Page 1

EM345-0

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

OPENNET CONTROLLER

Page 2

SAFETY PRECAUTIONS

Warning

Warning notices are used to emphasize that improper operation may cause

severe personal injury or death.

Caution

Caution notices are used where inattention might cause personal injury or

damage to equipment.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

• Read this user’s manual to make sure of correct operation before starting installation, wiring, operation, maintenance, and

inspection of the OpenNet Controller.

• All OpenNet Controller modules are manufactured under IDEC’s rigorous quality control system, but users must add a

backup or failsafe provision to the control system using the OpenNet Controller in applications where heavy damage or

personal injury may be caused in case the OpenNet Controller should fail.

• In this user’s manual, safety precautions are categorized in order of importance to Warning and Caution:

• Turn off the power to the OpenNet Controller before starting installation, removal, wiring, maintenance, and inspection of

the OpenNet Controller. Failure to turn power off may cause electrical shocks or fire hazard.

• Special expertise is required to install, wire, program, and operate the OpenNet Controller. People without such expertise

must not use the

• Emergency stop and interlocking circuits must be configured outside the

inside the OpenNet Controller, failure of the OpenNet Controller may cause disorder of the control system, damage, or

accidents.

• Install the OpenNet Controller according to instructions described in this user’s manual. Improper installation will result in

falling, failure, or malfunction of the OpenNet Controller.

• The OpenNet Controller is designed for installation in a cabinet. Do not install the OpenNet Controller outside a cabinet.

• Install the OpenNet Controller in environments described in this user’s manual. If the OpenNet Controller is used in places

where the OpenNet Controller is subjected to high-temperature, high-humidity, condensation, corrosive gases, excessive

vibrations, and excessive shocks, then electrical shocks, fire hazard, or malfunction will result.

• The environment for using the OpenNet Controller is “Pollution degree 2.” Use the OpenNet Controller in environments of

pollution degree 2 (according to IEC 60664-1).

• The DC power applicable to the OpenNet Controller is “PS2” type (according to EN 61131).

• Prevent the OpenNet Controller from falling while moving or transporting the OpenNet Controller, otherwise damage or

malfunction of the OpenNet Controller will result.

• Prevent metal fragments and pieces of wire from dropping inside the OpenNet Controller housing. Put a cov er on the Open-

Net Controller

or malfunction.

• Use a power supply of the rated value. Use of a wrong power supply may cause fire hazard.

• Use wires of a proper size to meet voltage and current requirements. Tighten terminal screws to a proper tightening torque

of 0.5 to 0.6 N·m.

• Use an IEC 60127-approved fuse on the power line outside the OpenNet Controller. This is required when equipment con-

taining the

• Use an IEC 60127-approved fuse on the output circuit. This is required when equipment containing the

is destined for Europe.

• Use an EU-approved circuit breaker. This is required when equipment containing the

Europe.

• Make sure of safety before starting and stopping the

outputs on or off. Incorrect operation on the OpenNet Controller may cause machine damage or accidents.

• If relays or transistors in the OpenNet Controller output modules should fail, outputs may remain on or off. For output signals which may cause heavy accidents, provide a monitor circuit outside the OpenNet Controller.

• Do not connect to the ground directly from the OpenNet Controller. Connect a protective ground to the cabinet containing

OpenNet Controller using an M4 or larger screw. This is required when equipment containing the OpenNet Controller is

destined for Europe.

• Do not disassemble, repair, or modify the OpenNet Controller modules.

• Dispose of the battery in the

tions. When storing or disposing of the battery, use a proper container prepared for this purpose. This is required when

equipment containing the OpenNet Controller is destined for Europe.

• When disposing of the

OpenNet Controller.

OpenNet Controller. If such a circuit is configured

modules during installation and wiring. Ingress of such fragments and chips may cause fire hazard, damage,

OpenNet Controller is destined for Europe.

OpenNet Controller

OpenNet Controller is destined for

OpenNet Controller or when operating the OpenNet Controller to force

OpenNet Controller modules when the battery is dead in accordance with pertaining regula-

OpenNet Controller, do so as an industrial waste.

OPENNET CONTROLLER USER’S MANUAL PREFACE-1

Page 3

About This Manual

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

This user’s manual primarily describes entire functions of the OpenNet Controller CPU modules, digital I/O modules, analog I/O modules. Also included are powerful communications of the OpenNet Controller.

CHAPTER 1: GENERAL INFORMATION

General information about the OpenNet Controller, features, brief description on special functions, and various system

setup configurations for communication.

CHAPTER 2: MODULE SPECIFICATIONS

Specifications of CPU, digital and analog I/O, expansion power supply, remote I/O master, OpenNet interface modules.

CHAPTER 3: INSTALLATION AND WIRING

Methods and precautions for installing and wiring OpenNet Controller modules.

CHAPTER 4: OPERATION BASICS

General information about setting up the basic OpenNet Controller system for programming, starting and stopping Open-

Net Controller

toring the OpenNet Controller operation.

CHAPTER 5: SPECIAL FUNCTIONS

Stop/reset inputs, run/stop selection at memory backup error, keep designation for internal relays, shift registers, counters,

and data registers. Also included are module ID selection and run/stop operation upon disparity, input filter, catch input,

high-speed counter, key matrix input, and user program read/write protection.

CHAPTER 6: ALLOCATION NUMBERS

Allocation numbers available for the OpenNet Controller CPU module to program basic and advanced instructions. Special internal relays and special data registers are also described.

operation, and simple operating procedures from creating a user program using WindLDR on a PC to moni-

CHAPTER 7: BASIC INSTRUCTIONS

Programming of the basic instructions, available operands, and sample programs.

CHAPTER 8: ADVANCED INSTRUCTIONS

General rules of using advanced instructions, terms, data types, and formats used for advanced instructions.

CHAPTER 9 THROUGH CHAPTER 20:

Detailed descriptions on advanced instructions grouped into 12 chapters.

CHAPTER 21 THROUGH CHAPTER 26:

Various communication functions such as data link, computer link, modem mode, remote I/O system, Devicenet slave

module, and LONWORKS interface module.

CHAPTER 27: TROUBLESHOOTING

Procedures to determine the cause of trouble and actions to be taken when any trouble occurs while operating the OpenNet

Controller

.

APPENDIX

Additional information about execution times for instructions, I/O delay time, and OpenNet Controller type list.

INDEX

Alphabetical listing of key words.

IMPORTANT INFORMATION

Under no circumstances shall IDEC Corporation be held liable or responsible for indirect or consequential damages resulting

from the use of or the application of IDEC PLC components, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit their application and for choosing an application appropriate for the component, individually or in combination with other equipment.

All diagrams and examples in this manual are for illustrative purposes only. In no way does including these diagrams and

examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all programs, prior to installation, is the responsibility of the end user.

PREFACE-2 OPENNET CONTROLLER USER’S MANUAL

Page 4

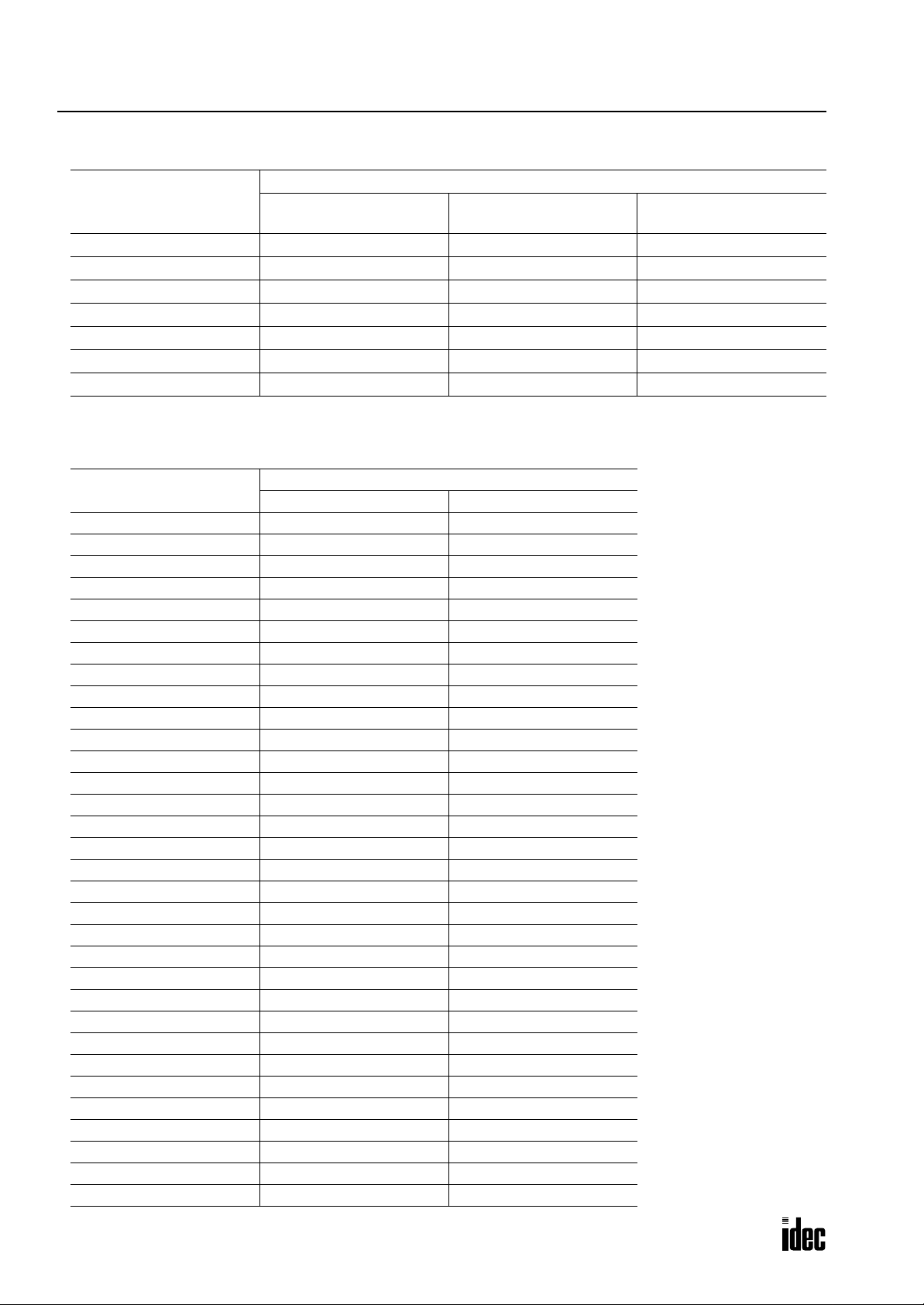

TABLE OF CONTENTS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

HAPTER 1: GENERAL INFORMATION

C

About the OpenNet Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

HAPTER 2: MODULE SPECIFICATIONS

C

CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Analog Input Module (A/D Converter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Analog Output Module (D/A Converter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Expansion Power Supply Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Remote I/O Master Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

DeviceNet Slave Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

LonWorks Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

HAPTER 3: INSTALLATION AND WIRING

C

Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Assembling Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Disassembling Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Mounting on DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removing from DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installation in Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Mounting Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Data Link Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Analog Input/Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Terminal Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

HAPTER 4: OPERATION BASICS

C

Connecting OpenNet Controller to PC (1:1 Computer Link System) . . . . . . . . . . . . . . . . . 4-1

Start/Stop Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Simple Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

HAPTER 5: SPECIAL FUNCTIONS

C

Stop Input and Reset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Run/Stop Selection at Memory Backup Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Keep Designation for Internal Relays, Shift Registers, Counters, and Data Registers . . . . 5-3

Module ID Selection and Run/Stop Operation upon Disparity . . . . . . . . . . . . . . . . . . . . . 5-5

Input Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Catch Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

High-speed Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Key Matrix Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

User Program Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Constant Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

OPENNET CONTROLLER USER’S MANUAL i

Page 5

TABLE OF CONTENTS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

HAPTER 6: ALLOCATION NUMBERS

C

Operand Allocation Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Operand Allocation Numbers for Functional Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Operand Allocation Numbers for Master Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Operand Allocation Numbers for Data Link Master Station . . . . . . . . . . . . . . . . . . . . . . . 6-5

Operand Allocation Numbers for Data Link Slave Station . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Special Internal Relay Allocation Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Special Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Digital I/O Module Operands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Functional Module Operands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Bit Designation of Link Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

HAPTER 7: BASIC INSTRUCTIONS

C

Basic Instruction List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

LOD (Load) and LODN (Load Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

OUT (Output) and OUTN (Output Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

SET and RST (Reset) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

AND and ANDN (And Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

OR and ORN (Or Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

AND LOD (Load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

OR LOD (Load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

BPS (Bit Push), BRD (Bit Read), and BPP (Bit Pop) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

TML, TIM, TMH, and TMS (Timer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

CNT, CDP, and CUD (Counter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

CC= and CC≥ (Counter Comparison) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

TC= and TC≥ (Timer Comparison) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

DC= and DC≥ (Data Register Comparison) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

SFR and SFRN (Forward and Reverse Shift Register) . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

SOTU and SOTD (Single Output Up and Down) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

MCS and MCR (Master Control Set and Reset) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

JMP (Jump) and JEND (Jump End) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

END . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

HAPTER 8: ADVANCED INSTRUCTIONS

C

Advanced Instruction List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Structure of an Advanced Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Input Condition for Advanced Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Source and Destination Operands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Using Timer or Counter as Source Operand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Using Timer or Counter as Destination Operand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Data Types for Advanced Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Discontinuity of Operand Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

NOP (No Operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

HAPTER 9: MOVE INSTRUCTIONS

C

MOV (Move) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

MOVN (Move Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

IMOV (Indirect Move) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

IMOVN (Indirect Move Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

BMOV (Block Move) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

NSET (N Data Set) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

NRS (N Data Repeat Set) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

IBMV (Indirect Bit Move) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

IBMVN (Indirect Bit Move Not) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

XCHG (Exchange) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

ii OPENNET CONTROLLER USER’S MANUAL

Page 6

HAPTER 10: DATA COMPARISON INSTRUCTIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

C

CMP= (Compare Equal To) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

CMP<> (Compare Unequal To) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

CMP< (Compare Less Than) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

CMP> (Compare Greater Than) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

CMP<= (Compare Less Than or Equal To) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

CMP>= (Compare Greater Than or Equal To) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

ICMP>= (Interval Compare Greater Than or Equal To) . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

HAPTER 11: BINARY ARITHMETIC INSTRUCTIONS

C

ADD (Addition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

SUB (Subtraction) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

MUL (Multiplication) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

DIV (Division) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

INC (Increment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

DEC (Decrement) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

ROOT (Root) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

SUM (Sum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

HAPTER 12: BOOLEAN COMPUTATION INSTRUCTIONS

C

ANDW (AND Word) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

ORW (OR Word) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

XORW (Exclusive OR Word) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

NEG (Negate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

TABLE OF CONTENTS

HAPTER 13: BIT SHIFT / ROTATE INSTRUCTIONS

C

SFTL (Shift Left) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

SFTR (Shift Right) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

ROTL (Rotate Left) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-5

ROTR (Rotate Right) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-7

ROTLC (Rotate Left with Carry) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-9

ROTRC (Rotate Right with Carry) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-11

BCDLS (BCD Left Shift) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-13

HAPTER 14: DATA CONVERSION INSTRUCTIONS

C

HTOB (Hex to BCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

BTOH (BCD to Hex) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

HTOA (Hex to ASCII) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-5

ATOH (ASCII to Hex) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

BTOA (BCD to ASCII) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-9

ATOB (ASCII to BCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-11

DTDV (Data Divide) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-13

DTCB (Data Combine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-14

HAPTER 15: WEEK PROGRAMMER INSTRUCTIONS

C

WKCMP ON (Week Compare ON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

WKCMP OFF (Week Compare OFF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

WKTBL (Week Table) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-2

Setting Calendar/Clock Using WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-7

Setting Calendar/Clock Using a User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-7

Adjusting Clock Using a User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-8

OPENNET CONTROLLER USER’S MANUAL iii

Page 7

TABLE OF CONTENTS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

HAPTER 16: INTERFACE INSTRUCTIONS

C

DISP (Display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

DGRD (Digital Read) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-3

CDISP (Character Display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-5

HAPTER 17: USER COMMUNICATION INSTRUCTIONS

C

User Communication Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

User Communication System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-2

TXD1 (Transmit 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-4

TXD2 (Transmit 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-4

RXD1 (Receive 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-13

RXD2 (Receive 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-13

User Communication Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-25

ASCII Character Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-26

RS232C Line Control Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-27

Sample Program – User Communication TXD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-31

Sample Program – User Communication RXD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-33

HAPTER 18: PROGRAM BRANCHING INSTRUCTIONS

C

LABEL (Label) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

LJMP (Label Jump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

LCAL (Label Call) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-3

LRET (Label Return) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-3

DJNZ (Decrement Jump Non-zero) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-5

HAPTER 19: COORDINATE CONVERSION INSTRUCTIONS

C

XYFS (XY Format Set) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1

CVXTY (Convert X to Y) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-2

CVYTX (Convert Y to X) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-3

AVRG (Average) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-6

HAPTER 20: PID INSTRUCTION

C

PID (PID Control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

Application Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-14

HAPTER 21: DATA LINK COMMUNICATION

C

Data Link Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-1

Data Link System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-2

Data Register Allocation for Transmit/Receive Data . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-3

Special Data Registers for Data Link Communication Error . . . . . . . . . . . . . . . . . . . . . . 21-4

Data Link Communication between Master and Slave Stations . . . . . . . . . . . . . . . . . . . 21-5

Special Internal Relays for Data Link Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 21-6

Programming WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-7

Refresh Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-8

Operating Procedure for Data Link System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-11

Data Link with Other Equipment (Separate Refresh Mode) . . . . . . . . . . . . . . . . . . . . . 21-12

HAPTER 22: COMPUTER LINK COMMUNICATION

C

Computer Link System Setup (1:N Computer Link System) . . . . . . . . . . . . . . . . . . . . . . 22-1

Monitoring PLC Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-2

iv OPENNET CONTROLLER USER’S MANUAL

Page 8

HAPTER 23: MODEM MODE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

C

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-1

Applicable Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-2

Internal Relays for Modem Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-2

Data Registers for Modem Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-3

Originate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-4

Disconnect Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-6

AT General Command Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-6

Answer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-7

Modem Mode Status Data Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-8

Initialization String Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-9

Preparation for Using Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-10

Setting Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-10

Programming Data Registers and Internal Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-11

Setting Up the CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-11

Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-11

Sample Program for Modem Originate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-12

Sample Program for Modem Answer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-13

Troubleshooting in Modem Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-14

HAPTER 24: REMOTE I/O SYSTEM

C

Remote I/O System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-2

Link Registers for Remote I/O System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-2

About INTERBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-2

Data Communication between Remote I/O Master and Slave Stations . . . . . . . . . . . . . 24-3

Logical Device Number and Node Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-4

Data Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-5

Special Data Registers for Remote I/O Node Information . . . . . . . . . . . . . . . . . . . . . . 24-6

Special Data Registers for INTERBUS Master Information . . . . . . . . . . . . . . . . . . . . . 24-10

Special Internal Relays for INTERBUS Master Information . . . . . . . . . . . . . . . . . . . . . 24-11

Calculation of the INTERBUS Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-12

Start and Stop of Remote I/O Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-12

Function Area Setting for Remote I/O Master Station . . . . . . . . . . . . . . . . . . . . . . . . 24-13

Precautions for Wiring INTERBUS Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-15

INTERBUS Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-16

TABLE OF CONTENTS

HAPTER 25: DEVICENET SLAVE MODULE

C

DeviceNet Slave Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-1

About DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-1

DeviceNet Network System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-2

DeviceNet Slave Module Parts Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-3

DeviceNet Slave Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-4

Wiring DeviceNet Slave Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-5

DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-6

Link Registers for DeviceNet Network Communication . . . . . . . . . . . . . . . . . . . . . . . . . 25-7

Function Area Setting for DeviceNet Slave Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-8

Programming Transmit/Receive Data Using WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . 25-9

Starting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-9

Transmission Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-10

DeviceNet Network Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-11

OPENNET CONTROLLER USER’S MANUAL v

Page 9

TABLE OF CONTENTS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

HAPTER 26: LONWORKS INTERFACE MODULE

C

LonWorks Interface Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-1

About LON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-1

LonWorks Network Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-2

LonWorks Network System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-3

LonWorks Interface Module Parts Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-4

LonWorks Interface Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-5

Wiring LonWorks Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-6

Terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-7

Link Registers for LonWorks Network Communication . . . . . . . . . . . . . . . . . . . . . . . . . 26-8

Transmission Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-9

Function Area Setting for LonWorks Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-10

Programming Transmit/Receive Data Using WindLDR . . . . . . . . . . . . . . . . . . . . . . . . . 26-11

Starting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-12

Network Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-12

Precautions for Modifying Application Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-13

LonWorks Interface Module Internal Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-14

Data Exchange between LonWorks Interface Module and CPU Module . . . . . . . . . . . . . 26-16

Application Program Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-18

Defined Network Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-23

LonWorks Network Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-25

HAPTER 27: TROUBLESHOOTING

C

ERROR LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-1

Reading Error Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-1

Special Data Registers for Error Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-3

General Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-3

OpenNet Controller Operating Status, Output, and ERROR LED during Errors . . . . . . . . . 27-4

Error Causes and Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-4

User Program Execution Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-6

Troubleshooting Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-7

PPENDIX

A

Execution Times for Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Breakdown of END Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

I/O Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Type List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

NDEX

I

vi OPENNET CONTROLLER USER’S MANUAL

Page 10

1: GENERAL INFORMATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

This chapter describes general information for understanding the OpenNet Controller and system setups for using the

OpenNet Controller in various ways of communication.

About the OpenNet Controller

IDEC’s OpenNet Controller is a programmable logic controller with enhanced communication capabilities. The OpenNet

Controller

cation of these networks are expanding at a fast pace, the OpenNet Controller is ideal for use in multi-vendor control systems.

In addition, the OpenNet Controller has user communication functions to communicate with various communication

equipment. Modem communication is also very easy using the built-in modem communication functions to communicate

with remote devices through telephone lines. For these communication applications, the OpenNet Controller CPU module

features two RS232C ports and one RS485 port.

User programs for the OpenNet Controller can be edited using WindLDR on a W indows PC. Since WindLDR can load existing user programs made for IDEC’s preceding PLCs such as all FA series, MICRO-1, MICRO3, and MICRO

ware assets can be used in the new control system.

Digital I/O points can be 480 total at the maximum when using an expansion power supply module.

Program capacity is 16K words (8K steps).

is compatible with world’s three major open networks; INTERBUS, DeviceNet, and LONWORKS. Since appli-

3

C, your soft-

Features

Connect to Open Networks

The OpenNet Controller can be connected to the three major open networks; INTERBUS, DeviceNet, and LONWORKS.

The versatile communication capabilities reduce the time and cost needed when constructing, expanding, or modifying

production lines. Maintenance for communication lines will also become even easier.

Master Station (Remote I/O) INTERBUS

Slave Station DeviceNet, L

High-performance CPU Module

The OpenNet Controller CPU module has multiple functions to work as a brain of the control system connected to the

open networks. Optimum control systems can be made possible using the OpenNet Controller.

Powerful Communication Functions

In addition to connection to the open networks, the OpenNet Controller features three more communication functions.

User Communication

Data Link

Computer Link

The OpenNet Controller can be linked to external RS232C devices such as computers,

modems, printers, and barcode readers, using the user communication function.

One OpenNet Controller at the master station can communicate with 31 slave stations

through the RS485 line to exchange data and perform distributed control effectively.

When the OpenNet Controller is connected to a computer, operating status and I/O status

can be monitored on the computer, data in the CPU can be monitored or updated, and user

programs can be downloaded and uploaded. A maximum of 32 OpenNet Controller CPUs can

be connected to one computer in the 1:N computer link system.

ONWORKS

International Safety Standards and Approvals

The OpenNet Controller is certified by UL and CSA.

OPENNET CONTROLLER USER’S MANUAL 1-1

Page 11

1: GENERAL INFORMATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Special Functions

The OpenNet Controller features various special functions packed in the small housing as described below. For details

about these functions, see the following chapters.

“Keep” or “Clear” Designation of CPU Data

Internal relays, shift register bits, counter current values, and data register values can be designated to be kept or cleared

when the CPU is powered down. All of these data or a specified range of these operands can be designated as keep or clear

types.

Catch Input Function

The catch input function makes sure to receive short input pulses (rising pulse of 40 µsec or falling pulse of 150 µsec minimum) from sensors without regard to the scan time.

Input Filter Function

The input filter can be adjusted for the pulse widths to accept or reject input signals. This function is useful for eliminating

input noises and chatter in limit switches.

High-speed Counter Function

The OpenNet Controller has a built-in high-speed counter to make it possible to count up to 65,535 (FFFFh) high-speed

pulses which cannot be counted by the normal user program processing. The maximum count input frequency is 10 kHz.

This function can be used for simple positioning control and simple motor control.

Key Matrix Function

A matrix configuration consisting of 16 inputs and 16 outputs enables to read a maximum of 256 input signals.

User Program Read/Write Protection

The user program in the CPU module can be protected against reading and/or writing by including a password in the user

program. This function is effective for security of user programs.

Week Programmer Function

Week programmer instructions can be programmed to compare the preset date and time with the internal realtime calendar/clock. When the preset values are reached, designated outputs can be turned on and off as programmed for the week.

RUN/STOP Selection at Startup when “Keep” Data is Broken

When data to be kept such as “keep” designated counter values are broken while the CPU is powered down, the user can

select whether the CPU starts to run or not to prevent undesirable operation at the next startup.

Module ID Registration

Another protection method to run or stop operation is the module ID registration. When disparity is found between the

module ID registration and actual modules in the system setup, the CPU can be made to start to run or not.

User Memory Download from Memory Card

A user program can be transferred using WindLDR from a computer to a miniature memory card. The handy miniature card

can be inserted into the CPU module to download the user program. User programs can be replaced without the need for

connecting to a computer. This feature is available on CPU modules FC3A-CP2KM and FC3A-CP2SM.

Constant Scan Time

The scan time may vary whether basic and advanced instructions are executed or not depending on input conditions to

these instructions. When performing repetitive control, the scan time can be made constant by entering a required scan

time value into a special data register reserved for constant scan time.

Keep Output Status during User Program Download

Outputs can be designated to maintain the current statuses when downloading a user program from WindLDR to the CPU.

This function can be used when the output status change does not occur frequently.

Stop and Reset Inputs

Any input number can be designated as a stop or reset input to control the OpenNet Controller operation.

1-2 OPENNET CONTROLLER USER’S MANUAL

Page 12

1: GENERAL INFORMATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

System Setup

This section describes various system setup configurations for using powerful communication functions of the OpenNet

Controller

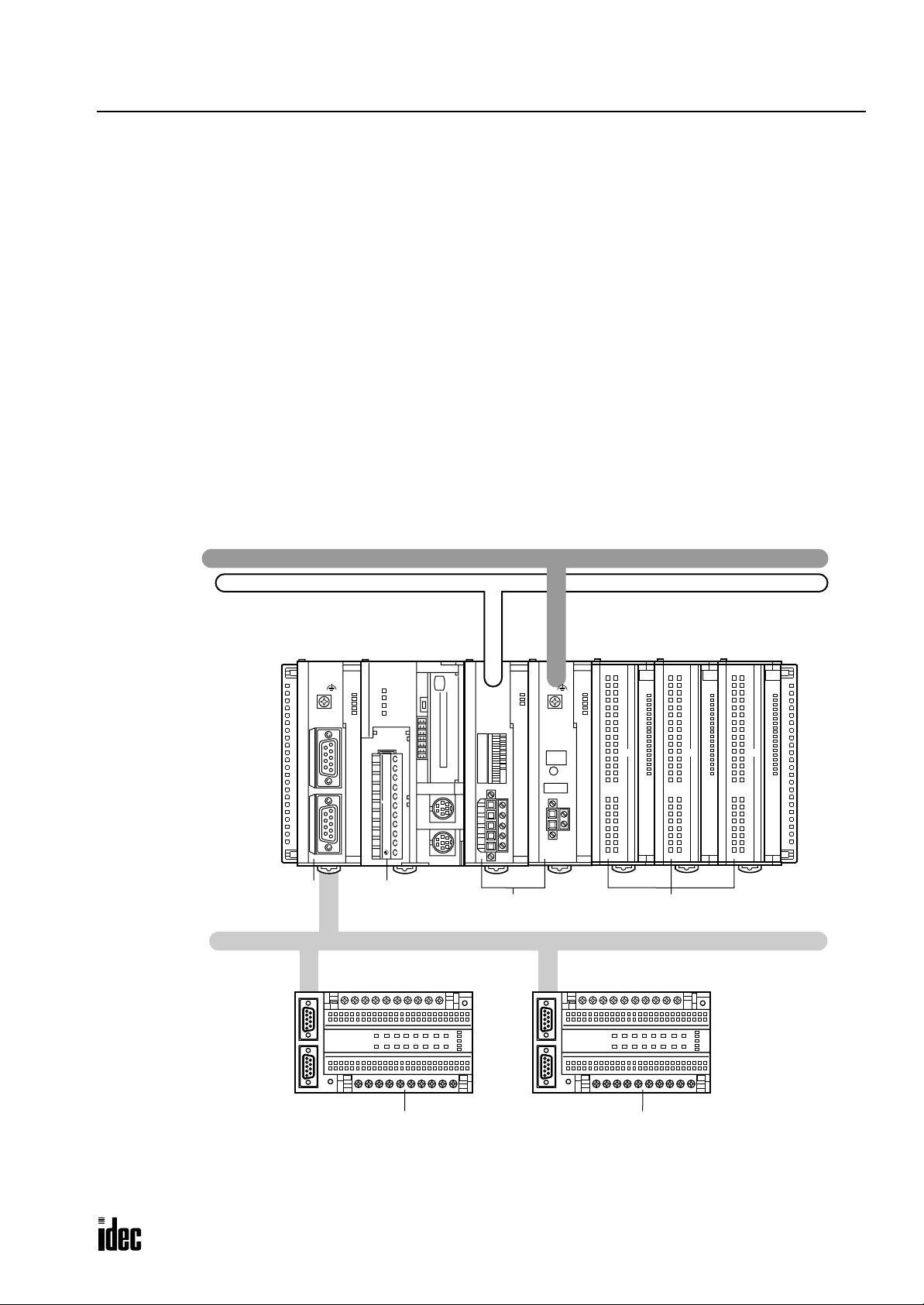

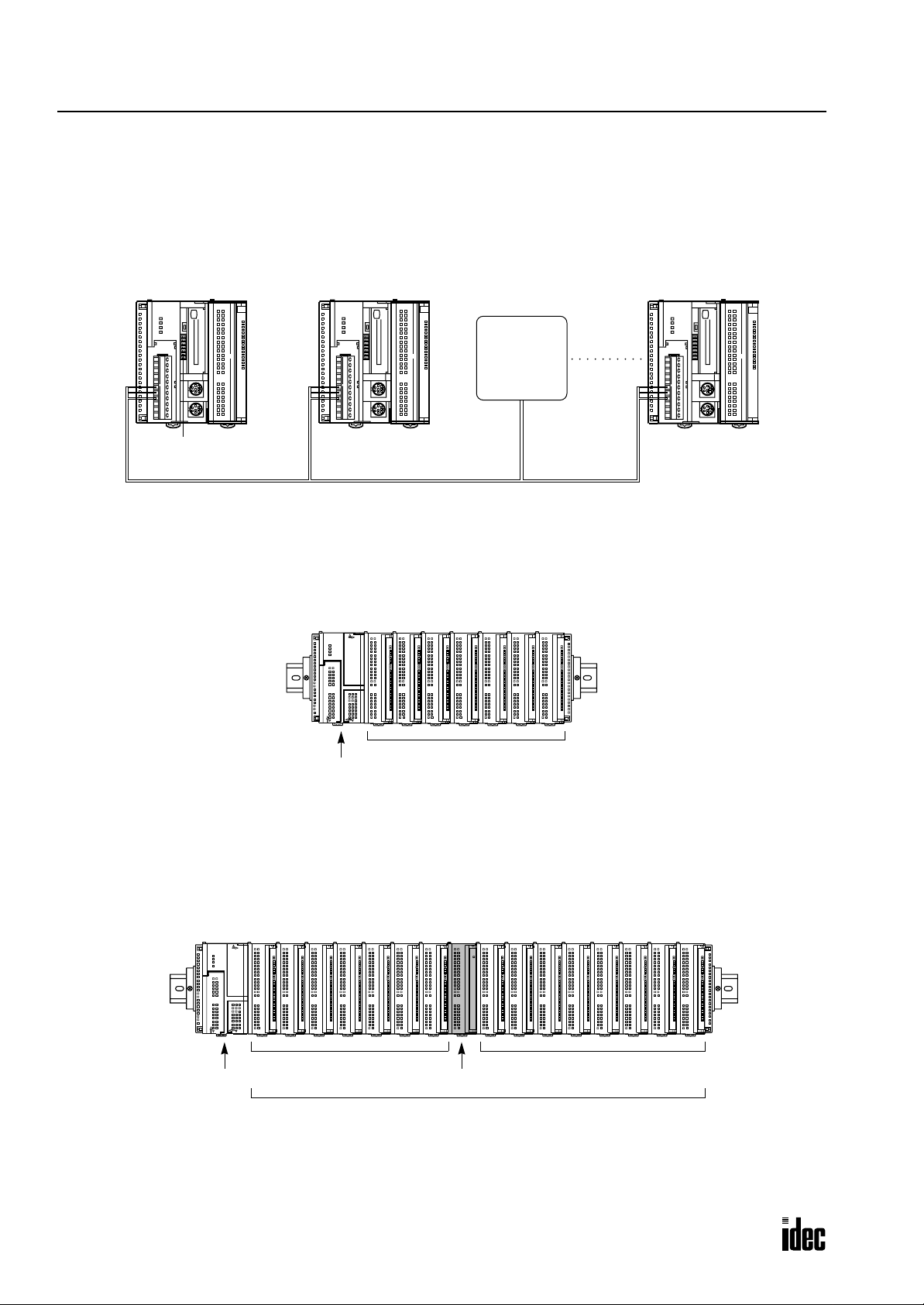

Open Network Communication System

The OpenNet Controller can be connected to three open network communication lines — DeviceNet, LONWORKS, and

INTERBUS.

OpenNet interface modules are available for communication through DeviceNet and LONWORKS networks. The OpenNet

interface modules, such as DeviceNet slav e modules and LONWORKS interface modules, serv e as a sla ve station or node in

the network.

A remote I/O system can be set up using a remote I/O master module mounted next to the CPU module and SX5S communication I/O terminals at remote I/O slave stations. When using 32 SX5S modules with 16 input or output points, a total of

512 I/O points can be distributed to 32 remote s lave stations at the maximum. The remote I/O network uses the INTERBUS protocol for communication. The total cable length can be 12.8 km (7.95 miles) maximum.

One remote I/O master module can be mounted with the

seven functional modules including OpenNet interface modules and analog I/O modules can be mounted with one Open-

Net Controller

.

OpenNet Controller CPU module. In addition, a maximum of

CPU module.

LONWORKS

DeviceNet

INTERBUS

Remote I/O

Master Module

V.24 InterfaceREMOTE OUT

RDY/

POWER

RUN

RUN

FAIL

BSA

ERROR

PF

HF

HSC OUT

COM A B Z

HSC

OUT

ABG

RS485

+24V 0V

idec

POW

MNS

I O

NO

H/L

DR1

DR0

NA5

NA4

NA3

NA2

NA1

NA0

idec

SERVICE

REQUEST

LON

POW

RUN

ERR

I/O

SER

idec

0

1

2

3

4

5

6

7

10

11

12

13

14

15

16

17

0

1

2

3

4

5

6

7

10

11

12

13

14

15

16

17

0

1

2

3

4

5

6

7

10

11

12

13

14

15

16

17

CPU

Module

OpenNet Interface Modules I/O Modules

UL

RC

BA

ER

RD

REMOTE OUT REMOTE IN

REMOTE OUT REMOTE IN

SX5S

INTERBUS

Remote I/O

REMOTE OUT REMOTE IN

REMOTE OUT REMOTE IN

SX5S

INTERBUS

Remote I/O

SX5S Communication I/O Terminals

OPENNET CONTROLLER USER’S MANUAL 1-3

UL

RC

BA

ER

RD

Page 13

1: GENERAL INFORMATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

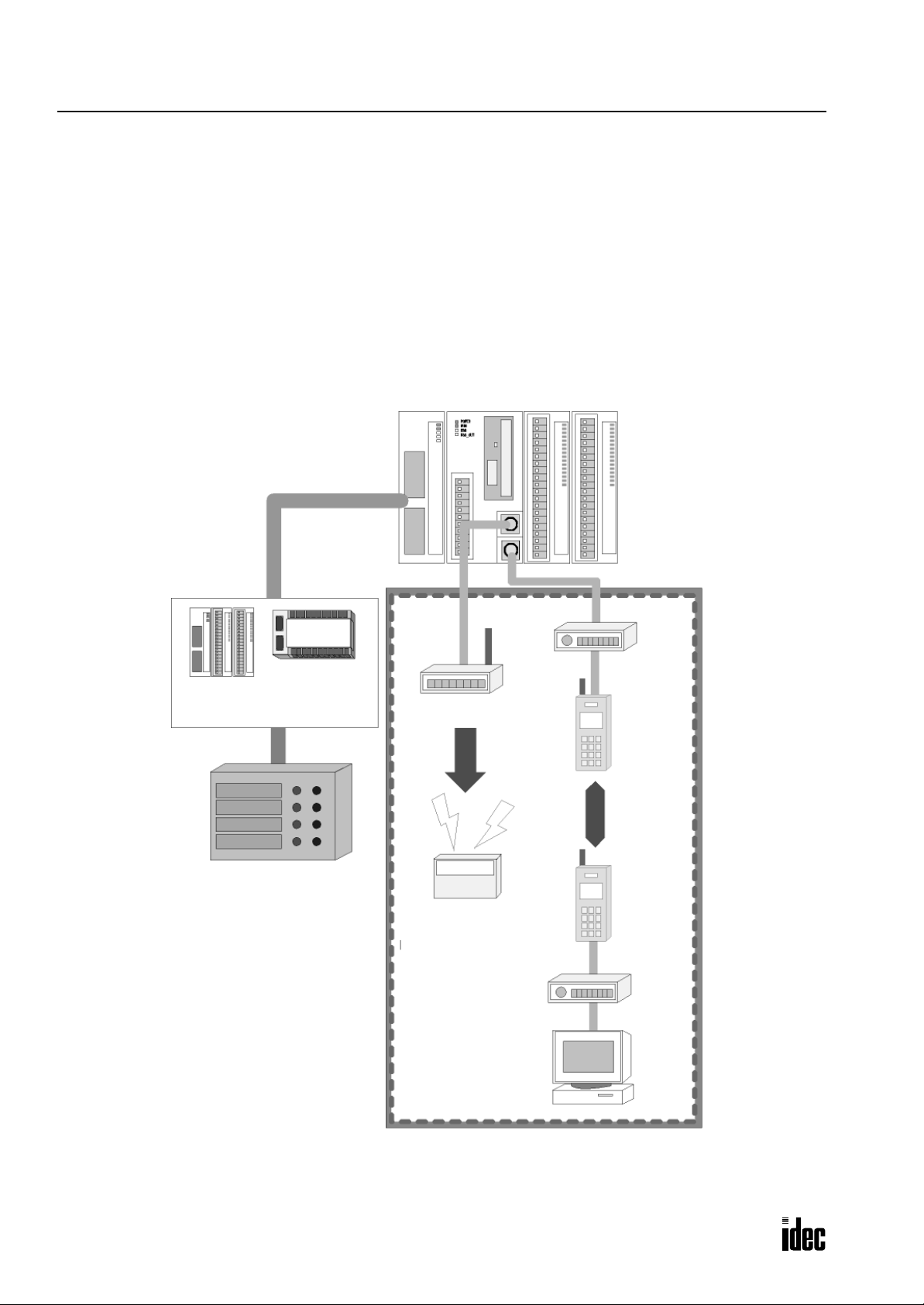

User Communication System

The OpenNet Controller CPU module has two RS232C ports and one RS485 port to control two RS232C devices and one

RS485 device such as IDEC’s HG series operator interface at the same time.

The figure below illustrates a system setup of remote I/O and user communication. In this example, the I/O statuses of a

remote machine are transferred through the remote I/O line to the CPU. The data received through modems is monitored

on a computer and also sent to a pager transmitter.

For details about the remote I/O system, see page 24-1.

For details about the modem mode, see page 23-1.

OpenNet Controller Master Station

Module Type

Slave Station

Remote Machine

Modem

Terminal Block Type

Pager Transmitter

Data

Transmission

Data

Communication

Pager

Modem

Computer

1-4 OPENNET CONTROLLER USER’S MANUAL

Page 14

1: GENERAL INFORMATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

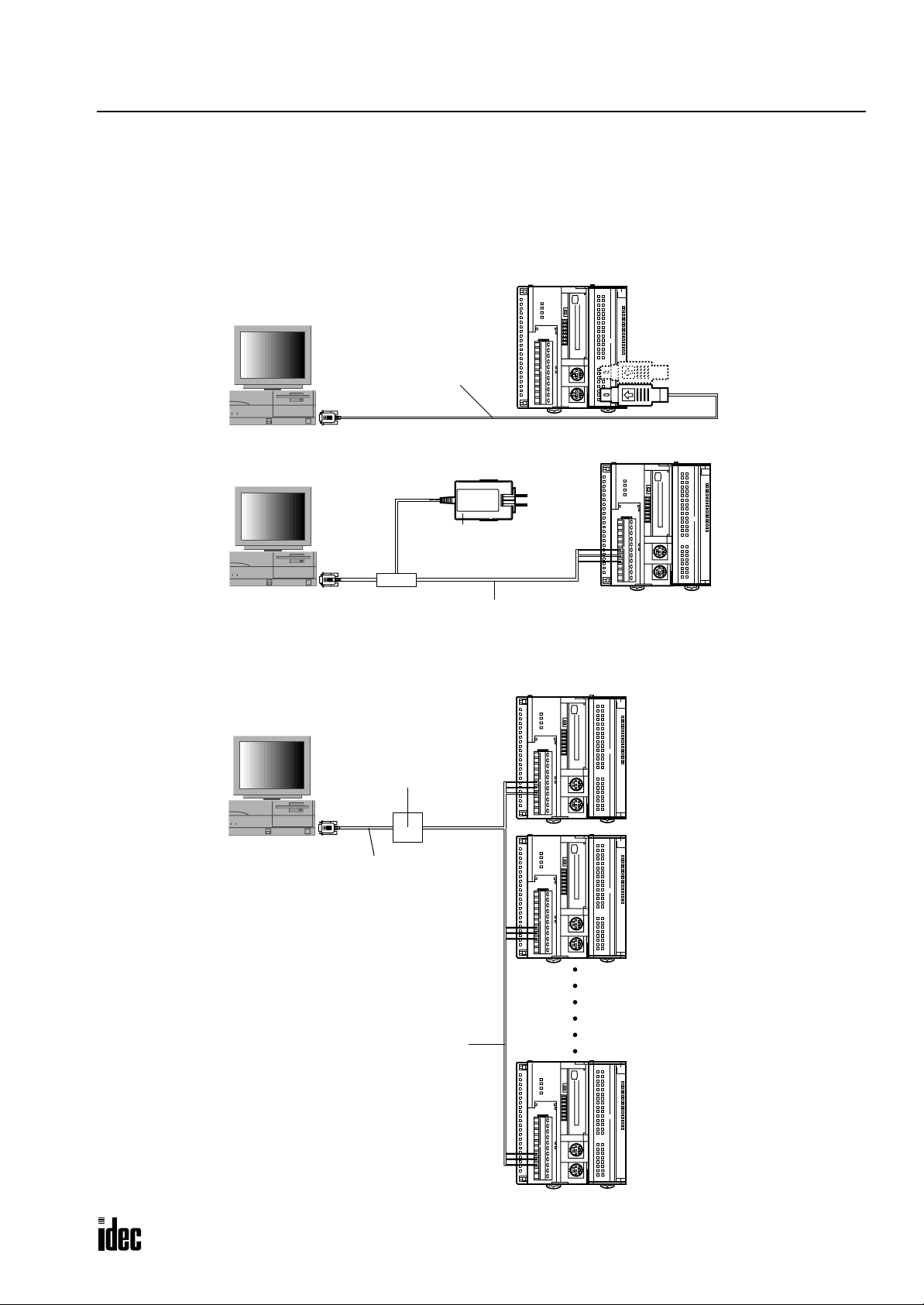

Computer Link System

When the OpenNet Controller is connected to a computer, operating status and I/O status can be monitored on the computer, data in the CPU module can be monitored or updated, and user programs can be downloaded and uploaded. A maximum of 32 OpenNet Controller CPU modules can be connected to one computer in the 1:N computer link system.

For details about the computer link communication, see page 22-1.

Computer Link 1:1 Communication

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

RS232C Port 1 or Port 2

17

Computer Link Cable 4C

FC2A-KC4C

3m (9.84 ft.) long

D-sub 9-pin Female Connector

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

AC Adapter

RS485

17

D-sub 9-pin

Female Connector

Computer Link 1:N Communication

RS232C/RS485 Converter

D-sub 9-pin

Female Connector

Twist-pair Shielded Cable

FC2A-MD1

RS232C Cable

HD9Z-C52

1.5m (4.92 ft.) long

Computer Link Cable 6C

FC2A-KC6C

2m (6.56 ft.) long

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1st Unit

2nd Unit

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

32nd Unit

16

17

RS485

OPENNET CONTROLLER USER’S MANUAL 1-5

Page 15

1: GENERAL INFORMATION

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Data Link System

One OpenNet Controller at the master station can communicate with 31 slave stations through the RS485 line to exchange

data and perform distributed control effecti vely. The RS485 terminals are connected with each other using a 2-core twisted

pair cable.

For details about the data link communication, see page 21-1.

Master Station Slave Station 1 Slave Station 2

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

HG Series

Operator

Interface

Slave Station 31

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Communication

Selector

DIP Switch

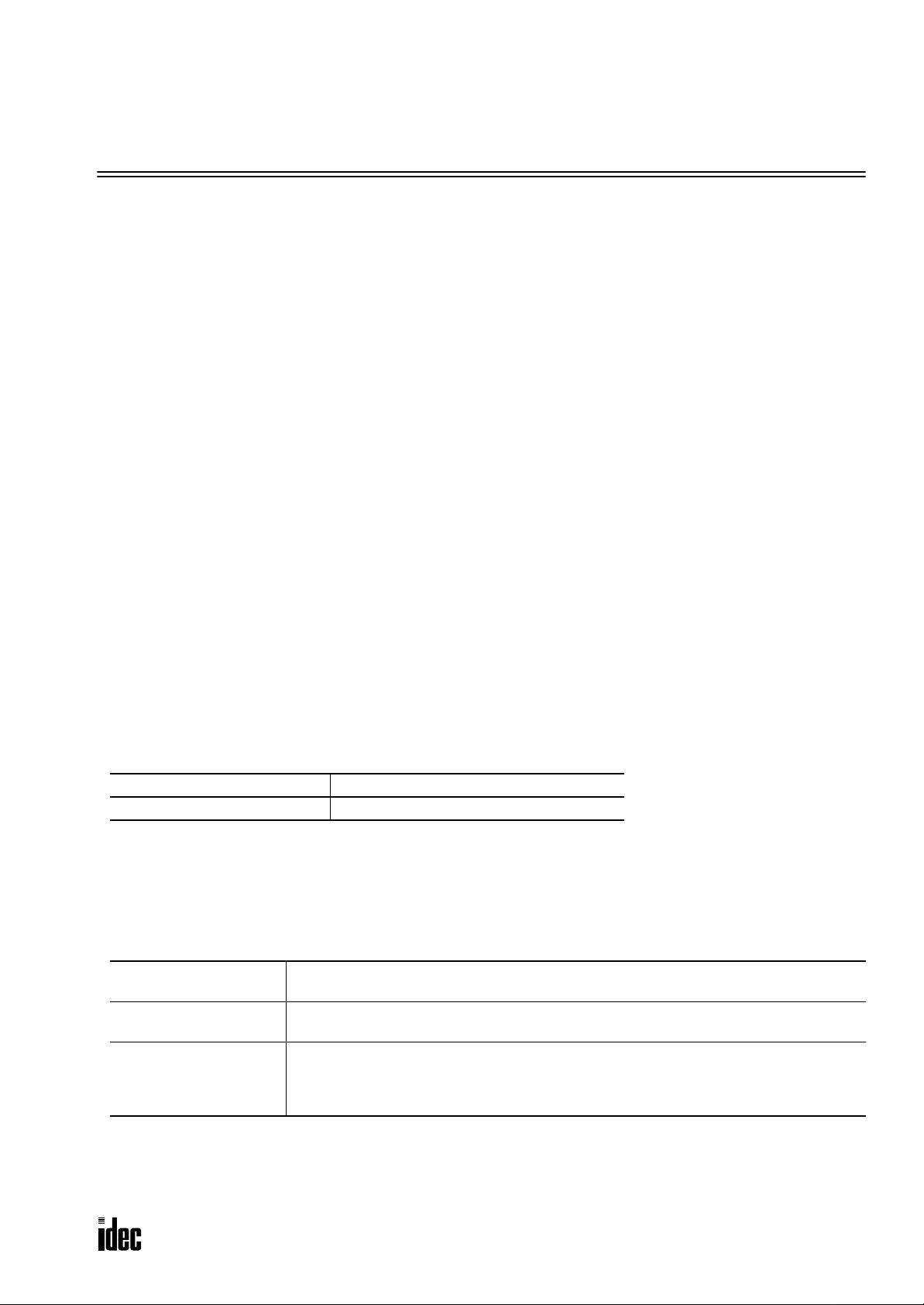

Basic System

The OpenNet Controller CPU module can be mounted with seven modules including digital I/O and functional modules

such as analog I/O, DeviceNet slave, and LONWORKS interf ace modules to set up a stand alone system. When using seven

digital I/O modules, the I/O points can be 224 points at the maximum.

7 modules (I/O and functional)

CPU Module

Expansion System

The FC3A-EA1 expansion power supply module is used to mount more than seven I/O and functional modules. When a

maximum of 15 I/O modules are mounted, the number of I/O points is expanded from 224 to 480 maximum.

Whether an expansion power supply module is used or not, sev en functional modules such as analog I/O, De viceNet sla ve,

ONWORKS interface modules can be mounted at the maximum in either the normal or expansion slots.

and L

CPU Module

7 modules (I/O and functional)

Expansion Power Supply Module

A maximum of 7 functional modules can be mounted in any of 15 slots

8 modules (I/O and functional)

1-6 OPENNET CONTROLLER USER’S MANUAL

Page 16

2: MODULE SPECIFICATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

This chapter describes OpenNet Controller modules, parts names and specifications of each module.

Available modules include CPU modules, digital I/O modules, analog I/O modules, expansion power supply module,

remote I/O master module, and OpenNet interface modules such as DeviceNet slave and LONWORKS interface modules.

Analog I/O modules and OpenNet interface modules are also called functional modules. A maximum of seven functional

modules can be mounted with one CPU module.

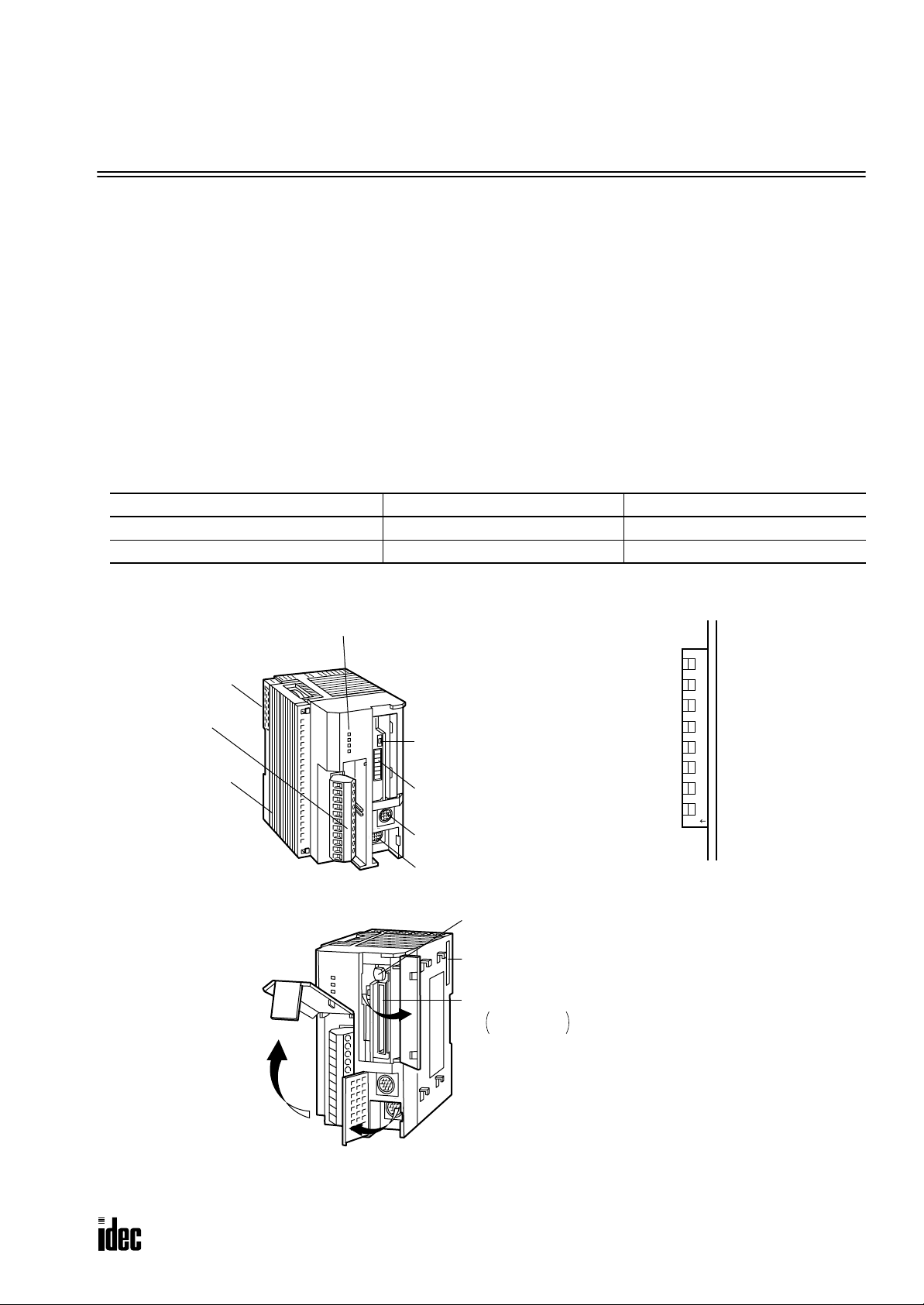

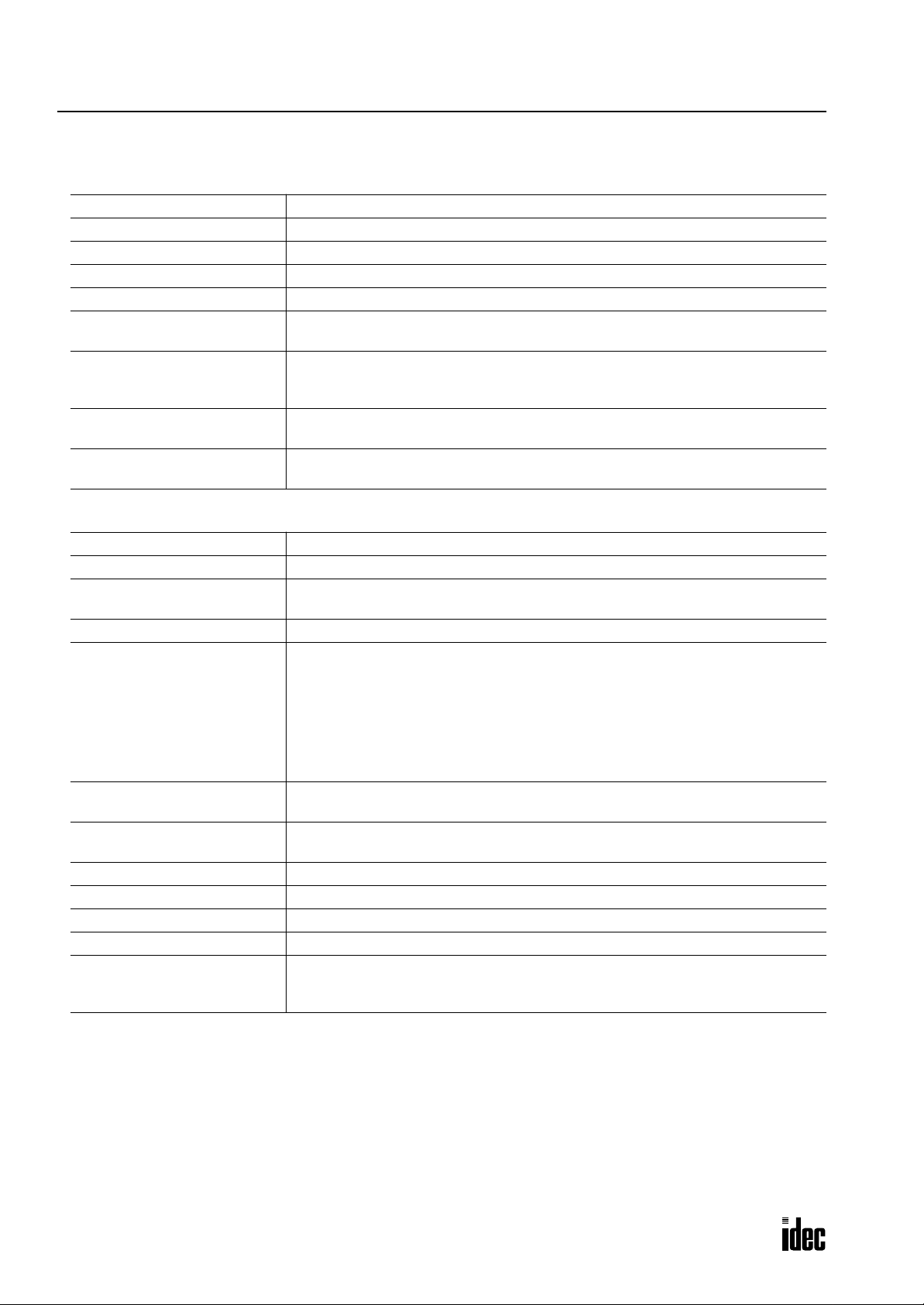

CPU Module

The CPU modules are available in sink and source output types which have a transistor sink or source output of the highspeed counter, respectively. Either type is available with or without a memory card connector. All CPU modules have two

RS232C ports and one RS485 port.

CPU Module Type Numbers

CPU Module Types Without Memory Card Connector With Memory Card Connector

High-speed Counter Sink Output Type FC3A-CP2K FC3A-CP2KM

High-speed Counter Source Output Type FC3A-CP2S FC3A-CP2SM

Parts Description

(10) Remote I/O

Master Module

Connector

(8) Terminal Block

(11) End Plate

(1) Status LED

(2) Communication

Enable Button

(3) Communication

Selector

DIP Switch

(7) RS232C Port 2

(6) RS232C Port 1

(5) Memory Card

Eject Button

(9) Expansion Connector

(4) Memory Card Connector

FC3A-CP2KM

FC3A-CP2SM

12345678

O

N

Communication Selector DIP Switch

Opening the Covers

Functions of each part are described on the following pages.

OPENNET CONTROLLER USER’S MANUAL 2-1

Page 17

2: MODULE SPECIFICATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

(1) Status LED

POWER Turns on when power is supplied to the CPU

RUN Turns on when the CPU is running

ERROR Turns on or flashes when an error occurs

HSC OUT Turns on when the high-speed counter comparison output is on

(2) Communication Enable Button

Enables the communication mode selected with the communication selector DIP switch. When the communication selector DIP switch setting is changed while the CPU is powered up, press this button to enable the new communication mode

for the RS485 and RS232C ports.

(3) Communication Selector DIP Switch

Selects the communication mode for the RS485 and RS232C ports, and also selects the device number for the CPU in the

computer link or data link communication network.

DIP Switch No. Function Setting

1 RS485 port communication mode ON: Data link mode OFF: Maintenance mode

2 RS232C port 1 communication mode ON: User communication mode OFF: Maintenance mode

3 RS232C port 2 communication mode ON: User communication mode OFF: Maintenance mode

4 to 8 Device number selection

Device numbers 0 through 31 for the CPU in the computer

link or data link communication network

Data link mode: Used for data link communication

User communication mode: Used for user communication or modem communication

Maintenance mode: Used for computer link communication between the CPU and WindLDR on computer

After changing the settings of the communication selector DIP switch while the CPU is powered up, press the communication enable button for more than 4 seconds until the ERROR LED blinks once; then the new communication mode for the

RS485 or RS232C port takes effect. When the CPU is powered up, the CPU checks the settings of the communication

selector DIP switch and enables the selected communication mode and device number automatically . You have to press the

communication enable button only when you change the DIP switch settings while the CPU is powered up.

Do not power up the CPU while the communication enable button is depressed and do not press the button unless it is necessary.

(4) Memory Card Connector

Plug a miniature memory card into the memory card connector. When a memory card is inserted, the CPU runs the user

program contained in the memory card instead of the user program stored in the CPU memory.

The memory card connector is provided on CPU modules FC3A-CP2KM and FC3A-CP2SM.

(5) Memory Card Eject Button

Press this button to eject the memory card from the CPU module.

(6) RS232C Port 1

Communication port used for the maintenance and user communication modes. User communication instructions TXD1

and RXD1 send and receive data through this port.

(7) RS232C Port 2

Communication port used for the maintenance and user communication modes. User communication instructions TXD2

and RXD2 send and receive data through this port.

2-2 OPENNET CONTROLLER USER’S MANUAL

Page 18

2: MODULE SPECIFICATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

(8) Terminal Block

Function Terminal No. Symbol Assignment

1 COM High-speed counter COM

High-speed Counter

Terminals

RS485 Port

Power Supply Terminals

(9) Expansion Connector

For connecting a digital I/O module or functional module.

(10) Remote I/O Master Module Connector

For connecting a remote I/O master module compatible with INTERBUS. This connector is located on the left side of the

CPU module and usually covered with an end plate. When connecting a remote I/O master module, remove the end plate

from the CPU module and attach the remote I/O master module.

2A High-speed counter phase A

3B High-speed counter phase B

4Z High-speed counter phase Z

5 HSC OUT High-speed counter comparison output

6 RS485 A RS485 line A

7 RS485 B RS485 line B

8 RS485 G RS485 line SG

9 +24V Power supply +24V DC

10 0V Power supply 0V DC

11 Frame ground

(11) End Plate

A pair of end plates are supplied with the CPU module. Remove the end plate from the CPU module before connecting

digital I/O and functional modules, then attach the end plates on both sides of the assembly. For removing the end plates,

see page 3-3.

OPENNET CONTROLLER USER’S MANUAL 2-3

Page 19

2: MODULE SPECIFICATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

General Specifications

Normal Operating Conditions

Operating Temperature 0 to 55°C (operating ambient temperature)

Storage Temperature –25 to +70°C

Relative Humidity Level RH1, 30 to 95% (non-condensing)

Pollution Degree 2 (IEC 60664-1)

Corrosion Immunity Free from corrosive gases

Altitude

Vibration Resistance

Shock Resistance

Weight (approx.)

Power Supply

Rated Power Voltage 24V DC

Allowable Voltage Range 19 to 30V DC (including ripple)

Dielectric Strength

Maximum Input Current 1.5A at 24V DC

Power Consumption

Allowable Momentary Power

Interruption

Insulation Resistance

Inrush Current 40A maximum (24V DC)

Ground Grounding resistance: 100Ω maximum

Grounding Wire UL1015 AWG22, UL1007 AWG18

Power Supply Wire UL1015 AWG22, UL1007 AWG18

Effect of Improper Power

Supply Connection

Operation: 0 to 2,000m (0 to 6,565 feet)

Transport: 0 to 3,000m (0 to 9,840 feet)

10 to 57 Hz amplitude 0.075 mm, 57 to 150 Hz acceleration 9.8 m/sec

10 sweep cycles per axis on each of three mutually perpendicular axes

(total 80 minutes each) (IEC1131)

147 m/sec

dicular axes (IEC1131)

FC3A-CP2K/CP2S (w/o memory card connector): 290g

FC3A-CP2KM/CP2SM (w/memory card connector): 300g

Between power terminal and FG: 500V AC, 1 minute

Between I/O terminal and FG: 1,500V AC, 1 minute

8.4W (24V): CPU module + 48 I/Os (32-DC input module + 16-relay output module)

18W (24V): CPU module + 128 I/Os (32-DC input module × 2 + 16-DC input mod-

11.8W (24V): CPU module + remote I/O master module + 48 I/Os (32-DC input mod-

21.4W (24V): CPU module + remote I/O master module + 128 I/Os (32-DC input

10 msec (24V DC), Level PS-2 (EN61131)

Between power terminal and FG: 10 MΩ minimum (500V DC megger)

Between I/O terminal and FG: 10 MΩ minimum (500V DC megger)

Reverse polarity: No operation, no damage

Improper voltage or frequency: Permanent damage may be caused

Improper lead connection: Permanent damage may be caused

2

(15G), 11 msec duration, 3 shocks per axis, on three mutually perpen-

ule + 16-relay output module × 3)

ule + 16-relay output module)

module × 2 + 16-DC input module + 16-relay output module × 3)

2

(1G)

2-4 OPENNET CONTROLLER USER’S MANUAL

Page 20

2: MODULE SPECIFICATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Function Specifications

CPU Module Specifications

Program Capacity 16K words (8K steps)

Quantity of Slots

I/O

User Program Memory Flash ROM, RAM, memory card

RAM

Backup

Control System Stored program system (not in compliance with EN61131-3)

Instruction Words

Processing Time

Internal Relay 2,048 points

Data Register 8,000 points

Counter 256 points (adding, dual pulse reversible, up/down selection reversible)

Timer 256 points (1-sec, 100-msec, 10-msec, 1-msec)

Catch Input

Calendar/Clock

Self-diagnostic Function

Start/Stop Method

Maximum Digital

I/O Points

Backup Duration Approx. 30 days (typical) at 25°C after backup battery fully charged

Backup Data Internal relay, shift register, counter, data register

Battery Lithium secondary battery

Charging Speed Approx. 2 hours from 0% to 90% of full charge

Battery Life Approx. 10 years using in cycles of 9-hour charging, 15-hour discharging

Replaceability Impossible

7 slots maximum (without using expansion power supply module)

15 slots maximum (when using expansion power supply module)

224 points (without using expansion power supply module)

480 points (when using expansion power supply module)

• 56 points when using 7 modules of 8-point I/O

• 112 points when using 7 modules of 16-point I/O

• 224 points when using 7 modules of 32-point I/O

• 480 points when using 15 modules of 32-point I/O

37 basic instructions

65 advanced instructions

Basic/advanced instruction: See page A-1.

END processing: See page A-2.

Clock/calendar processing: One cycle in 100 msec (see page A-2)

Data link master station processing: See pages page 21-1 and page 21-10.

First 8 channels of each input module can be designated as catch inputs

Minimum turn on pulse width: 40 µsec maximum

Minimum turn off pulse width: 150 µsec maximum

Accuracy: ±30 sec/month at 25°C (typical)

Backup duration: Approx. 30 days 25°C (typical)

Keep data sum check, WDT check, user program RAM sum check, user program ROM

sum check, user program write check, power failure check, timer/counter preset

value sum check, calendar/clock error check, user program syntax check, data link

connection check, I/O bus check, I/O bus initialization check, user program execution

check

Turning power on and off

Start/stop command in WindLDR

Turning start control special internal relay M8000 on and off

Turning designated stop or reset input off and on

OPENNET CONTROLLER USER’S MANUAL 2-5

Page 21

2: MODULE SPECIFICATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

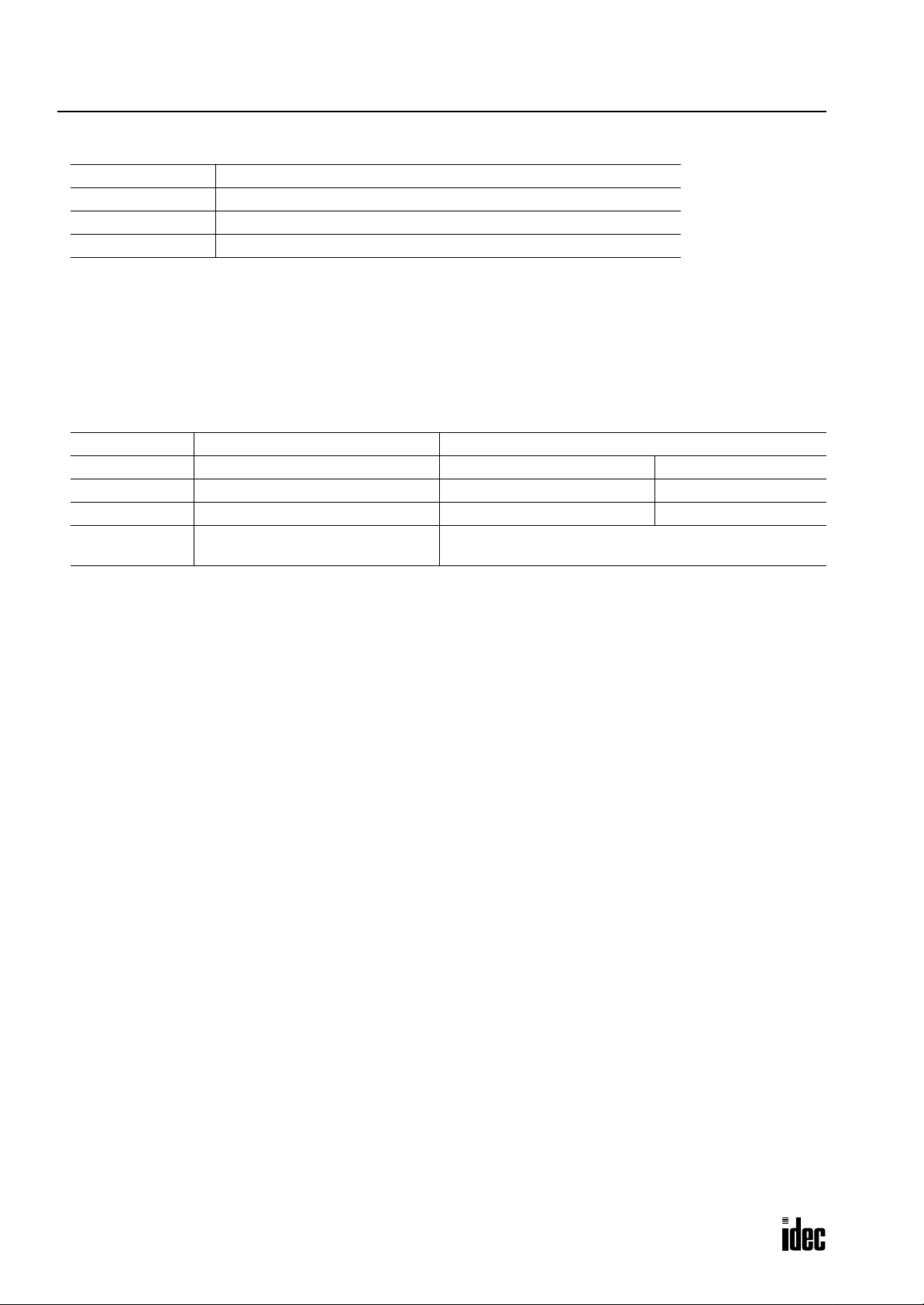

System Statuses at Stop, Reset, and Restart

Internal Relays, Shift Registers,

Mode Outputs

Run Operating Operating Operating Operating Operating

Reset (Reset input ON) OFF OFF/Reset to zero OFF/Reset to zero Reset to zero Reset to zero

Stop (Stop input ON) OFF Unchanged Unchanged Unchanged Unchanged

Restart Unchanged Unchanged OFF/Reset to zero Reset to preset Unchanged

Note: Link registers used as outputs are turned off like outputs.

Counters, Data Registers

Keep Type Clear Type

Communication Function

Communication Port RS232C Port 1 RS232C Port 2 RS485 Port

Standards EIA RS232C EIA RS232C EIA RS485

Baud Rate 19,200 bps 19,200 bps

Maintenance Communication Possible Possible Possible

User Communication Possible Possible Impossible

Data Link Communication Impossible Impossible Possible

Quantity of Slave Stations ——31

Maximum Cable Length Special cable Special cable 200m *

Isolation between Power Supply and

Communication Port

Not isolated Not isolated Not isolated

Timer

Current Value

Computer link: 19,200 bps

Data link: 38,400 bps

Link Register

(Note)

* Recommended cable for data link: Twisted-pair shielded cable with a minimum core wire diameter of 0.9 mm.

Conductor resistance 85 Ω/km maximum, shield resistance 20 Ω/km maximum.

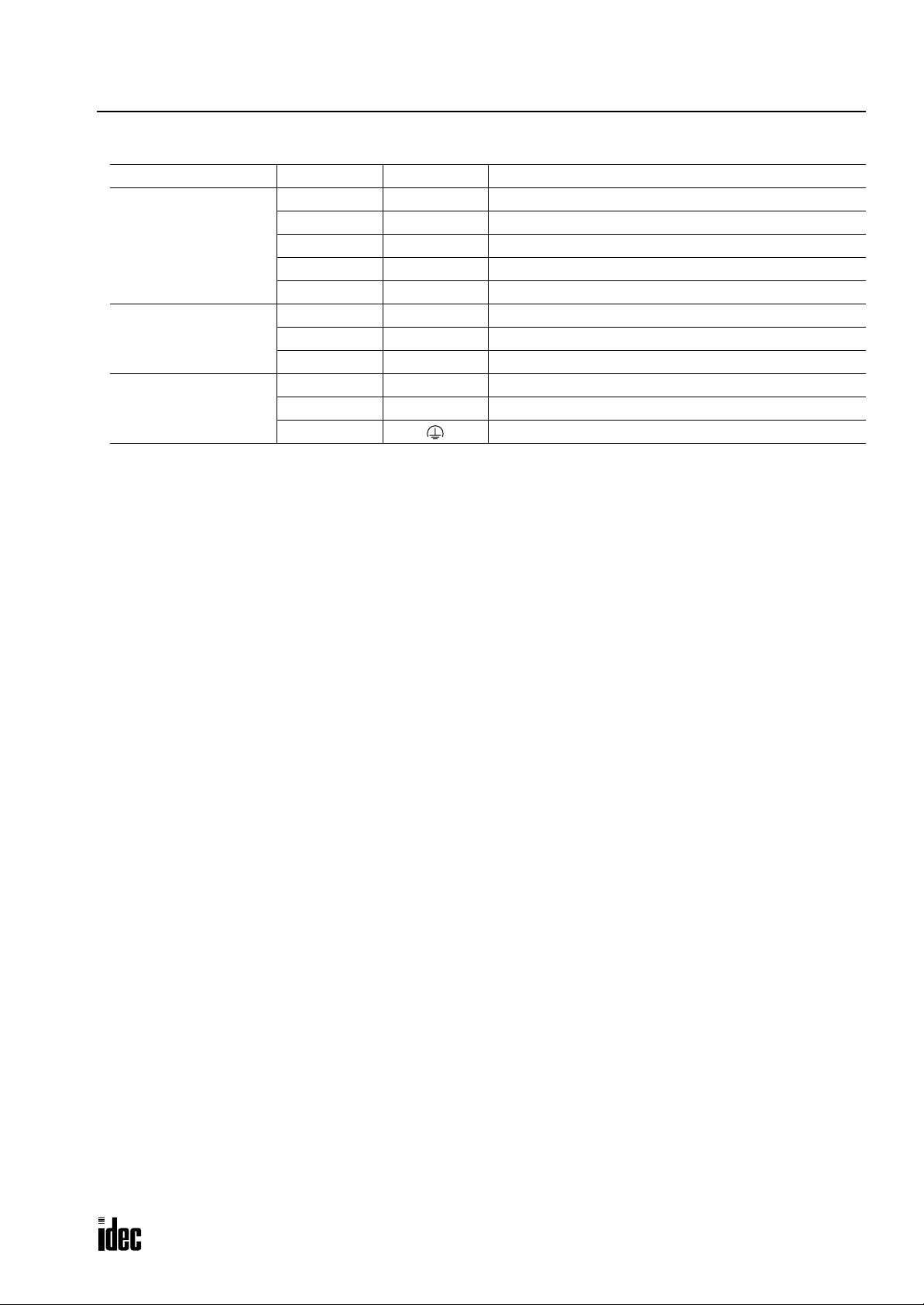

Communication Selector DIP Switch Settings

DIP Switch No. Function Setting

1 RS485 port communication mode ON: Data link mode OFF: Maintenance mode

2 RS232C port 1 communication mode ON: User communication mode OFF: Maintenance mode

3 RS232C port 2 communication mode ON: User communication mode OFF: Maintenance mode

4 to 8 Device number selection Device numbers 0 through 31 for the CPU

Memory Card

Card Type Miniature memory card

Accessible Memory Capacity 2MB, 5V type

Download Destination CPU module (FC3A-CP2KM and -CP2SM)

Software for Writing Card WindLDR

Quantity of Stored Programs One user program stored on one memory card

Program Execution Priority When a memory card is inserted, user program on the memory card is executed.

High-speed Counter

Maximum Counting Frequency 10 kHz

Counting Range 0 to 65535 (16 bits)

Operation Mode

Comparison Output

Rotary encoder mode

Dual-pulse reversible counter mode

Transistor sink or source output 1 point (500mA)

Output delay: 20 µsec

2-6 OPENNET CONTROLLER USER’S MANUAL

Page 22

2: MODULE SPECIFICATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

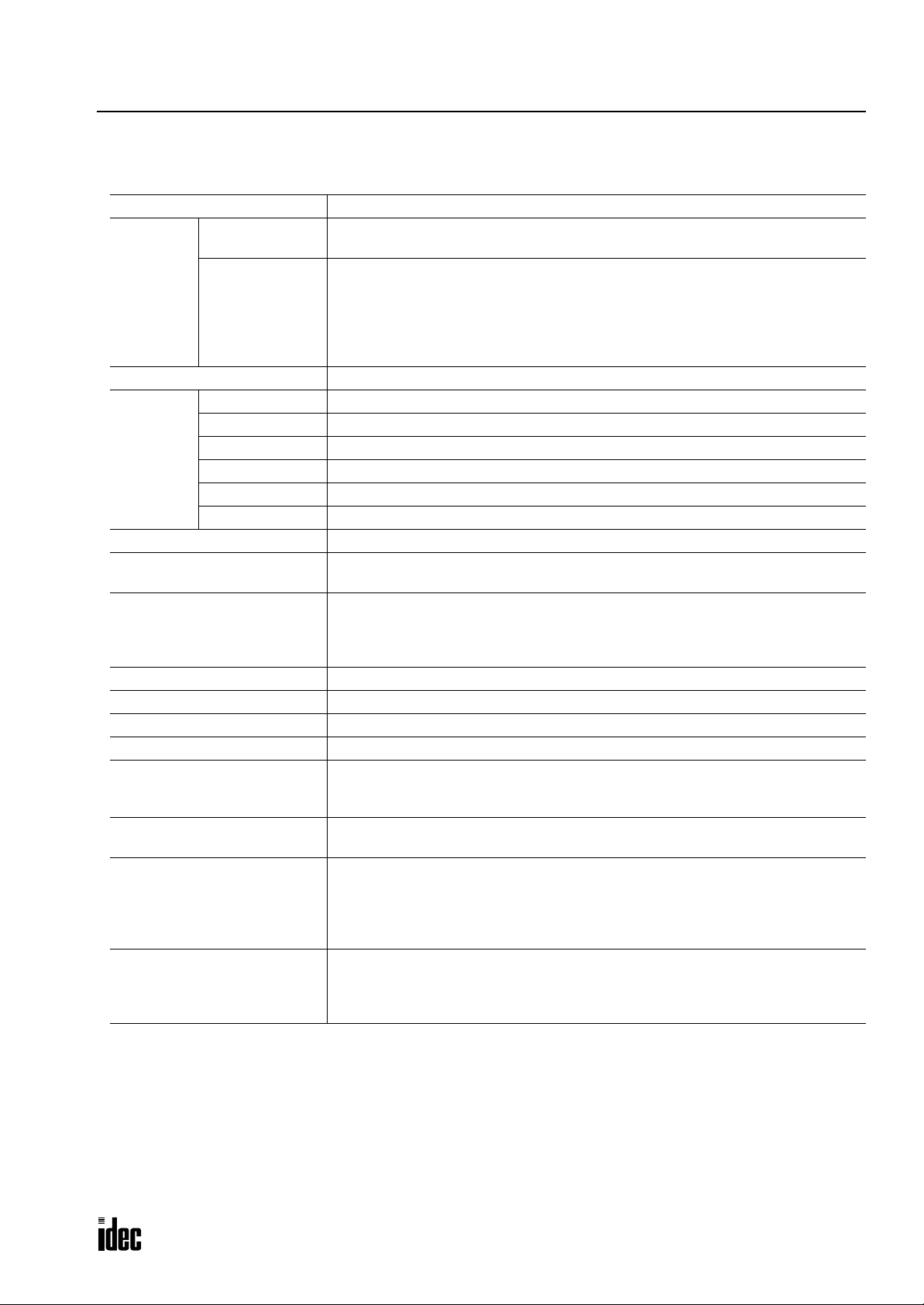

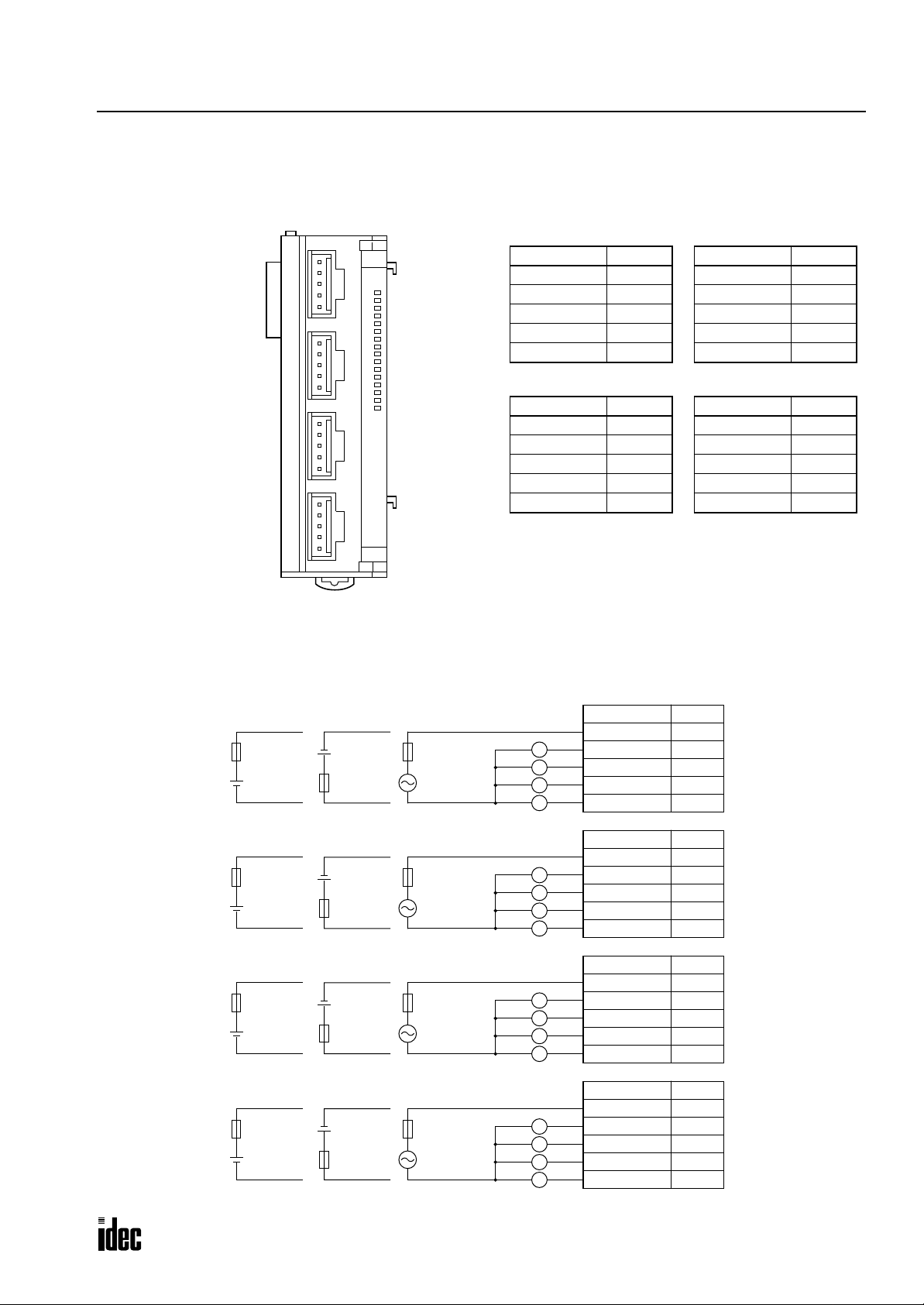

Input Module

Digital input modules are available in 16- and 32-point DC input modules and 8-point AC input modules. Four different

connector/terminal styles are available.

Input Module Type Numbers

Module Name 16-point DC Input 32-point DC Input 8-point AC Input

Screw Terminal FC3A-N16B1 — FC3A-N08A11

Nylon Connector

Fujitsu Connector — FC3A-N32B5 —

Parts Description

(6) Expansion Connector

FC3A-N16B3 ——

— FC3A-N32B4 —

(1) Module ID

(2) Status LED

(3) Terminal Block Cover

(4) Cable Terminal/Connector

This figure illustrates a screw terminal type input module.

(5) Terminal Label

(1) Module ID Indicates the input module ID.

DC IN: 24V DC sink/source input, 16 or 32 points

AC IN: 100V AC input, 8 points

(2) Status LED Turns on when input is on.

(3) Terminal Block Cover The terminal block cover flips open to the right.

When using long ferrules for wiring, the terminal block cover may be removed.

(4) Cable Terminal/Connector Five different terminal/connector styles are available for wiring.

(5) Terminal Label Indicates terminal numbers 1 through 20 on the terminal block.

(6) Expansion Connector Connects to CPU and other modules.

OPENNET CONTROLLER USER’S MANUAL 2-7

Page 23

2: MODULE SPECIFICATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

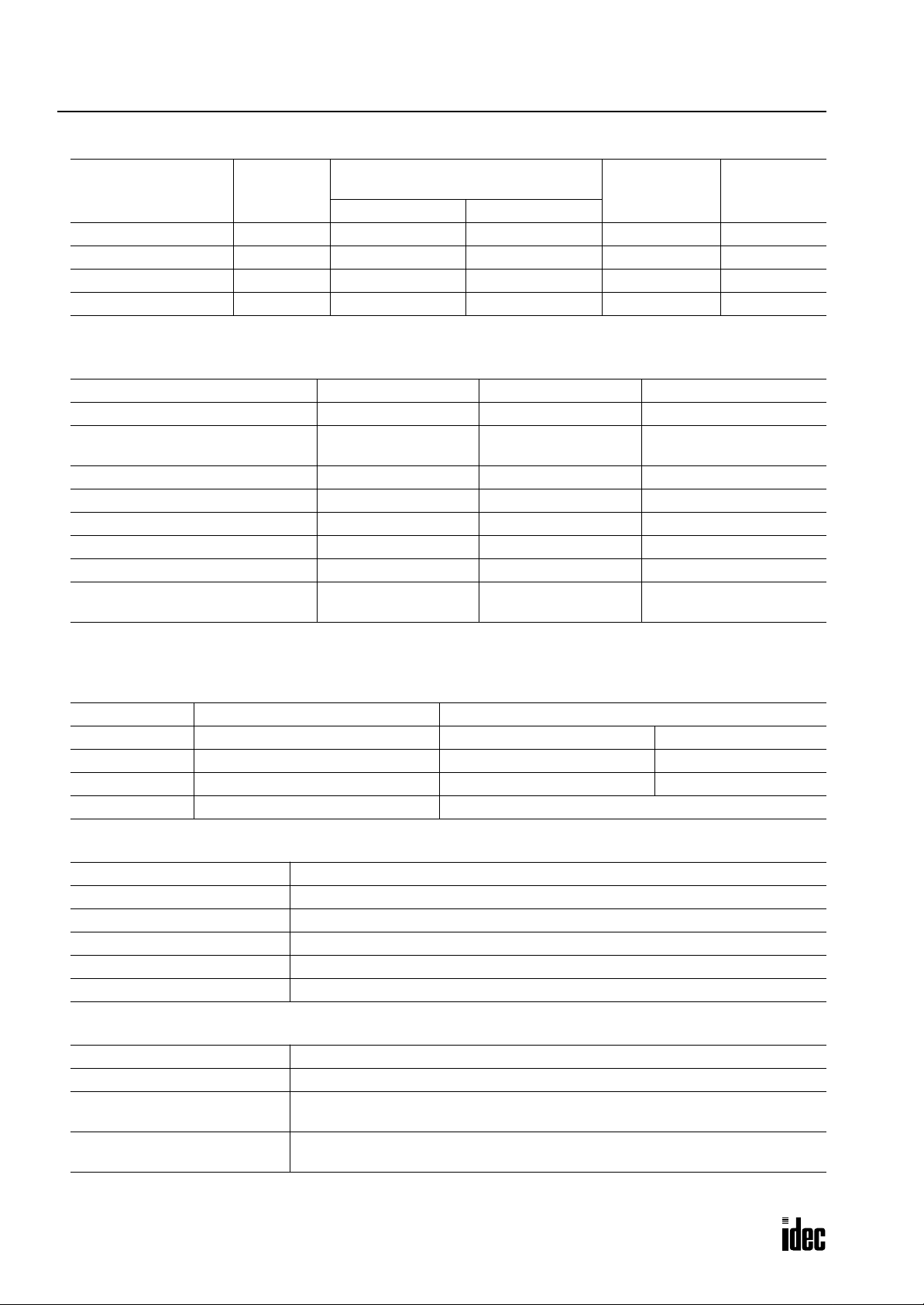

16-point DC Input Module Specifications

Type No. FC3A-N16B1 FC3A-N16B3

Rated Input Voltage 24V DC sink/source input signal

Input Voltage Range 19 to 30V DC

Rated Input Current 7 mA/point (24V DC)

Terminal Arrangement See Terminal Arrangement charts on pages 2-11 and 2-12.

Input Impedance 3.4 kΩ

Turn ON Time (24V DC) 20 µsec + filter preset

Turn OFF Time (24V DC) 120 µsec + filter preset

Input Filter 0 msec, 0.5 msec, 1 msec, 2 msec, 4 msec, 8 msec, 16 msec, 32 msec

Isolation

External Load for I/O Interconnection Not needed

Signal Determination Method Static

Effect of Improper Input Connection

Cable Length 3m (9.84 ft.) in compliance with electromagnetic immunity

Connector on Mother Board

Connector Insertion/Removal Durability 100 times minimum 50 times minimum

Internal Current Draw

Weight (approx.) 210g 180g

Between input terminals: Not isolated

Internal circuit: Photocoupler isolated

Both sinking and sourcing input signals can be connected. If any input

exceeding the rated value is applied, permanent damage may be caused.

Screw Terminal Block

MSTBA2.5/20-G5.08

(Phoenix Contact)

Nylon Connector

B10PS-VH × 2

(J.S.T. Mfg.)

All inputs ON: 40 mA (24V DC)

All inputs OFF: 10 mA (24V DC)

Input Operating Range

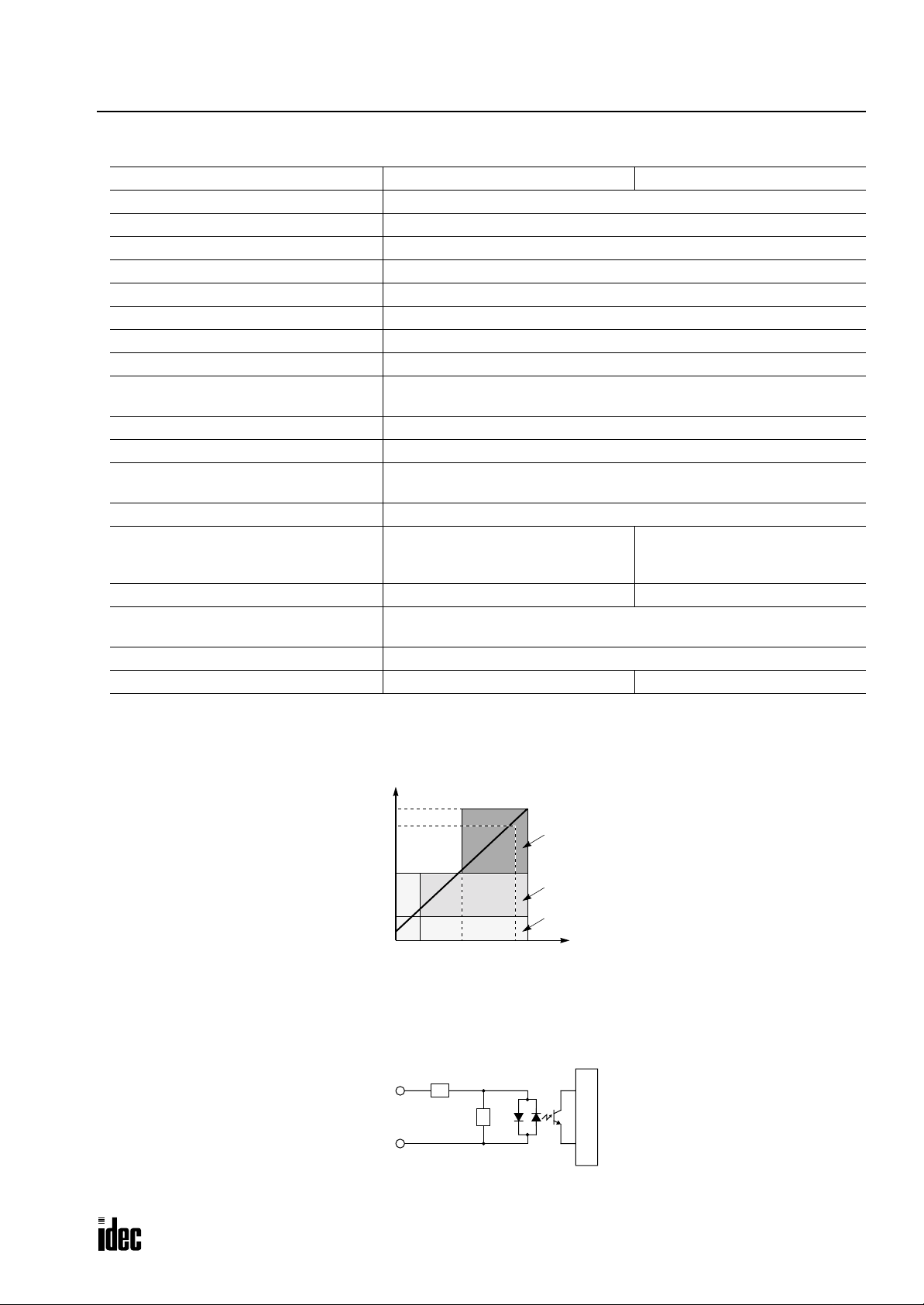

The input operating range of the Type 1 (EN61131) input module is shown below:

30

24

15

Input Voltage (V DC)

5

0

1.5 8.8

Input Current (mA)

74.4

ON Area

Transition

Area

OFF Area

Input Internal Circuit

COM

Input

3.3 kΩ

Internal Circuit

2-8 OPENNET CONTROLLER USER’S MANUAL

Page 24

2: MODULE SPECIFICATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

32-point DC Input Module Specifications

Type No. FC3A-N32B4 FC3A-N32B5

Rated Input Voltage 24V DC sink/source input signal

Input Voltage Range 20.4 to 27.6V DC

Rated Input Current 4.9 mA/point (24V DC)

Terminal Arrangement See Terminal Arrangement charts on pages 2-13 and 2-14.

Input Impedance 4.7 kΩ

Turn ON Time (24V DC) 20 µsec + filter preset

Turn OFF Time (24V DC) 120 µsec + filter preset

Input Filter 0 msec, 0.5 msec, 1 msec, 2 msec, 4 msec, 8 msec, 16 msec, 32 msec

Isolation

External Load for I/O Interconnection Not needed

Signal Determination Method Static

Effect of Improper Input Connection

Cable Length 3m (9.84 ft.) in compliance with electromagnetic immunity

Connector on Mother Board

Connector Insertion/Removal Durability 50 times minimum 500 times minimum

Internal Current Draw

Allowable Simultaneous ON Inputs 70% maximum

Weight (approx.) 230g 240g

Between input terminals: Not isolated

Internal circuit: Photocoupler isolated

Both sinking and sourcing input signals can be connected. If any input

exceeding the rated value is applied, permanent damage may be caused.

Nylon Connector

BS18P-SHF-1AA × 2

(J.S.T. Mfg.)

Fujitsu Connector

FCN-365P040-AU

(Fujitsu)

All inputs ON: 50 mA (24V DC)

All inputs OFF: 10 mA (24V DC)

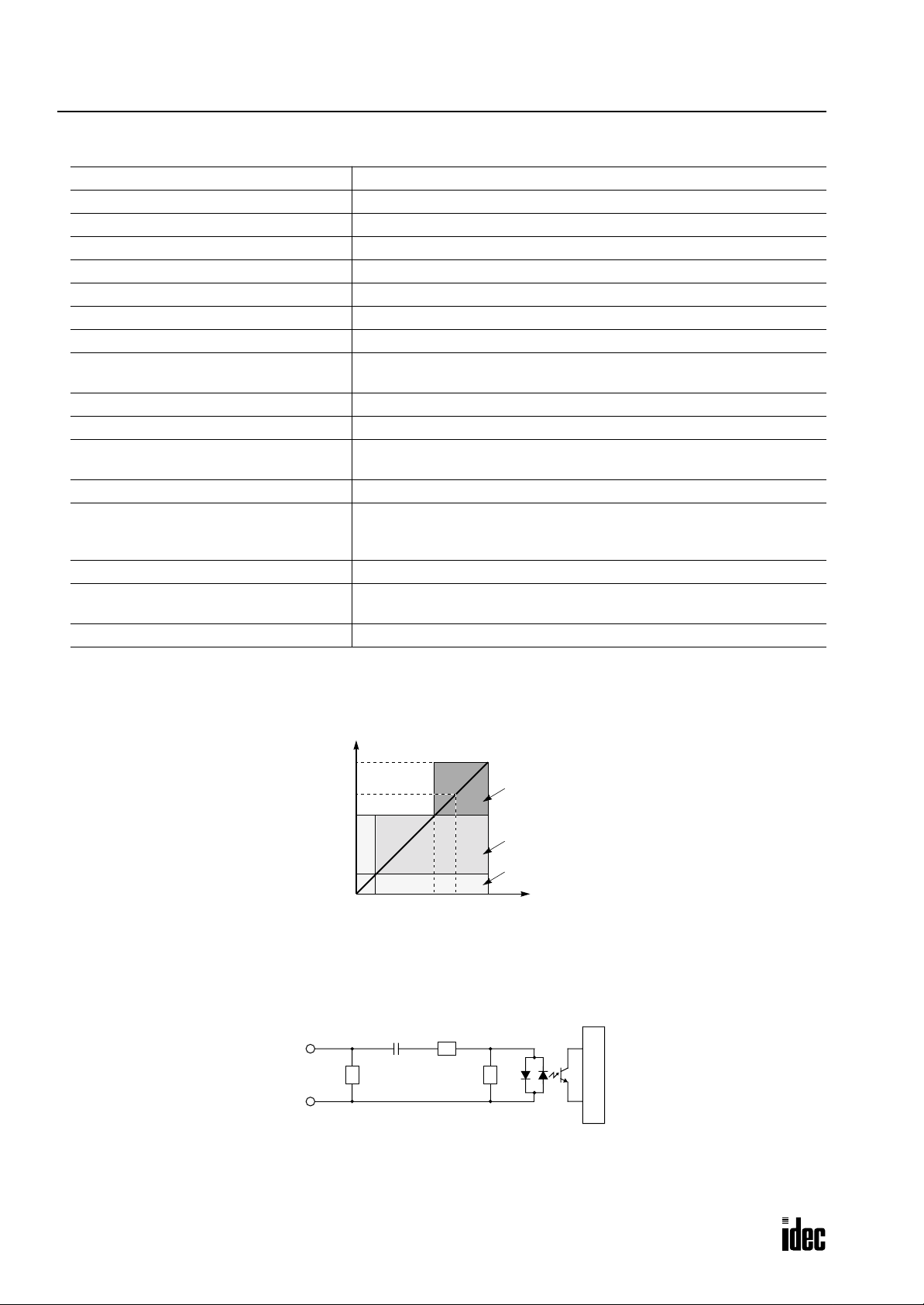

Input Operating Range

The input operating range of the Type 1 (EN61131) input module is shown below:

27.6

24

15

5

Input Voltage (V DC)

0

1 5.4

Input Current (mA)

4.4

4.9

ON Area

Transition

Area

OFF Area

Input Internal Circuit

COM

Input

4.7 kΩ

Internal Circuit

OPENNET CONTROLLER USER’S MANUAL 2-9

Page 25

2: MODULE SPECIFICATIONS

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

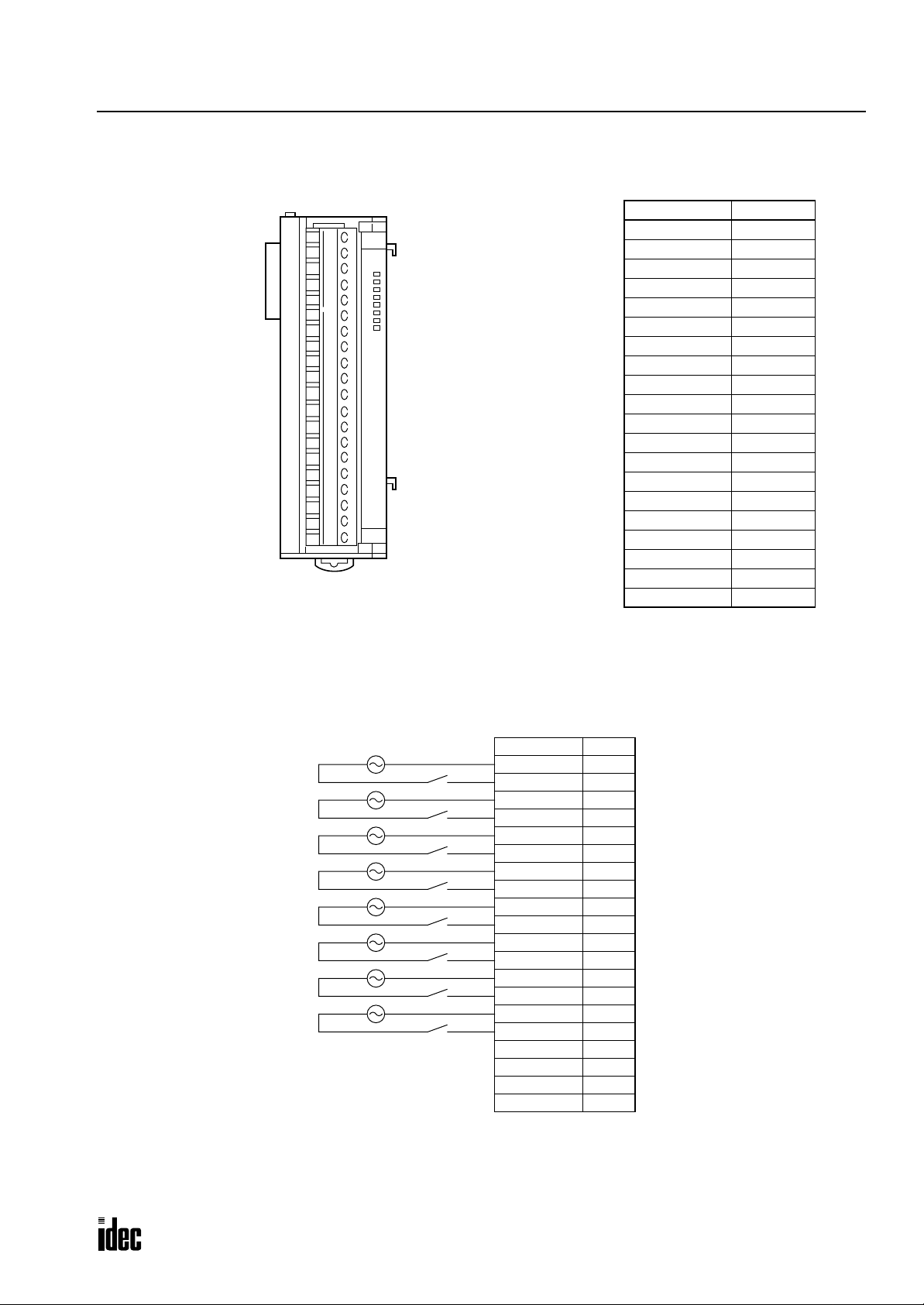

8-point AC Input Module Specifications

Type No. FC3A-N08A11

Rated Input Voltage 100 to 120V AC

Input Voltage Range 85 to 132V AC

Rated Input Current 8.3 mA/point (100V AC, 60 Hz)

Terminal Arrangement See Terminal Arrangement chart on page 2-15.

Input Impedance 12 kΩ (60 Hz)

Turn ON Time (100V AC) 20 msec maximum

Turn OFF Time (100V AC) 20 msec maximum

Isolation

External Load for I/O Interconnection Not needed

Signal Determination Method Static

Effect of Improper Input Connection

Cable Length 3m (9.84 ft.) in compliance with electromagnetic immunity

Connector on Mother Board

Connector Insertion/Removal Durability 100 times minimum

Internal Current Draw

Weight (approx.) 220g

Between input terminals: Not isolated

Internal circuit: Photocoupler isolated

If any input exceeding the rated value is applied, permanent damage may

be caused.

Screw Terminal Block

MSTBA2.5/20-G5.08

(Phoenix Contact)

All inputs ON: 30 mA (24V DC)

All inputs OFF: 20 mA (24V DC)

Input Operating Range

The input operating range of the Type 1 (EN61131) input module is shown below:

132

100

79

Input Voltage (V AC)

20

0

1.6 11

Input Current (mA)

8.36.5

ON Area

Transition

Area

OFF Area

Input Internal Circuit

COM

Input

Internal Circuit

2-10 OPENNET CONTROLLER USER’S MANUAL

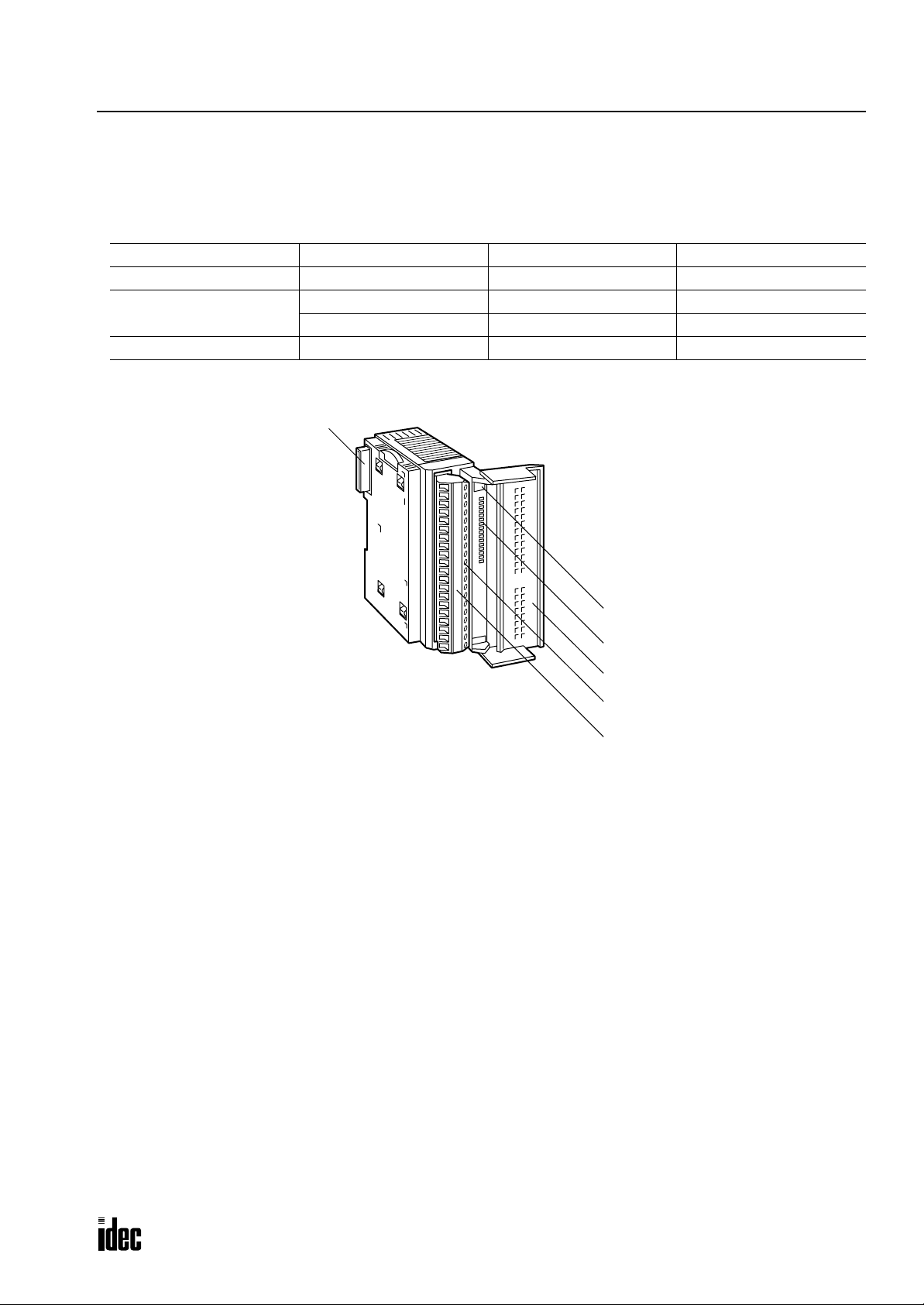

Page 26

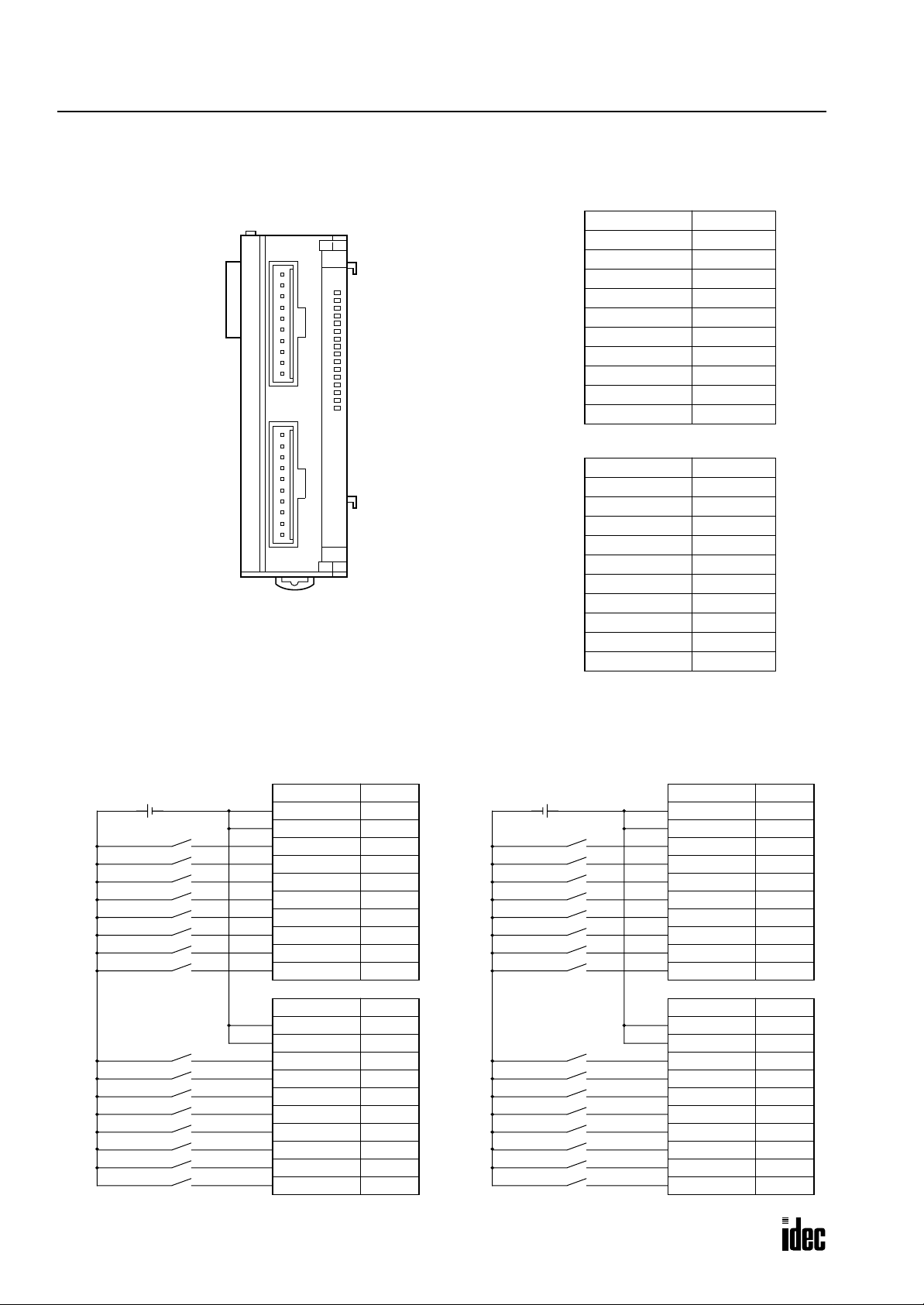

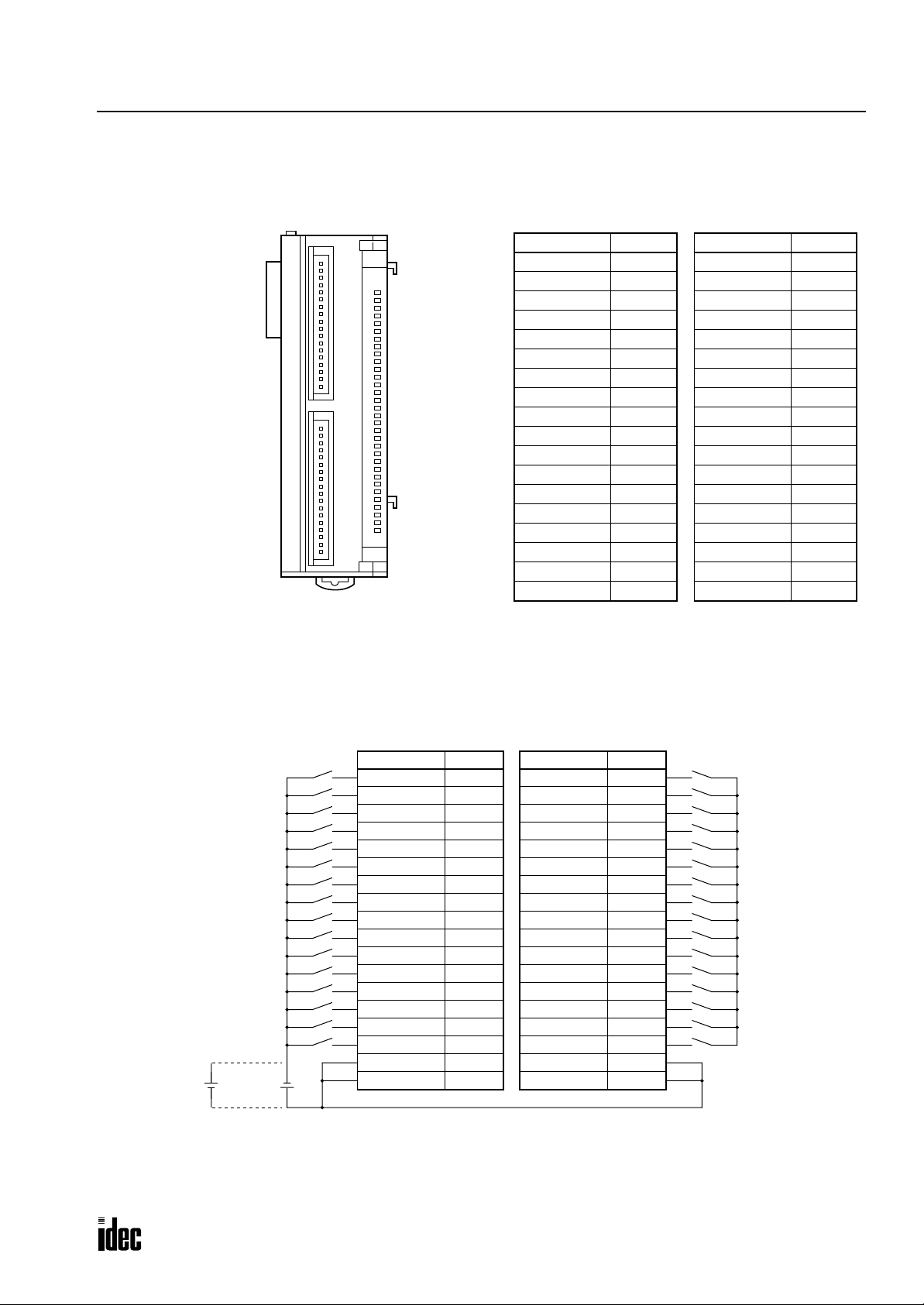

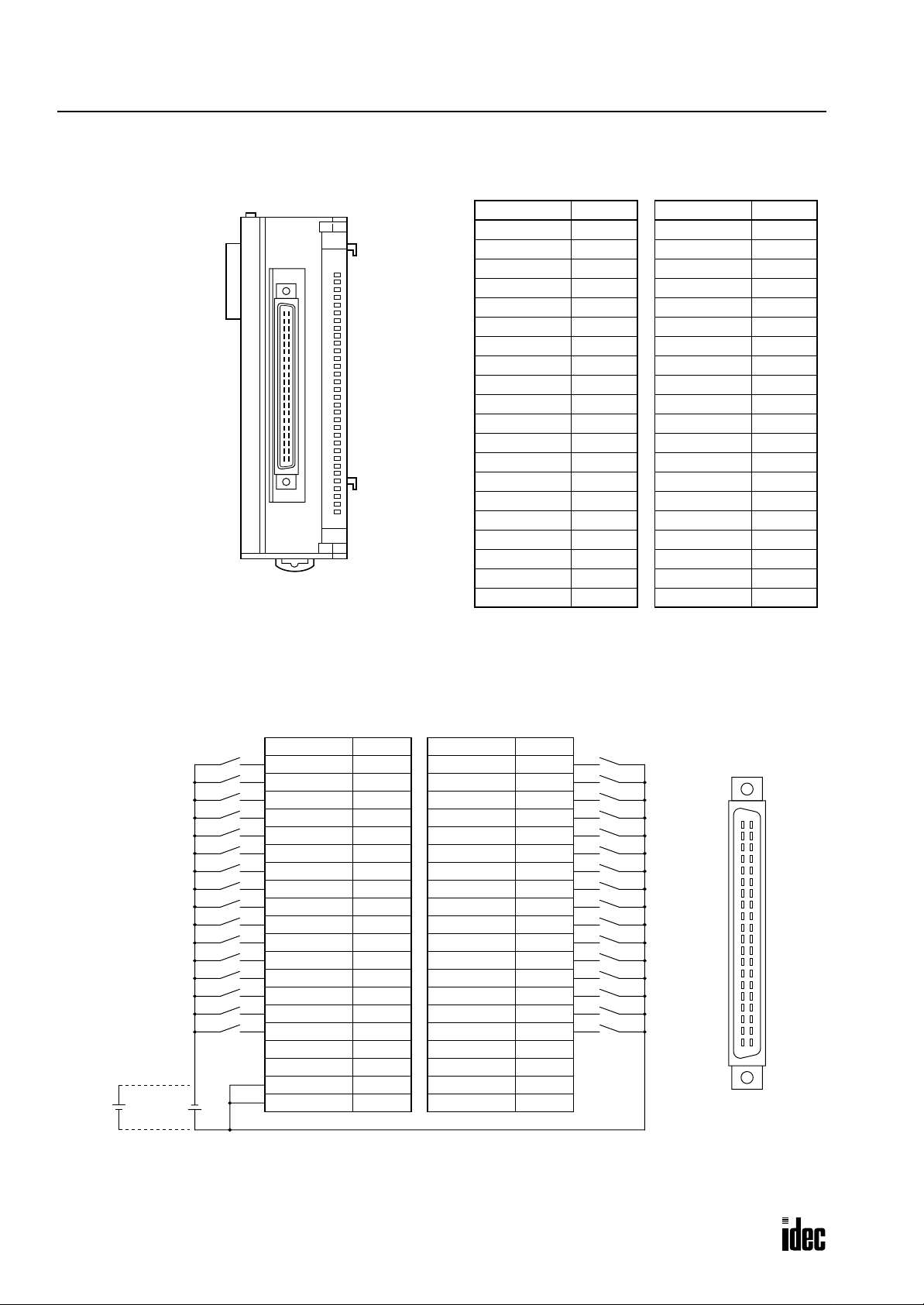

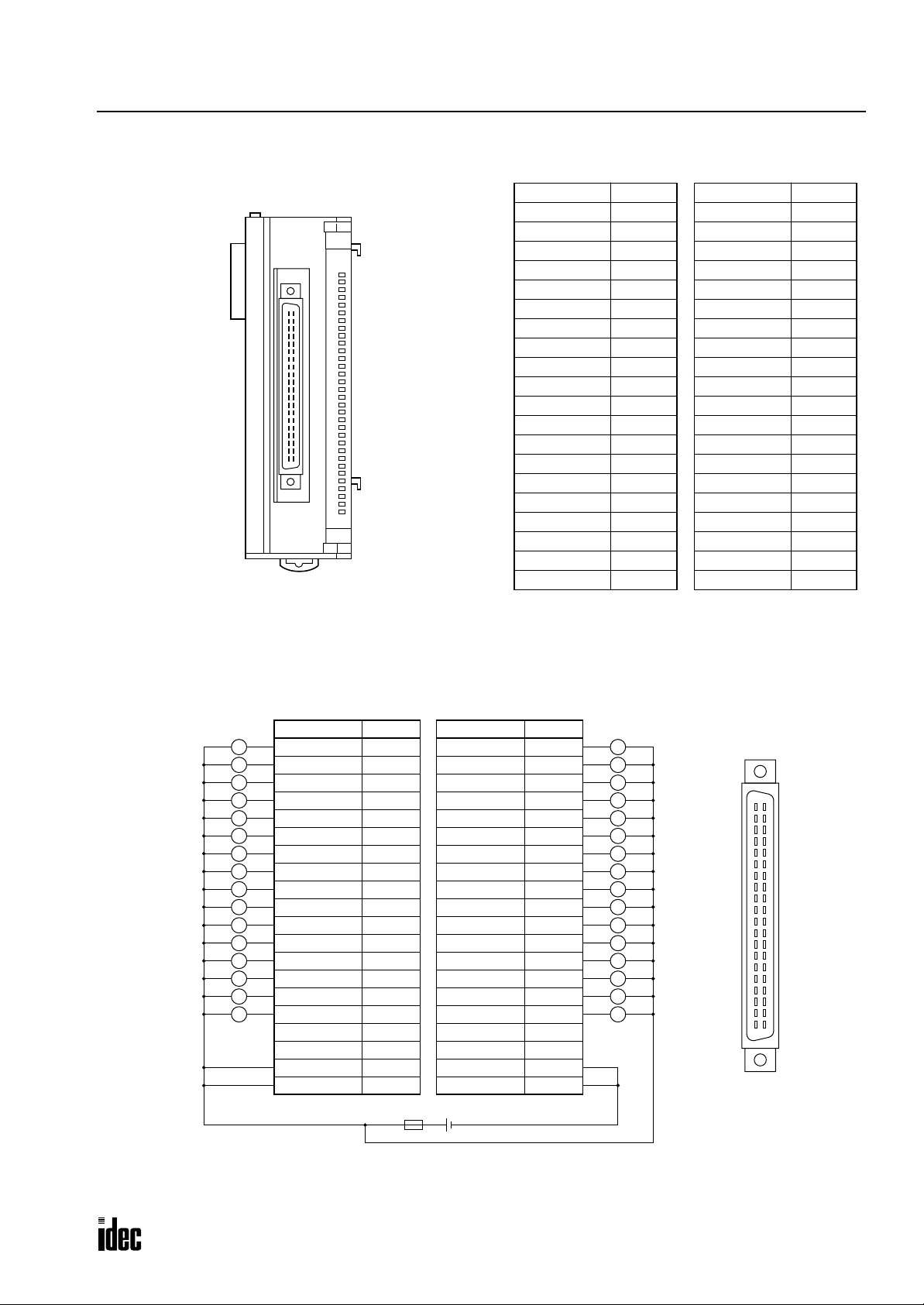

Input Module Terminal Arrangement

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

FC3A-N16B1 (16-point DC Input Module) — Screw Terminal Type

Applicable Connector: SMSTB2.5/20-ST-5.08 (Phoenix Contact)

DC

IN

0

1

2

3

4

5

6

7

10

11

12

13

14

15

16

17

2: MODULE SPECIFICATIONS

Terminal No. Name

1 COM

2 COM

3I0

4I1

5I2

6I3

7I4

8I5

9I6

10 I7

11 COM

12 COM

13 I10

14 I11

15 I12

16 I13

17 I14

18 I15

19 I16

20 I17