Page 1

April 22, 2002

OPENNET CONTROLLER

PID INSTRUCTION

Page 2

PID INSTRUCTION

Introduction

The PID instruction implements a PID (proportional, integral, and derivative) algorithm with built-in auto tuning to determine PID parameters, such as proportional gain, integral time, derivative time, and control action automatically. The PID

instruction is primarily designed for use with an analog I/O module to read analog input data, and turns on and off a designated output to perform PID control in applications such as temperature control described in the application example on

page 14. In addition, when the output manipulated variable is converted, the PID instruction can also generate an analog

output using an analog I/O module.

Warning

• Special technical knowledge about the PID control is required to use the PID function of the

OpenNet Controller. Use of the PID function without understanding the PID control may cause

the OpenNet Controller to perform unexpected operation, resulting in disorder of the control system, damage, or accidents.

• When using the PID instruction for feedback control, emergency stop and interlocking circuits

must be configured outside the OpenNet Controller. If such a circuit is configured inside the

OpenNet Controller, failure of inputting the process variable may cause equipment damage or

accidents.

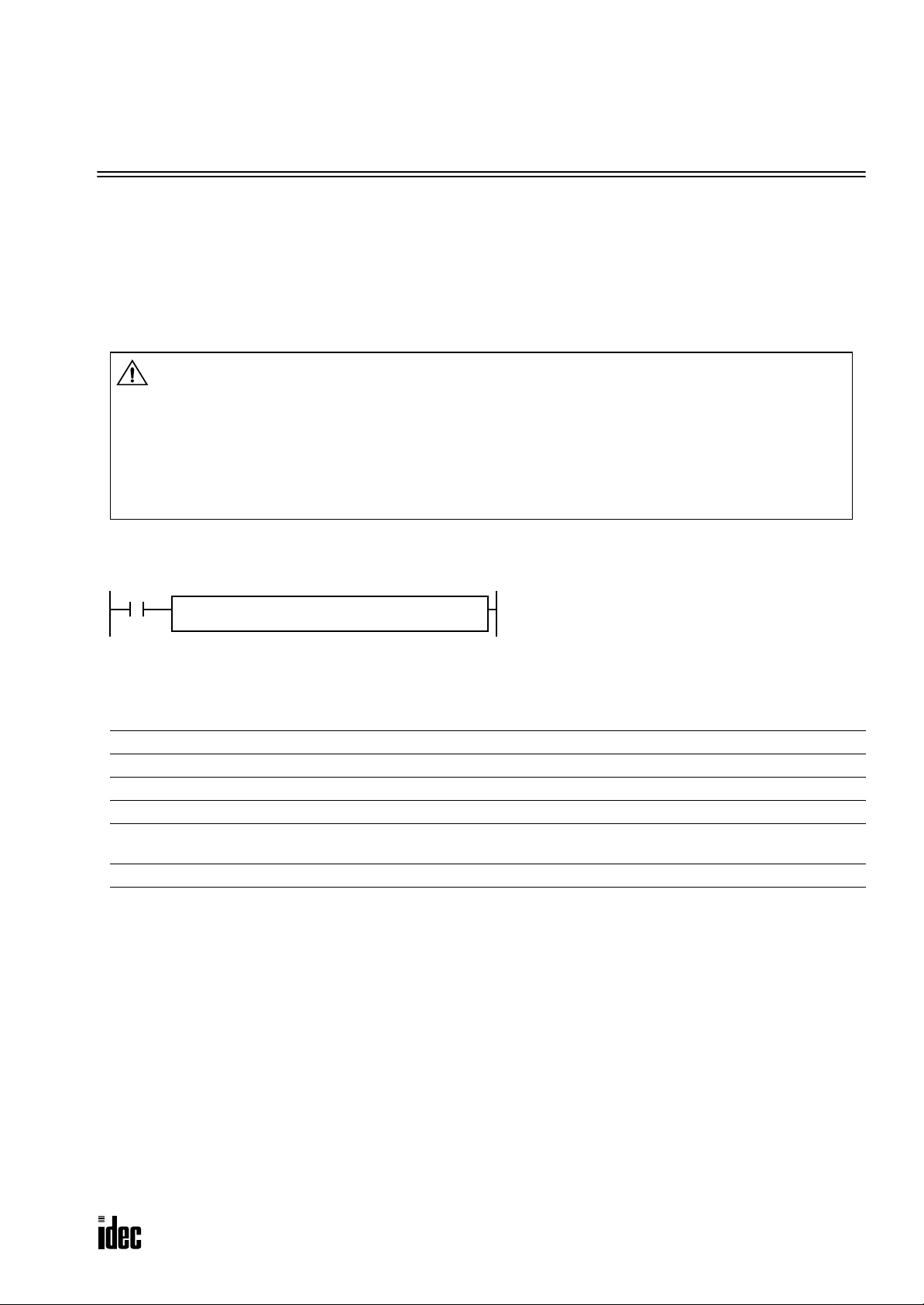

PID (PID Control)

PID

Valid Operands

Operand Function I Q M R T C D L Constant

S1 (Source 1) Control register — — — — — — D0-D7973 — —

S2 (Source 2) Control relay — Q0-Q590 M0-M2550 — — — — — —

S3 (Source 3) Set point — — — — — — D0-D7999 — 0-4000

S4 (Source 4)

D1 (Destination 1) Manipulated variable — — — — — — D0-D7999 — —

S1

*****

Process variable

(before conversion)

S2

*****S3*****S4*****

— — — — — — D0-D7999 L100-L705 —

D1

*****

When input is on, auto tuning and/or PID action is executed according to the value (0 through 2) stored in a

data register operand assigned for operation mode.

A maximum of 42 PID instructions can be used in a

user program.

Source operand S1 (control register) uses 27 data registers starting with the operand designated as S1. Data registers D0

through D7973 can be designated as S1. For details, see the following pages.

Source operand S2 (control relay) uses 8 points of outputs or internal relays starting with the operand designated as S2.

Outputs Q0 through Q590 or internal relays M0 through M2550 can be designated as S2. For details, see page 10.

Source operand S3 (set point): When the linear con version is disabled (S1+4 set to 0), the valid range of the set point (S3)

is 0 through 4000 which can be designated using a data register or constant. When the linear conversion is enabled (S1+4

set to 1), the valid range is –32768 to 32767 that is a value after linear conversion. Use a data register to designate a negative value for a set point when the linear conversion is used. For details, see page 12.

Source operand S4 (process variable) is designated using a data register or link register. When reading input data from an

analog input module, designate a proper link register number depending on the slot position of the analog input module

and the channel number connected to the analog input. For details, see page 12.

Destination operand D1 (manipulated variable) stores –32768 through 32767 that is a calculation result of the PID action.

For details, see page 13.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 1

Page 3

PID INSTRUCTION

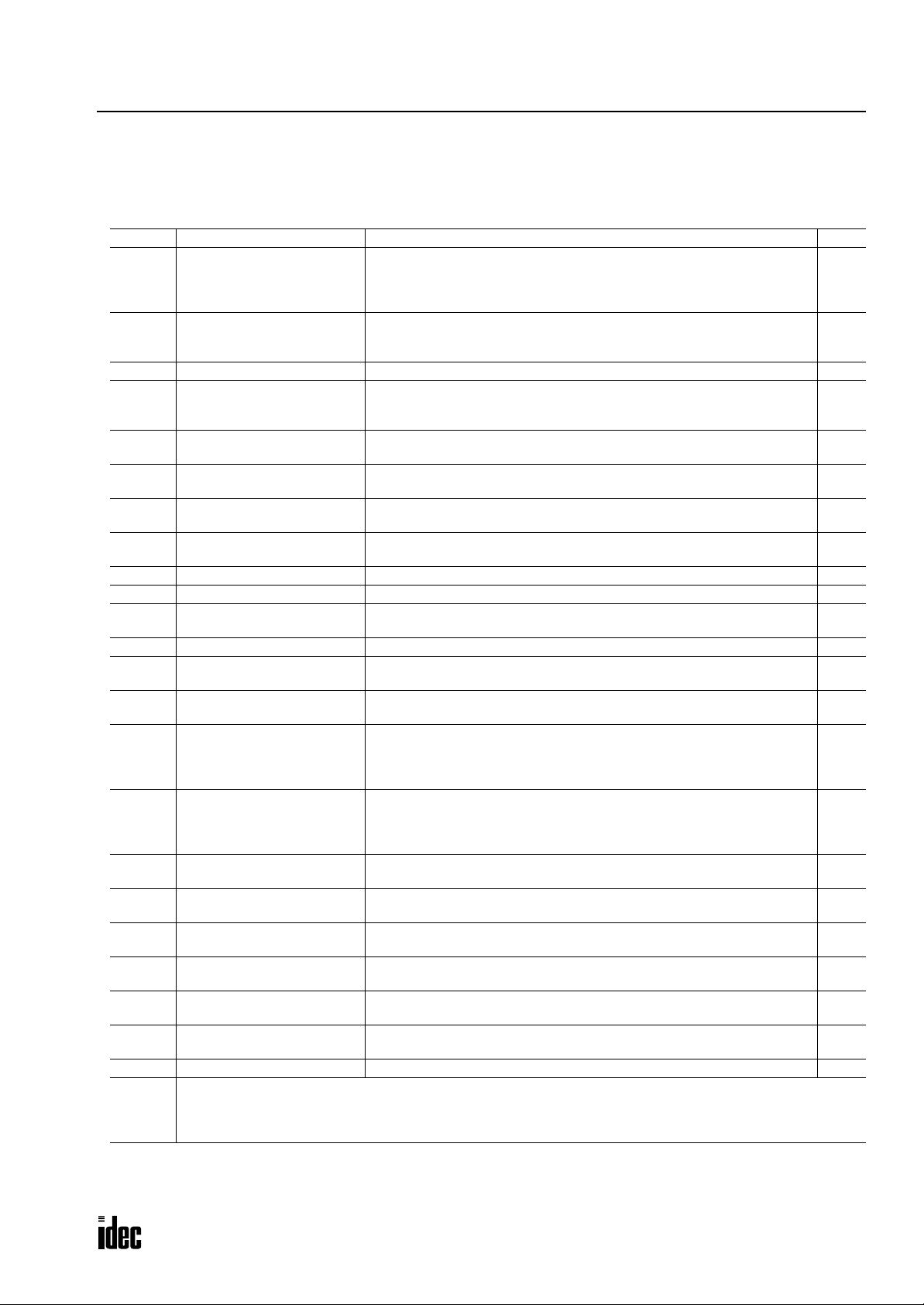

Source Operand S1 (Control Register)

Store appropriate values to data registers starting with the operand designated by S1 before executing the PID instruction

as required, and make sure that the values are within the valid range. Operands S1+0 through S1+2 are for read only, and

operands S1+23 through S1+26 are reserved for the system program.

Operand Function Description R/W

When S1+4 (linear conversion) = 1 (enable linear conversion):

S1+0

S1+1 Output manipulated variable

S1+2 Operating status Stores the operating or error status of the PID instruction. R

S1+3 Operation mode

S1+4 Linear conversion

S1+5

S1+6

S1+7 Proportional gain

S1+8 Integral time 1 to 65535 (0.1 sec to 6553.5 sec), 0 disables integral action R/W

S1+9 Derivative time 1 to 65535 (0.1 sec to 6553.5 sec), 0 disables derivative action R/W

S1+10 Integral start coefficient

S1+11 Input filter coefficient 0 to 99 (0% to 99%), ≥100 designates 99% R/W

S1+12 Sampling period

S1+13 Control period

S1+14 High alarm value

S1+15 Low alarm value

S1+16

S1+17

S1+18

S1+19 AT sampling period

S1+20 AT control period

S1+21 AT set point

S1+22 AT output manipulated variable 0 to 100 (≥101 designates 100) R/W

S1+23

S1+24

S1+25

S1+26

Process variable

(after conversion)

Linear conversion maximum

value

Linear conversion minimum

value

Output manipulated variable

upper limit

Output manipulated variable

lower limit

Manual mode output

manipulated variable

Stores the process variable after conversion.

When S1+4 (linear conversion) = 0 (disable linear conversion):

Stores the process variable without conversion.

Stores the output manipulated variable (manual mode output variable and AT

output manipulated variable) in percent.

0 to 100 (0% to 100%)

0: PID action

1: AT (auto tuning) + PID action

2: AT (auto tuning)

0: Disable linear conversion

1: Enable linear conversion

–32768 to +32767 R/W

–32768 to +32767 R/W

1 to 10000 (0.01% to 100.00%)

0 designates 0.01%, ≥10001 designates 100.00%

1 to 100 (1% to 100%), 0 and ≥101 (except 200) designate 100%

200 executes integral action within the proportional range

1 to 10000 (0.01 sec to 100.00 sec)

0 designates 0.01 sec, ≥10001 designates 100.00 sec

1 to 500 (0.1 sec to 50.0 sec)

0 designates 0.1 sec, ≥501 designates 50.0 sec

When S1+4 (linear conversion) = 0: 0 to 4000 (≥4001 designates 4000)

When S1+4 = 1: Linear conversion min. ≤ High alarm ≤ Linear conversion max.

When S1+14 < S1+6 (linear conversion min.), S1+6 becomes high alarm.

When S1+14 > S1+5 (linear conversion max.), S1+5 becomes high alarm.

When S1+4 (linear conversion) = 0: 0 to 4000 (≥4001 designates 4000)

When S1+4 = 1: Linear conversion min. ≤ Low alarm ≤ Linear conversion max.

When S1+15 < S1+6 (linear conversion min.), S1+6 becomes low alarm.

When S1+15 > S1+5 (linear conversion max.), S1+5 becomes low alarm.

0 to 100, 10001 to 10099 (other values designate 100) R/W

0 to 100 (≥101 designates 100) R/W

0 to 100 (≥101 designates 100) R/W

1 to 10000 (0.01 sec to 100.00 sec)

0 designates 0.01 sec, ≥10001 designates 100.00 sec

1 to 500 (0.1 sec to 50.0 sec)

0 designates 0.1 sec, ≥501 designates 50.0 sec

When S1+4 (linear conversion) = 0: 0 to 4000 (≥4001 designates 4000)

When S1+4 = 1: Linear conversion min. ≤ AT set point ≤ Linear conversion max.

— Reserved for processing the PID instruction —

R

R

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Note: The value stored in the data register designated by S1+3 (operation mode) is checked only when the start input for

the PID instruction is turned on. Values in all other control registers are refreshed in every scan.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 2

Page 4

PID INSTRUCTION

S1+0 Process Variable (after conversion)

When the linear conversion is enabled (S1+4 set to 1), the data register designated by operand S1+0 stores the linear conversion result of the process variable designated by operand S4. The process variable (S1+0) takes a value between the linear conversion minimum value (S1+6) and the linear conversion maximum value (S1+5).

When the linear conversion is disabled (S1+4 is set to 0), the data register designated by operand S1+0 stores the same

value as the process variable designated by operand S4.

S1+1 Output Manipulated Variable

While the PID action is in progress, the data register designated by operand S1+1 holds 0 through 100 read from the

manipulated variable, –32768 through 32767, stored in the data register designated by operand D1, omitting values less

than 0 and greater than 100. The percent value in S1+1 determines the ON duration of the control output (S2+6) in proportion to the control period (S1+13).

While manual mode is enabled with the auto/manual mode control relay (S2+1) set to on, S1+1 stores 0 through 100 read

from the manual mode output manipulated variable (S1+18).

While auto tuning (AT) is in progress, S1+1 stores 0 through 100 read from the AT output manipulated variable (S1+22).

S1+2 Operating Status

The data register designated by operand S1+2 stores the operating or error status of the PID instruction.

Status codes 1X through 6X contain the time elapsed after starting auto tuning or PID action. X changes from 0 through 9

in 10-minute increments to represent 0 through 90 minutes. The time code remains 9 after 90 minutes has elapsed. When

the operation mode (S1+3) is set to 1 (AT+PID), the time code is reset to 0 at the transition from AT to PID.

Status codes 100 and above indicate an error, stopping the auto tuning or PID action. When these errors occur, a user program execution error will result, turning on the ERR LED and special internal relay M8004 (user program execution

error). To continue operation, enter correct parameters and turn on the start input for the PID instruction.

Status Code Description Operation

1X AT in progress

2X AT completed

5X PID action in progress

6X

100 The operation mode (S1+3) is set to a value over 2.

101 The linear conversion (S1+4) is set to a value over 1.

102

103

104

105

106

107

200

201

PID set point (S3) is reached. Status code changes from 5X to 6X once the PID set point is

reached.

When the linear conversion is enabled (S1+4 to 1), the linear conversion maximum value

(S1+5) and the linear conversion minimum value (S1+6) are set to the same value.

The output manipulated variable upper limit (S1+16) is set to a value smaller than the output manipulated variable lower limit (S1+17).

When the linear conversion is enabled (S1+4 set to 1), the AT set point (S1+21) is set to a

value larger than the linear conversion maximum value (S1+5) or smaller than the linear conversion minimum value (S1+6).

When the linear conversion is disabled (S1+4 set to 0), the AT set point (S1+21) is set to a

value larger than 4000.

When the linear conversion is enabled (S1+4 set to 1), the set point (S3) is set to a value

larger than the linear conversion maximum value (S1+5) or smaller than the linear conversion minimum value (S1+6).

When the linear conversion is disabled (S1+4 set to 0), the set point (S3) is set to a value

larger than 4000.

The current control action (S2+0) differs from that determined at the start of AT. To restart

AT, set correct parameters referring to the probable causes listed below:

• The manipulated variable (D1) or the control output (S2+6) is not outputted to the control

target correctly.

• The process variable is not stored to the operand designated by S4.

• The AT output manipulated variable (S1+22) is not set to a large value so that the process

variable (S4) can change sufficiently.

• A large disturbance occurred.

AT failed to complete normally because the process variable (S4) fluctuated excessively. To

restart AT, set the AT sampling period (S1+19) or the input filter coefficient (S1+11) to a

larger value.

AT is normal.

PID action is normal.

PID action or AT is

stopped because of

incorrect parameter

settings.

AT is stopped because

of AT execution error.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 3

Page 5

PID INSTRUCTION

S1+3 Operation Mode

When the start input for the PID instruction is turned on, the CPU module checks the value stored in the data register designated by S1+3 and executes the selected operation. The selection cannot be changed while ex ecuting the PID instruction.

0: PID action

The PID action is executed according to the designated PID parameters such as proportional gain (S1+7), integral time

(S1+8), derivative time (S1+9), and control action (S2+0).

1: AT (auto tuning) + PID action

Auto tuning is first executed according to the designated AT parameters such as AT sampling period (S1+19), AT control period (S1+20), AT set point (S1+21), and AT output manipulated variable (S1+22). As a result of auto tuning, PID

parameters are determined such as proportional gain (S1+7), integral time (S1+8), derivative time (S1+9), and control

direction (S2+0), then PID action is executed according to the derived PID parameters.

2: AT (auto tuning)

Auto tuning is executed according to designated AT parameters to determine PID parameters such as proportional gain

(S1+7), integral time (S1+8), derivative time (S1+9), and control direction (S2+0); PID action is not executed.

S1+4 Linear Conversion

0: Disable linear conversion

Linear conversion is not executed. When the linear conversion is disabled (S1+4 set to 0), the analog input data (0

through 4000) from the analog I/O module is stored to the process variable (S4), and the same value is stored to the

process variable (S1+0) without conversion.

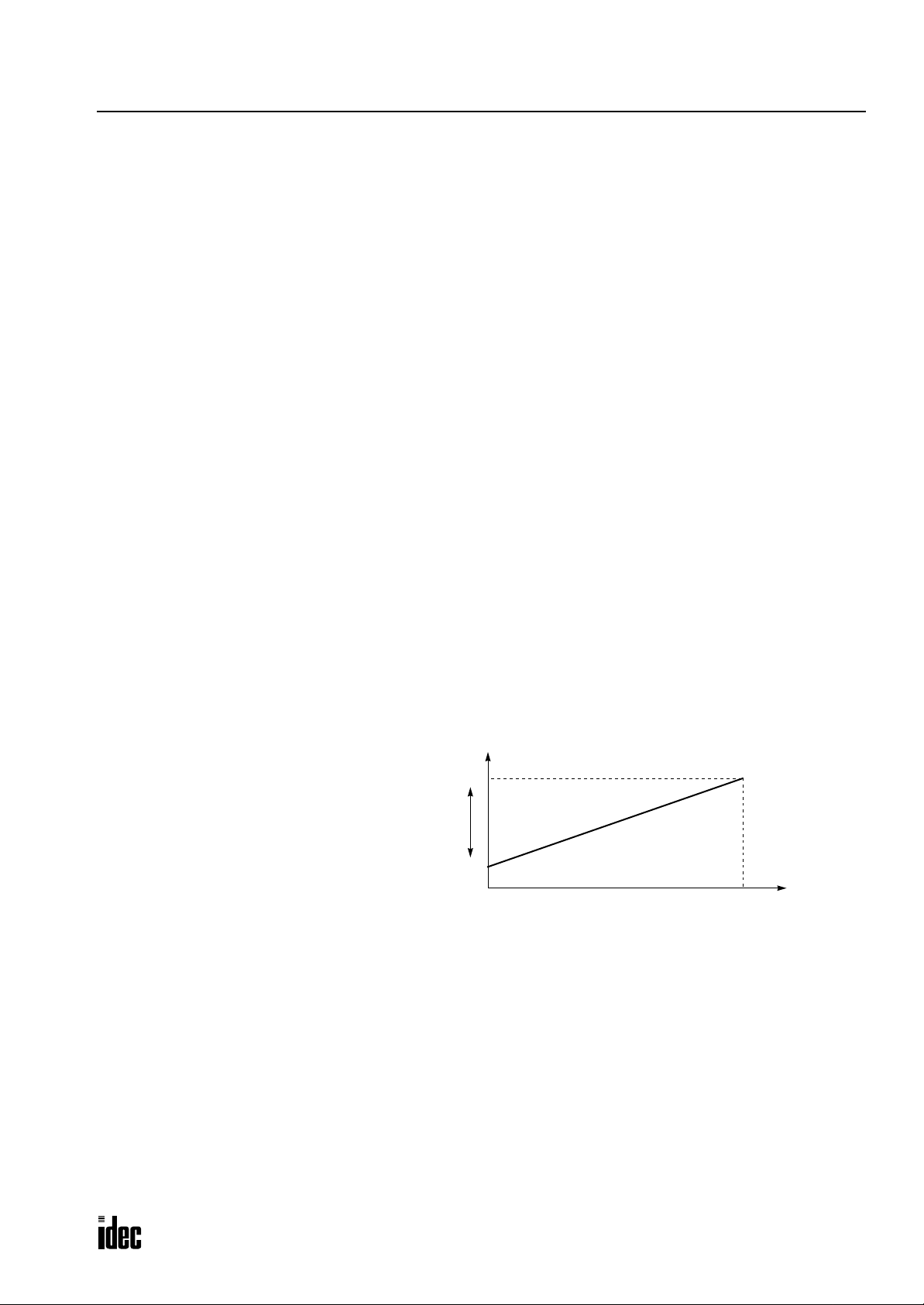

1: Enable linear conversion

The linear conversion function is useful for scaling the process variable to the actual measured value in engineering

units.

When the linear conversion is enabled (S1+4 set to 1), the analog input data (0 through 4000) from the analog I/O module is linear-converted, and the result is stored to the process variable (S1+0). When using the linear conversion, set

proper values to the linear conversion maximum value (S1+5) and linear conv ersion minimum value (S1+6) to specify

the linear conversion output range. When using the linear conversion function in a temperature control application,

temperature values can be used to designate the set point (S3), high alarm value (S1+14), lo w alarm v alue (S1+15), and

AT set point (S1+21), and also to read the process variable (S1+0).

Linear Conversion Result

Linear Conversion Maximum Value (S1+5)

Set point (S3), AT set point (S1+21), and process

variable (S1+0) must be within this range.

Linear Conversion Minimum Value (S1+6)

4000

S1+5 Linear Conversion Maximum Value

0

Analog Input Data

When the linear conversion is enabled (S1+4 set to 1), set the linear conversion maximum value to the data register designated by operand S1+5. Valid values are –32768 through 32767, and the linear conversion maximum value must be larger

than the linear conversion minimum v alue (S1+6). Select an appropriate v alue for the linear conversion maximum value to

represent the maximum value of the input signal to the analog I/O module.

When the linear conversion is disabled (S1+4 set to 0), you don’ t ha v e to set the linear conversion maximum value (S1+5).

S1+6 Linear Conversion Minimum Value

When the linear conversion is enabled (S1+4 set to 1), set the linear conversion minimum value to the data register designated by operand S1+6. Valid values are –32768 through 32767, and the linear conv ersion minimum v alue must be smaller

than the linear conversion maximum v alue (S1+5). Select an appropriate v alue for the linear conversion minimum value to

represent the minimum value of the input signal to the analog I/O module.

When the linear conversion is disabled (S1+4 set to 0), you don’t have to set the linear conversion minimum value (S1+6).

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 4

Page 6

PID INSTRUCTION

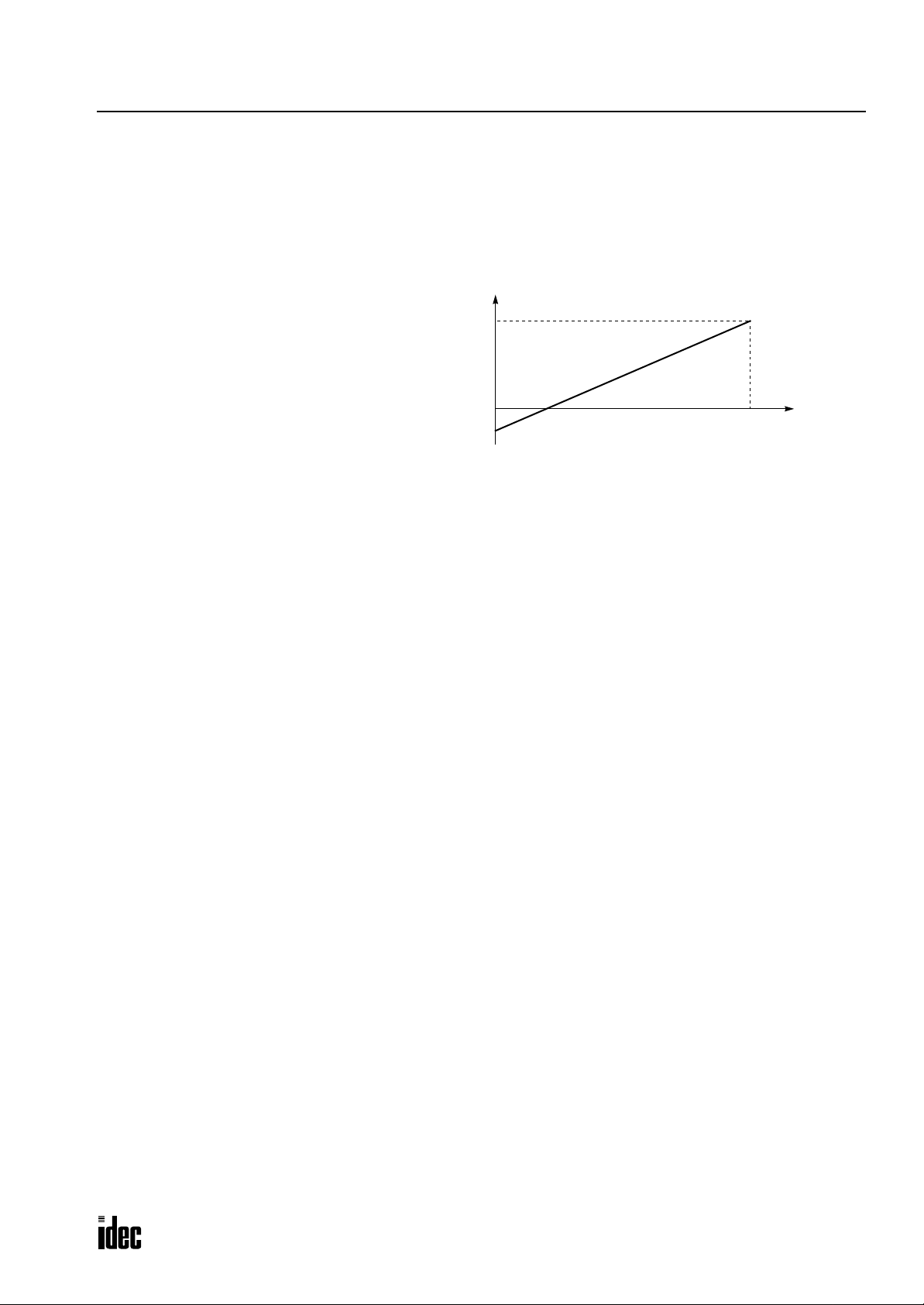

Example:

When the transducer connected to the analog input module has an input range of –50°C through +199°C, set the following

values. The temperature values are multiplied by 10 to calculate the process variable.

Control mode (S1+4): 1 (enable linear conversion)

Linear conversion maximum value (S1+5): 1990 (199.0°C)

Linear conversion minimum value (S1+6): –500 (–50.0°C)

Process Variable after Conversion (S1+0)

Linear Conversion Maximum Value (S1+5): 1990 (199.0°C)

Linear Conversion Minimum Value (S1+6): –500 (–50.0°C)

S1+7 Proportional Gain

0

Digital Output from Analog Input Module

4000

The proportional gain is a parameter to determine the amount of proportional action in the proportional band.

When auto tuning is used by setting the operation mode (S1+3) to 1 (AT+PID) or 2 (AT), a proportional gain is determined

automatically and does not have to be specified by the user.

When auto tuning is not used by setting the operation mode (S1+3) to 0 (PID), set a required value of 1 through 10000 to

specify a proportional gain of 0.01% through 100.00% to the data register designated by operand S1+7. When S1+7 stores

0, the proportional gain is set to 0.01%. When S1+7 stores a value larger than 10000, the proportional gain is set to

100.00%.

When the proportional gain is set to a large value, the proportional band becomes small and the response becomes fast, b ut

overshoot and hunching will be caused. In contrast, when the proportional gain is set to a small value, overshoot and

hunching are suppressed, but response to disturbance will become slow.

While the PID action is in progress, the proportional gain value can be changed by the user.

S1+8 Integral Time

When only the proportional action is used, a certain amount of difference (offset) between the set point (S3) and the process variable (S1+0) remains after the control target has reached a stable state. An integral action is needed to reduce the

offset to zero. The integral time is a parameter to determine the amount of integral action.

When auto tuning is used by setting the operation mode (S1+3) to 1 (AT+PID) or 2 (AT), an integral time is determined

automatically and does not have to be specified by the user.

When auto tuning is not used by setting the operation mode (S1+3) to 0 (PID), set a required value of 1 through 65535 to

specify an integral time of 0.1 sec through 6553.5 sec to the data register designated by operand S1+8. When S1+8 is set to

0, the integral action is disabled.

When the integral time is too short, the integral action becomes too large, resulting in hunching of a long period. In contrast, when the integral time is too long, it takes a long time before the process variable (S1+0) reaches the set point (S3).

While the PID action is in progress, the integral time value can be changed by the user.

S1+9 Derivative Time

The derivati v e action is a function to adjust the process v ariable (S1+0) to the set point (S3) by increasing the manipulated

variable (D1) when the set point (S3) is changed or when the difference between the process variable (S1+0) and the set

point (S3) is increased due to disturbance. The deriv ative time is a parameter to determine the amount of derivative action.

When auto tuning is used by setting the operation mode (S1+3) to 1 (AT+PID) or 2 (AT), a derivative time is determined

automatically and does not have to be specified by the user.

When auto tuning is not used by setting the operation mode (S1+3) to 0 (PID), set a required value of 1 through 65535 to

specify a derivative time of 0.1 sec through 6553.5 sec to the data register designated by operand S1+9. When S1+9 is set

to 0, the derivative action is disabled.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 5

Page 7

PID INSTRUCTION

When the derivative time is set to a large value, the derivative action becomes large. When the derivative action is too

large, hunching of a short period is caused.

While the PID action is in progress, the derivative time value can be changed by the user.

S1+10 Integral Start Coefficient

The integral start coefficient is a parameter to determine the point, in percent of the proportional term, where to start the

integral action. Normally, the data register designated by operand S1+10 (integral start coefficient) stores 0 to select an

integral start coefficient of 100% and the integral start coefficient disable control relay (S2+3) is turned off to enable integral start coefficient. When the PID action is e xecuted according to the PID parameters determined by auto tuning, proper

control is ensured with a moderate overshoot and no offset.

It is also possible to set a required value of 1 through 100 to start the integral action at 1% through 100% to the data register designated by operand S1+10. When S1+10 stores 0 or a value larger than 100 (except for 200), the integral start coefficient is set to 100%.

When 200 is set to S1+10, the integral action is enabled only while the process variable (S4) is within the proportional

band. When the process variable runs of f the proportional band due to disturbance or changing of the set point, the inte gral

action is disabled, so that adjustment of the output manipulated variable (S1+1) is improved with little overshoot and

undershoot.

To enable the integral start coefficient, turn off the integral start coefficient disable control relay (S2+3). When S2+3 is

turned on, the integral start coefficient is disabled and the integral term takes effect at the start of the PID action.

When the integral term is enabled at the start of the PID action, a large overshoot is caused. The overshoot can be suppressed by delaying the execution of the integral action in coordination with the proportional term. The PID instruction is

designed to achieve proper control with a small or moderate overshoot when the integral start coefficient is set to 100%.

Overshoot is most suppressed when the integral start coefficient is set to 1% and is least suppressed when the inte gral start

coefficient is set to 100%. When the integral start coefficient is too small, overshoot is eliminated but offset is caused.

S1+11 Input Filter Coefficient

The input filter has an effect to smooth out fluctuations of the process variable (S4). Set a required v alue of 0 through 99 to

specify an input filter coefficient of 0% through 99% to the data register designated by operand S1+11. When S1+11 stores

a value larger than 99, the input filter coefficient is set to 99%. The larger the coefficient, the larger the input filter effect.

The input filter is effective for reading a process variable (S4) such as temperature data when the value changes at each

sampling time. The input filter coefficient is in effect during auto tuning and PID action.

S1+12 Sampling Period

The sampling period determines the interval to execute the PID instruction. Set a required value of 1 through 10000 to

specify a sampling period of 0.01 sec through 100.00 sec to the data register designated by operand S1+12. When S1+12

stores 0, the sampling period is set to 0.01 sec. When S1+12 stores a value lar ger than 10000, the sampling period is set to

100.00 sec.

When a sampling period is set to a value smaller than the scan time, the PID instruction is executed every scan.

Example – Sampling period: 40 msec, Scan time: 80 msec (Sampling period ≤ Scan time)

1 scan

PID

Executed

80 msec 80 msec 80 msec 80 msec 80 msec

1 scan 1 scan 1 scan 1 scan 1 scan

PID

Executed

PID

Executed

PID

Executed

PID

Executed

PID

Executed

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 6

Page 8

Example – Sampling period: 80 msec, Scan time: 60 msec (Sampling period > Scan time)

PID INSTRUCTION

1 scan

PID

Executed

1 scan 1 scan 1 scan 1 scan 1 scan 1 scan 1 scan

60 msec

60 msec (120 msec)

60 msec 60 msec 60 msec 60 msec 60 msec 60 msec

PID Not

Executed

40 msec

PID

Executed

(100 msec)

20 msec

PID

Executed

80 msec

0 msec

PID

Executed

60 msec (120 msec)

PID Not

Executed

40 msec

PID

Executed

(100 msec)

20 msec

PID

Executed

S1+13 Control Period

The control period determines the duration of the ON/OFF cycle of the control output (S2+6) that is turned on and off

according to the output manipulated variable (S1+1) calculated by the PID action or derived from the manual mode output

manipulated variable (S1+18). Set a required value of 1 through 500 to specify a control period of 0.1 sec through 50.0 sec

to the data register designated by operand S1+13. When S1+13 stores 0, the control period is set to 0.1 sec. When S1+13 is

set to a value larger than 500, the control period is set to 50.0 sec.

The ON pulse duration of the control output (S2+6) is determined by the product of the control period (S1+13) and the

output manipulated variable (S1+1).

Example – Control period: 5 sec (S1+13 is set to 50)

80% 60% 50%Output Manipulated Variable (S1+1)

ON (4 sec) OFF ON (3 sec) ON (2.5 sec)OFF OFFOFFControl Output (S2+6)

Control Period (S1+13)

5 sec

5 sec 5 sec

S1+14 High Alarm Value

The high alarm value is the upper limit of the process variable (S1+0) to generate an alarm. When the process variable is

higher than or equal to the high alarm value while the start input for the PID instruction is on, the high alarm output control

relay (S2+4) is turned on. When the process variable is lo wer than the high alarm v alue, the high alarm output control relay

(S2+4) is turned off.

When the linear conversion is disabled (S1+4 set to 0), set a required high alarm value of 0 through 4000 to the data register designated by operand S1+14. When S1+14 stores a value larger than 4000, the high alarm value is set to 4000.

When the linear conversion is enabled (S1+4 set to 1), set a required high alarm v alue of –32768 through 32767 to the data

register designated by operand S1+14. The high alarm value must be larger than or equal to the linear conversion minimum value (S1+6) and must be smaller than or equal to the linear conversion maximum value (S1+5). If the high alarm

value is set to a value smaller than the linear con v ersion minimum v alue (S1+6), the linear conversion minimum value will

become the high alarm value. If the high alarm value is set to a value larger than the linear conversion maximum value

(S1+5), the linear conversion maximum value will become the high alarm value.

S1+15 Low Alarm Value

The low alarm value is the lower limit of the process variable (S1+0) to generate an alarm. When the process variable is

lower than or equal to the low alarm value while the start input for the PID instruction is on, the low alarm output control

relay (S2+5) is turned on. When the process variable is higher than the lo w alarm v alue, the low alarm output control relay

(S2+5) is turned off.

When the linear conversion is disabled (S1+4 set to 0), set a required lo w alarm v alue of 0 through 4000 to the data register

designated by operand S1+15. When S1+15 stores a value larger than 4000, the low alarm value is set to 4000.

When the linear conversion is enabled (S1+4 set to 1), set a required low alarm value of –32768 through 32767 to the data

register designated by operand S1+15. The low alarm v alue must be lar ger than or equal to the linear conversion minimum

value (S1+6) and must be smaller than or equal to the linear conversion maximum value (S1+5). If the low alarm value is

set to a value smaller than the linear conv ersion minimum v alue (S1+6), the linear con v ersion minimum v alue will become

the low alarm value. If the low alarm value is set to a value larger than the linear conversion maximum value (S1+5), the

linear conversion maximum value will become the low alarm value.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 7

Page 9

PID INSTRUCTION

S1+16 Output Manipulated Variable Upper Limit

The value contained in the data register designated by operand S1+16 specifies the upper limit of the output manipulated

variable (S1+1) in two ways: direct and proportional.

S1+16 Value 0 through 100

When S1+16 contains a value 0 through 100, the value directly determines the upper limit of the output manipulated variable (S1+1). If the manipulated variable (D1) is greater than or equal to the upper limit value (S1+1), the upper limit v alue

is outputted to the output manipulated variable (S1+1). Set a required value of 0 through 100 for the output manipulated

variable upper limit to the data register designated by operand S1+16. When S1+16 stores a value larger than 100 (except

10001 through 10099), the output manipulated variable upper limit (S1+16) is set to 100. The output manipulated v ariable

upper limit (S1+16) must be larger than the output manipulated variable lower limit (S1+17).

To enable the manipulated variable upper limit, turn on the output manipulated variable limit enable control relay (S2+2).

When S2+2 is turned off, the output manipulated variable upper limit (S1+16) has no effect.

S1+16 Value 10001 through 10099 (disables Output Manipulated Variable Lower Limit S1+17)

When S1+16 contains a value 10001 through 10099, the value minus 10000 determines the ratio of the output manipulated

variable (S1+1) in proportion to the manipulated variable (D1) of 0 through 100. The output manipulated variable (S1+1)

can be calculated by the following equation:

Output manipulated variable (S1+1) = Manipulated variable (D1) × (N – 10000)

where N is the value stored in the output manipulated variable upper limit (S1+16), 10001 through 10099.

If the manipulated variable (D1) is greater than or equal to 100, 100 multiplied by (N – 10000) is outputted to the output

manipulated variable (S1+1). If D1 is less than or equal to 0, 0 is outputted to S1+1.

To enable the manipulated variable upper limit, turn on the output manipulated variable limit enable control relay (S2+2).

When S2+2 is turned off, the output manipulated variable upper limit (S1+16) has no effect.

When S1+16 is set to a value 10001 through 10099, the output manipulated variable lower limit (S1+17) is disabled.

S1+17 Output Manipulated Variable Lower Limit

The value contained in the data register designated by operand S1+17 specifies the lower limit of the output manipulated

variable (S1+1). Set a required value of 0 through 100 for the output manipulated variable lower limit to the data register

designated by operand S1+17. When S1+17 stores a value larger than 100, the output manipulated variable lower limit is

set to 100. The output manipulated variable lower limit (S1+17) must be smaller than the output manipulated variable

upper limit (S1+16).

To enable the output manipulated variable lower limit, turn on the output manipulated variable limit enable control relay

(S2+2), and set the output manipulated variable upper limit (S1+16) to a value other than 10001 through 10099. When the

manipulated variable (D1) is smaller than or equal to the specified lower limit, the lo wer limit value is outputted to the output manipulated variable (S1+1).

When the output manipulated variable limit enable control relay (S2+2) is turned off, the output manipulated variable

lower limit (S1+17) has no effect.

S1+18 Manual Mode Output Manipulated Variable

The manual mode output manipulated variable specifies the output manipulated variable (0 through 100) for manual mode.

Set a required value of 0 through 100 for the manual mode output manipulated variable to the data register designated by

operand S1+18. When S1+18 stores a value larger than 100, the manual mode output manipulated variable is set to 100.

To enable the manual mode, turn on the auto/manual mode control relay (S2+1). While in manual mode, the PID action is

disabled. The specified value of the manual mode output manipulated variable (S1+18) is outputted to the output manipulated variable (S1+1), and the control output (S2+6) is turned on and off according to the control period (S1+13) and the

manual mode output manipulated variable (S1+18).

S1+19 AT Sampling Period

The AT sampling period determines the interval of sampling during auto tuning. When using auto tuning, set a required

value of 1 through 10000 to specify an AT sampling period of 0.01 sec through 100.00 sec to the data register designated

by operand S1+19. When S1+19 stores 0, the AT sampling period is set to 0.01 sec. When S1+19 stores a value lar ger than

10000, the AT sampling period is set to 100.00 sec.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 8

Page 10

PID INSTRUCTION

Set the AT sampling period to a long value to make sure that the current process variable is smaller than or equal to the previous process variable during direct control action (S2+0 is on) or that the current process variable is lar ger than or equal to

the previous process variable during reverse control action (S2+0 is off).

S1+20 AT Control Period

The AT control period determines the duration of the ON/OFF cycle of the control output (S2+6) during auto tuning. For

operation of the control output, see Control Period on page 7.

When using auto tuning, set a required value of 1 through 500 to specify an AT control period of 0.1 sec through 50.0 sec

to the data register designated by operand S1+20. When S1+20 stores 0, the AT control period is set to 0.1 sec. When

S1+20 stores a value larger than 500, the AT control period is set to 50.0 sec.

S1+21 AT Set Point

While auto tuning is executed, the AT output manipulated variable (S1+22) is outputted to the output manipulated variable

(S1+1) until the process variable (S1+0) reaches the AT set point (S1+21). When the process variable (S1+0) reaches the

AT set point (S1+21), auto tuning is complete and the output manipulated variable (S1+1) is reduced to zero. When PID

action is selected with operation mode (S1+3) set to 1 (AT+PID), the PID action follows immediately.

When the linear conversion is disabled (S1+4 set to 0), set a required AT set point of 0 through 4000 to the data register

designated by operand S1+21. When S1+21 stores a value larger than 4000, the AT set point is set to 4000.

When the linear conversion is enabled (S1+4 set to 1), set a required AT set point of –32768 through 32767 to the data re gister designated by operand S1+21. The AT set point must be larger than or equal to the linear conversion minimum value

(S1+6) and must be smaller than or equal to the linear conversion maximum value (S1+5).

In the direct control action (see page 10), set the AT set point (S1+21) to a value sufficiently smaller than the process variable (S4) at the start of the auto tuning. In the reverse control action, set the AT set point (S1+21) to a value sufficiently

larger than the process variable (S4) at the start of the auto tuning.

S1+22 AT Output Manipulated Variable

The AT output manipulated variable specifies the amount of the output manipulated variable (0 through 100) during auto

tuning. When using auto tuning, set a required AT output manipulated variable of 0 through 100 to the data register designated by operand S1+22. When S1+22 stores a value larger than 100, the AT output manipulated variable is set to 100.

While auto tuning is executed, the specified value of the AT output manipulated v ariable (S1+22) is outputted to the output

manipulated variable (S1+1), and the control output (S2+6) is turned on and off according to the AT control period

(S1+20) and the AT output manipulated variable (S1+22). To keep the control output (S2+6) on during auto tuning, set 100

to S1+22.

Auto Tuning (AT)

When auto tuning is selected with the operation mode (S1+3) set to 1 (AT+PID) or 2 (AT), the auto tuning is executed

before starting PID control to determine PID parameters, such as proportional gain (S1+7), integral time (S1+8), deriv ativ e

time (S1+9), and control action (S2+0) automatically. The OpenNet Controller uses the step response method to execute

auto tuning. To enable auto tuning, set four parameters for auto tuning before executing the PID instruction, such as AT

sampling period (S1+19), AT control period (S1+20), AT set point (S1+21), and AT output manipulated variable (S1+22).

Step Response Method

The OpenNet Controller uses the step response method to execute

auto tuning and determine PID parameters such as proportional

Process Variable (S1+0)

Maximum Slope

gain (S1+7), integral time (S1+8), deriv ati v e time (S1+9), and control action (S2+0) automatically. The auto tuning is ex ecuted in the

AT Set Point (S1+21)

following steps:

1. Calculate the maximum slope of the process variable (S1+0)

before the process variable reaches the AT set point (S1+21).

2. Calculate the dead time based on the derived maximum slope.

3. Based on the maximum slope and dead time, calculate the four

Dead Time

PID parameters.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 9

Page 11

PID INSTRUCTION

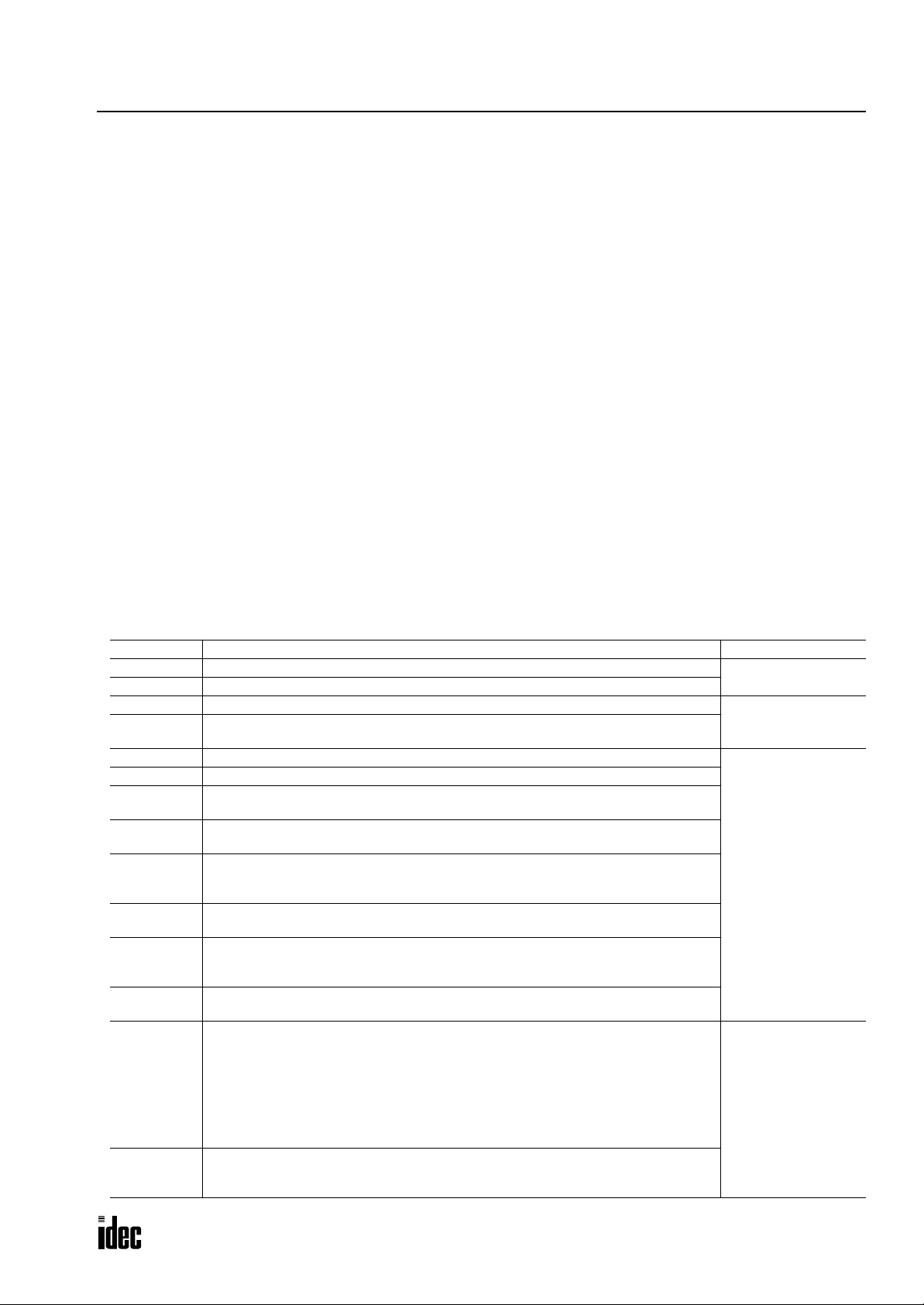

Source Operand S2 (Control Relay)

Turn on or off appropriate outputs or internal relays starting with the operand designated by S2 before executing the PID

instruction as required. Operands S2+4 through S2+7 are for read only to reflect the PID and auto tuning statuses.

Operand Function Description R/W

S2+0 Control action

S2+1 Auto/manual mode

S2+2

S2+3

S2+4 High alarm output

S2+5 Low alarm output

S2+6 Control output Goes on and off according to the AT parameters or PID calculation results R

S2+7 AT complete output Goes on when AT is complete or failed, and remains on until reset R

Output manipulated

variable limit enable

Integral start coefficient

disable

S2+0 Control Action

When auto tuning is executed with the operation mode (S1+3) set to 1 (AT+PID) or 2 (AT), the control action is determined automatically. When auto tuning results in a direct control action, the control action control relay designated by

operand S2+0 is turned on. When auto tuning results in a rev erse control action, the control action control relay designated

by operand S2+0 is turned off. The PID action is ex ecuted according to the derived control action, which remains in effect

during the PID action.

When auto tuning is not executed with the operation mode

(S1+3) set to 0 (PID), turn on or off the control action control

relay (S2+0) to select a direct or reverse control action, respectively, before executing the PID instruction.

In the direct control action, the manipulated variable (D1) is

increased while the process variable (S1+0) is larger than the

set point (S3). Temperature control for cooling is executed in

the direct control action.

In the reverse control action, the manipulated variable (D1) is

increased while the process variable (S1+0) is smaller than the

set point (S3). Temperature control for heating is executed in

the reverse control action.

In either the direct or reverse control action, the manipulated

variable (D1) is increased while the difference between the

process variable (S1+0) and the set point (S3) increases.

S2+1 Auto/Manual Mode

To select auto mode, turn off the auto/manual mode control relay designated by operand S2+1 before or after starting the

PID instruction. In auto mode, the PID action is executed and the manipulated variable (D1) stores the PID calculation

result. The control output (S2+6) is turned on and off according to the control period (S1+13) and the output manipulated

variable (S1+1).

To select manual mode, turn on the auto/manual mode control relay (S2+1). When using manual mode, set a required

value to the manual mode output manipulated variable (S1+18) before enabling manual mode. In manual mode, the output

manipulated variable (S1+1) stores the manual mode output manipulated variable (S1+18), and the control output (S2+6)

is turned on and off according to the control period (S1+13) and the manual mode output manipulated variable (S1+18).

While auto tuning is in progress, manual mode cannot be enabled. Only after auto tuning is complete, auto or manual

mode can be enabled. Auto/manual mode can also be switched while executing the PID instruction.

ON: Direct control action

OFF: Reverse control action

ON: Manual mode

OFF: Auto mode

ON: Enable output manipulated variable upper and lower limits (S1+16 and S1+17)

OFF: Disable output manipulated variable upper and lower limits (S1+16 and S1+17)

ON: Disable integral start coefficient (S1+10)

OFF: Enable integral start coefficient (S1+10)

ON: When process variable (S1+0) ≥ high alarm value (S1+14)

OFF: When process variable (S1+0) < high alarm value (S1+14)

ON: When process variable (S1+0) ≤ low alarm value (S1+15)

OFF: When process variable (S1+0) > low alarm value (S1+15)

Process Variable (S1+0)

Direct Control Action

Set Point (S3)

Process Variable (S1+0)

Set Point (S3)

Reverse Control Action

R/W

R/W

R/W

R/W

R

R

Time

Time

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 10

Page 12

PID INSTRUCTION

S2+2 Output Manipulated Variable Limit Enable

The output manipulated variable upper limit (S1+16) and the output manipulated variable lo wer limit (S1+17) are enabled

or disabled using the output manipulated variable limit enable control relay designated by operand S2+2.

To enable the output manipulated variable upper/lower limits, turn on S2+2.

To disable the output manipulated variable upper/lower limits, turn off S2+2.

S2+3 Integral Start Coefficient Disable

The integral start coefficient (S1+10) is enabled or disabled using the integral start coefficient disable control relay designated by operand S2+3.

To enable the integral start coefficient (S1+10), turn off S2+3; the inte gral term is enabled as specified by the inte gral start

coefficient (S1+10).

To disable the integral start coefficient (S1+10), turn on S2+3; the integral term is enabled at the start of the PID action.

S2+4 High Alarm Output

When the process variable (S1+0) is higher than or equal to the high alarm value (S1+14) while the start input for the PID

instruction is on, the high alarm output control relay designated by operand S2+4 goes on. When S1+0 is lower than

S1+14, S2+4 is off.

S2+5 Low Alarm Output

When the process variable (S1+0) is lower than or equal to the low alarm value (S1+15) while the start input for the PID

instruction is on, the low alarm output control relay designated by operand S2+5 goes on. When S1+0 is higher than

S1+15, S2+5 is off.

S2+6 Control Output

During auto tuning in auto mode with the auto/manual mode control relay (S2+1) set to off, the control output designated

by operand S2+6 is turned on and off according to the AT control period (S1+20) and AT output manipulated variable

(S1+22).

During PID action in auto mode with the auto/manual mode control relay (S2+1) set to off, the control output (S2+6) is

turned on and off according to the control period (S1+13) and the output manipulated variable (S1+1) calculated by the

PID action.

In manual mode with the auto/manual mode control relay (S2+1) set to on, the control output (S2+6) is turned on and off

according to the control period (S1+13) and the manual mode output manipulated variable (S1+18).

S2+7 AT Complete Output

The AT complete output control relay designated by operand S2+7 goes on when auto tuning is complete or failed, and

remains on until reset. Operating status codes are stored to the operating status control register (S1+2). See page 3.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 11

Page 13

PID INSTRUCTION

Source Operand S3 (Set Point)

The PID action is executed to adjust the process variable (S1+0) to the set point (S3).

When the linear conversion is disabled (S1+4 set to 0), set a required set point value of 0 through 4000 to the operand des-

ignated by S3. Valid operands are data register and constant.

When the linear conversion is enabled (S1+4 set to 1), designate a data register as operand S3 and set a required set point

value of –32768 through 32767 to the data register designated by operand S3. Since the PID instruction uses the word data

type, negative constants cannot be entered directly to operand S3. Use the MOV instruction with the integer (I) data type to

store a negative value to a data register. The set point value (S3) must be larger than or equal to the linear conversion minimum value (S1+6) and smaller than or equal to the linear conversion maximum value (S1+5).

When an invalid value is designated as a set point, the PID action is stopped and an error code is stored to the data register

designated by operand S1+2. See Operating Status on page 3.

Source Operand S4 (Process Variable before Conversion)

The analog output from the transducer is inputted to the analog input module, which converts the input data to a digital

value of 0 through 4000. The digital value is stored to a link register L100 through L705 depending on the mounting position of the analog input module and the analog input channel connected to the transducer. Designate a link register as

source operand S4 to store the process variable.

For example, when the analog input module is mounted in the first slot from the CPU module among all functional modules such as analog I/O and OpenNet interface modules (not including digital I/O modules) and when the analog input is

connected to channel 0 of the analog input module, designate link register L100 as source operand S4. When the analog

input module is mounted in the third slot and the analog input is connected to channel 4, designate link register L304 as

source operand S4.

Link Register Allocation Numbers for Source Operand S4

Analog Input Module Position

Functional Module 1 L100 L101 L102 L103 L104 L105

Functional Module 2 L200 L201 L202 L203 L204 L205

Functional Module 3 L300 L301 L302 L303 L304 L305

Functional Module 4 L400 L401 L402 L403 L404 L405

Functional Module 5 L500 L501 L502 L503 L504 L505

Functional Module 6 L600 L601 L602 L603 L604 L605

Functional Module 7 L700 L701 L702 L703 L704 L705

012345

Analog Input Channel

When an analog input module is not used, a data register can also be designated as source operand S4 (process variable).

When designating a data register as S4, make sure that the S4 data takes a value between 0 and 4000. When S4 stores a

value larger than 4000, the process variable is set to 4000.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 12

Page 14

PID INSTRUCTION

Destination Operand D1 (Manipulated Variable)

The data register designated by destination operand D1 stores the manipulated variable of –32768 through 32767 calculated by the PID action. When the calculation result is less than –32768, D1 stores –32768. When the calculation result is

greater than 32767, D1 stores 32767. While the calculation result is less than –32768 or greater than 32767, the PID action

still continues.

When the output manipulated variable limit is disabled (S2+2 set to off) while the PID action is in progress, the data register designated by operand S1+1 holds 0 through 100 of the manipulated variable (D1), omitting values less than 0 and

greater than 100. The percent value in S1+1 determines the ON duration of the control output (S2+6) in proportion to the

control period (S1+13).

When the output manipulated variable limit is enabled (S2+2 set to on), the manipulated variable (D1) is stored to the output manipulated variable (S1+1) according to the output manipulated variable upper limit (S1+16) and the output manipulated variable lower limit (S1+17) as summarized in the table below.

While manual mode is enabled with the auto/manual mode control relay (S2+1) set to on, S1+1 stores 0 through 100 of the

manual mode output manipulated variable (S1+18), and D1 stores an indefinite value.

While auto tuning is in progress, S1+1 stores 0 through 100 of the AT output manipulated variable (S1+22), and D1 stores

an indefinite value.

Examples of Output Manipulated Variable Values

Output Manipulated

Variable Limit Enable

(S2+2)

OFF (disabled) — —

ON (enabled)

Output Manipulated

Variable Upper Limit

(S1+16)

50 25

10050 —

Output Manipulated

Variable Lower Limit

(S1+17)

Manipulated Variable

(D1)

≥ 100 100

1 to 99 1 to 99

≤ 00

≥ 50 50

26 to 49 26 to 49

≤ 25 25

≥ 100 50

1 to 99 (1 to 99) × 0.5

≤ 00

Output Manipulated

Variable

(S1+1)

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 13

Page 15

PID INSTRUCTION

Application Example

This application example demonstrates a PID control for a heater to keep the temperature at 200°C.

In this example, when the program is started, the PID instruction first executes auto tuning according to the designated AT

parameters, such as AT sampling period, AT control period, AT set point, and AT output manipulated variable, and also the

temperature data inputted to the analog input module. The control output remains on to keep the heater on until the temperature reaches the AT set point of 150°C. Auto tuning determines PID parameters such as proportional gain, integral

time, derivative time, and control action.

When the temperature reaches 150°C, PID action starts to control the temperature to 200°C using the derived PID parameters. The heater is turned on and off according to the output manipulated v ariable calculated by the PID action. When the

heater temperature is higher than or equal to 250°C, an alarm light is turned on by the high alarm output.

The analog input module data is also monitored to force off the heater power switch.

Operand Settings

Operand Function Description

S1+3 Operation mode AT (auto tuning) + PID action D3 (1)

S1+4 Linear conversion Enable linear conversion D4 (1)

S1+5 Linear conversion maximum value 500°C D5 (5000)

S1+6 Linear conversion minimum value –50°C D6 (–500)

S1+10 Integral start coefficient 100% D10 (0)

S1+11 Input filter coefficient 70% D11 (70)

S1+12 Sampling period 500 msec D12 (50)

S1+13 Control period 1 sec D13 (10)

S1+14 High alarm value 250°C D14 (2500)

S1+19 AT sampling period 1.5 sec D19 (150)

S1+20 AT control period 3 sec D20 (30)

S1+21 AT set point 150°C D21 (1500)

S1+22 AT output manipulated variable 100% (Note) D22 (100)

S2+1 Auto/manual mode Auto mode M1 (OFF)

S2+2

S2+3 Integral start coefficient disable Enable integral start coefficient (S1+10) M3 (OFF)

S2+4 High alarm output

S2+6 Control output

S3 Set point 200°C D100 (2000)

S4 Process variable

D1 Manipulated variable Stores PID calculation result (–32768 to 32767) D102

Output manipulated variable limit

enable

PID start input Starts to execute the PID instruction I0

Monitor input

Heater power switch Turned on and off by control output M6 Q0

High alarm light Turned on and off by high alarm output M4 Q1

Disable output manipulated variable limits M2 (OFF)

ON: When temperature ≥ 250°C

OFF: When temperature < 250°C

Remains on during auto tuning;

Goes on and off according to the control period

(S1+13) and output manipulated variable (S1+1)

during PID action

Analog input module is mounted at the first slot

among functional modules and the analog input

is connected to channel 0 of the analog input

module; stores 0 through 4000

Starts to monitor the analog input module data

for high alarm

Allocation No.

(Value)

M4

M6

L100

I1

Note: The output manipulated variable during auto tuning is a constant value. In this example, the AT output manipulated

variable is set to the maximum value of 100 (100%), so the control output (S2+6) remains on during auto tuning.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 14

Page 16

System Setup

PID INSTRUCTION

Analog Input Module

FC3A-AD1261

1

A/D

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

High Alarm LightOutput Q1

–50° to 500°C

L

24V DC

CPU Module

POWER

RUN

ERROR

HSC OUT

COM A B Z

HSC

OUT

ABG

RS485

Fuse

+24V 0V

+

Relay Output Module

FC3A-R161

Ry

1

OUT

2

3

0

1

4

2

3

5

4

5

6

6

7

7

10

11

8

12

13

9

14

15

10

16

17

11

12

13

14

15

16

17

18

19

20

_

Output Q0 Heater Power Switch

Digital Output from Analog Input Module vs. Process Variable after Conversion

Process Variable after Conversion (S1+0)

Linear Conversion Maximum Value (S1+5): 5000 (500°C)

Transducer

Thermocouple

Heater

High Alarm Value (S1+14): 2500 (250°C)

Set Point (S3): 2000 (200°C)

AT Set Point (S1+21): 1500 (150°C)

0

Linear Conversion Minimum Value (S1+6): –500 (–50°C)

Temperature Control by Auto Tuning and PID Action

Process Variable after Conversion (S1+0)

High Alarm Value (S1+14): 2500 (250°C)

Set Point (S3): 2000 (200°C)

AT Set Point (S1+21): 1500 (150°C)

4000

Digital Output from Analog Input Module

Time

PID Action

Auto Tuning

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 15

Page 17

PID INSTRUCTION

Ladder Program

The ladder diagram shown below describes an example of using the PID instruction. The user program must be modified

according to the application and simulation must be performed before actual operation.

SOTU

I0

MOV(W) REP

MOV(W)

MOV(W) REP

MOV(I) REP

MOV(I) REP

MOV(W) REP

MOV(W)

MOV(W) REP

MOV(W) REP

MOV(W) REP

MOV(W) REP

MOV(W)

MOV(W) REP

MOV(W) REP

MOV(W) REP

S1 –0D1 R

S1 –1D1 –

S1 –1D1 –

S1 –

5000

S1 –

–500

S1 –0D1 –

S1 –70D1 –

S1 –50D1 –

S1 –10D1 –

S1 –

2500

S1 –

150

S1 –30D1 –

S1 –

1500

S1 –

100

S1 –

2000

D0

D3

D4

D1 –

D5

D1 –

D6

D10

D11

D12

D13

D1 –

D14

D1 –

D19

D20

D1 –

D21

D1 –

D22

D1 –

D100

27

REP

REP

REP

When input I0 is turned on, 0 is stored to 27 data registers

D0 through D26 designated as control registers.

D3 (operation mode): 1 (AT+PID)

D4 (linear conversion): 1 (enable linear conversion)

D5 (linear conversion maximum value): 5000 (500°C)

D6 (linear conversion minimum value): –500 (–50°C)

D10 (integral start coefficient): 0 (100%)

D11 (input filter coefficient): 70 (70%)

D12 (sampling period): 50 (500 msec)

D13 (control period): 10 (1 sec)

D14 (high alarm value): 2500 (250°C)

D19 (AT sampling period): 150 (1.5 sec)

D20 (AT control period): 30 (3 sec)

D21 (AT set point): 1500 (150°C)

D22 (AT output manipulated variable): 100 (100%)

D100 (set point): 2000 (200°C)

When input I0 is turned on, 3 internal relays M1 through

R

M1

M3 designated as control relays are turned off.

M1 (auto/manual mode): Auto mode

R

M2

R

M3

PID

I0

S1

D0

S2

M0S3D100

S4

L100

D1

D102

M2 (output manipulated variable limit enable): Disable

M3 (integral start coefficient disable): Enable

While input I0 is on, the PID instruction is executed.

D0-D26: control registers

M0-M7: control relays

M6

M4

Q0

D100: set point

L100: process variable

D102: manipulated variable

M4

Continued on the next page.

Q1

When internal relay M6 (control output) is turned on, output Q0 (heater power switch) is turned on.

When internal relay M4 (high alarm output) is turned on,

output Q1 (high alarm light) is turned on.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 16

Page 18

Ladder Program (continued)

PID INSTRUCTION

CMP>=(W) S2 –

I1

M10 I1

L100

769

D1 –

M10

REPS1 –

R

Q0

While monitor input I1 is on, the temperature is monitored.

When the temperature is higher than or equal to 250°C,

M10 is turned on.

4000 × 250/1300 = 769.23

When M10 is on while monitor input I1 is on, Q0 (heater

S

Q1

power switch) is forced off and Q1 (high alarm light) is

forced on.

Notes for Using the PID Instruction:

• Since the PID instruction requires continuous operation, keep on the start input for the PID instruction.

• The high alarm output (S2+4) and the low alarm output (S2+5) work while the start input for the PID instruction is on.

These alarm outputs, however, do not work when a PID instruction execution error occurs (S1+2 stores 100 through 107)

due to data error in control data registers S1+0 through S1+26 or while the start input for the PID instruction is off. Provide a program to monitor the process variable (S4) separately.

• When a PID execution error occurs (S1+2 stores 100 through 107) or when auto tuning is completed, the manipulated

variable (D1) stores 0 and the control output (S2+6) turns off.

• Do not use the PID instruction in program branching instructions: LABEL, LJMP, LCAL, LRET, JMP, JEND, MCS, and

MCR. The PID instruction may not operate correctly in these instructions.

• The PID instruction, using the difference between the set point (S3) and process variable (S4) as input, calculates the

manipulated variable (D1) according to the PID parameters, such as proportional gain (S1+7), integral time (S1+8), and

derivative time (S1+9). When the set point (S3) or process variable (S4) is changed due to disturbance, overshoot or

undershoot will be caused. Before putting the PID control into actual application, perform simulation tests by changing

the set point and process variable (disturbance) to anticipated values in the application.

• The PID parameters, such as proportional gain (S1+7), integral time (S1+8), and derivative time (S1+9), determined by

the auto tuning may not always be the optimum values depending on the actual application. To make sure of the best

results, adjust the parameters. Once the best PID parameters are determined, perform only the PID action in usual operation unless the control object is changed.

• When a feedback control is executed using the control output (S2+6), the optimum control may not be achiev ed depend-

ing on the controlled object. If this is the case, use of the manipulated variable (D1) in the feedback control is recommended.

OPENNET CONTROLLER PID INSTRUCTION USER’S MANUAL 17

Loading...

Loading...