Idec RF1V-2A2B-D12, RF1V-2A2BL-D12, RF1V-2A2B-D24, RF1V-2A2BL-D24, RF1V-2A2B-D48 User guide

...Page 1

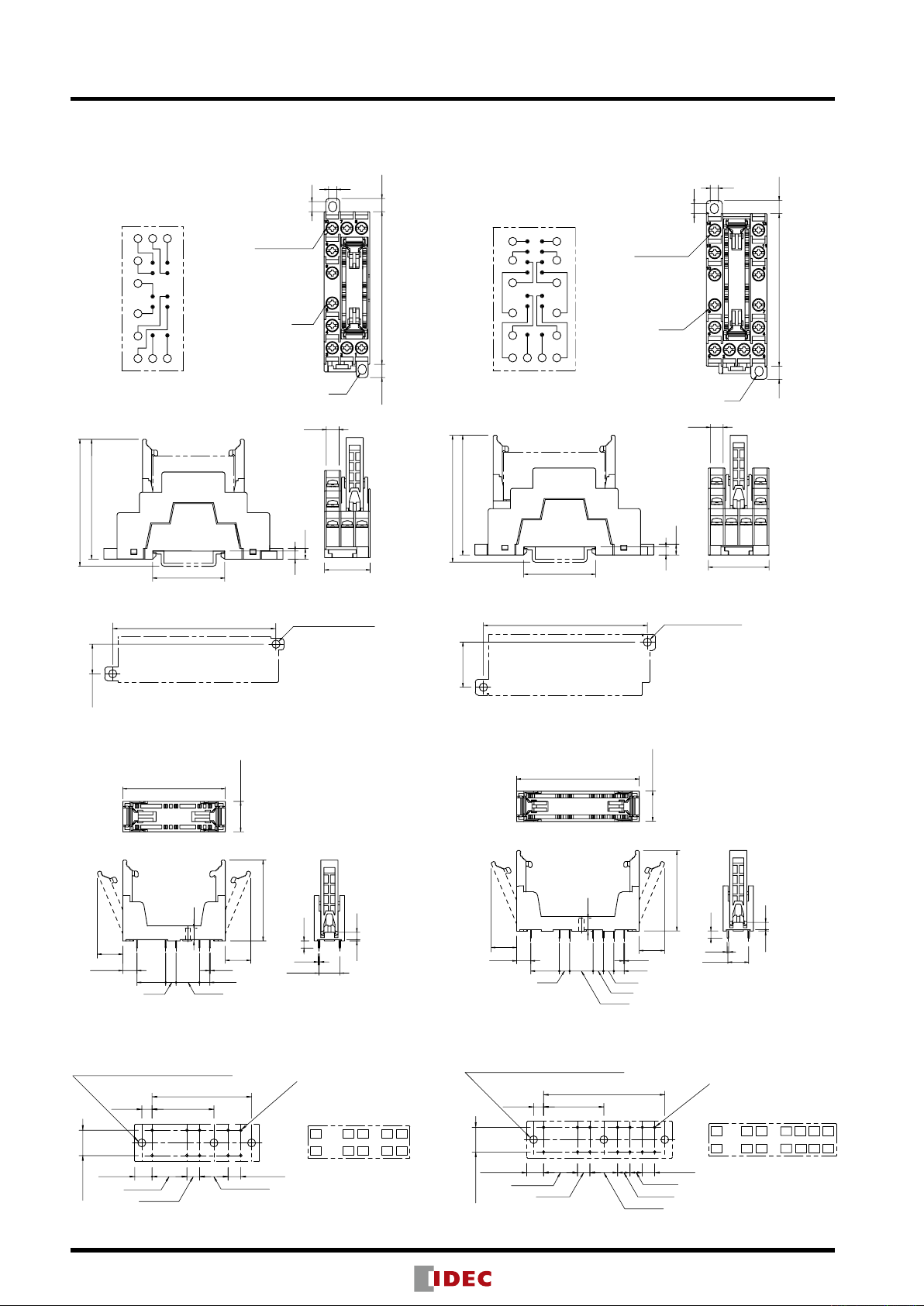

RF1V Force Guided Relays

(090319)

SF1V Relay Sockets

Page 2

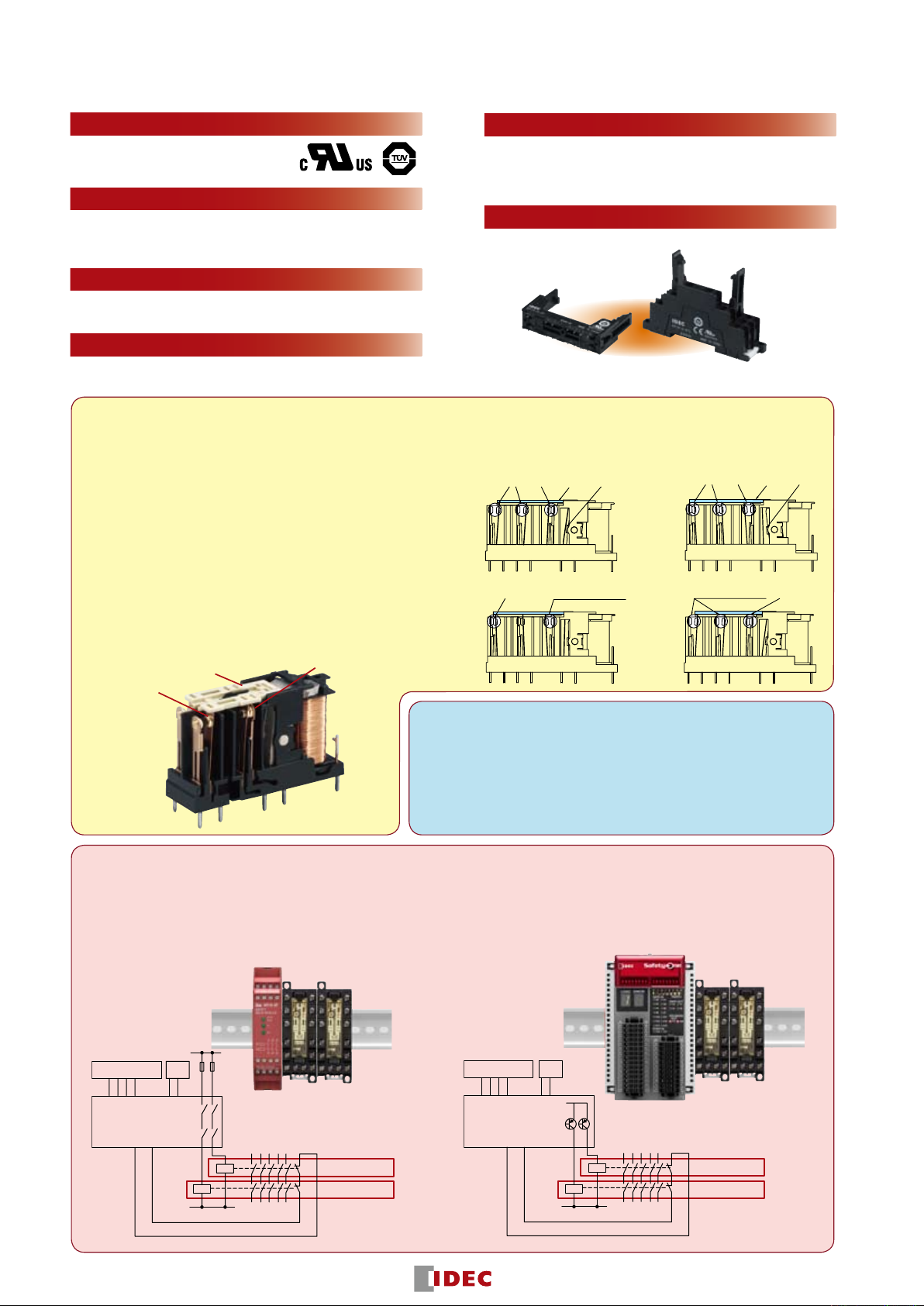

Safety Relay Module

Interlock Switch/

Emergency Stop Switch

Start

Switch

K2

K1

F1

F2

EDM Input

Safety Output Expansion

Force Guided Relays

Force Guided Relays

De-energized

(Normal

Condition)

Energized

(Normal

Condition)

A gap of at least

0.5 mm is maintained

NO contact

is welded

De-energized

(Abnormal

Condition)

Energized

(Abnormal

Condition)

A gap of at least

0.5 mm is maintained

NC contact

is welded

ArmatureGuide

NC

contact

NO

contact

ArmatureGuide

NC

contact

NO

contact

K2

K1

24V

Interlock Switch/

Emergency Stop Switch

Start

Switch

Safety Controller

EDM Input

Safety Output Expansion

Force Guided Relays

Force Guided Relays

Enablesexibleconstructionofsafetycircuits

(090319)

Complies with International Standards

Force guided contact mechanism

(EN50205 Type A TÜV approved)

Compact and Slim

Compact size enables size reduction of PC board.

4-pole type: 13W × 40D × 24H mm

6-pole type: 13W × 50D × 24H mm

Fast Response Time

Response time of 8 ms.

Ensures safety by turning the load off quickly.

(200 m/s2 minimum)

Socket Variation

PC board mount and DIN rail mount sockets are available.

High Shock Resistance

High shock resistant suitable for use in machine tools and in

environments subjected to vibration and shocks.

Clear Visiblilty

Available with a built-in LED.

PC board mount DIN rail mount

What is a force guided relay?

Relays used in safety circuits to detect failures such as contact welding and damage to the

contact spring.

Contacts of a force guided relay are forced to open and

close by a guide connected to the armature.

Due to requirements of standard EN50205, a force guided

relay has independent NO and NC contacts. If a NO contact welds, a NC contact will not close even when the relay

coil is turned off (de-energized) and must maintain a gap of

at least 0.5 mm. Furthermore, if a NC contact welds, a NO

contact will not close when the relay is turned on (energized) and must maintain a gap of at least 0.5 mm.

(General-purpose relays do not have the above characteristics.)

Guide

NO contact

NC contact

Applications

Force guided relays are used in safety circuits in combination with interlock switches, light curtains, and emergency stop switches to control

outputs.

They can also be used to expand outputs for safety relay modules and

safety controllers.

Output expansion for safety relay modules and safety controllers

FS1A Safety Controller•HR1S Safety Relay Module•

Cost effective and easy method to expand mechanical

contact outputs.

Circuit Example• Circuit Example•

EDM input: External device monitor input

2

Solid state safety outputs of safety controllers can be converted

to mechanical contact outputs.

Page 3

RF1V

(090319)

Force Guided Relays / SF1V Relay Sockets

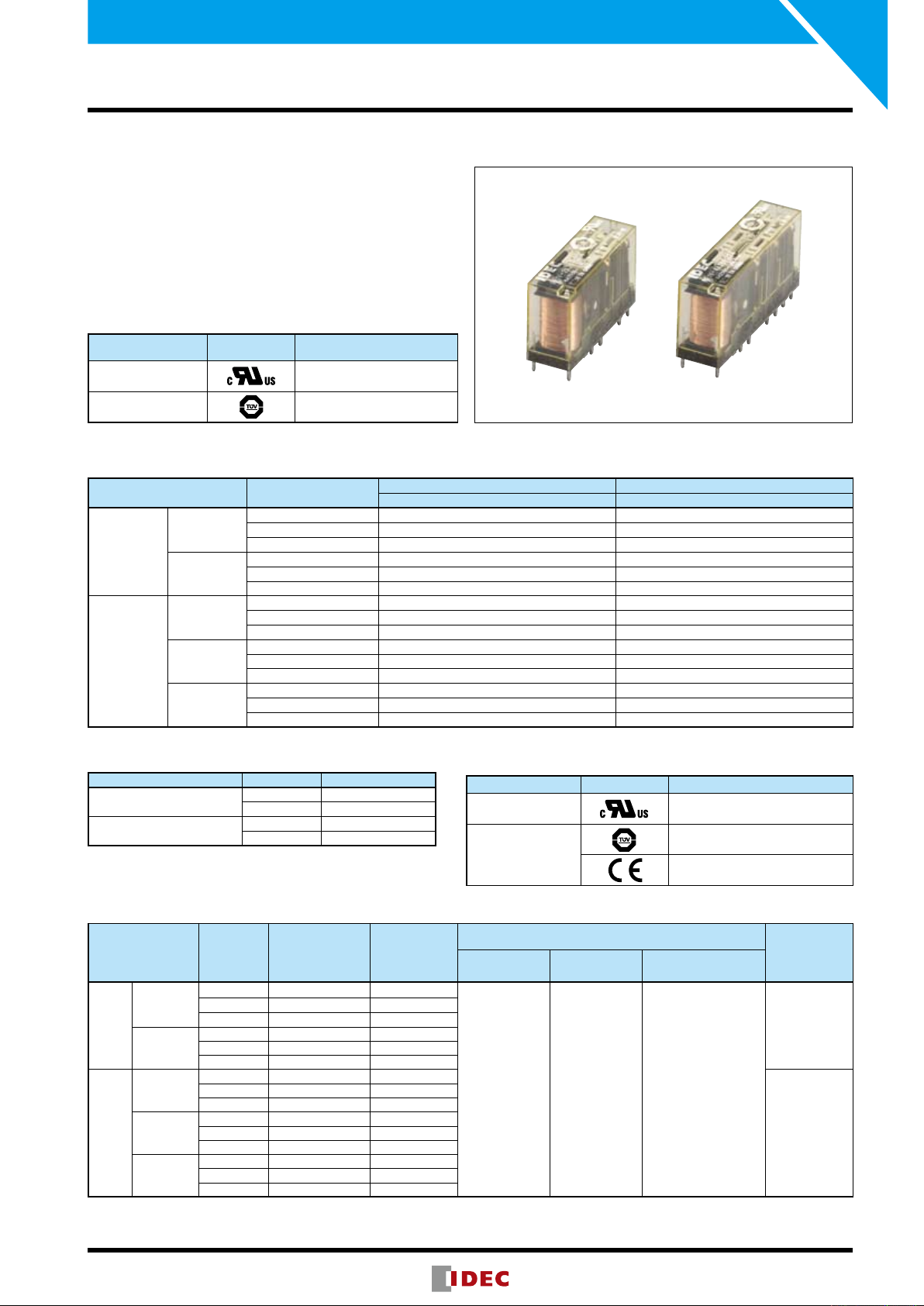

Compact and EN compliant RF1V force guided relays.

Force guided contact mechanism •

(EN50205 Type A TÜV approved)

Contactconguration •

4-pole (2NO-2NC, 3NO-1NC)

6-pole (4NO-2NC, 5NO-1NC, 3NO-3NC)

Built-in LED indicator available.•

Fast response time (8 ms maximum).•

High shock resistance (200 m/s•

Finger-safe DIN rail mount socket and PC board •

mount socket.

Applicable Standard Marking

UL508

CSA C22.2 No.14

EN50205

EN61810-1

Types

Force Guided Relays•

Contact Rated Coil Voltage

2NO-2NC

4-pole

3NO-1NC

4NO-2NC

6-pole

5NO-1NC

3NO-3NC

2

minimum)

CerticationOrganization/

File No.

UL/c-UL File No. E55996

TÜV SÜD

Without LED Indicator With LED Indicator

12V DC RF1V-2A2B-D12 RF1V-2A2BL-D12

24V DC RF1V-2A2B-D24 RF1V-2A2BL-D24

48V DC RF1V-2A2B-D48 RF1V-2A2BL-D48

12V DC RF1V-3A1B-D12 RF1V-3A1BL-D12

24V DC RF1V-3A1B-D24 RF1V-3A1BL-D24

48V DC RF1V-3A1B-D48 RF1V-3A1BL-D48

12V DC RF1V-4A2B-D12 RF1V-4A2BL-D12

24V DC RF1V-4A2B-D24 RF1V-4A2BL-D24

48V DC RF1V-4A2B-D48 RF1V-4A2BL-D48

12V DC RF1V-5A1B-D12 RF1V-5A1BL-D12

24V DC RF1V-5A1B-D24 RF1V-5A1BL-D24

48V DC RF1V-5A1B-D48 RF1V-5A1BL-D48

12V DC RF1V-3A3B-D12 RF1V-3A3BL-D12

24V DC RF1V-3A3B-D24 RF1V-3A3BL-D24

48V DC RF1V-3A3B-D48 RF1V-3A3BL-D48

Ordering Type No. Ordering Type No.

Sockets•

Types No. of Poles Ordering Type No.

DIN Rail Mount Sockets

PC Board Mount Sockets

4 SF1V-4-07L

6 SF1V-6-07L

4 SF1V-4-61

6 SF1V-6-61

CerticationforSockets

Applicable Standard Marking CerticationOrganization/FileNo.

UL508

CSA C22.2 No.14

EN147000

EN147100

Coil Ratings

Contact

2NO-2NC

4-pole

3NO-1NC

4NO-2NC

6-pole

Note 1: For relays with LED indicator, the rated current increases by approx. 2 mA.

Note 2: Maximum continuous applied voltage is the maximum voltage that can be applied to relay coils.

5NO-1NC

3NO-3NC

Rated Coil

Voltage (V)

12V DC 30 400

24V DC 15 1600

48V DC 7.5 6400

12V DC 30 400

24V DC 15 1600

48V DC 7.5 6400

12V DC 41.7 288

24V DC 20.8 1152

48V DC 10.4 4608

12V DC 41.7 288

24V DC 20.8 1152

48V DC 10.4 4608

12V DC 41.7 288

24V DC 20.8 1152

48V DC 10.4 4608

Rated Current

(mA) ±10%

(at 20°C) (Note 1)

Coil

Resistance(Ω)

±10% (at 20°C)

Pickup Voltage Dropout Voltage

75% maximum 10% minimum 110%

Operating Characteristics

(at 20°C)

UL/c-UL File No. E62437

TÜV SÜD

EC Low Voltage Directive

(DIN rail mount sockets only)

Maximum Continuous

Applied Voltage (Note 2)

Power

Consumption

Approx. 0.36W

Approx. 0.5W

3

Page 4

4

RF1V Force Guided Relays / SF1V Relay Sockets

6.5 min.

4.0 max.

6.3 max.

3.0 min.

(090319)

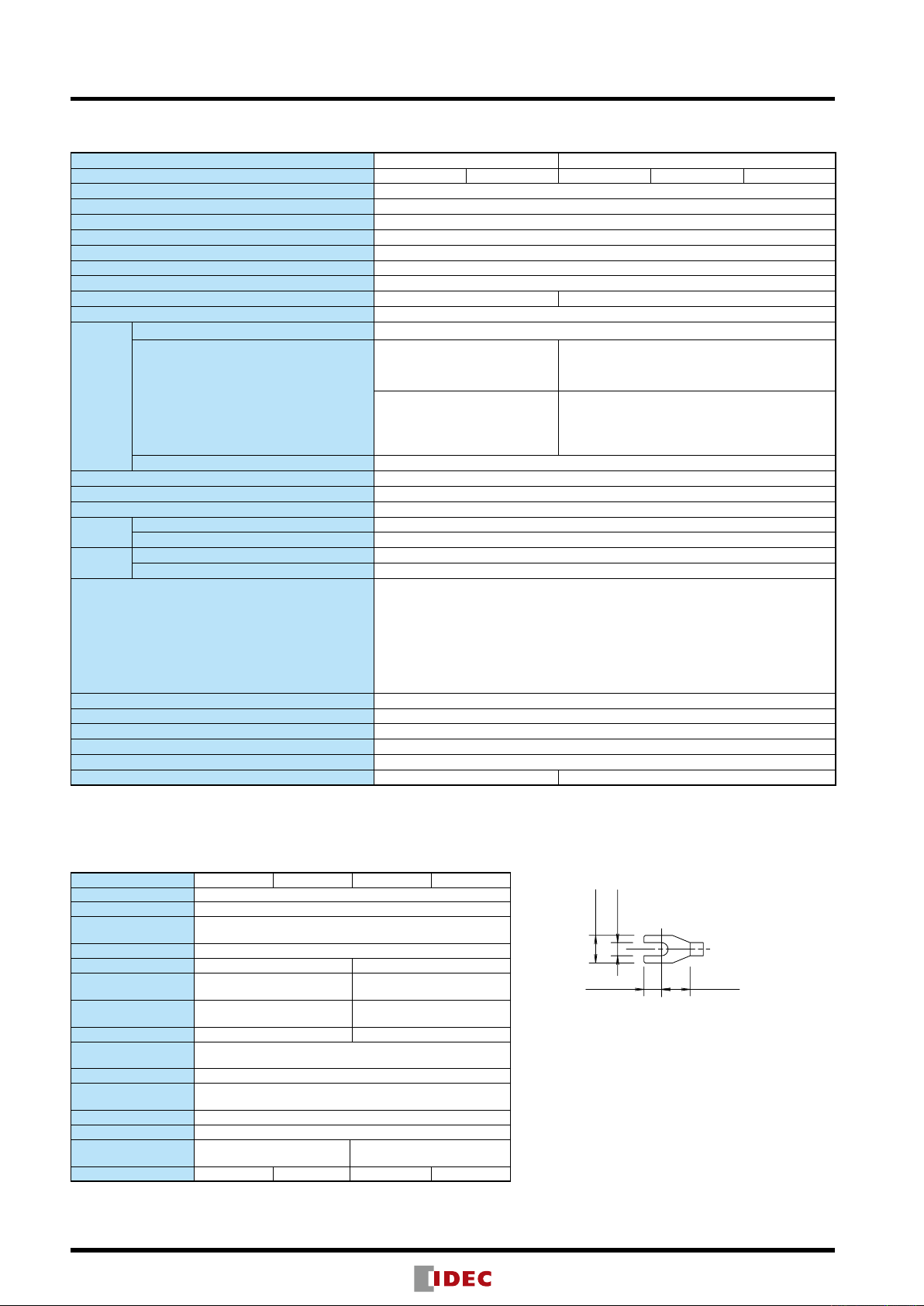

Relay Specifications

Number of Poles 4-pole 6-pole

ContactConguration 2NO-2NC 3NO-1NC 4NO-2NC 5NO-1NC 3NO-3NC

Contact Resistance (initial value) (Note 1) 100mΩmaximum

Contact Material AgSnO

Rated Load (resistive load) 6A 250V AC, 6A 30V DC

Allowable Switching Power (resistive load) 1500 VA, 180W

Allowable Switching Voltage 250V AC, 30V DC

Allowable Switching Current 6A

Minimum Applicable Load (Note 2) 5V DC, 1 mA (reference value)

Power Consumption (approx.) 0.36W 0.5W

Insulation Resistance

Between contact and coil 4000V AC, 1 minute

Dielectric

Strength

Operate Time (at 20°C) 20 ms maximum (at the rated coil voltage, excluding contact bounce time)

Response Time (at 20°C) (Note 3)

Release Time (at 20°C) 20 ms maximum (at the rated coil voltage, excluding contact bounce time)

Vibration

Resistance

Shock

Resistance

Electrical Life

Mechanical Life 10 million operations minimum (operating frequency 10,800 operations per hour)

Operating Temperature (Note 4) –40 to +85°C (no freezing)

Operating Humidity 5 to 85%RH (no condensation)

Storage Temperature –40 to +85°C

Operating Frequency (rated load) 1200 operations per hour

Weight (approx.) 20g 23g

Note 1: Measured using 6V DC,1A voltage drop method.

Note 2: Failure rate level P (reference value)

Note 3: Response time is the time until NO contact opens, after the coil voltage is turned off.

Note 4: When using at 70 to 85°C, reduce the switching current by 0.1A/°C.

Between contacts of different poles

Between contacts of the same pole 1500V AC, 1 minute

Operating Extremes 10 to 55 Hz, amplitude 0.75 mm

Damage Limits 10 to 55 Hz, amplitude 0.75 mm

Operating Extremes (half sine-wave pulse: 11 ms)

Damage Limits (half sine-wave pulse: 6 ms) 1000 m/s

(Auashed)

2

1000MΩminimum(500VDCmegger,samemeasurementpositionsasthedielectricstrength)

2500V AC, 1 minute

2500V AC, 1 minute

Between contacts 7-8 and 9

4000V AC, 1 min.

Between contacts 3-4 and 5-6

Between contacts 3-4 and 7-8

Between contacts 5-6 and 9-10

8 ms maximum (at the rated coil voltage, excluding contact bounce time)

200 m/s2, when mounted on DIN rail mount socket: 150 m/s2

2

250V AC 6A resistive load: 100,000 operations minimum (operating frequency 1200 per hour)

30V DC 6A resistive load: 100,000 operations minimum (operating frequency 1200 per hour)

250V AC 1A resistive load: 500,000 operations minimum (operating frequency 1800 per hour)

30V DC 1A resistive load: 500,000 operations minimum (operating frequency 1800 per hour)

[AC 15] 240V AC 2A inductive load: 100,000 operations minimum

(operating frequency 1200 per hour, cos ø = 0.3)

[DC 13] 24V DC 1A inductive load: 100,000 operations minimum

(operating frequency 1200 per hour, L/R = 48 ms)

-

Between contacts 7-8 and 11-12

10

Between contacts 9-10 and 13-14

Between contacts 11-12 and 13-14

4000V AC, 1 min.

Between contacts 3-4 and 5-6

Between contacts 3-4 and 7-8

Between contacts 5-6 and 9-10

Between contacts 7-8 and 9-10

Socket Specifications

Type SF1V-4-07L SF1V-6-07L SF1V-4-61 SF1V-6-61

Rated Current 6A

Rated Voltage 250V AC/DC

Insulation Resistance

Dielectric Strength 2500V AC, 1 minute (between terminals)

Screw Terminal Style M3 slotted Phillips screw —

Applicable Wire

Recommended Screw

Tightening Torque

Terminal Strength Wire tensile strength: 50N min. —

Vibration Resistance

Shock Resistance 1000 m/s

Operating Temperature

(Note)

Operating Humidity 5 to 85% RH (no condensation)

Storage Humidity

Degree of Protection

Weight (approx.) 40g 55g 9g 10g

Note: When using at 70 to 85°C, reduce the switching current by 0.1A/°C.

1000MΩminimum

(500V DC megger, between terminals)

2

1.65 mm

0.7 to

(18 AWG to 14 AWG)

0.5 to 0.8 N·m —

Damage limits: 10 to 55 Hz, amplitude 0.75 mm

Resonance: 10 to 55 Hz, amplitude 0.75 mm

2

40 to +85°C (no freezing)

–

40 to +85°C

–

IP20

(nger-safescrewterminals)

—

—

Applicable Crimping Terminals

Note: Ring tongue terminals cannot be used.

Page 5

5

RF1V Force Guided Relays / SF1V Relay Sockets

6

250

10

0.1

1

100

1

10

AC Resistive Load

Load Voltage (V)

DC Resistive Load

Load Current (A)

0.11

100

10

1

500

10

30V DC Resistive Load

Load Current (A)

Life (×10,000 operations)

250V AC Resistive Load

50 max.

13 max.

24 max.

3.5

10.16

1.0

1.83

13.97

5.08

11.43

5.08

5.08

5.08

0.5

13 max.

24 max.

3.5

10.16

1.0

1.83

13.97

5.08

11.43

5.08

0.5

40 max.

10- 1.4 hole

13.97

5.08

±0.1

±0.1

±0.1

±0.1

11.43

5.08

10.16

(1.83)

14- 1.4 hole

11.43

±0.1

±0.1

±0.1

±0.1

±0.1

±0.1

±0.1

5.08

5.08

5.08

13.97

5.08

10.16

(1.83)

1

2

34

5678910

+

–

4NO-2NC Contact3NO-3NC Contact5NO-1NC Contact

–

–

+

–

+

–

+

–

+

–

+

1

23456

7 81112

91013 14

1234567811 12

9101314

1234567811 12

9101314

4NO-2NC Contact3NO-3NC Contact5NO-1NC Contact

+

1

23456

7811 12

9101314

1234567 81112

9101314

1234567 81112

9101314

2NO-2NC Contact

3NO1NC Contact

2NO-2NC Contact

3NO-1NC Contact

123 4567 8

910

12345678

910

1234567 8

910

123 4567 8

910

+

–

+

–

+

–

+

–

(090319)

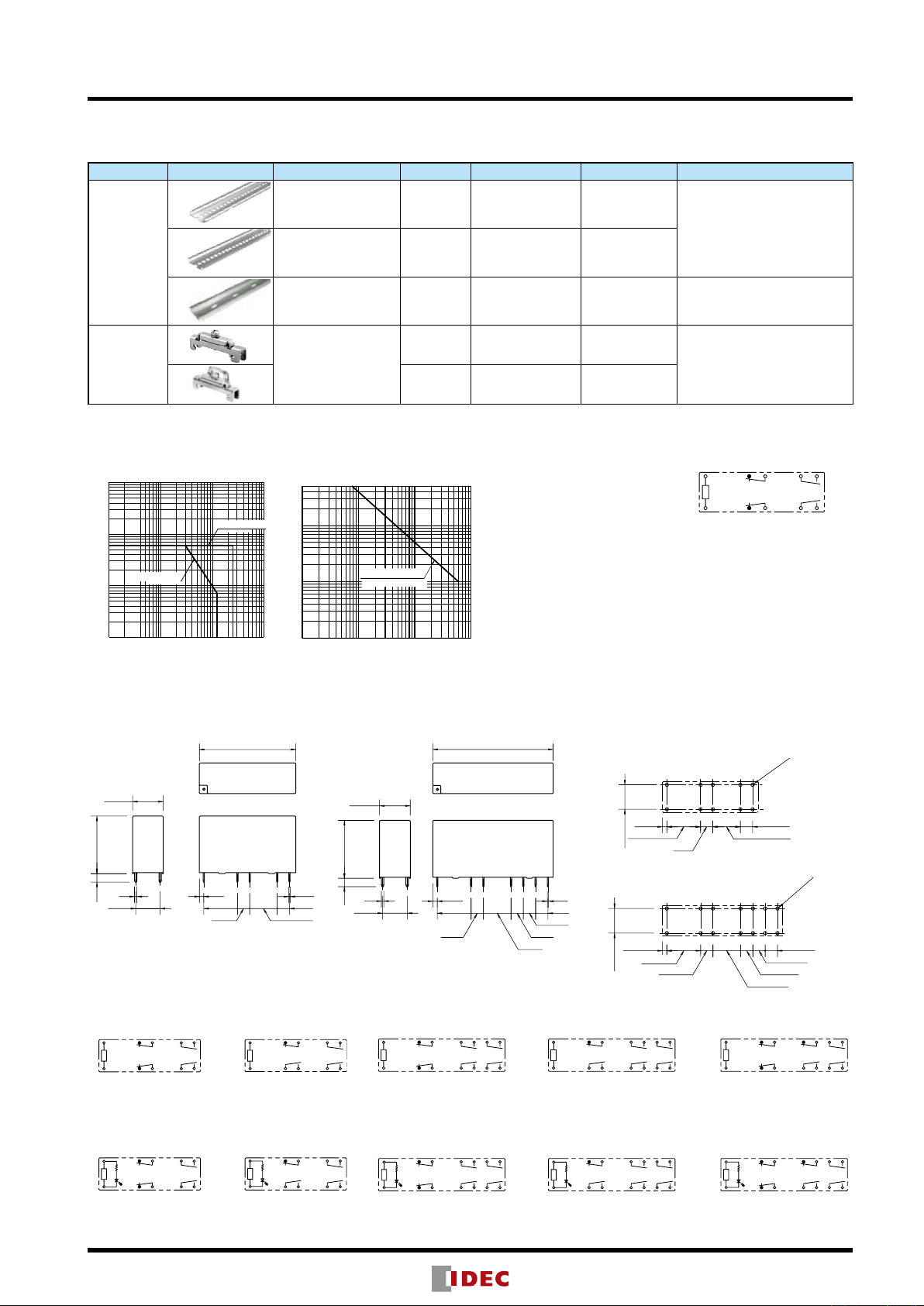

Accessories

Item Appearance Specications Type No. Ordering Type No. Package Quantity Remarks

DIN Rail

Aluminum

Weight: Approx. 200g

Steel

Weight: Approx. 320g

Aluminum

Weight: Approx. 250g

BAA1000 BAA1000PN10 10

BAP1000 BAP1000PN10 10

BNDN1000 BNDN1000 1

Length: 1m

Width: 35 mm

North American standard product

Length: 1m

Width: 35 mm

BNL5 BNL5PN10 10

End Clip

Metal (zinc plated steel)

Weight: Approx. 15g

—

BNL6 BNL6PN10 10

Characteristics Notes on Contact Gaps except Welded

Maximum Switching Capacity• Electrical Life Curve•

Contacts

Example: RF1V-2A2B-D24

If the NO contact (7-8 or 9-10) welds, the NC contact (3-4 or •

5-6) remains open even when the relay coil is de-energized,

maintaining a gap of 0.5 mm. The remaining unwelded NO

contact (9-10 or 7-8) is either open or closed.

If the NC contact (3-4 or 5-6) welds, the NO contact (7-8 or •

9-10) remains open even when the relay coil is energized,

maintaining a gap of 0.5 mm. The remaining unwelded NC

contact (5-6 or 3-4) is either open or closed.

RF1V Dimensions

RF1V (4-pole)•

Internal Connection (Bottom View)

Without LED Indicator Without LED Indicator

With LED Indicator With LED Indicator

RF1V (6-pole)•

RF1V (6-pole)•RF1V (4-pole)•

PC Board Terminal Type

Mounting Hole Layout

RF1V (4-pole)•

RF1V (6-pole)•

(Bottom View)

Page 6

6

RF1V Force Guided Relays / SF1V Relay Sockets

22

±0.2

80.0

±0.2

2–M3.5 or ø4 holes

(13)

40 max.

50 max.

15 max.

6.2

0.6

3.6

5.08

13.97

6.93

(13)

10.16

0.8

3.5

11.43

5.08

0.4

15 max.

6.2

3.6

0.6

(13)

(13)

0.4

6.93

5.08

5.08

5.08

11.43

13.97

5.08

0.8

10.16

3.5

40 max.

60 max.

35.4

58.9

62.4

75

6.5 6.5

ø6.2

R2

M3 Terminal

Screw

5.3

4

22.4

6.3

5

4

4

5.3

29.8

35.4

58.9

62.4

4

6.3

6.5

75

6.5

5

M3 Terminal

Screw

ø6.2

R2

80.0

14.5

±0.2

±0.2

2–M3.5 or ø4 holes

8

2

3

4

5

6

7

9

10

11

12

13

14

1

10

1

2

3

4

5

6

7

8

9

5.08

±0.1

11.43

±0.1

5.08

±0.1

13.97

±0.1

10.16

±0.1

4.1

±0.1

24.8

±0.1

39.9

±0.1

10- ø1.1 hole

(6.93)

3-ø3.2 holes for M3 self-tapping screws

±0.1

±0.1

±0.1

±0.1

±0.1

±0.1

±0.1

±0.1

±0.1

49.9

4.1

24.8

11.43

5.08

5.08

5.08

5.08

13.97

10.16

14-ø1.1 hole

(6.93)

3-ø3.2 holes for M3 self-tapping screws

1

2

3

546

10

8

9

7

1

2

3

546

10

8

9

7

14

12

13

11

(090319)

SF1V DIN Rail Mount Socket Dimensions

SF1V-4-07L (4-pole)•

SF1V-6-07L (6-pole)•

(Internal Connection) (Internal Connection)

(Top View) (Top View)

(Panel Mounting Hole Layout)

(Panel Mounting Hole Layout)

SF1V PC Board Mount Sockets

SF1V-4-61 (4-pole)•

PC Board Mounting Hole Layout / Terminal Arrangement •

(Bottom View)

(Top View)

(Top View)

SF1V-6-61 (6-pole)•

PC Board Mounting Hole Layout / Terminal Arrangement •

(Bottom View)

All dimensions in mm.

Page 7

7

RF1V Force Guided Relays / SF1V Relay Sockets

Instructions

+

–

R

Smoothing

Capacitor

Relay

Pulsation

Emin Emax Emean

DC

Ripple Factor (%) × 100%

Emax –

Emin

Emax= Maximum of pulsating current

Emin= Minimum of pulsating current

Emean = DC mean value

Emean

R

Vin

EAC

TE

Load

V

in

E

AC

R

TE

lo

R

R

Counter emf

suppressing diode

Relay

+

–

Power

CR

Ind. Load

C

R

Power

Ind. Load

+

–

D

Power

Ind. Load

Varistor

Power

Ind. Load

Power

C

Load

C

Load

Power

Tolerance Range

(Avoid freezing

when using at

temperatures

below 0ºC)

(Avoid

condensation

when using at

temperatures

above 0ºC)

85

5

0–40

85

Humidity (%RH)

Temperature (ºC)

(090319)

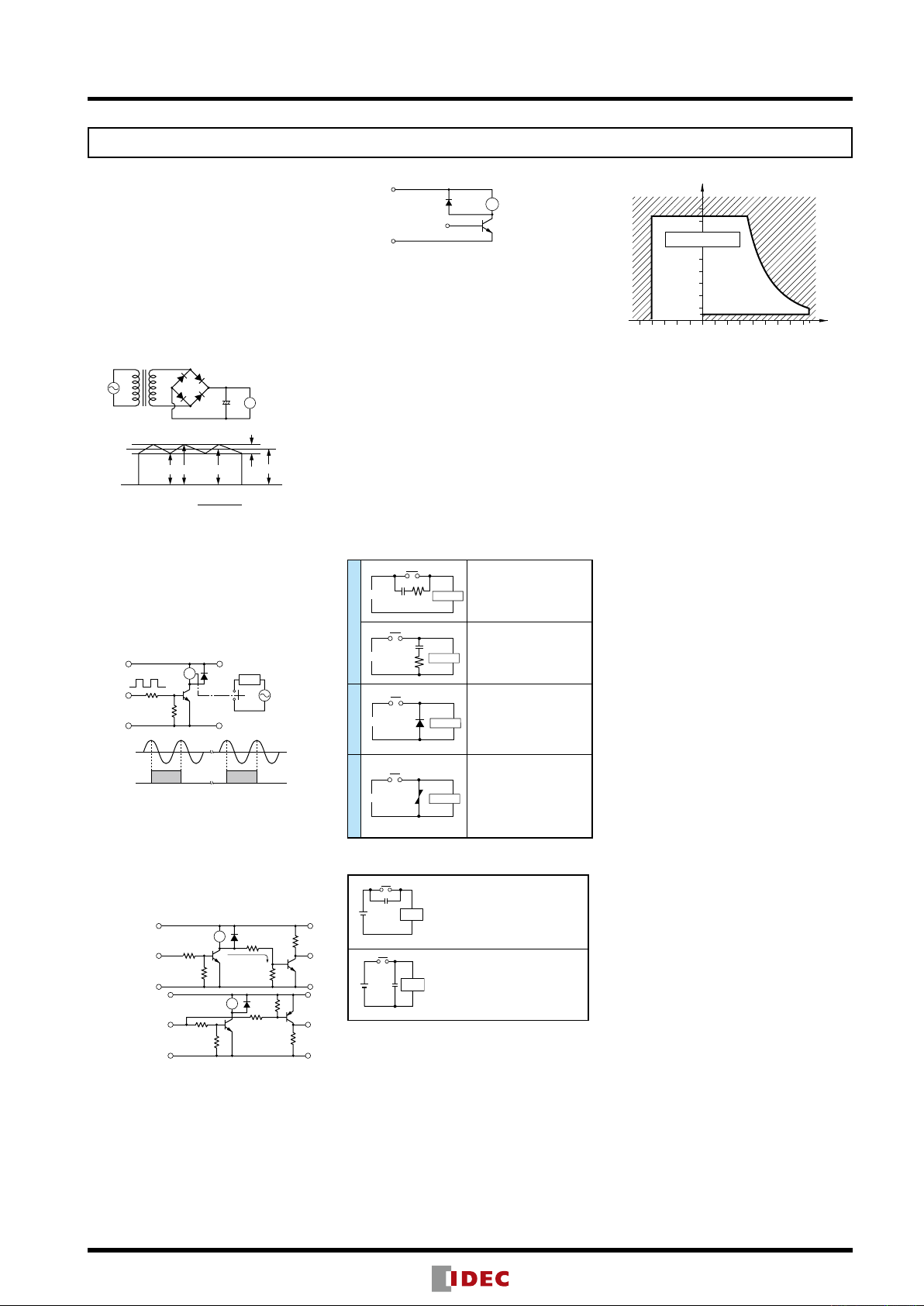

1. Driving Circuit for Relays

1. To make sure of correct relay operation, apply

2. Input voltage for DC coil:

3. Operating the relay in sync with an AC load:

If the relay operates in sync with AC power volt-

4. Leakage current while relay is off:

When driving an element at the same time as

Incorrect

Correct

5. Surge suppression for transistor driving circuits:

rated voltage to the relay coil. Pickup and dropout voltages may differ according to operating

temperature and conditions.

A complete DC voltage is best for the coil power

to make sure of stable operation. When using a

power supply containing a ripple voltage, suppress the ripple factor within 5%. When power

issuppliedthrougharecticationscircuit,relay

operating characteristics, such as pickup voltage and dropout voltage, depend on the ripple

factor. Connect a smoothing capacitor for better

operating characteristics as shown below.

age of the load, the relay life may be reduced. If

this is the case, select a relay in consideration of

the required reliability for the load. Or, make the

relay turn on and off irrespective of the AC power

phase or near the point where the AC phase

crosses zero voltage.

the relay operation, special consideration is

needed for the circuit design. As shown in the

incorrect circuit below, leakage current (Io)

owsthroughtherelaycoilwhiletherelayisoff.

Leakage current causes coil release failure or

adversely affects the vibration resistance and

shock resistance. Design a circuit as shown in

the correct example.

When the relay coil is turned off, a high-voltage

pulse is generated. Be sure to connect a diode

to suppress the counter electromotive force.

Then, the coil release time becomes slightly

longer. To shorten the coil release time, connect

a Zener diode between the collector and emitter

of the controlling transistor. Select a Zener diode

with a Zener voltage slightly higher than the

power voltage.

6. The coil terminal of the relay has polarity.

Connect terminals according to the internal

connection diagram. Incorrect wiring may cause

malfunction.

2. Protection for Relay Contacts

1. The contact ratings show maximum values.

Make sure that these values are not exceeded.

Whenaninrushcurrentowsthroughtheload,

the contact may become welded. If this is the

case, connect a contact protection circuit, such

as a current limiting resistor.

2. Contact protection circuit:

When switching an inductive load, arcing causes

carbides to form on the contacts, resulting in an

increased contact resistance. In consideration

of contact reliability, contact life, and noise

suppression, use of a surge absorbing circuit

is recommended. Note that the release time

of the load becomes slightly longer. Check the

operation using an actual load. Incorrect use of

a contact protection circuit will adversely affect

switching characteristics. Four typical examples

of contact protection circuits are shown in the

following table:

This protection circuit can be

used when the load impedance is

smaller than the RC impedance in

an AC load power circuit.

R: Resistor of approximately the

same resistance value as the load

RC

Diode

Varistor

3. Do not use a contact protection circuit as shown

below:

Generally,switchingaDCinductiveloadismoredifcult

than switching a DC resistive load. Using an appropriate

arc suppressor will improve the switching characteristics of

a DC inductive load.

3. Usage, transport, and storage conditions

1. Temperature, humidity, atmospheric pressure

during usage, transport, and storage.

➀ Temperature: –45°C to +85°C (no freezing)

When the temperature is 70 to 80°C, reduce

the 6A max. switching current by 0.1 A/°C

➁ Humidity: 5 to 85%RH (no condensation)

The humidity range varies with temperature.

Use within the range indicated in the chart

below.

➂ Atmospheric pressure: 86 to 106 kPa

C:0.1to1μF

This protection circuit can be used

for both AC and DC load power

circuits.

R: Resistor of approximately the

same resistance value as the load

C:0.1to1μF

This protection circuit can be used

for DC load power circuits. Use a

diode with the following ratings.

Reverse withstand voltage:

Power voltage of the load circuit

× 10

Forward current:

More than the load current

This protection circuit can be used

for both AC and DC load power

circuits.

For a best result, when using on a

power voltage of 24 to 48V AC/DC,

connect a varistor across the load.

When using on a power voltage

of 100 to 240V AC/DC, connect a

varistor across the contacts.

This protection circuit is very effective in arc

suppression when opening the contacts. But,

the capacitor is charged while the contacts

are opened. When the contacts are closed,

the capacitor is discharged through the

contacts, increasing the possibility of contact

welding.

This protection circuit is very effective in arc

suppression when opening the contacts.

But, when the contacts are closed, a current

owstochargethecapacitor,causingcontact

welding.

Operating temperature and humidity range

2. Condensation

Condensation occurs when there is a sudden

change in temperature under high temperature

and high humidity conditions. The relay insulation may deteriorate due to condensation.

3. Freezing

Condensation or other moisture may freeze on

the relay when the temperatures is lower than

0ºC. This causes problems such as sticking of

movable parts or delay in operation.

4. Low temperature, low humidity environments

Plastic parts may become brittle when used in

low temperature and low humidity environments.

4. Panel Mounting

When mounting DIN rail mount sockets on a panel,

take the following into consideration.

Use M3.5 screws, spring washers, and hex nuts.•

For mounting hole layout, see page 6.•

Keep the tightening torque within 0.49 to 0.68 •

m. Excessive tightening may cause damage to

N

·

the socket.

5. Others

1. General notice:

➀ To maintain the initial characteristics, do not

drop or shock the relay.

➁ The relay cover cannot be removed from the

base during normal operation. To maintain

the initial characteristics, do not remove the

relay cover.

➂ Use the relay in environments free from

condensation, dust, sulfur dioxide (SO

hydrogensulde(H

S).

2

), and

2

➃ The RF1V relay cannot be washed as it is not

asealedtype.Alsomakesurethatuxdoes

not leak to the PC board and enter the relay.

2. Connecting outputs to electronic circuits:

When the output is connected to a load which

responds very quickly, such as an electronic

circuit, contact bouncing causes incorrect operation of the load. Take the following measures

into consideration.

➀ Connect an integration circuit.

➁ Suppress the pulse voltage due to bouncing

within the noise margin of the load.

3. Do not use relays in the vicinity of strong mag-

neticeld,asthismayaffectrelayoperation.

4. UL and CSA ratings may differ from product

rated values determined by IDEC.

6. Notes on PC Board Mounting

When mounting 2 or more relays on a PC board, •

keep a minimum spacing of 10 mm in each

direction. If used without spacing of 10 mm,

rated current and operating temperature differs.

Consult IDEC.

Manual soldering: Solder the terminals at 400°C•

within 3 sec.

Auto-soldering: Preliminary heating at 120°C •

within 120 sec. Solder at

Becausetheterminalpartislledwithepoxy•

resin, do not excessively solder or bend the

terminal. Otherwise, air tightness will degrade.

Avoid the soldering iron from touching the relay •

coverortheepoxylledterminalpart.

Useanon-corrosiveresinux.

260°C±5°C within 6 sec.

Page 8

RF1V Force Guided Relays/ SF1V Relay Sockets

(4)

(3)

K3

K1

KM1

M

S2

RF1V force guided contacts

L (–)

0V

F3 to F5

K2

KM2

KM1

KM2

K1

K3

K2

F2

Safety guard open

12

HS6B

Subminiature Interlock Switch

S1

4

3

F1

L(+)

24V DC

(1)

(2)

(5)

S1: HS6B subminiature

interlock switch

S2: Start switch

Start switch (S2)

ON→OFF

K3: Force guided

contacts

Safety guard open

Safety guard closed

K1, K2: Force guided

contacts

Safety contactor output

(KM1

,

KM2)

IDEC CORPORATION (USA)

1175 Elko Drive, Sunnyvale, CA 94089-2209, USA

Tel: +1-408-747-0550 / (800) 262-IDEC (4332)

Fax: +1-408-744-9055 / (800) 635-6246

E-mail: opencontact@idec.com

IDEC CANADA LIMITED

3155 Pepper Mill Court, Unit 4, Mississauga,

Ontario, L5L 4X7, Canada

Tel: +1-905-890-8561, Toll Free: (888) 317-4332

Fax: +1-905-890-8562

E-mail: sales@ca.idec.com

IDEC AUSTRALIA PTY. LTD.

2/3 Macro Court, Rowville, Victoria 3178, Australia

Tel: +61-3-9763-3244, Toll Free: 1800-68-4332

Fax: +61-3-9763-3255

E-mail: sales@au.idec.com

IDEC ELECTRONICS LIMITED

Unit 2, Beechwood, Chineham Business Park,

Basingstoke, Hampshire RG24 8WA, UK

Tel: +44-1256-321000, Fax: +44-1256-327755

E-mail: sales@uk.idec.com

7-31, Nishi-Miyahara 1-Chome, Yodogawa-ku, Osaka 532-8550, Japan

Tel: +81-6-6398-2571, Fax: +81-6-6392-9731

E-mail: marketing@idec.co.jp

Specifications and other descriptions in this catalog are subject to change without notice.

Cat. No. EP1260-0 MARCH 2009 8.2T PRINTED IN JAPAN

IDEC ELEKTROTECHNIK GmbH

Wendenstrasse 331, 20537 Hamburg, Germany

Tel: +49-40-25 30 54 - 0, Fax: +49-40-25 30 54 - 24

E-mail: service@idec.de

IDEC (SHANGHAI) CORPORATION

Room 608-609, 6F, Gangtai Plaza, No. 700,

Yan'an East Road, Shanghai 200001, PRC

Tel: +86-21-5353-1000, Fax: +86-21-5353-1263

E-mail: idec@cn.idec.com

IDEC (BEIJING) CORPORATION

Room 211B, Tower B, The Grand Pacific Building,

8A Guanghua Road, Chaoyang District,

Beijing 100026, PRC

Tel: +86-10-6581-6131, Fax: +86-10-6581-5119

IDEC (SHENZHEN) CORPORATION

Unit AB-3B2, Tian Xiang Building, Tian’an Cyber Park,

Fu Tian District, Shenzhen, Guang Dong 518040, PRC

Tel: +86-755-8356-2977, Fax: +86-755-8356-2944

IDEC IZUMI (H.K.) CO., LTD.

Units 11-15, Level 27, Tower 1,

Millennium City 1, 388 Kwun Tong Road,

Kwun Tong, Kowloon, Hong Kong

Tel: +852-2803-8989, Fax: +852-2565-0171

E-mail: info@hk.idec.com

IDEC TAIWAN CORPORATION

8F-1, No. 79, Hsin Tai Wu Road, Sec. 1,

Hsi-Chih, Taipei County, Taiwan

Tel: +886-2-2698-3929, Fax: +886-2-2698-3931

E-mail: service@tw.idec.com

IDEC IZUMI ASIA PTE. LTD.

No. 31, Tannery Lane #05-01,

HB Centre 2, Singapore 347788

Tel: +65-6746-1155, Fax: +65-6844-5995

E-mail: info@sg.idec.com

www.idec.com

(090319)

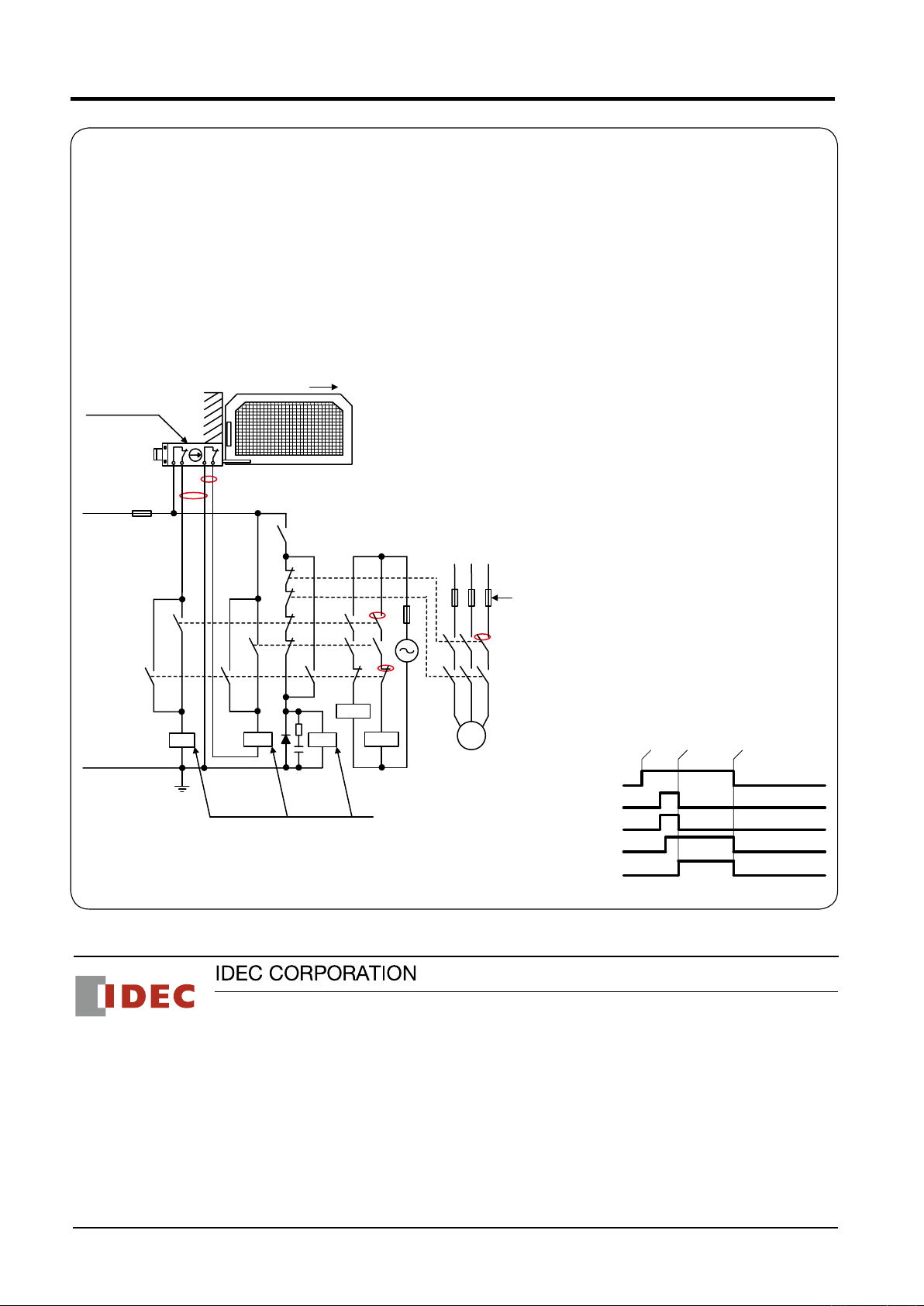

Control circuits conforming with safety categories 2, 3, and 4 can be constructed.

Safety category 4 control circuits•

The circuit example below consisting of interlock

switches, force guided relays, and safety contactors are

only a part of a safety-related system in a machine. In

actual machines, risk assessment must be performed

taking various aspects into consideration such as

hazard types, safeguarding measures, and change of

hazard level in operating mode, in order to reduce the

risk of the entire machine to a tolerable level. The safety

category of a machine needs to be evaluated for the

entire safety-related system.

Safety function at occurrence of single faults•

1. If a short-circuit failure occurs at either of the S1 channels, when

the safety guard is opened, K2 does not turn off but K1 turns off, so

safety function (power interruption to the motor) is maintained. The

system does not restart because the NC contact of K2 remains open

and K3 is not energized even when S2 is turned on.

2. If a short-circuit failure occurs between S1 channels, the potential difference of K1 and K2 coils become 0V, turning K1 and K2 off. (Fault

detection function between safety input circuits)

3. If NO contact of KM1 is welded, KM2 turns off when the safety guard

is opened, so the safety function (power interruption to the motor)

is maintained. The system does not restart because the NC contact

remains open and K3 is not energized even when S2 is turned on.

4. If the NO contact of K1 is welded, K2 turns off when the safety guard

is opened, so the safety function (power interruption to the motor) is

maintained. The system does not restart because the NC contact of

K1 remains open and K3 is not energized even when S2 is turned on.

5. If NC contact of K3 is welded, K1 and K2 turn off when the safety

guard is opened, so the safety function (power interruption to the

motor) is maintained. Also, the system does not restart because NO

contact of K3 does not shut, therefore K1 and K2 cannot be energized.

S1: HS6B subminiature interlock switch

S2: Start switch (HW series momentary type)

K1, K2, K3: RF1V force guided relays

KM1, KM2: Safety contactor

M: Motor

F1: Protection fuse for safety circuit

F2: Protection fuse for mechanical contact

output of force guided relay contact

F3 to F5: Protection fuse for mechanical contact

output of safety contactors

Time Chart•

Loading...

Loading...