - Tr x 100%

Tr

= ± Tt - T20 x 100%

T20

= ± Average of Measured Values - Set Value x 100%

Maximum Scale Value

Timing Accuracy Formulas

880

www.IDEC.com

Loading...

Loading...